Design and Characterization of Electrically Conductive Structures Additively Manufactured by Material Extrusion

Abstract

:1. Introduction

2. Additively Manufactured Electrically Conductive Structures

2.1. Applications of Additively Manufactured Integrated Electrically Conductive Structures

2.2. Characterization of Electrically Conductive Composite Materials Additively Manufactured by MEX

3. Experimental

3.1. Experimental Set-Up

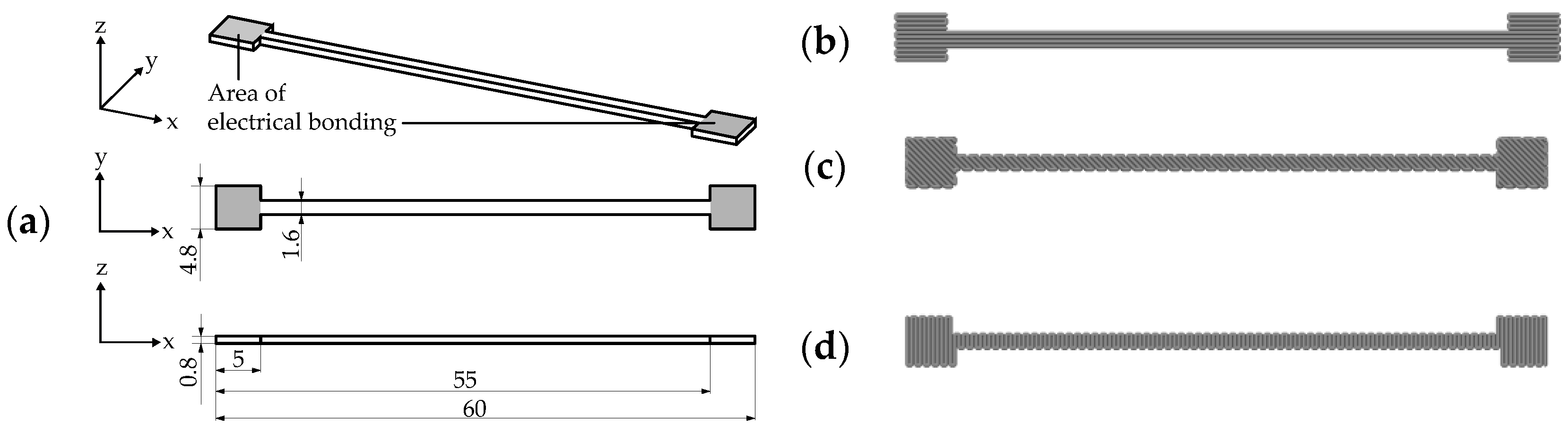

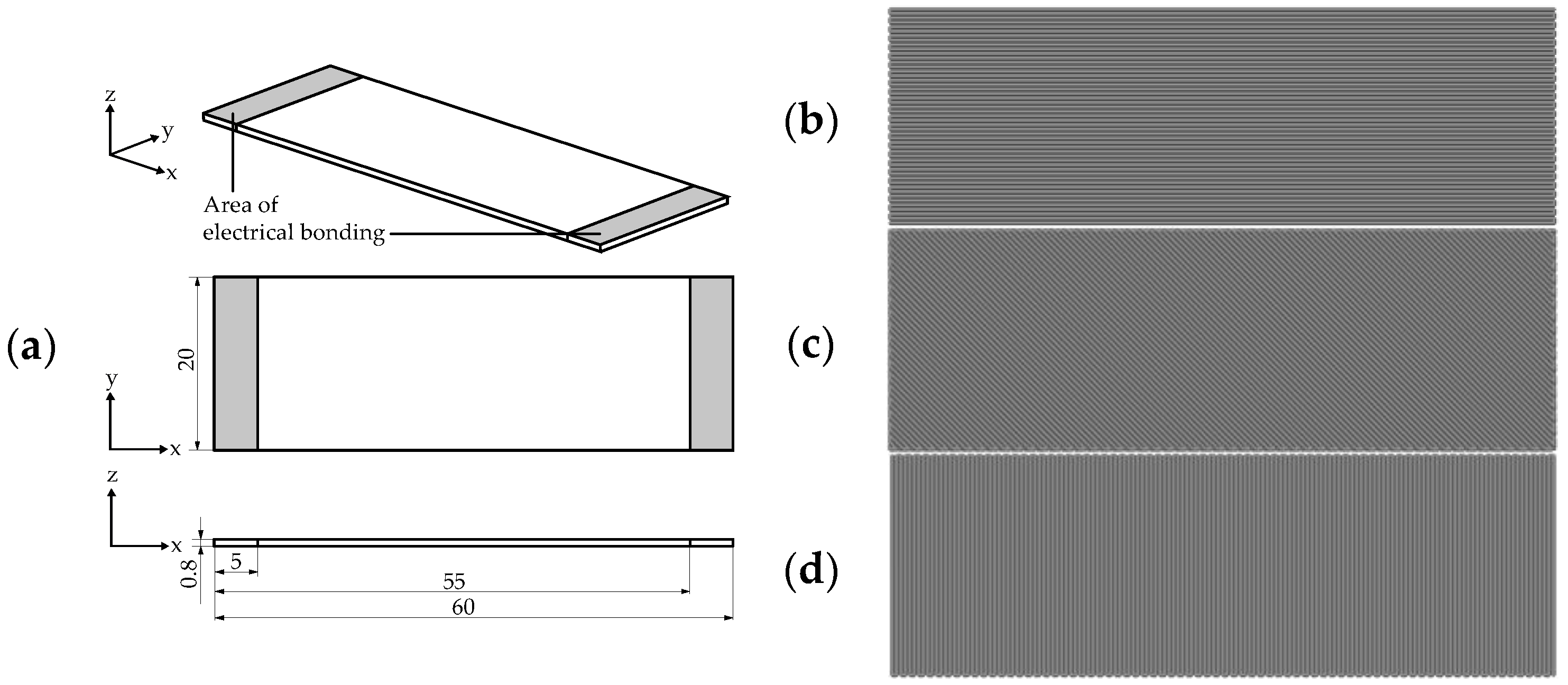

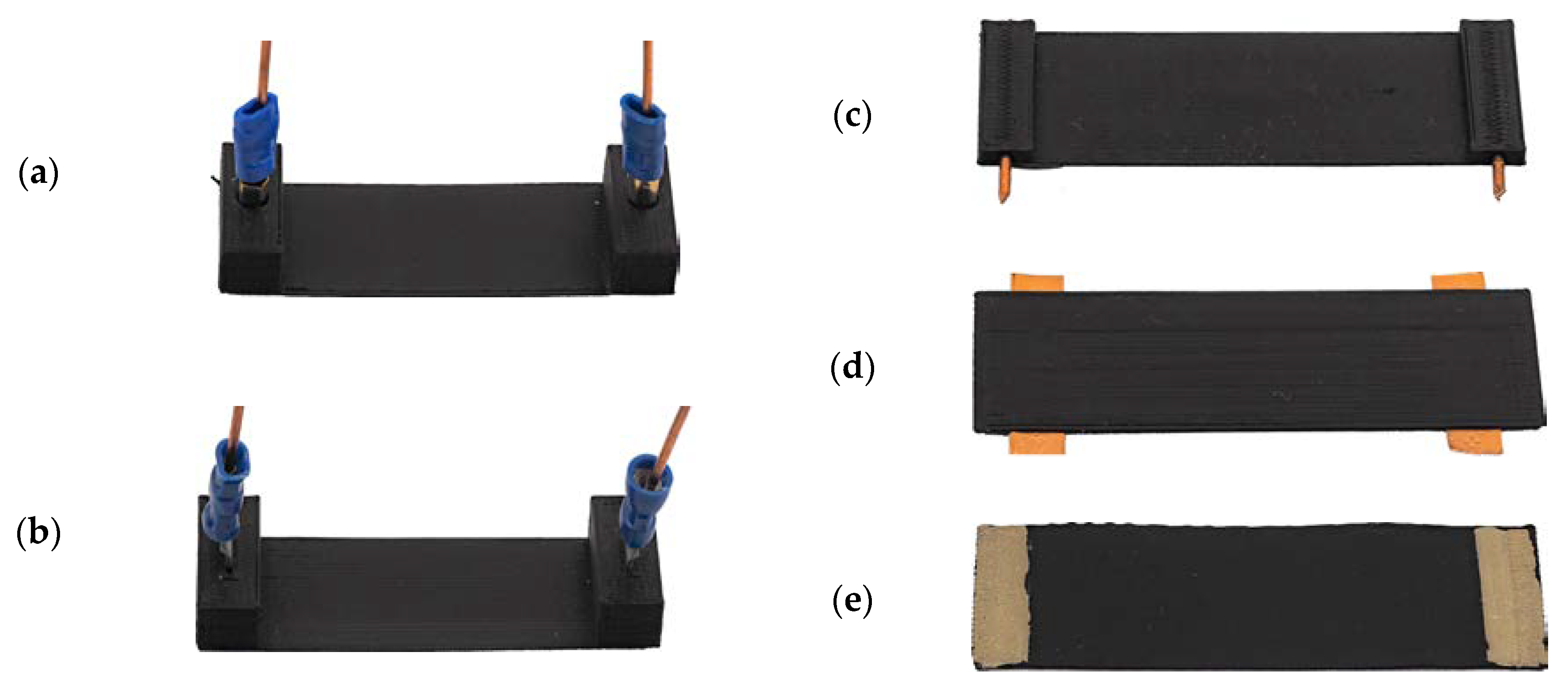

3.1.1. Test Specimens, Methods and Design of Experiments

3.1.2. Machine and Manufacturing of Test Specimens

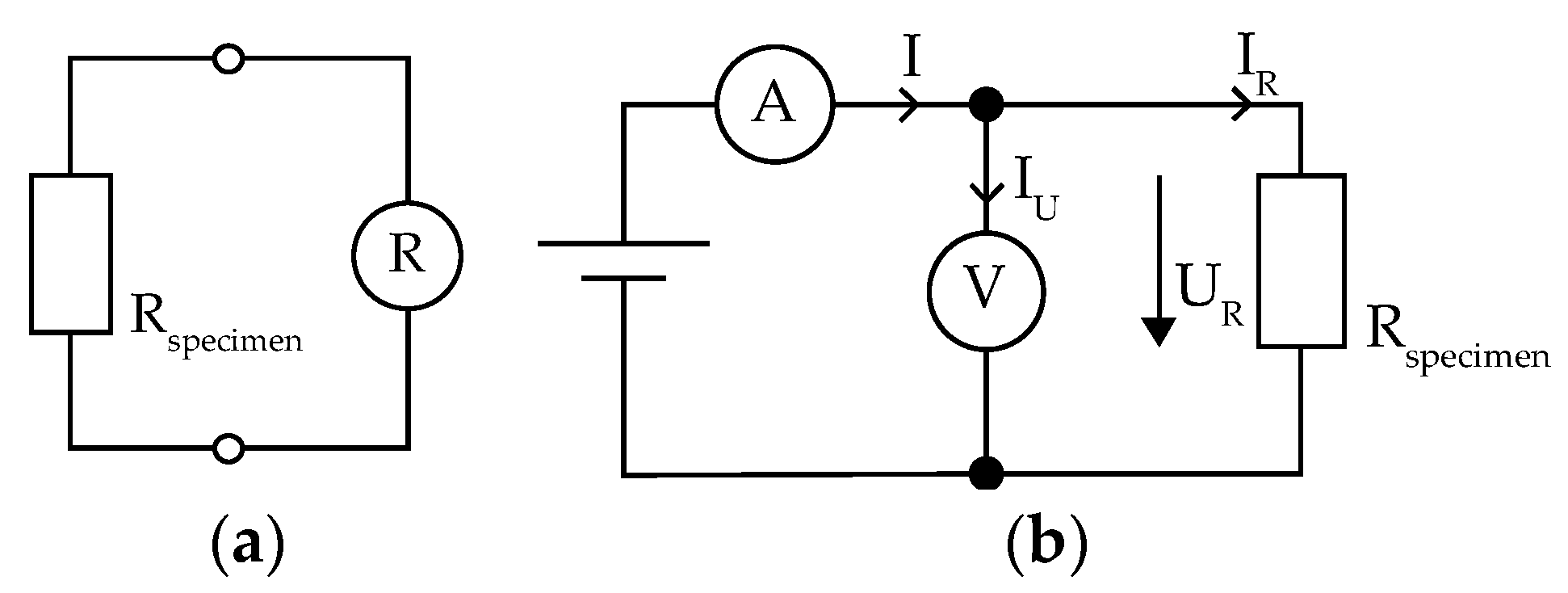

3.2. Preliminary Investigations on Electrical Bonding

4. Results and Discussion

4.1. Analysis of Influencing Factors on Resistivity

4.1.1. Filler and Raster Angle Orientation

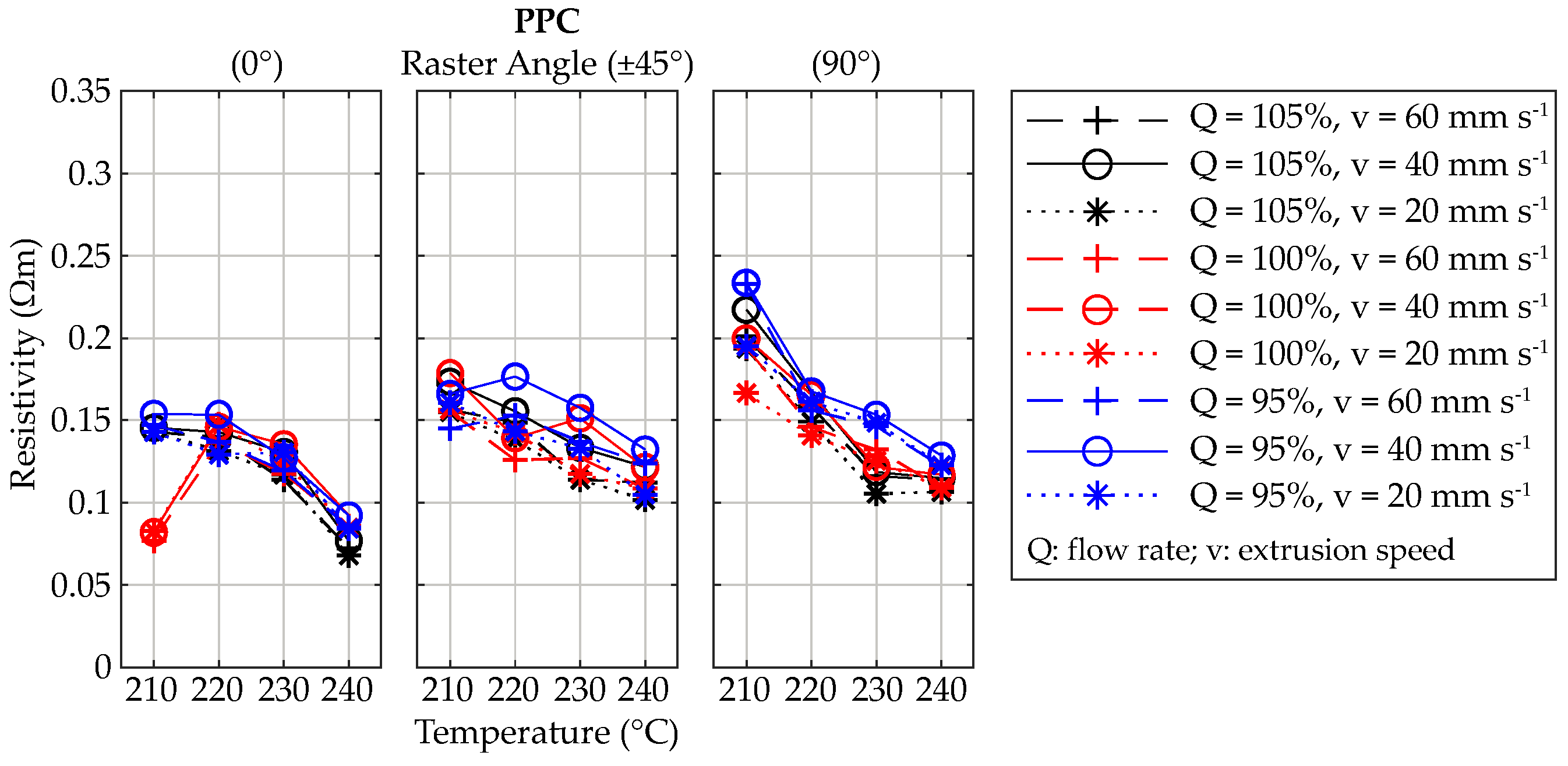

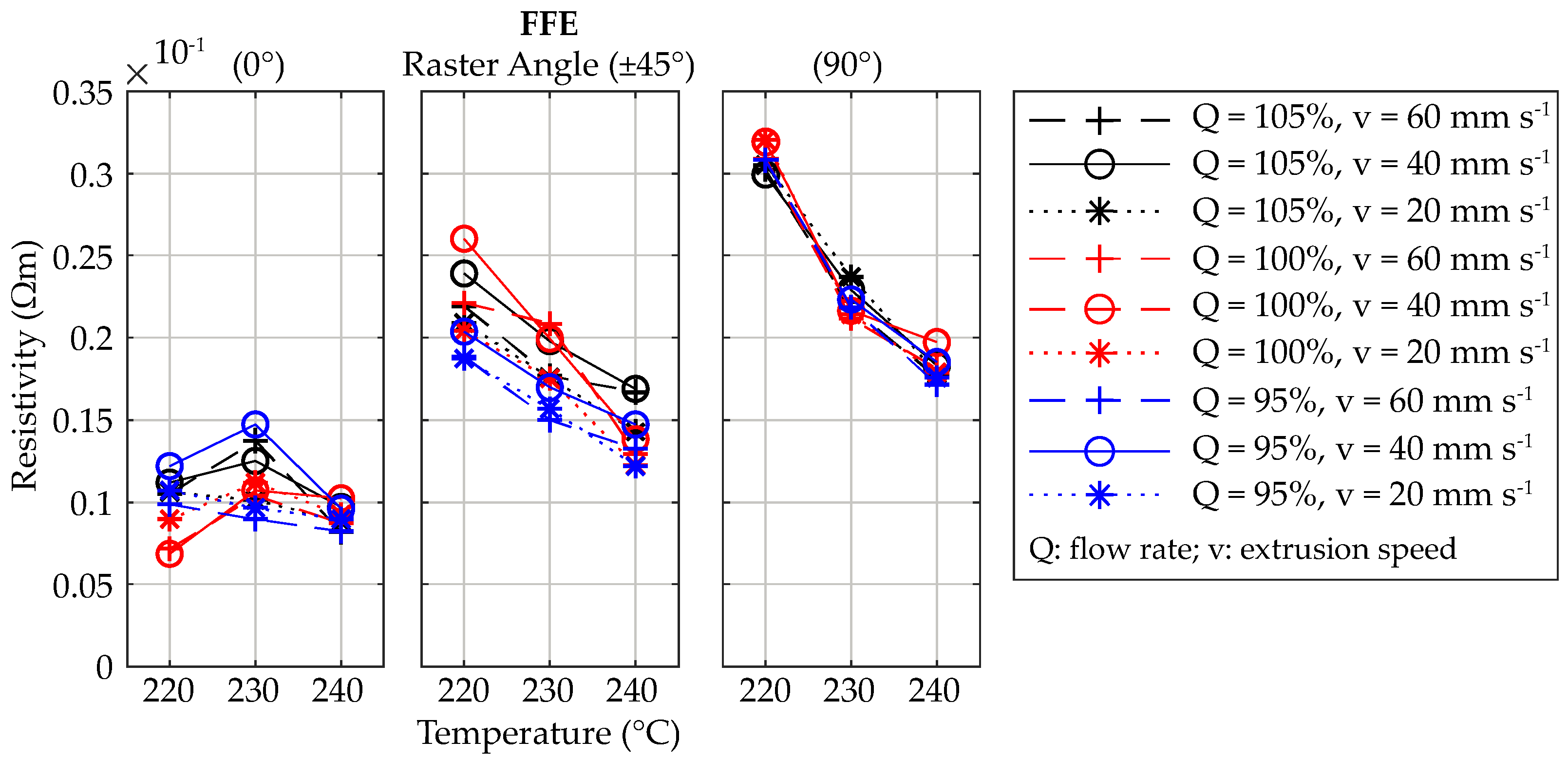

4.1.2. Extrusion Temperature, Speed and Flow Rate

4.2. Heat Resistivity

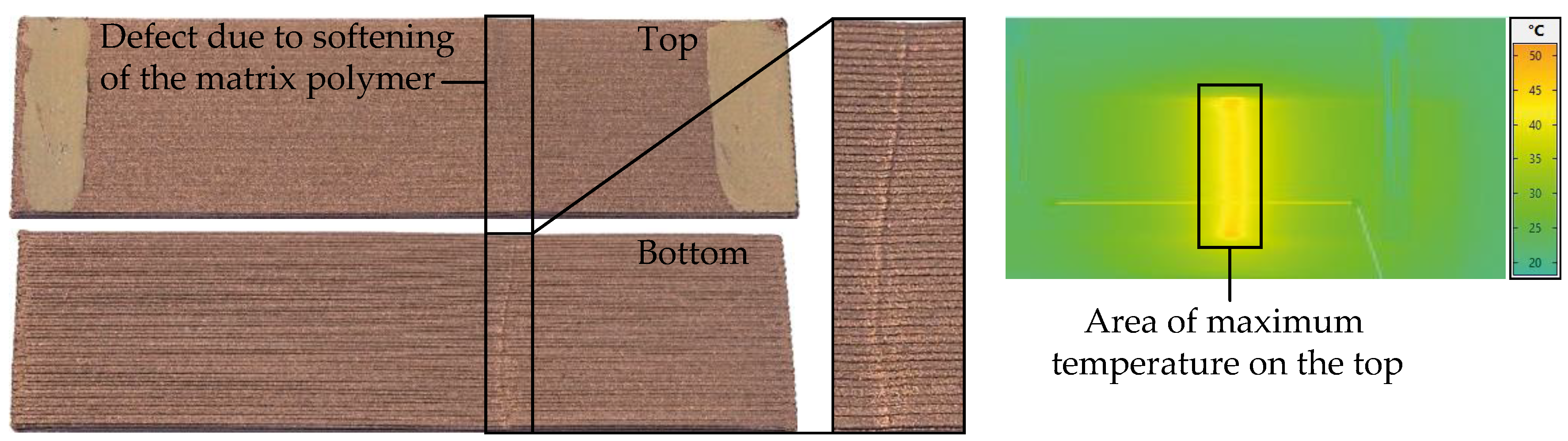

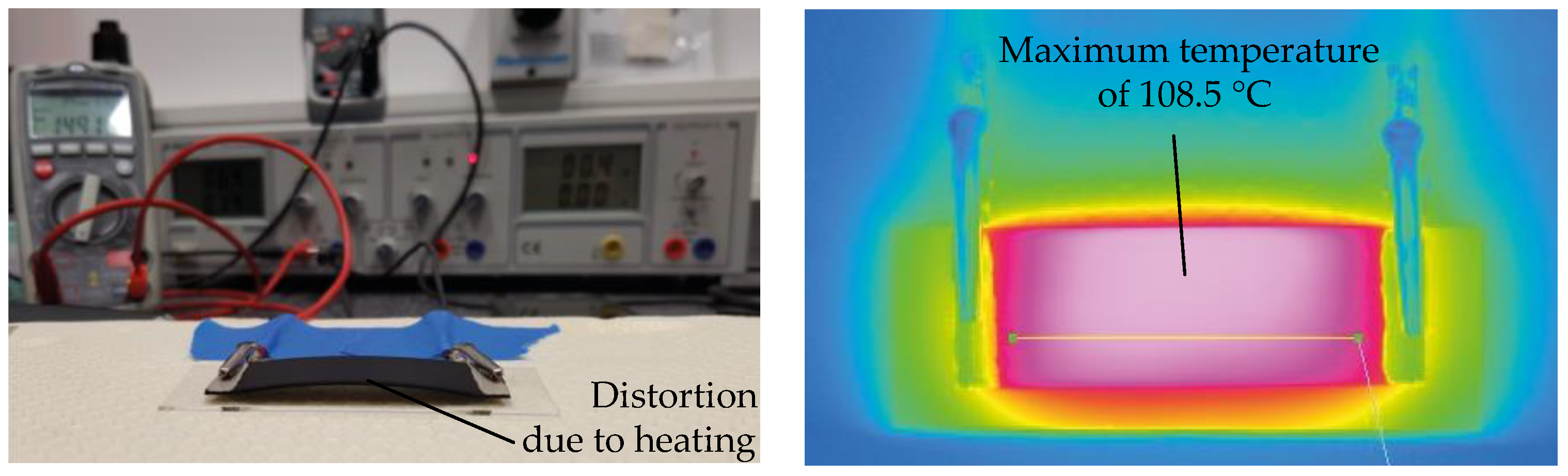

4.2.1. Heat Distribution

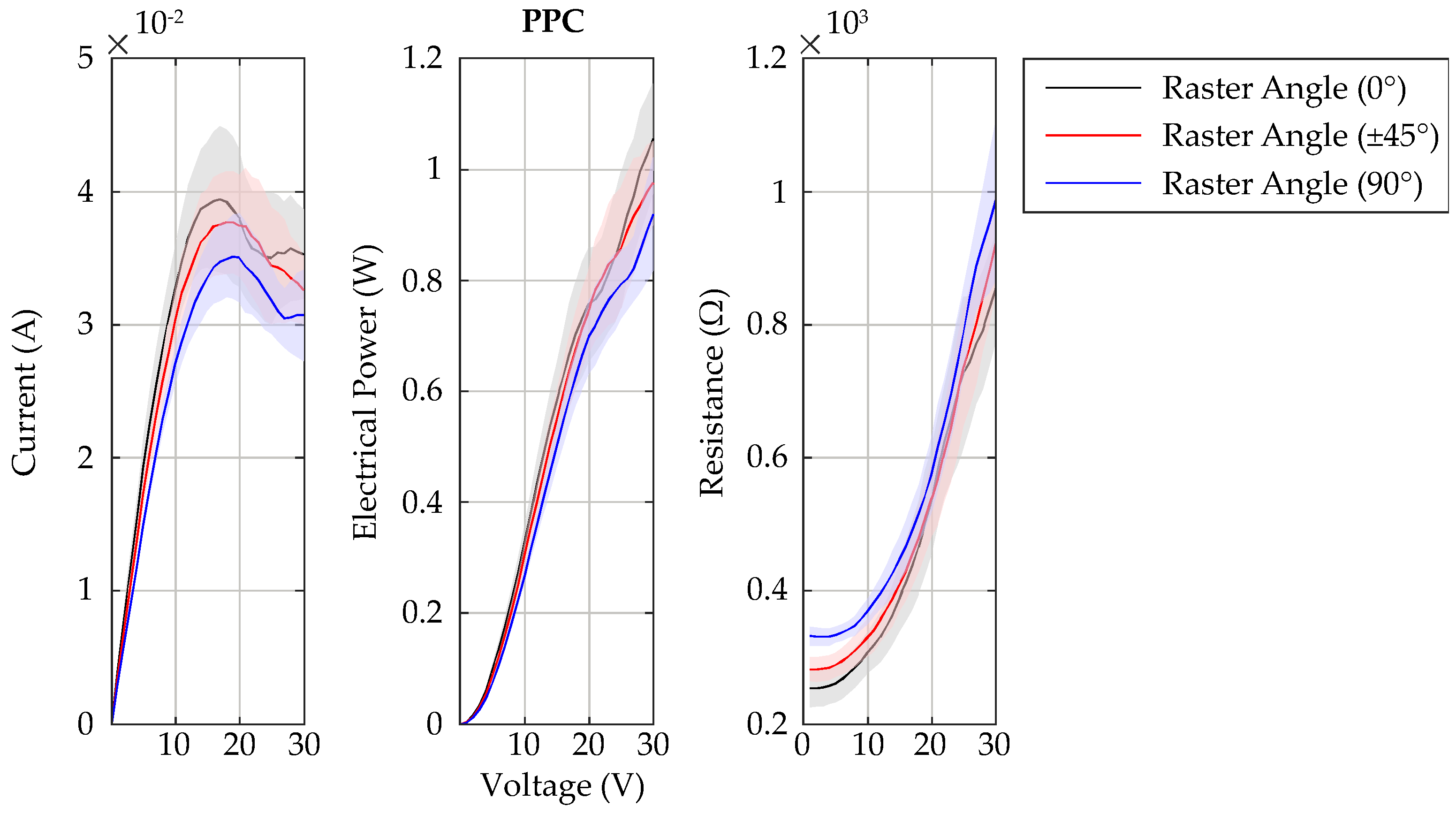

4.2.2. Dependencies of Currencies, Electrical Power, and Resistance on Voltage

4.3. Derivation of Design Principles

5. Application Based on an Incorporated Heating Surface

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Watschke, H.; Rautenberg, D.; Waalkes, L.; Junior, C.S.; Vietor, T. Integration of conductive functions based on Fused Layer Modeling. In Proceedings of the 14th Rapid. Tech Conference, Erfurt, Germany, 20–22 June 2017; Kynast, M., Eichmann, M., Witt, G., Eds.; Carl Hanser: München, Germany; pp. 419–432.

- Dul, S.; Fambri, L.; Pegoretti, A. Filaments Production and Fused Deposition Modelling of ABS/Carbon Nanotubes Composites. Nanomaterials 2018, 8, 49. [Google Scholar] [CrossRef]

- Gnanasekaran, K.; Heijmans, T.; van Bennekom, S.; Woldhuis, H.; Wijnia, S.; de With, G.; Friedrich, H. 3D printing of CNT- and graphene-based conductive polymer nanocomposites by fused deposition modeling. Appl. Mater. Today 2017, 9, 21–28. [Google Scholar] [CrossRef]

- Hampel, B.; Monshausen, S.; Schilling, M. Properties and applications of electrically conductive thermoplastics for additive manufacturing of sensors. Tech. Mess. 2017, 84, 593–599. [Google Scholar] [CrossRef]

- Leigh, S.J.; Bradley, R.J.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A. A simple, low-cost conductive composite material for 3D printing of electronic sensors. PLoS ONE 2012, 7, e49365. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Huang, N.; Xu, F.; Tong, J.; Chen, Z.; Gui, X.; Fu, Y.; Lao, C. 3D Printing Technologies for Flexible Tactile Sensors toward Wearable Electronics and Electronic Skin. Polymers 2018, 10, 629. [Google Scholar] [CrossRef]

- Vaezi, M.; Chianrabutra, S.; Mellor, B.; Yang, S. Multiple material additive manufacturing—Part 1: A review. Virtual Phys. Prototyp. 2013, 8, 19–50. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping and Direct Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2015; pp. 147–160. ISBN 978-1-4939-2113-3. [Google Scholar]

- Kim, S.; Rosen, D.W.; Witherell, P.; Ko, H. Linking Part Design To Process Planning By Design For Additive Manufacturing Ontology. In Proceedings of the 3rd International Conference on Progress in Additive Manufacturing (Pro-AM 2018), Singapore, 14–17 May 2018; Nanyang Technological University: Singapore, 2018; pp. 303–308. [Google Scholar]

- Laverne, F.; Segonds, F.; D’Antonio, G.; Le Coq, M. Enriching design with X through tailored additive manufacturing knowledge: A methodological proposal. Int. J. Interact. Des. Manuf. 2017, 11, 279–288. [Google Scholar] [CrossRef]

- Yao, X.; Ki Moon, S.; Bi, G.; Wei, J. A multi-material part design framework in additive manufacturing. Int. J. Adv. Manuf. Technol. 2018, 99, 2111–2119. [Google Scholar] [CrossRef]

- Blösch-Paidosh, A.; Shea, K. Design Heuristics for Additive Manufacturing. In Proceedings of the 21st International Conference on Engineering Design (ICED 17), Vancouver, BC, Canada, 21–25 August 2017; Maier, A., Škec, S., Kim, H., Kokkolaras, M., Oehmen, J., Fadel, G., Salustri, F., Van der Loss, M., Eds.; The Design Society: Glasgow, Scotland, 2017; Volume 5, pp. 91–100. [Google Scholar]

- Kumke, M.; Watschke, H.; Hartogh, P.; Bavendiek, A.-K.; Vietor, T. Methods and tools for identifying and leveraging additive manufacturing design potentials. Int. J. Interact. Des. Manuf. 2017, 12, 481–493. [Google Scholar] [CrossRef]

- Adam, G.A.O.; Zimmer, D. Design for Additive Manufacturing—Element transitions and aggregated structures. CIRP J. Manuf. Sci. Technol. 2014, 7, 20–28. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimization of fused deposition modeling process parameters: A review of current research and future prospects. Adv. Manuf. 2015, 3, 42–53. [Google Scholar] [CrossRef]

- Lee, J.-Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Tan, J.C.; Low, H.Y. Embedded electrical tracks in 3D printed objects by fused filament fabrication of highly conductive composites. Addit. Manuf. 2018, 23, 294–302. [Google Scholar] [CrossRef]

- Reyes, C.; Somogyi, R.; Niu, S.; Cruz, M.A.; Yang, F.; Catenacci, M.J.; Rhodes, C.P.; Wiley, B.J. Three-Dimensional Printing of a Complete Lithium Ion Battery with Fused Filament Fabrication. ACS Appl. Energy Mater. 2018, 1, 5268–5279. [Google Scholar] [CrossRef]

- Zhang, D.; Chi, B.; Li, B.; Gao, Z.; Du, Y.; Guo, J.; Wei, J. Fabrication of highly conductive graphene flexible circuits by 3D printing. Synth. Met. 2016, 217, 79–86. [Google Scholar] [CrossRef]

- Kwok, S.W.; Goh, K.H.H.; Tan, Z.D.; Tan, S.T.M.; Tjiu, W.W.; Soh, J.Y.; Ng, Z.J.G.; Chan, Y.Z.; Hui, H.K.; Goh, K.E.J. Electrically conductive filament for 3D-printed circuits and sensors. Appl. Mater. Today 2017, 9, 167–175. [Google Scholar] [CrossRef]

- Christ, J.F.; Aliheidari, N.; Ameli, A.; Pötschke, P. 3D printed highly elastic strain sensors of multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites. Mater. Des. 2017, 131, 394–401. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, B.; Fu, F.; You, F.; Dong, X.; Dai, M. Resistivity and Its Anisotropy Characterization of 3D-Printed Acrylonitrile Butadiene Styrene Copolymer (ABS)/Carbon Black (CB) Composites. Appl. Sci. 2017, 7, 20. [Google Scholar] [CrossRef]

- Kim, K.; Park, J.; Suh, J.-H.; Kim, M.; Jeong, Y.; Park, I. 3D printing of multiaxial force sensors using carbon nanotube (CNT)/thermoplastic polyurethane (TPU) filaments. Sens. Actuators A Phys. 2017, 263, 493–500. [Google Scholar] [CrossRef]

- Technical Data—Proto-Pasta Conductive PLA. Available online: https://www.proto-pasta.com/pages/conductive-pla (accessed on 4 January 2019).

- Technical Data—3dkonductive—Elektrisch Leitfähig. Available online: https://3dk.berlin/de/spezial/169-3dkonductive.html (accessed on 4 January 2019).

- Technical Data—Functionalize F-Electric™ PLA. Available online: http://functionalize.com/about/functionalize-f-electric-highly-conductive-filament/ (accessed on 4 January 2019).

- Technical Data—Electrifi Conductive Filament. Available online: https://www.multi3dllc.com/product/electrifi/ (accessed on 4 January 2019).

- Watschke, H.; Waalkes, L.; Schumacher, C.; Vietor, T. Development of Novel Test Specimens for Characterization of Multi-Material Parts Manufactured by Material Extrusion. Appl. Sci. 2018, 8, 1220. [Google Scholar] [CrossRef]

- Technical Data—Silver Paste EMS #12640. Available online: https://www.emsdiasum.com/microscopy/technical/datasheet/12640.aspx (accessed on 4 January 2019).

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly oriented carbon fiber–polymer composites via additive manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef]

- Sun, Q.; Rizvi, G.M.; Bellehumeur, C.T.; Gu, P. Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp. J. 2008, 14, 72–80. [Google Scholar] [CrossRef]

| Variation Parameter | Study | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [1] | [2] | [3] | [4] | [5] | [18] | [19] | [20] | [21] | [22] | [23] | [24] | ||

| Material | Filler | CB | CNT | CNT, G 1 | CB | CB | Nickel, tin alloy | G, Super P, MWCNT 3 | G | CB | MWCNT 3 | CB | MWCNT 3 |

| Filler Content | X | X | X | X | X | X | |||||||

| Matrix Material | PLA | ABS | PBT 2 | PLA | PCL | PA6, HDPE | PLA | PLA | PP | TPU | ABS | TPU | |

| Electr. Bonding | (X) | ||||||||||||

| Process Parameter | Build Orientation | X | X | X | X | X | |||||||

| Layer Height | X | X | |||||||||||

| Raster Angle | X | (X) | |||||||||||

| Raster Width | X | ||||||||||||

| Air Gap/Flow Rate | X | X | |||||||||||

| Extrusion Temp. | X | X | |||||||||||

| Extrusion Speed | (X) | X | |||||||||||

| Cooling | X | ||||||||||||

| Characterization | Young’s Modulus | X | X | X | |||||||||

| Strength | X | X | X | ||||||||||

| Elongation | X | X | X | ||||||||||

| Storage Modulus | X | X | |||||||||||

| Electr. Resistivity | X | X | X | X | X | X | X | X | X | X | X | X | |

| Resistive Heating | X | X | |||||||||||

| Mutli-Material MEX | X | X | X | X | X | X | X | X | X | X | |||

| Name | Filler/Matrix Material | Temperature (°C) | Resistivity 1 (Ωm) | ||

|---|---|---|---|---|---|

| Build Platform | Nozzle | Feedstock Material | Processed (x/y and z) | ||

| PPC [25] | CB/PLA | <50 | 215–230 | 0.15 | 0.3/1.15 |

| 3dk [26] | CB/PLA | 60–70 | 200–230 | 0.24 | 0.23/n/a |

| FFE [27] | CNT/PLA | <70 | 215–230 | 75 × 10−4 | n/a |

| M3D [28] | Copper Nanowires/PCL | Room temperature | 130–160 | 6 × 10−5 | n/a |

| Material | Temperature (°C) | Raster Angle (°) | Speed (mm/s) (∆ = 20) | Flow Rate (%) (∆ = 5) | |

|---|---|---|---|---|---|

| Build Platform | Nozzle (∆ = 10) | ||||

| PPC | 60 | 210–240 | 0, ±45, 90 | 20–60 | 95–105 |

| 3dk | 60 | 210–240 | 0, ±45, 90 | 20–60 | 95–105 |

| FFE | 60 | 220–240 | 0, ±45, 90 | 20–60 | 95–105 |

| M3D | Room temperature 1 | 170–180 | 0, ±45, 90 | 20–60 | 95–105 |

| No. | Name of Electrical Bonding Variant | Resistance (Ω) |

|---|---|---|

| Without electrical bonding | 6850–8500 1 | |

| (a) | Crimp connector (round); pressed in | 403–597 1 |

| (b) | Crimp connector (flat); pressed in | 845–1209 1 |

| (c) | Copper wire (Ø 1.3 mm); pressed in | 963–1504 1 |

| (d) | Copper tape (width 5.5 mm); inlaid during manufacturing process | 791 |

| (e) | Silver paste (EMS 12640); deposited after manufacturing process [30] | 50.5 |

| Material | Raster Angle (°) | Extrusion Temperature (°C) | Speed (mm/s) | Flow Rate (%) |

|---|---|---|---|---|

| PPC | 0 | 240 | 20 | 105 |

| ±45 | 240 | 20 | 105 | |

| 90 | 240 | 20 | 105 | |

| 3dk | 0 | 240 | 20 | 105 |

| ±45 | 240 | 20 | 105 | |

| 90 | 240 | 20 | 100 | |

| FFE | 0 | 240 | 60 | 105 |

| ±45 | 240 | 60 | 100 | |

| 90 | 240 | 60 | 105 | |

| M3D | 0 | 170 | 20 | 105 |

| ±45 | 170 | 40 | 105 | |

| 90 | 170 | 20 | 105 |

| Design Principle | Utilized Effect | Material-/Process-Specific Levers | Advises for Design |

|---|---|---|---|

| Variable electrical resistance (cf. [4]) | Adjustability of resistance | Geometry; e.g., raster angle, temperature; filler | Dependency of geometry and process parameters, e.g., speed at turnaround points |

| Heat-activated fuse | Resistive heating; adjustability of resistance; heat-activated softening | Geometry (e.g., cross section, length); raster angle; filler, matrix polymer | Reversible thermal induced softening; adjustment of the maximum current by raster angle and matrix polymer |

| Heating Surface with variable heat radiation capacity | Resistive heating; adjustability of resistivity | Geometry; e.g., raster angle, temperature | Avoidance of support structures below the heat radiant surfaces |

| Thermally induced optical signals (cf. [1]) | Resistive heating; thermal induced color-change | Geometry; e.g., raster angle | Adjustment of the heat radiation to determine the electrical power for activation |

| Thermal induced activation of shape memory polymers | Resistive heating, shape memory effect | Geometry; e.g., raster angle | Adjustment of the heat radiation to influence speed of the heat-activated deformation |

| Heated through-flowed structures (e.g., lattices) | Resistive heating; AM’s design freedom | Geometry (e.g., cross section); e.g., raster angle, temperature | Surface roughness could positively influence heat transfer due to turbulences, thin features hardly to manufacture due to the filler |

| Temperature sensor (cf. [21]) | Thermal induced increase of resistance | Geometry; e.g., raster angle, temperature; filler | The temperature range is limited to the glass transition temperature due to annealing and distortion as these lead to a change of initial resistance |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Watschke, H.; Hilbig, K.; Vietor, T. Design and Characterization of Electrically Conductive Structures Additively Manufactured by Material Extrusion. Appl. Sci. 2019, 9, 779. https://doi.org/10.3390/app9040779

Watschke H, Hilbig K, Vietor T. Design and Characterization of Electrically Conductive Structures Additively Manufactured by Material Extrusion. Applied Sciences. 2019; 9(4):779. https://doi.org/10.3390/app9040779

Chicago/Turabian StyleWatschke, Hagen, Karl Hilbig, and Thomas Vietor. 2019. "Design and Characterization of Electrically Conductive Structures Additively Manufactured by Material Extrusion" Applied Sciences 9, no. 4: 779. https://doi.org/10.3390/app9040779

APA StyleWatschke, H., Hilbig, K., & Vietor, T. (2019). Design and Characterization of Electrically Conductive Structures Additively Manufactured by Material Extrusion. Applied Sciences, 9(4), 779. https://doi.org/10.3390/app9040779