4.1. Simulation of the Optimization Process

The main discrimination index of the offline optimization process was the smell function: bestSmellbestIndex, and the IAE time was 0.2 s.

Figure 9 is an optimization iteration diagram composed of the reciprocal of the control error IAE index in each control loop.

Figure 9a represents the reciprocal of the control error IAE index of reactive power;

Figure 9b represents the index of reactive power;

Figure 9c represents the index of the

d-axis component of the output control error; and

Figure 9d represents the index of the

q-axis component of the output control error.

Table 1 shows the comparison of offline optimization key parameters between a population size of 100 and a population size of 200. The computation time of each fruit fly individual was 5.6 s in the offline optimization simulation process. Comparisons of the final optimized parameters suggested that the larger the population size, the larger the search space range and the smaller the number of iterations, but no significant difference was found between the final optimal values. Furthermore, the increase in the population scale meant the extension of optimization time. The total time for the offline optimization calculation was 15.7 h when the fruit fly population was 100. When the fruit fly population was 200, the total simulation time increased to 31.4 h.

Table 2 shows the comparisons of the parameters between different controllers after population optimization. It can be seen from the table that the parameters of different controllers differed a lot in population scale.

Figure 10 shows the comparison unit step–response curves between the initial value and the optimal unit step–response of the optimization calculation process. It can be seen from the figure that the step–response results of the optimal controller parameters significantly outperformed those of the initial controller parameters. The unit step–response rising time of the

d-axis component was 1.11434 × 10

−6 s, and the average deviation rate of steady-state error was 0.298%, while the initial controller was 2.56119 × 10

−5 s and 5.542%, respectively. Correspondingly, the unit step–response rising time and the average deviation rate of the steady-state error of the

q-axis component was 8.21158 × 10

−7 s and 0.271%, respectively, while the initial controller increased to 2.77256 × 10

−5 s and 6.727%, respectively. It was noted that the responses of the optimized controllers became faster with a smaller steady-state error, and the control performance of these controllers was improved.

The improved dynamic performance of the controller after parameter optimization has been proven by

Figure 10, shown above.

Figure 11 shows the poles and zeros analysis results of the initial and optimal control loop. The initial control loop had three domain poles to influence the control performance (

Figure 11a). The zeros were concentrated near the origin point. The three domain poles influenced each other.

Figure 11b shows the new poles and zeros results after parameter optimization. There was only one domain pole on the negative real-axis. The other domain poles, which were close to the zero points, cannot be regarded as effective domain poles. The system changed to become more controllable and more stable.

The inverter output current and output power simulation comparison curves are shown in

Figure 12 and

Figure 13, and the parameters of the simulation circuit element are given in

Table A1 in

Appendix A. The detailed indicators comparing the results of dynamic performances have been listed in

Table 3. The active power target was 12 kW, and the reactive power target was 3 kVar. The curves showed the VSI start operation process with grid support. The sampling time was 5 × 10

−5 s, and the control time of the controller was 2 × 10

−4 s in the simulation process. In

Figure 12a, the results showed that the overshoot reduced from 32.3% to 9.1%, and the settling time shortened from 1.151 s to 0.38 s. These dynamic characteristic indicators in

Figure 12b also reduced from 12.73% to 4.46% and shortened from 0.4 s to 0.375 s. With the improvement of the control performance of the

d-axis and

q-axis, the peak amplitude of current output exceeding the set value reduced from 28.79% to 7.58%, and the settling time shortened from 0.805 s to 0.3 s (as

Figure 12c shows).

The curves of

Figure 13 show active and reactive power output comparison results. According to

Figure 13a and

Table 3, the overshoot of the active power reduced from 31.6% to 8.3%, the settling time shortened from 1.146 s to 0.353 s, and the average steady-state error reduced from 5.83% to 0.96%. These characteristic indicators of the comparison results in

Figure 13b also have been reduced and shortened (as

Table 3 shows). With the improvement of settling time, overshoot time, and rise time, the dynamic performance of the output controller had comprehensively improved. Because of the difference between the actual system and the theoretical approximation model, the results of the simulation performance comparison under the same model need to be further verified by actual system experiments.

4.2. Comparison of Online Optimization

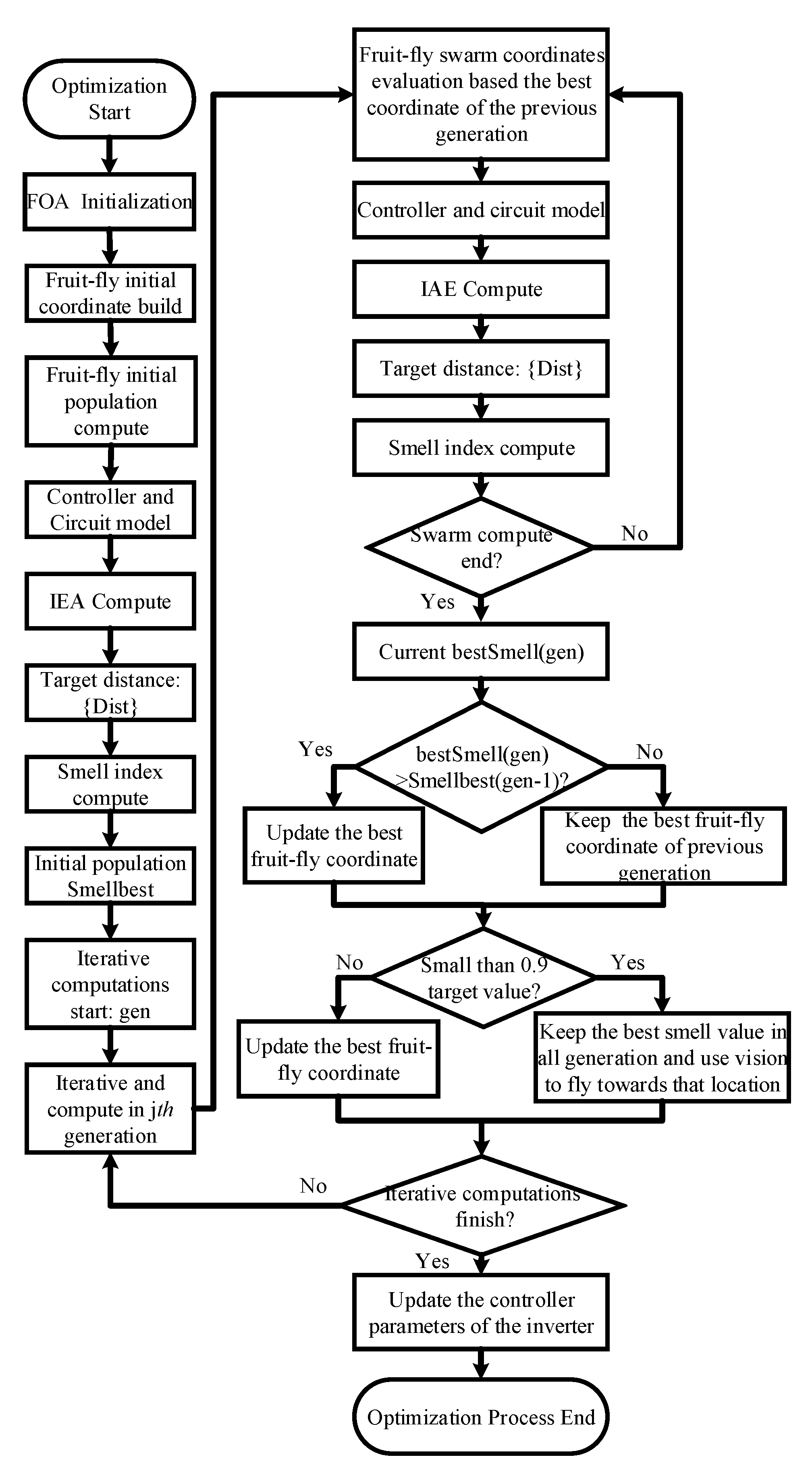

Unlike the offline optimization process, the FOA-based online optimization process refers to the online self-tuning optimization of the parameters on the basis of calculating the time sequence sampling data during the step–response in the practical operation of the controllers. In other words, the offline process involves a step–response simulation for each fruit fly via the object model, while online optimization refers to the self-tuning optimization of real-time parameters in the manner of time sequence optimizing for all the fruit fly populations in the same step–response process.

Figure 14 shows the optimization result curve of the parameter self-tuning process with a population size of 10, and a total number of iterations of 100.The curves in

Figure 14a–c demonstrate a process of decline before rebound, which was because the main discrimination index of the online optimization consisted of the slope IE of the sampling point curve in the step–response. According to the above-mentioned rules for online optimization, we should first solve the maximum of the IE value and then the minimum in the step–response process of the system. Therefore, regarding the discrimination rules of the overall smell function (Si), we should first solve the minimum and then the maximum, so as to be consistent with the tendencies of the curves in

Figure 14a,b.

Table 4 shows the comparisons of the major parameters in the self-tuning process.

Table 4 shows the major parameter indexes at the initial moment and the end moment of parameter self-tuning in the optimization process.

In order to fully compare the performance of the online self-tuning controller, the offline optimization controller, and the original controller, a comparison experiment was undertaken on an experimental verification platform (as

Figure 15 shows). The experimental platform was a representative family photovoltaic micro-grid project in Binhai District, Tianjin, China. The micro-grid system had two photovoltaic arrays, two photovoltaic grid inverters as VSIs, and a monitoring software platform with a communication and control parameter adjustment function. Throughout the whole experimental process, the controller parameters at each sampling time were self-tuned. The complete power step–responses of the online optimization parameters, the offline optimization parameters, and the initial parameters during the startup process were compared (as

Figure 16 shows).

Figure 16a shows the contrast curves of the original controller, the self-tuning parameter controller, and the offline optimized controller with the active and reactive power response in the practical operation process of the system.

Figure 16b presents the curves with the reactive power response. A comparison between the curves before optimization and after optimization indicated that the oscillation amplitude of the curve increased, but its frequency declined, in the process of the step–response. In particular, it can be seen from

Figure 16b that, after achieving the steady-state, the fluctuation frequency and steady-state error in the curve after optimization were lowered, but the oscillation amplitude increased compared with the curve before optimization. It can be noted from the figure that there were many oscillations and fluctuations, both in the rising process and the steady process of the VSI startup. The oscillations and fluctuations of the curves also helped to verify the low inertia, high sensitivity, and the oscillation ripple wave with a small signal disturbance of VSIs, as described in Radwan’s work [

34].

Table 5 reveals that the response speed of the online self-tuned controller was improved with the online parameter self-tuning method, and the rising time during the step–response was longer than that of the initial controller and the offline optimized controller. In terms of steady-state error, the initial controller had steady-state error in the process of reactive power adjustment, while that of the offline controller was relatively smaller. The overshoot of the offline optimized controller was significantly smaller than that of the initial controller and the online self-tuned controller. In the steady-state of the controller after parameter optimization, the fluctuation amplitude was large, but the fluctuation frequency declined. Since the fluctuation amplitude still fell within an acceptable steady-state margin, no further optimization was needed. Therefore, we can introduce smell discrimination criteria (smell) to further improve the problem of fluctuation amplitude during the optimization.

The experimental results in

Figure 16 are essentially a zero initial-state step–response. All state variables needed to be regulated from the zero initial-state to the target state. Therefore, the difference of the comparison curves was not obvious in

Figure 16. In order to comprehensively compare the performance of the original controller, the offline optimized controller, and the online self-tuned controller, the IAEs in the process of the step–response in the zero initial-state were compared horizontally.

Figure 17 gives the comparisons of the IAEs of different control loops. It can be seen from the figure that a dramatic drop was witnessed by the IAEs of online optimization in active power adjustment and q component adjustment, along with slight rises in reactive power adjustment and d component adjustment. This was a result of the fact that multiple PI controllers in serial and parallel structures worked together to constitute a complicated closed-loop control network, and any changes of a parameter affected other controller properties. Moreover, there were many zero initial-state variables that needed to be regulated in the zero initial step–response, and the step–response characteristics of each part were different for the zero initial-state. Under the comprehensive limitations of the reasons mentioned above and the various interferences (e.g., noise interference, communication delay, and response delay of the system components), the performance contrast shown in

Figure 17 is not obvious.

As mentioned above, the result of IAE was affected by the parameter-coupling relationship of the PI controller in the parameter tuning process. The results of IAEs were affected by the parameter-coupling relationship of the PI controllers. A comparison result of the IAE values needed to be considered rather than one of the IAE values. The IAE indicator value was not fixed because of the influence of factors such as integration time, sampling time, control time, operating conditions, step amplitude, equipment parameters, environmental noise interference, and population size of the optimization algorithm. Therefore, the optimization tuning result was not judged according to the comparison value of the IAEs of a certain working condition or that of a certain control ring, but was based on the comprehensive comparison of the IAE values of all the control rings under different operating conditions.

In order to further verify the improvement of VSI output performance by optimizing parameters, an experimental comparison of variable load output during normal operation of the system was conducted (as

Figure 18 shows). Due to the change in load demand, the target-setting values of the VSI output changed from 10 kW and 3 kVar to 10 kW and 3 kVar when the operation time was 35.5 s. The detailed indicator comparison results of the step–response process are listed in

Table 6. Compared with the initial parameter results, the overshoot of response curves with online optimization and offline optimization (in

Figure 18a) reduced from 38.5% to 28% and 26%, respectively. The settling time shortened from the 0.157 s to 0.092 s and 0.087 s, respectively. The indicators of

d-axis in

Figure 18b also have been improved. According to

Figure 18 and

Table 6, the response speed of the controller with optimization parameters improved, and the overshoot, oscillation, and average steady-state errors were reduced. The IAE comparison results of the variable load process are shown in

Figure 19. It can be seen that the IAE value of the controller with optimized parameters was greatly reduced in each control loop. Compared with the startup phase in

Figure 17, the performance improvement was more obvious during normal operation because of the reduction of the zero initial-state variables of the device.

Due to the strong load randomness characteristics, high intermittent characteristics of the power supplies, low inertia characteristics, and the effect of random noise disturbances and delays, the oscillations and fluctuations cannot be avoided during the normal operation process of a micro-grid (as

Figure 18 shows). To verify the anti-shock performance of the system caused by the strong randomness of the load, the impulse response of VSI was compared in this paper (as

Figure 20 shows). The load mutation appeared when the operation time was 15.4 s, and disappeared at 15.6 s. Since the target-setting values of VSI output were changed, the control system experienced two impulse response processes as the power changed, caused by load mutations. The main dynamic comparison indicators are listed in

Table 7. Compared with the initial parameter curve, the active power output curve with optimized parameters had smaller spike amplitudes in the process of the impulse response and a quicker recovery of the stable state. The IAE comparison results of this process are shown in

Figure 21. The improvement of IAEs in active power control loops and the

d-axis control loop was clear, while the improvement effect in other control loops was relatively small. Although the performance improvement of reactive power output was limited, the comprehensive performance of the control system improved by optimizing control parameters without changing the overall control structure, method, and usage of energy storage.