An Experimental Investigation of Moisture-Induced Softening Mechanism of Marble Based on Quantitative Analysis of Acoustic Emission Waveforms

Abstract

:1. Introduction

2. Experimental Approach

2.1. Sample Preparation

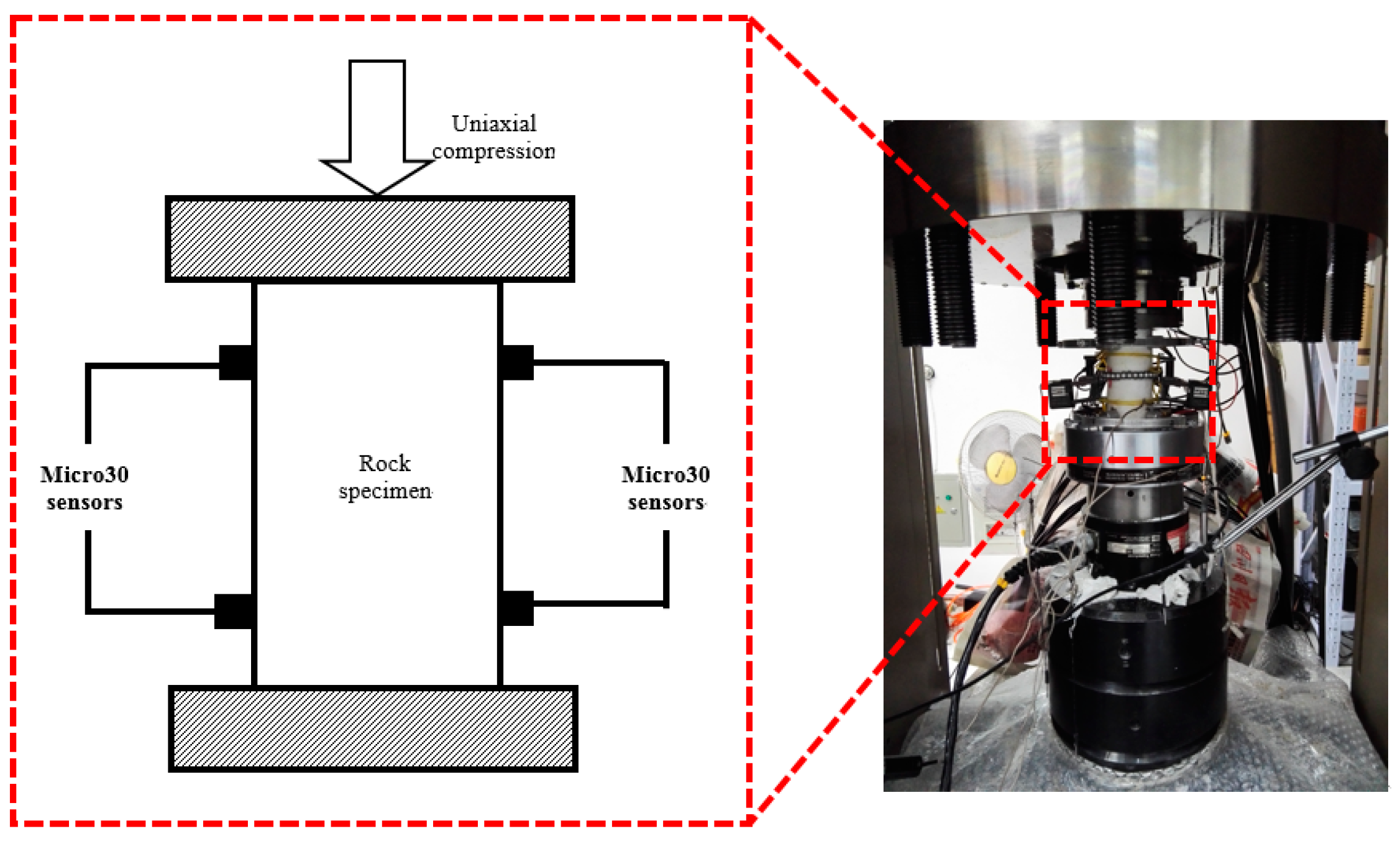

2.2. Experimental Setup and Equipment

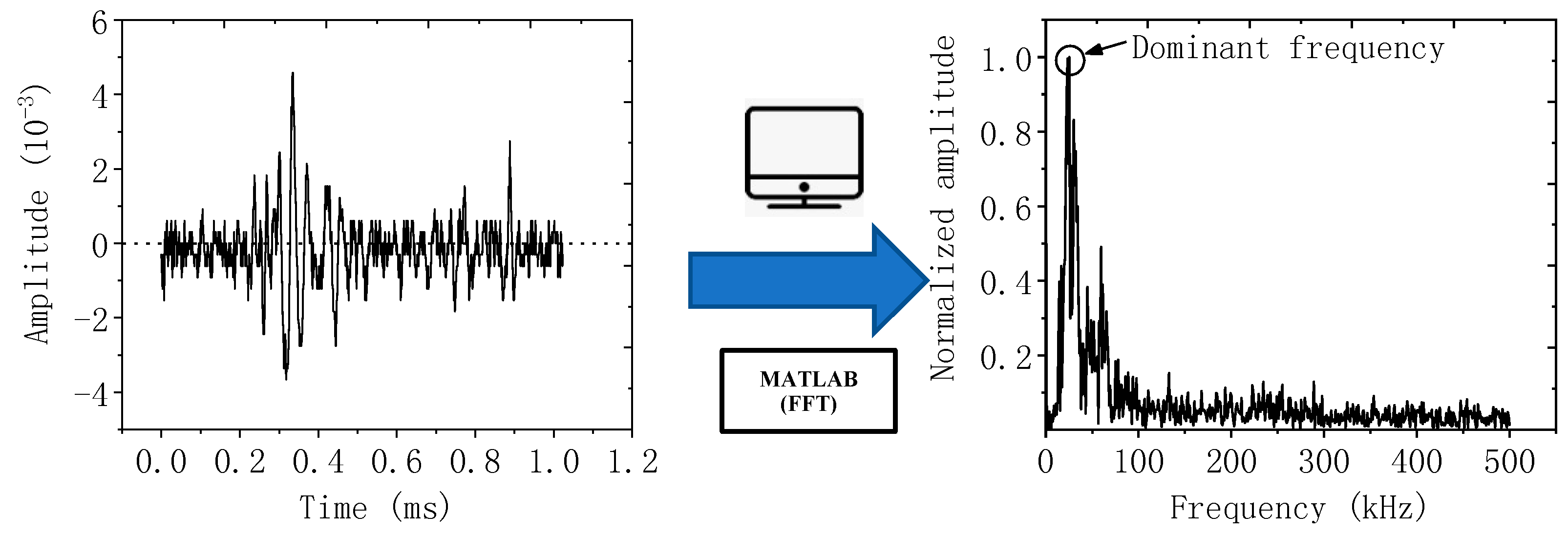

2.3. Waveform Data Processing

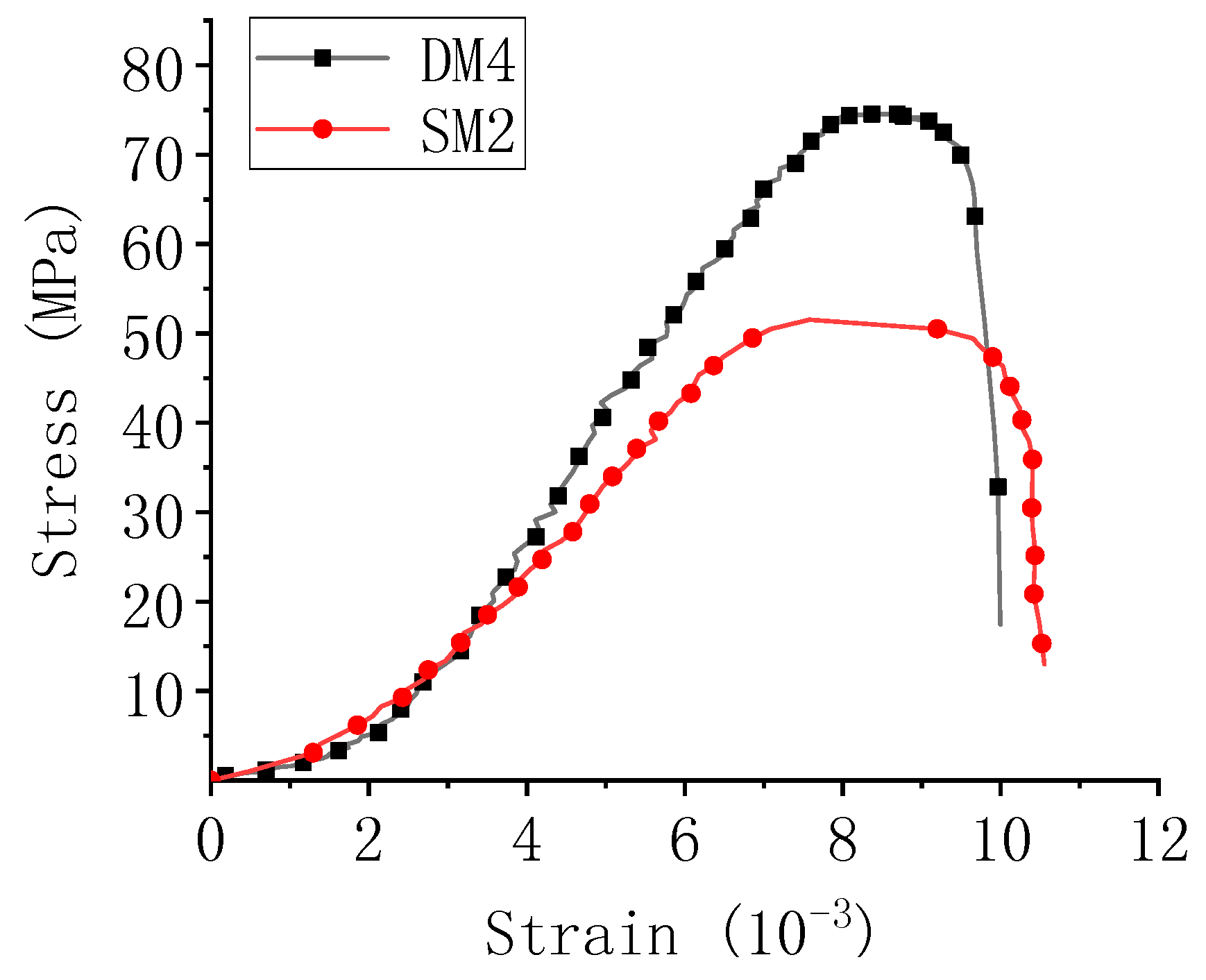

3. Testing Results

3.1. Macroscopic Failure Patterns

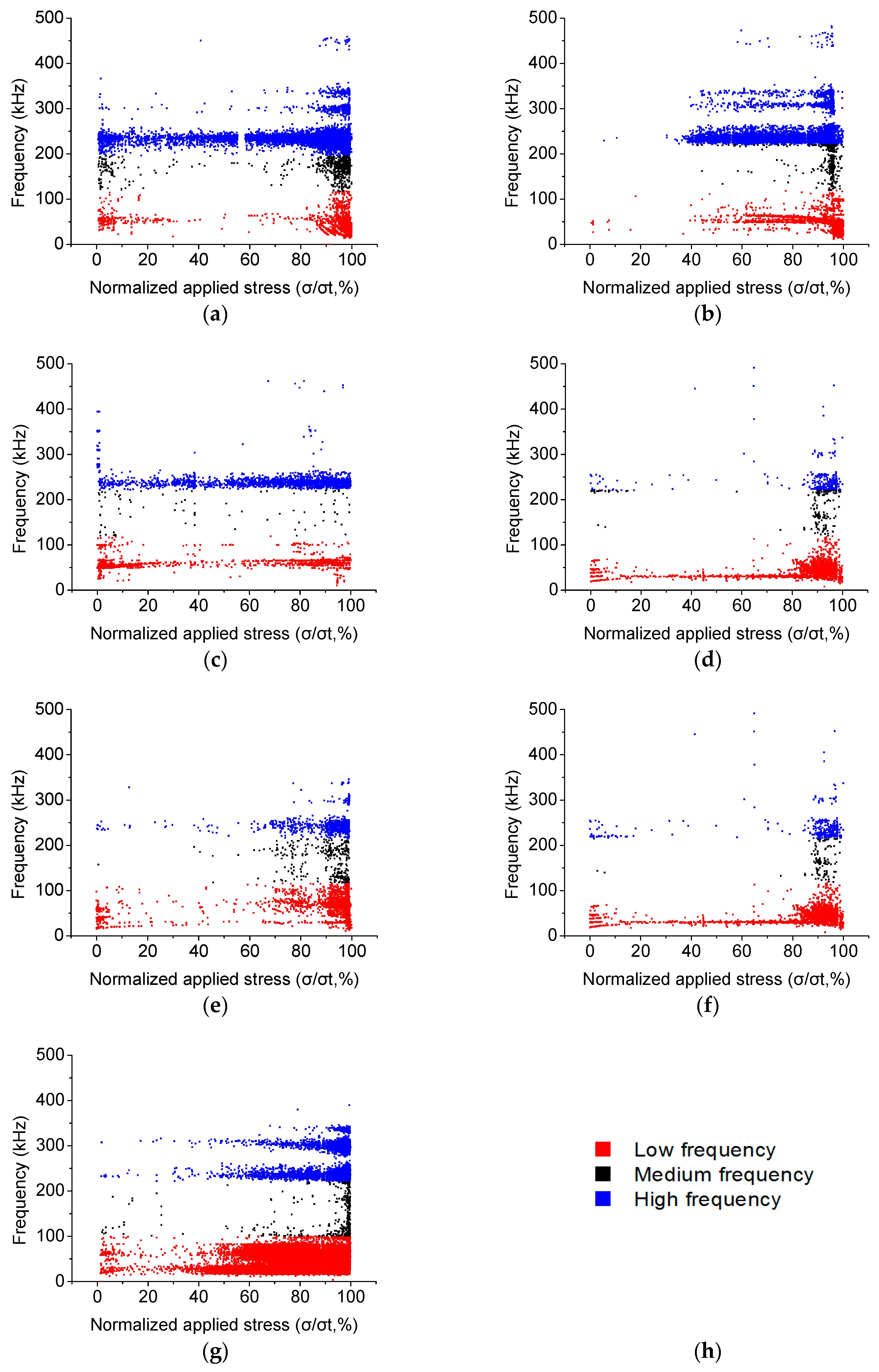

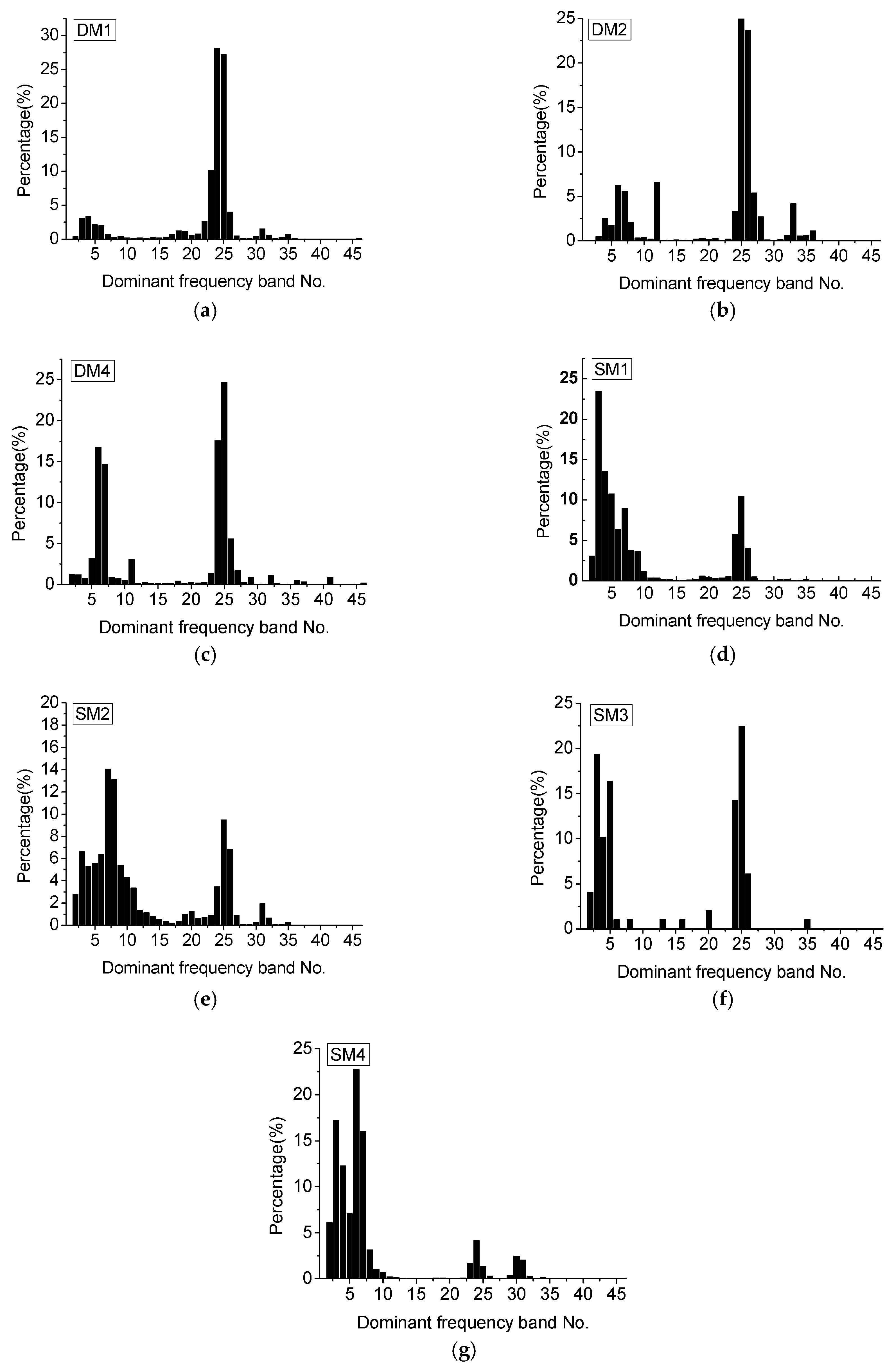

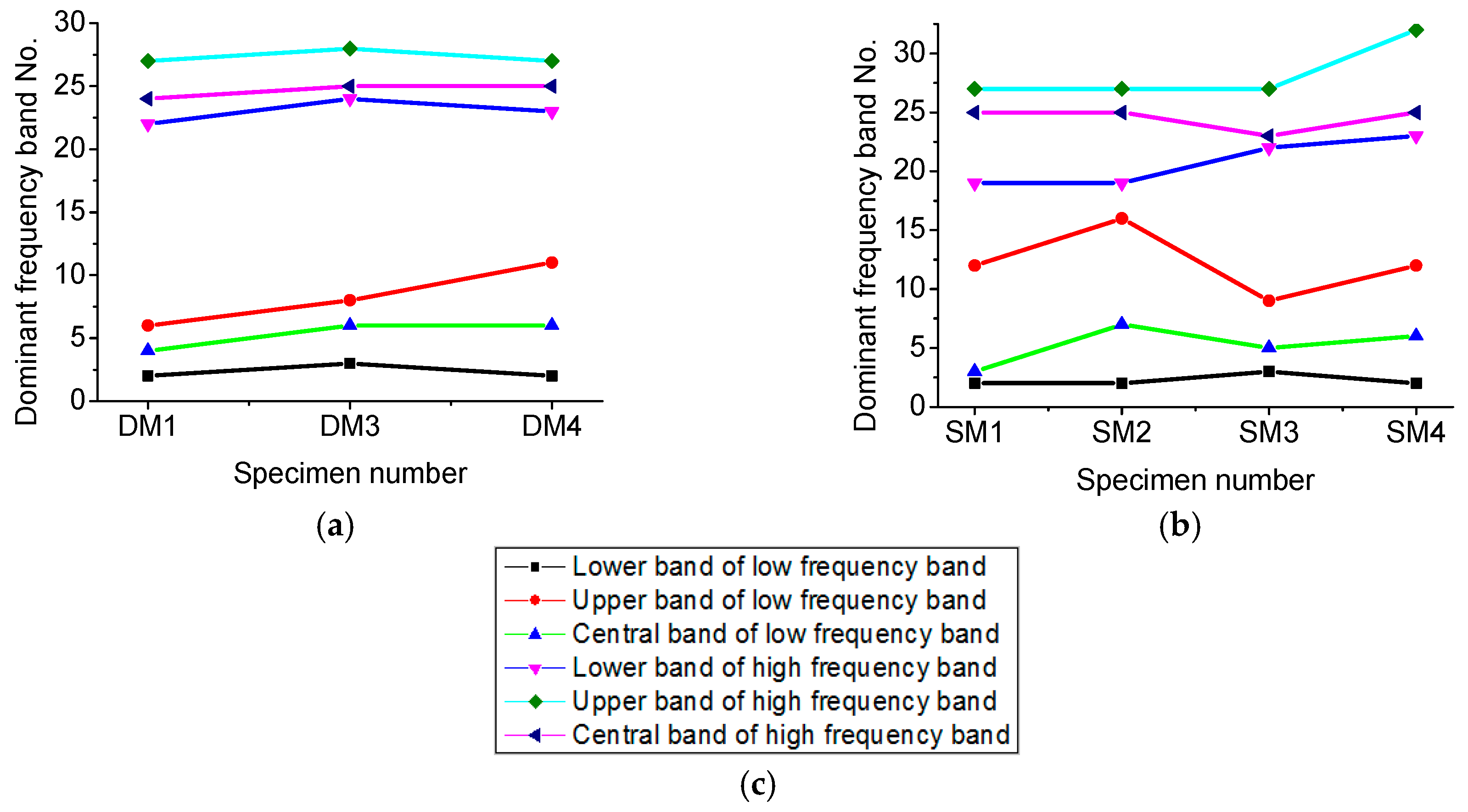

3.2. Frequency Characteristics

3.3. Energy Characteristics

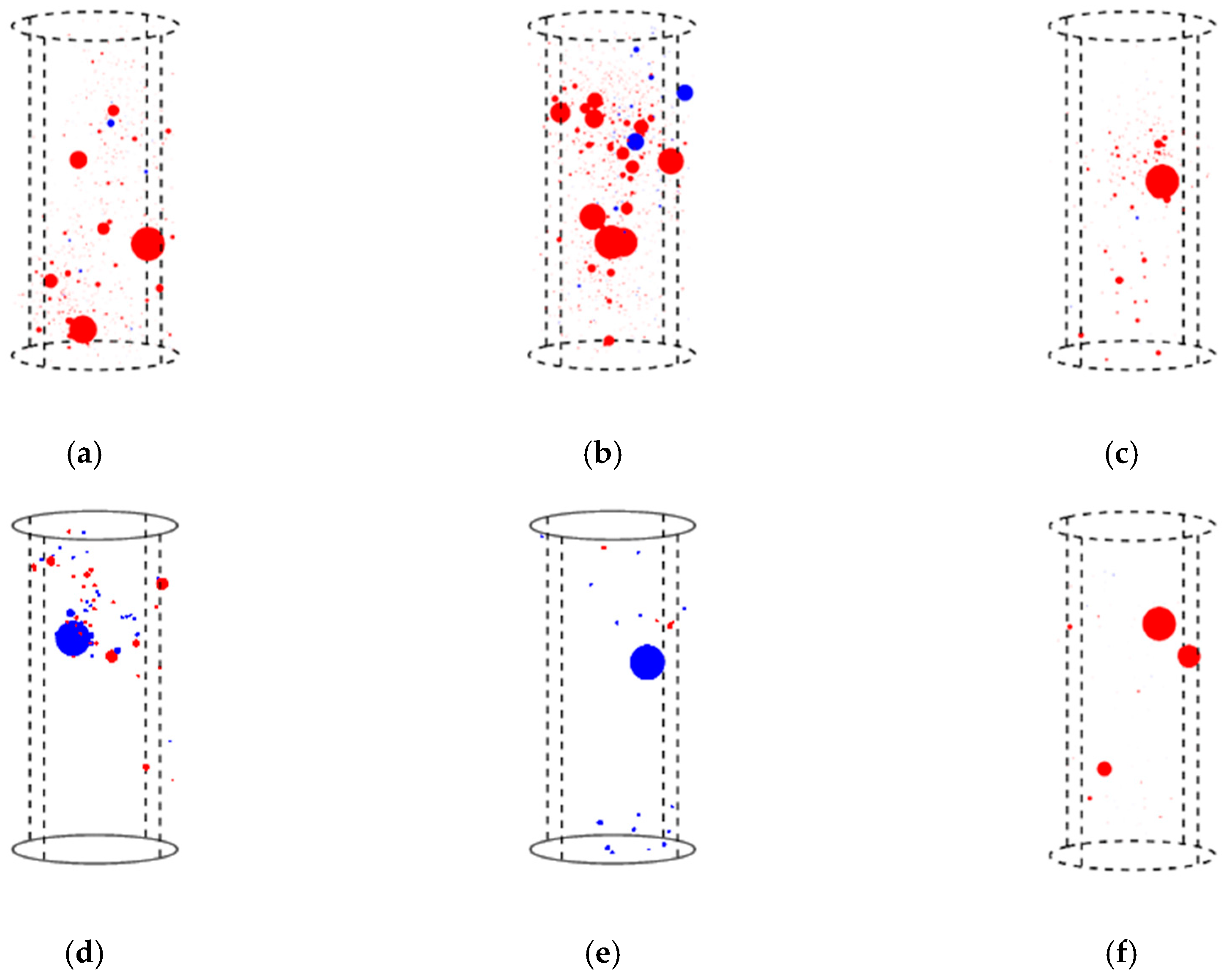

4. Distinctions Between Failure Mechanisms of Dried and Saturated Rocks

4.1. Macroscopic Failure Mechanism

4.2. Microscopic Failure Mechanism

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Price, N.J. The compressive strength of coal measure rocks. Colliery Eng. 1960, 37, 283–292. [Google Scholar]

- Hawkins, A.B.; Mcconnell, B.J. Sensitivity of sandstone strength and deformability to changes in moisture content. Q. J. Eng. Geol. Hydrogeol. 1992, 25, 115–130. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, Q. Triaxial tests of effects of varied saturations on strength and modulus for sandstone. Rock Soil Mech. 2014, 35, 951–958. [Google Scholar]

- Jones, F.O. A laboratory study of the effects of confining pressure on fracture flow and storage capacity in carbonate rocks. J. Pet. Technol. 1975, 27, 21–27. [Google Scholar] [CrossRef]

- Rajabzadeh, M.A.; Moosavinasab, Z.; Rakhshandehroo, G. Effects of Rock Classes and Porosity on the Relation between Uniaxial Compressive Strength and Some Rock Properties for Carbonate Rocks. Rock Mech. Rock Eng. 2012, 45, 113–122. [Google Scholar] [CrossRef]

- Erguler, Z.A.; Ulusay, R. Water-induced variations in mechanical properties of clay-bearing rocks. Int. J. Rock Mech. Min. Sci. 2009, 46, 355–370. [Google Scholar] [CrossRef]

- Simpson, D.R.; Fergus, J.H. The effect of water on the compressive strength of diabase. J. Geophys. Res. 1968, 73, 6591–6594. [Google Scholar] [CrossRef]

- Chen, T.C.; Yeung, M.R.; Mori, N. Effect of water saturation on deterioration of welded tuff due to freeze-thaw action. Cold Reg. Sci. Technol. 2004, 38, 127–136. [Google Scholar] [CrossRef]

- Çelik, M.Y.; Ergül, A. The influence of the water saturation on the strength of volcanic tuffs used as building stones. Environ. Earth Sci. 2015, 74, 1–17. [Google Scholar] [CrossRef]

- Kessler, D.; Insley, H.; Sligh, W. Physical, mineralogical and durability studies on the building and monumental granites of the United States. J. Res. Natl. Bur. Stand. 1940, 24, 161–206. [Google Scholar] [CrossRef]

- Ruiz, M.D. Some technological of twenty-six characteristics Brazilian rock types. In Proceedings of the 1st Congress of the International Society of Rock Mechanics, Lisbon, Portugal, 25 September–1 October 1966. [Google Scholar]

- Lau, J.S.O.; Gorski, B.; Jackson, R. The Effects of Temperature and Water-saturation on Mechanical Properties of Lac Du Bonnet Pink Granite. In Proceedings of the 8th ISRM Congress, Tokyo, Japan, 25–29 September 1995. [Google Scholar]

- Jang, H.S.; Kang, S.S.; Jang, B.A. Determination of Joint Roughness Coefficients Using Roughness Parameters. Rock Mech. Rock Eng. 2014, 47, 2061–2073. [Google Scholar] [CrossRef]

- Yuan, P. A Study of AE Characteristics of Marble Specimens Under Uniaxial Compression—Failure Prediction. J. Kunming Univ. Sci. Technol. 1987, 2, 12–17. [Google Scholar]

- Ohnaka, M.; Mogi, K. Frequency characteristics of acoustic emission in rocks under uniaxial compression and its relation to the fracturing process to failure. J. Geophys. Res. Solid Earth 1982, 87, 3873–3884. [Google Scholar] [CrossRef]

- Zhang, C.; Liang, W.; Li, Z.; Xu, S.; Zhao, Y. Observations of acoustic emission of three salt rocks under uniaxial compression. Int. J. Rock Mech. Min. Sci. 2015, 77, 19–26. [Google Scholar] [CrossRef]

- Filipussi, D.A.; Guzmán, C.A.; Xargay, H.D.; Hucailuk, C.; Torres, D.N. Study of Acoustic Emission in a Compression Test of Andesite Rock. Procedia Mater. Sci. 2015, 9, 292–297. [Google Scholar] [CrossRef] [Green Version]

- Triantis, D. Acoustic emission monitoring of marble specimens under uniaxial compression. Precursor phenomena in the near-failure phase. Struct. Integr. Procedia 2018, 10, 11–17. [Google Scholar] [CrossRef]

- Ling, T.; Liao, Y.; Zhang, S. Application of wavelet packet method in frequency band energy distribution of rock acoustic emission signals under impact loading. J. Vib. Shock 2010, 29, 127–130. [Google Scholar]

- Armstrong, B.H. Acoustic emission prior to rockbursts and earthquakes. Bull. Seismol. Soc. Am. 1969, 59, 1259–1279. [Google Scholar]

- Aggelis, D.G.; Soulioti, D.V.; Sapouridis, N.; Barkoula, N.M.; Paipetis, A.S.; Matikas, T.E. Acoustic emission characterization of the fracture process in fibre reinforced concrete. Constr. Build. Mater. 2011, 25, 4126–4131. [Google Scholar] [CrossRef]

- Aggelis, D.G. Classification of cracking mode in concrete by acoustic emission parameters. Mech. Res. Commun. 2011, 38, 153–157. [Google Scholar] [CrossRef]

- Ohno, K.; Ohtsu, M. Crack classification in concrete based on acoustic emission. Constr. Build. Mater. 2010, 24, 2339–2346. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Mpalaskas, A.C.; Ntalakas, D.; Matikas, T.E. Effect of wave distortion on acoustic emission characterization of cementitious materials. Constr. Build. Mater. 2012, 35, 183–190. [Google Scholar] [CrossRef]

- Shiotani, T.; Ohtsu, M.; Ikeda, K. Detection and evaluation of AE waves due to rock deformation. Constr. Build. Mater. 2001, 15, 235–246. [Google Scholar] [CrossRef]

- Behnia, A.; Chai, H.K.; Shiotani, T. Advanced structural health monitoring of concrete structures with the aid of acoustic emission. Constr. Build. Mater. 2014, 65, 282–302. [Google Scholar] [CrossRef]

- Aker, E.; Kühn, D.; Vavryčuk, V.; Soldal, M.; Oye, V. Experimental investigation of acoustic emissions and their moment tensors in rock during failure. Int. J. Rock Mech. Min. Sci. 2014, 70, 286–295. [Google Scholar] [CrossRef]

- Liu, J.P.; Li, Y.H.; Xu, S.D.; Xu, S.; Jin, C. Cracking mechanisms in granite rocks subjected to uniaxial compression by moment tensor analysis of acoustic emission. Theor. Appl. Fract. Mech. 2015, 75, 151–159. [Google Scholar]

- Li, L.R.; Deng, J.H.; Zheng, L.; Liu, J.F. Dominant Frequency Characteristics of Acoustic Emissions in White Marble During Direct Tensile Tests. Rock Mech. Rock Eng. 2017, 50, 1337–1446. [Google Scholar] [CrossRef]

- Committee, R.T. Recommendation of RILEM TC 212-ACD: Acoustic emission and related NDE techniques for crack detection and damage evaluation in concrete. Mater. Struct. 2010, 43, 1187–1189. [Google Scholar]

- Li, L.R. Dominant Frequencies and Their Mechanical Mechanism of Acoustic Emissions in Rock Failures. Ph.D. Thesis, Sichuan University, Chengdu, China, 2017. [Google Scholar]

- Jaeger, J.C.; Cook, N.G.W.; Zimmerman, R.W. Fundamentals of Rock Mechanics, 4th ed.; Blackwell Publishing: Hoboken, NJ, USA, 2007. [Google Scholar]

- Zhang, Z.H.; Deng, J.H.; Zhu, J.B.; Li, L.R. An Experimental Investigation of the Failure Mechanisms of Jointed and Intact Marble under Compression Based on Quantitative Analysis of Acoustic Emission Waveforms. Rock Mech. Rock Eng. 2018, 51, 2299–2307. [Google Scholar] [CrossRef]

| Specimen No. | UCS (MPa) |

|---|---|

| DM1 | 67.06 |

| DM2 | 68.86 |

| DM4 | 74.57 |

| SM1 | 61.72 |

| SM2 | 52.90 |

| SM3 | 69.03 |

| SM4 | 61.33 |

| Specimen No. | Percentage of Low Frequency Bands (%) | Percentage of High Frequency Bands (%) |

|---|---|---|

| DM1 | 17.43 | 77.03 |

| DM2 | 26.06 | 72.49 |

| DM4 | 42.91 | 53.41 |

| SM1 | 75.41 | 22.08 |

| SM2 | 68.25 | 25.24 |

| SM3 | 52.04 | 43.88 |

| SM4 | 86.29 | 12.41 |

| Specimen No. | Percentage of Energy of Low Frequency Waveforms (%) | Percentage of Energy of High Frequency Waveforms (%) |

|---|---|---|

| DM1 | 13.99 | 79.28 |

| DM2 | 15.86 | 80.20 |

| DM4 | 27.03 | 71.21 |

| SM1 | 69.35 | 29.29 |

| SM2 | 84.71 | 15.02 |

| SM3 | 39.04 | 56.97 |

| SM4 | 64.62 | 35.17 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Deng, J.; Zhu, J. An Experimental Investigation of Moisture-Induced Softening Mechanism of Marble Based on Quantitative Analysis of Acoustic Emission Waveforms. Appl. Sci. 2019, 9, 446. https://doi.org/10.3390/app9030446

Huang Y, Deng J, Zhu J. An Experimental Investigation of Moisture-Induced Softening Mechanism of Marble Based on Quantitative Analysis of Acoustic Emission Waveforms. Applied Sciences. 2019; 9(3):446. https://doi.org/10.3390/app9030446

Chicago/Turabian StyleHuang, Yiming, Jianhui Deng, and Jun Zhu. 2019. "An Experimental Investigation of Moisture-Induced Softening Mechanism of Marble Based on Quantitative Analysis of Acoustic Emission Waveforms" Applied Sciences 9, no. 3: 446. https://doi.org/10.3390/app9030446