Metamodelling for Design of Mechatronic and Cyber-Physical Systems

Abstract

:Featured Application

Abstract

1. Introduction

2. Modelling Mechatronic Systems

- Interface modelling—information exchange between crucial components of the system and between the system and external environment (including other systems) [16];

- Hardware and software modelling—models of system’s software and hardware components; limitations must be considered that stem from the following sources: adopted business model, functional requirements, law regulations;

- Use case modelling—definition of interactions between various client types and the system itself, broad spectrum of use case specificity;

- Control target modelling—modelling of architecture and properties of the controlled object; enables parametrization of the proposed solution in simulations;

- Control software modelling—modelling of architecture and features of the software solution used to control the developed system.

2.1. Model-Based Design Paradigm

- Final product’s conformity to the specified requirements,

- Reduction of software errors,

- Verification of the project’s goals without building a physical prototype,

- Development of test-case scenarios and their validation in a simulation environment,

- Easier management of complex projects.

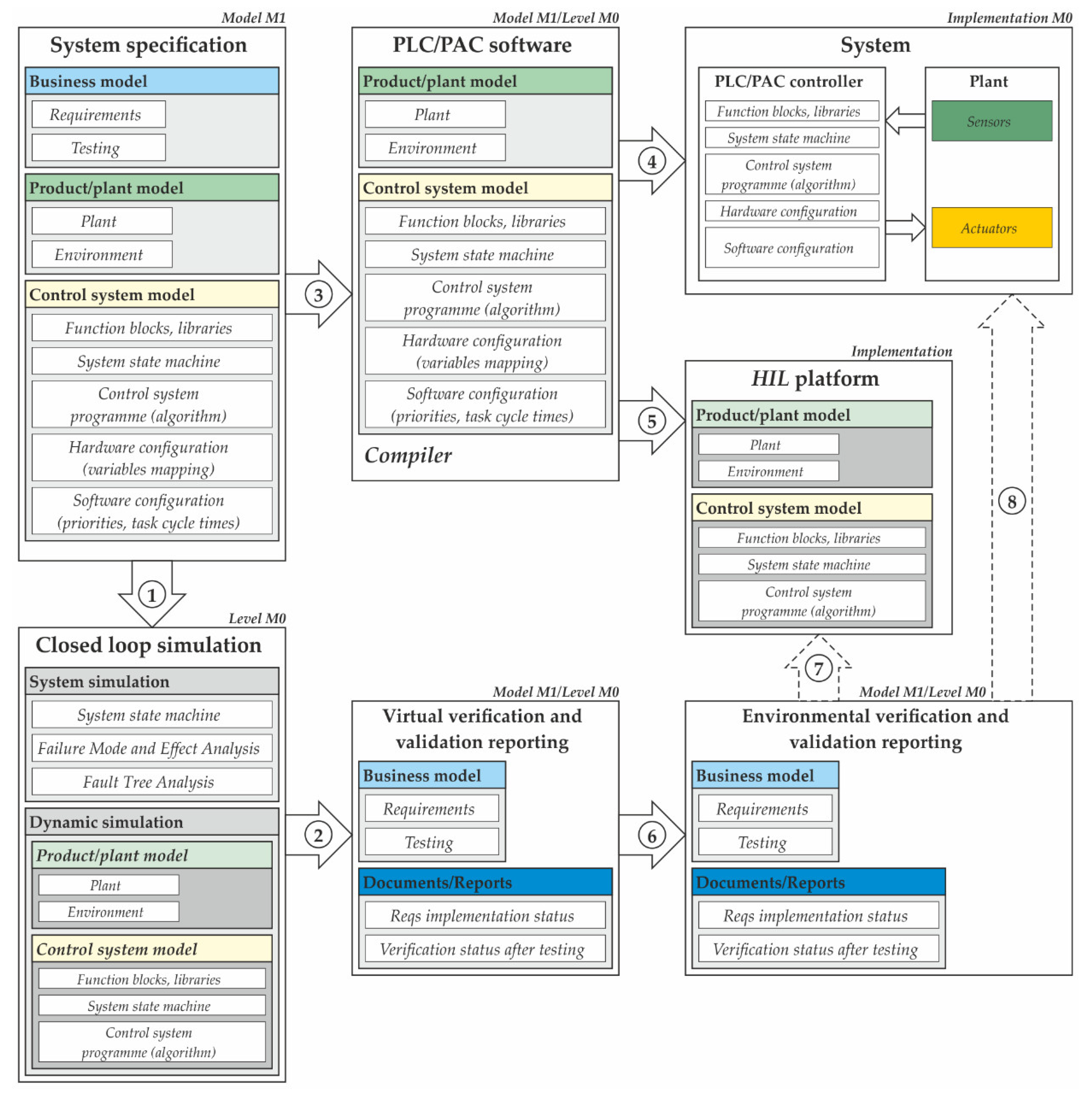

- Implementation and adoption of verification and validation procedures:

- (I) Control algorithm modelling (open loop)—no validation support; specifications include only operational level information;

- (II) System design simulation (closed loop)—closed loop simulations are used to provide feedback data for designers; real-time testing before moving the control system to a target platform allows to eliminate most errors from the final product without the risk of damaging its physical components (e.g., sensors, actuators);

- (III) Requirements-based development—requirements management is ingrained in the system design process;

- Implementation of automatic code generation procedures:

- (1) Simulation—code generation supports only system and dynamic simulation calculations; no real-time code is generated;

- (2) Real-time testing—real-time tests are additionally supported by automatic code generation procedures;

- (3) Production code—this highest level of software development is achieved by utilizing toolchains that support code generation for the final product directly out of the system’s specifications.

2.1.1. Graphical Executable Specification (MBD-1)

2.1.2. System Design Prototyping (MBD-2)

2.1.3. Graphical Programming (MBD-3)

2.1.4. Simulation in a Closed-loop Control System (MBD-4)

2.1.5. Hardware-in-the-loop Simulation (MBD-5)

2.1.6. Simulation-based Design (MBD-6)

2.1.7. Virtual Verification and Validation (MBD-7)

2.1.8. System Validation (MBD-8)

2.1.9. Full Implementation of Model-Based Design (MBD-9)

2.2. Modelling Workflow

2.3. Modelling Approaches

2.3.1. INCOSE Object-Oriented Systems Engineering Method (OOSEM)

2.3.2. MagicGrid

2.4. Modelling Tools

- Cameo Systems Modeler (formerly known as: MagicDraw with SysML plugin); Vendor: NoMagic; Web: http://www.nomagic.com/products/cameo-systems-modeler.html,

- Innoslate; Vendor: SPEC Innovations; Web: https://www.innoslate.com/,

- Enterprise Architect with SysML plugin;Vendor: SparxSystems; Web: http://www.sparxsystems.com/products/mdg_sysml.html,

- Modelio; Vendor: ModelioSoft; Web: http://www.modeliosoft.com/en/products/solutions/system-architect-solution-overview.html,

- Papyrus 4 SysML, Web: http://www.eclipse.org/modeling/mdt/papyrus/,

- IBM Rhapsody; Vendor: IBM; Web: http://www.ibm.com/software/rational/products/rhapsody/sysarchitect/,

- ARTiSAN Studio; Vendor PTC; Web: http://www.atego.com/products/artisan-studio/.

- Matlab/Simulink; Vendor: Mathworks,

- MapleSim; Vendor: Maplesoft,

- LMS Imagine.Lab Amesim; Vendor: Siemens,

- Scilab, open source project, initially started by INRIA, France,

- HOPSAN, from Linkoping University of Technology, Sweden,

- OpenModelica, open-source Modelica-based modelling and simulation environment, supported mainly by the Open Source Modelica Consortium (OSMC),

- Dymola.

2.5. MBSE in Practice

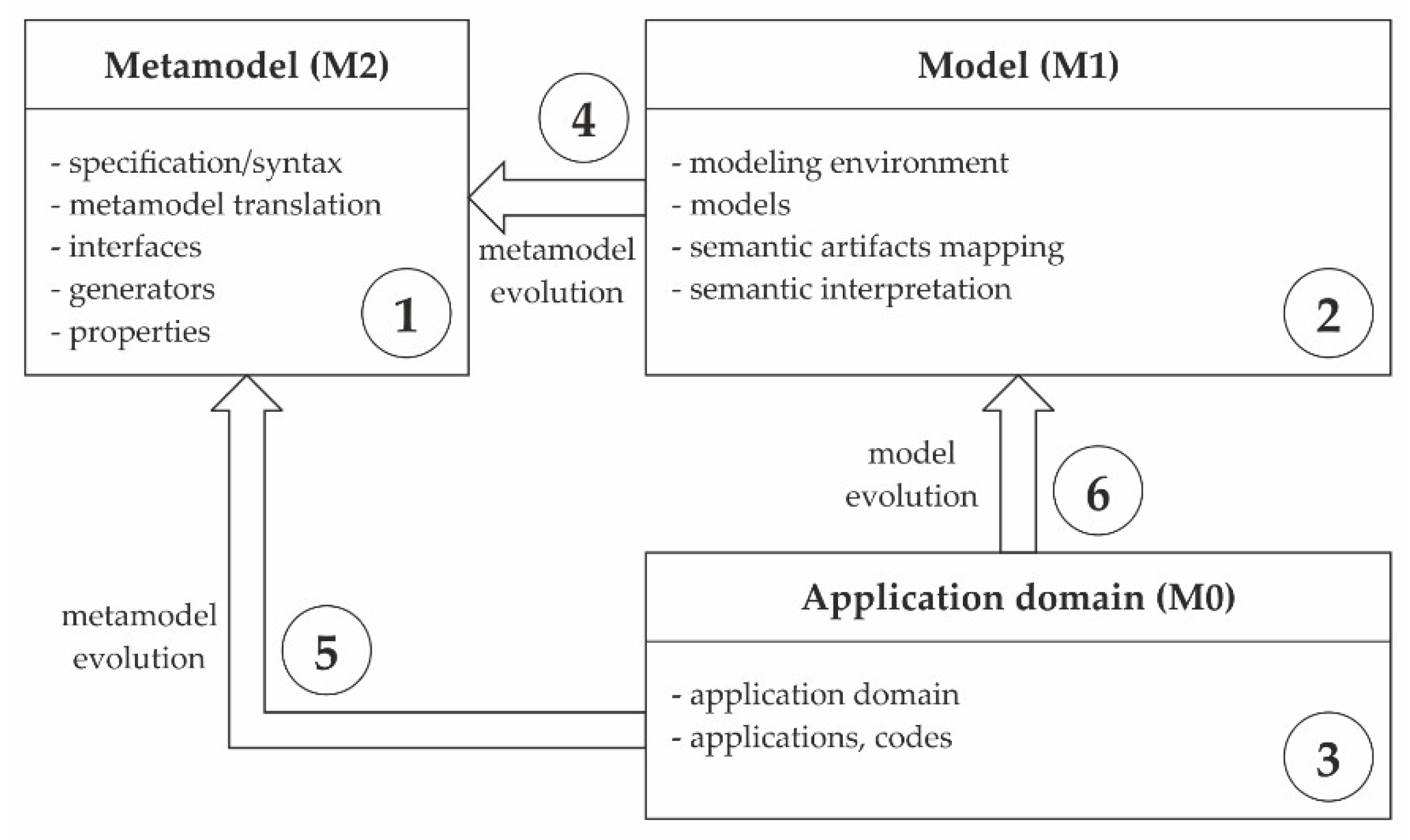

3. Metamodeling. Domain-specific Modelling Languages

3.1. Metamodeling Concepts

- Meta-metamodel (M3) defines metamodel (M2);

- Metamodel (M2) conforms to meta-metamodel (M3);

- Metamodel (M2) defines syntax of model (M1);

- Model (M1) conforms to metamodel (M2);

- Model (M1) abstracts modelling/semantic artefacts (M0);

- Modelling artefacts (M0) implement model (M1).

3.2. Metamodeling Goals

Example

3.3. Meta-Object Facility. Graph Object Property Relationship Role

- MOF: diagram—GOPRR: Graph;

- MOF: stereotype—GOPRR: Object;

- MOF: tagged value—GOPRR: Property;

- MOF: connector—GOPRR: Relationships;

- MOF: role—GOPRR: Role.

3.4. Metamodeling as a Stage in Design Process

3.5. Metamodeling Utilization for Control Engineering Projects

- Prototyping of control systems:

- Systems engineering:

- Systemic approach to design of automation systems (from Business Model Canvas to INCOSE/NoMagic MagicGrid systems engineering process) [31],

- Standardization:

- Management:

3.6. Metamodeling in Engineering Practice

4. Mechatronic Systems Under Consideration

4.1. AVIA X-5, 5-axis Machining Centre. New Product Development

- A construction assembly of 5-axis milling machine in the form of CAD drawings (M1) is transformed (Simscape Multibody Link, MathWorks, M2 definitions) into a simplified multi-body dynamic model (M1);

- The simplified multi-body model is extended with models of actuators, friction, dynamics and control. The resulting full Simulink model can be used for virtual verification and validation (M1 level for conducting calculations at M0 level);

- Optimization follows in which the constraints are considered, that is, dynamic stiffness, geometrical errors, volumetric errors, integral errors; controller’s gains are tuned in accordance with the type of motor used (PMSM/PMLM);

- The construction assembly is modified; different variants of measurements, actuator types are considered. The assembly is updated and the process falls back to Step 2.

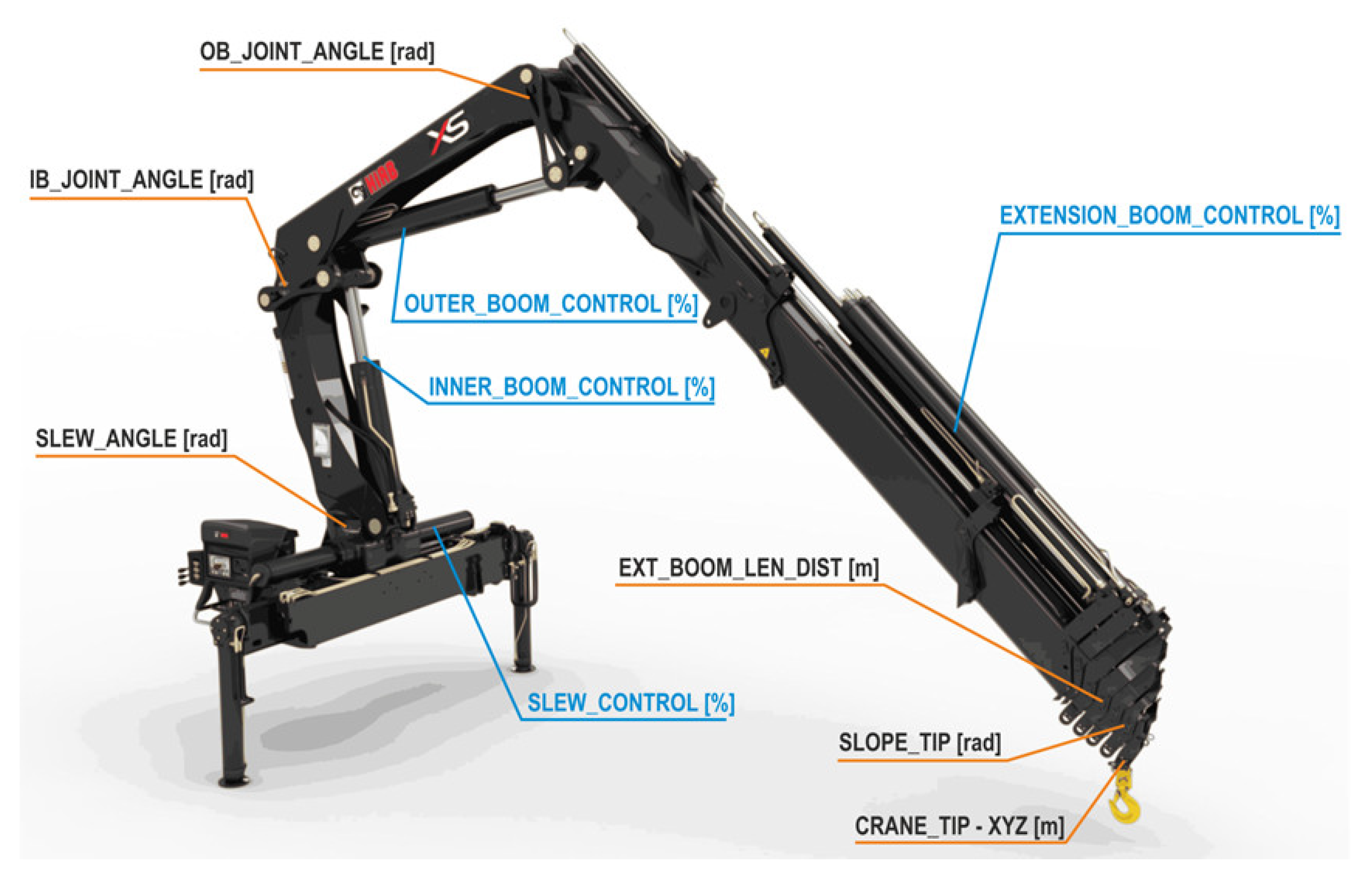

4.2. iLOAD Project. Focus on Product and the Process

- Product aspect—prototyping of new control system functions for loading task without the need to build costly physical prototypes,

- Process aspect—possibility of quick reconfiguration of a chosen control system element. This demand was caused by the ever-changing or yet unpublished, operational safety regulations,

- Management aspect—improvements in monitoring and management of EU projects. A necessity, considering the rotation of team members.

- Product Aspect—3 team members

- Process Aspect—8 team members

- Management Aspect—4 team members

- Full MBD knowledge—3 team members

- New control features lead to 30% faster adaptation of the designed product by inexperienced operators—the learning curve was successfully reduced. A test scenario was specially designed to verify this target goal;

- Movement precision was greatly improved in comparison to the previously applied control system;

- Modular architecture of the control system lead to parallel development of system’s algo rithms. This resulted in a faster implementation of new control functions.

4.3. Modelling and Metamodeling Aspects in the Presented Projects

- AVIA X-5 project (Figure 11),

- SolidWorks CAD drawings (M1) converted with Simscape Multibody Link (M2) into Simulink models (M1);

- Simulink models (M1) executed during dynamic simulations (M0);

- Documents/reports (M0) generated out of the Simulink models (M1);

- Results from calculations (M0) used for manual update of the construction model (M1);

- iLOAD project (Figure 15),

- Modelling language SpecScop (M2) used for specification of system components (M1);

- Automatic Matlab/Simulink generation (M2) of simulation models (M1) from specifications (M1); functionality implemented directly in Matlab/Simulink;

- Libraries (M1) of components created in Matlab/Simulink are automatically updated (M2) with new specifications (M1);

- Control system code (M0) generated from models (M1);

- Dynamic simulation (M0) conducted with predefined, parametrized models (M1);

- General/detailed documentation (M0) automatically generated from models (M1).

5. Discussion

- Control systems prototyping is a very important aspect in machine design. The same can be said about simulations conducted in a closed loop. Essential information is gathered that can help to evaluate the feasibility of the proposed design.

- Requirements engineering is essential for testing the product both in simulations and in a real environment.

- The rationale for employing the Model-Based Design increases with the number of requirements and standards that the product must adhere to.

- Model-Based Design is especially useful in projects which involve different participating parties. In the case of the projects presented in the previous section, the cooperation involved representatives from industry and academia. It benefitted everyone and resulted in deeper understanding of the encountered problems.

- Using metamodels that are already built-in the utilized tools (AVIA X-5 Project) allows to solve complex problems without the need to modify the modelling process.

- Possibility of metamodel modification and creation of custom generators (iLOAD Project) opens limitless possibilities in the area of project process creation. However, this is only possible with personnel that is experienced in the field of model design. These engineers are called metamodellers.

- Utilization of commercially available tools for modelling and requirement management is quickly becoming burdensome for the users. The offered functionality soon becomes inadequate to fully describe the modelled process.

- Parametrization and multi-criterion optimization of systems with multi-source requirements is possible only when custom-made modelling languages are created; these languages must consider the requirements’ parameters and relations between them and systems’ components or documentation.

- Metamodeling allows to apply a hybrid approach to project management. This means interspersing heuristic and standard methods within one management process.

- Several years of experience in a given problem domain is required in order to properly apply Model-Based Design. The benefits of the MBD approach cannot be fully appreciated without complete knowledge of the field in which it is applied.

- Full knowledge of all MBD aspects is not required when it is adopted for the first time—simultaneous and effective implementation of its every feature is impossible.

- Some aspects of Model-Based Design can be used even in small groups; with larger teams the payoff is even bigger as more MBD elements are used.

- Motivation for applying Model-Based Design in mechatronic and cyber-physical systems is often independent from the product itself. It can be a result of research and development projects in which industry and academia partners cooperate to create new products or processes. This is an unusual order-of-business for both parties, additionally limited by the specifics of research program and its funding.

- The issues caused by changes in team’s personnel also prove the Model-Based Design to be beneficial. It enables seamless introduction of new employees into the project and enables safe continuation whenever a more experienced team member leaves.

- Model-Based Design improves communication between the stakeholders and the project team that designs the system in question.

Generic Workflow for Model-Based Design

- Introduce MagicGrid process (including VDI 2206 [81] V-model approach at each stage, no matter if modelling requirements, use cases, system architecture or functions),

- Define Domain-Specific Language use cases for the project,

- Propose initial version of the language; model part of the system as a pilot sub-project,

- Update modelling language, define abstraction levels/layers for modelling,

- Define scope for code/documentation generation,

- Define scope for data import/export and select candidate objects,

- Model most of the system and close code/documentation generation loops,

- Integrate the proposed modelling language with project management methodology, for example, SCRUM, Project Cycle Management or propose custom modelling process.

- control system development, including development of new control functions, components selection, dynamic simulation and code generation,

- systems engineering, including virtual verification and validation, hardware in the loop simulation, requirements engineering at each stage of the project; integration of multicriteria indices (similar to the proposed in Reference [62] mechatronic design quotient MDQ) for ensuring high quality of the resulting system,

- project management: higher quality of decision-making process achieved by rapid analysis of the project’s state.

- Utilization of General Purpose Languages (UML, SysML) takes a lot of time compared with Domain-Specific Languages. This is true even for languages that take basic concepts from SysML (like Requirement or Use Case). This conclusion is similar to [109],

- Issues were observed with engineers that observe their increasing efficiency—they are exhibiting problematic social behaviour that stems from the increased quality and efficiency. This is a common problem in digitalization projects, when engineers are forced to use new toolchains which are usually far more efficient than the currently used. This problem, however, is outside the scope of this paper and needs further research.

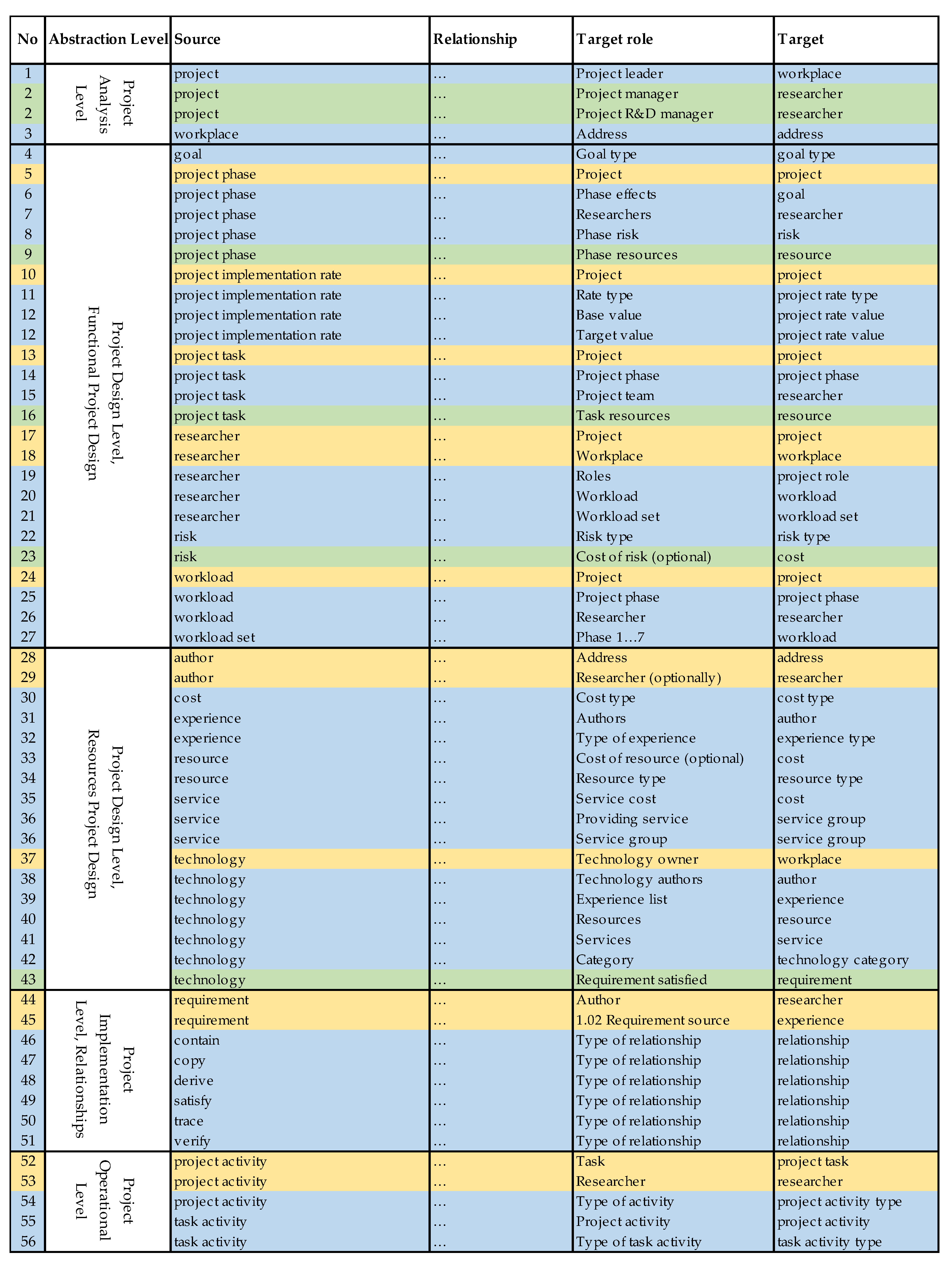

6. ResearchML

6.1. ResearchML Goals

6.1.1. Activity Management and Effective Reporting

6.1.2. Information Flow Optimization

6.1.3. Fast Adaptation

6.1.4. Compensation for Lack of Managerial Experience

- reporting,

- preparing grant applications,

- storage and organization of project’s information,

- project management,

- management and organization of research infrastructure,

- monitoring workload of each project member,

- career development plan for employees, training plans for acquiring new skills.

6.2. ResearchML Design

- Project Analysis Level (address, project, workplace),

- Project Design Level, Functional Project Design (goal, goal type, project phase, project implementation rate, project rate type, project rate value, project role, project task, researcher, risk, risk type, workload, workload set),

- Project Design Level, Resources Project Design (author, cost, cost type, experience, experience type, resource, resource type, service, service group, technology, technology category),

- Project Implementation Level (requirement, relationship),

- Project Implementation Level, Relationships (contain, copy, derive, satisfy, trace, verify),

- Project Operational Level (project activity, project activity type, task activity, task activity type).

6.2.1. Project Analysis Level

6.2.2. Project Design Level, Functional Project Design

6.2.3. Project Design Level, Resources Project Design

6.2.4. Project Implementation Level, Relationships

6.2.5. Project Operational Level

6.3. Reporting, Specifications

6.3.1. Documentation Generation

6.3.2. Two-way Data Exchange with Model’s Environment

7. Conclusions

- Top-down—from more abstract layers/levels to precise definitions of properties and objects;

- Bottom-up—from precise definitions of properties and objects to more abstract levels including project architecture;

- Free—new objects are created when needed;

Funding

Conflicts of Interest

References

- Herb, S. Hybrid (PAC) systems: Pathway to productivity. Assem. Autom. 2008, 28, 10–17. [Google Scholar] [CrossRef]

- Pietrusewicz, K. CNC open architectures. Control Eng. 2008, 55, 17–18. [Google Scholar]

- Ma, X.B.; Han, Z.Y.; Wang, Y.Z.; Fu, H.Y. Development of a PC-based open architecture software-CNC system. Chin. J. Aeronaut. 2007, 20, 272–281. [Google Scholar] [CrossRef]

- Holt, J.; Perry, S.A.; Brownsword, M. Model-Based Requirements Engineering; The Institution of Engineering and Technology: London, UK, 2012; ISBN 9781849194877. [Google Scholar]

- Friedenthal, S.; Moore, A.; Steiner, R. A Practical Guide to SysML: The Systems Modeling Language; Morgan Kaufmann: Burlington, MA, USA, 2015. [Google Scholar]

- Pietrusewicz, K.; Bonisławski, M.; Pajdzik, R. Open architecture digital servodrive for PMSM/PMLM-based machine-tool table feed-drives. Arch. Electr. Eng. 2013, 62, 289–305. [Google Scholar] [CrossRef]

- Aarenstrup, R. Managing Model-Based Design; The MathWorks, Inc.: Natick, MA, USA, 2015; ISBN 978-1512036138. [Google Scholar]

- Smith, D.; Simpson, K. Functional Safety. A Straightforward Guide to Applying IEC 61508 and Related Standards; Routledge: Abingdon, UK, 2004; ISBN 9780750662697. [Google Scholar]

- Barg, J.; Eisenhut-Fuchsberger, F. 10 Steps to Performance Level: Handbook for the Implementation of Functional Safety according to ISO 13849; Bosch Rexroth, Drive & Control Academy, 2012. [Google Scholar]

- Smith, D.J.; Simpson, K.G.L. Safety Critical Systems Handbook; Butterworth-Heinemann: Oxford, UK, 2011; ISBN 9780080967813. [Google Scholar]

- Noureen, A.; Amjad, A.; Azam, F. Model Driven Architecture - Issues, Challenges and Future Directions. J. Softw. 2016, 11, 924–933. [Google Scholar] [CrossRef] [Green Version]

- Kelly, S.; Tolvanen, J.-P. Domain-Specific Modeling. Enabling Full Code Generation; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Mhenni, F.; Choley, J.-Y.; Penas, O.; Plateaux, R.; Hammadi, M. A SysML-based methodology for mechatronic systems architectural design. Adv. Eng. Inform. 2014, 28, 218–231. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; John Wiley & Sons: Hoboken, NJ, USA, 2010; ISBN 978-0-470-87641-1. [Google Scholar]

- Holder, K.; Zech, A.; Ramsaier, M.; Stetter, R.; Niedermeier, H.-P.; Rudolph, S.; Till, M. Model-Based Requirements Management in Gear Systems Design Based on Graph-Based Design Languages. Appl. Sci. 2017, 7, 1112. [Google Scholar] [CrossRef]

- Zheng, C.; Hehenberger, P.; Le Duigou, J.; Bricogne, M.; Eynard, B. Multidisciplinary design methodology for mechatronic systems based on interface model. Res. Eng. Des. 2017, 28, 333–356. [Google Scholar] [CrossRef]

- Wymore, A.W. Model-Based Systems Engineering, 1st ed.; CRC Press: Boca Raton, FL, USA, 1993. [Google Scholar]

- Patrice, M. Model-Based Systems Engineering. Fundamentals and Methods; Wiley: Hoboken, NJ, USA, 2014; ISBN 978-1848214699. [Google Scholar]

- Estefan, J.A. Survey of Model-Based Systems Engineering (MBSE) Methodologies 2. Differentiating Methodologies from Processes, Methods, and Lifecycle Models. Jet Propuls. Lab. Rep. 2008, 25, 1–70. [Google Scholar] [CrossRef]

- Groß, J.; Rudolph, S. Generating simulation models from UML—A FireSat example. In Proceedings of the 2012 Symposium on Theory of Modeling and Simulation, Orlando, FL, USA, 26–30 March 2012; Volume 44, pp. 182–189. [Google Scholar]

- Hirz, M. An approach supporting integrated modeling and design of complex mechatronics products by the example of automotive applications. In Proceedings of the 22nd Multi-Conference on Systemics, Cybernetics and Informatics-WMSCI, Orlando, FL, USA, 8–11 July 2018. [Google Scholar]

- Pietrusewicz, K.; Dworak, P.; Misztal, H. Rapid prototyping of the temperature control algorithms within the PLCs. Prz. Elektrotech. 2010, 86, 304–306. [Google Scholar]

- Pietrusewicz, K.; Urbański, Ł. Balancing PLCs, PACs and IPCs. What controller fits your application? Control Eng. 2011, 58, 28–32. [Google Scholar]

- Gross, J.; Rudolph, S. Geometry and simulation modeling in design languages. Aerosp. Sci. Technol. 2016, 54, 183–191. [Google Scholar] [CrossRef]

- Gross, J.; Rudolph, S. Modeling graph-based satellite design languages. Aerosp. Sci. Technol. 2016, 49, 63–72. [Google Scholar] [CrossRef]

- Moreira, T.G.; Wehrmeister, M.A.; Pereira, C.E.; Pétin, J.F.; Levrat, E. Automatic code generation for embedded systems: From UML specifications to VHDL code. IEEE Int. Conf. Ind. Inform. 2010, 1085–1090. [Google Scholar] [CrossRef]

- Di Natale, M.; Perillo, D.; Chirico, F.; Sindico, A.; Sangiovanni-Vincentelli, A. A Model-based approach for the synthesis of software to firmware adapters for use with automatically generated components. Softw. Syst. Model. 2018, 17, 11–33. [Google Scholar] [CrossRef]

- Petko, M. Wybrane Metody Projektowania Mechatronicznego; Wydawnictwo Naukowe Instytutu Technologii Eksploatacji—PIB: Kraków, Radom, 2008; ISBN 978-83-7204-709-0. [Google Scholar]

- Lambrechts, P.; Boerlage, M.; Steinbuch, M. Trajectory planning and feedforward design for high performance motion systems. Proc. Am. Control Conf. 2004, 5, 4637–4642. [Google Scholar] [CrossRef]

- Lambrechts, P.; Boerlage, M.; Steinbuch, M. Trajectory planning and feedforward design for electromechanical motion systems. Control Eng. Pract. 2005, 135, 145–157. [Google Scholar] [CrossRef]

- Dori, D. Model-Based Systems Engineering with OPM and SysML; Springer: New York, NY, USA, 2016; ISBN 9781493932955. [Google Scholar]

- Paredis, C.J.J.; Bernard, Y.; Burkhart, R.M.; de Koning, H.-P.; Friedenthal, S.; Fritzson, P.; Rouquette, N.F.; Schamai, W. An Overview of the SysML-Modelica Transformation Specification. INCOSE Int. Symp. 2010, 20, 709–722. [Google Scholar] [CrossRef]

- Ślączka, W.; Pietrusewicz, K.; Marcinek, M. Intelligent Container in Water–Land Transport. In MBSE Approach for System Design BT-Smart Solutions in Today’s Transport; Mikulski, J., Ed.; Springer International Publishing: Cham, Switzerland, 2017; pp. 344–359. [Google Scholar]

- ISO 12100:2010, Safety of Machinery-General Principles for Design-Risk Assessment and Risk Reduction; ISO: Geneva, Switzerland, 2013.

- International Electrotechnical Commission. EN 61508. Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems, Parts 1–7. International Standard, TC 65/SC 65A. Available online: https://www.iec.ch/functionalsafety/standards/page2.htm (accessed on 29 November 2018).

- IEC 62061:2005. Safety of Machinery–Functional Safety of Safety-Related Electrical, Electronic and Programmable Electronic Control Systems; IEC: Geneva, Switzerland, 2005. [Google Scholar]

- John, K.H.; Tiegelkamp, M. IEC 61131-3: Programming Industrial Automation Systems. Concepts and Programming Languages, Requirements for Programming Systems, Decision-Making Aids; Springer-Verlag: Heidelberg, Germany, 2010; Volume 2, ISBN 978-3-642-12014-5. [Google Scholar]

- International Electrotechnical Commission. IEC 61131–3:2013. Programmable controllers—Part 3: Programming Languages, International Standards, TC 65/SC 65B—Measurement and control devices. Available online: https://webstore.iec.ch/publication/4552#additionalinfo (accessed on 29 November 2018).

- Vulliez, P.; Gazeau, J.P.; Laguillaumie, P.; Mnyusiwalla, H.; Seguin, P. Focus on the mechatronics design of a new dexterous robotic hand for inside hand manipulation. Robotica 2018, 36, 1206–1224. [Google Scholar] [CrossRef]

- Mnyusiwalla, H.; Vulliez, P.; Gazeau, J.P.; Zeghloul, S. A New Dexterous Hand Based on Bio-Inspired Finger Design for Inside-Hand Manipulation. IEEE Trans. Syst. Man, Cybern. Syst. 2016, 46, 809–817. [Google Scholar] [CrossRef]

- Handono, K.; Sumarno, E.; Haryanto, D.; Setiadipura, T.; Indrakoesoema, K.; Tangerang, S. Mechatronic design and analysis of Reaktor Daya experimental components. Int. J. Mech. Eng. Technol. 2018, 9, 405–414. [Google Scholar]

- Giberti, H.; Sbaglia, L.; Silvestri, M. Mechatronic Design for an Extrusion-Based Additive Manufacturing Machine. Machines 2017, 5, 29. [Google Scholar] [CrossRef]

- Pietrusewicz, K. Automatic code generation as a key for innovative algorithms. Automotion 2011, 7, 42–44. [Google Scholar]

- Wenger, M.; Zoitl, A. IEC 61131-3 Model for Model-Driven Development. In Proceedings of the IECON 2012—38th Annual Conference on IEEE Industrial Electronics Society, Montreal, QC, Canada, 25–28 October 2012; pp. 3744–3749. [Google Scholar]

- Meta-Object Facility. Available online: http://www.omg.org/mof/ (accessed on 29 November 2018).

- Bézivin, J. In search of a basic principle for Model Driven Engineering. Spec. Novatica Issue UML Model Eng. 2004, 5, 21–24. [Google Scholar]

- Tolvanen, J.-P. MetaEdit+: Integrated modeling and metamodeling environment for domain-specific languages. In Proceedings of the Companion to the 21st ACM SIGPLAN Symposium on Object-Oriented Programming Systems, Languages, and Applications, Portland, Oregon, USA, 22–26 October 2006; p. 690. [Google Scholar] [CrossRef]

- Ferreira, E.; Paulo, R.; da Cruz, D.; Henriques, P. Integration of the ST language in a model-based engineering environment for control systems—An approach for compiler implementation. Comput. Sci. Inf. Syst. 2008, 5, 87–101. [Google Scholar] [CrossRef]

- Yu, L.; Quir, G.; Krausser, T.; Epple, U. IEC 61131-3 + ACPLT = Dynamic Reconfigurable Models. Softwaretechnik-Trends 2012, 32, 90–91. [Google Scholar] [CrossRef] [Green Version]

- Pietrusewicz, K. Considerations on prototyping within the digital servodrives of the CNCs machine tool feed drive modules. Prz. Elektrotech. 2012, 88, 167–170. [Google Scholar]

- Pietrusewicz, K.; Waszczuk, P. Rapid prototyping in development of numerically controlled machine tool feed drive module control system. In Proceedings of the 14th International Carpathian Control Conference (ICCC), Rytro, Poland, 26–29 May 2013; pp. 302–306. [Google Scholar]

- Zaeh, M.F.; Poernbacher, C.; Milberg, J. A Model-Based Method to Develop PLC Software for Machine Tools. CIRP Ann. 2005, 54, 371–374. [Google Scholar] [CrossRef]

- Babic, J.; Marijan, S.; Petrovic, I. Introducing Model-Based Techniques into Development of Real-Time Embedded Applications. Automatika 2011, 52, 329–338. [Google Scholar] [CrossRef] [Green Version]

- Basha, N.M.J.; Moiz, S.A.; Rizwanullah, M. Model based Software Development: Issues & Challenges. Int. J. Comput. Sci. Inform. 2012, 2, 226–230. [Google Scholar]

- Pietrusewicz, K.; Scopchanov, M. Domain specific language for structural modeling of logically controlled discrete-event mechatronic systems. In Proceedings of the 2017 22nd International Conference on Methods and Models in Automation and Robotics (MMAR), Międzyzdroje, Poland, 28–31 August 2017; pp. 1–6. [Google Scholar]

- Pietrusewicz, K.; Scopchanov, M. Projektowanie mechatroniczne. Graficzna specyfikacja systemów. Napędy i Sterow. 2016, 18, 76–88. [Google Scholar]

- Hauksson, H. Metamodeling for Business Model Design. Master Thesis, Department of Computer and Systems Sciences, KTH, Stockholm, Sweden, 2013. Available online: http://www.diva-portal.org/smash/get/diva2:680504/FULLTEXT01.pdf (accessed on 29 November 2018).

- Hauksson, H.; Johannesson, P. Metamodeling for Business Model Design Facilitating development and communication of Business Model Canvas (BMC) models with an OMG standards-based metamodel. 2014. Available online: https://www.uio.no/studier/emner/matnat/ifi/INF5120/v16/ressurser/lectures/bmc-metamodel.pdf (accessed on 29 November 2018).

- Sjöstedt, C. Modeling and Simulation of Physical Systems in a Mechatronic Context. Ph.D. Thesis, KTH, Stockholm, Sweden, 2009. [Google Scholar]

- Sakairi, T.; Palachi, E.; Cohen, C.; Hatsutori, Y.; Shimizu, J.; Miyashita, H. Model Based Control System Design Using SysML, Simulink, and Computer Algebra System. J. Control Sci. Eng. 2013, 2013, 1–14. [Google Scholar] [CrossRef]

- Paśnicki, P.; Pietrusewicz, K.; Pajor, M.; Staniek, R. Mechatronic integration facilitates control system design. Control Eng. 2013, 9, 17. [Google Scholar]

- Moulianitis, V.C.; Zachiotis, G.A.D.; Aspragathos, N.A. A new index based on mechatronics abilities for the conceptual design evaluation. Mechatronics 2018, 49, 67–76. [Google Scholar] [CrossRef]

- Scheeren, I.; Pereira, C.E. Combining Model-Based Systems Engineering, Simulation and Domain Engineering in the Development of Industrial Automation Systems: Industrial Case Study. In Proceedings of the 2014 IEEE 17th International Symposium on Object/Component/Service-Oriented Real-Time Distributed Computing, Reno, Nevada, 10–12 June 2014; pp. 40–47. [Google Scholar]

- Bunse, C.; Gross, H.G.; Peper, C. Applying a model-based approach for embedded system development. In Proceedings of the 33rd EUROMICRO Conference on Software Engineering and Advanced Applications, SEAA 2007, Lübeck, Germany, 28–31 August 2007; pp. 121–128. [Google Scholar]

- Vogel-Heuser, B.; Fischer, J.; Feldmann, S.; Ulewicz, S.; Rosch, S. Modularity and architecture of PLC-based software for automated production systems: An analysis in industrial companies (journal-first abstract). In Proceedings of the 2018 IEEE 25th International Conference on Software Analysis, Evolution and Reengineering (SANER), Campobasso, Italy, 20–23 March 2018; p. 473. [Google Scholar] [CrossRef]

- Fischer, J.; Vogel-Heuser, B.; Friedrich, D. Configuration of PLC software for automated warehouses based on reusable components—An industrial case study. In Proceedings of the 2015 IEEE 20th Conference on Emerging Technologies & Factory Automation (ETFA), Luxembourg, 8–11 September 2015; pp. 1–7. [Google Scholar]

- Um, J.; Fischer, K.; Spieldenner, T.; Kolberg, D. Development a Modular Factory with Modular Software Components. Procedia Manuf. 2017, 11, 922–930. [Google Scholar] [CrossRef]

- Vogel-Heuser, B.; Fischer, J.; Neumann, E.M.; Diehm, S. Key maturity indicators for module libraries for PLC-based control software in the domain of automated Production Systems. IFAC-PapersOnLine 2018, 51, 1610–1617. [Google Scholar] [CrossRef]

- David, P.; Shawky, M.; David, P.; Supporting, M.S.; Esrel, L.; David, P.; Shawky, M. Supporting ISO 26262 with SysML, Benefits and Limits. In Proceedings of the ESREL 2010, Rhodes, Greece, 5–9 September 2010; p. 8. [Google Scholar]

- Sari, B.; Reuss, H. Model-based Development of Safety-critical Functions and ISO 26262 Work Products using modified EAST-ADL. Adv. Sci. Technol. Eng. Syst. J. 2017, 2, 1252–1259. [Google Scholar] [CrossRef] [Green Version]

- Luo, Y.; Van Den Brand, M.; Engelen, L.; Favaro, J. Extracting Models from ISO 26262 for Reusable Safety Assurance; Lecture Notes in Computer Science; Favaro, J., Morisio, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 7925, ISBN 978-3-642-38976-4. [Google Scholar]

- Sternudd, P. Unambiguous requirements in Functional Safety and ISO 26262: Dream or Reality? Master thesis, Uppsala Universitet, Uppsala, Sweden, 2011. Available online: http://www.diva-portal.org/smash/get/diva2:470633/FULLTEXT01.pdfUPTEC (accessed on 29 November 2018).

- Conrad, M. Verification and Validation According to ISO 26262: A Workflow to Facilitate the Development of High-Integrity Software. In Proceedings of the Embedded Real Time Software and Systems ERTS2, Toulouse, France, 1–3 February 2012. [Google Scholar]

- Estevez, E.; Marcos, M.; Irisarri, E. Analysis of IEC 61131-3 Compliance through PLCopen XML Interface. In Proceedings of the 2009 7th IEEE International Conference on Industrial Informatics, Wales, UK, 23–26 June 2009; pp. 757–762. [Google Scholar] [CrossRef]

- Estévez, E.; Marcos, M.; Orive, D. Automatic generation of PLC automation projects from component-based models. Int. J. Adv. Manuf. Technol. 2007, 35, 527–540. [Google Scholar] [CrossRef]

- Soliman, D.; Frey, G. Verification and validation of safety applications based on PLCopen safety function blocks. Control Eng. Pract. 2011, 19, 929–946. [Google Scholar] [CrossRef]

- Vogel-Heuser, B.; Schütz, D.; Frank, T.; Legat, C. Model-driven engineering of Manufacturing Automation Software Projects—A SysML-based approach. Mechatronics 2014, 24, 883–897. [Google Scholar] [CrossRef]

- Öhman, M.; Johansson, S.; Arzén, K.E. Implementation aspects of the PLC standard IEC 1131-3. Control Eng. Pract. 1998, 6, 547–555. [Google Scholar] [CrossRef] [Green Version]

- Practical Industrial Programming Using IEC 61131-3 for PLCs; IDC Technologies: Milpitas, CA, USA, 2007.

- Cressent, R.; Idasiak, V.; Kratz, F.; David, P. Mastering safety and reliability in a model based process. In Proceedings of the Annual Reliability and Maintainability Symposium, Lake Buena Vista, FL, USA, 24–27 January 2011. [Google Scholar] [CrossRef]

- VDI-Association of German Engineers. VDI 2206-Design Methodology for Mechatronic Systems; Verein Deutscher Ingenieure Technical Repository: Düsseldorf, Germany, 2004. [Google Scholar]

- Escobar, L.; Carvajal, N.; Naranjo, J.; Ibarra, A.; Villacis, C.; Zambrano, M.; Galarraga, F. Design and implementation of complex systems using Mechatronics and Cyber-Physical Systems approaches. In Proceedings of the 2017 IEEE International Conference on Mechatronics and Automation (ICMA), Takamatsu, Japan, 6–9 August 2017; pp. 147–154. [Google Scholar] [CrossRef]

- Enoiu, E.P.; Marinescu, R.; Seceleanu, C.; Pettersson, P. ViTAL: A Verification Tool for EAST-ADL Models Using UPPAAL PORT. In Proceedings of the 2012 IEEE 17th International Conference on Engineering of Complex Computer Systems, Paris, France, 18–20 July 2012; pp. 328–337. [Google Scholar] [CrossRef]

- Debruyne, V.; Simonot-Lion, F.; Trinquet, Y. EAST-ADL—An Architecture Description Language. In Architecture Description Languages; Springer: New York, NY, USA, 2004; pp. 181–195. [Google Scholar]

- Qureshi, T.N.; Chen, D.; Lönn, H.; Törngren, M. From EAST-ADL to AUTOSAR Software Architecture: A Mapping Scheme; Springer: Berlin/Heidelberg, Germany, 2011; pp. 328–335. [Google Scholar]

- Chen, D.; Feng, L.; Qureshi, T.N.; Lönn, H.; Hagl, F. An architectural approach to the analysis, verification and validation of software intensive embedded systems. Computing 2013, 95, 649–688. [Google Scholar] [CrossRef]

- Qureshi, T.N. Enhancing Model-Based Development of Embedded Systems; KTH: Stockholm, Sweden, 2012. [Google Scholar]

- Schweichhart, K. Reference Architectural Model Industrie 4.0 (RAMI 4.0). An Introduction. Available online: https://www.plattform-i40.de/I40/Redaktion/EN/Downloads/Publikation/rami40-an-introduction.pdf?__blob=publicationFile&v=7 (accessed on 29 November 2018).

- Uslar, M.; Göring, A.; Institut, O.; Heidel, R.; Neureiter, C.; Engel, D.; Schulte, S. An Open Source 3D Visualization for the RAMI 4. 0 Reference Model. In Proceedings VDE Kongress; VDE: Mannheim, Germany, 2016; p. 676. [Google Scholar]

- Uslar, M.; Hanna, S. Model-driven requirements engineering using RAMI 4.0 based visualizations. CEUR Workshop Proc. 2018, 2060, 21–30. [Google Scholar]

- Binder, C.; Neureiter, C.; Lastro, G.; Uslar, M.; Lieber, P. Towards a Standards-Based Domain Specific Language for Industry 4.0 Architectures. In Complex Systems Design & Management; Bonjour, E., Krob, D., Palladino, L., Stephan, F., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 44–55. [Google Scholar]

- Farwick, M.; Pasquazzo, W.; Breu, R.; Schweda, C.M.; Voges, K.; Hanschke, I. A meta-model for automated enterprise architecture model maintenance. In Proceedings of the 2012 IEEE 16th International Enterprise Distributed Object Computing Conference, Beijing, China, 10–14 September 2012; pp. 1–10. [Google Scholar] [CrossRef]

- Mordecai, Y.; Dori, D. Model-based requirements engineering: Architecting for system requirements with stakeholders in mind. In Proceedings of the 2017 IEEE International Systems Engineering Symposium (ISSE), Vienna, Austria, 11–13 October 2017. [Google Scholar] [CrossRef]

- Sonnemann, G.; Margni, M. Life Cycle Management; Springer: Berlin, Germany, 2015; ISBN 9789401772204. Available online: https://link.springer.com/book/10.1007%2F978-94-017-7221-1 (accessed on 29 November 2018).

- Zheng, C.; Bricogne, M.; Le Duigou, J.; Eynard, B. Mechatronic design process: A survey of product data model. Procedia CIRP 2014, 21, 282–287. [Google Scholar] [CrossRef]

- Larman, C. Practices for Scaling Lean & Agile Development; Pearson Education India: London, UK, 2010; ISBN 9780321636409. [Google Scholar]

- Shamieh, C. Continuous Engineering for Dummies; Wiley: Hoboken, NJ, USA, 2014; ISBN 9781118904404. [Google Scholar]

- Gracel, J.; Łebkowski, P. Analiza stopnia integracji procesów i systemów w modelu dojrzałości technologicznej firmy produkcyjnej Manutech Maturity Model (MTMM) w Przemyśle 4.0. In Proceedings of the Conference Innovation in Management and Production Engineering, Zakopane, Poland, 25–27 February 2018; pp. 541–553. [Google Scholar]

- Gracel, J.; Lebkowski, P. The Concept of Industry 4.0 Related Manufacturing Technology Maturity Model. In Proceedings of the International Conference on Decision Making in Manufacturing and Services, Zakopane, Poland, 26–30 September 2017; pp. 73–86. [Google Scholar]

- Neureiter, C.; Engel, D.; Trefke, J.; Santodomingo, R.; Rohjans, S.; Uslar, M. Towards consistent smart grid architecture tool support: From use cases to visualization. In Proceedings of the 2014 IEEE PES Innovative Smart Grid Technologies Conference Europe (ISGT Europe), Istanbul, Turkey, 12–15 October 2014; pp. 1–6. [Google Scholar]

- Neureiter, C.; Uslar, M.; Engel, D.; Lastro, G. A standards-based approach for domain specific modelling of smart grid system architectures. In Proceedings of the 2016 11th Systems of Systems Engineering Conference, SoSE 2016, Kongsberg, Norway, 12–16 June 2016; pp. 1–6. [Google Scholar]

- Neureiter, C.; Engel, D.; Uslar, M. Domain Specific and Model Based Systems Engineering in the Smart Grid as Prerequesite for Security by Design. Electronics 2016, 5, 24. [Google Scholar] [CrossRef]

- Pietrusewicz, K.; Dworak, P. Implementation of modern control algorithms in PLCs. In Proceedings of the 7th Conference Computer Methods and Systems: CMS ’09, Kraków, Poland, 26–27 November 2009; pp. 369–374. [Google Scholar]

- Pietrusewicz, K. Multi-degree of freedom robust control of the CNC X-Y table PMSM-based feed-drive module. Arch. Electr. Eng. 2012, 61, 15–31. [Google Scholar] [CrossRef] [Green Version]

- Rydahl, L.; Pietrusewicz, K.; Scopchanov, M. D4.4. Control System Standard Proposition (iLoad Project Deliverable); Hudiksvall, Sweden, 2015. [Google Scholar]

- Guerineau, B.; Bricogne, M.; Durupt, A.; Rivest, L. Mechatronics vs. cyber physical systems: Towards a conceptual framework for a suitable design methodology. In Proceedings of the 2016 11th France-Japan & 9th Europe-Asia Congress on Mechatronics (MECATRONICS)/17th International Conference on Research and Education in Mechatronics (REM), Compiegne, France, 15–17 June 2016; pp. 314–320. [Google Scholar] [CrossRef]

- Monostori, L.; Kádár, B.; Bauernhansl, T.; Kondoh, S.; Kumara, S.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-physical systems in manufacturing. CIRP Ann. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Blackburn, M.; Denno, P. Virtual Design and Verification of Cyber-physical Systems: Industrial Process Plant Design. Procedia Comput. Sci. 2014, 28, 883–890. [Google Scholar] [CrossRef] [Green Version]

- Alfred, S.; Hehenberger, P. Using design languages in model-based mechatronic system design processes. Int. J. Agil. Syst. Manag. 2017, 10, 73–91. [Google Scholar]

- Inżynieria Produkcji. Inżynieria Produkcji. Kompendium Wiedzy, 1st ed.; Knosala, R., Ed.; Polskie Wydawnictwo Ekonomiczne: Warszawa, Poland, 2017; ISBN 978-83-208-2270-0. [Google Scholar]

- Conrad, M.; Fey, I. ISO 26262–Exemplary Tool Classification of Model-Based Design Tools 1 Tool Qualification According to ISO Example: Model. Softwaretechnik-Trends 2011, 31, 56. [Google Scholar]

- Weissnegger, R.; Pistauer, M.; Kreiner, C.; Roemer, K.; Steger, C. A Novel Design Method for Automotive Safety-Critical Systems based on UML/MARTE. In Proceedings of the Forum on Specification {&} Design Languages (FDL 2015), Barcelona, Spain, 14–16 September 2015; pp. 35–42. [Google Scholar]

| Modelling Aspects | AVIA X-5 Project | iLOAD Project |

|---|---|---|

| Control system prototyping and development | -dynamic simulation of motion control algorithms, -parametric identification, -modal analysis of machine construction, -dynamic simulation of proposed measurement architectures, -dynamic simulation of PMSM/PMLM motor actuators | -dynamic simulation: hydraulic components, mechanical design, control platform, control algorithm, new sensor technologies, new measurement schemes, new materials, -dynamic simulation of loader cane features, including safety related algorithms |

| Systems and requirements engineering | -hardware/software architecture optimization, -virtual verification of construction prototypes, -closed-loop simulation, -simplified textual requirements (Excel sheets) | -hardware architecture validation, -virtual verification and validation, -graphical specification, -hardware-in-the-loop simulation, -closed-loop simulation, -systematic requirements engineering |

| Standardization and standard compliance | -IEC 61508. Functional safety of electrical/electronic/programmable electronic safety-related systems, Parts 1-7, -IEC 61131-3:2013. Programmable controllers. Part 3: Programming languages, -ISO/IEC/ IEEE 29148:2011 – textual requirements (template) | -IEC 61508. Functional safety of electrical/electronic/programmable electronic safety-related systems, Parts 1–7, -IEC 61131-3:2013. Programmable controllers. Part 3: Programming languages, -EN 12999:2011+A1. Cranes—Loader cranes, -ISO 13849-2:2012. Safety of machinery—Safety-related parts of control systems—Part 2: Validation, -ISO 15442:2005. Cranes—Safety requirements for loader cranes, -IEC 62061:2005. Safety of machinery—Functional safety of safety-related electrical, electronic and programmable electronic control systems, -VDI—Association of German Engineers VDI 2206—Design methodology for mechatronic systems. Design 2004, 118, -own domain-specific modelling language (EAST-ADL inspired) |

| Project management support | -industry—university cooperation, -factory testing planning (new for university members) | -industry—university cooperation, -project resources planning, -EU Participant Portal reporting, -SCRUM project management, -certified laboratory testing, -project budget monitoring, -team members training planning, -time-sheets monitoring |

| Metamodeling Aspects | AVIA X-5 Project | iLOAD Project |

|---|---|---|

| Control system prototyping and development | -Matlab/Simulink, -Siemens/Haidenhain software tools, -CAD drawings (SolidWorks) transformation into dynamic models, -reports generation, -existing metamodels | -Matlab/Simulink, -MetaEdit+, -automatic Simulink models generation, -PLC code generation, -creation of new metamodels |

| Systems and requirements engineering | -Matlab/Simulink tools, -existing metamodels | -EAST-ADL, SysML, -creation of new metamodels, -MetaEdit+ requirements import/export, -Matlab/Simulink, -Latex, Microsoft Office integration |

| Standardization and standard compliance | -Matlab/Simulink, -textual management, -existing metamodels | -creation of new metamodels, SysML, -Microsoft Office integration, -import/export of model objects |

| Project management support | -Microsoft Office, -no methodology used, -existing metamodels | -creation of new metamodels, -Microsoft Office integration, -SCRUM tools and process, -Enterprise Architect |

| Team-Related Aspects | AVIA X-5 Project | iLOAD Project |

|---|---|---|

| Experience | -Matlab/Simulink, -SolidWorks (CAD), -project participation/management, -control system design, -mechanical system design | -Matlab/Simulink, HOPSAN, -CAD software, -Domain-Specific Modelling, -modelling of production processes, -project participation/management |

| Size | 3 engineers | 16 engineers, incl. 3 managers |

| Expertise | -control engineering, -mechanical engineering | -control engineering, robotics, -mechanical engineering, -hydraulic engineering, -IT, ICT, -project management, -standardization, functional safety |

| Motivation/rationale | -business needs, -industry – university cooperation, -new machine/product development | -business needs, -industry—university cooperation, -new machine/product development, -new process, -standards compliance, -new people, -new materials |

| Method adoption time | 1 month | 12 months |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pietrusewicz, K. Metamodelling for Design of Mechatronic and Cyber-Physical Systems. Appl. Sci. 2019, 9, 376. https://doi.org/10.3390/app9030376

Pietrusewicz K. Metamodelling for Design of Mechatronic and Cyber-Physical Systems. Applied Sciences. 2019; 9(3):376. https://doi.org/10.3390/app9030376

Chicago/Turabian StylePietrusewicz, Krzysztof. 2019. "Metamodelling for Design of Mechatronic and Cyber-Physical Systems" Applied Sciences 9, no. 3: 376. https://doi.org/10.3390/app9030376

APA StylePietrusewicz, K. (2019). Metamodelling for Design of Mechatronic and Cyber-Physical Systems. Applied Sciences, 9(3), 376. https://doi.org/10.3390/app9030376