Passive Thermal Management of Tablet PCs Using Phase Change Materials: Intermittent Operation

Abstract

:Featured Application

Abstract

1. Introduction

2. Experimental Setup

2.1. Phase Change Material

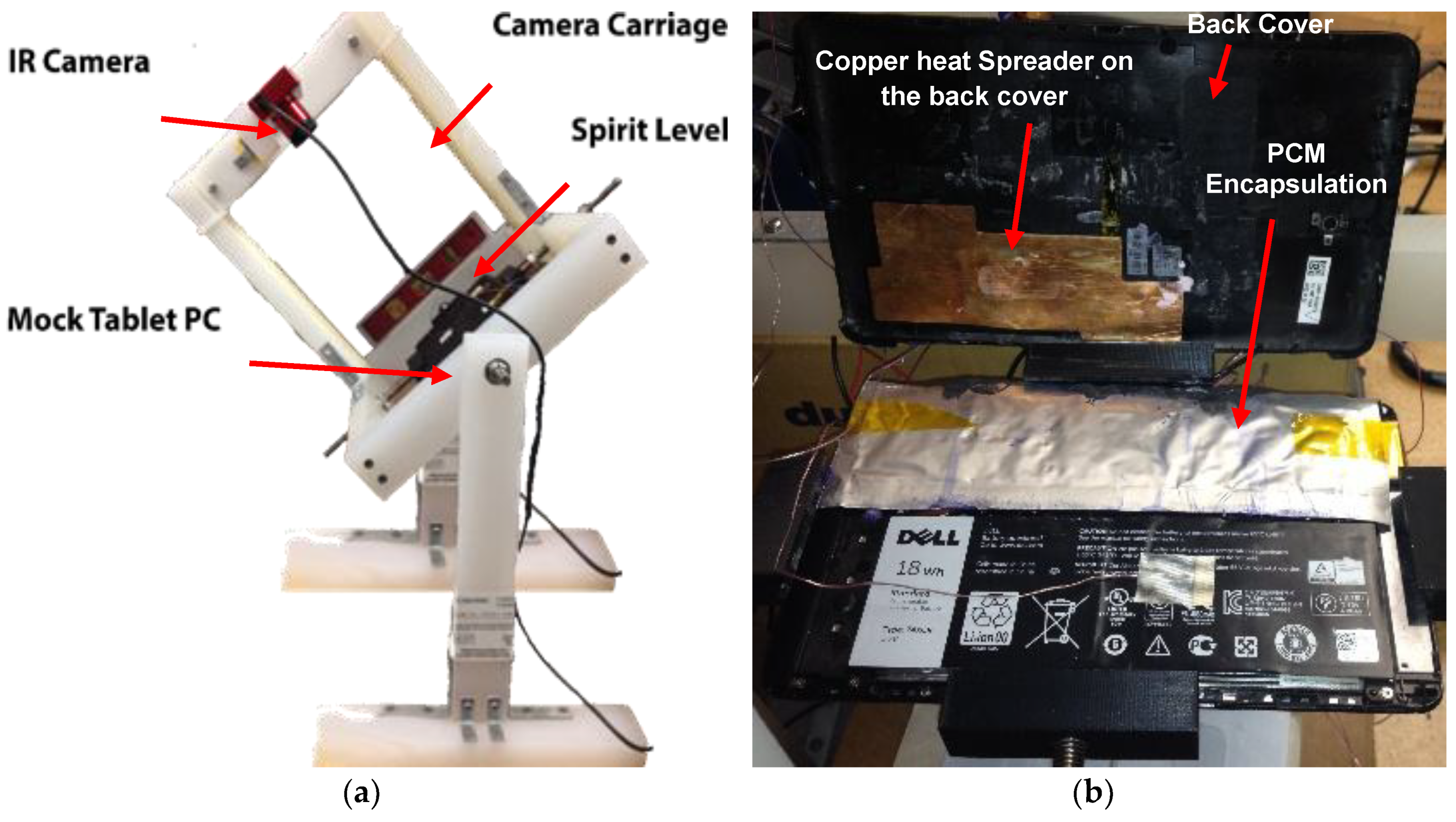

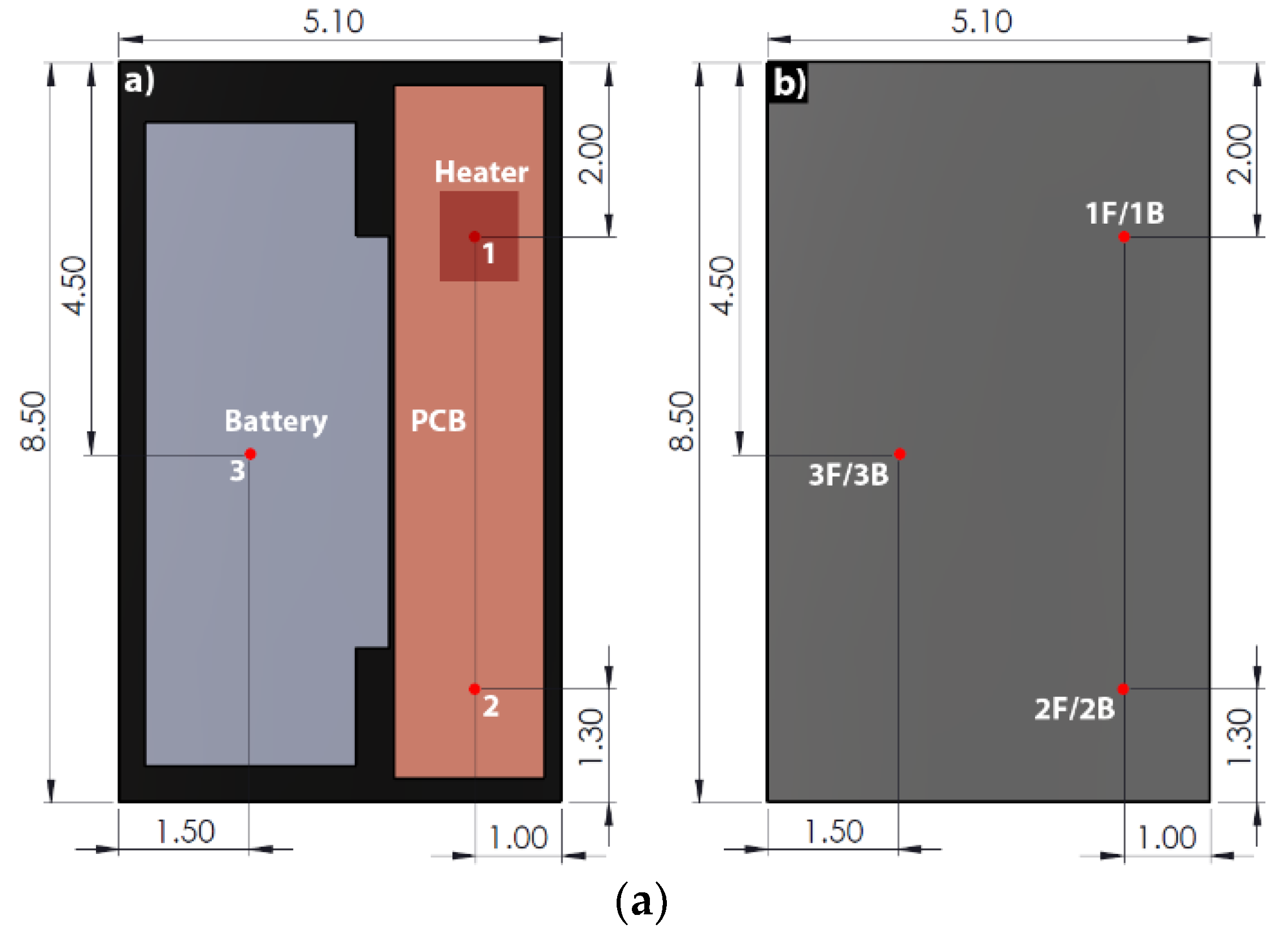

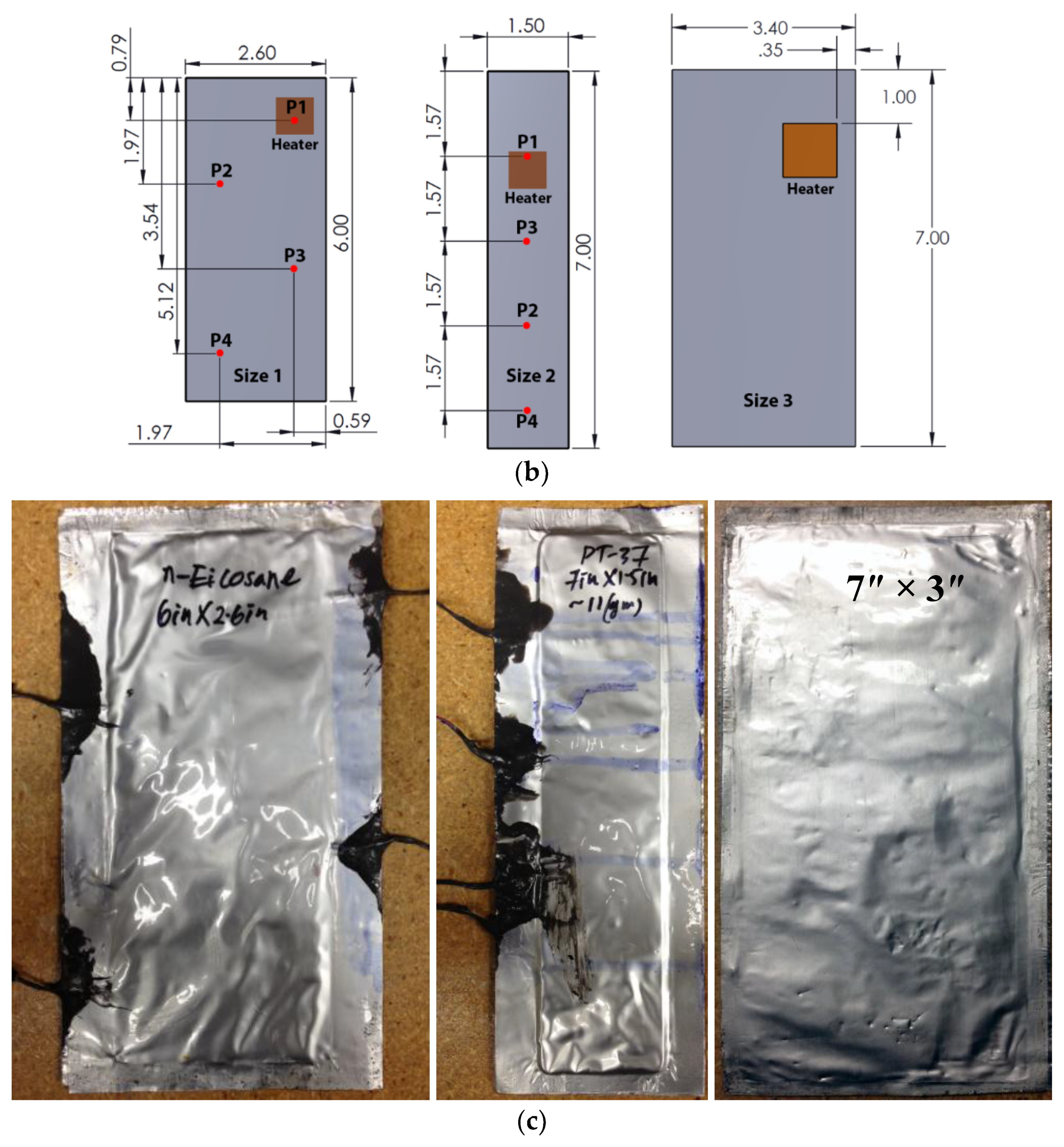

2.2. Apparatus

2.3. Procedure

2.4. Sources of Uncertainties

3. Results and Discussion

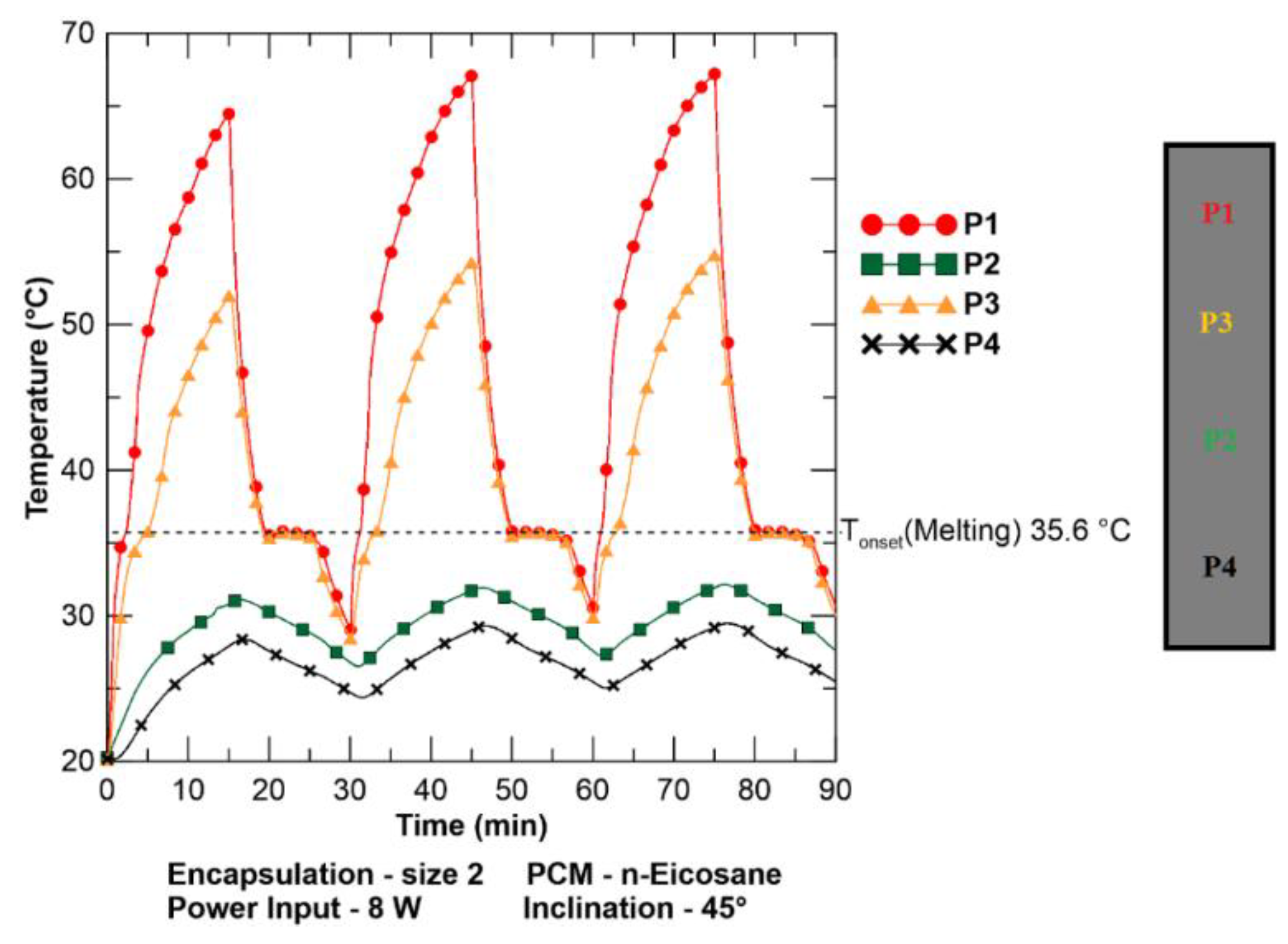

3.1. Thermal Response of the PCMs

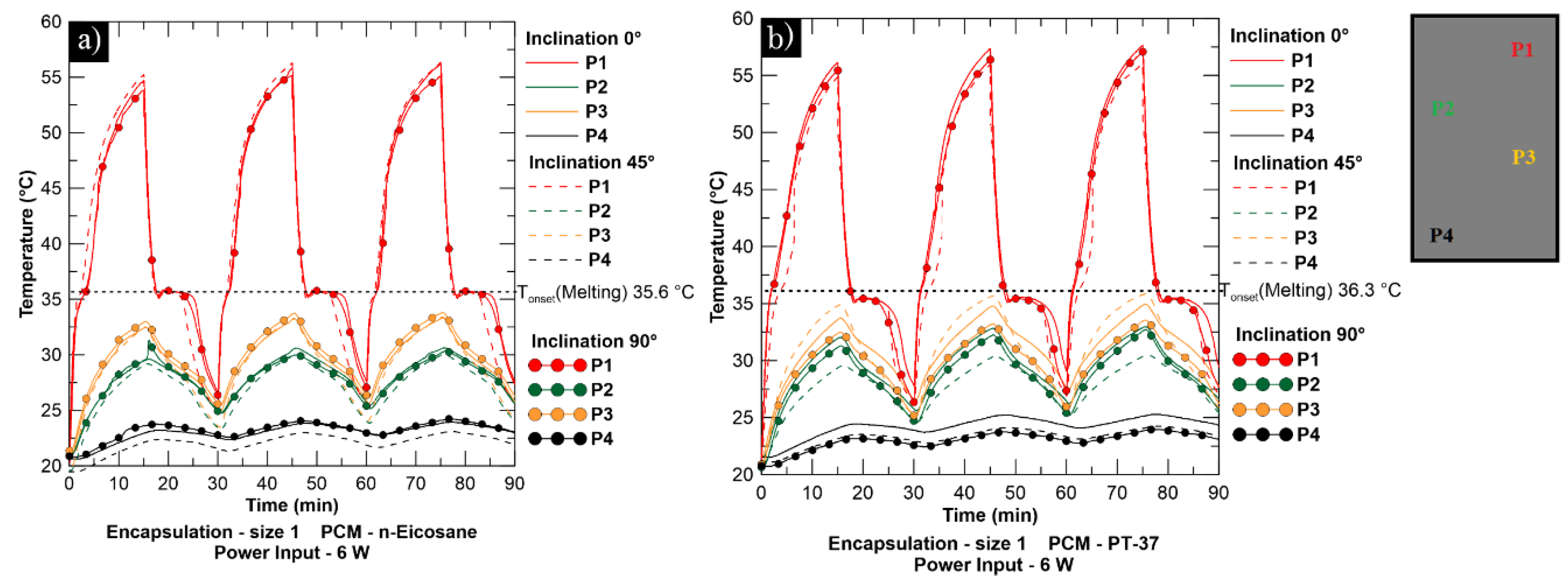

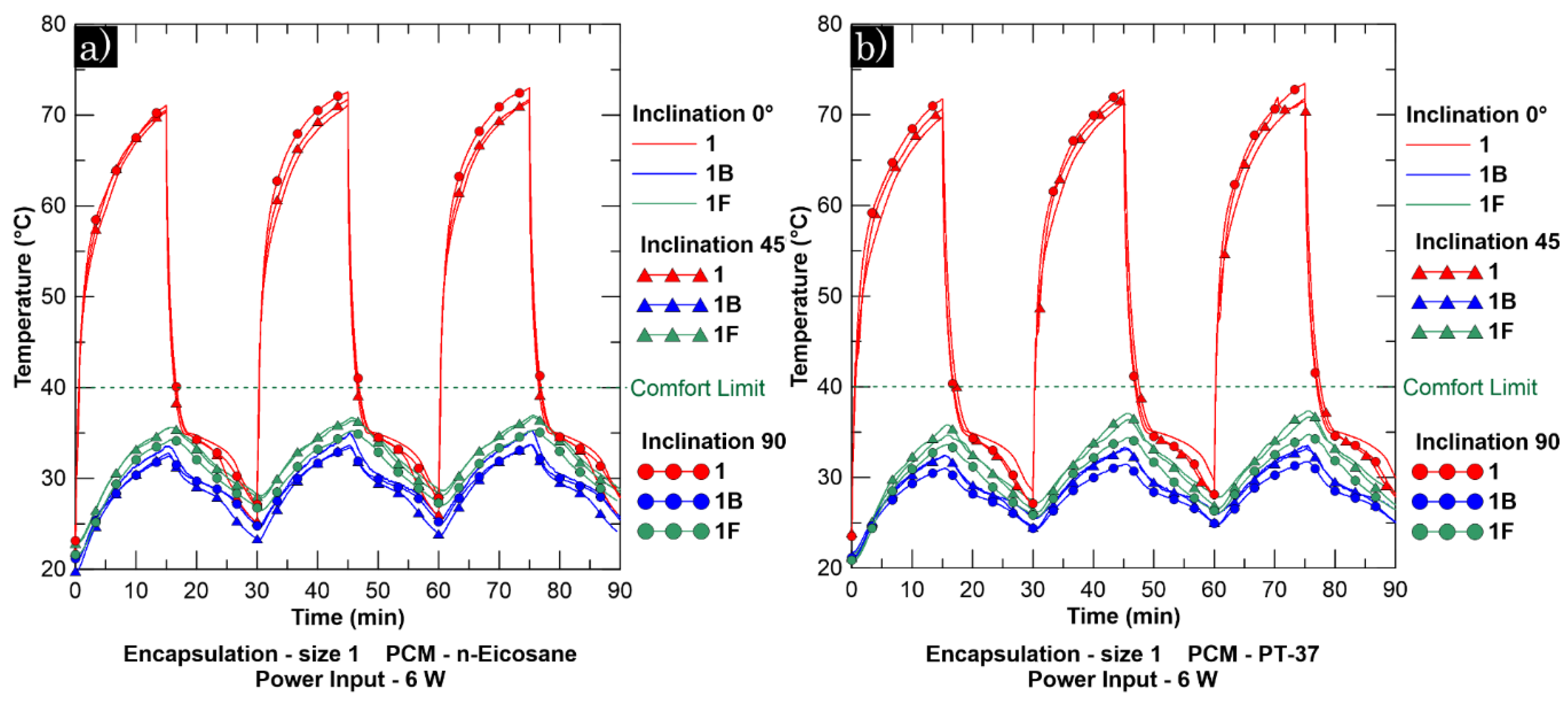

3.1.1. Influence of Inclination

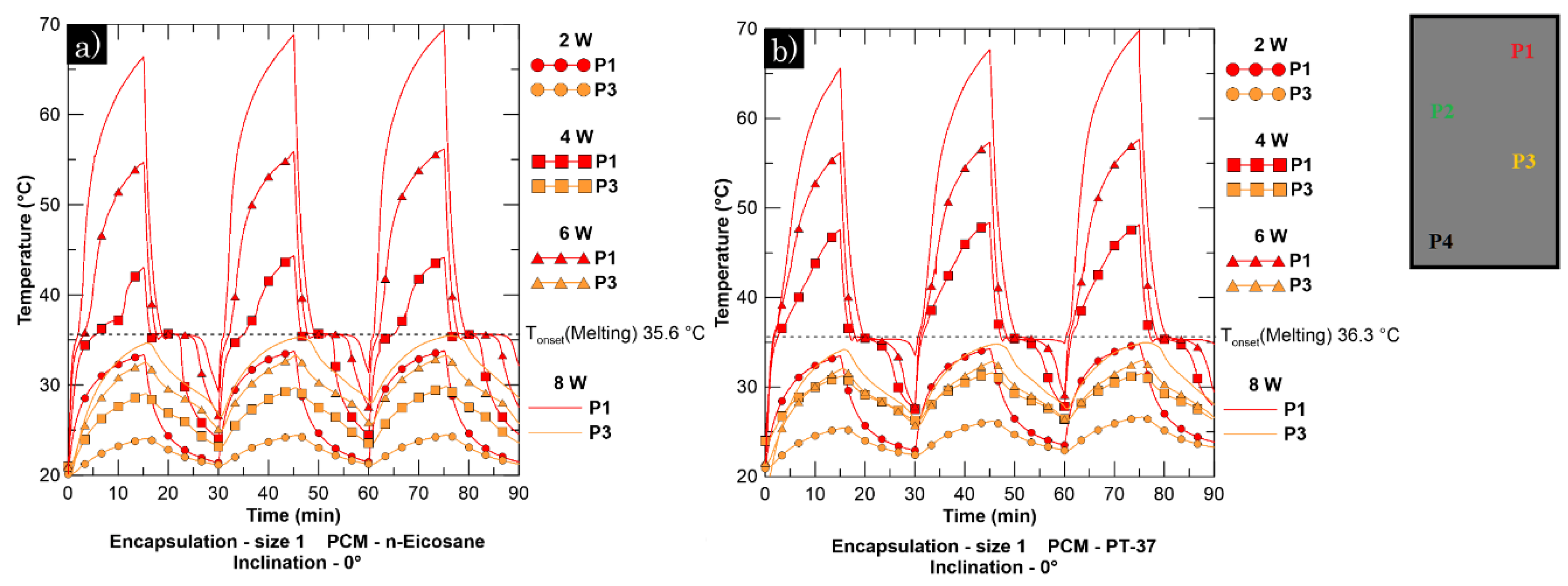

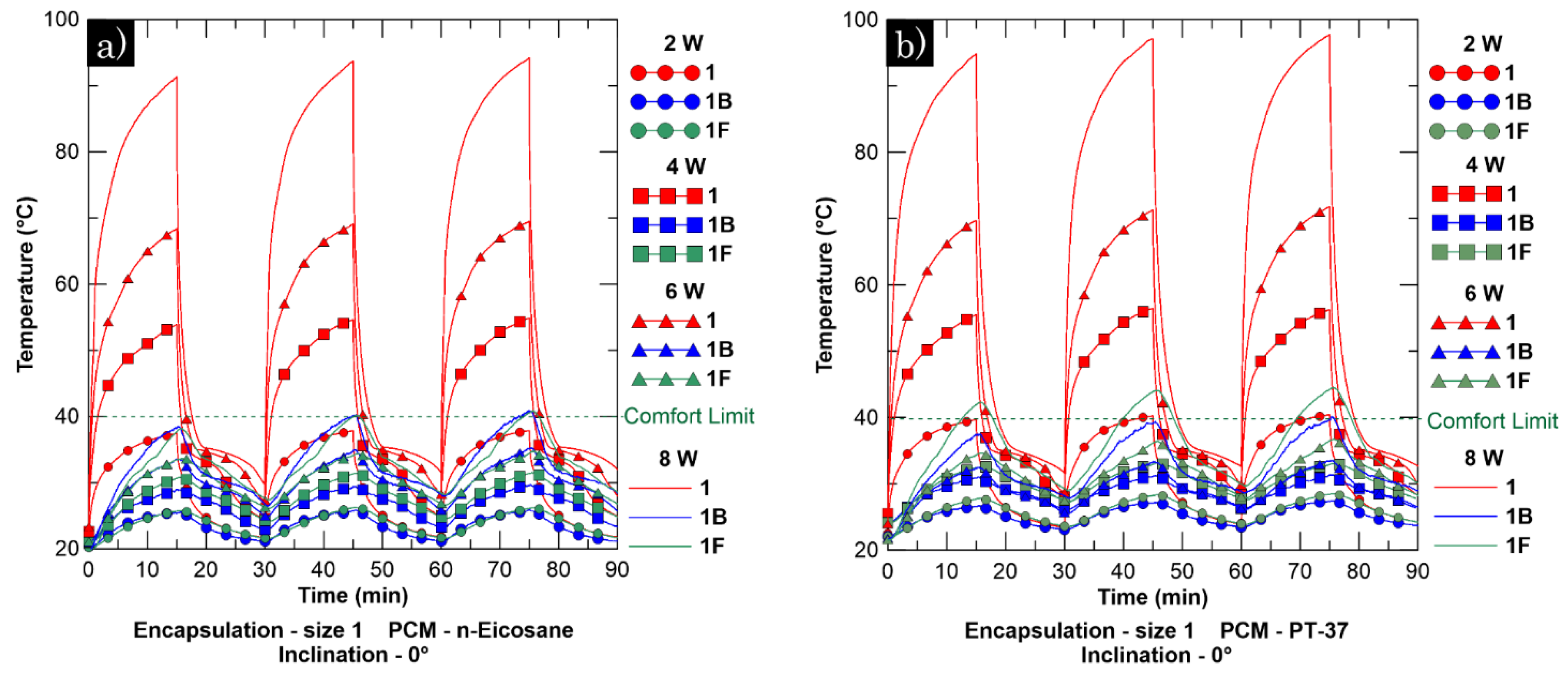

3.1.2. Influence of Power Input Levels

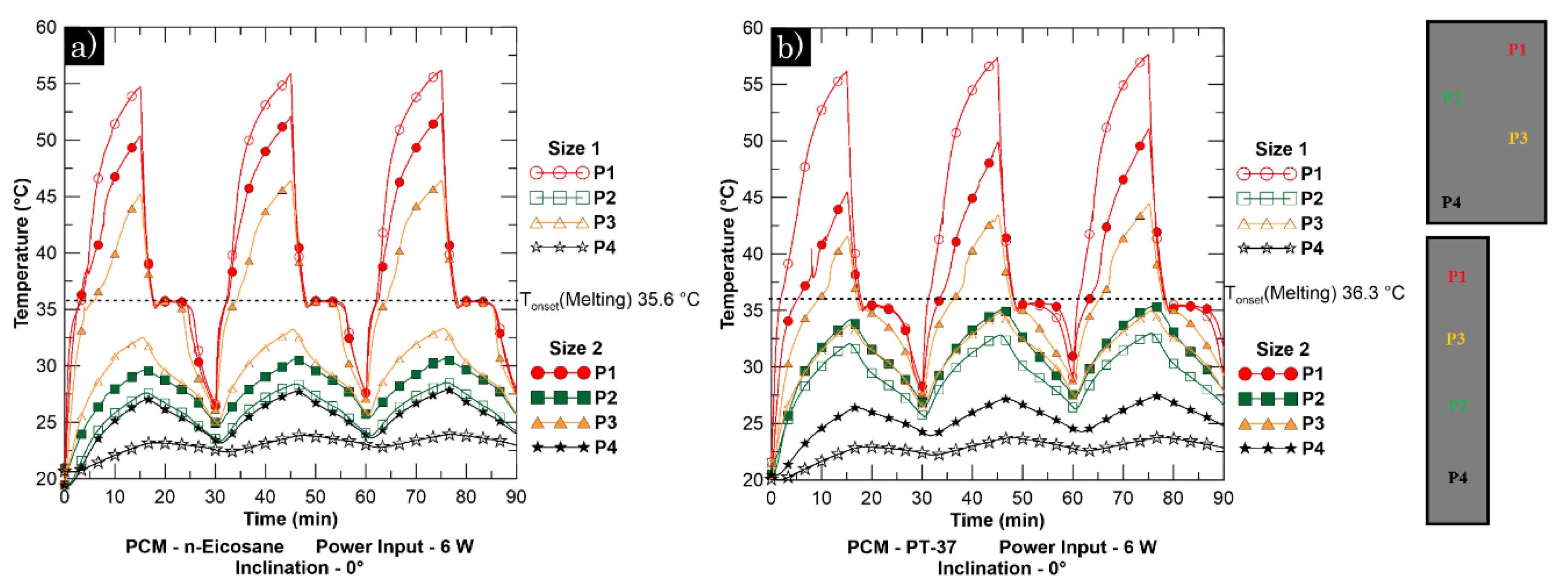

3.1.3. Influence of TES Unit Size

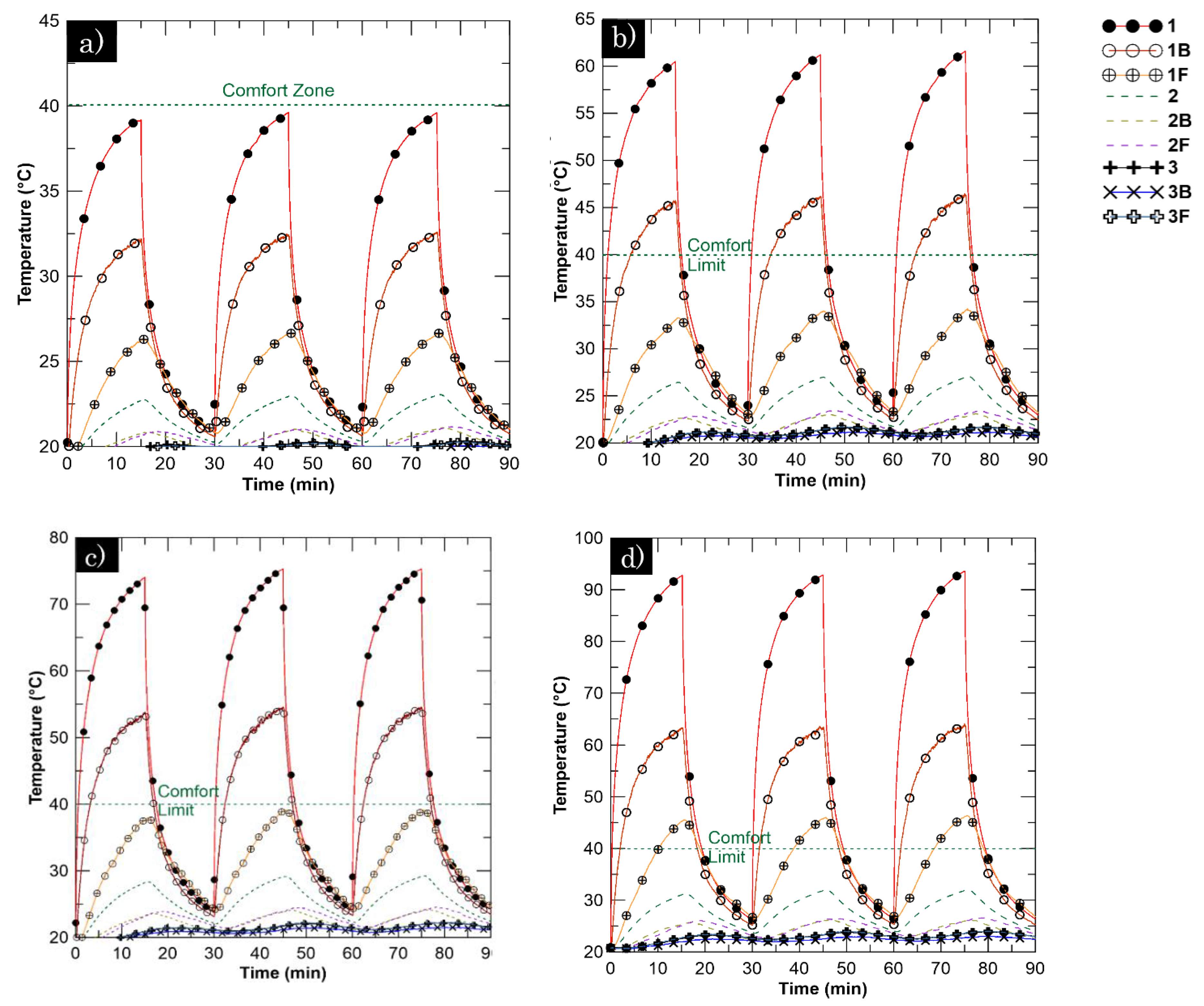

3.2. Performance of the Tablet PC

3.2.1. Influence of Inclination

3.2.2. Influence of Power Input Levels

3.2.3. Influence of TES Unit Size

3.2.4. Influence of Varying Latent Heat

4. Conclusions

- Applications of PCM TES units lead to significant temperature reduction after each 15-min charging cycle. Back-cover temperature reduction is more than 20 °C at 6 W power input. At 8 W heat input level, the tablet PC temperature was maintained below the comfort limit of 40 °C at all times with PCM TES units, although the SOC temperature exceeded the allowed maximum.

- The effect of tablet PC orientation on thermal performance of TES units is negligible.

- PCM TES units provide a comfortable back-cover temperature at all tested power input levels (2 W to 8 W). At higher power input level, more PCM melts, storing more latent heat. As a result, a longer time is required to release latent heat in the discharging phase at higher power input levels. Though PCM TES units provide acceptable back-cover temperature of the tablet PC at 8 W power input, the chip temperature rises beyond 85 °C. Hence, for the system studied here, power input of 8 W and higher should be avoided for reliable operation of the tablet PC combined with current PCM TES units.

- Larger PCM TES units result in better thermal performance due to the removal of most of the air gap and higher thermal storage from more PCM.

- Smaller PCM-based TES units placed on heat-generating components (i.e., heater) provide the best temperature reduction of the heater, even compared to regular PCM TES units, since the temperature reduction is significantly increased due to larger amounts of PCM melting during the charging phase. However, the back-cover temperature suffers from slightly higher temperatures (hot spot) with these types of PCM TES units.

- The thermal behavior of the tablet PC does not show significant sensitivity to the variety of PCMs tested, although both PCMs have slightly different thermophysical properties.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Patapoutian, A.; Peier, A.M.; Story, G.M.; Viswanath, V. ThermoTRP channels and beyond: Mechanisms of temperature sensation. Nat. Rev. Neurosci. 2003, 4, 529–539. [Google Scholar] [CrossRef] [PubMed]

- Greenspan, J.D.; Roy, E.A.; Caldwell, P.A.; Farooq, N.S. Thermosensory intensity and affect throughout the perceptible range. Somatosens. Mot. Res. 2003, 20, 19–26. [Google Scholar] [CrossRef] [PubMed]

- Story, G.M. The emerging role of TRP channels in mechanisms of temperature and pain sensation. Curr. Neuropharmacol. 2006, 4, 183. [Google Scholar] [CrossRef] [PubMed]

- McPherson, J.W. Reliability Physics and Engineering: Time-To-Failure Modeling; Springer: Berlin, Germany, 2010. [Google Scholar]

- Kandasamy, R.; Wang, X.-Q.; Mujumdar, A.S. Transient cooling of electronics using phase change material (PCM)-based heat sinks. Appl. Therm. Eng. 2008, 28, 1047–1057. [Google Scholar] [CrossRef]

- Kandasamy, R.; Wang, X.-Q.; Mujumdar, A.S. Application of phase change materials in thermal management of electronics. Appl. Therm. Eng. 2007, 27, 2822–2832. [Google Scholar] [CrossRef]

- Tan, F.; Tso, C.P. Cooling of mobile electronic devices using phase change materials. Appl. Therm. Eng. 2004, 24, 159–169. [Google Scholar] [CrossRef]

- Tan, F.; Shen, W.; Fok, S. Thermal Performance of PCM-Cooled Mobile Phone. In Proceedings of the IEEE 2009 11th Electronics Packaging Technology Conference, Singapore, 9–11 December 2009; pp. 640–645. [Google Scholar]

- Alawadhi, E.M.; Amon, C.H. PCM thermal control unit for portable electronic devices: Experimental and numerical studies. IEEE Trans. Compon. Packag. Technol. 2003, 26, 116–125. [Google Scholar] [CrossRef]

- Gharbi, S.; Harmand, S.; Jabrallah, S.B. Experimental study of the cooling performance of phase change material with discrete heat sources—Continuous and intermittent regimes. Appl. Therm. Eng. 2017, 111, 103–111. [Google Scholar] [CrossRef]

- Weng, Y.-C.; Cho, H.-P.; Chang, C.-C.; Chen, S.-L. Heat pipe with PCM for electronic cooling. Appl. Energy 2011, 88, 1825–1833. [Google Scholar] [CrossRef]

- Tomizawa, Y.; Sasaki, K.; Kuroda, A.; Takeda, R.; Kaito, Y. Experimental and numerical study on phase change material (PCM) for thermal management of mobile devices. Appl. Therm. Eng. 2016, 98, 320–329. [Google Scholar] [CrossRef] [Green Version]

- Sponagle, B.; Maranda, S.; Groulx, D. Investigation of the Thermal Behaviour of Thin Phase Change Material Packages as a Solution to Temperature Control in Electronics. In Proceedings of the ASME 2017 Summer Heat Transfer Conference, Bellevue, WA, USA, 9–14 July 2017. [Google Scholar]

- Sponagle, B.N.; Groulx, D. Numerical Study of Temperature Control in Tablet Computers using Phase Change Material Thermal Energy Storage. In Proceedings of the 4th International Forum on Heat Transfer, IFHT2016, Sendai, Japan, 2–4 November 2016. [Google Scholar]

- Ahmed, T.; Bhouri, M.; Groulx, D.; White, M.A. Passive thermal management of tablet PCs using phase change materials: Continuous operation. Int. J. Therm. Sci. 2018, 134, 101–115. [Google Scholar] [CrossRef]

- He, J.; Yang, X.; Zhang, G. A phase change material with enhanced thermal conductivity and secondary heat dissipation capability by introducing a binary thermal conductive skeleton for battery thermal management. Appl. Therm. Eng. 2019, 148, 984–991. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, X.; Xin, C.; Rao, Z. An experimental study on thermal management of lithium ion battery packs using an improved passive method. Appl. Therm. Eng. 2018, 134, 163–170. [Google Scholar] [CrossRef]

- Huang, Y.-H.; Cheng, W.-L.; Zhao, R. Thermal management of Li-ion battery pack with the application of flexible form-stable composite phase change materials. Energy Convers. Manag. 2019, 182, 9–20. [Google Scholar] [CrossRef]

- Ali, H.M.; Arshad, A.; Janjua, M.M.; Baig, W.; Sajjad, U. Thermal performance of LHSU for electronics under steady and transient operations modes. Int. J. Heat Mass Transf. 2018, 127, 1223–1232. [Google Scholar] [CrossRef]

- Sponagle, B.; Groulx, D. Thermal Modeling of Tablets: Temperature Management using Phase Change Materials. In Proceedings of the 1st Thermal and Fluid Engineering Summer Conference, TFESC, New York, NY, USA, 9–12 August 2015. [Google Scholar]

- Ahmed, T.; Bhouri, M.; Kahwaji, S.; Groulx, D.; White, M.A. Experimental Investigation of Thermal Management of Tablet Computers Using Phase Change Materials (PCMs). In Proceedings of the ASME 2016 Summer Heat Transfer Conference, Washington, DC, USA, 10–14 July 2016. [Google Scholar]

- Ahmed, T. Development of a Novel Thermal Management Technology of Tablet Computers Using Phase Change Materials. Master’s Thesis, Dalhousie University, Halifax, NS, Canada, 2016. [Google Scholar]

- Sarvar, F.; Poole, N.J.; Witting, P.A. PCB glass-fibre laminates: Thermal conductivity measurements and their effect on simulation. J. Electron. Mater. 1990, 19, 1345–1350. [Google Scholar] [CrossRef]

- Desgrosseilliers, L.; Groulx, D.; White, M.A. Heat conduction in laminate multilayer bodies with applied finite heat source. Int. J. Therm. Sci. 2013, 72, 47–59. [Google Scholar] [CrossRef]

- Sim, C.; Loh, J.S. Fanless Design for Embedded Applications. Intel Technol. J. 2009, 13, 13. [Google Scholar]

| Properties | n-Eicosane | PT-37 |

|---|---|---|

| ΔfusH | 239 ± 24 J/g | 206 ± 21 J/g |

| Tm | 35.6 ± 1.5 °C | 36.4 ± 1.5 °C |

| Cp,s | 1.8 ± 0.2 J/g K for T = 20 °C | 1.8 ± 0.2 J/g K for T = 20 °C |

| Cp,l | 2.3 ± 0.2 J/g K for T = 50 °C | 2.1 ± 0.2 J/g K for T = 50 °C |

| ks | 0.46 ± 0.05 W/m K for T = −21 to 29 °C | 0.28 ± 0.03 W/m K for T = −21 to 29 °C |

| ρ | 0.79 kg/m3 | 0.84 kg/m3 |

| Encapsulation | Base Area | Average Thickness | Amount of PCM, mpcm | Total Latent Heat (kJ) m pcm × ΔfusH | |

|---|---|---|---|---|---|

| n-eicosane | PT-37 | ||||

| Size 1 | 6″ × 2.6″ (152.4 × 66 mm2) | 1/16″ (2 mm) | 16 g | 3.82 | 3.25 |

| Size 2 | 7″ × 1.5″ (177.8 × 38 mm2) | 1/16″ (2 mm) | 11 g | 2.63 | 2.27 |

| Size 3 | 7″ × 3.4″ (177.8 × 86 mm2) | 1/16″ (2 mm) | 25 g | 6.00 | 5.15 |

| Thickness 1 | 2″ × 2″ (51 × 51 mm2) | 0.13″ (3 mm) | 6 g | 1.42 | 1.23 |

| Thickness 2 | 2″ × 2″ (51 × 51 mm2) | 0.16″ (4 mm) | 8 g | 1.89 | 1.64 |

| Thickness 3 | 2″ × 2″ (51 × 51 mm2) | 0.20″ (5 mm) | 10 g | 2.36 | 2.05 |

| Observations | PCMs | Size of TES Unit (Mass of PCMs) | Inclination | Power Input | Operation Mode |

|---|---|---|---|---|---|

| Melting-Solidification of PCMs | n-eicosane PT-37 | Size 1 (16 g) | 0° (horizontal) | 2 W | 3 cycles of: Charging—15 min. Discharging—15 min. |

| 4 W | |||||

| 6 W | |||||

| Size 2 (11 g) | 45° | 6 W | |||

| 90° (vertical) | 8 W | ||||

| Performance of the Tablet PC | n-eicosane PT-37 | Size 1 (16 g) | 0° (horizontal) | 2 W | 3 cycles of: Charging—15 min. Discharging—15 min. |

| Size 2 (11g) | 45° | 2 W | |||

| Size 3 (25 g) | 4 W | ||||

| 2ʺ × 2ʺ × 0.12ʺ (6 g) | 90° (vertical) | 6 W | |||

| 2ʺ × 2ʺ × 0.16ʺ (8 g) | 8 W | ||||

| 2ʺ × 2ʺ × 0.20ʺ (10 g) |

| Power Input | Maximum Uncertainty in the Supplied Voltage | Maximum Uncertainty in the Supplied Power |

|---|---|---|

| 2 W | ±4% | ±8% |

| 4 W | ±2.8% | ±5.75% |

| 6 W | ±2.3% | ±5% |

| 8 W | ±2% | ±3.75% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, T.; Bhouri, M.; Groulx, D.; White, M.A. Passive Thermal Management of Tablet PCs Using Phase Change Materials: Intermittent Operation. Appl. Sci. 2019, 9, 902. https://doi.org/10.3390/app9050902

Ahmed T, Bhouri M, Groulx D, White MA. Passive Thermal Management of Tablet PCs Using Phase Change Materials: Intermittent Operation. Applied Sciences. 2019; 9(5):902. https://doi.org/10.3390/app9050902

Chicago/Turabian StyleAhmed, Tousif, Maha Bhouri, Dominic Groulx, and Mary Anne White. 2019. "Passive Thermal Management of Tablet PCs Using Phase Change Materials: Intermittent Operation" Applied Sciences 9, no. 5: 902. https://doi.org/10.3390/app9050902

APA StyleAhmed, T., Bhouri, M., Groulx, D., & White, M. A. (2019). Passive Thermal Management of Tablet PCs Using Phase Change Materials: Intermittent Operation. Applied Sciences, 9(5), 902. https://doi.org/10.3390/app9050902