1. Introduction

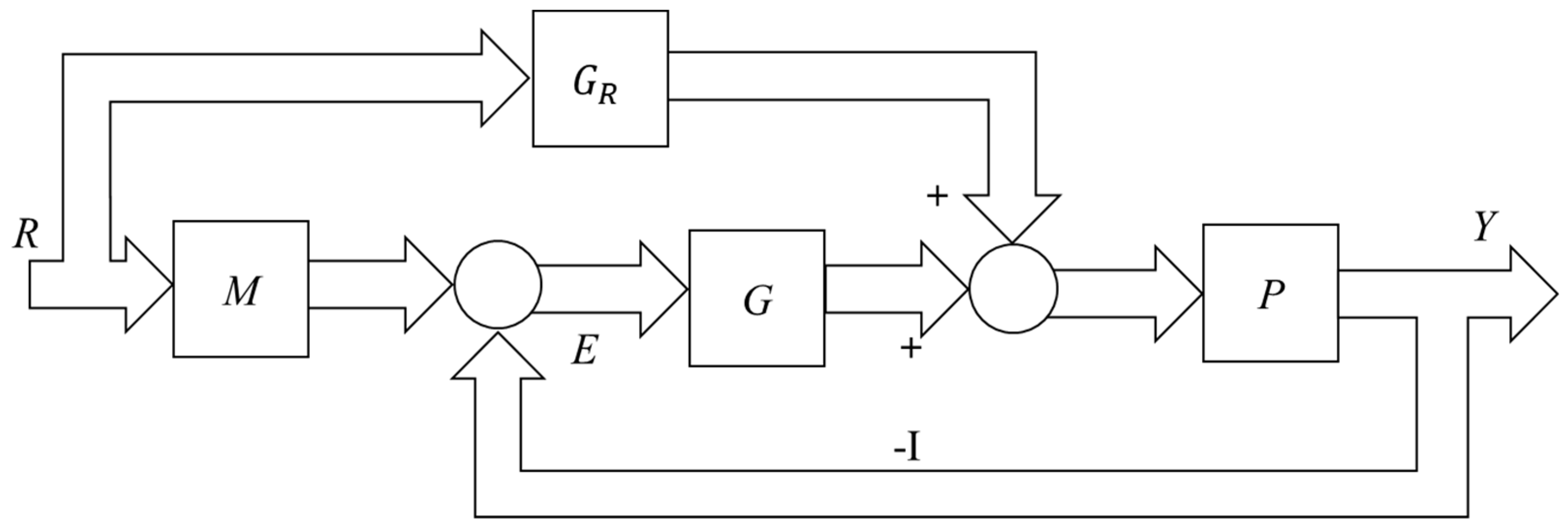

The fundamental limitations imposed by one degree of freedom (DOF) is overcome by the 2-DOF control structure and one such control is a combination of feedforward/feedback control as shown in

Figure 1. Robust feedback control theory, such as quantitative feedback theory (QFT) [

1], is essentially a 2-DOF structure containing a feedback controller (

G) and a prefilter (

F). The feedback controller is designed to desensitize the closed loop against the unknown (bounded) disturbance, system uncertainty to certain level, and the prefilter element is designed to satisfy the tracking specification. The main objective in QFT design is to minimize the feedback cost (high-frequency controller gain) which relates the bandwidth and sensor noise amplification [

1]. In general, the MIMO design methodologies are generalized as the sequential design method and the non-sequential one [

2]. In the former design, an equivalent single-input single-output (SISO) system considered is updated after each successive design and the latter one is design independent. These methods convert the MIMO design problem into a set of SISO equivalent design problems which in-turn has their own advantages and drawbacks. Tracking, disturbance attenuation and stability stand as the core problems in control systems [

3]. The tracking problem in QFT is solved in two ways [

4]: (i) classical tracking specification, keeping the magnitude of the tracking response within two given bounds [

4,

5], and (ii) tracking error specification (TES), establishing tolerances on the magnitude of the difference between certain reference models and the tracking transfer function [

6,

7]. In a TES approach (also known as model matching), phase information is captured in the specification, which has potential benefits for certain applications and reduction of overdesign as compared to the classical approach.

The tracking and disturbance rejection, performances can be improved by the feedforward controller without losing the robustness [

8]. In general, the feedforward controllers are designed using the plant inversion technique [

8,

9] An inversion-based feedforward controller strategy improves the tracking performance relative to a pure feedback control as discussed in Reference [

10] and the references therein. A sufficient condition for tracking performance is given as the plant uncertainty should be smaller than the size of the nominal plant divided by its condition number. The design of feedforward controller for the tracking problem in the MIMO process is addressed in Reference [

11]. Based on the analytical decoupling technique, the feedforward signals are determined and the multi-objective optimization problem is solved to find the transition time of each output subject to actuator constraint, but it is not extended to uncertain systems. In the context of QFT, the multivariable model matching problem is addressed in Reference [

6,

7]. The drawbacks of these methods are over design, the prefilter design in Reference [

7] is an approximation procedure and it may result in improper solutions. Recently, a novel MIMO QFT design methodology is proposed in Reference [

4] to address both the model matching and the (uncertain) disturbance rejection problems. The approach derives the non-conservative controller bounds based on the quadratic inequalities which are computationally expensive for large number of uncertain parameters. This is due to the possible combination of pairing between the plants (in model matching problem) and/or between the plant and the disturbance (in disturbance rejection problem). The designer needs some experience for selecting the bound balancing coefficients and the tolerance tightening factors (the factors multiplying the tolerances) at each design frequency, so the Elso et al. method [

4] is not so simple to use.

This motivates us to develop a simple and computationally efficient non-sequential design method. The approach we employed here is equivalent disturbance attenuation (EDA) concept. The EDA method has been applied to solve the classical tracking specification problem [

12]. To the best of the authors’ knowledge, the EDA method is not explored for the MIMO TES problem with the inversion feedforward, except the work on single input single output (SISO) case in Reference [

13]. Consequently, the main technical contributions are summarized as follows.

- (1)

A computationally efficient and simple method to solve the multivariable TES problem with inversion feedforward for the large number of uncertain parameter is proposed.

- (2)

The proposed formulation converts the original MIMO uncertain system into a set of equivalent SISO systems using the EDA concept. By doing this, it works on the nominal plant of the equivalent SISO system and the TES bounds for each of the SISO systems are computed by solving the single inequality at each phase.

- (3)

The proposed method is free of pairing requirement and does not require any tuning factors as in the case of existing methods such as Elso et al. method [

4].

- (4)

The proposed approach is applied to the benchmark MIMO magnetic levitation system and a comparative work with existing methods is undertaken to demonstrate some advantages.

The rest of this paper is divided as follows.

Section 2 states the problem statement.

Section 3 discusses about the development of the proposed feedback controller design method for the model matching. The effectiveness of the new design approach is illustrated using a challenging and benchmark maglev system in

Section 4 and

Section 5 briefly concludes this work.

Notation: The (n × n) plant transfer matrix is denoted as P belonging to uncertain set P. The (n × n) diagonal feedback controller matrix is denoted as G and M that in turn denotes the (n × n) desired response model matrix. The notation GR denotes the (n × n) tracking feedforward controller matrix. The nominal element of the uncertain system is denoted by the subscript notation “0”. The notation “diag” represent the diagonal matrices. The (i, j)th element of the plant and the desired response model are denoted as pij and mij respectively. The dependence on s and jω is not written explicitly for ease in notation in the rest of this paper. The terms such as model matching and tracking, the on-channel (on-diagonal) and control loop are interchangeably used in the rest of the paper.

4. Case Study: MIMO Magnetic Levitation System

Motion control of magnetic levitation system has become an increasingly important area of research for many engineering systems. Some of them are dual axis motion control [

16], rotary table with 6-DOF [

17], precision-positioning stages [

18], maglev trains, and the reader can refer to the papers in References [

19,

20] for more applications. The proposed non-sequential design in

Section 3 is illustrated by means of a challenging and benchmark magnetic levitation system [

21]. The magnetic levitation system (refer to

Figure 4a) is set up as the MIMO system (2 × 2) with two control loops: Channel-11 (Control loop-1) that consists of the lower magnet and coil. Input to this control loop is the voltage applied to lower coil to levitate the lower magnet and the output is displacement of lower magnet. Channel-22 (Control loop-2) consists of the upper magnet and coil. Input to this control loop is the voltage applied to upper coil to levitate the upper magnet and the output is the displacement of upper magnet. The displacement of the magnets produces interaction between the loops.

The objective was to design a “non-interacting” stable control system which satisfies the model matching specifications. The uncertain plant sets for MIMO configuration of a magnetic levitation system [

21] are:

where,

A = [1445; 1565],

B = [944,000; 1,036,000],

C = [1271; 1289],

D = [391,800; 401,200],

E = [205,600; 241,000],

H = [2604; 2819],

F = [214,100; 251,000],

I = [1,608,000; 1,767,000].

The nominal plant values were A0 = 1565; B0 = 1,036,000; C0 =1289; D0 = 401,200; E0 = 241,000; H0 = 2819; F0 = 251,000; I0 = 1,767,000.

4.1. Design Specifications

4.2. System Analysis and Results

Figure 4b shows the Bode plot of the plant p11 (lower magnet) for 6561 randomly selected plants. Here, the phase shift occurs due to the resonance peak at frequencies 22.7, 25.6, and 27.3. The design frequency set is chosen to include all such resonance frequencies and it becomes Ω = [0.1; 0.25; 0.4; 0.5; 1; 2; 3.66; 5.5; 6.5; 9; 15; 20; 22.7; 23.2; 25.6; 27.3; 27.8; 50]. Because of this resonance, the control problem becomes a challenging one.

4.2.1. Feedforward (GR) and Feedback Controller (G) design

The inversion-based strategy suggests that the diagonal tracking feedforward controller

GR =

diag(

gr11;

gr22), as given in

Table 1. The feedback controller bounds generated using the proposed method (inequality 17) are combined with the stability margin bounds, as shown in

Figure 5a, along with the loop shaping plot for channel-11. The bound comparison between the proposed method and the pure feedback design is shown in

Figure 5b.

Figure 6 shows the nominal loop shaping plot for channel-22. The designed diagonal feedback controller is

In the loop shaping plot of channel-11 in

Figure 5a, the nominal loop transmission function (

l110) at

ω ≈ 22.7 makes the phase shift of 180°. Similarly, the phase shift occurs at frequencies

ω ≈ 25, 27.3. The phase change is due to the phase shift of

p11 at these frequencies as seen in the bode diagram (

Figure 4). Similarly, the same situation occurs for the nominal loop shaping (

l220) plot of channel-22. Next, just for comparison purposes, a pure feedback design is done (independent design) [

12]. The nominal loop shaping plots for the pure feedback controller (

Gfb) are omitted for simplicity and the designed controller is given in

Table 1.

4.2.2. Design Validation and Analysis

Figure 7 shows the tracking errors obtained with the proposed design for the on-diagonal element of the closed loop uncertain system. It shows that the magnitudes of the closed loop system (for 6561 randomly selected plants) remain within the limits specified by the tolerance (

Be) in equation (18). The closed loop responses of the uncertain system (for 6561 random plants) for a unit step are shown in

Figure 8. The responses with the proposed feedback controller design (Equation (19)) along with the feedforward controllers (refer to

Table 1) for channels-11 and -22 track the desired model (

M) responses within the tolerances (

Be).

Figure 9 compares the control effort with the proposed design (

G + GR) and the pure feedback controller (

Gfb) for both the channels. It is seen that the control effort with the proposed feedback controller alone (

G) was much less than the pure feedback controller (

Gfb) and the combined feedback + inversion feedforward (

G +

GR) control. The biggest share of the control effort produced by the proposed feedback + inversion feedforward design was due to the inversion feedforward control as shown in

Figure 9. In practice, this implies a reduction in actuator fatigue, savings in energy, and avoidance of noise-induced saturation as mentioned in Reference [

21]. It was noted that the demand for the feedback control was very less because of the feedforward action. This reduces the feedback cost measured in terms of high frequency gain. Hence, the main purpose of the QFT design can be achieved.

To analyze the interaction effect, a unit step input signal was applied at time instant t = 0 s and t = 4 s, for channels-11 and -22, respectively. The closed loop responses of the uncertain system (for 6561 random plants) with the proposed feedback controller design (equation 19) along with the feedforward controllers (equation 19 and

Table 1) for channels-11 and -22 track the desired model (

M) responses within the tolerances (

Be) as shown in

Figure 10, while the interaction effects are within the limits of specification (<0.1).

Figure 11 compares the frequency response magnitude of the feedback controllers between the proposed method and the pure feedback method for both the channels. The proposed feedback controller (

G) gives a high frequency (HF) gain reduction of 20 dB over the pure feedback design (

Gfb) for both the channels. This implies that the proposed design is less sensitive to the sensor noise amplification problem (termed as “cost of feedback” in QFT). It is interesting to explore the experimental validation of the proposed design in the magnetic levitation system.

4.2.3. Comparison with an Existing TES Method

The bound generation quadratic equality of Elso et al. [

4] method (Appendix in Reference [

4]) involves “pairing” of two plants

p111 and

p112 from the plant set

p11 (channel-11). The “pairing” has to be done for all possible pairs of plants from

p11. Thus, it can become a computational bottleneck, when

p11 is represented by a large number of plants, such as when the number of uncertain plant parameters is large. The number of plants in

p11 considered is 3

8 = 6561 for a grid size of three and the plant pairs to be considered in quadratic inequality becomes 3

8 × 3

8 = 43,046,721. This requires very large computational time in method [

4] due to “pairing requirement” in the specifications. The proposed method does not require “pairing” and it takes 0.5 sec for generating performance bounds in both the channels. Another drawback in Reference [

4], the bound balancing values and the tolerance tightening factors are selected, such that performance bound reaches an optimal configuration. These values were chosen by tuning at each performance design frequency and it needs an experienced designer, so the Elso et al. method [

4] is not simple. The proposed method does not require any tuning and is simple, computationally efficient. The Elso et al. method [

4] can still be applied after manipulating the plant template using the special methods such as the interval math, the affine plant representation, or methods to compute the outer border of the template but this is beyond the scope of the paper.