Research on Control Methods for the Pressure Continuous Regulation Electrohydraulic Proportional Axial Piston Pump of an Aircraft Hydraulic System

Abstract

:Featured Application

Abstract

1. Introduction

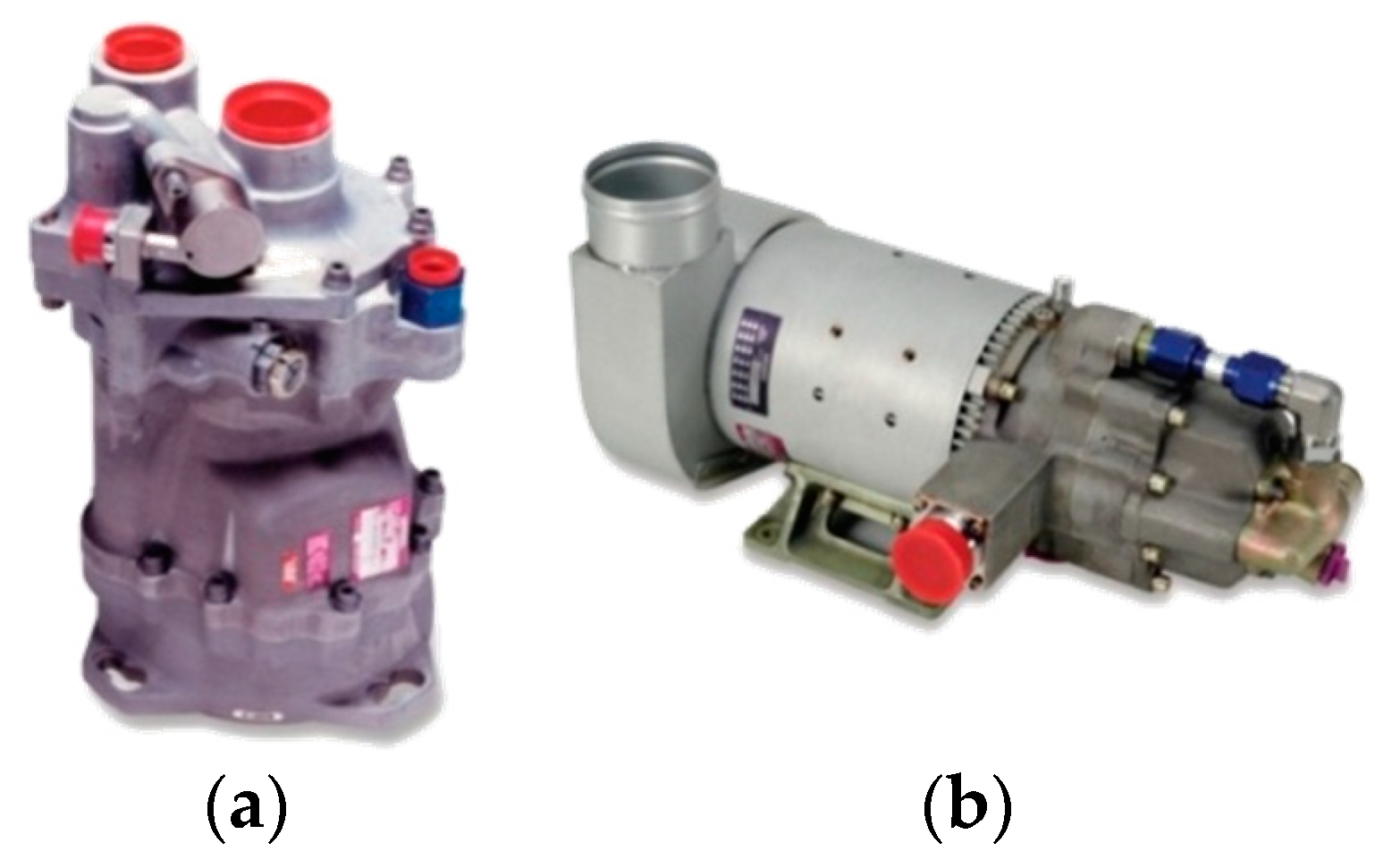

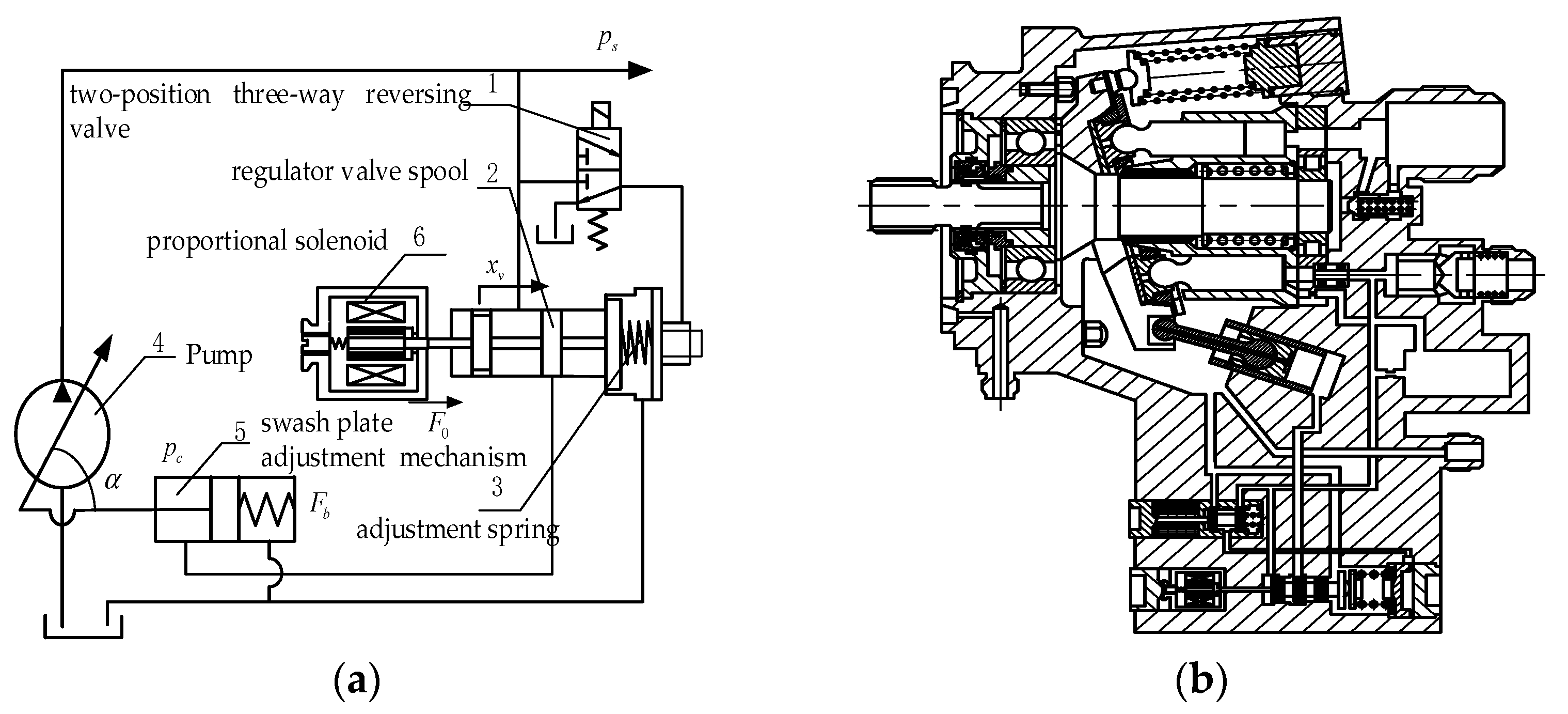

2. Program of Pressure Continuous Regulation for EHPAAPP

3. Characteristic Analysis of EHPAAPP

3.1. Mathematical Model of the Pump

3.1.1. Model of Electro Hydraulic Proportional Regulation

3.1.2. Model of the Pump Section

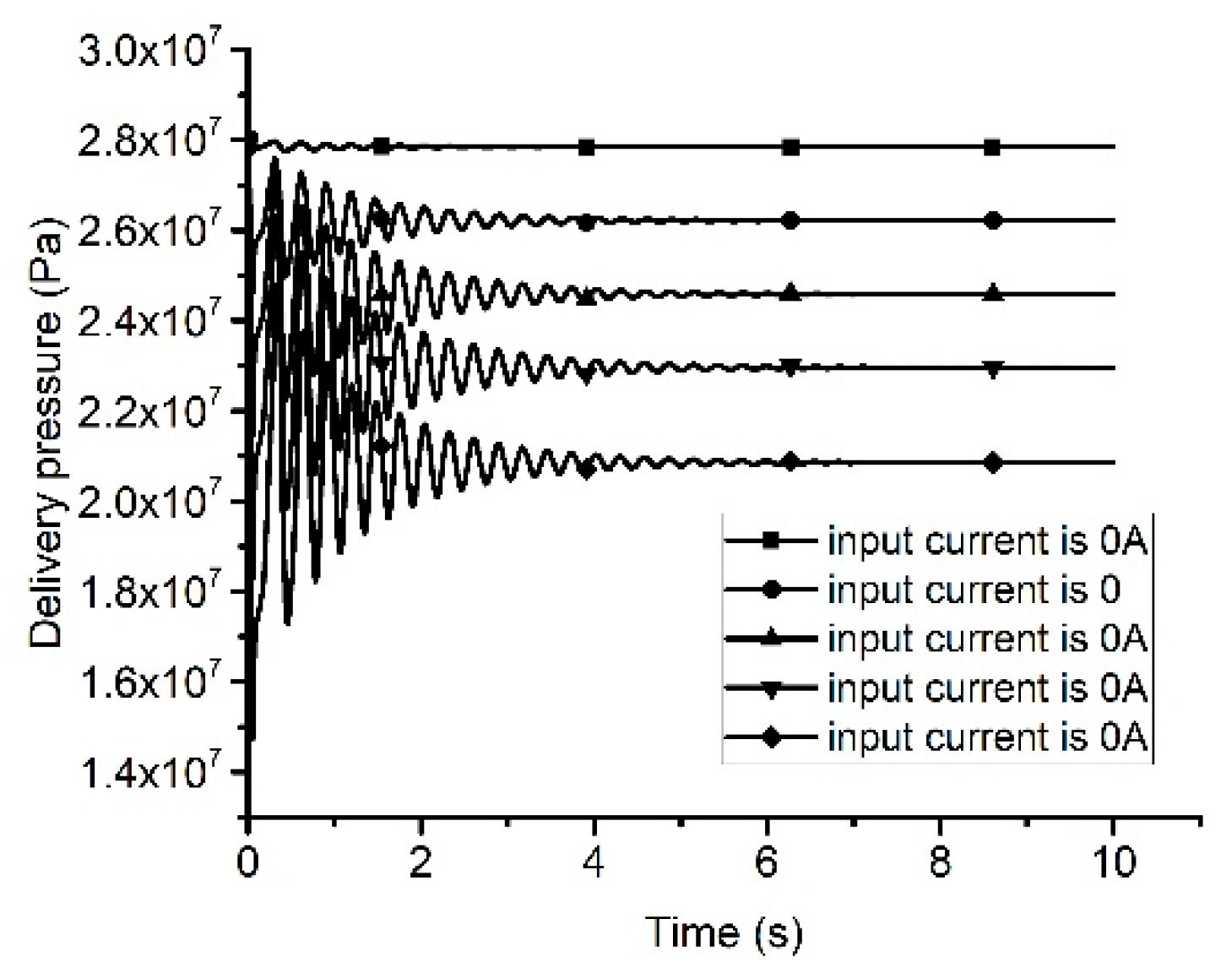

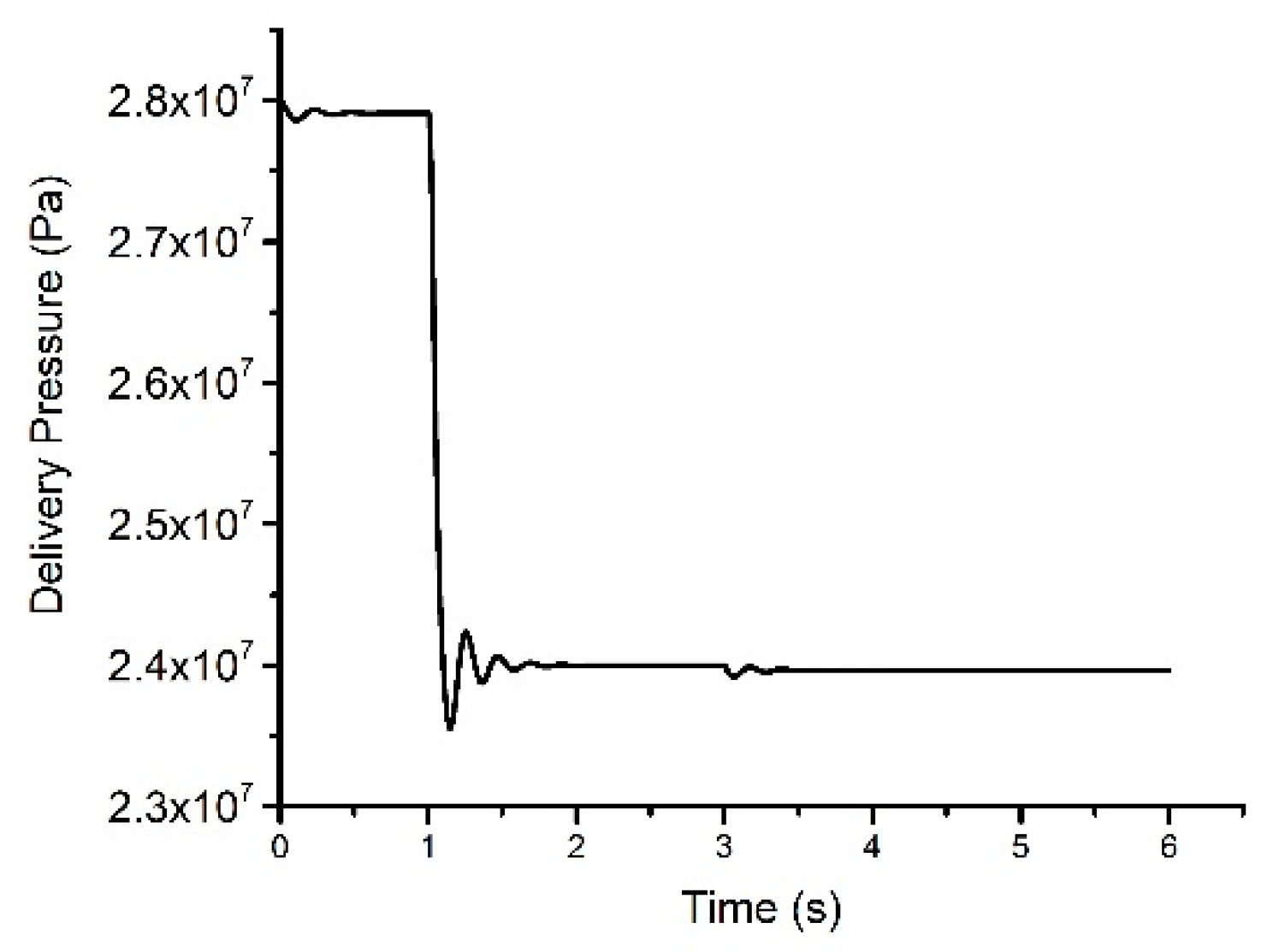

3.2. Response Analysis of the Pump

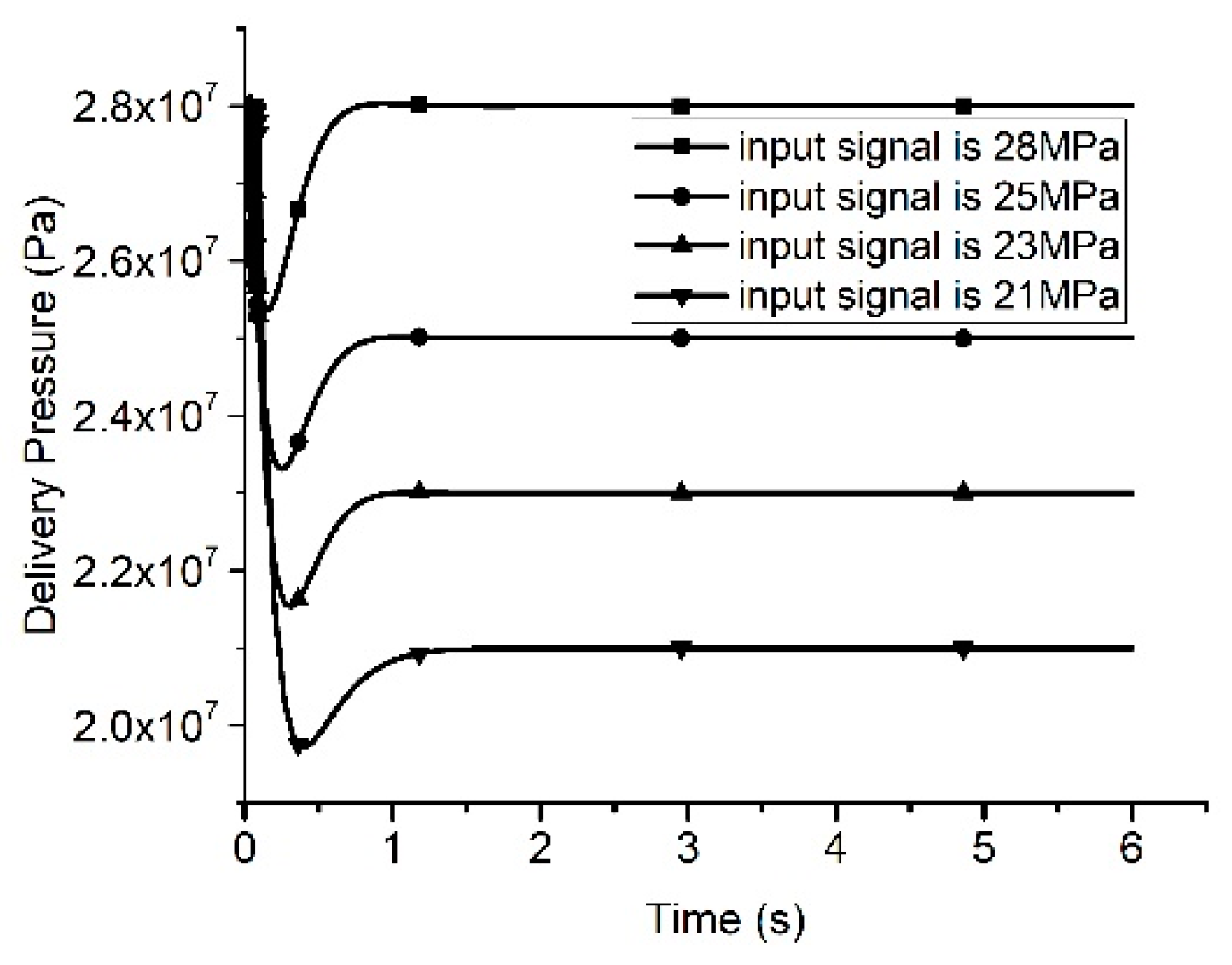

4. Control Method Design of the Pump

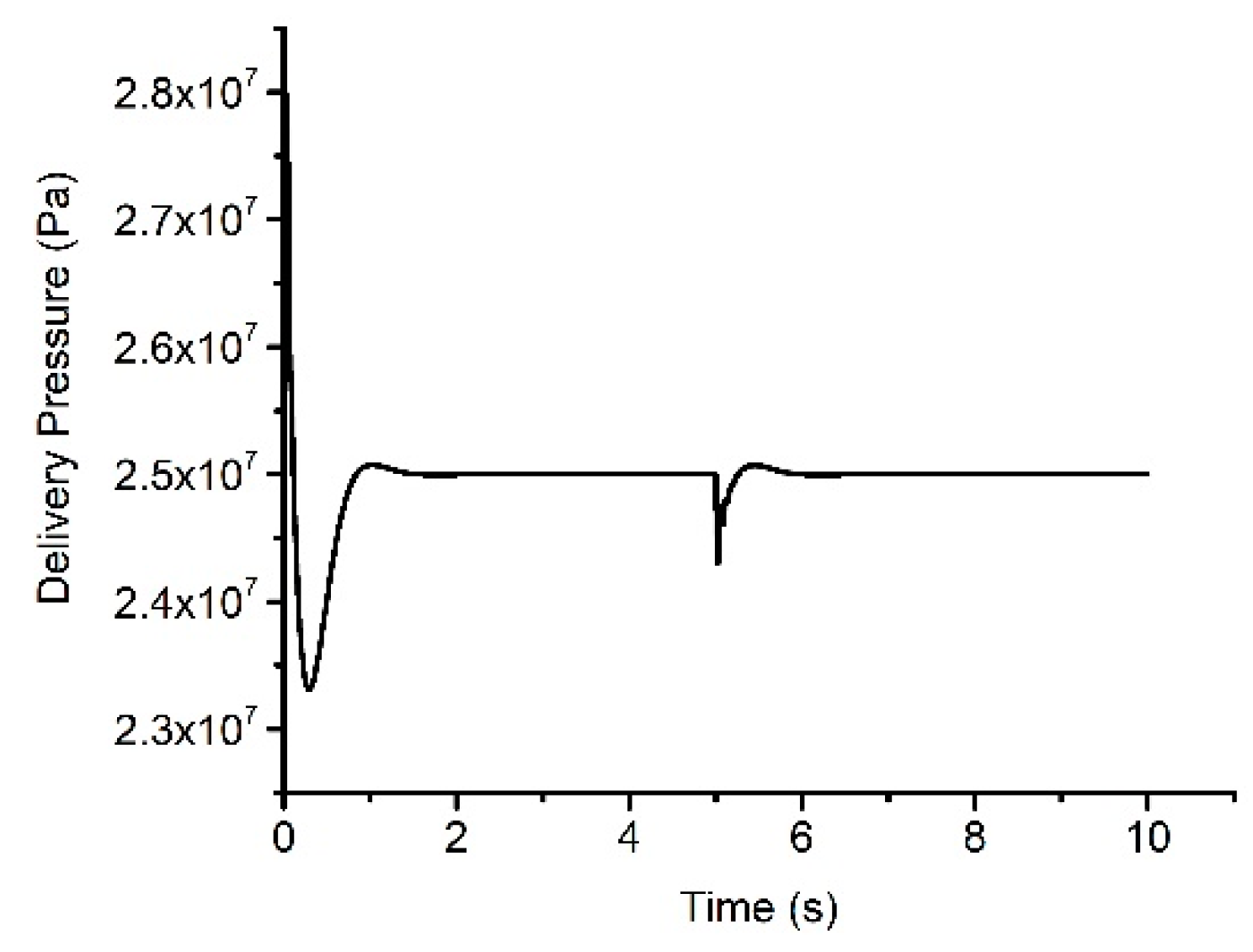

4.1. PID Control Method

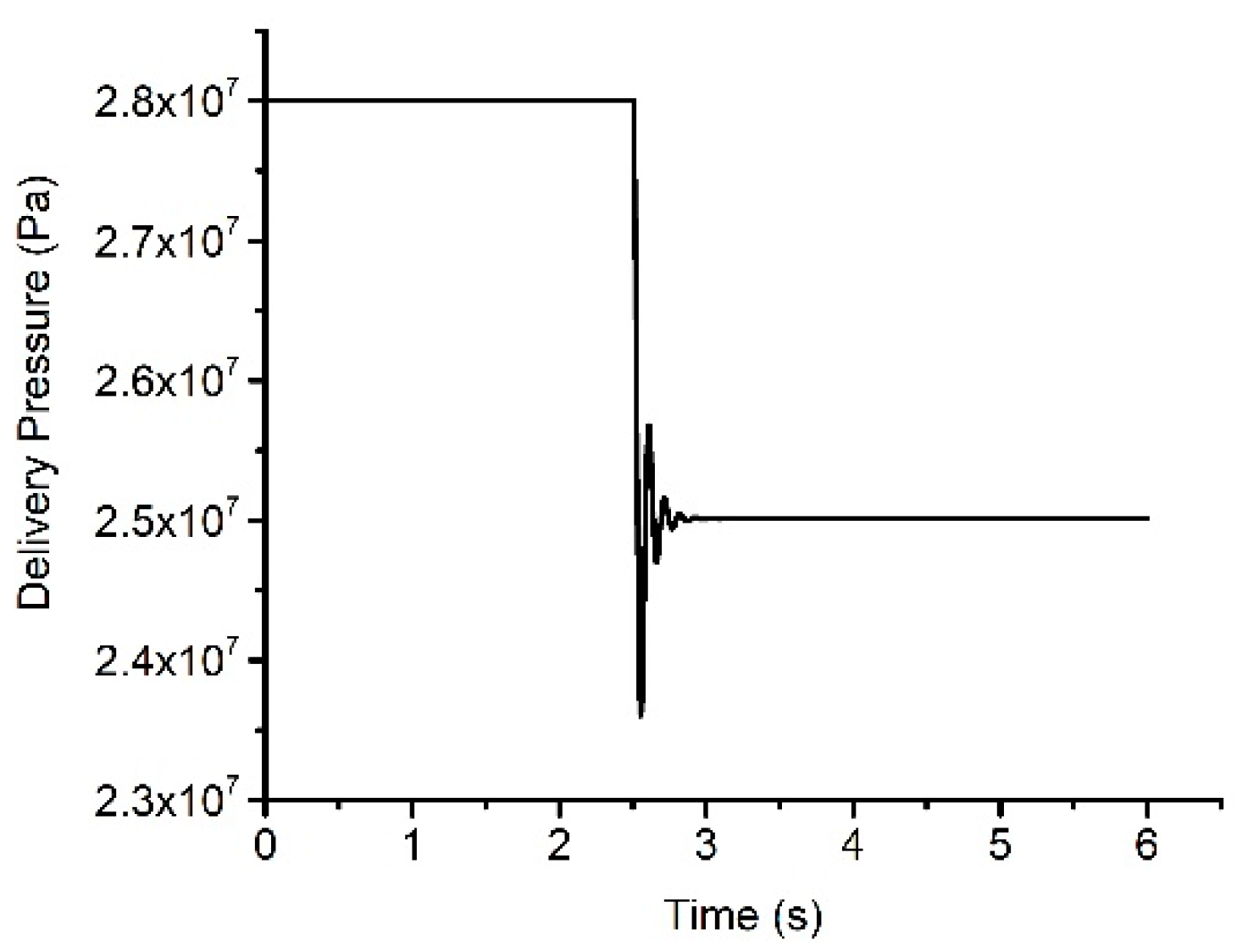

4.2. LQR Control Method

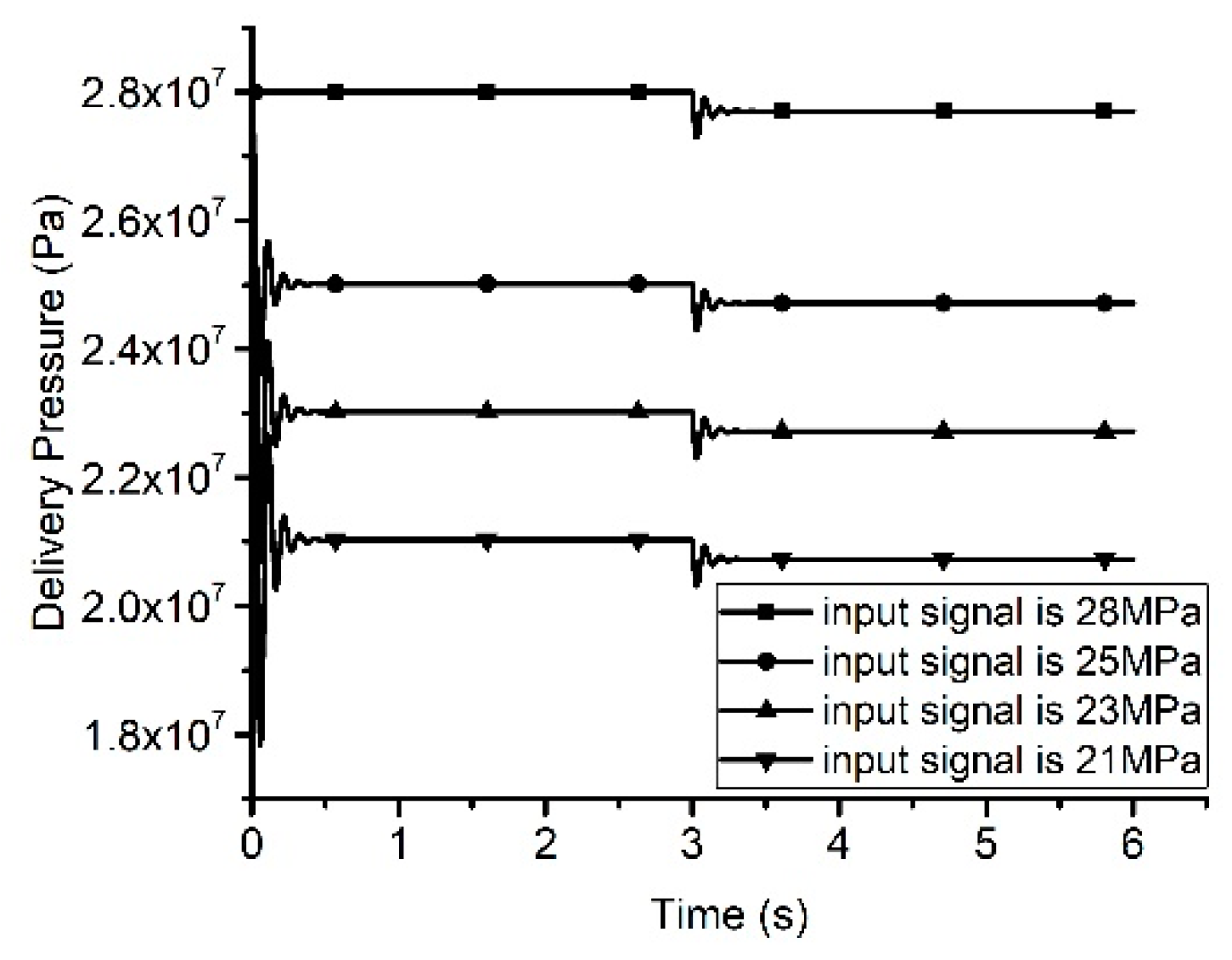

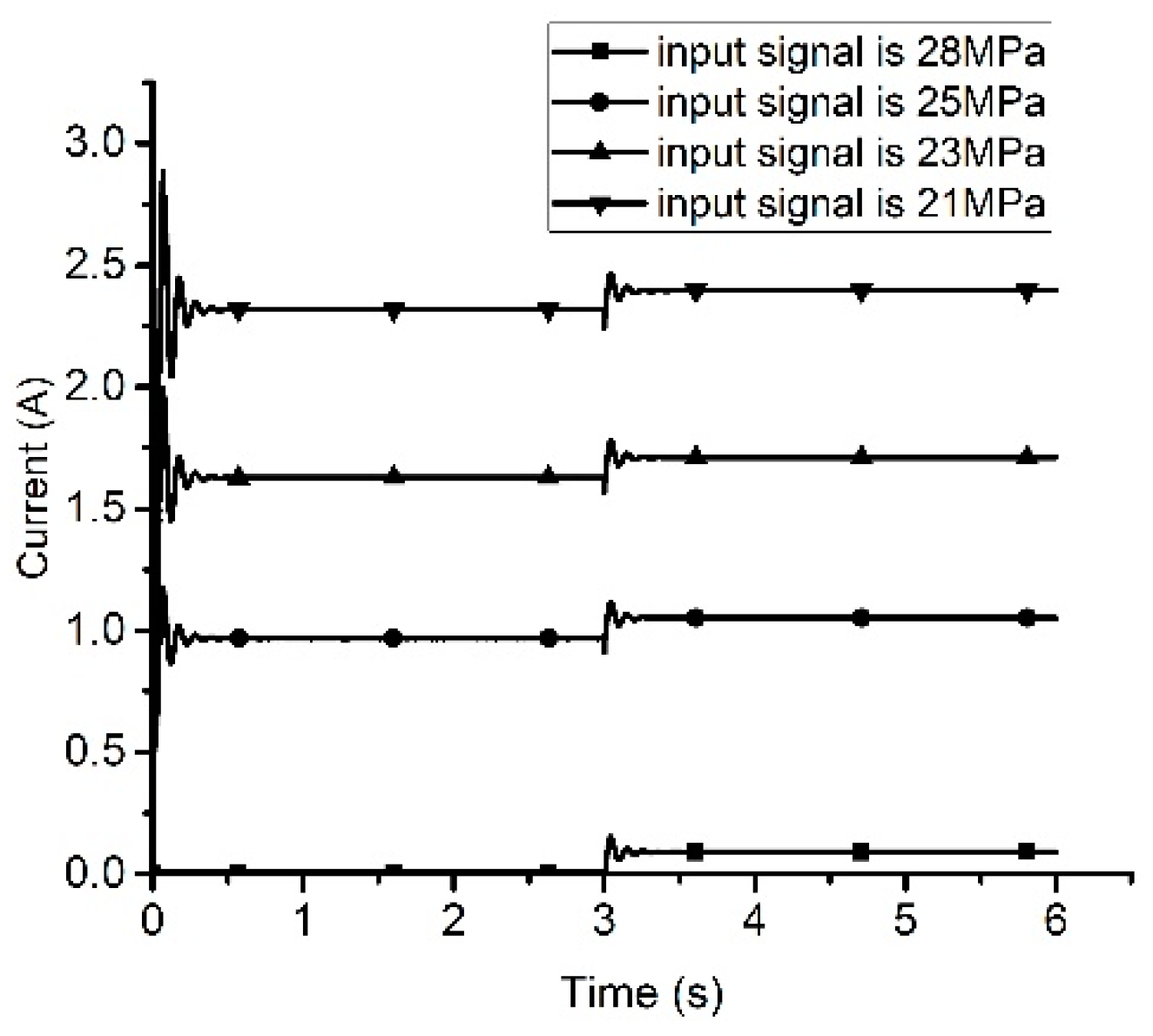

4.3. Backstepping Sliding Control Method

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| cross-sectional area of the control actuator | |

| cross-sectional area of a single piston within the pump | |

| cross-sectional area of the spool valve | |

| effective viscous-drag coefficient for the swash plate | |

| valve discharge-coefficient | |

| compressed force of the bias-spring when the swash-plate angle is zero | |

| force exerted on the swash-plate by the bias actuator | |

| force of electromagnetic hysteresis | |

| reaction force between the nth piston-slipper assembly and the swash plate | |

| axial thrust of the armature | |

| coulomb friction | |

| steady-state fluid force of the valve | |

| pump flow-gain | |

| mass moment-of-inertia for the swash-plate | |

| input current of proportional electromagnet | |

| pump-leakage coefficient | |

| spring rate for the bias-spring | |

| current-force gain | |

| spring rate for the valve-spring | |

| coil induced back EMF coefficient | |

| fixed moment-arm for the bias and control actuators | |

| instantaneous moment-arm for the control actuator | |

| instantaneous moment-arm for the nth piston-slipper assembly | |

| coil inductance | |

| mass of the control actuator | |

| mass of a single piston within the pump | |

| control pressure | |

| pump discharge pressure | |

| pump intake-pressure | |

| instantaneous pressure within the nth piston chamber | |

| volumetric flow-rate into the control actuator | |

| volumetric flow-rate being drawn from the discharge line by the system load | |

| volumetric flow-rate from the pump | |

| piston-pitch radius within the pump | |

| internal resistance of coil and proportional control amplifier | |

| underlapped dimension for the open-centered spool valve | |

| input voltage of the coil | |

| nominal volume of the control actuator | |

| Vh | volume of the discharge line |

| area gradient of valve port | |

| displacement of the spool valve | |

| displacement of the control actuator | |

| limit displacement of the spool | |

| displacement of the nth piston-slipper assembly | |

| delay time | |

| number of pistons within the pump | |

| swash-plate angle | |

| fluid bulk modulus-of-elasticity | |

| valve plate pressure carryover-angle | |

| angular displacement of the nth piston | |

| fluid mass-density | |

| input shaft-speed for the pump | |

| EHPAAPP | electrohydraulic proportional aviation axial piston pump |

References

- Li, Y.J. Aircraft Hydraulic Transmission and Control; Science Press: Beijing, China, 2009; pp. 10–13. [Google Scholar]

- Wang, Z.L. Aircraft High Pressure Energy System; Beihang University Press: Beijing, China, 2004; pp. 11–15. [Google Scholar]

- Spencer, J.E. Development of variable pressure hydraulic systems for military aircraft utilising the smart hydraulic pump. Proc. Inst. Mech. Eng. Part H 1993, 6, 101. [Google Scholar]

- Wang, S.P.; Tomovic, M.; Liu, H. Commercial Aircraft Hydraulic System; Shanghai Jiao Tong University Press: Shanghai, China, 2015; pp. 186–190. [Google Scholar]

- Ouyang, X.-P.; Li, L.; Fang, X.; Yang, H.-Y. Dynamic characteristics of dual-pressure switch for aircraft piston pump. J. Zhejiang Univ. (Eng. Sci.) 2016, 50, 397–404. [Google Scholar]

- Lu, N.; Fu, Y.L.; Sun, X.X. Digital modeling of double press axial piston pump and its thermal analysis basing on AMEsim. J. Beihang Univ. 2006, 32, 1055–1058. [Google Scholar]

- Peter, T. Microprocessor Control of Aerospace Hydraulic Pumps; SAE Tcch. Pap. Ser. 871863; SAE: Warrendale, PA, USA, 1987. [Google Scholar]

- Hupp, R.V.; Haning, R.K. Power efficient hydraulic system. Rockwell International (1988). Vol.1 (Research) ADA203900.

- Hupp, R.V.; Haning, R.K. Power Efficient Hydraulic System. Rockwell International (1988), vol.1 (Experiment) ADA203900.

- Huang, B.; Wang, S.; Meng, Y.; Shi, J. Energy-saving optimization for intelligent pumps based on performance reliability restriction. J. Beihang Univ. 2013, 4, 559–563. [Google Scholar]

- Lu, L.; Tang, Z.; Li, H.; Pei, Z. Fuzzy PID control of intelligent pump. In Proceedings of the 2011 International Conference on IEEE Fluid Power and Mechatronics (FPM), Beijing, China, 17–20 August 2011; pp. 803–808. [Google Scholar]

- Song, X.D.; Yao, X.X.; Gong, Z.B. Model reference adaptive control for variable pressure pumping source. J. Beijing Inst. Technol. 2011, 31, 944–948. [Google Scholar]

- Li, H.; Tang, Z.Y.; Pei, Z.C.; Peng, J. PID control of airbone intelligent pump system. Mach. Tool Hydraul. 2010, 38, 97–98. [Google Scholar]

- Fiebing, C.; Xiujuan, L.; Smolka, S. Pressure compensator (PC) pressure overshoot analysis and experimental research of an open circuit pump. In Proceedings of the IEEE 2015 International Conference on Fluid Power and Mechatronics (FPM), Harbin, China, 5–7 August 2015; pp. 910–913. [Google Scholar]

- Achten, P. Dynamic high-frequency behaviour of the swash plate in a variable displacement axial piston pump. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2013, 227, 529–540. [Google Scholar] [CrossRef]

- Manring, N.D.; Mehta, V.S. Physical limitations for the bandwidth frequency of a pressure controlled, axial-piston pump. J. Dyn. Syst. Meas. Control 2011, 133, 061005. [Google Scholar] [CrossRef]

- Mandal, N.P.; Saha, R.; Mookherjee, S.; Sanyal, D. Pressure compensator design for a swash plate axial piston pump. J. Dyn. Syst. Meas. Control 2014, 136, 021001. [Google Scholar] [CrossRef]

- Kemmetmüller, W.; Fuchshumer, F.; Kugi, A. Nonlinear pressure control of self-supplied variable displacement axial piston pumps. Control Eng. Pract. 2009, 18, 84–93. [Google Scholar] [CrossRef]

- Wang, S. Generic Modeling and Control of an Open-Circuit Piston Pump—Part I: Theoretical Model and Analysis. J. Dyn. Syst. Meas. Control 2016, 138, 041004. [Google Scholar] [CrossRef]

- Wang, S. Generic Modeling and Control of an Open-Circuit Piston Pump—Part II: Control Strategies and Designs. J. Dyn. Syst. Meas. Control 2016, 138, 041005. [Google Scholar] [CrossRef]

- Koivumäki, J.; Mattila, J. Adaptive and nonlinear control of discharge pressure for variable displacement axial piston pumps. J. Dyn. Syst. Meas. Control 2017, 139, 101008. [Google Scholar] [CrossRef]

- Wei, J.; Guo, K.; Fang, J.; Tian, Q. Nonlinear supply pressure control for a variable displacement axial piston pump. Proc. Inst. Mech. Eng. Part I: J. Syst. Control Eng. 2015, 229, 614–624. [Google Scholar] [CrossRef]

- Castañeda, L.A.; Luviano-Juárez, A.; Chairez, I. Robust trajectory tracking of a delta robot through adaptive active disturbance rejection control. IEEE Trans. Control Syst. Technol. 2015, 23, 1387–1398. [Google Scholar] [CrossRef]

- Chen, C. Backstepping control design and its applications to vehicle lateral control in automated highway systems. Ph.D. Thesis, University of California, Berkeley, CA, USA, 1996. [Google Scholar]

| Symbol | Value | Unit |

|---|---|---|

| 4.55 × 10−2 | ||

| 1000 | ||

| 3.5 × 10−3 | ||

| 9 | Null | |

| 265 × 10−6 | ||

| 150 × 10−6 | ||

| 12.5 × 10−6 | ||

| 60 | ||

| 1.15 × 10−2 | ||

| 2.85 × 10−1 | ||

| 2.14 × 10−11 | ||

| 20 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Li, Y. Research on Control Methods for the Pressure Continuous Regulation Electrohydraulic Proportional Axial Piston Pump of an Aircraft Hydraulic System. Appl. Sci. 2019, 9, 1376. https://doi.org/10.3390/app9071376

Zhang P, Li Y. Research on Control Methods for the Pressure Continuous Regulation Electrohydraulic Proportional Axial Piston Pump of an Aircraft Hydraulic System. Applied Sciences. 2019; 9(7):1376. https://doi.org/10.3390/app9071376

Chicago/Turabian StyleZhang, Peng, and Yunhua Li. 2019. "Research on Control Methods for the Pressure Continuous Regulation Electrohydraulic Proportional Axial Piston Pump of an Aircraft Hydraulic System" Applied Sciences 9, no. 7: 1376. https://doi.org/10.3390/app9071376

APA StyleZhang, P., & Li, Y. (2019). Research on Control Methods for the Pressure Continuous Regulation Electrohydraulic Proportional Axial Piston Pump of an Aircraft Hydraulic System. Applied Sciences, 9(7), 1376. https://doi.org/10.3390/app9071376