Beam Control in an Intracavity Frequency-Doubling Semiconductor Disk Laser

Abstract

:1. Introduction

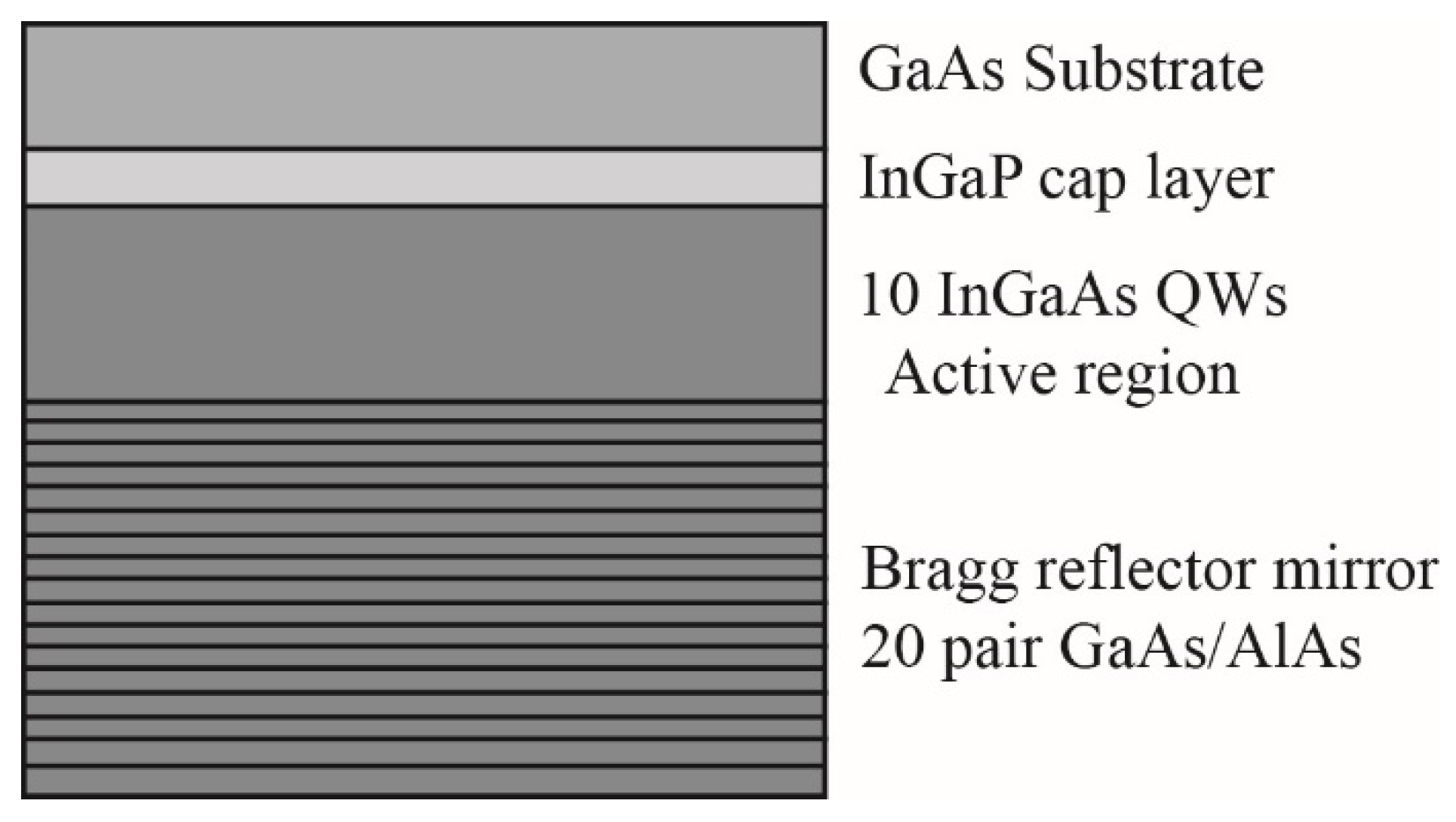

2. Semiconductor Disk Laser (SDL) Design and Bonding Process

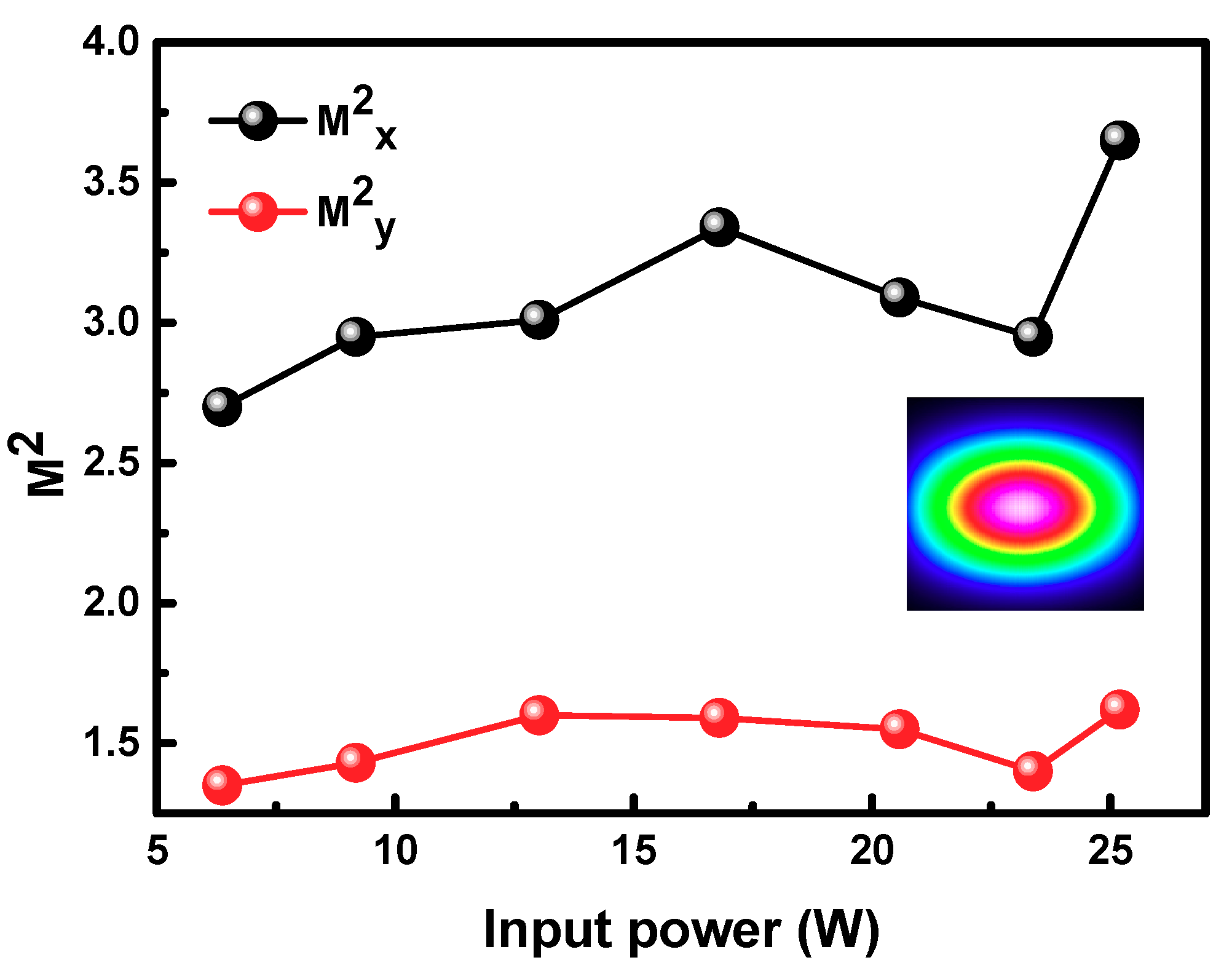

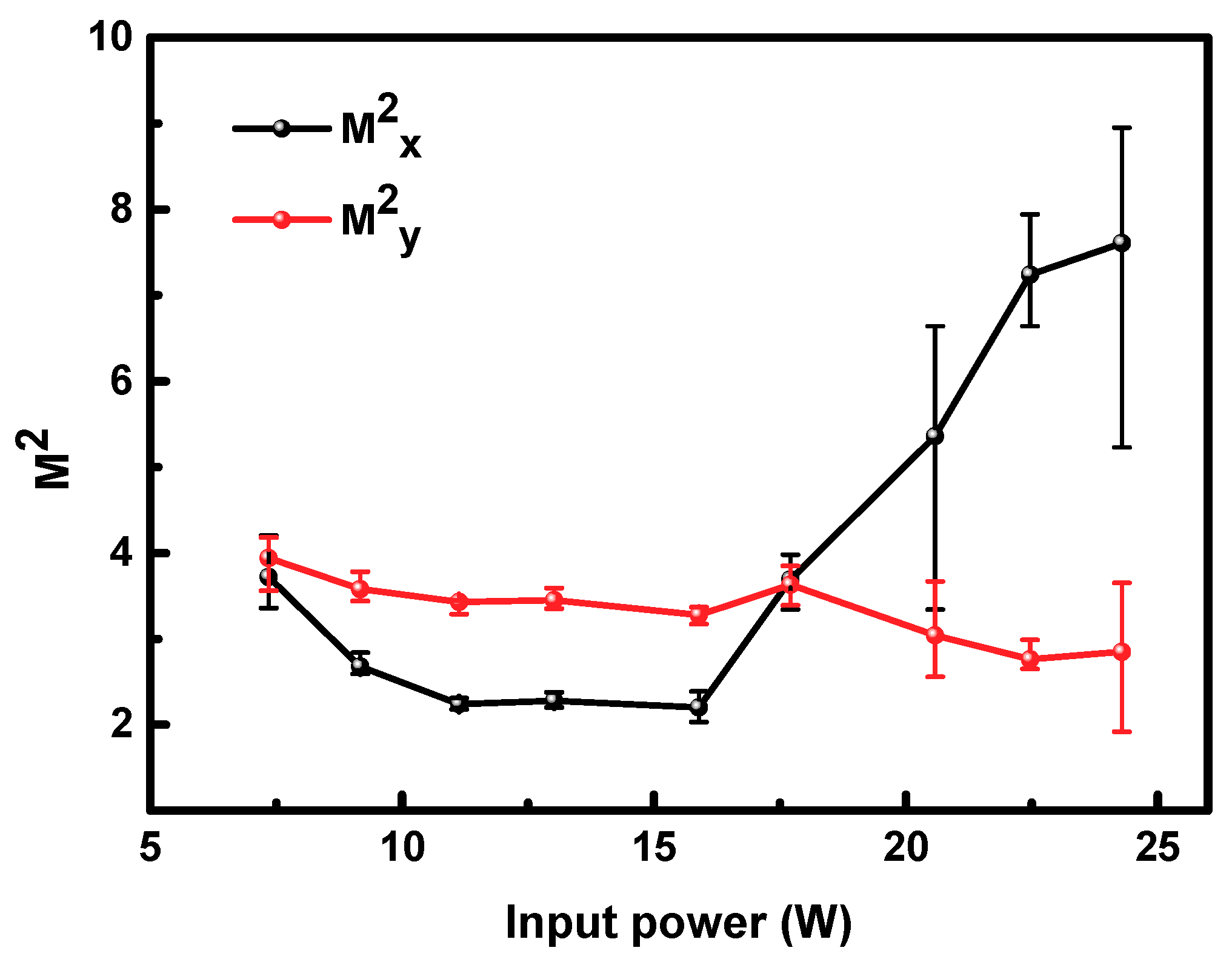

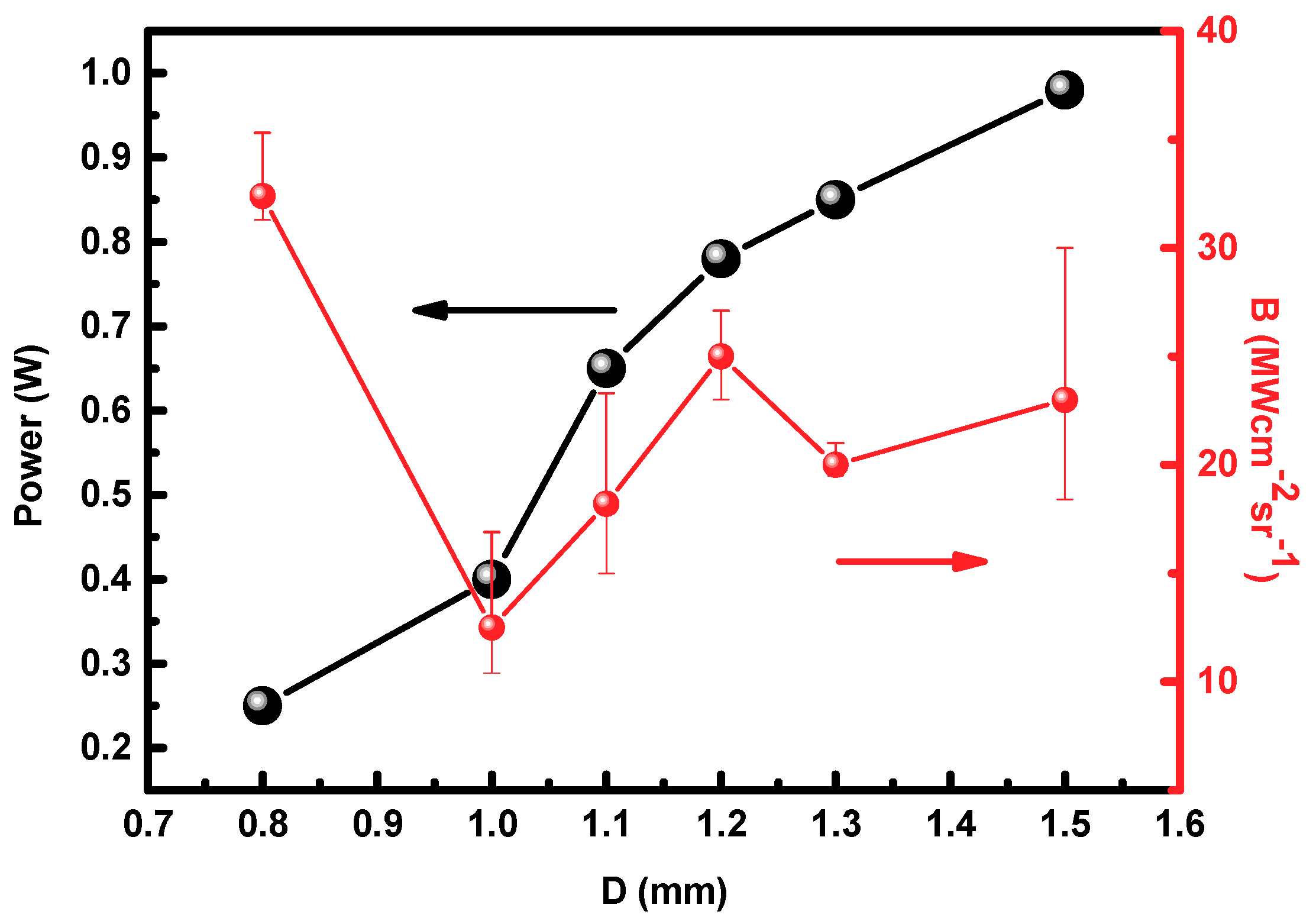

3. Experimental Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Weng, G.; Mei, Y.; Liu, J.; Hofmann, W.; Ying, L.; Zhang, J.; Bu, Y.; Li, Z.; Yang, H.; Zhang, B. Low threshold continuous-wave lasing of yellow-green InGaN-QD vertical-cavity surface-emitting lasers. Opt. Express 2016, 24, 15546–15553. [Google Scholar] [CrossRef] [PubMed]

- Miyoshi, T.; Masui, S.; Okada, T.; Yanamoto, T.; Kozaki, T.; Nagahama, S.; Mukai, T. 510–515 nm InGaN-Based Green Laser Diodes onc-Plane GaN Substrate. Appl. Phys. Express 2009, 2, 062201. [Google Scholar] [CrossRef]

- Enya, Y.; Yoshizumi, Y.; Kyono, T.; Akita, K.; Ueno, M.; Adachi, M.; Sumitomo, T.; Tokuyama, S.; Ikegami, T.; Katayama, K.; et al. 531 nm green lasing of InGaN based laser diodes on semi-polar {2021} free-standing GaN substrates. Appl. Phys. Express 2009, 2, 082101. [Google Scholar] [CrossRef]

- Kasahara, D.; Morita, D.; Kosugi, T.; Nakagawa, K.; Kawamata, J.; Higuchi, Y.; Matsumura, H.; Mukai, T. Demonstration of Blue and Green GaN-Based Vertical-Cavity Surface-Emitting Lasers by Current Injection at Room Temperature. Appl. Phys. Express 2011, 4, 072103. [Google Scholar] [CrossRef]

- Bai, J.; Chen, G. Continuous-wave diode-laser end-pumped Nd:YVO 4 /KTP high-power solid-state green laser. Opt. Laser Technol. 2002, 34, 333–336. [Google Scholar] [CrossRef]

- Jacquemet, M.; Domenech, M.; Lucas-Leclin, G.; Georges, P.; Dion, J.; Strassner, M.; Sagnes, I.; Garnache, A. Single-frequency cw vertical external cavity surface emitting semiconductor laser at 1003 nm and 501 nm by intracavity frequency doubling. Appl. Phys. B 2006, 86, 503–510. [Google Scholar] [CrossRef]

- Seelert, W.; Kubasiak, S.; Negendank, J.; Elm, R.V.; Chilla, J.; Zhou, H.; Weiss, E. Optically-pumped semiconductor lasers at 505-nm in the power range above 100 mW. Proc. SPIE 2006, 6100, 610002. [Google Scholar] [CrossRef]

- Lutgen, S.; Kuehnelt, M.; Steegmueller, U.; Brick, P.; Albrecht, T.; Reill, W.; Luft, J.; Kunert, B.; Reinhard, S.; Volz, K. Green semiconductor disk laser with 0.7 W cw output power. Proc. SPIE 2005, 5737, 109–113. [Google Scholar] [CrossRef]

- Hartke, R.; Heumann, E.; Huber, G.; Kühnelt, M.; Steegmüller, U. Efficient green generation bintracavity frequency doubling of an optically pumped semiconductor disk laser. Appl. Phys. B 2007, 87, 95–99. [Google Scholar] [CrossRef]

- Tropper, A.C.; Berger, J.D.; Anthon, D.W.; Caprara, A.; Chilla, J.L.; Govorkov, S.V.; Lepert, A.Y.; Mefferd, W.; Shu, Q.Z.; Spinelli, L. 20 Watt CW TEM00 intracavity doubled optically pumped semiconductor laser at 532 nm. Proc. SPIE 2012, 8242, 824206. [Google Scholar] [CrossRef]

- Lee, J.; Lee, S.; Kim, T.; Park, Y. 7 W high-efficiency continuous-wave green light generation by intracavity frequency doubling of an end-pumped vertical external-cavity surface emitting semiconductor laser. Appl. Phys. Lett. 2006, 89, 241107. [Google Scholar] [CrossRef]

- Zhang, F.; Heinen, B.; Wichmann, M.; Moller, C.; Kunert, B.; Rahimi-Iman, A.; Stolz, W.; Koch, M. A 23-watt single-frequency vertical-external-cavity surface-emitting laser. Opt. Express 2014, 22, 12817–12822. [Google Scholar] [CrossRef] [PubMed]

- Matthias, W.; Mohammad Khaled, S.; Fan, Z.; Bernd, H.; Maik, S.; Arash, R.I.; Wolfgang, S.; Moloney, J.V.; Koch, S.W.; Martin, K. Evolution of multi-mode operation in vertical-external-cavity surface-emitting lasers. Opt. Express 2013, 21, 31940–31950. [Google Scholar] [CrossRef]

- Gaafar, M.; Moller, C.; Wichmann, M.; Heinen, B.; Kunert, B.; Rahimi-Iman, A.; Stolz, W.; Koch, M. Harmonic self-mode-locking of optically pumped semiconductor disc laser. Electron. Lett. 2014, 50, 542–543. [Google Scholar] [CrossRef]

- Chilla, J.L.A.; Butterworth, S.D.; Zeitschel, A.; Charles, J.P.; Caprara, A.L.; Reed, M.K.; Spinelli, L. High power optically pumped semiconductor lasers. Proc. SPIE 2004, 5332, 143–151. [Google Scholar] [CrossRef]

- Lukowski, M.L.; Meyer, J.T.; Hessenius, C.; Wright, E.M.; Fallahi, M. Generation of high-power spatially structured beams using vertical external cavity surface emitting lasers. Opt. Express 2017, 25, 25504–25514. [Google Scholar] [CrossRef] [PubMed]

- Laurain, A.; Myara, M.; Beaudoin, G.; Sagnes, I.; Garnache, A. Multiwatt-power highly-coherent compact single-frequency tunable vertical-external-cavity-surface-emitting-semiconductor-laser. Opt. Express 2010, 18, 14627–14636. [Google Scholar] [CrossRef] [PubMed]

- Mueller, M.; Linder, N.; Karnutsch, C.; Schmid, W.; Streubel, K.P.; Luft, J.; Beyertt, S.S.; Giesen, A.; Doehler, G.H. Optically pumped semiconductor thin-disk laser with external cavity operating at 660 nm. Proc. SPIE 2002, 4649, 265–272. [Google Scholar] [CrossRef]

- Hou, G.Y.; Shu, S.; Feng, J.; Andreas, P.; Berthold, S.; Lu, H.Y.; Wang, L.J.; Tian, S.C.; Tong, C.Z.; Wang, L.J. High power (>27 W) semiconductor disk laser based on pre-metallized diamond heat-spreader. IEEE Photonics J. 2019, in press. [Google Scholar]

- Kim, G.B.; Kim, J.Y.; Lee, J.; Yoo, J.; Kim, K.-S.; Lee, S.-M.; Cho, S.; Lim, S.J.; Kim, T.; Park, Y. End-pumped green and blue vertical external cavity surface emitting laser devices. Appl. Phys. Lett. 2006, 89, 181106. [Google Scholar] [CrossRef]

- Diehl, R.D.; Diehl, R.L. High-Power Diode Lasers: Fundamentals, Technology, Applications; Springer: Berlin/Heidelberg, Germany, 2000. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, G.; Wang, L.; Feng, J.; Popp, A.; Schmidt, B.; Lu, H.; Shu, S.; Tian, S.; Tong, C.; Wang, L. Beam Control in an Intracavity Frequency-Doubling Semiconductor Disk Laser. Appl. Sci. 2019, 9, 1584. https://doi.org/10.3390/app9081584

Hou G, Wang L, Feng J, Popp A, Schmidt B, Lu H, Shu S, Tian S, Tong C, Wang L. Beam Control in an Intracavity Frequency-Doubling Semiconductor Disk Laser. Applied Sciences. 2019; 9(8):1584. https://doi.org/10.3390/app9081584

Chicago/Turabian StyleHou, Guanyu, Lijie Wang, Jian Feng, Andreas Popp, Berthold Schmidt, Huanyu Lu, Shili Shu, Sicong Tian, Cunzhu Tong, and Lijun Wang. 2019. "Beam Control in an Intracavity Frequency-Doubling Semiconductor Disk Laser" Applied Sciences 9, no. 8: 1584. https://doi.org/10.3390/app9081584

APA StyleHou, G., Wang, L., Feng, J., Popp, A., Schmidt, B., Lu, H., Shu, S., Tian, S., Tong, C., & Wang, L. (2019). Beam Control in an Intracavity Frequency-Doubling Semiconductor Disk Laser. Applied Sciences, 9(8), 1584. https://doi.org/10.3390/app9081584