Crustacean Waste-Derived Chitosan: Antioxidant Properties and Future Perspective

Abstract

1. Introduction

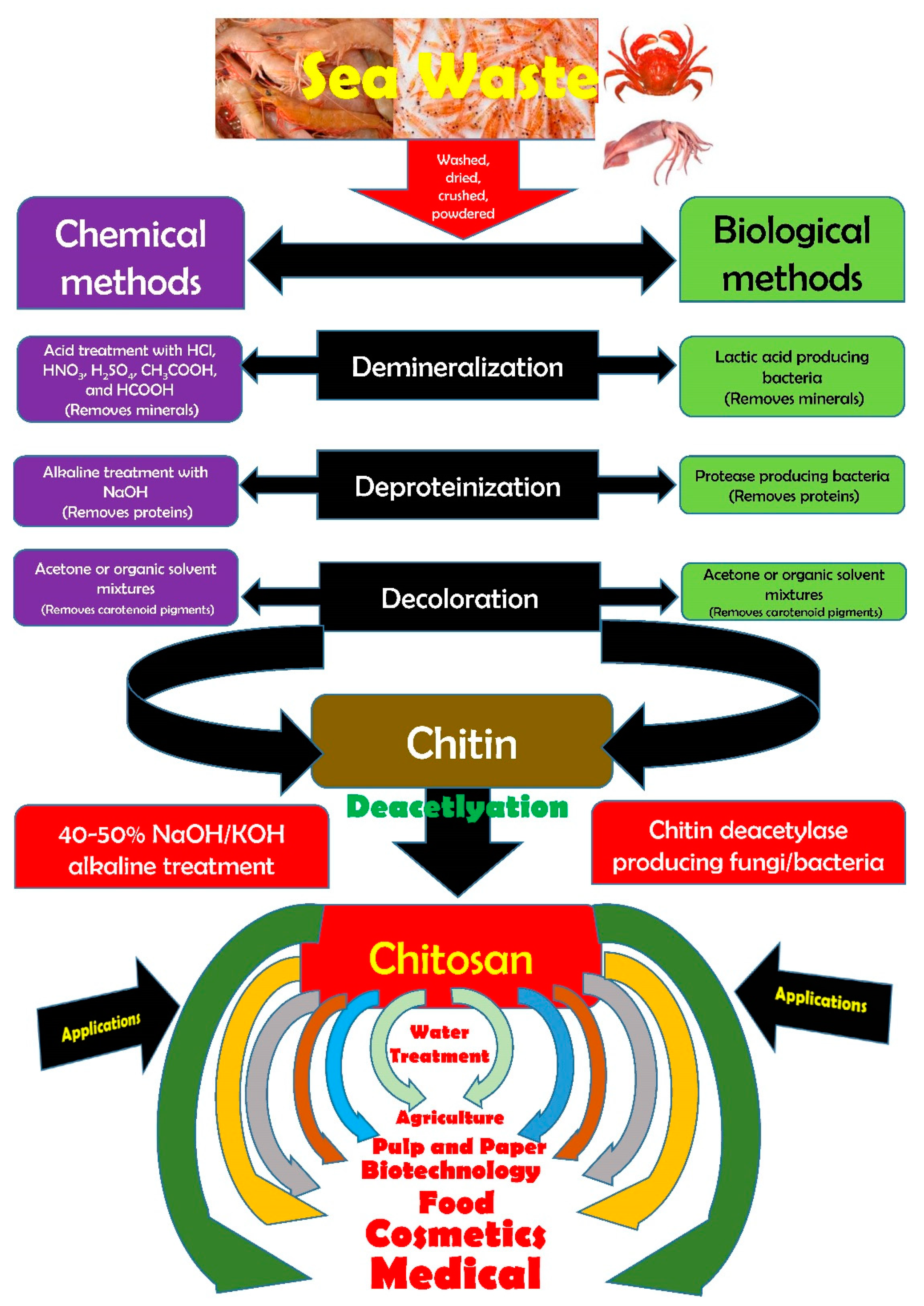

2. Chitin–Chitosan Metamorphosis

3. Snap Shot of the Bioactive Properties of Chitosan

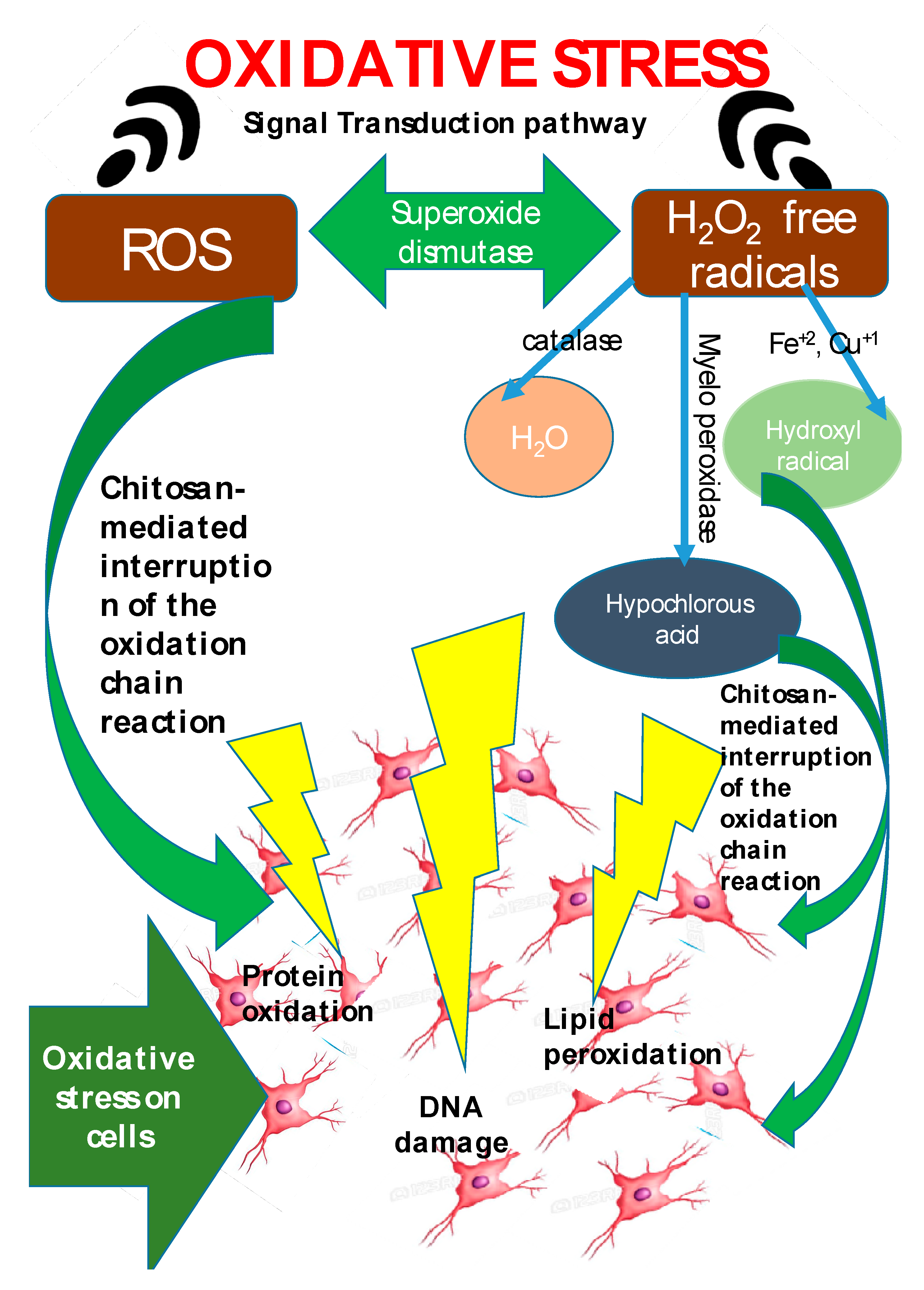

4. Antioxidant Activity of Chitosan

5. The State-of-the-Art Chitosan Trends

6. Future Perspective and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Einbu, A.; Vårum, K.M. Characterization of chitin and its hydrolysis to GlcNAc and GlcN. Biomacromolecules 2008, 9, 1870–1875. [Google Scholar] [CrossRef] [PubMed]

- Sato, H.; Mitzutani, S.; Tsuge, S. Determination of the degree of acetylation of chitin/chitosan by pyrolysis-gas chromatography in the presence of oxalic acid. Anal. Chem. 1998, 70, 7–12. [Google Scholar] [CrossRef] [PubMed]

- Kikkawa, Y.; Tokuhisa, H.; Shingai, H.; Hiraishi, T.; Houjou, H.; Kanesato, M.; Imanaka, T.; Tanaka, T. Interaction force of chitin-binding domains onto chitin surface. Biomacromolecules 2008, 9, 2126–2131. [Google Scholar] [CrossRef] [PubMed]

- Shahidi, F.; Abuzaytoun, R. Chitin, chitosan, and co-products: Chemistry, production, applications, and health effects. Adv. Food Nutr. Res. 2005, 49, 93–135. [Google Scholar] [PubMed]

- Wang, X.; Xing, B. Importance of structural makeup of biopolymers for organic contaminant sorption. Environ. Sci. Technol. 2007, 41, 3559–3565. [Google Scholar] [CrossRef] [PubMed]

- Zargar, V.; Asghari, M.; Dashti, A. A review on chitin and chitosan polymers: Structure, chemistry, solubility, derivatives, and applications. Chembioeng. Rev. 2015, 2, 204–226. [Google Scholar] [CrossRef]

- Yan, N.; Chen, X. Sustainability: Don’t waste seafood waste. Nat. News 2015, 524, 155. [Google Scholar] [CrossRef]

- Kjartansson, G.T.; Zivanovic, S.; Kristbergsson, K.; Weiss, J. Sonication-assisted extraction of chitin from North Atlantic shrimps (Pandalus borealis). J. Agric. Food Chem. 2006, 54, 5894–5902. [Google Scholar] [CrossRef]

- Chang, K.L.B.; Tsai, G. Response surface optimization and kinetics of isolating chitin from pink shrimp (Solenocera melantho) shell waste. J. Agric. Food Chem. 1997, 45, 1900–1904. [Google Scholar] [CrossRef]

- Mojarrad, J.S.; Nemati, M.; Valizadeh, H.; Ansarin, M.; Bourbour, S. Preparation of glucosamine from exoskeleton of shrimp and predicting production yield by response surface. J. Agric. Food Chem. 2007, 55, 2246–2250. [Google Scholar] [CrossRef]

- Xu, Y.; Gallert, C.; Winter, J. Chitin purification from shrimp wastes by microbial deproteination and decalcification. Appl. Microbiol. Biotechnol. 2008, 79, 687–697. [Google Scholar] [CrossRef] [PubMed]

- Zhai, X.; Hawkins, S.J. Interactions of aquaculture and waste disposal in the coastal zone. J. Ocean. Univ. Qingdao 2002, 1, 8–12. [Google Scholar]

- Gimeno, M.; Ramirez-Hernandez, J.Y.; Mártinez-Ibarra, C.; Pacheco, N.; Garcia-Arrazola, R.; Barzana, E.; Shirai, K. One-solvent extraction of astaxanthin from lactic acid fermented shrimp wastes. J. Agric. Food Chem. 2007, 55, 10345–10350. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.L.; Chang, T.J.; Liang, T.W. Conversion and degradation of shellfish wastes by Serratia sp. TKU016 fermentation for the production of enzymes and bioactive materials. Biodegradation 2010, 21, 321–333. [Google Scholar] [CrossRef] [PubMed]

- Arbia, W.; Arbia, L.; Adour, L.; Amrane, A. Chitin extraction from crustacean shells using biological methods—A review. Food Technol. Biotech. 2013, 51, 12–25. [Google Scholar]

- Yadav, M.; Goswami, P.; Paritosh, K.; Kumar, M.; Pareek, N.; Vivekanand, V. Seafood waste: A source for preparation of commercially employable chitin/chitosan materials. Bioresour. Bioprocess. 2019, 6, 8. [Google Scholar] [CrossRef]

- Casadidio, C.; Peregrina, D.V.; Gigliobianco, M.R.; Deng, S.; Censi, R.; Di Martino, P. Chitin and chitosans: Characteristics, eco-friendly processes, and applications in cosmetic science. Mar. Drugs 2019, 17, 369. [Google Scholar] [CrossRef] [PubMed]

- Synowiecki, J.; Al-Khateeb, N.A. Production, properties, and some new applications of chitin and its derivatives. Crit. Rev. Food Sci. Nutr. 2003, 43, 145–171. [Google Scholar] [CrossRef]

- Tolaimate, A.; Desbrieres, J.; Rhazi, M.; Alagui, A. Contribution to the preparation of chitins and chitosans with controlled physico-chemical properties. Polymer 2003, 44, 7939–7952. [Google Scholar] [CrossRef]

- Das, S.; Ganesh, E.A. Extraction of chitin from trash crabs (Podophthalmus vigil) by an eccentric method. Curr. Res. J. Biol. Sci. 2010, 2, 72–75. [Google Scholar]

- Bajaj, M.; Winter, J.; Gallert, C. Effect of deproteination and deacetylation conditions on viscosity of chitin and chitosan extracted from Crangon crangon shrimp waste. Biochem. Eng. J. 2011, 56, 51–62. [Google Scholar] [CrossRef]

- Haddar, A.; Hmidet, N.; Ghorbel-Bellaaj, O.; Fakhfakh-Zouari, N.; Sellami-Kamoun, A.; Nasri, M. Alkaline proteases produced by Bacillus licheniformis rp1 grown on shrimp wastes: Application in chitin extraction, chicken feather-degradation and as a dehairing agent. Biotechnol. Bioprocess. Eng. 2011, 16, 669. [Google Scholar] [CrossRef]

- Sila, A.; Nasri, R.; Bougatef, A.; Nasri, M. Digestive alkaline proteases from the goby (Zosterisessor ophiocephalus): Characterization and potential application as detergent additive and in the deproteinization of shrimp wastes. J. Aquat. Food Prod. Technol. 2012, 21, 118–133. [Google Scholar] [CrossRef]

- Mhamdi, S.; Ktari, N.; Hajji, S.; Nasri, M.; Kamoun, A.S. Alkaline proteases from a newly isolated Micromonospora chaiyaphumensis s103: Characterization and application as a detergent additive and for chitin extraction from shrimp shell waste. Int. J. Biol. Macromol. 2017, 94, 415–422. [Google Scholar] [CrossRef] [PubMed]

- Hamdi, M.; Hammami, A.; Hajji, S.; Jridi, M.; Nasri, M.; Nasri, R. Chitin extraction from blue crab (Portunus segnis) and shrimp (Penaeus kerathurus) shells using digestive alkaline proteases from P. segnis viscera. Int. J. Biol. Macromol. 2017, 101, 455–463. [Google Scholar] [CrossRef] [PubMed]

- Castro, R.; Guerrero-Legarreta, I.; Bórquez, R. Chitin extraction from Allopetrolisthes punctatus crab using lactic fermentation. Biotechnol. Rep. 2018, 20, e00287. [Google Scholar] [CrossRef] [PubMed]

- Du, J.; Tan, E.; Kim, H.J.; Zhang, A.; Bhattacharya, R.; Yarema, K.J. Comparative evaluation of chitosan, cellulose acetate, and polyethersulfone nanofiber scaffolds for neural differentiation. Carbohydr. Polym. 2014, 99, 483–490. [Google Scholar] [CrossRef] [PubMed]

- Peter, M.G. Applications and Environmental Aspects of Chitin and Chitosan. J. Macromol. Sci. Part A 1995, 32, 629–640. [Google Scholar] [CrossRef]

- Kurita, K. Chemistry and application of chitin and chitosan. Polym. Degrad. Stab. 1998, 59, 117–120. [Google Scholar] [CrossRef]

- Kumar, R.M.N. A review of chitin and chitosan applications. React. Funct. Polym. 2000, 46, 1–27. [Google Scholar] [CrossRef]

- Dutta, P.K.; Dutta, J.; Tripathi, V.S. Chitin and chitosan: Chemistry, properties and applications. J. Sci. Ind. Res. India 2004, 63, 20–31. [Google Scholar]

- Rinaudo, M. Chitin and chitosan: Properties and applications. Prog. Polym. Sci. 2006, 31, 603–632. [Google Scholar] [CrossRef]

- Pillai, C.K.S.; Paul, W.; Sharma, C.P. Chitin and chitosan polymers: Chemistry, solubility and fiber formation. Prog. Polym. Sci. 2009, 34, 641–678. [Google Scholar] [CrossRef]

- Venkatesan, J.; Kim, S.K. Chitosan composites for bone tissue engineering—An overview. Mar. Drugs 2010, 8, 2252–2266. [Google Scholar] [CrossRef]

- Hembach, L.; Cord-Landwehr, S.; Moerschbacher, B.M. Enzymatic production of all fourteen partially acetylated chitosan tetramers using different chitin deacetylases acting in forward or reverse mode. Sci. Rep. 2017, 7, 17692. [Google Scholar] [CrossRef]

- Abdou, E.S.; Nagy, K.S.A.; Elsabee, M.Z. Extraction and characterization of chitin and chitosan from local sources. Bioresour. Technol. 2008, 99, 1359–1367. [Google Scholar] [CrossRef]

- Al-Hassan, A.A. Utilization of waste: Extraction and characterization of chitosan from shrimp byproducts. Civil. Environ. Res. 2016, 8, 117–123. [Google Scholar]

- Vilar Junior, J.C.; Ribeaux, D.R.; Alves da Silva, C.A.; Campos-Takaki, G.M. Physicochemical and antibacterial properties of chitosan extracted from waste shrimp shells. Int. J. Microbiol. 2016, 5127515, 1–7. [Google Scholar] [CrossRef]

- Sedaghat, F.; Yousefzadi, M.; Toiserkani, H.; Najafipour, S. Bioconversion of shrimp waste Penaeus merguiensis using lactic acid fermentation: An alternative procedure for chemical extraction of chitin and chitosan. Int. J. Biol. Macromol. 2017, 104, 883–888. [Google Scholar] [CrossRef]

- Varun, T.K.; Senani, S.; Jayapal, N.; Chikkerur, J.; Roy, S.; Tekulapally, V.B.; Gautam, M.; Kumar, N. Extraction of chitosan and its oligomers from shrimp shell waste, their characterization and antimicrobial effect. Vet. World 2017, 10, 170–175. [Google Scholar] [CrossRef]

- Aboudamia, F.Z.; Kharroubi, M.; Neffa, M.; Aatab, F.; Hanoune, S.; Bouchdoug, M.; Jaouad, A. Potential of discarded sardine scales (Sardina pilchardus) as chitosan sources. J. Air Waste Manag. Assoc. 2020, 70, 1186–1197. [Google Scholar] [CrossRef] [PubMed]

- Said Al Hoqani, H.A.; AL-Shaqsi, N.; Hossain, M.A.; Al Sibani, M.A. Isolation and optimization of the method for industrial production of chitin and chitosan from Omani shrimp shell. Carbohydr. Res. 2020, 492, 108001. [Google Scholar] [CrossRef] [PubMed]

- Sagheer, F.A.A.; Al-Sughayer, M.A.; Muslim, S.; Elsabee, M.Z. Extraction and characterization of chitin and chitosan from marine sources in Arabian Gulf. Carbohydr. Polym. 2009, 77, 410–419. [Google Scholar] [CrossRef]

- Samar, M.M.; El-Kalyoubi, M.; Khalaf, M.; El-Razik, M.A. Physicochemical, functional, antioxidant and antibacterial properties of chitosan extracted from shrimp wastes by microwave technique. Ann. Agric. Sci. 2013, 58, 33–41. [Google Scholar] [CrossRef]

- EL Knidri, H.; Dahmani, J.; Addaou, A.; Laajeb, A.; Lahsini, A. Rapid and efficient extraction of chitin and chitosan for scale-up production: Effect of process parameters on deacetylation degree and molecular weight. Int. J. Biol. Macromol. 2019, 139, 1092–1102. [Google Scholar] [CrossRef] [PubMed]

- Santos, V.P.; Maia, P.; Alencar, N.S.; Farias, L.; Andrade, R.F.S.; Souza, D.; Ribeaux, D.R.; Franco, L.O.; Campos-Takaki, G.M. Recovery of chitin and chitosan from shrimp waste with microwave technique and versatile application. Arq. Inst. Biol. 2019, 86, e0982018. [Google Scholar] [CrossRef]

- Hafsa, J.; Smach, M.A.; Charfeddine, B.; Limem, K.; Majdoub, H.; Rouatbi, S. Antioxidant and antimicrobial proprieties of chitin and chitosan extracted from Parapenaeus Longirostris shrimp shell waste. Ann. Pharm. Françaises 2016, 74, 27–33. [Google Scholar] [CrossRef]

- Borja-Urzola, A.D.C.; García-Gómez, R.S.; Flores, R.; Durán-Domínguez-de-Bazúa, M.D.C. Chitosan from shrimp residues with a saturated solution of calcium chloride in methanol and water. Carbohydr. Res. 2020, 497, 108116. [Google Scholar] [CrossRef]

- Huang, L.; Bi, S.; Pang, J.; Sun, M.; Feng, C.; Chen, X. Preparation and characterization of chitosan from crab shell (Portunus trituberculatus) by NaOH/urea solution freeze-thaw pretreatment procedure. Int. J. Biol. Macromol. 2020, 147, 931–936. [Google Scholar] [CrossRef]

- Gopal, J.; Muthu, M.; Dhakshanamurthy, T.; Kim, K.J.; Hasan, N.; Kwon, S.J.; Chun, S. Sustainable ecofriendly phytoextract mediated one pot green recovery of chitosan. Sci. Rep. 2019, 9, 13832. [Google Scholar] [CrossRef]

- Methacanon, P.; Prasitsilp, M.; Pothsree, T.; Pattaraarchachai, J. Heterogeneous N-deacetylation of squid chitin in alkaline solution. Carbohydr. Polym. 2003, 52, 119–123. [Google Scholar] [CrossRef]

- Chandumpai, A.; Singhpibulporn, N.; Faroongsarng, D.; Sornprasit, P. Preparation and physico-chemical characterization of chitin and chitosan from the pens of the squid species, Loligo lessoniana and Loligo formosana. Carbohydr. Polym. 2004, 58, 467–474. [Google Scholar] [CrossRef]

- Fernandez Cerveraa, M.; Heinamaki, J.; Rasanenc, M.; Maunuc, S.L.; Karjalainenb, M.; Nieto Acostaa, O.M.; Iraizoz Colartea, A.; Yliruusib, J. Solid-state characterization of chitosans derived from lobster chitin. Carbohydr. Polym. 2004, 58, 401–408. [Google Scholar] [CrossRef]

- Beaney, P.; Jaime, L.-M.; Healy, M. Comparison of chitins produced by chemical and bioprocessing methods. J. Chem. Technol. Biotechnol. 2005, 80, 145–150. [Google Scholar] [CrossRef]

- Rao, M.S.; Stevens, W.F. Chitin production by Lactobacillus fermentation of shrimp biowaste in a drum reactor and its chemical conversion to chitosan. J. Chem. Technol. Biotechnol. 2005, 80, 1080–1087. [Google Scholar] [CrossRef]

- Sini, T.K.; Santhosh, S.; Mathew, P.T. Study on the production of chitin and chitosan from shrimp shell by using Bacillus subtilis fermentation. Carbohydr. Res. 2007, 342, 2423–2429. [Google Scholar] [CrossRef]

- Weska, R.F.; Moura, J.M.; Batista, L.M.; Rizzi, J.; Pinto, L.A.A. Optimization of deacetylation in the production of chitosan from shrimp wastes: Use of response surface methodology. J. Food Eng. 2007, 80, 749–753. [Google Scholar] [CrossRef]

- Yen, M.T.; Yang, J.H.; Mau, J.L. Physicochemical characterization of chitin and chitosan from crab shells. Carbohydr. Polym. 2009, 75, 15–21. [Google Scholar] [CrossRef]

- Manni, L.; Ghorbel-Bellaaj, O.; Jellouli, K.; Younes, I.; Nasri, M. Extraction and characterization of chitin, chitosan, and protein hydrolysates prepared from shrimp waste by treatment with crude protease from Bacillus cereus SV1. Appl. Biochem. Biotechnol. 2010, 162, 345–357. [Google Scholar] [CrossRef]

- Zvezdova, D. Synthesis and characterization of chitosan from marine sources in Black Sea. Annu. Proc. Angel Kanchev Univ. Ruse 2010, 49, 65–69. [Google Scholar]

- Kucukgulmez, A.; Celik, M.; Yanar, Y.; Sen, D.; Polat, H.; Kadak, A.E. Physicochemical characterization of chitosan extracted from Metapenaeus stebbingi shells. Food Chem. 2011, 126, 1144–1148. [Google Scholar] [CrossRef]

- Benhabiles, M.S.; Salah, R.; Lounici, H.; Drouiche, N.; Goosen, M.F.A.; Mameri, N. Antibacterial activity of chitin, chitosan and its oligomers prepared from shrimp shell waste. Food Hydrocoll. 2012, 29, 48–56. [Google Scholar] [CrossRef]

- Prabu, K.; Natarajan, E. In Vitro Antimicrobial and Antioxidant Activity of Chitosan Isolated from Podophthalmus vigil. J. Appl. Pharm. Sci. 2012, 9, 75–82. [Google Scholar] [CrossRef][Green Version]

- Vino, A.B.; Ramasamy, P.; Shanmugam, V.; Shanmugam, A. Extraction, characterization and in vitro antioxidative potential of chitosan and sulfated chitosan from cuttlebone of Sepia aculeata Orbigny, 1848. Asian Pac. J. Trop. Biomed. 2012, 2, 14–18. [Google Scholar] [CrossRef]

- Younesa, I.; Ghorbel-Bellaaj, O.; Nasri, R.; Chaabouni, M.; Rinaudo, M.; Nasri, M. Chitin and chitosan preparation from shrimp shells using optimized enzymatic deproteinization. Process. Biochem. 2012, 47, 2032–2039. [Google Scholar] [CrossRef]

- Mohammed, M.H.; Williams, P.A.; Tverezovskaya, O. Extraction of chitin from prawn shells and conversion to low molecular mass chitosan. Food Hydrocoll. 2013, 31, 166–171. [Google Scholar] [CrossRef]

- Muslim, T.; Rahman, M.H.; Begum, H.A.; Rahman, M.A. Chitosan and carboxymethyl chitosan from fish scales of Labeo rohita. Dhaka Univ. J. Sci. 2013, 61, 145–148. [Google Scholar] [CrossRef]

- Dahmane, E.M.; Taourirte, M.; Eladlani, N.; Rhazi, M. Extraction and characterization of chitin and chitosan from Parapenaeus longirostris from Moroccan local sources. Int. J. Polym. Anal. Charact. 2014, 19, 342–351. [Google Scholar] [CrossRef]

- Hajji, S.; Younes, I.; Ghorbel-Bellaaj, O.; Hajji, R.; Rinaudo, M.; Nasri, M.; Jellouli, K. Structural differences between chitin and chitosan extracted from three different marine sources. Int. J. Biol. Macromol. 2014, 65, 298–306. [Google Scholar] [CrossRef]

- Mohanasrinivasan, V.; Mishra, M.; Paliwal, J.; Singh, S.; Selvarajan, E.; Suganthi, V.; Subathra Devi, C. Studies on heavy metal removal efficiency and antibacterial activity of chitosan prepared from shrimp shell waste. 3 Biotech 2014, 4, 167–175. [Google Scholar] [CrossRef]

- Nwe, N.; Furuike, T.; Tamura, H. Chapter One—Isolation and characterization of chitin and chitosan from marine origin. In Advances in Food and Nutrition Research; Se-Kwon, K., Ed.; Academic Press: Waltham, MA, USA, 2014; Volume 72, pp. 1–15. [Google Scholar]

- Younes, I.; Hajji, S.; Frachet, V.; Rinaudo, M.; Jellouli, K.; Nasri, M. Chitin extraction from shrimp shell using enzymatic treatment. Antitumor, antioxidant and antimicrobial activities of chitosan. Int. J. Biol. Macromol. 2014, 69, 489–498. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Rahman, R.M.; Hrdina, R.; Abdel-Mohsen, A.M.; Fouda, M.M.; Soliman, A.Y.; Mohamed, F.K.; Mohsin, K.; Pinto, T.D. Chitin and chitosan from Brazilian Atlantic Coast: Isolation, characterization and antibacterial activity. Int. J. Biol. Macromol. 2015, 80, 107–120. [Google Scholar] [CrossRef] [PubMed]

- Hajji, S.; Younes, I.; Rinaudo, M.; Jellouli, K.; Nasri, M. Characterization and in vitro evaluation of cytotoxicity, antimicrobial and antioxidant activities of chitosans extracted from three different marine sources. Appl. Biochem. Biotech. 2015, 177, 18–35. [Google Scholar] [CrossRef] [PubMed]

- Kumari, S.; Rath, P.; Kumar, A.S.H.; Tiwari, T. Extraction and characterization of chitin and chitosan from fishery waste by chemical method. Environ. Technol. Innov. 2015, 3, 77–85. [Google Scholar] [CrossRef]

- Ahing, F.A.; Wid, N. Extraction and characterization of chitosan from shrimp shell waste in Sabah. Trans. Sci. Technol. 2016, 3, 227–237. [Google Scholar]

- Apetroaei, M.R.; Zgarian, R.G.; Manea, A.M.; Rău, I.; Tihan, G.T.; Schroder, V. New source of chitosan from Black Sea marine Organisms identification. Mol. Cryst. Liq. Cryst. 2016, 628, 102–109. [Google Scholar] [CrossRef]

- Boarin-Alcalde, L.; Graciano-Fonseca, G. Alkali process for chitin extraction and chitosan production from Nile tilapia (Oreochromis niloticus) scales. Lat. Am. J. Aquat. Res. 2016, 44, 683–688. [Google Scholar] [CrossRef]

- Demir, D.; Öfkeli, F.; Ceylan, S.; Karagülle, N.B. Extraction and characterization of chitin and chitosan from blue crab and synthesis of chitosan cryogel scaffolds. J. Turk. Chem. Soc. Chem. 2016, 33, 131–144. [Google Scholar] [CrossRef]

- Duman, F.; Kaya, M. Crayfish chitosan for microencapsulation of coriander (Coriandrum sativum L.) essential oil. Int. J. Biol. Macromol. 2016, 92, 125–133. [Google Scholar] [CrossRef]

- He, X.; Xing, R.; Li, K.; Qin, Y.; Zou, P.; Liu, S.; Yu, H.; Li, P. Beta-chitosan extracted from Loligo Japonica for a potential use to inhibit Newcastle disease. Int. J. Biol. Macromol. 2016, 82, 614–620. [Google Scholar] [CrossRef]

- Karthik, R.; Manigandan, V.; Saravanan, R.; Rajesh, R.P.; Chandrika, B. Structural characterization and in vitro biomedical activities of sulfated chitosan from Sepia pharaonis. Int. J. Biol. Macromol. 2016, 84, 319–328. [Google Scholar] [CrossRef] [PubMed]

- Kumari, S.; Rath, P.; Sri Hari Kumar, A. Chitosan from shrimp shell (Crangon crangon) and fish scales (Labeorohita): Extraction and characterization. Afr. J. Biotechnol. 2016, 15, 1258–1268. [Google Scholar]

- Sayari, N.; Sila, A.; Abdelmalek, B.E.; Abdallah, R.B.; Ellouz-Chaabouni, S.; Bougatef, A.; Balti, R. Chitin and chitosan from the Norway lobster byproducts: Antimicrobial and anti-proliferative activities. Int. J. Biol. Macromol. 2016, 87, 163–171. [Google Scholar] [CrossRef] [PubMed]

- Abdelmalek, B.E.; Sila, A.; Haddar, A.; Bougatef, A.; Ayadi, M.A. β-Chitin and chitosan from squid gladius: Biological activities of chitosan and its application as clarifying agent for apple juice. Int. J. Biolog. Macromol. 2017, 104, 953–962. [Google Scholar] [CrossRef] [PubMed]

- Ben Seghir, B.; Benhamza, M.H. Preparation, optimization and characterization of chitosan polymer from shrimp shells. J. Food Meas. Charact. 2017, 11, 1137–1147. [Google Scholar] [CrossRef]

- Kumari, S.; Annamareddy, S.H.K.; Abanti, S.; Rath, P.K. Physicochemical properties and characterization of chitosan synthesized from fish scales, crab and shrimp shells. Int. J. Biol. Macromol. 2017, 104, 1697–1705. [Google Scholar] [CrossRef] [PubMed]

- Premasudha, P.; Vanathi, P.; Abirami, M. Extraction and characterization of chitosan from crustacean waste: A constructive waste management approach. Int. J. Sci. Res. 2017, 6, 1194–1198. [Google Scholar]

- de Queiroz Antonino, R.S.C.M.; Lia Fook, B.R.P.; de Oliveira Lima, V.A.; de Farias Rached, R.Í.; Lima, E.P.N.; da Silva Lima, R.J.; Peniche Covas, C.A.; Lia Fook, M.V. Preparation and characterization of chitosan obtained from shells of shrimp (Litopenaeus vannamei Boone). Mar. Drugs 2017, 15, 141. [Google Scholar] [CrossRef]

- Ramasamy, P.; Subhapradha, N.; Thinesh, T.; Selvin, J.; Selvan, K.M.; Shanmugam, V.; Shanmugam, A. Characterization of bioactive chitosan and sulfated chitosan from Doryteuthis singhalensis (Ortmann, 1891). Int. J. Biol. Macromol. 2017, 99, 682–691. [Google Scholar] [CrossRef]

- Takarina, N.D.; Fanani, A.A. Characterization of chitin and chitosan synthesized from red snapper (Lutjanus sp.) scale’s waste. AIP Conf. Proc. 2017, 1862. [Google Scholar] [CrossRef]

- Takarina, N.D.; Nasrul, A.A.; Nurmarina, A. Degree of deacetylation of chitosan extracted from white snapper (Lates sp.) scales waste. Int. J. Pharma Med. Biol. Sci. 2017, 6, 16–19. [Google Scholar] [CrossRef]

- Hamdi, M.; Hajji, S.; Affes, S.; Taktak, W.; Maâlej, H.; Nasri, M.; Nasri, R. Development of a controlled bioconversion process for the recovery of chitosan from blue crab (Portunus segnis) exoskeleton. Food Hydrocoll. 2018, 77, 534–548. [Google Scholar] [CrossRef]

- Huang, C.Y.; Kuo, C.H.; Wu, C.H.; Ku, M.W.; Chen, P.W. Extraction of crude chitosans from squid (Illex argentinus) pen by a compressional puffing-pretreatment process and evaluation of their antibacterial activity. Food Chem. 2018, 254, 217–223. [Google Scholar] [CrossRef] [PubMed]

- Muley, A.B.; Chaudhari, S.A.; Mulchandani, K.H.; Singhal, R.S. Extraction and characterization of chitosan from prawn shell waste and its conjugation with cutinase for enhanced thermo-stability. Int. J. Biol. Macromol. 2018, 111, 1047–1058. [Google Scholar] [CrossRef] [PubMed]

- Rubini, D.; Farisa Banu, S.; Veda Hari, B.N.; Ramya Devi, D.; Gowrishankar, S.; Karutha Pandian, S.; Nithyanand, P. Chitosan extracted from marine biowaste mitigates staphyloxanthin production and biofilms of Methicillin-resistant Staphylococcus aureus. Food Chem. Toxicol. 2018, 118, 733–744. [Google Scholar] [CrossRef] [PubMed]

- Srinivasan, H.; Velayutham, K.; Ravichandran, R. Chitin and chitosan preparation from shrimp shells Penaeus monodon and its human ovarian cancer cell line, PA-1. Int. J. Biol. Macromol. 2018, 107, 662–667. [Google Scholar] [CrossRef]

- Tokatli, K.; Demirdöven, A. Optimization of chitin and chitosan production from shrimp wastes and characterization. J. Food Process. Preserv. 2018, 42, e13494. [Google Scholar] [CrossRef]

- Arasukumar, B.; Prabakaran, G.; Gunalan, B.; Moovendhan, M. Chemical composition, structural features, surface morphology and bioactivities of chitosan derivatives from lobster (Thenus unimaculatus) shells. Int. J. Biol. Macromol. 2019, 135, 1237–1245. [Google Scholar] [CrossRef]

- Boudouaia, N.; Bengharez, Z.; Jellali, S. Preparation and characterization of chitosan extracted from shrimp shells waste and chitosan film: Application for Eriochrome black T removal from aqueous solutions. Appl. Water Sci. 2019, 9, 91. [Google Scholar] [CrossRef]

- Metin, C.; Alparslan, Y.; Baygar, T.; Baygar, T. Physicochemical, microstructural and thermal characterization of chitosan from blue crab shell waste and its bioactivity characteristics. J. Polym. Environ. 2019, 27, 2552–2561. [Google Scholar] [CrossRef]

- Ni’mah, Y.L.; Harmami, H.; Ulfin, I.; Suprapto, S.; Saleh, C.W. Water-soluble chitosan preparation from marine sources. Mal. J. Fund. Appl. Sci. 2019, 15, 159–163. [Google Scholar] [CrossRef]

- Pădurețu, C.C.; Isopescu, R.; Rău, I.; Apetroaei, M.R.; Schröder, V. Influence of the parameters of chitin deacetylation process on the chitosan obtained from crab shell waste. Korean J. Chem. Eng. 2019, 36, 1890–1899. [Google Scholar] [CrossRef]

- Pădurețu, C.C.; Isopescu, R.; Gîjiu, C.L.; Rău, I.; Apetroaei, M.R.; Schröder, V. Optimization of chitin extraction procedure from shrimp waste using Taguchi method and chitosan characterization. Mol. Cryst. Liq. Cryst. 2019, 695, 19–28. [Google Scholar] [CrossRef]

- Singh, A.; Benjakul, S.; Prodpran, T. Ultrasound-assisted extraction of chitosan from squid pen: Molecular characterization and fat binding capacity. J. Food Sci. 2019, 84, 224–234. [Google Scholar] [CrossRef]

- Tolesa, L.D.; Gupta, B.S.; Lee, M.J. Chitin and chitosan production from shrimp shells using ammonium-based ionic liquids. Int. J. Biolog. Macromol. 2019, 130, 818–826. [Google Scholar] [CrossRef]

- Aldila, H.; Asmar Fabiani, V.A.; Dalimunthe, D.Y.; Irwanto, R. The effect of deproteinization temperature and NaOH concentration on deacetylation step in optimizing extraction of chitosan from shrimp shells waste. IOP Conf. Ser. Earth Environ. Sci. 2020, 599, 012003. [Google Scholar] [CrossRef]

- Trung, T.S.; Van Tan, N.; Van Hoa, N.; Minh, N.C.; Loc, P.T.; Stevens, W.F. Improved method for production of chitin and chitosan from shrimp shells. Carbohydr. Res. 2020, 489, 107913. [Google Scholar] [CrossRef]

- Salah, R.; Michaud, P.; Mati, F.; Harrat, Z.; Lounici, H.; Abdi, N.; Drouiche, N.; Mameri, N. Anticancer activity of chemically prepared shrimp low molecular weight chitin evaluation with the human monocyte leukaemia cell line, THP-1. Int. J. Biol. Macromol. 2013, 52, 333–339. [Google Scholar] [CrossRef]

- Yen, M.T.; Yang, J.H.; Mau, J.L. Antioxidant properties of chitosan from crab shells. Carbohydr. Polym. 2008, 74, 840–844. [Google Scholar] [CrossRef]

- Goy, R.C.; de Britto, D.; Assis, O.B.G. A review of the antimicrobial activity of chitosan. Polim. Cienc. E Tecnol. 2009, 19, 241–247. [Google Scholar] [CrossRef]

- Vongchan, P.; Sajomsang, W.; Kasinrerk, W.; Subyen, D.; Kongtawelert, P. Anticoagulant activities of the chitosan polysulfate synthesized from marine crab shell by semi-heterogeneous conditions. Sci. Asia 2003, 29, 115–120. [Google Scholar] [CrossRef]

- Dash, M.; Chiellini, F.; Ottenbrite, R.M.; Chiellini, E. Chitosan—A versatile semi-synthetic polymer in biomedical applications. Prog. Polym. Sci. 2011, 36, 981–1014. [Google Scholar] [CrossRef]

- Parvez, S.; Rahman, M.M.; Khan, M.A.; Khan, M.A.H.; Islam, J.M.M.; Ahmed, M.; Rahman, M.F.; Ahmed, B. Preparation and characterization of artificial skin using chitosan and gelatin composites for potential biomedical application. Polym. Bull. 2012, 69, 715–731. [Google Scholar] [CrossRef]

- Muzzarelli, R.A.; Muzzarelli, C. Chitosan chemistry: Relevance to the biomedical sciences. Adv. Polym. Sci. 2005, 186, 151–209. [Google Scholar]

- Riva, R.; Ragelle, H.; des Rieux, A.; Duhem, N.; Jérôme, C.; Préat, V. Chitosan and chitosan derivatives in drug delivery and tissue engineering. Adv. Polym. Sci. 2011, 244, 19–44. [Google Scholar]

- Mahmoud, N.S.; Ghaly, A.E.; Arab, F. Unconventional approach for demineralization of deproteinized crustacean shells for chitin production. Am. J. Biochem. Biotechnol. 2007, 3, 1–9. [Google Scholar] [CrossRef]

- Li, Q.; Dunn, E.T.; Grandmaison, E.W.; Goosen, M.F.A. Applications and properties of chitin and chitosan. In Applications of Chitin and Chitosan; Mattheus, F.A., Goosen, M.F.A., Eds.; Chitin Recovery; Technomic Publishing Company: Lancaster, PA, USA, 1997; Volume 37, pp. 1359–1366. [Google Scholar]

- Khoushab, F.; Yamabhai, M. Chitin research revisited. Mar. Drugs 2010, 8, 1988–2012. [Google Scholar] [CrossRef]

- Limam, Z.; Selmi, S.; Sadok, S.; El Abed, A. Extraction and characterization of chitin and chitosan from crustacean byproducts: Biological and physicochemical properties. Afr. J. Biotechnol. 2011, 10, 640–647. [Google Scholar]

- Kato, Y.; Onishi, H.; Machida, Y. Application of chitin and chitosan derivatives in the pharmaceutical field. Curr. Pharm. Biotechnol. 2003, 4, 303–309. [Google Scholar] [CrossRef]

- Kim, S.K.; Mendis, E. Bioactive compounds from marine processing byproducts—A review. Food Res. Int. 2006, 39, 383–393. [Google Scholar] [CrossRef]

- Muzzarelli, R.A.A.; Boudrant, J.; Meyer, D.; Manno, N.; Demarchis, M.; Paoletti, M.G. Current views on fungal chitin/chitosan, human chitinases, food preservation, glucans, pectins and inulin: A tribute to Henri Braconnot, precursor of the carbohydrate polymers science, on the chitin bicentennial. Carbohydr. Polym. 2012, 87, 995–1012. [Google Scholar] [CrossRef]

- Leceta, I.; Guerrero, P.; Cabezudo, S.; Caba, K.D.L. Environmental assessment of chitosan-based films. J. Clean. Prod. 2013, 41, 312–318. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Sillanpää, M. Applications of chitin-and chitosan-derivatives for the detoxification of water and wastewater-a short review. Adv. Colloid Interface 2009, 152, 26–38. [Google Scholar] [CrossRef] [PubMed]

- Jin, R.D.; Suh, J.W.; Park, R.D.; Kim, Y.W.; Krishnan, H.B.; Kim, K.Y. Effect of chitin compost and broth on biological control of Meloidogyne incognita on tomato (Lycopersicon esculentum Mill.). Nematology 2005, 7, 125–132. [Google Scholar] [CrossRef]

- Venkatesan, J.; Lowe, B.; Anil, S.; Manivasagan, P.; Kheraif, A.A.A.; Kang, K.H.; Kim, S.K. Seaweed polysaccharides and their potential biomedical applications. Starch 2015, 67, 381–390. [Google Scholar] [CrossRef]

- Aranaz, I.; Harris, R.; Heras, A. Chitosan amphiphilic derivatives. Chemistry and applications. Curr. Org. Chem. 2010, 14, 308–330. [Google Scholar] [CrossRef]

- Cárdenas, G.; Cabrera, G.; Taboada, E.; Rinaudo, M. Synthesis and characterization of chitosan alkyl phosphates. J. Chil. Chem. Soc. 2006, 51, 815–820. [Google Scholar] [CrossRef]

- Jayakumar, R.; Nagahama, H.; Furuike, T.; Tamura, H. Synthesis of phosphorylated chitosan by novel method and its characterization. Int. J. Biol. Macromol. 2008, 42, 335–339. [Google Scholar] [CrossRef]

- Jayakumar, R.; Nwe, N.; Tokura, S.; Tamura, H. Sulfated chitin and chitosan as novel biomaterials. Int. J. Biol. Macromol. 2007, 40, 175–181. [Google Scholar] [CrossRef]

- Jayakumar, R.; Reis, R.; Mano, J. Chemistry and applications of phosphorylated chitin and chitosan. e-Polymers 2006, 35, 1–16. [Google Scholar] [CrossRef]

- Jayakumar, R.; Selvamurugan, N.; Nair, S.; Tokura, S.; Tamura, H. Preparative methods of phosphorylated chitin and chitosan—An overview. Int. J. Biol. Macromol. 2008, 43, 221–225. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Huang, L.; Wang, X.; Ma, J.; Xie, F. Biodegradation and compressive strength of phosphorylated chitosan/chitosan/hydroxyapatite bio-composites. Mater. Des. 2011, 32, 4543–4547. [Google Scholar] [CrossRef]

- Li, B.; Huang, L.; Wang, X.; Ma, J.; Xie, F.; Xia, L. Effect of micropores and citric acid on the bioactivity of phosphorylated chitosan/chitosan/hydroxyapatite composites. Ceram. Int. 2013, 39, 3423–3427. [Google Scholar] [CrossRef]

- Li, Q.L.; Chen, Z.Q.; Darvell, B.W.; Liu, L.K.; Jiang, H.B.; Zen, Q.; Peng, Q.; Ou, G.M. Chitosan-phosphorylated chitosan polyelectrolyte complex hydrogel as an osteoblast carrier. J. Biomed. Mater. Res. 2007, 82, 481–486. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Chen, Z.; Darvell, B.; Zeng, Q.; Li, G.; Ou, G.; Wu, M. Biomimetic synthesis of the composites of hydroxyapatite and chitosan–phosphorylated chitosan polyelectrolyte complex. Mater. Lett. 2006, 60, 3533–3536. [Google Scholar] [CrossRef]

- Li, Q.; Huang, L.N.; Chen, Z.; Tang, X. Biomimetic synthesis of the nanocomposite of phosphorylatd chitosan and hydroxyapatite and its bioactivity in vitro. Key Eng. Mater. 2007, 330–332, 721–724. [Google Scholar] [CrossRef]

- Li, Z.; Ramay, H.R.; Hauch, K.D.; Xiao, D.; Zhang, M. Chitosan-alginate hybrid scaffolds for bone tissue engineering. Biomaterials 2005, 26, 3919–3928. [Google Scholar] [CrossRef]

- Chesnutt, B.M.; Yuan, Y.; Brahmandam, N.; Yang, Y.; Ong, J.L.; Haggard, W.O.; Bumgardner, J.D. Characterization of biomimetic calcium phosphate on phosphorylated chitosan films. J. Biomed. Mater. Res. Part A 2007, 82, 343–353. [Google Scholar] [CrossRef]

- Cao, Z.; Xu, H.; Tang, R.; Wei, W.; Xu, W. Synthesis, characterization and molluscicidal activity of triphenyltin phosphorylated chitosan. Chem. Bull./Huaxue Tongbao 2008, 71, 528–532. [Google Scholar]

- Datta, P.; Dhara, S.; Chatterjee, J. Hydrogels and electrospun nanofibrous scaffolds of N-methylene phosphonic chitosan as bioinspired osteoconductive materials for bone grafting. Carbohydr. Polym. 2012, 87, 1354–1362. [Google Scholar] [CrossRef]

- Liu, J.; Zheng, Y.; Wang, W.; Wang, A. Preparation and swelling properties of semi-IPN hydrogels based on chitosan-g-poly(acrylic acid) and phosphorylated polyvinyl alcohol. J. Appl. Polym. Sci. 2009, 114, 643–652. [Google Scholar] [CrossRef]

- Srakaew, V.; Ruangsri, P.; Suthin, K.; Thunyakitpisal, P.; Tachaboonyakiat, W. Sodium-phosphorylated chitosan/zinc oxide complexes and evaluation of their cytocompatibility: An approach for periodontal dressing. J. Biomater. Appl. 2012, 27, 403–412. [Google Scholar] [CrossRef] [PubMed]

- Yeh, H.Y.; Lin, J.C. Surface phosphorylation for polyelectrolyte complex of chitosan and its sulfonated derivative: Surface analysis, blood compatibility and adipose derived stem cell contact properties. J. Biomater. Sci. Polym. Ed. 2012, 23, 233–250. [Google Scholar] [CrossRef]

- Zhao, D.; Xu, J.; Wang, L.; Du, J.; Dong, K.; Wang, C.; Liu, X. Study of two chitosan derivatives phosphorylated at hydroxyl or amino groups for application as flocculants. J. Appl. Polym. Sci. 2012, 125, E299–E305. [Google Scholar] [CrossRef]

- Saiki, I.; Murata, J.; Nakajima, M.; Tokura, S.; Azuma, I. Inhibition by sulfated chitin derivatives of invasion through extracellular matrix and enzymatic degradation by metastatic melanoma cells. Cancer Res. 1990, 50, 3631–3637. [Google Scholar]

- Ryzhenkov, V.E.; Solovyeva, M.A.; Remesova, O.V.; Okunevich, I.V. Hypolipidemic action of sulfated polysaccharides. Voprosy Meditsinskoj Khimii 1996, 42, 118–119. [Google Scholar]

- Kornilaeva, G.V.; Makarova, T.V.; Gamzazade, A.I.; Sklyar, A.M.; Nasibov, S.M.; Karamov, E.V. Sulphated chitosan derivatives as HIV-infection inhibitors. Immunologiya 1995, 1, 13–16. [Google Scholar]

- Hirano, S.; Tanaka, Y.; Hasegawa, M.; Tobetto, K.; Nishioka, A. Effect of sulfated derivatives of chitosan on some blood coagulant factors. Carbohydr. Res. 1985, 137, 205–215. [Google Scholar] [CrossRef]

- Gamzazade, A.; Sklyar, A.; Nasibov, S.; Sushkov, I.; Shashkov, A.; Knirel, Y. Structural features of sulfated chitosans. Carbohydr. Polym. 1997, 34, 113–116. [Google Scholar] [CrossRef]

- Mariappan, M.R.; Alas, E.A.; Williams, J.G.; Prager, M.D. Chitosan and chitosan sulfate have opposing effects on collagen-fibroblast interactions. Wound Repair Regen. 1999, 7, 400–406. [Google Scholar] [CrossRef]

- Ma, B.; Huang, W.; Kang, W.; Yan, J. Studies on preparation of sulfated derivatives of chitosan from Mucor rouxianus. Ion Exch. Adsorpt. 2007, 23, 451–458. [Google Scholar]

- Vongchan, P.; Sajomasang, W.; Subyen, D.; Kongtawelert, P. Anticoagulant activity of a sulfated chitosan. Carbohydr. Res. 2002, 337, 1239–1242. [Google Scholar] [CrossRef]

- Ou, Y.; Wu, Y.; Li, H.; Wang, K.; Zhang, D. Synthesis, characterization and antibacterial activity of hybrid materials of rare earth and chitosan. J. Chin. Rare Earth Soc. 2013, 31, 211–216. [Google Scholar] [CrossRef]

- Xing, R.; Liu, S.; Yu, H.; Zhang, Q.; Li, Z.; Li, P. Preparation of low-molecular-weight and highsulfate-content chitosans under microwave radiation and their potential antioxidant activity in vitro. Carbohyd. Res. 2004, 339, 2515–2519. [Google Scholar] [CrossRef] [PubMed]

- Xing, R.; Yu, H.; Liu, S.; Zhang, W.; Zhang, Q.; Li, Z. Antioxidative activity of differently regioselective chitosan sulfates in vitro. Bioorg. Med. Chem. 2005, 13, 1387–1392. [Google Scholar] [CrossRef]

- Karadeniz, F.; Karagozlu, M.Z.; Pyun, S.Y.; Kim, S.K. Sulfation of chitosan oligomers enhances their anti-adipogenic effect in 3T3-L1 adipocytes. Carbohydr. Polym. 2011, 86, 666–671. [Google Scholar] [CrossRef]

- Fan, L.; Wu, P.; Zhang, J.; Gao, S.; Wang, L.; Li, M.; Sha, M.; Xie, W.; Nie, M. Synthesis and anticoagulant activity of the quaternary ammonium chitosan sulfates. Int. J. Biol. Macromol. 2012, 50, 31–37. [Google Scholar] [CrossRef]

- Pires, N.R.; Cunha, P.L.; Maciel, J.S.; Angelim, A.L.; Melo, V.M.; De Paula, R.C.; Feitosa, J.P. Sulfated chitosan as tear substitute with no antimicrobial activity. Carbohydr. Polym. 2013, 91, 92–99. [Google Scholar] [CrossRef]

- Shelma, R.; Sharma, C.P. Development of lauroyl sulfated chitosan for enhancing hemocompatibility of chitosan. Colloid. Surf. B 2011, 84, 561–570. [Google Scholar] [CrossRef]

- Fang, S.W.; Li, C.F.; Shih, D.Y.C. Antifungal activity of chitosan and its preservative effect on low-sugar candied kumwuat. J. Food Prot. 1994, 56, 136–140. [Google Scholar] [CrossRef]

- Chung, Y.-C.; Chen, C.-Y. Antibacterial characteristics and activity of acid-soluble chitosan. Bioresour. Technol. 2008, 99, 2806–2814. [Google Scholar] [CrossRef] [PubMed]

- Eaton, P.; Fernandes, J.C.; Pereira, E.; Pintado, M.E.; Malcata, F.X. Atomic force microscopy study of the antibacterial effects of chitosans on Escherichia coli and Staphylococcus aureus. Ultramicroscopy 2008, 108, 1128–1134. [Google Scholar] [CrossRef] [PubMed]

- Helander, I.M.; Nurmiaho-Lassila, E.L.; Ahvenainen, R.; Rhoades, J.; Roller, S. Chitosan disrupts the barrier properties of the outer membrane of gram-negative bacteria. Int. J. Food Microbiol. 2001, 71, 235–244. [Google Scholar] [CrossRef]

- Assis, O.B.G.; Pessoa, J.D.C. Scientific note: Preparation of thin films of chitosan for use as edible coatings to inhibit fungal growth on sliced fruits. Braz. J. Food Sci. Tech. 2004, 7, 17–22. [Google Scholar]

- Másson, M.; Holappa, J.; Hjálmarsdóttir, M.; Rúnarsson, Ö.; Nevalainen, T.; Järvinen, T. Antimicrobial activity of piperazine derivatives of chitosan. Carbohydr. Polym. 2008, 74, 566–571. [Google Scholar] [CrossRef]

- Khanafari, A.; Marandi, R.; Sanatei, S. Recovery of chitin and chitosan from shrimp waste by chemical and microbal methods. Iran. J. Environ. Health Sci. Eng. 2008, 5, 19–24. [Google Scholar]

- Li, Q.; Dunn, E.T.; Grandmaison, E.W.; Goosen, M.F.A. Applications and properties of chitosan. J. Bioact. Compat. Polym. 1992, 7, 370–397. [Google Scholar] [CrossRef]

- Farley, J.; Clear, N.; Leroy, B.; Davis, T.; Mcpherson, G. Age, growth and preliminary estimates of maturity of bigeye tuna, Thunnus obesus, in the Australian region. Mar. Freshwater Res. 2006, 57, 713–724. [Google Scholar] [CrossRef]

- Lee, J.K.; Lim, H.S.; Kim, J.H. Cytotoxic activity of aminoderivatized cationic chitosan derivatives. J. Bioorgan. Med. Chem. Lett. 2002, 12, 2949–2951. [Google Scholar] [CrossRef]

- Lee, D.-W.; Shirley, S.A.; Lockey, R.F.; Mohapatra, S.S. Thiolated chitosan nanoparticles enhance anti-inflammatory effects of intranasally delivered theophylline. Respir. Res. 2006, 7, 112. [Google Scholar] [CrossRef]

- Quan, H.; Zhu, F.; Han, X.; Xu, Z.; Zhao, Y.; Miao, Z. Mechanism of anti-angiogenic activities of chitooligosaccharides may be through inhibiting heparanase activity. Med. Hypotheses 2009, 73, 205–206. [Google Scholar] [CrossRef] [PubMed]

- Pangestuti, R.; Kim, S.-K. Neuroprotective properties of chitosan and its derivatives. Mar. Drugs 2010, 8, 2117–2128. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, J.C.; Tavaria, F.K.; Soares, J.C.; Ramos, O.S.; Monteiro, M.J.; Pintado, M.E.; Xavier Malcata, F. Antimicrobial effects of chitosans and chitooligosaccharides, upon Staphylococcus aureus and Escherichia coli, in food model systems. Food Microbiol. 2008, 25, 922–928. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhou, P.; Yu, J.; Pan, X.; Wang, P.; Lan, W.; Tao, S. Antimicrobial effect of chitooligosaccharides produced by chitosanase from Pseudomonas CUY8. Asia Pac. J. Clin. Nutr. 2007, 16, 174–177. [Google Scholar] [PubMed]

- Yang, E.J.; Kim, J.G.; Kim, J.Y.; Kim, S.C.; Lee, N.H.; Hyun, C.G. Anti-inflammatory effect of chitosan oligosaccharides in RAW 264.7 cells. Cent. Eur. J. Biol. 2010, 5, 95–102. [Google Scholar] [CrossRef]

- Sonia, T.A.; Sharma, C.P. Chitosan and Its Derivatives for Drug Delivery Perspective. Adv. Polym. Sci. 2011, 243, 23–54. [Google Scholar]

- Mourya, V.K.; Inamdar, N.N. Trimethyl chitosan and its applications in drug delivery. J. Mater. Sci. Mater. Med. 2009, 20, 1057–1079. [Google Scholar] [CrossRef]

- Jarmila, V.; Vavríková, E. Chitosan derivatives with antimicrobial, antitumour and antioxidant activities-a review. Curr. Pharm. Des. 2011, 17, 3596–3607. [Google Scholar]

- Kato, Y.; Onishi, H.; Machida, Y. Contribution of chitosan and its derivatives to cancer chemotherapy. In Vivo 2005, 19, 301–310. [Google Scholar]

- Bayat, A.; Sadeghi, A.M.M.; Avadi, M.R.; Amini, M.; Rafiee-Tehrani, M.; Shafiee, A.; Majlesi, R.; Junginger, H.E. Synthesis of N,N-dimethyl N-ethyl chitosan as a carrier for oral delivery of peptide drugs. J. Bioact. Compat. Polym. 2006, 21, 433–444. [Google Scholar] [CrossRef]

- Kofuji, K.; Qian, C.J.; Nishimura, M.; Sugiyama, I.; Murata, Y.; Kawashima, S. Relationship between physicochemical characteristics and functional properties of chitosan. Eur. Polym. J. 2005, 41, 2784–2791. [Google Scholar] [CrossRef]

- Cerdá, C.; Sánchez, C.; Climent, B.; Vázquez, A.; Iradi, A.; El Amrani, F.; Bediaga, A.; Sáez, G.T. Oxidative stress and DNA damage in obesity-related tumorigenesis. Adv. Exp. Med. Biol. 2014, 824, 5–17. [Google Scholar] [PubMed]

- Wölfle, U.; Seelinger, G.; Bauer, G.; Meinke, M.C.; Lademann, J.; Schempp, C.M. Reactive molecule species and antioxidative mechanisms in normal skin and skin aging. Ski. Pharmacol. Physiol. 2014, 27, 316–332. [Google Scholar] [CrossRef] [PubMed]

- Ito, N.; Hirose, M.; Fukushima, H.; Tsuda, T.; Shirai, T.; Tatenatsu, M. Studies on antioxidants: Their carcinogenic and modifying effects on chemical carcinogens. Food Chem. Toxicol. 1986, 24, 1071–1092. [Google Scholar] [CrossRef]

- Manda, G.; Nechifor, M.T.; Neagu, T.M. Reactive oxygen species, cancer and anticancer therapies. Curr. Chem. Biol. 2009, 3, 342–366. [Google Scholar] [CrossRef]

- Zhang, N.; Bradley, T.A.; Zhang, C. Inflammation and reactive oxygen species in cardiovascular Disease. World J. Cardiol. 2010, 2, 408–410. [Google Scholar] [CrossRef]

- Zhang, J.; Xia, W.; Liu, P.; Cheng, Q.; Tahirou, T.; Gu, W.; Li, B. Chitosan modification and pharmaceutical/biomedical applications. Mar. Drugs 2010, 8, 1962–1987. [Google Scholar] [CrossRef]

- Cui, H.; Kong, Y.; Zhang, H. Oxidative stress, mitochondrial dysfunction, and aging. J. Signal. Transduct 2012, 2012, 646354. [Google Scholar] [CrossRef]

- Filippin, L.I.; Vercelino, R.; Marroni, N.P.; Xavier, R.M. Redox signalling and the inflammatory response in rheumatoid arthritis. Clin. Exp. Immunol. 2008, 152, 415–422. [Google Scholar] [CrossRef]

- Park, B.K.; Kim, M.-M. Applications of chitin and its derivatives in biological medicine. Int. J. Mol. Sci. 2010, 11, 5152–5164. [Google Scholar] [CrossRef]

- Kerch, G. The potential of chitosan and its derivatives in prevention and treatment of age-related diseases. Mar. Drugs 2015, 13, 2158–2182. [Google Scholar] [CrossRef] [PubMed]

- Younes, I.; Rinaudo, M. Chitin and chitosan preparation from marine sources. Structure, properties and applications. Mar. Drugs 2015, 13, 1133–1174. [Google Scholar] [CrossRef] [PubMed]

- Harish Prashanth, K.V.; Tharanathan, R.N. Chitin/chitosan: Modifications and their unlimited application potential—An overview. Trends Food Sci. Technol. 2007, 18, 117–131. [Google Scholar] [CrossRef]

- Tharanathan, R.N.; Kittur, F.S. Chitin—The undisputed biomolecule of great potential. Crit. Rev. Food Sci. Nutr. 2003, 43, 61–87. [Google Scholar] [CrossRef]

- No, H.K.; Meyers, S.P.; Prinyawiwatkul, W.; Xu, Z. Applications of chitosan for improvement of quality and shelf life of foods: A review. J. Food Sci. 2007, 72, 87–100. [Google Scholar] [CrossRef] [PubMed]

- Kamil, J.Y.V.A.; Jeon, Y.J.; Shahidi, F. Antioxidative activity of chitosans of different viscosity in cooked comminuted flesh of herring (Clupea harengus). Food Chem. 2002, 79, 69–77. [Google Scholar] [CrossRef]

- Kim, K.W.; Thomas, R.L. Antioxidative activity of chitosans with varying molecular weights. Food Chem. 2007, 101, 308–313. [Google Scholar] [CrossRef]

- Pittayapruek, P.; Meephansan, J.; Prapapan, O.; Komine, M.; Ohtsuki, M.; Maki, M. Role of matrix metalloproteinases in photoaging and photocarcinogenesis. Int. J. Mol. Sci. 2016, 17, 868. [Google Scholar] [CrossRef]

- Yoo, S.-J.; Go, E.; Kim, Y.-E.; Lee, S.; Kwon, J. Roles of reactive oxygen species in rheumatoid arthritis pathogenesis. J. Rheum. Dis. 2016, 23, 340–347. [Google Scholar] [CrossRef]

- Mirshafiey, A.; Mohsenzadegan, M. The role of reactive oxygen species in immunopathogenesis of rheumatoid arthritis. Iran. J. Allergy Asthma Immunol. 2008, 7, 195–202. [Google Scholar]

- Rahman, T.; Hosen, I.; Islam, M.M.T.; Shekhar, H.U. Oxidative stress and human health. Adv. Biosci. Biotechnol. 2012, 3, 997–1019. [Google Scholar] [CrossRef]

- Aranaz, I.; Mengíbar, M.; Harris, R.; Paños, I.; Miralles, B.; Acosta, N.; Galed, G.; Heras, A. Functional characterization of chitin and chitosan. Curr. Chem. Biol. 2009, 3, 203–230. [Google Scholar]

- Bhattacharya, S. Reactive oxygen species and cellular defense system. In Free Radicals in Human Health and Disease; Rani, V., Yadav, U.C.S., Eds.; Springer: New Delhi, India, 2015; pp. 17–29. [Google Scholar]

- Lushchak, V.I. Free radicals, reactive oxygen species, oxidative stress and its classification. Chem. Biol. Interact. 2014, 224, 164–175. [Google Scholar] [CrossRef] [PubMed]

- Patlevic, P.; Vascova, J.; Svork, P., Jr.; Vasko, L.; Svork, P. Reactive oxygen species and antioxidant defense in human gastrointestinal diseases. Integr. Med. Res. 2016, 5, 250–258. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Chattopadhyay, R.; Mitra, S.; Crowe, S.E. Oxidative stress: An essential factor in the pathogenesis of gastrointestinal mucosal diseases. Physiol. Rev. 2014, 94, 329–354. [Google Scholar] [CrossRef]

- Sun, T.; Zhou, D.; Xie, J.; Mao, F. Preparation of chitosan oligomers and their antioxidant activity. Eur. Food Res. Technol. 2007, 225, 451–456. [Google Scholar] [CrossRef]

- Chang, S.; Wu, C.; Tsai, G.J. Effects of chitosan molecular weight on its antioxidant and antimutagenic properties. Carbohydr. Polym. 2018, 181, 1026–1032. [Google Scholar] [CrossRef]

- Božič, M.; Gorgieva, S.; Kokol, V. Laccase-mediated functionalization of chitosan by caffeic and galic acids for modulating antioxidant and antimicrobial properties. Carbohydr. Polym. 2012, 87, 2388–2398. [Google Scholar] [CrossRef]

- Xie, W.; Xu, P.; Liu, Q. Antioxidant activity of water-soluble chitosan derivatives. Bioorg. Med. Chem. Lett. 2001, 11, 1699–1701. [Google Scholar] [CrossRef]

- Sousa, F.; Guebitz, G.M.; Kokol, V. Antimicrobial and antioxidant properties of chitosan enzymatically functionalized with flavonoids. Process. Biochem. 2009, 44, 749–756. [Google Scholar] [CrossRef]

- Fernandes, J.C.; Eaton, P.; Nascimento, H.; Gião, M.S.; Ramos, Ó.S.; Belo, L.; Santos-Silva, A.; Pintado, M.E.; Malcata, F.X. Antioxidant activity of chitooligosaccharides upon two biological systems: Erythrocytes and bacteriophages. Carbohydr. Polym. 2010, 79, 1101–1106. [Google Scholar] [CrossRef]

- Li, Q.; Sun, X.; Gu, G.; Guo, Z. Novel water soluble chitosan derivatives with 1,2,3-triazolium and their free radical-scavenging activity. Mar. Drugs 2018, 16, 107. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Sun, H.; Dong, F.; Xue, Q.; Wang, G.; Qin, S.; Guo, Z. The influence of the cation of quaternized chitosans on antioxidant activity. Carbohydr. Polym. 2009, 78, 439–443. [Google Scholar] [CrossRef]

- Wan, A.; Xu, Q.; Sun, Y.; Li, H. Antioxidant activity of high molecular weight chitosan and N,O-quaternized chitosans. J. Agric. Food Chem. 2013, 61, 6921–6928. [Google Scholar] [CrossRef]

- Rajoka, M.S.R.; Zhao, L.; Mehwish, H.M.; Wu, Y.; Mahmood, S. Chitosan and its derivatives: Synthesis, biotechnological applications, and future challenges. Appl. Microbiol. Biotechnol. 2019, 103, 1557–1571. [Google Scholar] [CrossRef]

- Iqbal, P.; Preece, J.A.; Mendes, P.M. Nanotechnology: The “top-down” and “bottom-up” approaches. In Supramolecular Chemistry; John Wiley & Sons: Chichester, UK, 2012. [Google Scholar]

- Liu, D.G.; Chang, P.R.; Chen, M.D.; Wu, Q.L. Chitosan colloidal suspension composed of mechanically disassembled nanofibers. J. Colloid Interface Sci. 2010, 354, 637–643. [Google Scholar] [CrossRef]

- Zhou, C.; Wu, Q. A novel polyacrylamide nanocomposite hydrogel reinforced with natural chitosan nanofibers. Colloids Surf. B Biointerfaces 2011, 84, 155–162. [Google Scholar] [CrossRef]

- Wijesena, R.; Tissera, N.; Kannankgara, Y.; Lin, Y.; Amaratunga, G.; de Silva, N. A method for top down preparation of chitosan nanoparticles and nanofibers. Carbohydr. Polym. 2015, 117, 731–738. [Google Scholar] [CrossRef]

- Ifuku, S.; Shervani, Z.; Saimoto, H. Preparation of chitin nanofibers and their composites. In Biopolymer Nanocomposite; Dufresne, A., Thomas, S., Pothan, L.A., Eds.; Wiley: Hoboken, NJ, USA, 2013; Volume 2, pp. 11–32. [Google Scholar]

- Fan, Y.M.; Saito, T.; Isogai, A. TEMPO-mediated oxidation of beta-chitin to prepare individual nanofibrils. Carbohydr. Polym. 2009, 77, 832–838. [Google Scholar] [CrossRef]

- Tanaka, K.; Yamamoto, K.; Kadokawa, J. Facile nanofibrillation of chitin derivatives by gas bubbling and ultrasonic treatments in water. Carbohydr. Res. 2014, 398, 25–30. [Google Scholar] [CrossRef]

- Kadokawa, J. Fabrication of nanostructured and microstructured chitin materials through gelation with suitable dispersion media. RSC Adv. 2015, 5, 12736–12746. [Google Scholar] [CrossRef]

- Li, F.; Zhang, X.; Li, H.; Xiang, L.; Chen, Y. Preparation of self-assembled nanoparticles of chitosan oligosaccharide-graft-polycaprolactone as a carrier of bovine serum albumin drug. Bio-Med. Mater. Eng. 2014, 24, 2041–2048. [Google Scholar] [CrossRef] [PubMed]

- Raja, M.A.; Zeenat, S.; Arif, M.; Liu, C. Self-assembled nanoparticles based on amphiphilic chitosan derivative and arginine for oral curcumin delivery. Int. J. Nanomed. 2016, 11, 4397–4412. [Google Scholar] [CrossRef]

- Raabe, D.; Romano, P.; Sachs, C.; Fabritius, H.; Al-Sawalmih, A.; Yi, S.B.; Servos, G.; Hartwig, H.G. Microstructure and crystallographic texture of the chitin-protein network in the biological composite material of the exoskeleton of the lobster Homarus americanus. Mater. Sci. Eng. 2006, 421, 143–153. [Google Scholar] [CrossRef]

- Ifuku, S.; Nogi, M.; Abe, K.; Yoshioka, M.; Morimoto, M.; Saimoto, H.; Yano, H. Simple preparation method of chitin nanofibers with a uniform width of 10–20 nm from prawn shell under neutral conditions. Carbohydr. Polym. 2011, 84, 762–764. [Google Scholar] [CrossRef]

- Kim, S.K. Chitin and Chitosan Derivatives: Advances in Drug Discovery and Developments; Kim, S.K., Ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Tan, W.; Krishnaraj, R.; Desai, T.A. Evaluation of nanostructured composite collagen-chitosan matrices for tissue engineering. Tissue Eng. 2001, 7, 203–210. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, M. Calcium phosphate/chitosan composite scaffolds for controlled in vitro antibiotic drug release. J. Biomed. Mater. Res. 2002, 62, 378–386. [Google Scholar] [CrossRef]

- Kong, L.; Gao, Y.; Cao, W.; Gong, Y.; Zhao, N.; Zhang, X. Preparation and characterization of nano-hydroxyapatite/chitosan composite scaffolds. J. Biomed. Mater. Res. A 2005, 75, 275–282. [Google Scholar] [CrossRef]

- Huang, R.Y.M.; Pal, R.; Moon, G.Y. Crosslinked chitosan composite membrane for the pervaporation dehydration of alcohol mixtures and enhancement of structural stability of chitosan/polysulfone composite membranes. J. Membr. Sci. 1999, 160, 17–30. [Google Scholar] [CrossRef]

- Martino, A.D.; Sittinger, M.; Risbud, M.V. Chitosan: A versatile biopolymer for orthopaedic tissue-engineering. Biomaterials 2005, 26, 5983–5990. [Google Scholar] [CrossRef]

- Thein-Han, W.; Misra, R. Biomimetic chitosan–nanohydroxyapatite composite scaffolds for bone tissue engineering. Acta Biomater. 2009, 5, 1182–1197. [Google Scholar] [CrossRef] [PubMed]

- Badawy, M.E.I.; Rabea, E.I.; Rogge, T.M.; Stevens, C.V.; Smagghe, G.; Steurbaut, W.; Hofte, M. Synthesis and fungicidal activity of new N,O-acyl chitosan derivatives. Biomacromolecules 2004, 5, 589–595. [Google Scholar] [CrossRef] [PubMed]

- Badawy, M.E.I.; Rabea, E.I.; Rogge, T.M.; Stevens, C.V.; Steurbaut, W.; Höfte, M.; Smagghe, G. Fungicidal and insecticidal activity of O-acyl chitosan derivatives. Polym. Bull. 2005, 54, 279–289. [Google Scholar] [CrossRef]

- Ruiz, G.A.M.; Corrales, H.F.Z. Chitosan, Chitosan Derivatives and their Biomedical Applications. In Biological Activities and Application of Marine Polysaccharides; Shalaby, E.A., Ed.; InTech Open: London, UK, 2017. [Google Scholar]

- Zahedi, S.; Ghomi, J.S.; Shahbazi-Alavi, H. Preparation of chitosan nanoparticles from shrimp shells and investigation of its catalytic effect in diastereoselective synthesis of dihydropyrroles. Ultrason. Sonochem. 2018, 40, 260–264. [Google Scholar] [CrossRef]

- Mourya, V.K.; Inamdar, N.N.; Choudhari, Y.M. Chitooligosaccharides: Synthesis, characterization and applications. Polym. Sci. Ser. A 2011, 53, 583–612. [Google Scholar] [CrossRef]

- Aam, B.B.; Heggset, E.B.; Norberg, A.L.; Sørlie, M.; Vårum, K.M.; Eijsink, V.G.H. Production of chitooligosaccharides and their potential applications in medicine. Mar. Drugs 2010, 8, 1482–1517. [Google Scholar] [CrossRef]

- Wang, H.; Mukherjee, S.; Yi, J.; Banerjee, P.; Chen, Q.; Zhou, S. Biocompatible chitosan-carbon dot hybrid nanogels for NIR-imaging-guided synergistic photothermal-chemo therapy. ACS Appl. Mater. Interfaces 2017, 9, 18639–18649. [Google Scholar] [CrossRef]

- Sahu, P.; Kashaw, S.K.; Jain, S.; Sau, S.; Iyer, A.K. Assessment of penetration potential of pH responsive double walled biodegradable nanogels coated with eucalyptus oil for the controlled delivery of 5-fluorouracil: In vitro and ex vivo studies. J. Control. Release 2017, 253, 122–136. [Google Scholar] [CrossRef]

- Belabassi, Y.; Moreau, J.; Gheran, V.; Henoumont, C.; Robert, A.; Callewaert, M.; Rigaux, G.; Cadiou, C.; Vander Elst, L.; Laurent, S.; et al. Synthesis and characterization of PEGylated and fluorinated chitosans: Application to the synthesis of targeted nanoparticles for drug delivery. Biomacromolecules 2017, 18, 2756–2766. [Google Scholar] [CrossRef]

- Ju, C.; Mo, R.; Xue, J.; Zhang, L.; Zhao, Z.; Xue, L.; Ping, Q.; Zhang, C. Sequential intra-intercellular nanoparticle delivery system for deep tumor penetration. Angew. Chem. Int. Ed. Engl. 2014, 53, 6253–6258. [Google Scholar] [CrossRef]

- Woraphatphadung, T.; Sajomsang, W.; Rojanarata, T.; Ngawhirunpat, T.; Tonglairoum, P.; Opanasopit, P. Development of chitosan-based pH-sensitive polymeric micelles containing curcumin for colon-targeted drug delivery. AAPS Pharm. Sci. Tech. 2018, 19, 991–1000. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Sun, J.; Qiu, Y.; Li, W.; Guo, X.; Li, Q.; Zhang, H.; Zhou, J.; Du, Y.; Yuan, H.; et al. Specific photothermal therapy to the tumors with high EphB4 receptor expression. Biomaterials 2015, 68, 32–41. [Google Scholar] [CrossRef] [PubMed]

- Shen, L.; Huang, Y.; Chen, D.; Qiu, F.; Ma, C.; Jin, X.; Zhu, X.; Zhou, G.; Zhang, Z. pH-responsive aerobic nanoparticles for effective photodynamic Therapy. Theranostics 2017, 7, 4537–4550. [Google Scholar] [CrossRef]

- Wang, G.; Wang, J.J.; Tang, X.J.; Du, L.; Li, F. In vitro and in vivo evaluation of functionalized chitosan-Pluronic micelles loaded with myricetin on glioblastoma cancer. Nanomedicine 2016, 12, 1263–1278. [Google Scholar] [CrossRef] [PubMed]

- Shi, S.; Zhang, Z.; Luo, Z.; Yu, J.; Liang, R.; Li, X.; Chen, H. Chitosan grafted methoxy poly(ethylene glycol)-poly(epsilon-caprolactone) nanosuspension for ocular delivery of hydrophobic diclofenac. Sci. Rep. 2015, 5, 11337–11348. [Google Scholar] [CrossRef]

- Zhao, X.; Zhou, L.; Li, Q.; Zou, Q.; Du, C. Biomimetic mineralization of carboxymethyl chitosan nanofibers with improved osteogenic activity in vitro and in vivo. Carbohydr. Polym. 2018, 195, 225–234. [Google Scholar] [CrossRef]

- Marques, J.; Valle-Delgado, J.J.; Urban, P.; Baro, E.; Prohens, R.; Mayor, A.; Cistero, P.; Delves, M.; Sinden, R.E.; Grandfils, C.; et al. Adaptation of targeted nanocarriers to changing requirements in antimalarial drug delivery. Nanomedicine 2017, 13, 515–525. [Google Scholar] [CrossRef]

- Li, F.; Mei, H.; Gao, Y.; Xie, X.; Nie, H.; Li, T.; Zhang, H.; Jia, L. Co-delivery of oxygen and erlotinib by aptamer-modified liposomal complexes to reverse hypoxia-induced drug resistance in lung cancer. Biomaterials 2017, 145, 56–71. [Google Scholar] [CrossRef]

- Luo, L.; Bian, Y.; Liu, Y.; Zhang, X.; Wang, M.; Xing, S.; Li, L.; Gao, D. Combined near infrared photothermal therapy and chemotherapy using gold nanoshells coated liposomes to enhance antitumor effect. Small 2016, 12, 4103–4112. [Google Scholar] [CrossRef]

- Sun, M.; Li, J.; Zhang, C.; Xie, Y.; Qiao, H.; Su, Z.; Oupicky, D.; Ping, Q. Arginine-modified nanostructured lipid carriers with charge-reversal and pH-sensitive membranolytic properties for anticancer drug delivery. Adv. Healthc. Mater. 2017, 6, 1600693–1600705. [Google Scholar] [CrossRef]

- Yan, L.; Crayton, S.H.; Thawani, J.P.; Amirshaghaghi, A.; Tsourkas, A.; Cheng, Z. A pH-responsive drug-delivery platform based on glycol chitosan-coated liposomes. Small 2015, 11, 4870–4874. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.Y.; Crake, C.; Teo, B.; Carugo, D.; de Saint Victor, M.; Seth, A.; Stride, E. Ultrasound-enhanced siRNA delivery using magnetic nanoparticle-loaded chitosan-deoxycholic acid nanodroplets. Adv. Healthc. Mater. 2017, 6, 1601246–1601254. [Google Scholar] [CrossRef] [PubMed]

- Kang, M.L.; Kim, J.E.; Im, G.I. Thermoresponsive nanospheres with independent dual drug release profiles for the treatment of osteoarthritis. Acta Biomater. 2016, 39, 65–78. [Google Scholar] [CrossRef] [PubMed]

- Jiang, K.; Chi, T.; Li, T.; Zheng, G.; Fan, L.; Liu, Y.; Chen, X.; Chen, S.; Jia, L.; Shao, J. A smart pH-responsive nano-carrier as a drug delivery system for the targeted delivery of ursolic acid: Suppresses cancer growth and metastasis by modulating P53/MMP-9/PTEN/CD44 mediated multiple signaling pathways. Nanoscale 2017, 9, 9428–9439. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; He, Z.; Sun, C.; Yang, C.; Zhao, P.; Liu, L.; Leong, K.W.; Mao, H.Q.; Liu, Z.; Chen, Y. Uniform core-shell nanoparticles with thiolated hyaluronic acid coating to enhance oral delivery of insulin. Adv. Healthc. Mater. 2018, 7, 1800285–1800296. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Svirskis, D.; Lu, W.; Ying, M.; Huang, Y.; Wen, J. N-trimethyl chitosan nanoparticles and CSKSSDYQC peptide: N-trimethyl chitosan conjugates enhance the oral bioavailability of gemcitabine to treat breast cancer. J. Control. Release 2018, 277, 142–153. [Google Scholar] [CrossRef] [PubMed]

- Nascimento, A.V.; Singh, A.; Bousbaa, H.; Ferreira, D.; Sarmento, B.; Amiji, M.M. Overcoming cisplatin resistance in non-small cell lung cancer with Mad2 silencing siRNA delivered systemically using EGFR-targeted chitosan nanoparticles. Acta Biomater. 2017, 47, 71–80. [Google Scholar] [CrossRef]

- Lee, J.Y.; Termsarasab, U.; Lee, M.Y.; Kim, D.H.; Lee, S.Y.; Kim, J.S.; Cho, H.J.; Kim, D.D. Chemosensitizing indomethacin-conjugated chitosan oligosaccharide nanoparticles for tumor-targeted drug delivery. Acta Biomater. 2017, 57, 262–273. [Google Scholar] [CrossRef]

- Taghavi, S.; Ramezani, M.; Alibolandi, M.; Abnous, K.; Taghdisi, S.M. Chitosan-modified PLGA nanoparticles tagged with 5TR1 aptamer for in vivo tumor-targeted drug delivery. Cancer Lett. 2017, 400, 1–8. [Google Scholar] [CrossRef]

| Source | Method | Type of Conditions | Deacetylation Degree (%) | References |

|---|---|---|---|---|

| Squid pens (Loligo formosana) | Chemical | Chitin was treated with 60% NaOH, 1/10 (w/v) for 60 min at 100 °C. | 90% | Methacanon et al. [51] |

| Squid pens (Loligo lessoniana and Loligo formosana) | Chemical | Chitin was treated with 50% NaOH, 1/15 (w/v) for 8 h at 100 °C. | 92–93% | Chandumpai et al. [52] |

| Lobster | Chemical | Chitin was treated with 45% NaOH, at 130 °C for 30 min. | 86% | Fernandez Cerveraa et al. [53] |

| Chemical | Chitin was treated with 49% NaOH, at 130 °C for 30 min. | 89% | ||

| Dublin Bay prawn shell waste (Nephrops norvegicus) | Chemical | Chitin (10 g) was added to reaction flasks, 100 cm3 of 500 g kg−1 NaOH solution was added to each flask, heated for 2 h at 100 °C under a nitrogen atmosphere. | 81.92% | Beaney et al. [54] |

| Shrimp biowaste (heads or shells) | Chemical | Chitin was added with 50% NaOH, 1:20 (w/v) at 50 °C for 48 h. | 81–84% | Rao and Stevens [55] |

| Shrimp shells (Metapenaeopsis dobsoni) | Chemical | Chitin was boiled with 40% NaOH until it got deacetylated to chitosan. | 81% | Sini et al. [56] |

| Shrimp waste | Chemical | Chitin was added with 45% NaOH solution stirring for 90 min and heating at 130 °C. | 90% | Weska et al. [57] |

| Crabs shells | Autoclave | Steeping in strong NaOH for 24 h before heating. Chitin was treated with 40% NaOH solution autoclaved (at 2-atmosphere pressure) for 2.5–3.0 h. | 95% | Abdou et al. [36] |

| Crayfish shells (Procambarus clarkia) | 95% | |||

| Brown shrimp shells (Penaeus aztecus) | 95% | |||

| Pink shrimp shells (Penaeus durarum) | 92% | |||

| Grooved tiger prawn (Penaeus semisulcatus) Jinga Shrimp (Metapenaeus affinis) Blue Swimming Crab-Male (Portunus pelagicus) Blue Swimming Crab-Female (Portunus pelagicus) Scyllarid Lobster (Thenus orientalis) Cuttlefish (Sepia spp.) | Chemical | Chitin was treated with 45% NaOH, 1/15 (w/v) for 10 h at 110 °C. | 88–94.4% | Sagheer et al. [43] |

| Microwave | Chitin was added with 45% NaOH solution and irradiated by microwave for 15 min at 600 W. | 87.5–93.0% | ||

| Snow crab (Chionoecetes opilio) | Chemical | Chitin was treated with 40% NaOH solution at 105 °C for 120 min. | 93.3% | Yen et al. [58] |

| Shrimp shells (Metapeneaus monoceros) | Chemical | Chitin was treated with 50% NaOH at 80 °C for 4 h. | - | Manni et al. [59] |

| Shrimp shells Crab shells | Chemical | Chitin (10 g) was treated with 50% NaOH at 60 °C for 8 h. | 79.80% 65.89% | Zvezdova [60] |

| Shrimp shells (Metapenaeus stebbingi) | Chemical | Chitin was treated with 50% NaOH for 6 h at 120 °C. | 92.19% | Kucukgulmez et al. [61] |

| Shrimp shells (Parapenaeus longirostris) | Chemical | Chitin was added in 50% NaOH solution, stirred for 3–5 h at 90–100 °C. | 80% | Benhabiles et al. [62] |

| Crab shells (Podophthalmus vigil) | Chemical | Chitin was treated in 40% NaOH for 6 h at 110 °C constant stirring. | - | Prabu and Natarajan [63] |

| Cuttlefish (Sepia aculeata) | Chemical | Chitin was treated in 40% NaOH solution by heating under reflux for 6 h at 110˚C. | 49.9% | Vino et al. [64] |

| Shrimp shells (Metapenaeus monoceros) | Chemical | Chitin was treated with 12.5 M NaOH, 1/10 (w/v) at 140 °C for 4 h. | 78% | Younesa et al. [65] |

| Prawn shells (Litopenaeus vannamei) | Chemical | Chitin was treated with 50% NaOH, 1/5 (w/v) for 2 h at 100 °C. | 80% | Mohammed et al. [66] |

| Fish scales (Labeo rohita) | Chemical | Chitin was added to 40% NaOH, 1/15 (w/v), and refluxed under nitrogen atmosphere for 8 h at 100 °C. | 78.2% | Muslim et al. [67] |

| Shrimp waste | Microwave | Chitin was treated with 50% NaOH solution and irradiated by microwave for 10 min at 1400 W. | 95.19% | Samar et al. [44] |

| Shrimp shells (Parapenaeus longirostris) | Chemical | Chitin was treated with 50% NaOH, 1/60 (w/v) for 5 h at 110 °C. | 90% | Dahmane et al. [68] |

| Crab shells (Carcinus mediterraneus) | Chemical | Chitin was treated with 12.5 M NaOH, 1:10 (w/v) for 4 h at 140 °C. | 83% | Hajji et al. [69] |

| Cuttlefish bones (Sepia officinalis) | 95% | |||

| Shrimp waste (Penaeus kerathurus) | 88% | |||

| Shrimp shell waste | Chemical | Chitin was added to 70% NaOH, 1/14 (w/v), and kept room temperature (RT) for 72 h. | 74.82% | Mohanasrinivasan et al. [70] |

| Squid chitin | Chemical | Chitin was treated with 60% NaOH, 1/10 (w/v) for 60 min at 100 °C. | 97.3% | Nwe et al. [71] |

| Crab chitin | Chemical | Chitin was treated with 40% NaOH, 1/30 (w/v) for 120 min at 105 °C. | 93.3% | |

| Shrimp chitin | Chemical | Chitin was treated with 50% NaOH for 20 h at 65 °C. | 87% | |

| Shrimp shells (Metapenaeus monoceros) | Chemical | Chitin was treated with 12.5 M NaOH, 1:10 (w/v) for 4 h at 140 °C. | 81% | Younes et al. [72] |

| Shrimp shells | Chemical | Chitin was refluxed with 50% NaOH, 1/10 (w/v) at 90 °C for 4 h. | 95.5% | Abdel-Rahman et al. [73] |

| Crab shells (Carcinus mediterraneus) | Chemical | Chitin was treated with 12.5 M NaOH, 1/10 (w/v) for 4 h at 140 °C | 83% | Hajji et al. [74] |

| Cuttlefish bones (Sepia officinalis) | 95% | |||

| Shrimp waste (Penaeus kerathurus) | 88% | |||

| Fish scales (Labeo rohita) | Chemical | Steeping in strong NaOH for 24 h before heating. Chitin was treated with 40–50% NaOH for 5–6 h at 100–160 °C. | 61% | Kumari et al. [75] |

| Shrimp shell waste | Chemical | Chitin was treated with 48% NaOH for 48 h at 25 °C. | 70–85%. | Ahing and Wid [76] |

| Shrimp waste | Autoclave | Chitin was added in 50% NaOH, 1/10 (w/v), and autoclaved for 20 min at 15 psi/121 °C. | 70.9% | Al-Hassan [37] |

| Spawning of veined rapa whelk (Rapana venosa) | Chemical | Ten grams of the sample was soaked in 4% NaOH, 1/15 (w/v) at 65 °C for 2 h. | - | Apetroaei et al. [77] |

| Warty crab shells (Eriphia verrucosa) | Chemical | Chitin was treated with 45% NaOH, 1:20 (w/v) at 100 °C, for 15 min. | - | |

| Fish scales (Oreochromis niloticus) | Chemical | Chitin was added in 40% NaOH, 1/40 (w/v), stirred for 6 h (300 rpm) at 117 °C. | 97.5% | Boarin-Alcalde and Graciano-Fonseca [78] |

| Blue crab shell wastes (Callinectes sapidus) | Chemical | Chitin was added in 50% NaOH, 1/10 (w/v), and heated for 4 h at 150 °C. | 85% | Demir et al. [79] |

| Crayfish shells | Chemical | Chitin was treated with 60% NaOH at 100 °C for 4 h. | (Pure chitosan was obtained) | Duman and Kaya [80] |

| Shrimp shells (Parapenaeus longirostris) | Chemical | Chitin was deacetylated with 15 M NaOH, 1/20 (w/v) at 110 °C under vacuum and constant stirring for 5 h. | 73.68% | Hafsa et al. [47] |

| Ultrasonic | Chitin was suspended with 15 M NaOH, 1/20 (w/v), irradiated by ultrasonic (v = 50 kHz) for 3 h. | 83.55% | ||

| Squid pens (Loligo japonica) | Chemical | Chitin was treated with 40% NaOH at 95 °C for 6 h. | 91.04% | He et al. [81] |

| Cuttlebone (Sepia pharaonic) | Chemical | Chitin was treated in hot concentrated NaOH (40–50%) solution to yield chitosan, which was sulfated using chlorosulfonic acid and stirred for 30 min to obtain sulfated chitosan. | 81% | Karthik et al. [82] |

| Shrimp shell (Crangon crangon) | Chemical | Chitin was refluxed in NaOH (50% by weight) at 90 to 100 °C, stirred for 6 h. | 76% | Kumari et al. [83] |

| Fish scale (Labeorohita) | 80% | |||

| Norway lobster (Nephrops norvegicus) | Chemical | Chitin was treated with 50% NaOH for 4 h at 120 °C. | 71.59% | Sayari et al. [84] |

| Shrimp shell (Litopenaeus vannamei) | Autoclave | Extracted with hot sulfuric acid at 95 °C overnight and autoclaved for 20 min at 121 °C. | 76% | Vilar Junior et al. [38] |

| Chemical | Treated with 40–50% NaOH, 1/20 (w/v) at 100–120 °C for 60–720 min. | 81.7% | ||

| Squid gladius (Sepioteuthis lessoniana) | Chemical | Chitin was treated with 50% NaOH at 120 °C for 4 h. | 71% | Abdelmalek et al. [85] |

| Shrimp shells (Parapenaeus longirostris) | Chemical | Chitin was treated with 28.6% NaOH at 81.15 °C for 9.55 h. | 98% | Ben Seghir et al. [86] |

| Crab shells (Crangon crangon) | Chemical | Chitin was treated with 40% KOH for 6 h at 90 °C. | 70% | Kumari et al. [87] |

| Fishery waste (Labeo rohita) | 75% | |||

| Shrimp shells (Crangon crangon) | 78% | |||

| Shrimp shells Crab shells | Chemical | Chitin was treated with 65% NaOH for 72 at 30 °C. | 88.48% 80.12% | Premasudha et al. [88] |

| Shrimp shells (Litopenaeus vannamei) | Chemical | Chitin was added with 12.5 M NaOH, 1:15 (w/v) cooled, kept at −83 °C for 24 h, and stirring (250 rpm) for 4 or 6 h at 115 °C. | 91% | de Queiroz Antonino et al. [89] |

| Squid pin (Doryteuthis singhalensis) | Chemical | Chitin was treated in 40% NaOH solution by heating under reflux for 6 h at 110˚C. | 83.76% | Ramasamy et al. [90] |

| Shrimp waste (Penaeus merguiensis) | Autoclave | Chitin was treated with 45% NaOH, 1/15 (w/v), and autoclaved for 30 min at 15 psi/121 °C. | 88% | Sedaghat et al. [39] |

| Microwave | Chitin was treated with 50% NaOH and irradiated by microwave for 10 min at 1400 W. | |||

| Chemical | Chitin was treated with 50% NaOH at a 1/5 (w/v) ratio for 2 h at 100 °C. | |||

| Shrimp shell waste | Autoclave | One gram of chitin was added in 50% NaOH and autoclaved for 1 h at 121 °C, 15 psi. | - | Varun et al. [40] |

| Fish scales (Red Snapper) | Chemical | Chitin was treated with 80% NaOH, 1/3 (w/v) for 4 h at 110 °C. | 90.83% | Takarina and Fanani [91] |

| Fish scales (White Snapper) | Chemical | Chitin was treated with 80% NaOH for 4 h at 120 °C. | 84.05% | Takarina et al. [92] |

| Blue crab shells (Portunus segnis) | Chemical | Chitin was treated with 12.5 M NaOH, 1/10 (w/v) for 4 h at 140 °C. | 90.39% | Hamdi et al. [93] |

| Squid pen (Illex argentines) | Chemical | Chitin was dissolved in 5% acetic acid, filtered, and precipitated with 8 N NaOH solution, washed with reverse osmosis (RO) water until pH reached 7.0. | 84% | Huang et al. [94] |

| Prawn shells | Chemical | Chitin was refluxed in 50% NaOH solution for 30–150 min at 100 °C. | 78.40% | Muley et al. [95] |

| Crab shells (Portunus sanguinolentus) | Chemical | Chitin was treated with 80% NaOH, 1:20 (w/v) at 90–95 °C for 5h. | 70.79% | Rubini et al. [96] |

| Shrimp shells (Penaeus monodon) | Chemical | One gram of chitin in 50 mL of 50% NaOH, stirred for 50 min at 90 °C, filtered, and treated with 80% alcohol in 1/30 (w/v) ratio for 24 h at 80 °C. | 65% | Srinivasan et al. [97] |

| Shrimp waste | Chemical | Chitosan-1: 40% NaOH 1/20 (w/v) at 120 °C for 300 min. Chitosan-2: 50% NaOH 1/20 (w/v) at 100 °C for 720 min. | 78.2% 84.95% | Tokatli and Demirdöven [98] |

| Lobster shells (Thenus unimaculatus) | Chemical | Chitin was added with 40% NaOH, stirred for 6 h at 110 °C, filtered, treated with 10% acetic acid for 12 h. | - | Arasukumar et al. [99] |

| Shrimp shells waste | Chemical | Chitin was treated with 50% NaOH under agitation for 4 h at 90 °C. | 88% | Boudouaia et al. [100] |

| Shrimp shells (Parapenaeus longirostris) | Microwave | Chitin was treated with 40% NaOH, 1:20 (w/v), heated by microwave at 650 W for 12 min. | 82.8% | EL Knidri et al. [45] |

| Blue crab shell (Callinectes sapidus) | Chemical | Chitin was treated with 50% NaOH, 1/10 (w/v) at 150 °C for 4 h. | 71% | Metin et al. [101] |

| Shrimp shell | Chemical | Chitin was treated with 50% NaOH at 60 °C, dry residue was added into 2% (w/w) acetic acid, 30% H2O2 was added and kept for 4 h. | 64.18% | Ni’mah et al. [102] |

| Mussel shell | 35.03% | |||

| Squid pen | 58.04% | |||

| Crab shell | 53.91% | |||

| Crab shell waste | Chemical | Chitin was treated with 50% NaOH, 1/10 (w/v) for 100 min at 100 °C. | 82% | Pădurețu et al. [103] |

| Shrimp waste | Chemical | Chitin was added with 50% NaOH, 1/15 (w/v), stirred for 2 h (1 h at RT and 1 h at 100 °C). | 84% | Pădurețu et al. [104] |

| Squid pens (Loligo formosana) | Chemical | Chitin was treated with 50% NaOH, 1:50 (w/v) for 8 h at 130 ℃. | 90% | Singh et al. [105] |

| Shrimp waste (Litopenaeus vannamei) | Microwave 1 | Chitin (16, 32, 60 mesh sizes) was treated 45% NaOH, 1/15 (w/v) irradiated in 6 pulses of 5 min at 600 W. | 81, 72, 78% | Santos et al. [46] |

| Microwave 2 | Between each interval, they were stirred for homogenization. | 81, 92, 89% | ||

| Shrimp shells | Chemical | Chitins were mixed with 40% NaOH, 1:10 (w/v), stirred overnight, and the mixture was heated for 12 h at 100 °C. | 93% | Tolesa et al. [106] |

| Fish waste (Sardina pilchardus) | Autoclave | Chitin was added with 40% NaOH and autoclaved for 20 min at 15 psi/121 °C. | 87% | Aboudamia et al. [41] |

| Shrimp shell waste | Chemical | Chitin was added with 50% NaOH, stirred for 1 h at 30 ℃. | 88.89% | Aldila et al. [107] |

| Shrimp residues (Farfantepenaeus aztecus) | Ultrasound | Two grams of shrimp residues powder in 50 mL of CaCl2–MeOH–H2O, stirred for 20 min at 60 °C, ultrasound at 40 kHz 30 min at 60 °C, rest for 48 h at RT. | 65.87% | Borja-Urzola et al. [48] |

| Crab shell (Portunus trituberculatus) | Ultrasonication | Chitin was treated with 50% NaOH, 1:15 (w/v), at 75 ℃ for 3.5 h with sonication. | 86.02% | Huang et al. [49] |

| Omani shrimp waste | Autoclave | Chitin was treated with 50% NaOH, 1:10 (w/v), autoclaved for 15 min at 121 °C. | - | Said Al Hoqani et al. [42] |

| Shrimp shells (Litopenaeus vannamei) | Chemical | Chitin samples (0–9) were treated with 12.5 M NaOH, 1:5 (w/v) at 65 °C for 12 h. | 56.10–88.76% | Trung et al. [108] |

| Shrimp shell and Crab Shells | Graviola extract with magnetic stirring | Shells interacted with graviola leaf extract with magnetic stirring. | 50.97–94.56% | Gopal et al. [50] |

| Nano-chitosan Morphology | Preparation Method | Applications | References |

|---|---|---|---|

| Nanogels | Covalent cross-linking, ion crosslinking, covalent modification | Photothermal therapy–chemotheraphy, controlled drug delivery, deep tumor penetration | [245,246,247,248] |

| Micelles | Covalent modification/self assembly, ion crosslinking | Drug delivery, photodynamic theraphy, ocular delivery | [249,250,251,252,253] |

| Nanofibers | Electrospinning process | Improve osteogenic activity | [254] |

| Liposomes | Covalent modification/self assembly, electrostatic adsorption | Anticancer drug delivery, antimalarial drug delivery, reverse drug resistance, photothermal, and chemotheraphy | [255,256,257,258,259] |

| Nanosphere | Covalent modification/self assembly, electrostatic adsorption, emulsification | siRNA delivery, drug delivery, drug release | [260,261,262] |

| Nanoparticles | Covalent modification/self assembly, ion crosslinking | Oral delivery, siRNA delivery, targeted therapy | [263,264,265,266] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muthu, M.; Gopal, J.; Chun, S.; Devadoss, A.J.P.; Hasan, N.; Sivanesan, I. Crustacean Waste-Derived Chitosan: Antioxidant Properties and Future Perspective. Antioxidants 2021, 10, 228. https://doi.org/10.3390/antiox10020228

Muthu M, Gopal J, Chun S, Devadoss AJP, Hasan N, Sivanesan I. Crustacean Waste-Derived Chitosan: Antioxidant Properties and Future Perspective. Antioxidants. 2021; 10(2):228. https://doi.org/10.3390/antiox10020228

Chicago/Turabian StyleMuthu, Manikandan, Judy Gopal, Sechul Chun, Anna Jacintha Prameela Devadoss, Nazim Hasan, and Iyyakkannu Sivanesan. 2021. "Crustacean Waste-Derived Chitosan: Antioxidant Properties and Future Perspective" Antioxidants 10, no. 2: 228. https://doi.org/10.3390/antiox10020228

APA StyleMuthu, M., Gopal, J., Chun, S., Devadoss, A. J. P., Hasan, N., & Sivanesan, I. (2021). Crustacean Waste-Derived Chitosan: Antioxidant Properties and Future Perspective. Antioxidants, 10(2), 228. https://doi.org/10.3390/antiox10020228