Optimization of Replaced Grinding Wheel Diameter for Minimum Grinding Cost in Internal Grinding

Abstract

:1. Introduction

2. Cost Analysis

3. Experimental Work

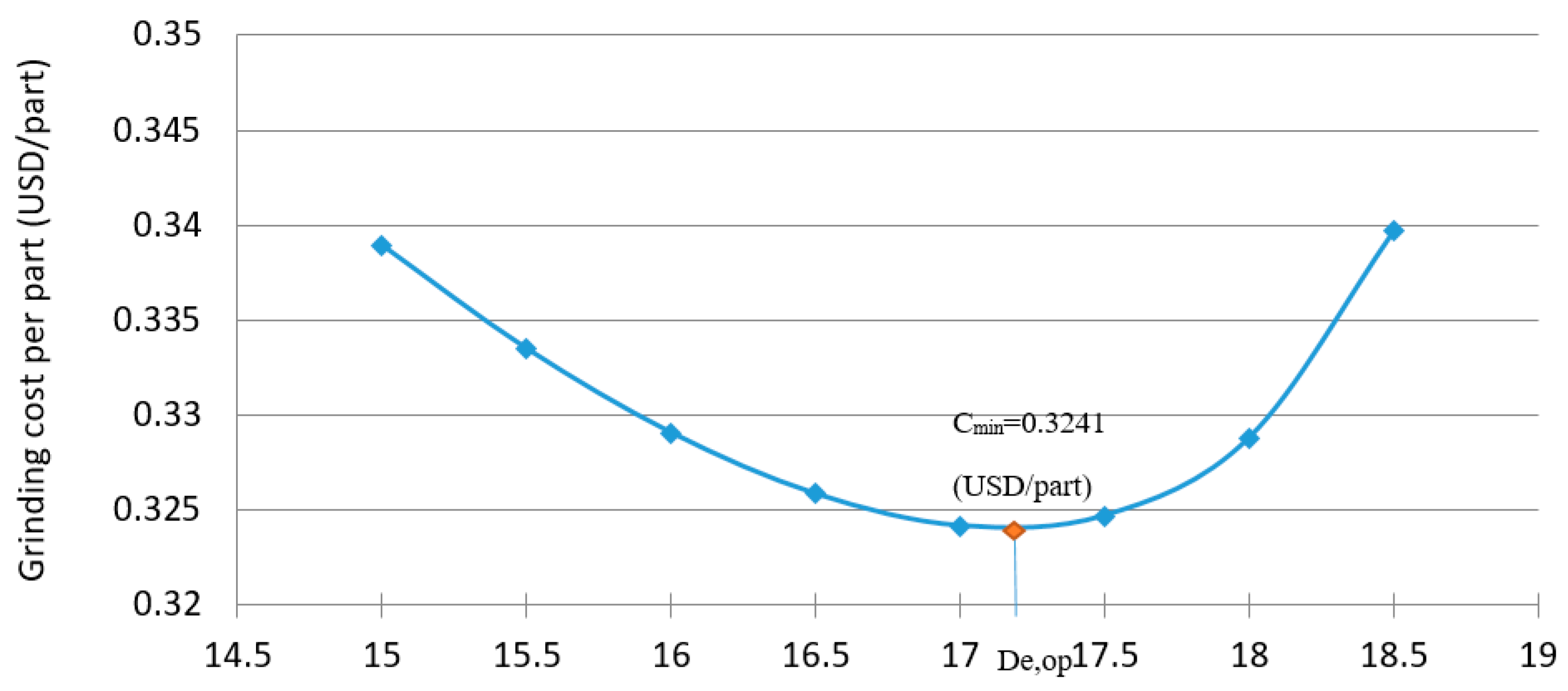

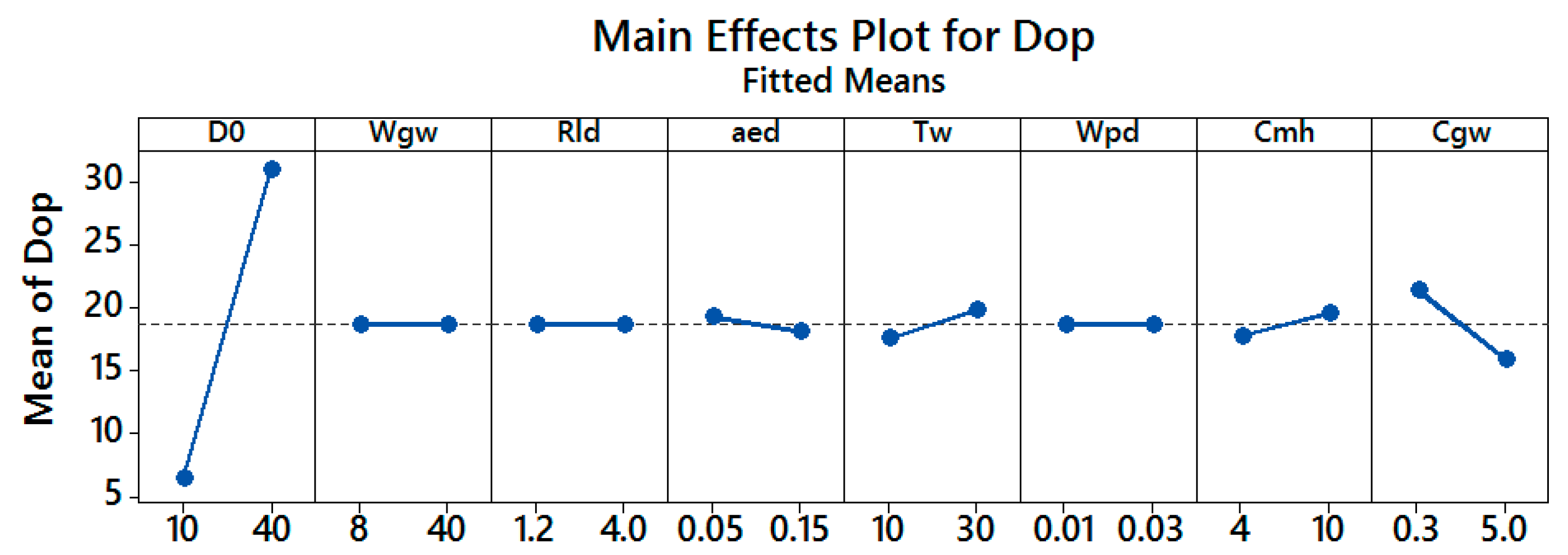

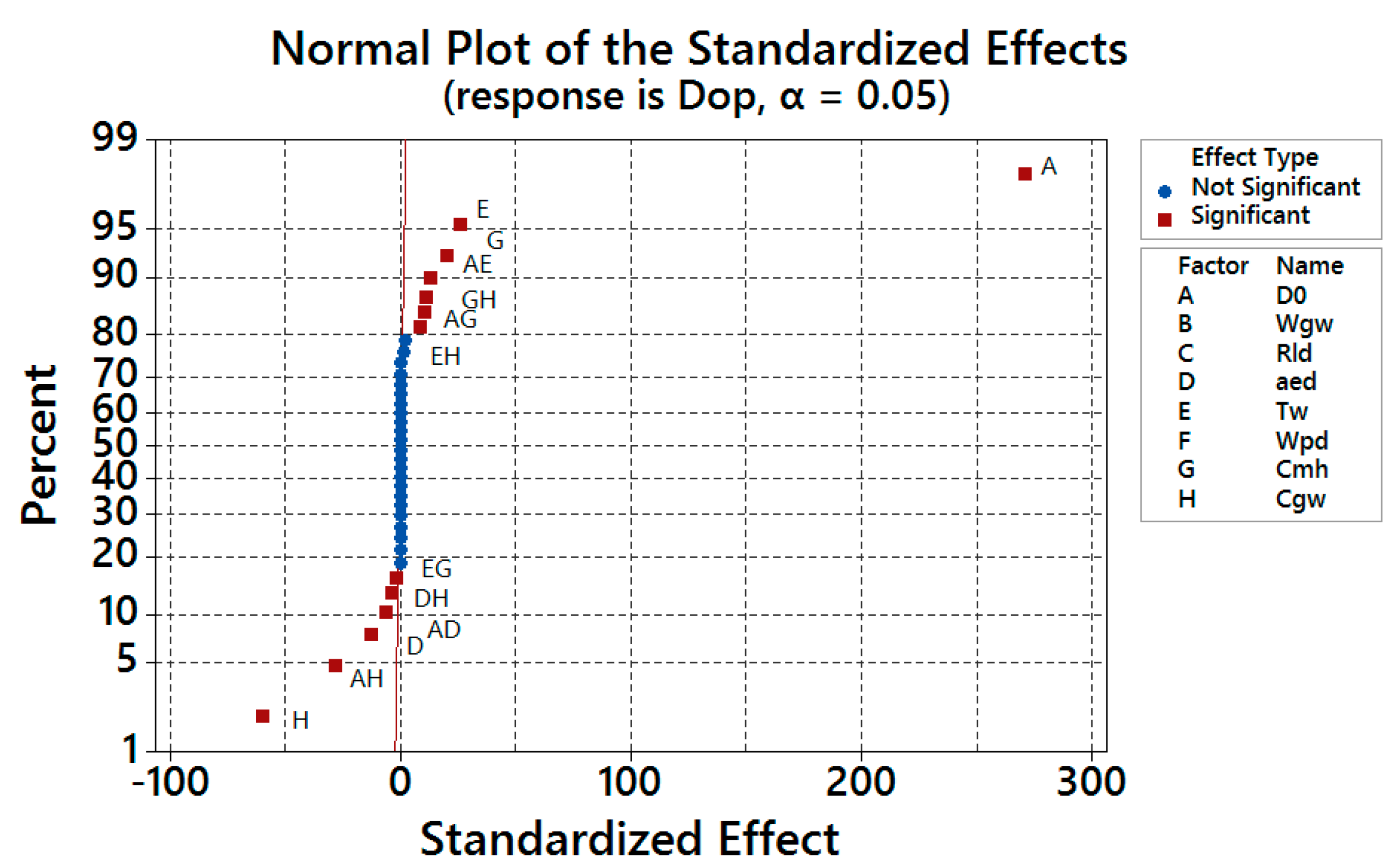

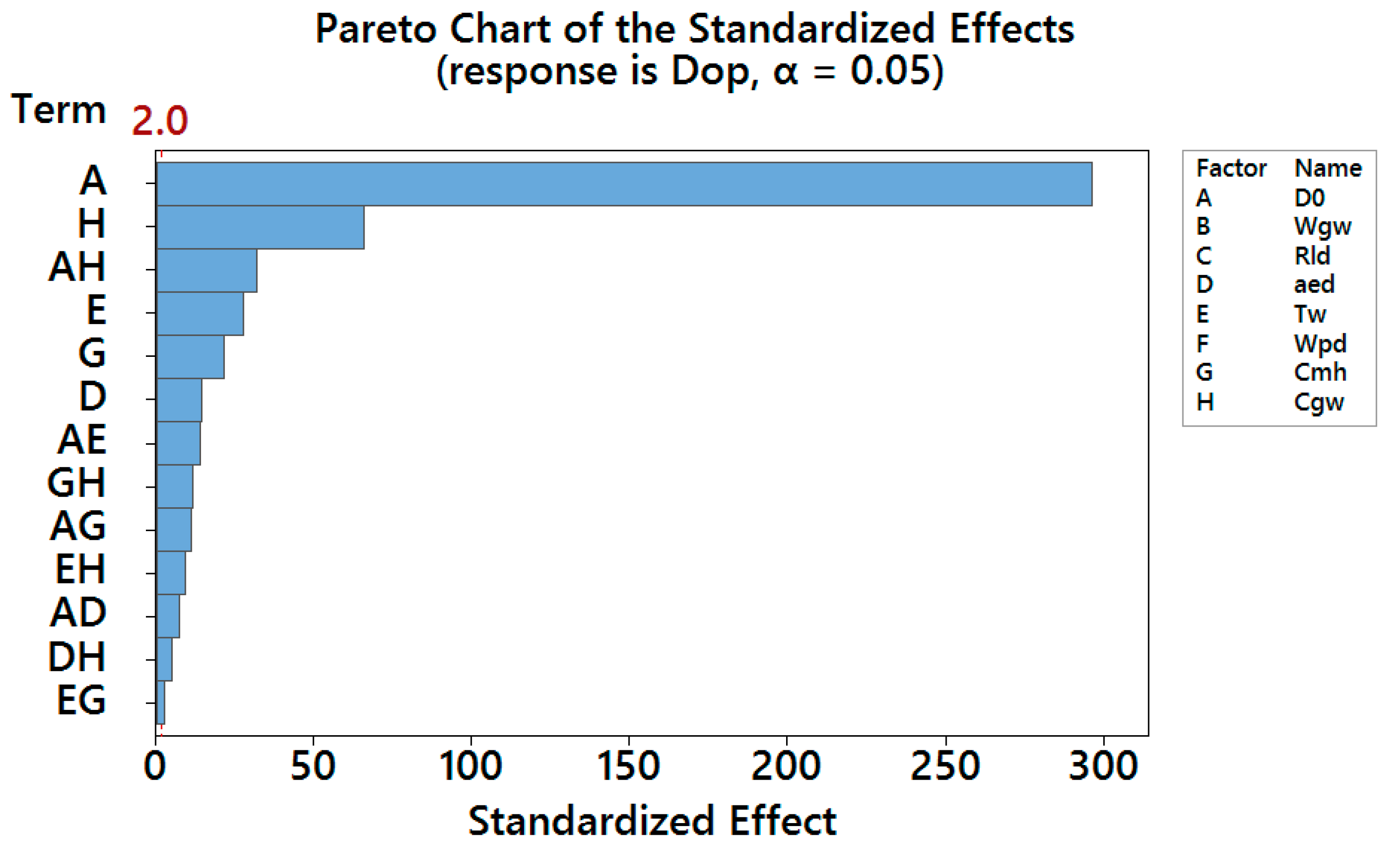

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Malkin, S.; Guo, C. Grinding Technology: Theory and Applications of Machining with Abrasives; Industrial Press: New York, NY, USA, 2008. [Google Scholar]

- Li, G.F.; Wang, L.S.; Yang, L.B. Multi-parameter optimization and control of the cylindrical grinding process. J. Mater. Process. Technol. 2002, 129, 232–236. [Google Scholar] [CrossRef]

- Gupta, R.; Shishodia, K.S.; Sekhon, G.S. Optimization of grinding process parameters using enumeration method. J. Mater. Process. Technol. 2001, 112, 63–67. [Google Scholar] [CrossRef]

- Chatterjee, S.; Rudrapati, R.; Kumar pal, P.; Nandi, G. Experiments, analysis and parametric optimization of cylindrical traverse cut grinding of aluminium bronze. Mater. Today: Proc. 2018, 5, 5272–5280. [Google Scholar] [CrossRef]

- Pi, V.N.; The, P.Q.; Khiem, V.H.; Huong, N.N. Cost optimization of external cylindrical grinding. Appl. Mech. Mater. 2013, 312, 982–989. [Google Scholar] [CrossRef]

- Rana, P.; Lalwani, D.I. Parameters optimization of surface grinding process using Modified ε constrained Differential Evolution. Mater. Today: Proc. 2017, 4, 10104–10108. [Google Scholar] [CrossRef]

- Warnecke, G.; Barth, C. Optimization of the Dynamic Behavior of Grinding Wheels for Grinding of Hard and Brittle Materials Using the Finite Element Method. CIRP Ann. Manuf. Technol. 1999, 48, 261–264. [Google Scholar] [CrossRef]

- Pi, V.N.; Tung, L.A.; Hung, L.X.; Ngoc, N.C. Experimental Determination of Optimum Replaced Diameter in Surface Grinding Process. J. Environ. Sci. Eng. 2017, 5, 85–89. [Google Scholar]

- Pandiyan, V.; Caesarendra, W. Tegoeh Tjahjowidodo, and Gunasekaran Praveen, Predictive Modelling and Analysis of Process Parameters on Material Removal Characteristics in Abrasive Belt Grinding Process. Appl. Sci. 2017, 7, 363. [Google Scholar] [CrossRef]

- Liu, Y.; Peng, H.; Yang, Y. Reliability Modeling and Evaluation Method of CNC Grinding Machine Tool. Appl. Sci. 2019, 9, 14. [Google Scholar] [CrossRef]

- Vu, N.P.; Nguyen, O.-X.; Tran, T.-H.; Le, H.-K.; Nguyen, A.-T.; Luu, A.-T.; Nguyen, V.-T.; Le, X.-H. Optimization of Grinding Parameters for Minimum Grinding Time When Grinding Tablet Punches by CBN Wheel on CNC Milling. Appl. Sci. 2019, 9, 957. [Google Scholar] [CrossRef]

- Inasaki, I. Monitoring and Optimization of Internal Grinding Process. CIRP Ann. Manuf. Technol. 1991, 40, 359–362. [Google Scholar] [CrossRef]

- Daneshi, A.; Jandaghi, N.; Tawakoli, T. Effect of Dressing on Internal Cylindrical Grinding. Procedia CIRP 2014, 14, 37–41. [Google Scholar] [CrossRef] [Green Version]

- Xiao, G.; Malkin, S. On-Line Optimization for Internal Plunge Grinding. CIRP Ann. Manuf. Technol. 1996, 45, 287–292. [Google Scholar] [CrossRef]

- Tönshoff, H.K.; Walter, A. Self-tuning fuzzy-controller for process control in internal grinding. Fuzzy Sets Syst. 1994, 63, 359–373. [Google Scholar] [CrossRef]

- Pi, V.N.; Hung, L.X.; Tung, L.N.; Long, B.T. Cost Optimization of Internal Grinding. J. Mater. Sci. Eng. B 2016, 6, 291–296. [Google Scholar]

- Brian Rowe, W. Principle of Modern Grinding Technology; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Long, B.T.; Pi, V.N.; Hung, L.X.; Tung, L.A. Building cutting regime formulas for internal grinding (In Vietnamese). J. Sci. Technol. 2016, 9, 15–18. [Google Scholar]

- Kozuro, L.M.; Panov, A.A.; Remizovski, E.I.; Tristosepdov, P.S. Handbook of Grinding (in Russian); Publish Housing of High-Education: Minsk, Russia, 1981. [Google Scholar]

- Hung, L.X.; Hong, T.T.; Ky, L.H.; Tuan, N.Q.; Tung, L.A.; Long, B.T.; Pi, V.N. A study on calculation of optimum exchanged grinding wheel diameter when internal grinding. In Proceedings of the 9th International Conference on Materials Processing and Characterization, Hyderabad, India, 8–10 March 2019. [Google Scholar]

| Coefficient depends on | Code | Value | Reference |

|---|---|---|---|

| Work-piece material and tolerance grade | c1 | [18] | |

| Grinding wheel diameter | c2 | [18] | |

| Measurement type | c3 | 1 (using micrometer) | [19] |

| Ratio of length to diameter of work-piece | c4 | [18] |

| Name | Code | Equation |

|---|---|---|

| Grinding time | tc | |

| Dressing time | td,p | |

| Wheel replacing time per work-piece | twr,p |

| Factor | Code | Unit | Low | High |

|---|---|---|---|---|

| Initial grinding wheel diameter | D0 | mm | 10 | 40 |

| Grinding wheel width | Wgw | mm | 8 | 40 |

| L/d ratio | Rld | - | 1.2 | 4 |

| Total depth of dressing cut | aed | mm | 0.05 | 0.15 |

| Life of wheel | Tw | min | 10 | 30 |

| Radial grinding wheel wear per dress | Wpd | mm | 0.01 | 0.03 |

| Cost of the grinding machine | Cm,h | USD/h | 4 | 10 |

| Wheel cost per piece | Cgw | USD/p. | 0.3 | 5 |

| StdOrder | RunOrder | CenterPt | Blocks | D0 | Wgw | Rld | aed | Tw | Wpd | Cm,h | Cgw | De,op |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 97 | 1 | 1 | 1 | 10 | 8 | 1.2 | 0.05 | 10 | 0.03 | 10 | 0.3 | 7.84 |

| 82 | 2 | 1 | 1 | 40 | 8 | 1.2 | 0.05 | 30 | 0.01 | 10 | 5 | 32.2 |

| 51 | 3 | 1 | 1 | 10 | 40 | 1.2 | 0.05 | 30 | 0.03 | 4 | 5 | 5.33 |

| 89 | 4 | 1 | 1 | 10 | 8 | 1.2 | 0.15 | 30 | 0.01 | 10 | 5 | 5.86 |

| 108 | 5 | 1 | 1 | 40 | 40 | 1.2 | 0.15 | 10 | 0.03 | 10 | 5 | 25.69 |

| 104 | 6 | 1 | 1 | 40 | 40 | 4 | 0.05 | 10 | 0.03 | 10 | 5 | 28.24 |

| … | ||||||||||||

| 54 | 127 | 1 | 1 | 40 | 8 | 4 | 0.05 | 30 | 0.03 | 4 | 0.3 | 36.23 |

| 9 | 128 | 1 | 1 | 10 | 8 | 1.2 | 0.15 | 10 | 0.01 | 4 | 5 | 3.23 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tran, T.-H.; Le, X.-H.; Nguyen, Q.-T.; Le, H.-K.; Hoang, T.-D.; Luu, A.-T.; Banh, T.-L.; Vu, N.-P. Optimization of Replaced Grinding Wheel Diameter for Minimum Grinding Cost in Internal Grinding. Appl. Sci. 2019, 9, 1363. https://doi.org/10.3390/app9071363

Tran T-H, Le X-H, Nguyen Q-T, Le H-K, Hoang T-D, Luu A-T, Banh T-L, Vu N-P. Optimization of Replaced Grinding Wheel Diameter for Minimum Grinding Cost in Internal Grinding. Applied Sciences. 2019; 9(7):1363. https://doi.org/10.3390/app9071363

Chicago/Turabian StyleTran, Thi-Hong, Xuan-Hung Le, Quoc-Tuan Nguyen, Hong-Ky Le, Tien-Dung Hoang, Anh-Tung Luu, Tien-Long Banh, and Ngoc-Pi Vu. 2019. "Optimization of Replaced Grinding Wheel Diameter for Minimum Grinding Cost in Internal Grinding" Applied Sciences 9, no. 7: 1363. https://doi.org/10.3390/app9071363

APA StyleTran, T.-H., Le, X.-H., Nguyen, Q.-T., Le, H.-K., Hoang, T.-D., Luu, A.-T., Banh, T.-L., & Vu, N.-P. (2019). Optimization of Replaced Grinding Wheel Diameter for Minimum Grinding Cost in Internal Grinding. Applied Sciences, 9(7), 1363. https://doi.org/10.3390/app9071363