Novel Crosslinked Anion Exchange Membranes Based on Thermally Cured Epoxy Resin: Synthesis, Structure and Mechanical and Ion Transport Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Materials

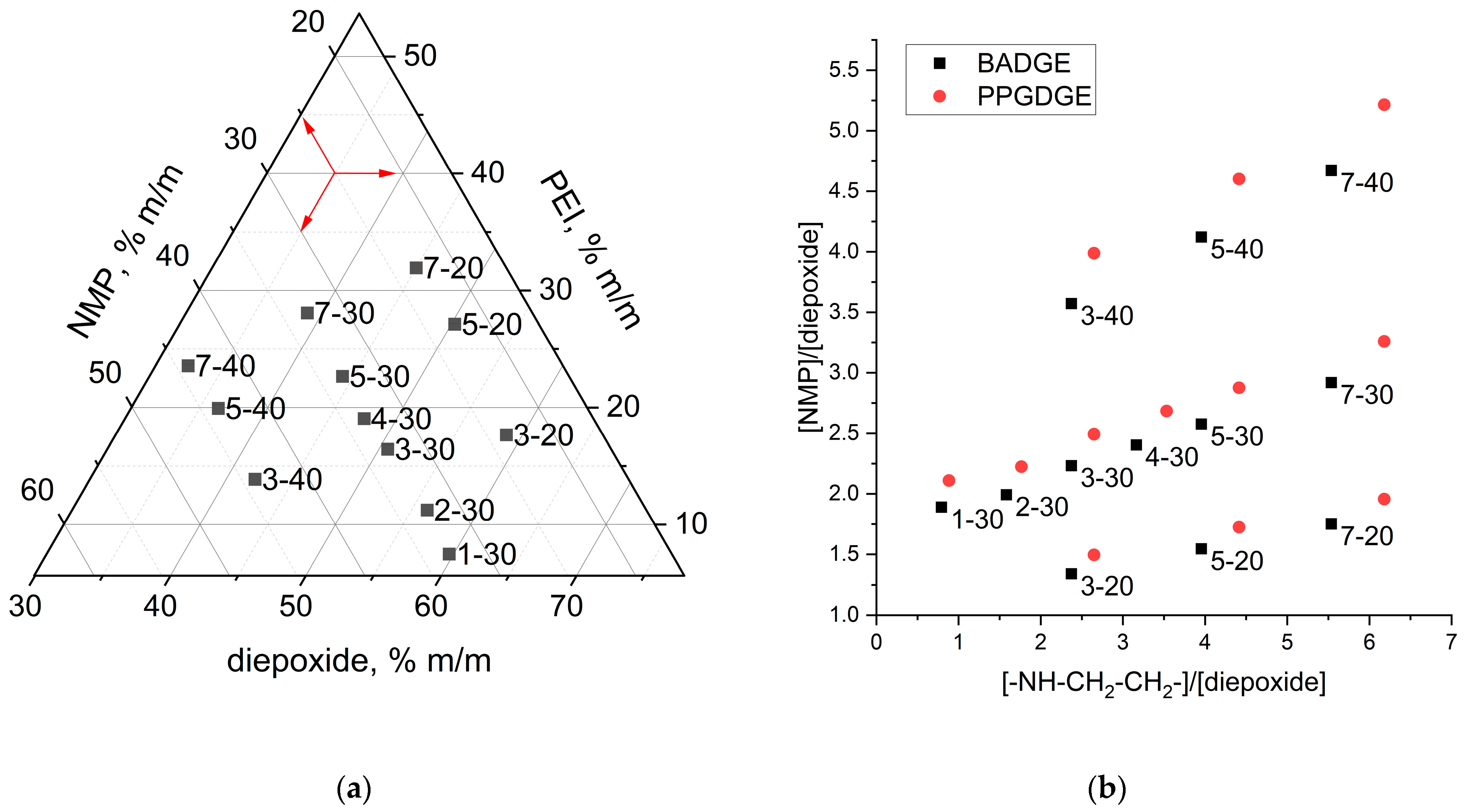

2.2. Membrane Fabrication

2.3. Membrane Structure and Composition

2.4. Membrane Water Uptake and Ion Exchange Capacity

2.5. Differential Scanning Calorimetry

2.6. Mechanical Properties

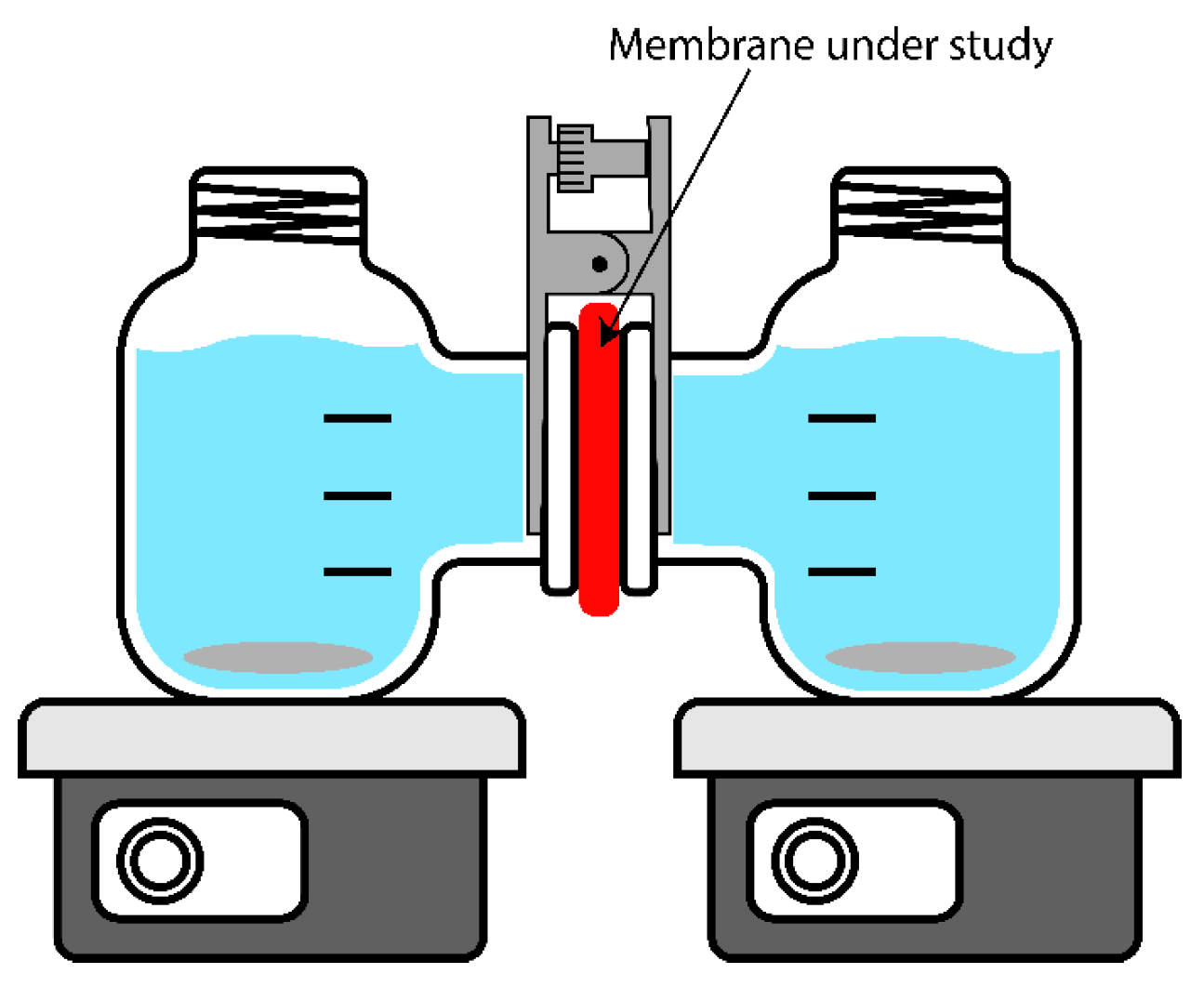

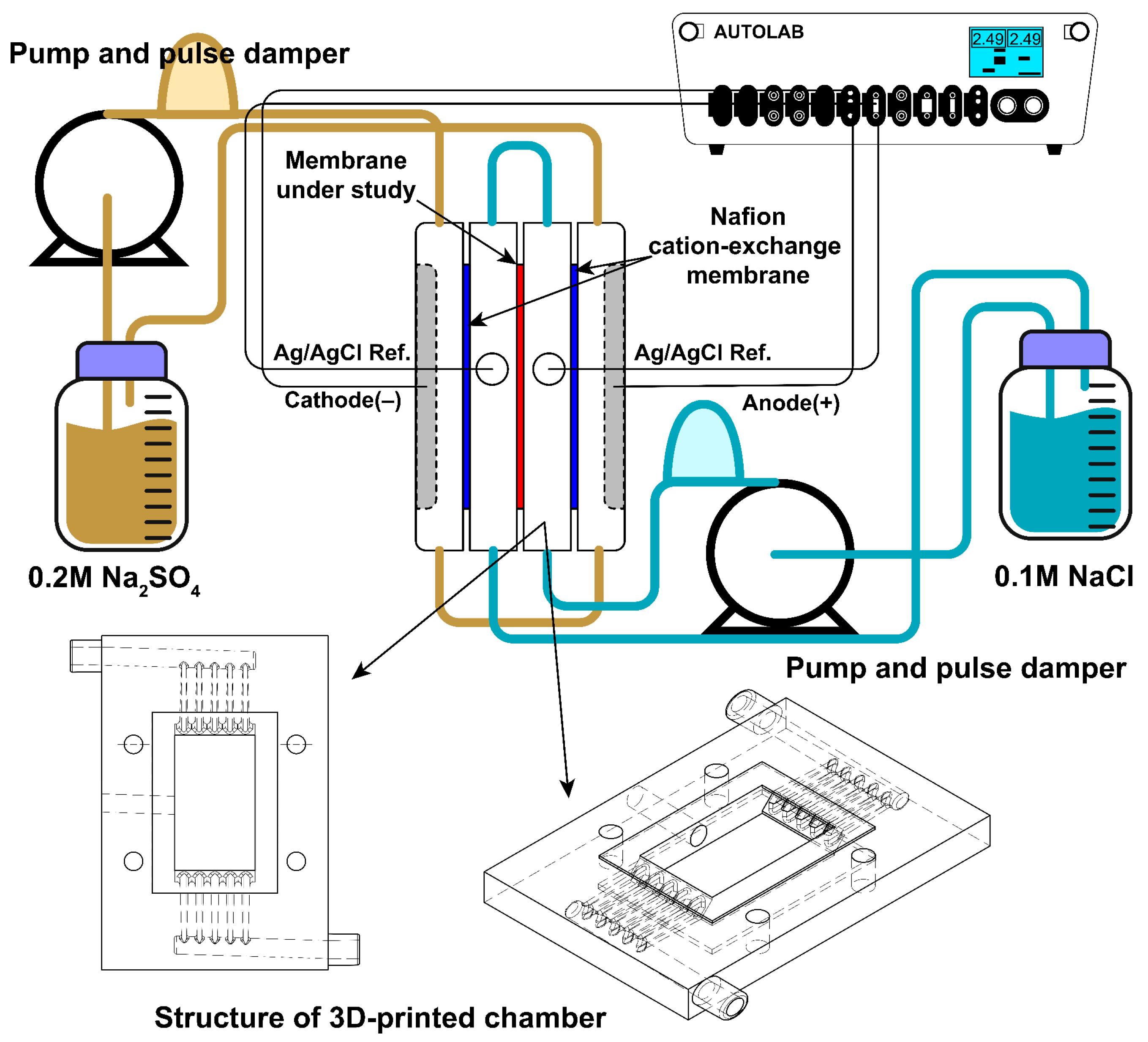

2.7. Membrane Ionic Conductivity, Permselectivity and Salt Diffusion Permeability

2.8. Membrane Voltammetric Characterization

2.9. Diffusion Dialysis Acid Recovery

3. Results and Discussion

3.1. DSC Study of Curing Reaction

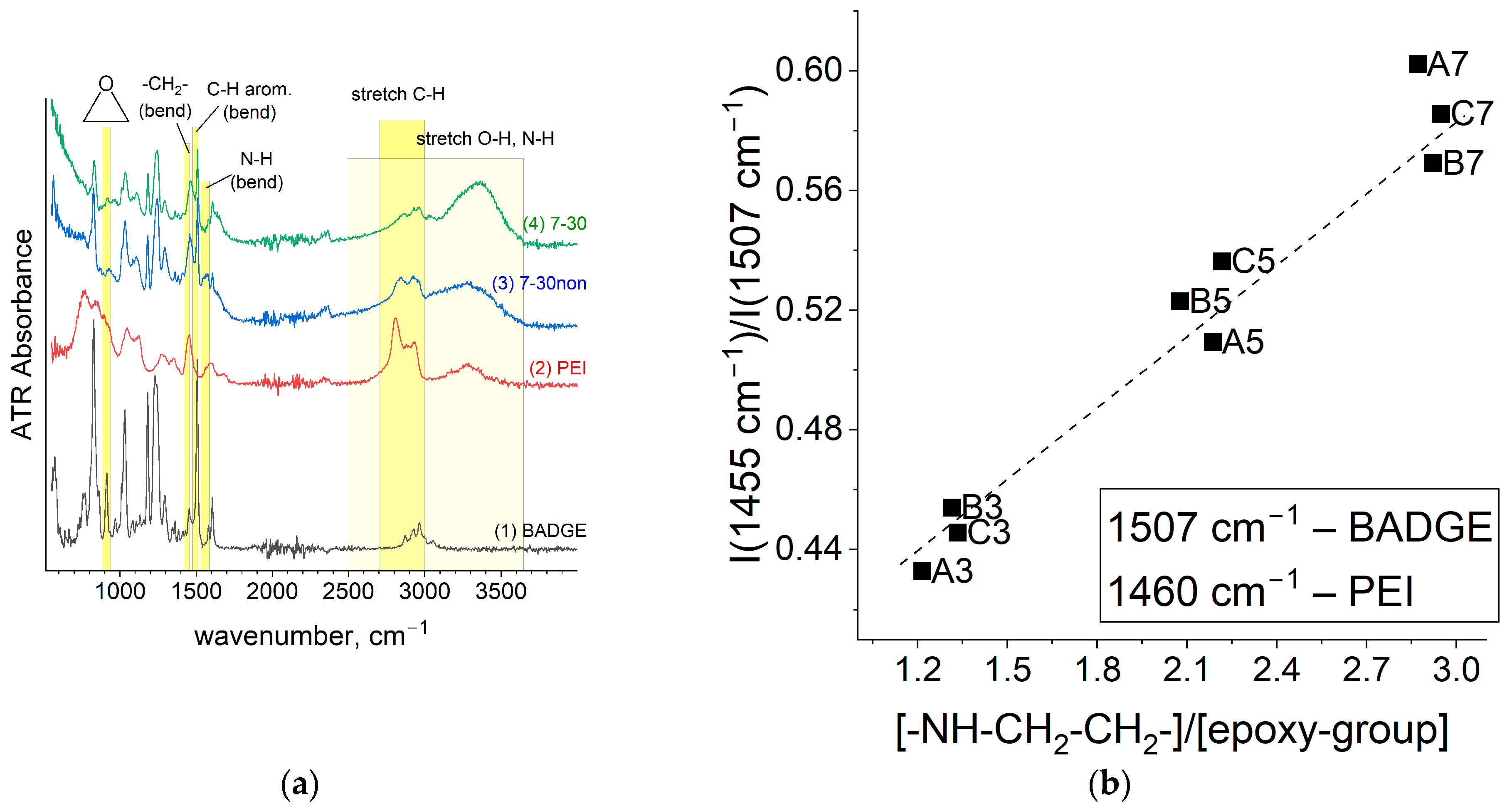

3.2. Membrane Morphology and Composition

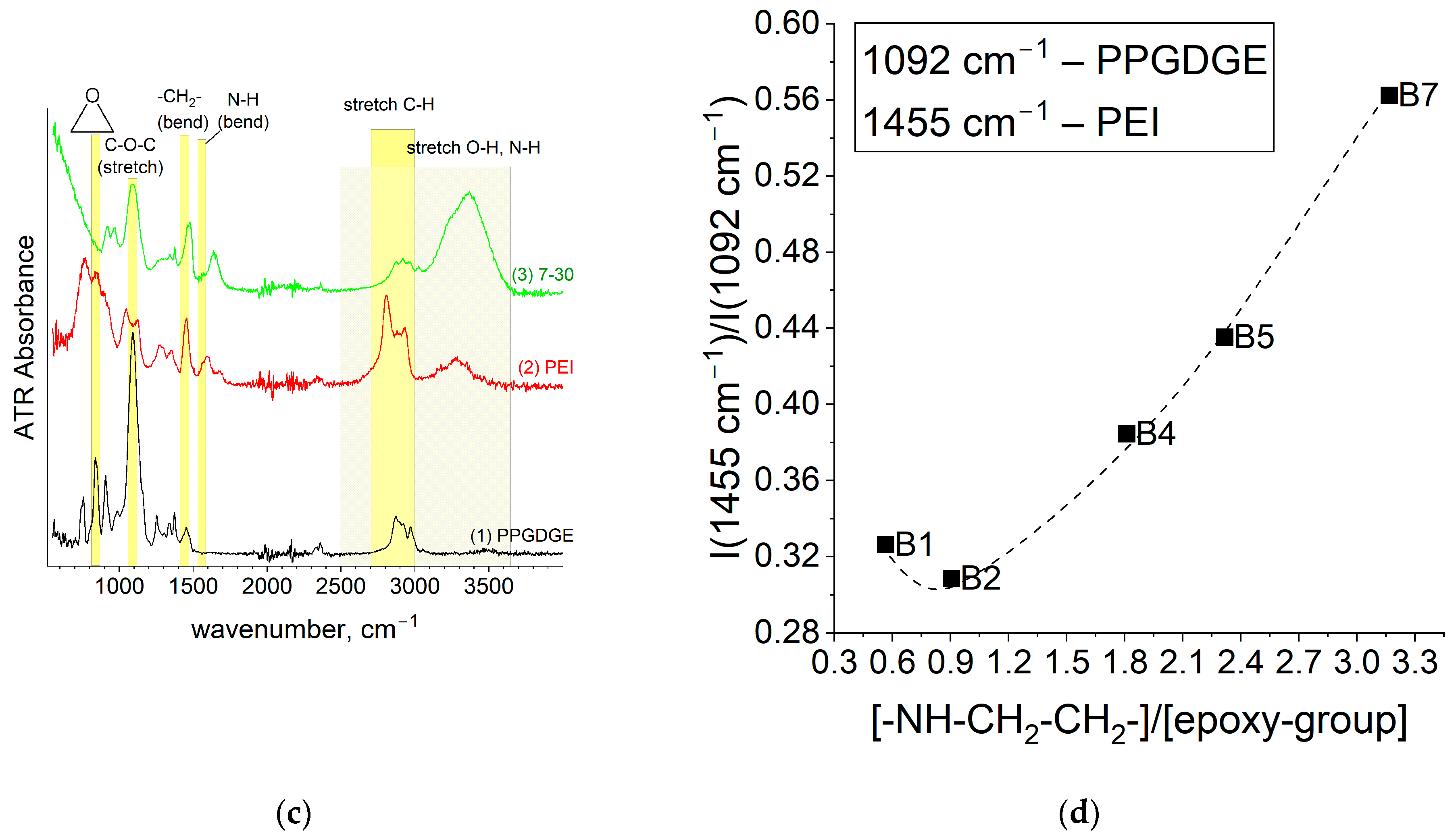

3.2.1. FTIR

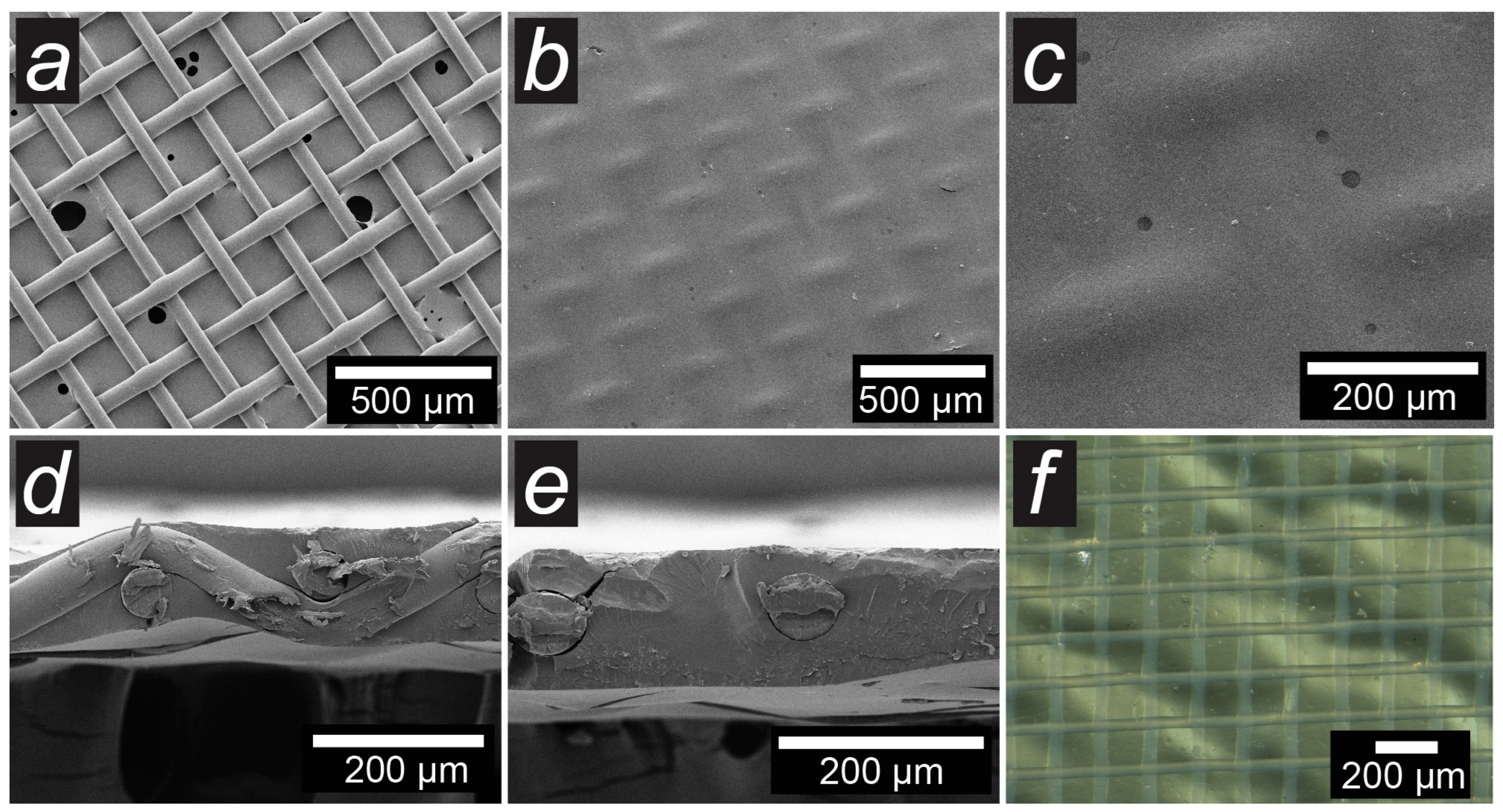

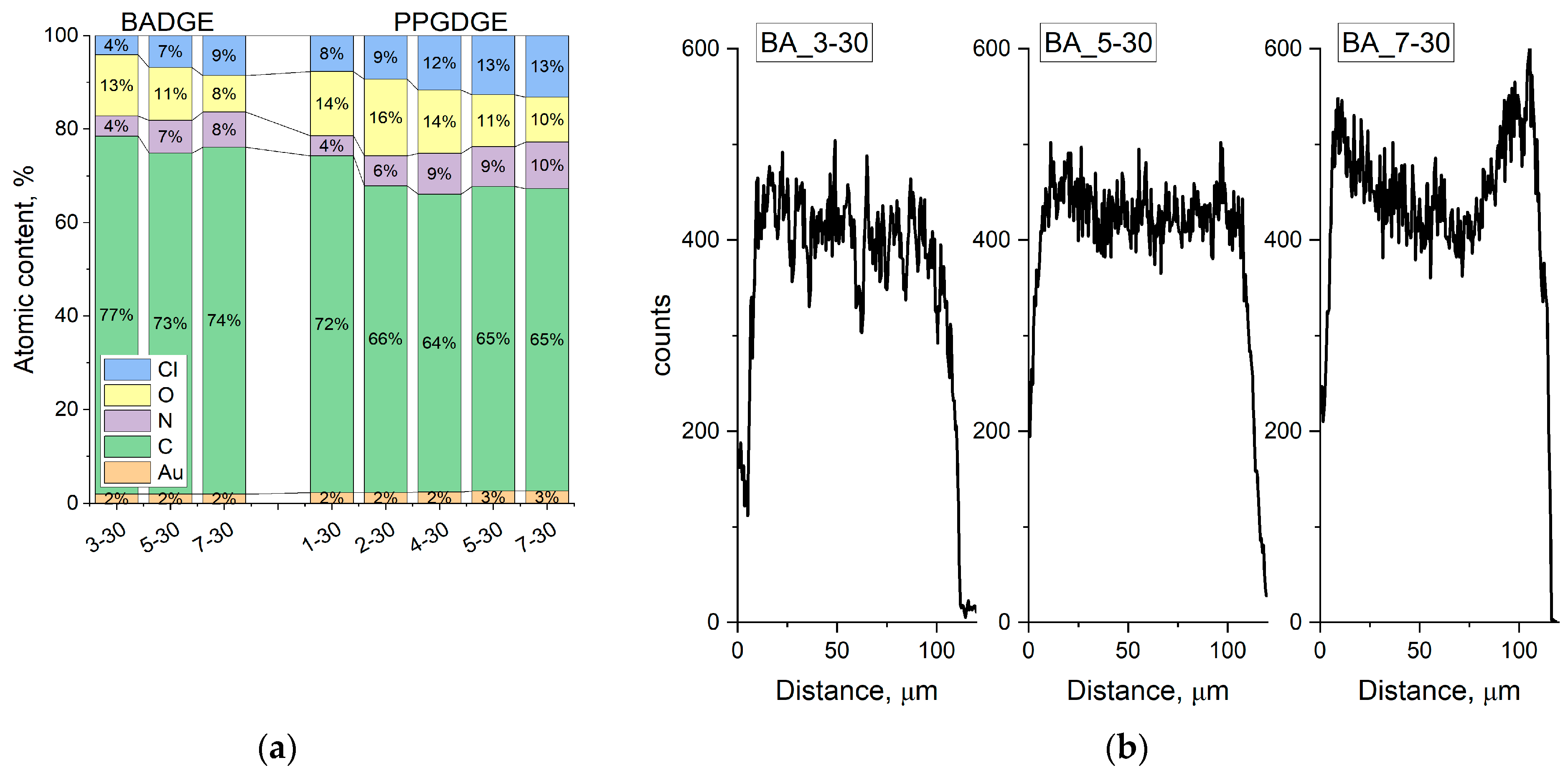

3.2.2. Electron and Optical Microscopy, EDX Elemental Analysis

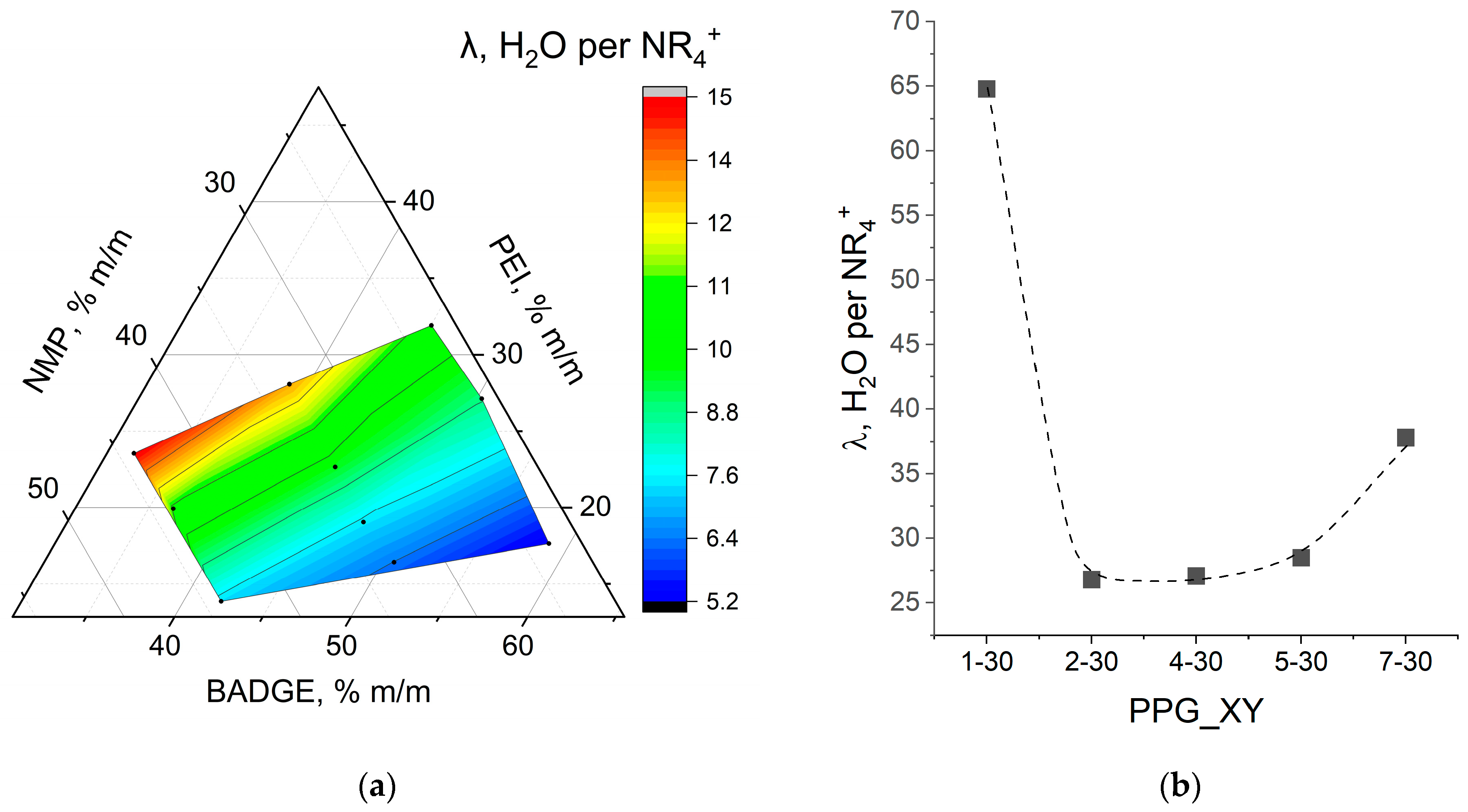

3.3. Ion-Exchange Capacity and Water Uptake

3.3.1. Influence of Reaction Mixture Composition

3.3.2. Influence of Synthesis Conditions

3.4. The Ionic Conductivity and Permselectivity

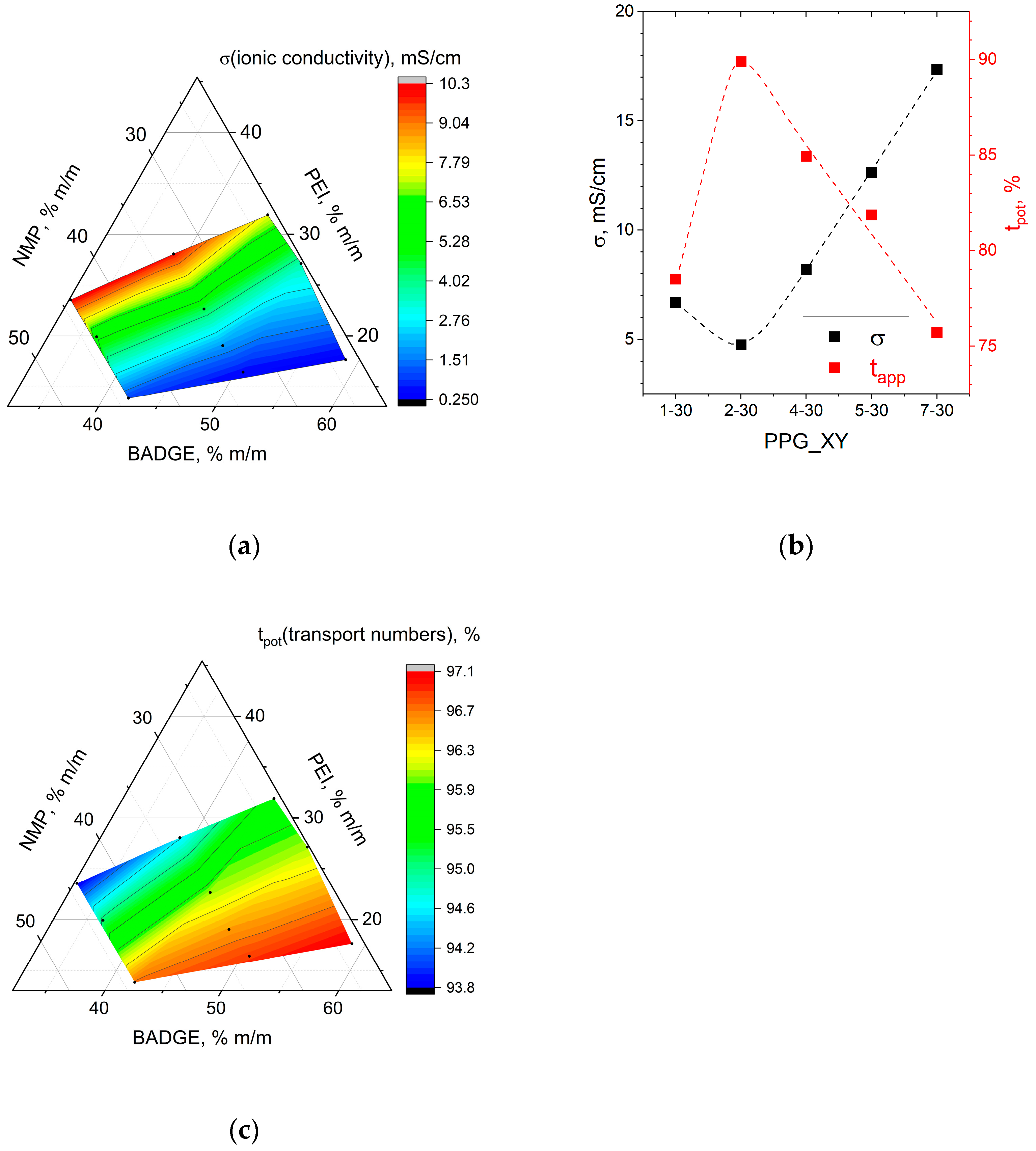

3.4.1. Influence of Reaction Mixture Composition

3.4.2. Influence of Synthesis Conditions

3.4.3. Various Reinforcing Materials: Membrane Defectiveness

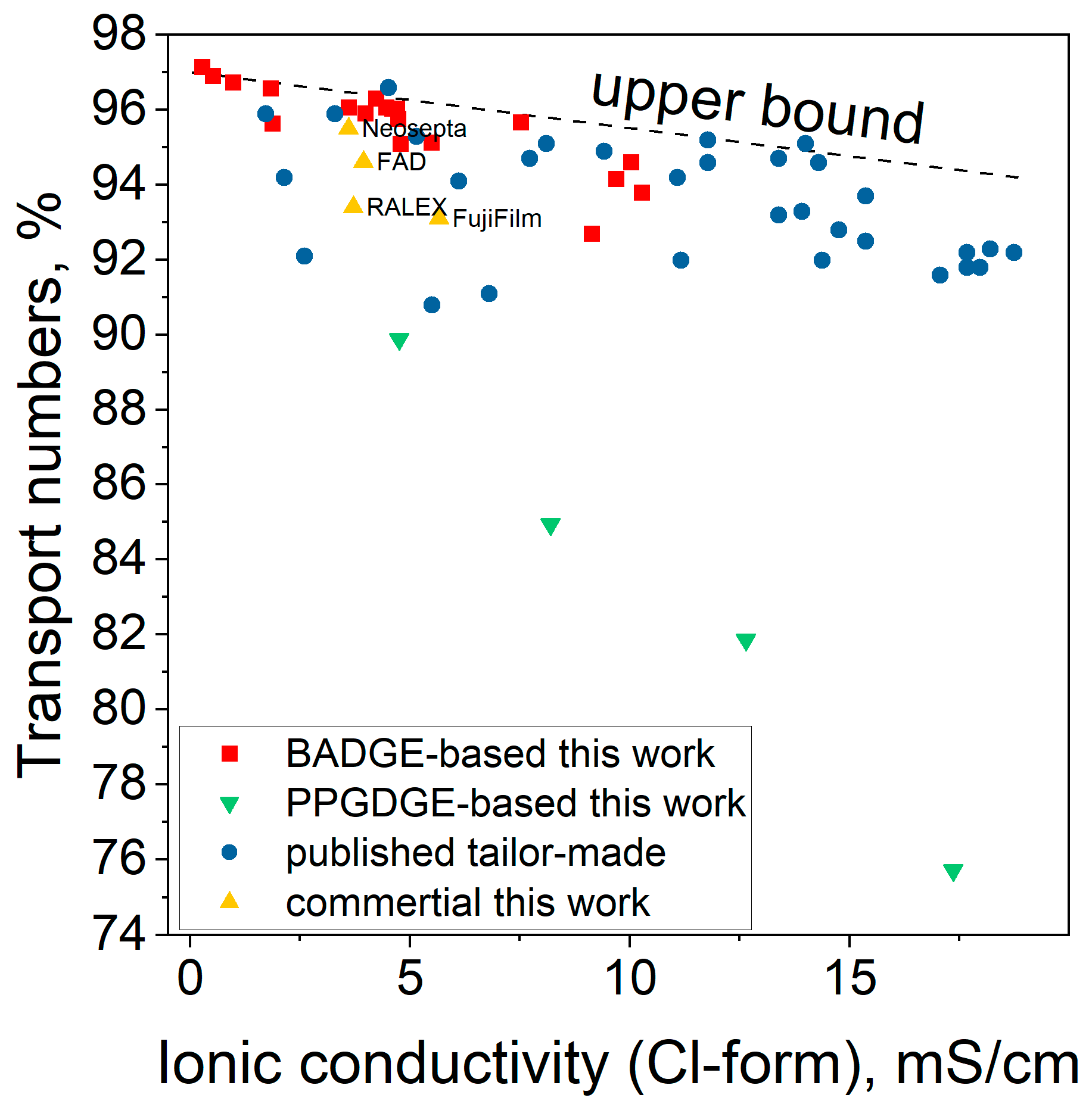

3.4.4. Selectivity-Conductivity Trade-Off and Comparison with Other Membranes

3.4.5. Stress-Test Stability in Acidic, Alkaline and Neutral Media

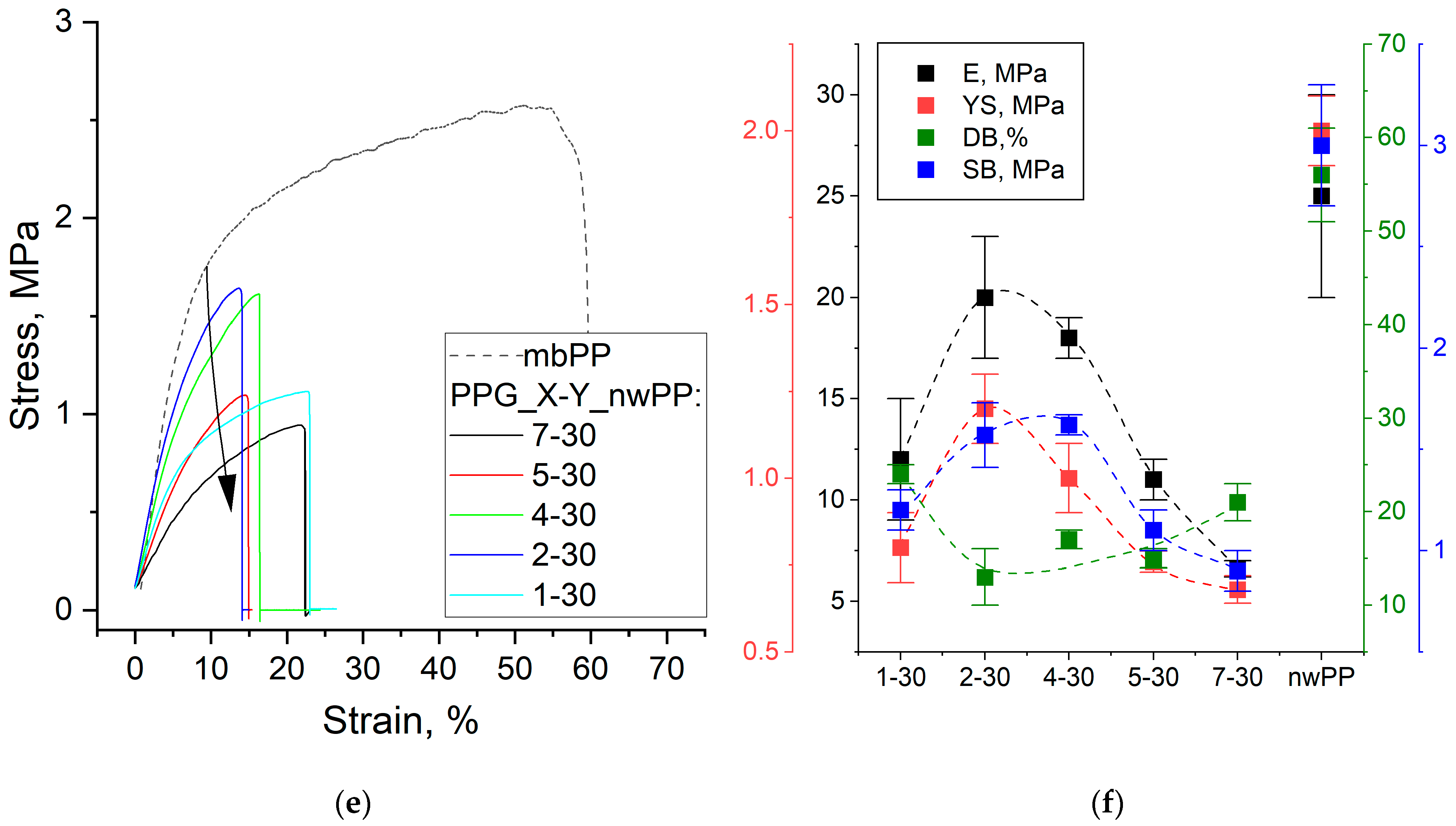

3.5. Mechanical Properties

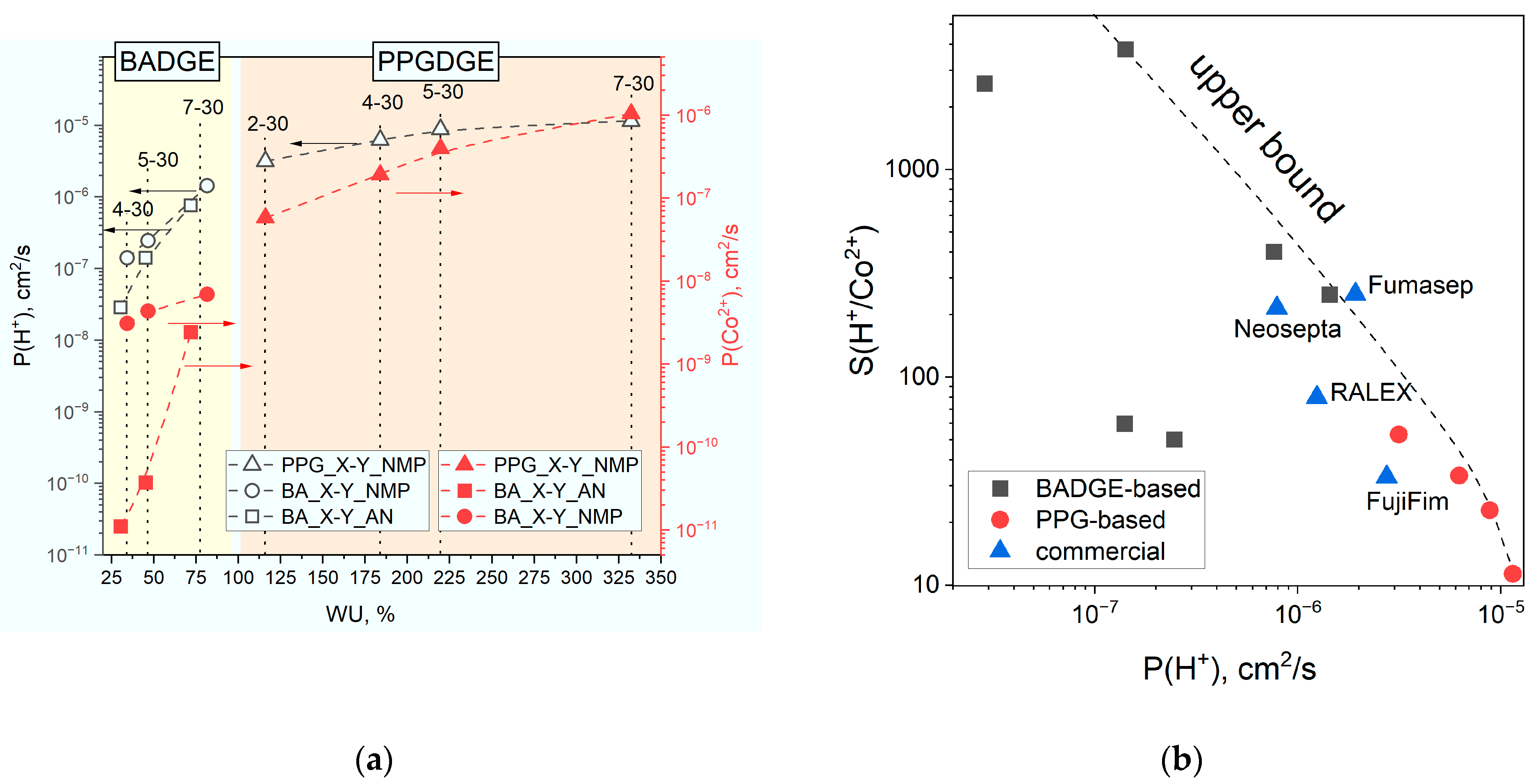

3.6. Diffusion Permeability of Acids and Heavy Metals

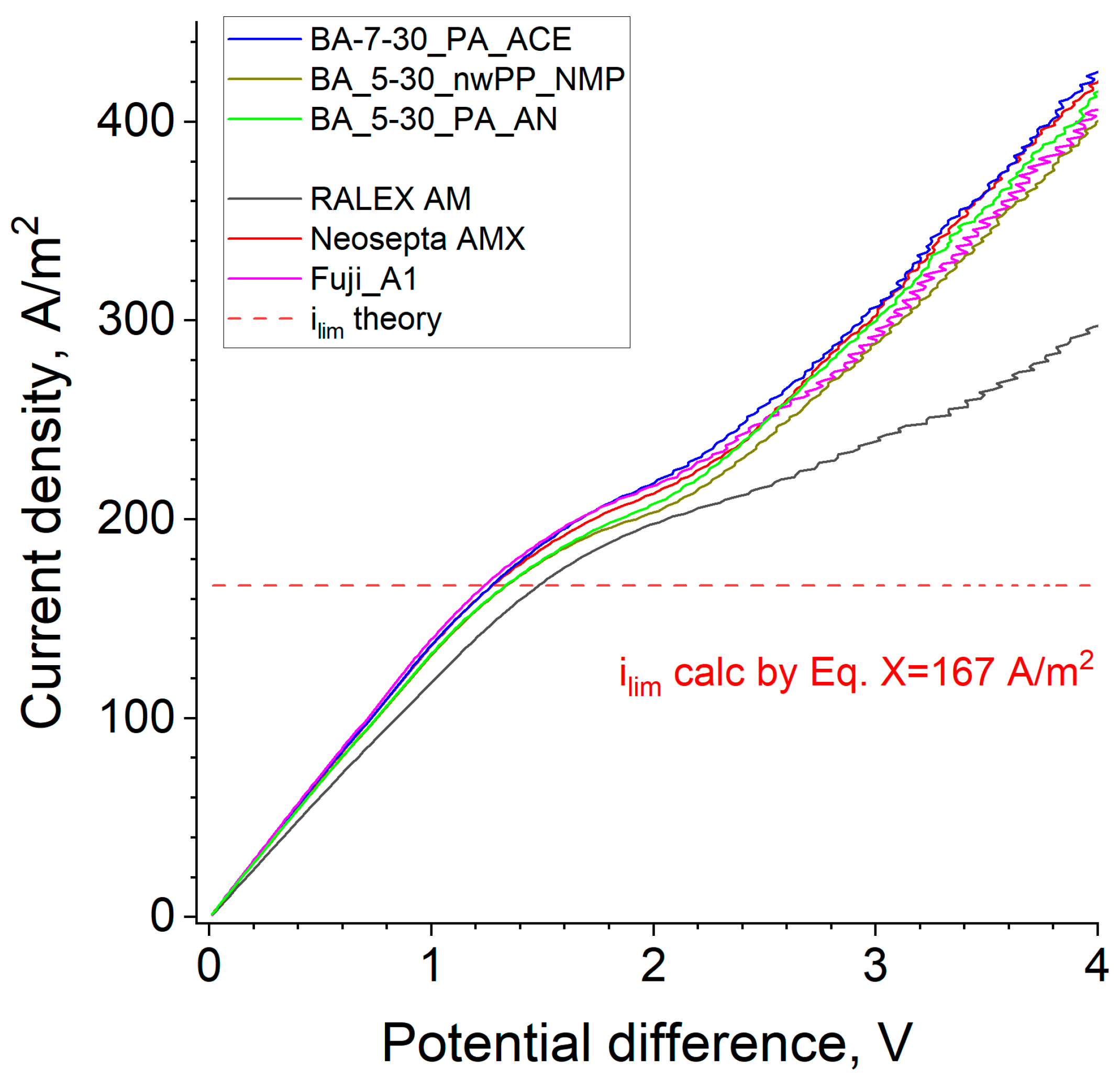

3.7. Current-Voltage Characteristic

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AEM | Anion exchange membrane |

| AN | Acrylonitrile |

| ACE | Acetone |

| BADGE or BA | Bisphenol A diglycidyl ether |

| DB | Deformation at break |

| DD | Diffusion dialysis |

| E | Young’s modulus |

| ED | Electrodialysis |

| IEC | Ion-exchange capacity |

| mPET | Polyethylene terephthalate |

| mPP | Polypropylene mesh |

| NMP | N-methylpyrolidone |

| nwPET | Non-woven polyethylene terephthalate fabric |

| nwPP | Non-woven polypropylene fabric |

| PA | Polyamide |

| PEI | Polyethyleneimine |

| PPGDGE or PPG | Poly(propylene glycol) diglycidyl ether |

| SB | Strength at break |

| TCM | Trichloromethane |

| WU | Water uptake |

| YS | Yield strength |

References

- Lin, J.; Huang, J.; Wang, J.; Yu, J.; You, X.; Lin, X.; Van der Bruggen, B.; Zhao, S. High-Performance Porous Anion Exchange Membranes for Efficient Acid Recovery from Acidic Wastewater by Diffusion Dialysis. J. Membr. Sci. 2021, 624, 119116. [Google Scholar] [CrossRef]

- Karri, R.R.; Ravindran, G.; Dehghani, M.H. Wastewater—Sources, Toxicity, and Their Consequences to Human Health. In Soft Computing Techniques in Solid Waste and Wastewater Management; Elsevier: Amsterdam, The Netherlands, 2021; pp. 3–33. ISBN 978-0-12-824463-0. [Google Scholar]

- Maree, J.P.; Du Plessis, P. Neutralization of Acid Mine Water with Calcium Carbonate. Water Sci. Technol. 1994, 29, 285–296. [Google Scholar] [CrossRef]

- Al-Harahsheh, M.; Batiha, M.; Kraishan, S.; Al-Zoubi, H. Precipitation Treatment of Effluent Acidic Wastewater from Phosphate-Containing Fertilizer Industry: Characterization of Solid and Liquid Products. Sep. Purif. Technol. 2014, 123, 190–199. [Google Scholar] [CrossRef]

- Kesieme, U.; Chrysanthou, A.; Catulli, M.; Cheng, C.Y. A Review of Acid Recovery from Acidic Mining Waste Solutions Using Solvent Extraction. J. Chem. Technol. Biotechnol. 2018, 93, 3374–3385. [Google Scholar] [CrossRef]

- Jeong, J.; Kim, M.; Kim, B.; Kim, S.; Kim, W.; Lee, J. Recovery of HSO from Waste Acid Solution by a Diffusion Dialysis Method. J. Hazard. Mater. 2005, 124, 230–235. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.-H.; Park, H.-S.; Seo, S.-J.; Park, J.-S.; Moon, S.-H.; Choi, Y.-W.; Jiong, Y.S.; Kim, D.H.; Kang, M.-S. Facile Surface Modification of Anion-Exchange Membranes for Improvement of Diffusion Dialysis Performance. J. Colloid Interface Sci. 2014, 416, 19–24. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, Y. Electrodialysis. In Progress in Filtration and Separation; Tarleton, S., Ed.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 207–284. ISBN 978-0-12-398307-7. [Google Scholar]

- Arar, Ö.; Yüksel, Ü.; Kabay, N.; Yüksel, M. Various Applications of Electrodeionization (EDI) Method for Water Treatment—A Short Review. Desalination 2014, 342, 16–22. [Google Scholar] [CrossRef]

- Havelka, J.; Fárová, H.; Jiríček, T.; Kotala, T.; Kroupa, J. Electrodialysis-Based Zero Liquid Discharge in Industrial Wastewater Treatment. Water Sci. Technol. 2019, 79, 1580–1586. [Google Scholar] [CrossRef]

- Haddad, M.; Bazinet, L.; Barbeau, B. Eco-Efficient Treatment of Ion Exchange Spent Brine via Electrodialysis to Recover NaCl and Minimize Waste Disposal. Sci. Total Environ. 2019, 690, 400–409. [Google Scholar] [CrossRef]

- Zhao, Y.; Mamrol, N.; Tarpeh, W.A.; Yang, X.; Gao, C.; Van Der Bruggen, B. Advanced Ion Transfer Materials in Electro-Driven Membrane Processes for Sustainable Ion-Resource Extraction and Recovery. Prog. Mater. Sci. 2022, 128, 100958. [Google Scholar] [CrossRef]

- Nagarale, R.K.; Gohil, G.S.; Shahi, V.K. Recent Developments on Ion-Exchange Membranes and Electro-Membrane Processes. Adv. Colloid Interface Sci. 2006, 119, 97–130. [Google Scholar] [CrossRef] [PubMed]

- Hagesteijn, K.F.L.; Jiang, S.; Ladewig, B.P. A Review of the Synthesis and Characterization of Anion Exchange Membranes. J. Mater. Sci. 2018, 53, 11131–11150. [Google Scholar] [CrossRef]

- Feng, Z.; Gupta, G.; Mamlouk, M. A Review of Anion Exchange Membranes Prepared via Friedel-Crafts Reaction for Fuel Cell and Water Electrolysis. Int. J. Hydrogen Energy 2023, S0360319923014222. [Google Scholar] [CrossRef]

- Patel, S.K.; Biesheuvel, P.M.; Elimelech, M. Energy Consumption of Brackish Water Desalination: Identifying the Sweet Spots for Electrodialysis and Reverse Osmosis. ACS EST Eng. 2021, 1, 851–864. [Google Scholar] [CrossRef]

- Clemens, A.L.; Jayathilake, B.S.; Karnes, J.J.; Schwartz, J.J.; Baker, S.E.; Duoss, E.B.; Oakdale, J.S. Tuning Alkaline Anion Exchange Membranes through Crosslinking: A Review of Synthetic Strategies and Property Relationships. Polymers 2023, 15, 1534. [Google Scholar] [CrossRef] [PubMed]

- Pascault, J.-P.; Williams, R.J. Thermosetting Polymers. Handb. Polym. Synth. Charact. Process. 2013, 519–533. [Google Scholar] [CrossRef]

- Fernández-Francos, X.; Santiago, D.; Ferrando, F.; Ramis, X.; Salla, J.M.; Serra, À.; Sangermano, M. Network Structure and Thermomechanical Properties of Hybrid DGEBA Networks Cured with 1-methylimidazole and Hyperbranched Poly(Ethyleneimine)s. J. Polym. Sci. B Polym. Phys. 2012, 50, 1489–1503. [Google Scholar] [CrossRef]

- Fernández-Francos, X.; Ramis, X. Structural Analysis of the Curing of Epoxy Thermosets Crosslinked with Hyperbranched Poly(Ethyleneimine)s. Eur. Polym. J. 2015, 70, 286–305. [Google Scholar] [CrossRef]

- Weckhuysen, B.M. A Sustainable Alternative to Bisphenol A. Nat. Sustain. 2023, 6, 1516–1517. [Google Scholar] [CrossRef]

- Verbeke, R.; Davenport, D.M.; Stassin, T.; Eyley, S.; Dickmann, M.; Cruz, A.J.; Dara, P.; Ritt, C.L.; Bogaerts, C.; Egger, W.; et al. Chlorine-Resistant Epoxide-Based Membranes for Sustainable Water Desalination. Environ. Sci. Technol. Lett. 2021, 8, 818–824. [Google Scholar] [CrossRef]

- Sakakibara, K.; Kagata, H.; Ishizuka, N.; Sato, T.; Tsujii, Y. Fabrication of Surface Skinless Membranes of Epoxy Resin-Based Mesoporous Monoliths toward Advanced Separators for Lithium Ion Batteries. J. Mater. Chem. A 2017, 5, 6866–6873. [Google Scholar] [CrossRef]

- Jeong, S.; Lee, J.; Woo, S.; Seo, J.; Min, B. Characterization of Anion Exchange Membrane Containing Epoxy Ring and C–Cl Bond Quaternized by Various Amine Groups for Application in Fuel Cells. Energies 2015, 8, 7084–7099. [Google Scholar] [CrossRef]

- Tripathi, B.P.; Kumar, M.; Shahi, V.K. Organic-Inorganic Hybrid Alkaline Membranes by Epoxide Ring Opening for Direct Methanol Fuel Cell Applications. J. Membr. Sci. 2010, 360, 90–101. [Google Scholar] [CrossRef]

- Boyd, T.J.; Schrock, R.R. Sulfonation and Epoxidation of Substituted Polynorbornenes and Construction of Light-Emitting Devices. Macromolecules 1999, 32, 6608–6618. [Google Scholar] [CrossRef]

- Wozniak, A.I.; Bermesheva, E.V.; Andreyanov, F.A.; Borisov, I.L.; Zarezin, D.P.; Bakhtin, D.S.; Gavrilova, N.N.; Ilyasov, I.R.; Nechaev, M.S.; Asachenko, A.F.; et al. Modifications of Addition Poly(5-Vinyl-2-Norbornene) and Gas-Transport Properties of the Obtained Polymers. React. Funct. Polym. 2020, 149, 104513. [Google Scholar] [CrossRef]

- Belov, N.A.; Gringolts, M.L.; Morontsev, A.A.; Starannikova, L.E.; Yampolskii, Y.P.; Finkelstein, E.S. Gas-Transport Properties of Epoxidated Metathesis Polynorbornenes. Polym. Sci. Ser. B 2017, 59, 560–569. [Google Scholar] [CrossRef]

- Zhou, J.; Ünlü, M.; Anestis-Richard, I.; Kohl, P.A. Crosslinked, Epoxy-Based Anion Conductive Membranes for Alkaline Membrane Fuel Cells. J. Membr. Sci. 2010, 350, 286–292. [Google Scholar] [CrossRef]

- Golubenko, D.; Karavanova, Y.; Yaroslavtsev, A. Effects of the Surface Layer Structure of the Heterogeneous Ion-Exchange Membranes on Their Impedance. J. Electroanal. Chem. 2016, 777, 1–7. [Google Scholar] [CrossRef]

- Kingsbury, R.S.; Flotron, S.; Zhu, S.; Call, D.F.; Coronell, O. Junction Potentials Bias Measurements of Ion Exchange Membrane Permselectivity. Environ. Sci. Technol. 2018, 52, 4929–4936. [Google Scholar] [CrossRef] [PubMed]

- Golubenko, D.V.; Van der Bruggen, B.; Yaroslavtsev, A.B. Novel Anion Exchange Membrane with Low Ionic Resistance Based on Chloromethylated/Quaternized-grafted Polystyrene for Energy Efficient Electromembrane Processes. J. Appl. Polym. Sci. 2020, 137, 48656. [Google Scholar] [CrossRef]

- Krol, J.J.; Wessling, M.; Strathmann, H. Concentration Polarization with Monopolar Ion Exchange Membranes: Current-Voltage Curves and Water Dissociation. J. Membr. Sci. 1999, 162, 145–154. [Google Scholar] [CrossRef]

- Belova, E.I.; Lopatkova, G.Y.; Pismenskaya, N.D.; Nikonenko, V.V.; Larchet, C.; Pourcelly, G. Effect of Anion-Exchange Membrane Surface Properties on Mechanisms of Overlimiting Mass Transfer. J. Phys. Chem. B 2006, 110, 13458–13469. [Google Scholar] [CrossRef] [PubMed]

- Santiago, D.; Fernández-Francos, X.; Ramis, X.; Salla, J.M.; Sangermano, M. Comparative Curing Kinetics and Thermal–Mechanical Properties of DGEBA Thermosets Cured with a Hyperbranched Poly(Ethyleneimine) and an Aliphatic Triamine. Thermochim. Acta 2011, 526, 9–21. [Google Scholar] [CrossRef]

- Severini, F.; Gallo, R.; Marullo, R. Differential Scanning Calorimetry Study of Reactions of Epoxides with Polyamines. J. Therm. Anal. 1982, 25, 515–523. [Google Scholar] [CrossRef]

- Socrates, G. Infrared and Raman Characteristic Group Frequencies: Tables and Charts. Occup. Med. 2001, 62, 347. [Google Scholar]

- Naga, N.; Sato, M.; Mori, K.; Nageh, H.; Nakano, T. Synthesis of Network Polymers by Means of Addition Reactions of Multifunctional-Amine and Poly(Ethylene Glycol) Diglycidyl Ether or Diacrylate Compounds. Polymers 2020, 12, 2047. [Google Scholar] [CrossRef]

- Chakraborty, A.; Salam, I.; Choolaei, M.; Lee, J.; Crean, C.; Whelligan, D.K.; Bance-Soualhi, R.; Varcoe, J.R. Changes in Permselectivity of Radiation-Grafted Anion-Exchange Membranes with Different Cationic Headgroup Chemistries Are Primarily Due to Water Content Differences. Mater. Adv. 2023, 4, 2099–2105. [Google Scholar] [CrossRef]

- Bonizzoni, S.; Stucchi, D.; Caielli, T.; Sediva, E.; Mauri, M.; Mustarelli, P. Morpholinium-Modified, Polyketone-Based Anion Exchange Membranes for Water Electrolysis. ChemElectroChem 2023, 10, e202201077. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, M.; Zhao, Z.; Lan, W. ScienceDirect Highly Alkaline Stable Fully-Interpenetrating Network Poly ( Styrene- Co -4-Vinyl Pyridine )/ Polyquaternium-10 Anion Exchange Membrane without Aryl Ether Linkages. Int. J. Hydrogen Energy 2022. [Google Scholar] [CrossRef]

- Bance-Soualhi, R.; Choolaei, M.; Franklin, S.A.; Willson, T.R.; Lee, J.; Whelligan, D.K.; Crean, C.; Varcoe, J.R. Radiation-Grafted Anion-Exchange Membranes for Reverse Electrodialysis: A Comparison of N, N, N′, N′-Tetramethylhexane-1,6-Diamine Crosslinking (Amination Stage) and Divinylbenzene Crosslinking (Grafting Stage). J. Mater. Chem. A 2021, 9, 22025–22038. [Google Scholar] [CrossRef]

- Tanaka, Y. Fundamental Properties of Ion Exchange Membranes. In Ion Exchange Membranes: Fundamentals and Application; Elsevier: Amsterdam, The Netherlands, 2015; pp. 29–65. ISBN 978-0-444-63319-4. [Google Scholar]

- Stenina, I.A.; Yaroslavtsev, A.B. Ionic Mobility in Ion-exchange Membranes. Membranes 2021, 11, 198. [Google Scholar] [CrossRef] [PubMed]

- Stenina, I.; Golubenko, D.; Nikonenko, V.; Yaroslavtsev, A. Selectivity of Transport Processes in Ion-Exchange Membranes: Relationship with the Structure and Methods for Its Improvement. Int. J. Mol. Sci. 2020, 21, 5517. [Google Scholar] [CrossRef] [PubMed]

- Porozhnyy, M.; Huguet, P.; Cretin, M.; Safronova, E.; Nikonenko, V. Mathematical Modeling of Transport Properties of Proton-Exchange Membranes Containing Immobilized Nanoparticles. Int. J. Hydrogen Energy 2016, 41, 15605–15614. [Google Scholar] [CrossRef]

- Luo, X.; Kushner, D.I.; Kusoglu, A. Anion Exchange Membranes: The Effect of Reinforcement in Water and Electrolyte. J. Membr. Sci. 2023, 685, 121945. [Google Scholar] [CrossRef]

- Stránská, E.; Neděla, D. Reinforcing Fabrics as the Mechanical Support of Ion Exchange Membranes. J. Ind. Text. 2018, 48, 432–447. [Google Scholar] [CrossRef]

- Kitto, D.; Kamcev, J. Predicting the Conductivity–Selectivity Trade-Off and Upper Bound in Ion-Exchange Membranes. ACS Energy Lett. 2024, 9, 1346–1352. [Google Scholar] [CrossRef]

- Kamcev, J. Reformulating the Permselectivity-Conductivity Tradeoff Relation in Ion-Exchange Membranes. J. Polym. Sci. 2021, 59, 2510–2520. [Google Scholar] [CrossRef]

- Park, H.B.; Kamcev, J.; Robeson, L.M.; Elimelech, M.; Freeman, B.D. Maximizing the Right Stuff: The Trade-off between Membrane Permeability and Selectivity. Science 2017, 356, eaab0530. [Google Scholar] [CrossRef]

- Liu, H.; She, Q. Influence of Membrane Structure-Dependent Water Transport on Conductivity-Permselectivity Trade-off and Salt/Water Selectivity in Electrodialysis: Implications for Osmotic Electrodialysis Using Porous Ion Exchange Membranes. J. Membr. Sci. 2022, 650, 120398. [Google Scholar] [CrossRef]

- Fan, H.; Yip, N.Y. Elucidating Conductivity-Permselectivity Tradeoffs in Electrodialysis and Reverse Electrodialysis by Structure-Property Analysis of Ion-Exchange Membranes. J. Membr. Sci. 2019, 573, 668–681. [Google Scholar] [CrossRef]

- Güler, E.; Elizen, R.; Vermaas, D.A.; Saakes, M.; Nijmeijer, K. Performance-Determining Membrane Properties in Reverse Electrodialysis. J. Membr. Sci. 2013, 446, 266–276. [Google Scholar] [CrossRef]

- Dlugolecki, P.; Nymeijer, K.; Metz, S.; Wessling, M. Current Status of Ion Exchange Membranes for Power Generation from Salinity Gradients. J. Membr. Sci. 2008, 319, 214–222. [Google Scholar] [CrossRef]

- Chen, N.; Lee, Y.M. Anion Exchange Polyelectrolytes for Membranes and Ionomers. Prog. Polym. Sci. 2021, 113, 101345. [Google Scholar] [CrossRef]

- Safronova, E.; Safronov, D.; Lysova, A.; Parshina, A.; Bobreshova, O.; Pourcelly, G.; Yaroslavtsev, A. Sensitivity of Potentiometric Sensors Based on Nafion®-Type Membranes and Effect of the Membranes Mechanical, Thermal, and Hydrothermal Treatments on the on Their Properties. Sens. Actuators B Chem. 2017, 240, 1016–1023. [Google Scholar] [CrossRef]

- Karimi, M.B.; Mohammadi, F.; Hooshyari, K. Recent Approaches to Improve Nafion Performance for Fuel Cell Applications: A Review. Int. J. Hydrogen Energy 2019, 44, 28919–28938. [Google Scholar] [CrossRef]

- Satterfield, M.B.; Benziger, J.B. Viscoelastic Properties of Nafion at Elevated Temperature and Humidity. J. Polym. Sci. Part B Polym. Phys. 2009, 47, 11–24. [Google Scholar] [CrossRef]

- Pourcelly, G.; Tugas, I.; Gavach, C. Electrotransport of Sulphuric Acid in Special Anion Exchange Membranes for the Recovery of Acids. J. Membr. Sci. 1994, 97, 99–107. [Google Scholar] [CrossRef]

- Merkel, A.; Čopák, L.; Golubenko, D.; Dvořák, L.; Vavro, M.; Yaroslavtsev, A.; Šeda, L. Recovery of Hydrochloric Acid from Industrial Wastewater by Diffusion Dialysis Using a Spiral-Wound Module. Int. J. Mol. Sci. 2022, 23, 6212. [Google Scholar] [CrossRef] [PubMed]

- Spiegler, K.S. Polarization at Ion Exchange Membrane-Solution Interfaces. Desalination 1971, 9, 367–385. [Google Scholar] [CrossRef]

- La Cerva, M.; Gurreri, L.; Tedesco, M.; Cipollina, A.; Ciofalo, M.; Tamburini, A.; Micale, G. Determination of Limiting Current Density and Current Efficiency in Electrodialysis Units. Desalination 2018, 445, 138–148. [Google Scholar] [CrossRef]

- Belloň, T.; Polezhaev, P.; Vobecká, L.; Svoboda, M.; Slouka, Z. Experimental Observation of Phenomena Developing on Ion-Exchange Systems during Current-Voltage Curve Measurement. J. Membr. Sci. 2019, 572, 607–618. [Google Scholar] [CrossRef]

| Composition | Max Heat Flow, mW/mg | Reaction Time, min | Total Heat Per Epoxide Group, kJ/mole |

|---|---|---|---|

| BA_3-20 | −2.00 | 46 | 113 |

| BA_3-30 | −1.45 | 59 | 99 |

| BA_3-40 | −0.925 | 83 | 96 |

| BA_5-20 | −2.77 | 26 | 112 |

| BA_5-30 | −2.02 | 26 | 109 |

| BA_5-40 | −1.72 | 37 | 116 |

| BA_7-20 | −3.08 | 21 | 113 |

| BA_7-30 | −2.75 | 30 | 102 |

| BA_7-40 | −1.79 | 44 | 101 |

| PPG_1-30 | −0.43 | 138 | 51 |

| PPG_2-30 | −0.78 | 92 | 87 |

| PPG_4-30 | −1.03 | 70 | 116 |

| PPG_5-30 | −1.06 | 62 | 116 |

| PPG_7-30 | −1.26 | 50 | 121 |

| Solvent | Non-Quaternized | Quaternized |

|---|---|---|

| water | 39.3 | 74.2 |

| ACE | 8.3 | 3.3 |

| AN | 4.8 | 1.7 |

| NMP | 72.7 | 6.7 |

| TCM | 65.4 | 4.1 |

| Membrane | Solvent | s-IEC ± 0.05, mmole/g | w-IEC ± 0.05, mmole/g | Weak-Base Amino Group Fraction, % | WU, % | σ (Cl Form, 20–22 °C) ± 0.5, mS/cm | tpot ± 0.3, % |

|---|---|---|---|---|---|---|---|

| BA_7-40_PA | ACE | 3.45 | 1.31 | 27 | 92.2 | 10.3 | 92.7 |

| BA_7-40_PA | AN | 2.80 | 1.45 | 34 | 87.9 | 8.9 | 92.2 |

| BA_7-40_PA | TCM | 2.90 | 1.33 | 32 | 81.5 | 10.0 | 92.2 |

| BA_7-40_PA | NMP | Sample collapse due to high swelling | |||||

| BA_7-30_nwPP | AN | 2.55 | 2.34 | 48 | 71.8 | 9.1 | 94.2 |

| BA_7-30_nwPP | NMP | 3.10 | 1.59 | 34 | 81.7 | 9.7 | 92.7 |

| Solution | WU, % | s-IEC, mmole/g | w-IEC, mmole/g |

|---|---|---|---|

| Reference | 70 | 2.70 | 1.50 |

| 5% m/m NaCl | 83 | 2.70 | 1.45 |

| 5% m/m NaOH | 130 | 1.40 | 2.80 |

| 5% m/m H2SO4 | 74 | 2.30 | 1.85 |

| Membrane | Rcell ± 0.8, Ω cm2 | Rmem ± 1.2, Ω cm2 | ilim, A/m2 |

|---|---|---|---|

| BA_5-30_PA_AN | 73.1 | 6.3 | 177 |

| BA_5-30_nwPP_NMP | 73.4 | 6.6 | 171 |

| BA_7-30_PA_ACE | 70.1 | 3.2 | 179 |

| RALEX® AM | 81.8 | 15.0 | 174 |

| Neosepta® AMX | 71.2 | 4.4 | 179 |

| FujiFilm® T1 | 69.4 | 2.6 | 185 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golubenko, D.; Ahmed, F.E.; Hilal, N. Novel Crosslinked Anion Exchange Membranes Based on Thermally Cured Epoxy Resin: Synthesis, Structure and Mechanical and Ion Transport Properties. Membranes 2024, 14, 138. https://doi.org/10.3390/membranes14060138

Golubenko D, Ahmed FE, Hilal N. Novel Crosslinked Anion Exchange Membranes Based on Thermally Cured Epoxy Resin: Synthesis, Structure and Mechanical and Ion Transport Properties. Membranes. 2024; 14(6):138. https://doi.org/10.3390/membranes14060138

Chicago/Turabian StyleGolubenko, Daniil, Farah Ejaz Ahmed, and Nidal Hilal. 2024. "Novel Crosslinked Anion Exchange Membranes Based on Thermally Cured Epoxy Resin: Synthesis, Structure and Mechanical and Ion Transport Properties" Membranes 14, no. 6: 138. https://doi.org/10.3390/membranes14060138

APA StyleGolubenko, D., Ahmed, F. E., & Hilal, N. (2024). Novel Crosslinked Anion Exchange Membranes Based on Thermally Cured Epoxy Resin: Synthesis, Structure and Mechanical and Ion Transport Properties. Membranes, 14(6), 138. https://doi.org/10.3390/membranes14060138