1. Introduction

Robots play an important role in the industrial production and human life and most of them require corresponding efficient end effectors to interact with the environments. Robot hands can mimic the basic functions of human hands and are a kind of popular end effector in the industrial sector, they are widely used in aerospace [

1,

2], agriculture [

3], medical devices [

4,

5], and industrial sectors [

6]. In the past 30 years, researchers have paid great attention to the development of robot hands [

7] and made many outstanding achievements.

According to the relationship of degree of freedom (DOF) and degree of the actuator (DOA), the robot hands can be divided into three categories, which include the redundant hand, full-actuated hand, and underactuated hand. As for the redundant hand and full-actuated hand, each joint DOF is driven by at least one actuator, and the gesture and movement of the finger joints can be controlled in a precise way. The redundant and full-actuated design methodology are widely used in the field of dexterous hands and many outstanding dexterous hands have been developed and studied, such as Utah/MIT hand [

8], NTU hand [

9], BCL-13 hand [

10], and TUAT/Karlsruhe hand [

11]. These dexterous hands can perform complex gestures and accomplish complex grasping tasks. However, they require as many actuators as the number of their DOF and often have complex or bulky control and sensing system to manage the whole device, as a result, the redundant and full-actuated hands are often expensive and difficult to build [

12]. These disadvantages restrict the application possibilities of these hands.

To maintain good performance and a relatively simple control, researchers propose the concept of the underactuated hand. By optimizing the structure design, the hands can perform the same functions with fewer actuators. The underactuated hand often means the DOA is smaller than the DOF, therefore it can simplify the control system of the robot hand due to the small number of actuators [

13]. In the past decades, researchers have made many achievements in the study of the underactuated hand. The examples of the underactuated hands are SDM hand [

14], PASA-GB hand [

15], and SARAH hand [

16]. These underactuated hands take advantages of springs or coupled linkages to achieve the underactuated grasping function.

Besides, many researchers have proposed some method to optimize the design of the underactuated hand system, Qiao et al. designed an underactuated hand based on a maximum grasping space [

17], Raymond et al. proposed the modular design solution for the underactuated hand [

18], and Irfan et al. proposed a method for optimizing the fingertip trajectories of the underactuated hand [

19]. Their studies help improve the performance in different aspects, but there is still no solution to optimize the pinching grasping mode and achieve the underactuated linear-parallel pinching function. The traditional underactuated hands make a combination between the multifunction and simple control system, and some of them can even perform parallel pinching and self-adaptive grasping modes to enlarge the usage. They can meet most application requirements, however, the end of robot hand executes a circle trace under the parallel grasping mode, which has a relatively small workspace and is not suitable for grasping thin objects on tables without manipulation of other devices. To overcome this bottleneck of the traditional underactuated hands, the linear-parallel pinching grasping mode was proposed in previous research [

20].

This paper proposes a novel straight-line mechanism, based on the mechanism a robot finger with a variable geometrical structure (called VGS finger) was designed and analyzed. The robot finger has hybrid grasping modes by using the variable geometrical structure, it can perform both the linear-parallel pinching and self-adaptive grasping mode. The VGS hand consists of two fingers and a palm, and can meet most application requirements. The hands can grasp objects with different potions, shapes, and sizes without the additional sensing system. The working principle, hybrid grasping modes, kinematics, contact force, and dynamic model of the hand are analyzed. Besides, the prototype of the VGS hand was manufactured and grasping experiments were conducted to verify the design and analysis. The VGS hand has many potential applications in the industrial sector.

The paper is organized as follows: The second part introduces the linear-parallel pinching and self-adaptive hybrid grasping modes; the third part gives the architecture, kinematics, and dynamics analysis of the VGS finger mechanism; the next part focuses on the contact force analysis; the fifth part shows the prototype, experiment platform, and corresponding grasping experiments of the hand.

2. Grasping Modes and Working Principle of the VGS Robot Finger

The proposed hand has multiple grasping modes, the detail grasping process of different grasping modes are shown in

Figure 1. Under the linear-parallel pinching grasping mode, the distal phalanx moves along a straight line and there is no displacement in the vertical direction. When the first phalanx touches objects firstly, the finger will work in the self-adaptive grasping mode that is after the first phalanx reaches the objects, the distal phalanx will continue to rotate until both phalanxes touch objects.

The shift between the different grasping modes is achieved by using the variable geometrical structure mechanism, and the detail working principle of the finger mechanism is shown in

Figure 2.

As shown in

Figure 2, under the linear-parallel pinching mode, point

E and

G are at the same position and the second phalanx will move along a straight line. Under the self-adaptive grasping mode, when the first phalanx cannot rotate anymore, the elastic component becomes longer, and then point

E and

G will be apart from each other. The geometrical structure of the VGS finger will change and the distal phalanx begins to rotate until it reaches objects. How the elastic component changes its length during the two different grasping modes is shown in

Figure 3.

Figure 3 shows how the elastic component changes its length from the linear-parallel pinching mode to the self-adaptive grasping mode. Actually, the shift between the two different grasping modes is executed automatically. During a grasping process, when the two phalanxes do not reach objects, the finger will work in the linear-parallel pinching mode; if the first phalanx reaches objects firstly, the finger will work under the self-adaptive grasping mode; on the other hand, if the distal phalanx touches objects firstly, the finger will work under the linear-parallel mode. The automatic shift between different grasping modes makes the VGS finger achieve a mechanism intelligence and can help reduce the complexity of the control system.

4. Contact Force Analysis

Another aspect to provide help for design and optimization work is the contact force analysis, which can determine the suitable application range of the hand device and can reveal the relationship between different parameters. The model of contact forces during the hybrid grasping modes was established in this part. The contact force diagram for the robot finger is shown in

Figure 8.

As

Figure 8 shows,

β1 and

β2 are the rotary angles of the first phalanx and the distal phalanx.

T is the torques produced by the driving gear,

F1 and

F2 are the contact force vectors by the objects,

FS is the forces produced by the elastic component when deformation occurs.

G1 and

G2 are the contact points.

h1 and

h2 are the distances between the contact points and the rotary axis. The vectors of the contact points

G1 and

G2 can be described as:

In order to simplify the mathematic model of the finger, the length of the linkage

CD and

DE are set as,

To achieve a straight-line output, points C, F, I, and G form a straight-line mechanism, besides, both the quadrilateral formed by points A, F, C, H and the quadrilateral surrounded by points A, F, G, B are parallelograms. Meanwhile, points E and G are at the same place because of the elastic component. According to the geometrical and length relationships of the linkages, it can be concluded that linkage AB is parallel with linkage FG, thus

β1 and

θ2 form a complementary angle. The relationship among

β1,

θ1, and

θ2 can be concluded:

According to the relationships shown in Equations (18) and (19) and the Law of Cosines, the relationship among

β2 and

θ0,

θ1 can be concluded,

In Equation (18), .

According to Lagrange’s equation and virtual work theory, one obtains,

According to the equations above, when the robot finger work under the linear-parallel pinching mode, the relationship among different parameters can be obtained. As shown in

Figure 9.

Similarly, one obtains the relationship among elastic force, driving torque and contact forces under the self-adaptive grasping mode, and the corresponding Jacobi matrixes can be calculated according to the equations above.

According to

Figure 9, one can conclude that when

l1 increases,

F2 decreases, when

h2 increases,

F2 decreases, when the output torque of the motor is constant. The contact force distribution is reasonable and by optimizing the design parameters the distribution of the force can meet different requirements.

5. Prototype and Grasping Experiments

In order to verify the design, analysis, and the basic function of the robot hand, a prototype of the VGS hand was manufactured, as shown in

Figure 10.

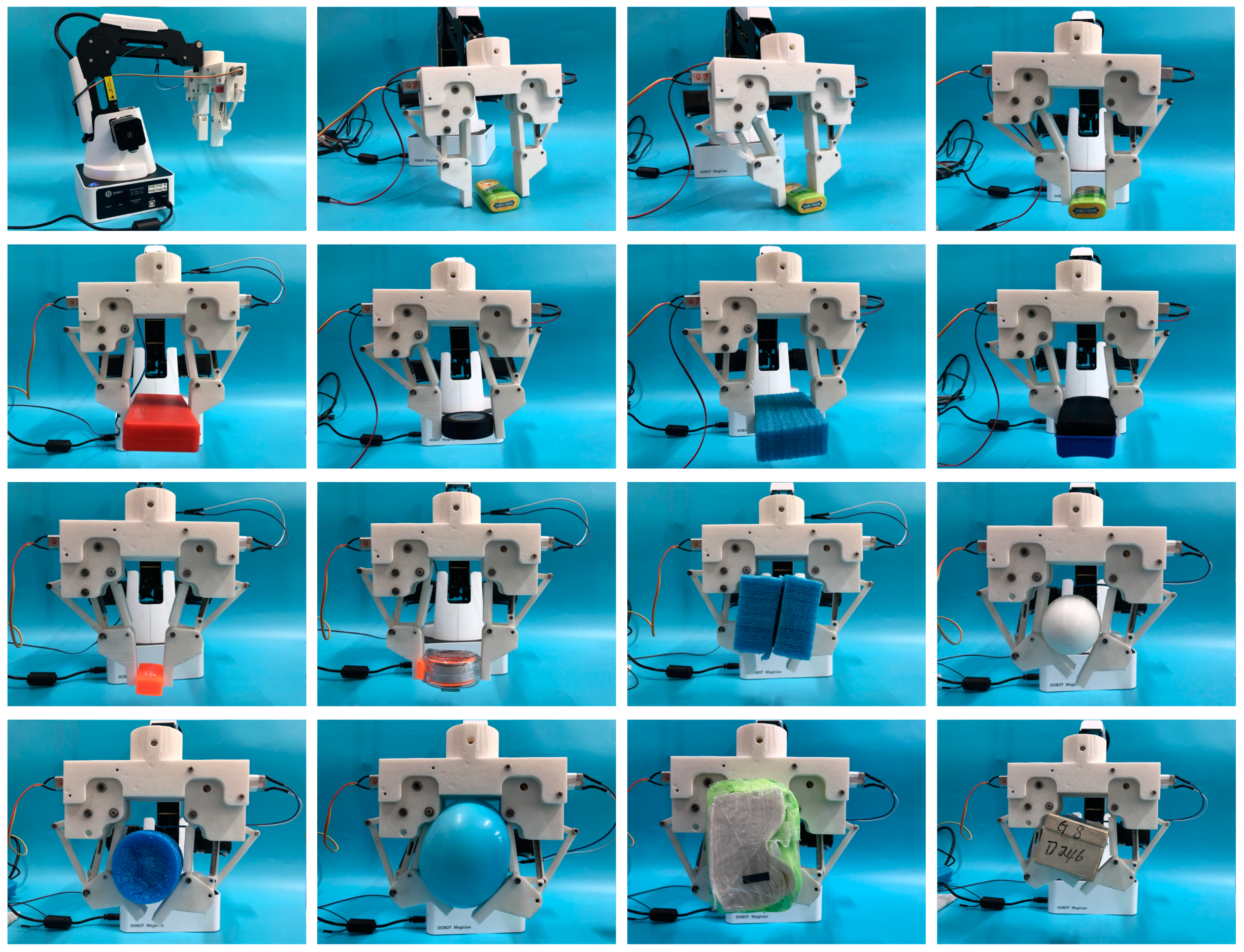

The prototype was controlled by Arduino and it was fixed on a robot arm to conduct the grasping experiments. The basic material used for the manufacture is the polylactic acid (PLA), which is small in density and has relatively good force properties. Both quantitative and qualitative experiments were conducted.

In practical experiments, both rigid and soft objects are used for grasping. In order to test the linear-parallel pinching function, no additional displacement from the robot arm was provided for the pinching process. In addition, for some pinching experiments, the two fingers have different rotational angles around the shaft, which can also help prove that the end of the finger moves along a straight line. The details of the experiments are shown in

Figure 11.

As shown in

Figure 11, the hand can perform hybrid grasping modes for different situations. It can grasp objects with different shapes and sizes and has a very good grasping ability to meet the requirements for industrial use, such as assembly or painting. Meanwhile, during the pinching process, the distal phalanx moves along a straight line as expected, which is suitable for grasping thin objects on a flat surface and overcomes the bottleneck of traditional hands. The prototype verifies the design and analysis to be reasonable. Some basic data and test results for the prototype are listed in

Table 1.

6. Conclusions

This paper proposes a novel linear-parallel and self-adaptive hybrid grasping modes robot hand with a variable geometrical structure. Structure design, kinematics, dynamics are discussed and a prototype was manufactured to conduct grasping experiments. Kinematics analysis verifies the design of the straight-line mechanism and provides a universal guide for different application situations; the dynamics analysis reveal the forces, torques, and acceleration in all the linkages, which can provide some scientific reference for the design and manufacture process. Grasping experiments of the VGS hand were conducted to verify the analysis and the hybrid grasping modes of the hand, the experiments results indicate that the hand can perform hybrid-grasping modes by using the variable geometrical structure mechanism. In the pinching mode, the end of the finger moves along a straight line, which is suitable for grasping thin objects on a platform. In addition, the hand can adapt objects with different sizes, positions, and shapes. The hand has many potential applications.