Efficient Demulsification of Acidic Oil-In-Water Emulsions with Silane-Coupled Modified TiO2 Pillared Montmorillonite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Preparation of Ti-Mt-APTES

2.3. Demulsification Tests

2.4. Characterizations

3. Results and Discussion

3.1. Characterization of Na-Mt, Ti-Mt, and Ti-Mt-APTES

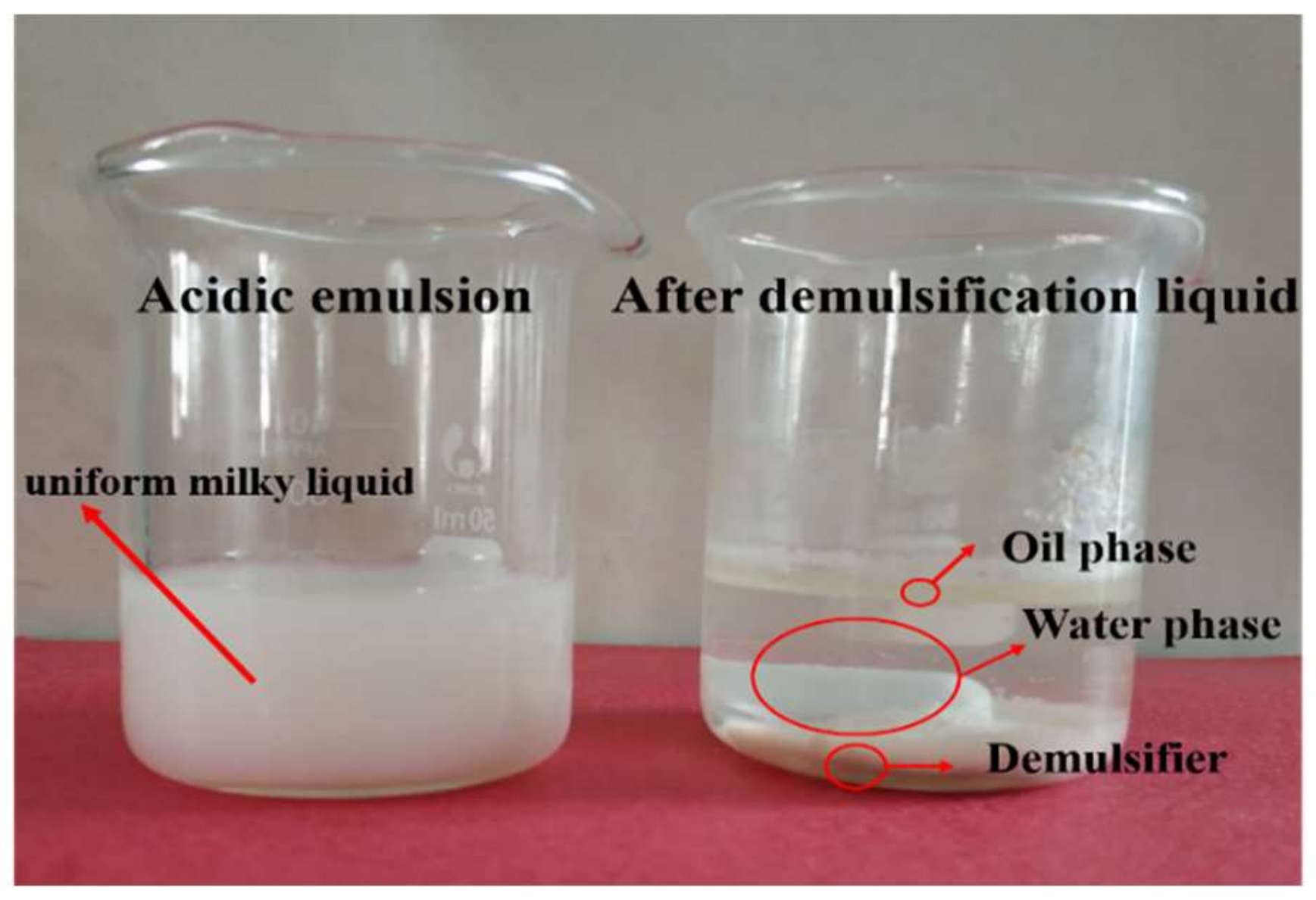

3.2. Demulsification Performance of Ti-Mt-APTES.

4. Demulsification Mechanism

5. Conclusions

- (1)

- The ED of Ti-Mt-APTES-0.10 at acidic conditions is above 94.8% at a dosage of 2.5 g/L after 5 h.

- (2)

- Under acidic conditions, oil droplets could be effectively attached onto Ti-Mt-APTES via electrostatic attraction. The hydrophobic groups located in montmorillonite were implicated in enhancing the demulsification performance.

- (3)

- Intercalation of titanium hydrate gives the material a larger specific surface area, which can adsorb oil droplets via van der Waals force.

Author Contributions

Funding

Conflicts of Interest

References

- Regel-Rosocka, M. A review on methods of regeneration of spent pickling solutions from steel processing. J. Hazard. Mater. 2010, 177, 57–69. [Google Scholar] [CrossRef] [PubMed]

- Devi, A.; Singhal, A.; Gupta, R.; Panzade, P. A study on treatment methods of spent pickling liquor generated by pickling process of steel. Clean Technol. Environ. Policy 2014, 16, 1515–1527. [Google Scholar] [CrossRef]

- Chen-Fu, L.; Ke-Jia, W.; Da-Zhong, C.; Shou-Juan, W.; Fan-gong, K. Review of development of inhibitors used in hydrochloric acid washing. J. Shandong Inst. Light Ind. 2011, 25, 5–8. [Google Scholar]

- Tian, Y.; Yin, Y.; Wei, L. Research on the technology of pickling waste liquid resource recyling. Ind. Water Treat. 2009, 29, 89–91. [Google Scholar]

- Agrawal, A.; Sahu, K.K. An overview of the recovery of acid from spent acidic solutions from steel and electroplating industries. J. Hazard. Mater. 2009, 171, 61–75. [Google Scholar] [CrossRef] [PubMed]

- Zhai, J.; Jiang, C.H.; Wu, J. Techniques for Treating Sulphuric Acid Pickling Waste Liquid of Steel Industry. Meteorol. Environ. Res. 2013, 4, 44–49. [Google Scholar]

- Rajak, V.K.; Relish, K.K.; Kumar, S.; Mandal, A. Mechanism and Kinetics of Separation of Oil From Oil-in-Water Emulsion by Air Flotation. Liquid Fuels Technol. 2015, 33, 1861–1868. [Google Scholar] [CrossRef]

- Cañzares, P.; Martínez, F.; Jiménez, C.; Sáez, C.; Rodrigo, M.A. Coagulation and electrocoagulation of oil-in-water emulsions. J. Hazard. Mater. 2008, 151, 44–51. [Google Scholar] [CrossRef] [PubMed]

- Hosny, A.Y. Separating oil from oil-water emulsions by electroflotation technique. Sep. Technol. 1996, 6, 9–17. [Google Scholar] [CrossRef]

- Frising, T.; Noïk, C.; Dalmazzone, C. The Liquid/Liquid Sedimentation Process: From Droplet Coalescence to Technologically Enhanced Water/Oil Emulsion Gravity Separators: A Review. J. Dispers. Sci. Technol. 2006, 27, 1035–1057. [Google Scholar] [CrossRef]

- Qin, D.; Liu, Z.; Bai, H.; Sun, D.D.; Song, X. A new nano-engineered hierarchical membrane for concurrent removal of surfactant and oil from oil-in-water nanoemulsion. Sci. Rep. 2016, 6, 24365–24377. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.Y.; Jia, W.H.; Ren, S.L.; Wang, J.Q. Novel and recyclable demulsifier of expanded perlite grafted by magnetic nanoparticles for oil separation from emulsified oil wastewaters. Chem. Eng. J. 2018, 337, 10–18. [Google Scholar] [CrossRef]

- Pei, Z.; Hui, W.; Xia, L.; Shi, X.; Jian, Z.; Yang, G.; Sun, K.; Wang, J. The dynamic interfacial adsorption and demulsification behaviors of novel amphiphilic dendrimers. Colloids Surf. A Physicochem. Eng. Asp. 2014, 443, 473–480. [Google Scholar]

- Li, H.; Jiang, B.; Zhang, L.; Yang, H.; Sun, Y.; Wang, B.; Na, Y. Efficient Demulsification of Diesel-in-Water Emulsions by Different Structural Dendrimer-Based Demulsifiers. Ind. Eng. Chem. Res. 2016, 55, 1748–1759. [Google Scholar]

- Hajivand, P.; Vaziri, A. Optimization of Demulsifier formulation for separation of water from crude oil emulsions. Braz. J. Chem. Eng. 2015, 32, 107–118. [Google Scholar] [CrossRef]

- Du, H.H.; Chen, W.L.; Cai, P.; Rong, X.M.; Dai, K.; Peacock, C.L.; Huang, Q.Y. Cd(II) Sorption on Montmorillonite-Humic acid-Bacteria Composites. Sci. Rep. 2016, 6, 19499–19508. [Google Scholar] [CrossRef] [PubMed]

- Ge, J.; Cui, S.; Qin, Y.; Wang, Y.; Wang, C. Research on APTES-modified montmorillonite and adsorption of methylene blue. New Chem. Mater. 2015, 43, 151–153. [Google Scholar]

- Zeng, A.R.; Zeng, A.R. Synthesis of a Quaternized Beta Cyclodextrin-Montmorillonite Composite and Its Adsorption Capacity for Cr(VI), Methyl Orange, and p-Nitrophenol. Water Air Soil Pollut. 2017, 228, 278–296. [Google Scholar] [CrossRef]

- Wang, S.F.; Shen, L.; Tong, Y.J.; Chen, L.; Phang, I.Y.; Lim, P.Q.; Liu, T.X. Biopolymer chitosan/montmorillonite nanocomposites: Preparation and characterization. Polym. Degrad. Stab. 2005, 90, 123–131. [Google Scholar] [CrossRef]

- Wei, Y.; Zhao, B.; Han, G.; Huang, J.; Zhang, X. Preparation of highly efficient and stable Fe, Zn, Al-pillared montmorillonite as heterogeneous catalyst for catalytic wet peroxide oxidation of Orange II. J. Porous Mater. 2016, 23, 301–310. [Google Scholar]

- Shao, H.; Zhang, Z.F.; Cao, N. Study on the Industrial Wastewater Treatment by Modified Bentonite. Appl. Mech. Mater. 2012, 182, 323–327. [Google Scholar]

- Wu, P.X. Microstructure changes of montmorillonite after acid treatment. Mod. Chem. Ind. 2005, 1, 36–40. [Google Scholar]

- Aiye, L.; Jie, M.; Guangsheng, M. Optimized Experiment for Ammonium Chloride-ethanol Method in Measurement of Bentonite Cationic Exchange Capacity. Railw. Investig. Surv. 2011, 1, 43–45. [Google Scholar]

- Yamanaka, S.; Nishihara, T.; Hattori, M. Preparation and properties of titania pillared clay. Mater. Chem. Phys. 1987, 17, 87–101. [Google Scholar] [CrossRef]

- Liang, J.; Li, H.; Yan, J.; Hou, W. Demulsification of Oleic-Acid-Coated Magnetite Nanoparticles for Cyclohexane-in-Water Nanoemulsions. Energy Fuels 2015, 28, 6172–6178. [Google Scholar] [CrossRef]

- Park, S.-J.; Kim, B.-J.; Seo, D.-I.; Rhee, K.-Y.; Lyu, Y.-Y. Effects of a silane treatment on the mechanical interfacial properties of montmorillonite/epoxy nanocomposites. Mater. Sci. Eng. A 2009, 526, 74–78. [Google Scholar] [CrossRef]

- Park, H.M.; Kim, G.H.; Ha, C.S. Preparation and characterization of biodegradable aliphatic polyester/thermoplastic starch/organoclay ternary hybrid nanocomposites. Instrum. Sci. Technol. 2007, 14, 427–438. [Google Scholar] [CrossRef]

- Lu, T.; Chen, Y.; Qi, D.M.; Cao, Z.H.; Zhang, D.; Zhao, H.T. Treatment of emulsified oil wastewaters by using chitosan grafted magnetic nanoparticles. J. Alloys Compd. 2017, 696, 1205–1212. [Google Scholar] [CrossRef]

- Shen, W.; He, H.P.; Zhu, J.X.; Yuan, P.; Ma, Y.H.; Liang, X.L. Preparation and characterization of 3-aminopropyltriethoxysilane grafted montmorillonite and acid-activated montmorillonite. Chin. Sci. Bull. 2009, 54, 265–271. [Google Scholar] [CrossRef]

- Chen, D.M.; Du, G.X.; Zhu, Q.; Zhou, F.S. Synthesis and characterization of TiO2 pillared montmorillonites: Application for methylene blue degradation. J. Colloid Interface Sci. 2013, 409, 151–157. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.-H.; Piao, H.; Vinu, A.; Elzatahry, A.A.; Paek, S.-M.; Choy, J.-H. TiO2-pillared clays with well-ordered porous structure and excellent photocatalytic activity. RSC Adv. 2015, 5, 8210–8215. [Google Scholar] [CrossRef]

- Chen, D.M.; Zhu, Q.; Zhou, F.S.; Deng, X.T.; Li, F.T. Synthesis and photocatalytic performances of the TiO2 pillared montmorillonite. J. Hazard. Mater. 2012, 235, 186–193. [Google Scholar] [CrossRef] [PubMed]

- Tahir, M. Synergistic effect in MMT-dispersed Au/TiO2 monolithic nanocatalyst for plasmon-absorption and metallic interband transitions dynamic CO2 photo-reduction to CO. Appl. Catal. B Environ. 2017, 219, 329–343. [Google Scholar] [CrossRef]

- Ma, Y.L.; Lv, L.; Guo, Y.R.; Fu, Y.J.; Shao, Q.; Wu, T.T.; Guo, S.J.; Sun, K.; Guo, X.K.; Wujcik, E.K.; et al. Porous lignin based poly (acrylic acid)/organo-montmorillonite nanocomposites: Swelling behaviors and rapid removal of Pb (II) ions. Polymer 2017, 128, 12–23. [Google Scholar] [CrossRef]

- Kang, S.C.; Zhao, Y.L.; Wang, W.; Zhang, T.T.; Chen, T.X.; Yi, H.; Rao, F.; Song, S.X. Removal of methylene blue from water with montmorillonite nanosheets/chitosan hydrogels as adsorbent. Appl. Surf. Sci. 2018, 448, 203–211. [Google Scholar] [CrossRef]

- Pereira, C.; Silva, R.A.; Carvalho, P.A.; Pires, J.; Freire, C. Vanadyl acetylacetonate anchored onto amine-functionalised clays and catalytic activity in the epoxidation of geraniol. J. Mol. Catal. A Chem. 2008, 283, 5–14. [Google Scholar] [CrossRef]

- Lü, T.; Zhang, S.; Qi, D.; Zhang, D.; Vance, G.F.; Zhao, H. Synthesis of pH-sensitive and recyclable magnetic nanoparticles for efficient separation of emulsified oil from aqueous environments. Appl. Surf. Sci. 2017, 396, 1604–1612. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zuo, G.; Du, Y.; Wei, L.; Yu, B.; Ye, S.; Zhang, X.; Hao, H. Efficient Demulsification of Acidic Oil-In-Water Emulsions with Silane-Coupled Modified TiO2 Pillared Montmorillonite. Appl. Sci. 2019, 9, 1008. https://doi.org/10.3390/app9051008

Zuo G, Du Y, Wei L, Yu B, Ye S, Zhang X, Hao H. Efficient Demulsification of Acidic Oil-In-Water Emulsions with Silane-Coupled Modified TiO2 Pillared Montmorillonite. Applied Sciences. 2019; 9(5):1008. https://doi.org/10.3390/app9051008

Chicago/Turabian StyleZuo, Gaohong, Yingchao Du, Lianqi Wei, Bo Yu, Shufeng Ye, Xiaomeng Zhang, and Hongshun Hao. 2019. "Efficient Demulsification of Acidic Oil-In-Water Emulsions with Silane-Coupled Modified TiO2 Pillared Montmorillonite" Applied Sciences 9, no. 5: 1008. https://doi.org/10.3390/app9051008

APA StyleZuo, G., Du, Y., Wei, L., Yu, B., Ye, S., Zhang, X., & Hao, H. (2019). Efficient Demulsification of Acidic Oil-In-Water Emulsions with Silane-Coupled Modified TiO2 Pillared Montmorillonite. Applied Sciences, 9(5), 1008. https://doi.org/10.3390/app9051008