Performance Test on Styrene-Butadiene-Styrene (SBS) Modified Asphalt Based on the Different Evaluation Methods

Abstract

:1. Introduction

2. Material

2.1. Matrix Asphalt

2.2. SBS Modifier

3. Results and Discussion

3.1. Performance Test of SBS Modified Asphalt with Chinese Evaluation Methods

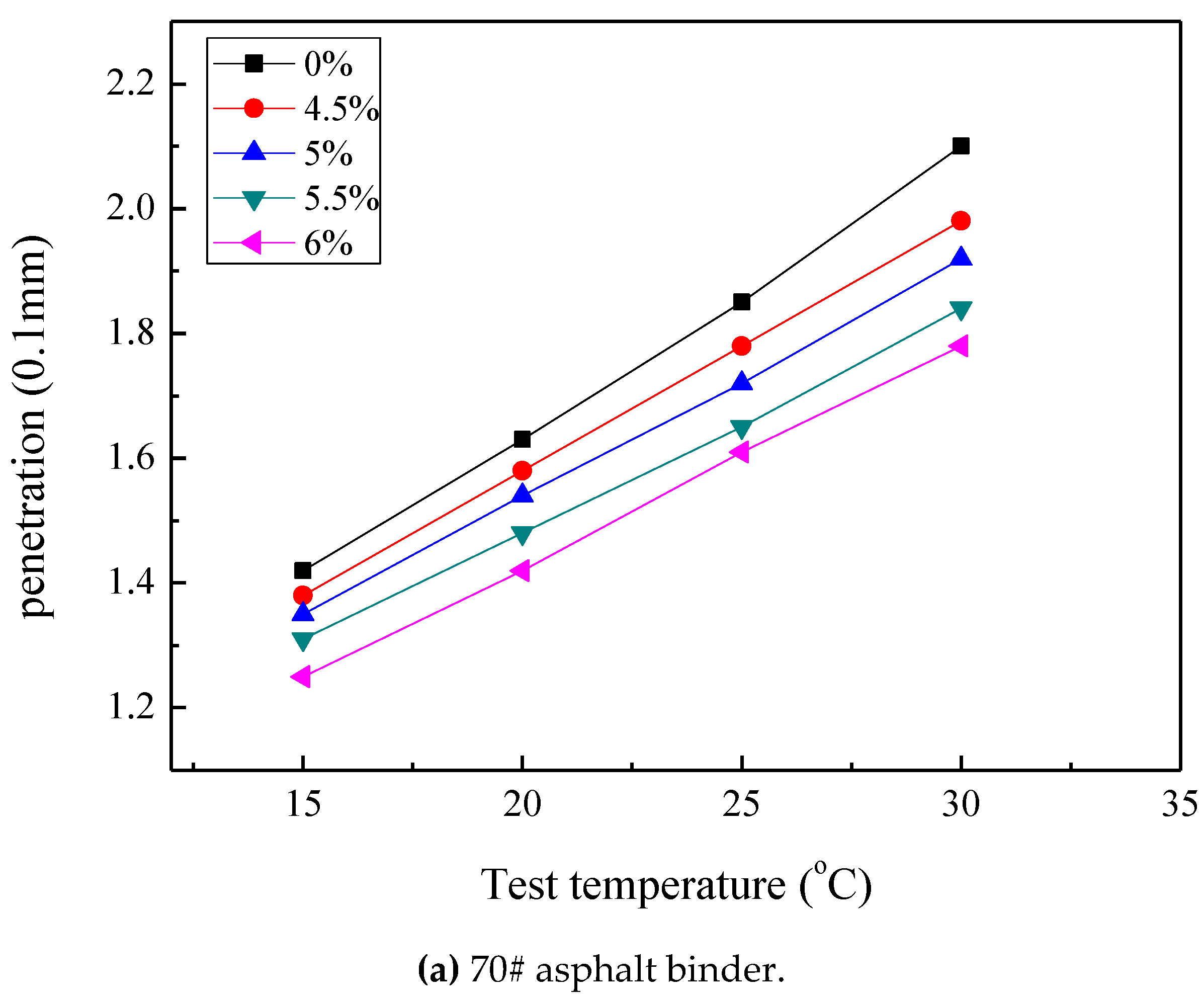

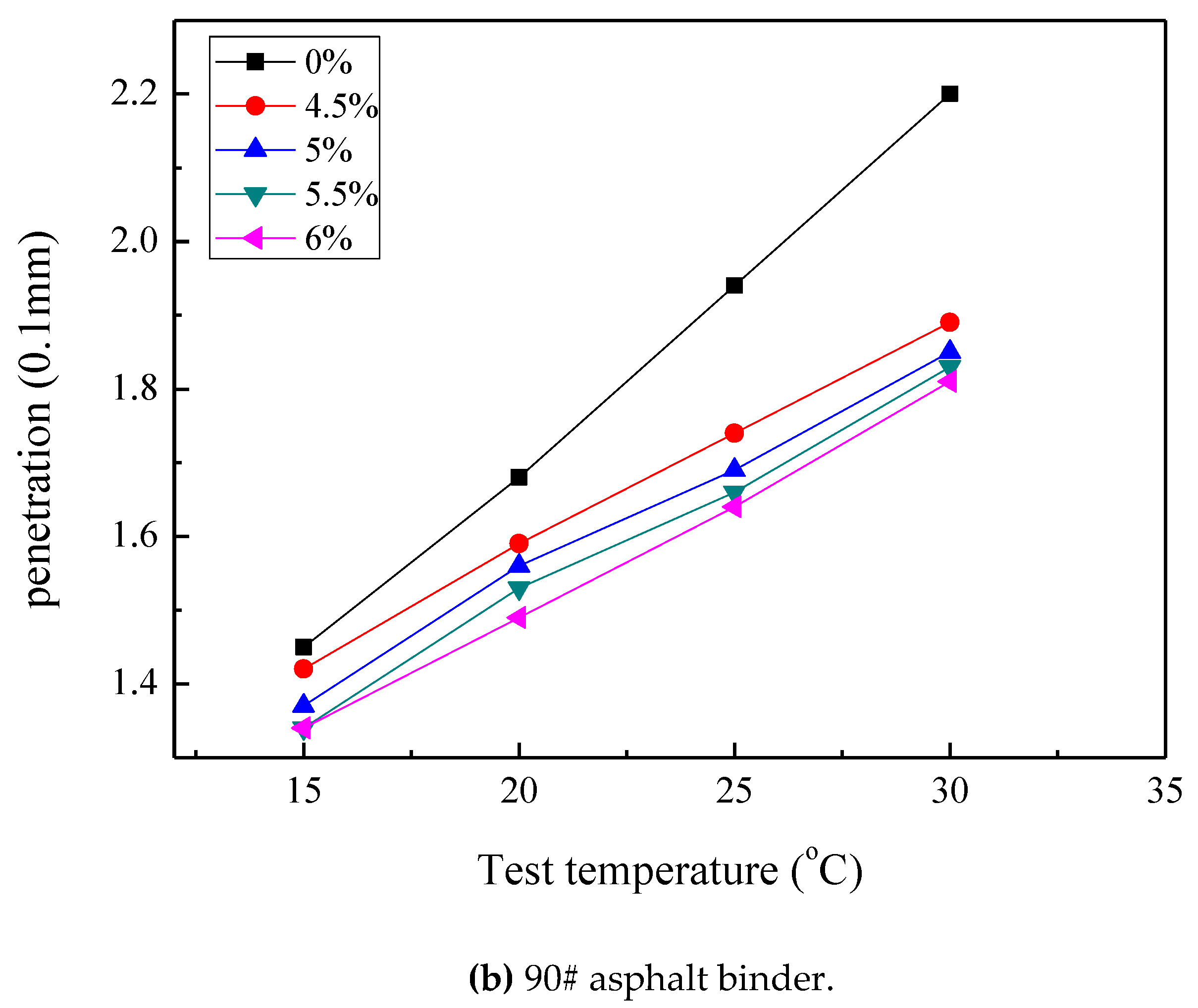

3.1.1. Penetration

3.1.2. Softening Point

3.1.3. Ductility and Elastic Recovery

3.2. Test Result of Superpave Method for SBS Modified Asphalt

3.2.1. Dynamic Shear Rheological (DSR) Test

3.2.2. Brookfield Rotary Viscosity Test

3.2.3. Bending Beam Rheometer (BBR) Test

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wen, G.; Zhang, Y.; Zhang, Y.; Sun, K.; Fan, Y. Rheological characterization of storage-stable SBS-modified asphalts. Polym. Test. 2002, 21, 295–302. [Google Scholar] [CrossRef]

- Park, T.S.; Cho, H.K. Evaluation of Mechanical Characteristics of SBS Polymer Modified Asphalt Mixtures upon Variation of Filler Contents. Neurochem. Res. 2002, 33, 1979–1989. [Google Scholar]

- Zhao, X.; Wang, S.; Wang, Q.; Yao, H. Rheological and structural evolution of SBS modified asphalts under natural weathering. Fuel 2016, 184, 242–247. [Google Scholar] [CrossRef]

- Khodaii, A.; Mehrara, A. Evaluation of permanent deformation of unmodified and SBS modified asphalt mixtures using dynamic creep test. Constr. Build. Mater. 2009, 23, 2586–2592. [Google Scholar] [CrossRef]

- Forough, S.A. Investigating the effects of loading frequency and temperature on moisture sensitivity of SBS-modified asphalt mixtures. J. Mater. Civ. Eng. 2014, 26, 897–903. [Google Scholar]

- Huang, W.; Tang, N. Characterizing SBS modified asphalt with sulfur using multiple stress creep recovery test. Constr. Build. Mater. 2015, 93, 514–521. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, L.; Zhou, J. Pavement performance evaluation of recycled styrene–butadiene–styrene-modified asphalt mixture. Int. J. Pavement Eng. 2017, 18, 404–413. [Google Scholar] [CrossRef]

- Fu, H.; Xie, L.; Dou, D.; Li, L.; Yu, M.; Yao, S. Storage stability and compatibility of asphalt binder modified by SBS graft copolymer. Constr. Build. Mater. 2007, 21, 1528–1533. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Fan, G.U.; Huang, X.M. Analysis on SBS Modified Asphalt Aging Characterization Based on Fourier Transform Infrared Spectroscopy. J. Build. Mater. 2011, 14, 620–623. [Google Scholar]

- Becker, M.Y.; Müller, A.J.; Rodriguez, Y. Use of rheological compatibility criteria to study SBS modified asphalts. J. Appl. Polym. Sci. 2003, 90, 1772–1782. [Google Scholar]

- Kim, T.W.; Baek, J.; Lee, H.J.; Choi, J.Y. Fatigue performance evaluation of SBS modified mastic asphalt mixtures. Constr. Build. Mater. 2013, 48, 908–916. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, H.; Gao, J.; Yang, X.; You, Z. Comprehensive performance evaluation and cost analysis of SBS-modified bioasphalt binders and mixtures. J. Mater. Civil. Eng. 2017, 29, 04017232. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; You, Z.; Mohd Hasan, M.; Lei, Y.; Irfan, M. Rheological behavior and sensitivity of wood-derived bio-oil modified asphalt binders. Appl. Sci. 2018, 8, 919. [Google Scholar] [CrossRef]

- Morrison, G.R.; Lee, J.K.; Hesp, S.A. Chlorinated polyolefins for asphalt binder modification. J. Appl. Polym. Sci. 2010, 54, 231–240. [Google Scholar] [CrossRef]

- Jasso, M.; Bakos, D.; Stastna, J.; Zanzotto, L. Conventional asphalt modified by physical mixtures of linear SBS and montmorillonite. Appl. Clay Sci. 2012, 70, 37–44. [Google Scholar] [CrossRef]

- Background, A.; Objective, B.; Materials, C. Understanding The Performance of Modified Asphalt Binders in Mixtures: High-Temperature Characterization; Federal Highway Administration: Washington, DC, USA, 2002.

- Galooyak, S.S.; Dabir, B.; Nazarbeygi, A.E.; Moeini, A. Rheological properties and storage stability of bitumen/SBS/montmorillonite composites. Constr. Build. Mater. 2010, 24, 300–307. [Google Scholar] [CrossRef]

- Zhang, L.; Greenfield, M.L. Relaxation time, diffusion, and viscosity analysis of model asphalt systems using molecular simulation. J. Chem. Phys. 2007, 127, 194502. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ji, X.P.; Zheng, N.X.; Yang, D.Q.; Hou, Y.Q. Research on Mixing Temperature of Hot-recycled Asphalt Mixture Based on Composite Curve of Viscosity-temperature. China J. Highw. Transp. 2010, 23, 16–21. [Google Scholar]

- Zhang, R.; Wang, H.; Gao, J.; You, Z.; Yang, X. High temperature performance of SBS modified bio-asphalt. Constr. Build. Mater. 2017, 144, 99–105. [Google Scholar] [CrossRef]

- Ma, T.; Huang, X.; Zhao, Y.; Yuan, H. Aging Behaviour and Mechanism of SBS-Modified Asphalt. J. Test. Eval. 2012, 40, 1186–1191. [Google Scholar] [CrossRef]

| Technical Indicators | Units | SK90# | SK70# | ||

|---|---|---|---|---|---|

| Test Result | Technical Requirement | Test Result | Technical Requirement | ||

| Penetration (15 °C, 100 g, 5 s) | 0.1 mm | 31 | / | 26 | / |

| Penetration (25 °C, 100 g, 5 s) | 0.1 mm | 91 | 80–100 | 73 | 60–80 |

| Penetration (30 °C, 100 g, 5 s) | 0.1 mm | 162 | / | 129 | / |

| PI | −1.24 | −1.5–+1.0 | −1.39 | −1.5–+1.0 | |

| Softening point | °C | 47 | ≥45 | 49 | ≥46 |

| Ductility (5 °C, 5 cm/min) | cm | 105.4 | ≥45 | 79.8 | ≥20 |

| Rotary viscosity (135 °C) | Pa·s | 0.756 | ≤3 | 0.723 | ≤3 |

| Density (15 °C) | g/cm3 | 0.913 | / | 0.974 | / |

| Technical Parameters | S/B Mass Ratio | Volatile (%) | Tensile Strength (MPa) | Ash (%) | 300% Stress at Definite Elongation (MPa) |

|---|---|---|---|---|---|

| Test Results | 30/70 | ≤0.7 | 18.5 | ≤0.2 | 2.4 |

| Source | df | F-Value | p-Value | |

|---|---|---|---|---|

| SBS modifier dosage | 70# matrix asphalt | 4 | 7.65 | 0.064 |

| 90# matrix asphalt | 4 | 5.89 | 0.076 | |

| Temperature | 70# matrix asphalt | 2 | 37.64 | 0.001 |

| 90# matrix asphalt | 2 | 16.88 | 0.007 | |

| Source | df | F-Value | p-Value | |

|---|---|---|---|---|

| SBS modifier dosage | 70# matrix asphalt | 4 | 268.47 | 0.25 |

| SBS modifier dosage | 90# matrix asphalt | 4 | 8641.65 | 0.02 |

| Source | df | F | Sig. | |

|---|---|---|---|---|

| Ductility | 70# matrix asphalt | 3 | 72.58 | 0.001 |

| 90# matrix asphalt | 3 | 36.47 | 0.002 | |

| Elastic recovery | 70# matrix asphalt | 3 | 874.62 | 0.001 |

| 90# matrix asphalt | 3 | 153.87 | 0.002 | |

| 0% | 4.5% | 5% | 5.5% | 6% | |

|---|---|---|---|---|---|

| 0% | ─ | S | S | S | S |

| 4.5% | ─ | S | S | S | |

| 5% | ─ | S | S | ||

| 5.5% | ─ | N | |||

| 6% | ─ |

| SBS Modifier Dosage | N | VTS | R2 |

|---|---|---|---|

| 4.5% | 3.426 | 0.869 | 0.997 |

| 5% | 3.351 | 0.743 | 0.997 |

| 5.5% | 3.254 | 0.715 | 0.995 |

| 6% | 3.139 | 0.637 | 0.993 |

| Source | df | F | Sig. | |

|---|---|---|---|---|

| SBS modifier dosage | −18 °C | 4 | 198.68 | 0.001 |

| −12 °C | 4 | 376.57 | 0.001 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Wang, H.; You, Z.; Gao, J.; Irfan, M. Performance Test on Styrene-Butadiene-Styrene (SBS) Modified Asphalt Based on the Different Evaluation Methods. Appl. Sci. 2019, 9, 467. https://doi.org/10.3390/app9030467

Zhang C, Wang H, You Z, Gao J, Irfan M. Performance Test on Styrene-Butadiene-Styrene (SBS) Modified Asphalt Based on the Different Evaluation Methods. Applied Sciences. 2019; 9(3):467. https://doi.org/10.3390/app9030467

Chicago/Turabian StyleZhang, Chen, Hainian Wang, Zhanping You, Junfeng Gao, and Muhammad Irfan. 2019. "Performance Test on Styrene-Butadiene-Styrene (SBS) Modified Asphalt Based on the Different Evaluation Methods" Applied Sciences 9, no. 3: 467. https://doi.org/10.3390/app9030467

APA StyleZhang, C., Wang, H., You, Z., Gao, J., & Irfan, M. (2019). Performance Test on Styrene-Butadiene-Styrene (SBS) Modified Asphalt Based on the Different Evaluation Methods. Applied Sciences, 9(3), 467. https://doi.org/10.3390/app9030467