Optimization of Processing Parameters for Water-Jet-Assisted Laser Etching of Polycrystalline Silicon

Abstract

:1. Introduction

2. Theoretical Analysis of the Influence of Water-Jet-Assisted Laser Etching

3. Experimental Methods and Analysis

4. Orthogonal Test Design

4.1. Design Table of Orthogonal Test Plan

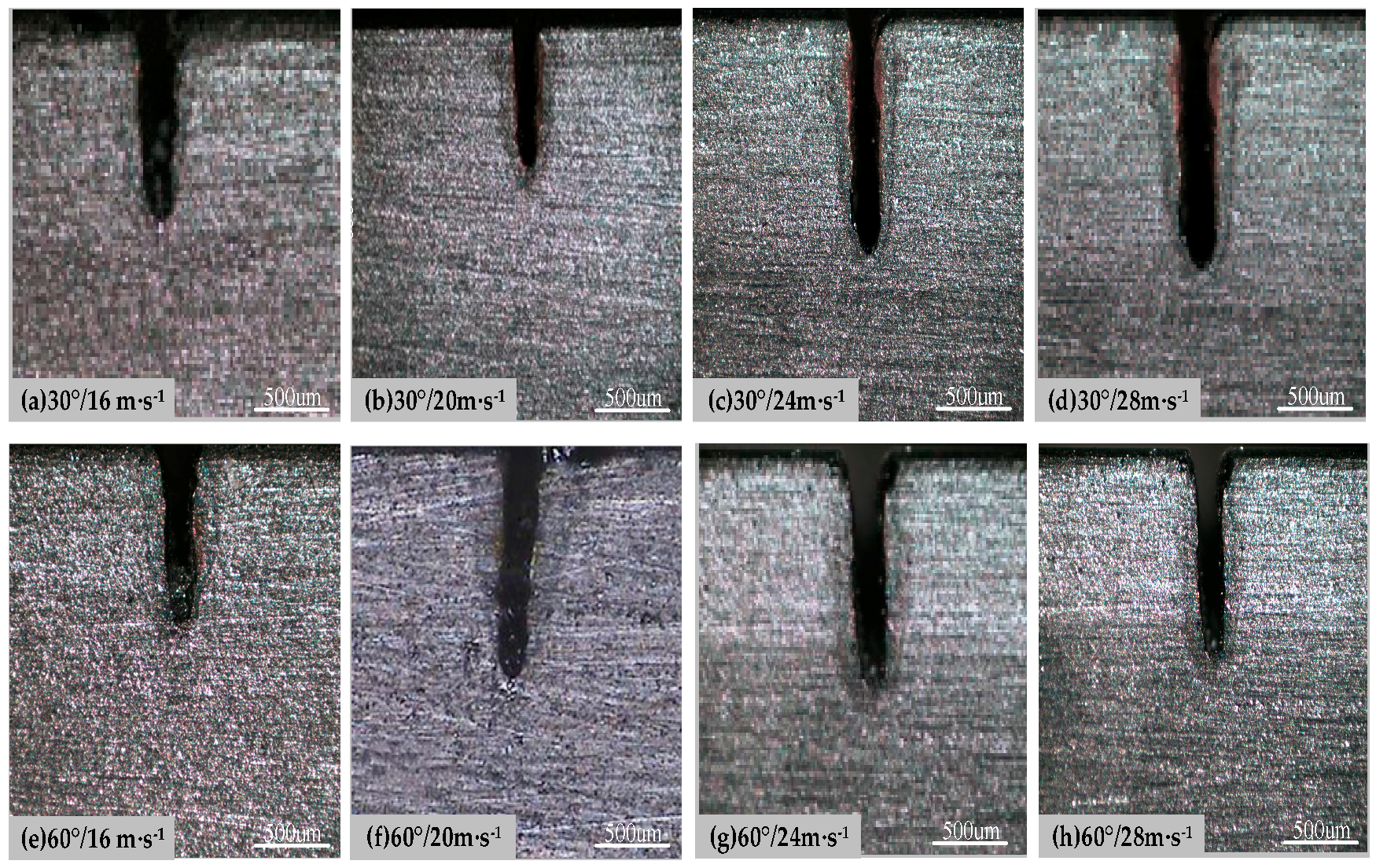

4.2. Experimental Results and Optimization Options

- If the required index must be as small as possible, we must consider the level corresponding to the smallest average.

- If the required index must be as large as possible, we must consider the level corresponding to the largest average.

- If the indicator must be moderate (a fixed value), we must consider the level corresponding to a moderate average.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Manickam, S.; Wang, J.; Huang, C. Laser–material interaction and grooving performance in ultrafast laser ablation of crystalline germanium under ambient conditions. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2013, 227, 1714–1723. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, J.; Huang, C. Analysis of the machining performance and surface integrity in laser milling of polycrystalline diamonds. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 903–917. [Google Scholar] [CrossRef]

- Wang, J. An Experimental Analysis and Optimisation of the CO2 Laser Cutting Process for Metallic Coated Sheet Steels. Int. J. Adv. Manuf. Technol. 2000, 16, 334–340. [Google Scholar] [CrossRef]

- Li, C.F.; Johnson, D.B.; Kovacevic, R. Modeling of waterjet guided laser grooving of silicon. Int. J. Mach. Tools Manuf. 2003, 43, 925–936. [Google Scholar] [CrossRef]

- Porter, J.A.; Louhisalmi, Y.A.; Karjalainen, J.A.; Füger, S. Cutting thin sheet metal with a water jet guided laser using various cutting distances, feed speeds and angles of incidence. Int. J. Adv. Manuf. Technol. 2007, 33, 961–967. [Google Scholar] [CrossRef]

- Hock, K.; Adelmann, B.; Hellmann, R. Comparative study of remote fiber laser and water-jet guided laser cutting of thin metal sheets. Phys. Procedia 2012, 39, 225–231. [Google Scholar] [CrossRef]

- Adelmann, B.; Ngo, C.; Hellmann, R. High aspect ratio cutting of metals using water jet guided laser. Int. J. Adv. Manuf. Technol. 2015, 80, 2053–2060. [Google Scholar] [CrossRef]

- Choubey, A.; Jain, R.K.; Ali, S.; Singh, R.; Vishwakarma, S.C.; Agrawal, D.K.; Arya, R.; Kaul, R.; Upadhyaya, B.N.; Oak, S.M. Studies on pulsed nd:yag laser cutting of thick stainless steel in dry air and underwater environment for dismantling applications. Opt. Laser Technol. 2015, 71, 6–15. [Google Scholar] [CrossRef]

- Mullick, S.; Madhukar, Y.K.; Roy, S.; Nath, A.K. An investigation of energy loss mechanisms in water-jet assisted underwater laser cutting process using an analytical model. Int. J. Mach. Tools Manuf. 2015, 91, 62–75. [Google Scholar] [CrossRef]

- Tsai, C.H.; Li, C.C. Investigation of underwater laser drilling for brittle substrates. J. Mater. Process. Technol. 2009, 209, 2838–2846. [Google Scholar] [CrossRef]

- Charee, W.; Tangwarodomnukun, V.; Dumkum, C. Laser ablation of silicon in water under different flow rates. Int. J. Adv. Manuf. Technol. 2015, 78, 19–29. [Google Scholar] [CrossRef]

- Kalyanasundaram, D. Mechanics Guided Design of Hybrid Laser/Waterjet System for Machining Hard and Brittle Materials. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2009. [Google Scholar]

- Tangwarodomnukun, V.; Wang, J.; Huang, C.Z.; Zhu, H.T. An investigation of hybrid laser-waterjet ablation of silicon substrates. Int. J. Mach. Tools Manuf. 2012, 56, 39–49. [Google Scholar] [CrossRef]

- Tangwarodomnukun, V.; Wang, J.; Huang, C.Z.; Zhu, H.T. Heating and material removal process in hybrid laser-waterjet ablation of silicon substrates. Int. J. Mach. Tools Manuf. 2014, 79, 1–16. [Google Scholar] [CrossRef]

- Bao, J.; Long, Y.; Tong, Y.; Yang, X.; Zhang, B.; Zhou, Z. Experiment and simulation study of laser dicing silicon with water-jet. Appl. Surf. Sci. 2016, 387, 491–496. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, J.; Yao, P.; Huang, C. Heat transfer and material ablation in hybrid laser-waterjet microgrooving of single crystalline germanium. Int. J. Mach. Tools Manuf. 2017, 116, 25–39. [Google Scholar] [CrossRef]

- Feng, S.; Huang, C.; Wang, J.; Zhu, H.; Yao, P.; Liu, Z. An analytical model for the prediction of temperature distribution and evolution in hybrid laser-waterjet micro-machining. Precis. Eng. 2017, 47, 33–45. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, Z.; Xu, K.; Xu, J.; Zhu, S.; Wang, A.; Qi, H. Performance Evaluation and Comparison between Direct and Chemical-Assisted Picosecond Laser Micro-Trepanning of Single Crystalline Silicon. Materials 2019, 12, 41. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.H.; Li, X.; Song, W.; Wu, C.; Zhang, Y. Effects of a low-pressure water jet assisting the laser etching of polycrystalline silicon. Appl. Phys. A 2018, 124, 556. [Google Scholar] [CrossRef]

- Wang, L.; Huang, C.; Wang, J.; Zhu, H.; Liang, X. An experimental investigation on laser assisted waterjet micro-milling of silicon nitride ceramics. Ceram. Int. 2018, 44, 5636–5645. [Google Scholar] [CrossRef]

| Technical Parameters | Current (A) | Pulse Width (ms) | Repeat Frequency (Hz) | Single Pulse Energy (J) | Processing Speed (mm·s−1) |

|---|---|---|---|---|---|

| Adjustment range | 100–400 | 0.1–20 | 0–150 | 0–90 | >0.1 |

| Level | Factor | |||

|---|---|---|---|---|

| A Water-Jet Velocity/m/s | B Pulse Width/ms | C Repeat Frequency/Hz | D Current/A | |

| 1 | 16 | 0.5 | 30 | 150 |

| 2 | 20 | 0.7 | 35 | 160 |

| 3 | 24 | 0.9 | 40 | 170 |

| 4 | 28 | 1.1 | 45 | 180 |

| Test Number | A | B | C | D | Test Plan |

|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | A1B1C1D1 |

| 2 | 1 | 2 | 2 | 2 | A1B2C2D2 |

| 3 | 1 | 3 | 3 | 3 | A1B3C3D3 |

| 4 | 1 | 4 | 4 | 4 | A1B4C4D4 |

| 5 | 2 | 1 | 2 | 3 | A2B1C2D3 |

| 6 | 2 | 2 | 1 | 4 | A2B2C1D4 |

| 7 | 2 | 3 | 4 | 1 | A2B3C4D1 |

| 8 | 2 | 4 | 3 | 2 | A2B4C3D2 |

| 9 | 3 | 1 | 3 | 4 | A3B1C3D4 |

| 10 | 3 | 2 | 4 | 3 | A3B2C4D3 |

| 11 | 3 | 3 | 1 | 2 | A3B3C1D2 |

| 12 | 3 | 4 | 2 | 1 | A3B4C2D1 |

| 13 | 4 | 1 | 4 | 2 | A4B1C4D2 |

| 14 | 4 | 2 | 3 | 1 | A4B2C3D1 |

| 15 | 4 | 3 | 2 | 4 | A4B3C2D4 |

| 16 | 4 | 4 | 1 | 3 | A4B4C1D3 |

| Index | A | B | C | D | |

|---|---|---|---|---|---|

| Section taper/° | 5.025 | 10.342 | 6.285 | 5.682 | |

| 6.647 | 4.258 | 6.707 | 4.640 | ||

| 6.200 | 3.710 | 3.162 | 7.717 | ||

| 3.752 | 3.315 | 5.470 | 3.585 | ||

| 2.895 | 7.027 | 3.545 | 4.132 | ||

| Section depth/mm | 1.455 | 0.900 | 1.238 | 1.513 | |

| 1.480 | 1.288 | 1.433 | 1.355 | ||

| 1.300 | 1.690 | 1.525 | 1.400 | ||

| 1.458 | 1.815 | 1.497 | 1.425 | ||

| 0.180 | 0.915 | 0.287 | 0.158 |

| Section Taper | Section Depth | |

|---|---|---|

| Primary and secondary factors | B, D, C, A | B, C, A, D |

| Excellent level | A4, B4, C3, D4 | A2, B4, C3, D1 |

| Optimal combination | B4D4C3A4 | B4C3A2D1 |

| Evaluation Index | Actual Requirements | Excellent Solution | Water-Jet Velocity/m/s | Pulse Width/ms | Repeat Frequency/Hz | Current/A |

|---|---|---|---|---|---|---|

| Section taper/° | Smaller and better | B4D4C3A4 | 28 | 1.1 | 40 | 180 |

| Section depth/mm | Bigger and better | B4C3A2D1 | 20 | 1.1 | 40 | 150 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Li, X.; Wu, C.; Ma, Y.; Zhang, Y.; Huang, L.; Liu, W. Optimization of Processing Parameters for Water-Jet-Assisted Laser Etching of Polycrystalline Silicon. Appl. Sci. 2019, 9, 1882. https://doi.org/10.3390/app9091882

Chen X, Li X, Wu C, Ma Y, Zhang Y, Huang L, Liu W. Optimization of Processing Parameters for Water-Jet-Assisted Laser Etching of Polycrystalline Silicon. Applied Sciences. 2019; 9(9):1882. https://doi.org/10.3390/app9091882

Chicago/Turabian StyleChen, Xuehui, Xiang Li, Chao Wu, Yuping Ma, Yao Zhang, Lei Huang, and Wei Liu. 2019. "Optimization of Processing Parameters for Water-Jet-Assisted Laser Etching of Polycrystalline Silicon" Applied Sciences 9, no. 9: 1882. https://doi.org/10.3390/app9091882

APA StyleChen, X., Li, X., Wu, C., Ma, Y., Zhang, Y., Huang, L., & Liu, W. (2019). Optimization of Processing Parameters for Water-Jet-Assisted Laser Etching of Polycrystalline Silicon. Applied Sciences, 9(9), 1882. https://doi.org/10.3390/app9091882