2.2.4. Torque-Coupled–Type Transmission

The aforementioned discussion examined the constraint of the TC-PIM. In this study, we select the spur gear for the TC-PIM. The flowing section discusses the design torque-coupled–type transmission based on speed-torque. The TC-PIM in this study uses the spur gear train to design and analyze the parallel hybrid transmission system. Spur gears are widely used in power transmission mechanisms. It is a simple mechanism that is used to transfer mechanical power. In spur gear-type transmission, a gear set comprises drive and driven gears. These gears have different dimensions and, thus, it can adjust torque and rotation speed. The relationship between the torque value and rotation speed value for drive and driven gears can be expressed using Equations (15) and (16). The term also represents the gear ratio.

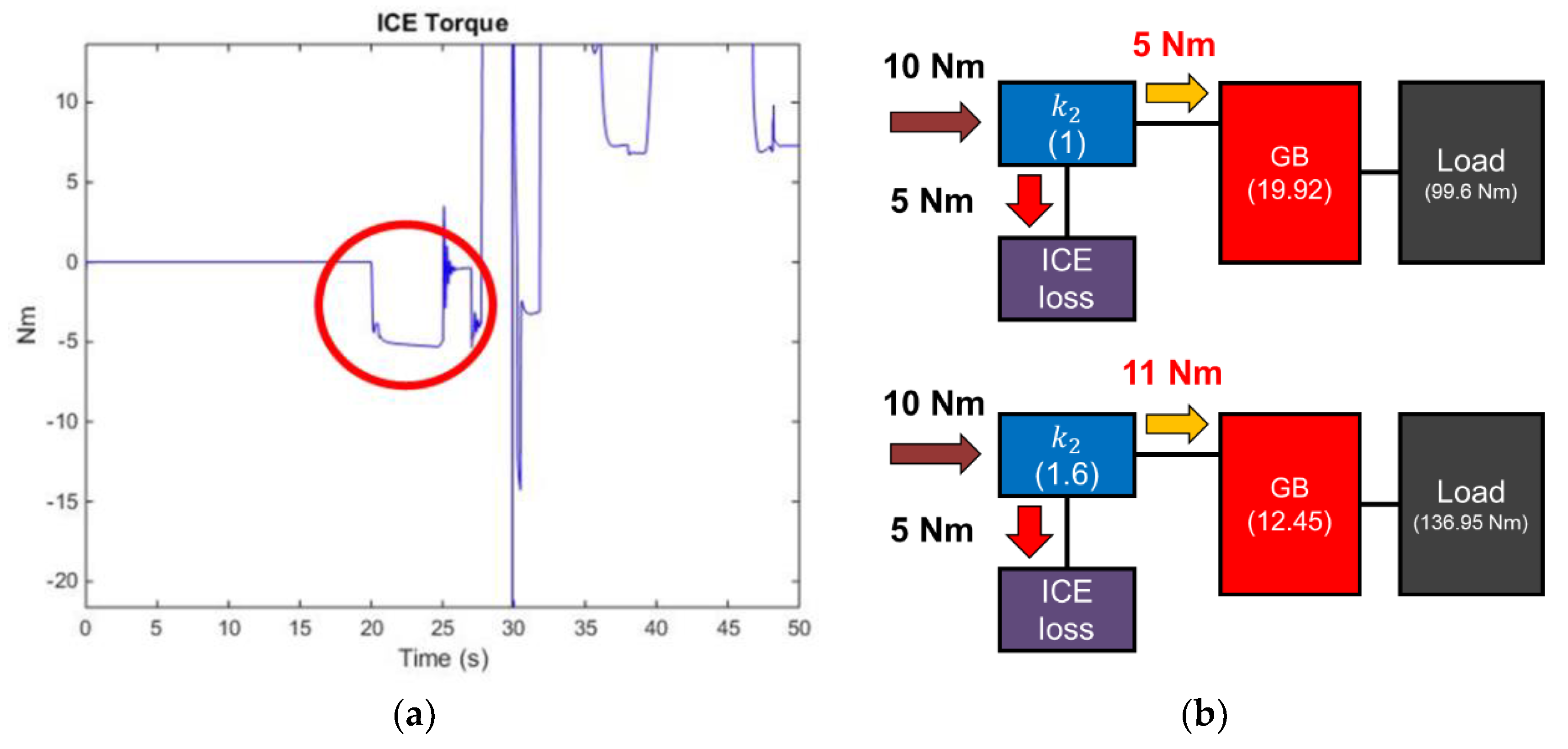

Figure 4a shows the basic driveline architecture for TC-PIM. In this architecture, the engine and motor are always connected with the TC-PIM, which indicates that each power unit cannot only provide power for the traction vehicle. To ensure that all of the driving modes can work, clutches or brakes must be installed in the driveline architecture. For the ICE mode and the smooth integration of mechanical power in the hybrid mode, a clutch must be installed between the EM and TC-PIM. To reduce the engine pumping loss, the clutch that is installed between the engine and TC-PIM is necessary.

Figure 4b shows the suitable clutches that were added in the driveline architecture for the TC-type parallel hybrid powertrain. A brake should not be installed in driveline, as the TC-PIM is one-degree-of-freedom mechanism. When the brake is installed in the driveline, it locks up all shafts; thus, the transfer of mechanical power to the TW becomes difficult.

In the parallel hybrid mode, the gearbox can be installed at three positions. To determine the position for the installation of the gearbox, the relationship between the speed-torque characteristic of power units and the constraints of the TC-PIM must be determined [

18]. The TC-PIM would restrict the angular speed when power is integrated. The speed relationship with power units and the TC-PIM can be expressed using Equation (17), as follows:

If , the gearbox or single gear must be installed between the engine and TC-PIM to ensure that the engine delivers complete power (GB1). If , the gearbox or single gear can be installed between the EM and TC-PIM to ensure that the EM delivers complete power (GB2). If , only the gearbox must be installed behind the TC-PIM and, thus, it can simplify system complexity (GB3). Therefore, the proper placement of gearbox for this primary simulation is behind TC-PIM.

Hybrid vehicles have three driving modes, namely EV mode, ICE mode, and hybrid power mode. To satisfy all of the driving modes for satisfactory performance, the gear ratio design must consider the requirements of each driving mode. Equation (17) can be used to calculate

, which influences the gearbox location. Therefore, the first step in designing the gear ratio is to determine the

and

of the TC-PIM. To ensure that all of the power units can provide power within an adequate speed range. The relationship between

and

, and power units with a capable speed can be obtained using the following Equation (18):

and

are compared to determine which term has a smaller value. The smaller term is determined for

and, thus, the theoretical value of

for another term can be obtained. For example,

and

are obtained for the maximum engine speed and maximum EM speed from

Table 1 and then substituted into Equation (18):

Thus, the maximum output power of the TC-PIM can be obtained for the hybrid driving mode, and all of the power units are operated in the capable speed range. This method is called the basic speed limit method.

In Equation (20), the

values can be proportionally changed for specific design requirements. If the

is used with a wrong design, the total integral power decreases. Moreover, the ideal maximum

can be expressed as Equation (21).

Equations (17)–(21) show that the appropriate

value is between 1 and 1.4912 for the complete power usage of power units. On the basis of the engine map and the motor map,

Figure 5a–d show the possible power regions for different

, that is,

to

conditions for the TC-type parallel hybrid propulsion system. The ideal maximum total power of 51 kW is summed by ICE peak power of 41 kW and electric motor of 10 kW, as in

Table 1. For

, the maximum total power (50.4712 kW) is less than the ideal value (51 kW), because the engine cannot provide maximum power in the hybrid mode. Due to the TC-PIM being constrained by the speed relationship, the maximum speed of the motor for TC-PIM is less than 5700 rpm at

.

The first step is to determine the gear ratio in the EV mode. The second step is to determine the overall gear ratio. The overall gear ratio must be determined stepwise for all driving modes due to the different parallel hybrid driving modes. The largest gear ratio in the EV mode can be expressed using Equation (22).

Substituted parameters in

Table 1 and

Table 2 into Equation (22) can determine

:

The number of gears for EV mode transmission can be designed using a single gear because the EM has constant power characteristics.

The third step is to determine the overall gear ratio in the ICE mode and hybrid mode. As the engine provides the primary power to the propulsion system, and the EM just provides start-stop and power assistance; the gear ratio is mainly designed for the engine with one extra gear for hybrid power. Thus, the overall gear ratio in the ICE mode and hybrid mode can be obtained. The largest gear ratio in the ICE and hybrid mode can be expressed using Equation (24).

can be determined by substituting parameters in

Table 1 and

Table 2 into Equation (24):

The forth step is to determine the smallest gear ratio in the ICE mode and the hybrid mode. In this study, a

optima design is used to determine the smallest gear base on the ICE design and to add one more gear for excess hybrid power, which can be expressed using Equation (26).

can be determined by substituting parameters in

Table 1 and

Table 2 into Equation (26):

The fifth step is to determine the intermediate gear ratio by using the progressive gear steps method at

.

Table 3 shows all of the gear ratios.

Figure 6 shows a traction force diagram with the designed gear ratio. The red lines indicate the total resistance under different slope and speed conditions, from bottom to top: 0% slope, 3% slope, 5% slope, 10% slope, 15% slope, 20% slope, and 25% slope. A blue line represents the motor traction force in the EV mode, and it can overcome the resistance of 25% slope at 10 km/h. Black lines represent the engine traction force with different gear ratios, from the top to bottom: first gear to fourth gear and top speed gear. With these designed gear ratios, the vehicle can reach a speed of approximately 160 and 170 km/h by using the engine and the hybrid mode, respectively.