Starch Granule Size Distribution and Pasting Characteristic Response to Post-Anthesis Combined Stress of Waterlogging and Shading

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Design

2.2. Measurement of Content of Starch, Starch Granule Size Distribution, and Starch Pasting Properties

2.3. Statistics

3. Results

3.1. Effect of Post-Anthesis WS Treatments on the Yield and the Pasting Characteristics of Starch in Wheat Mature Grains

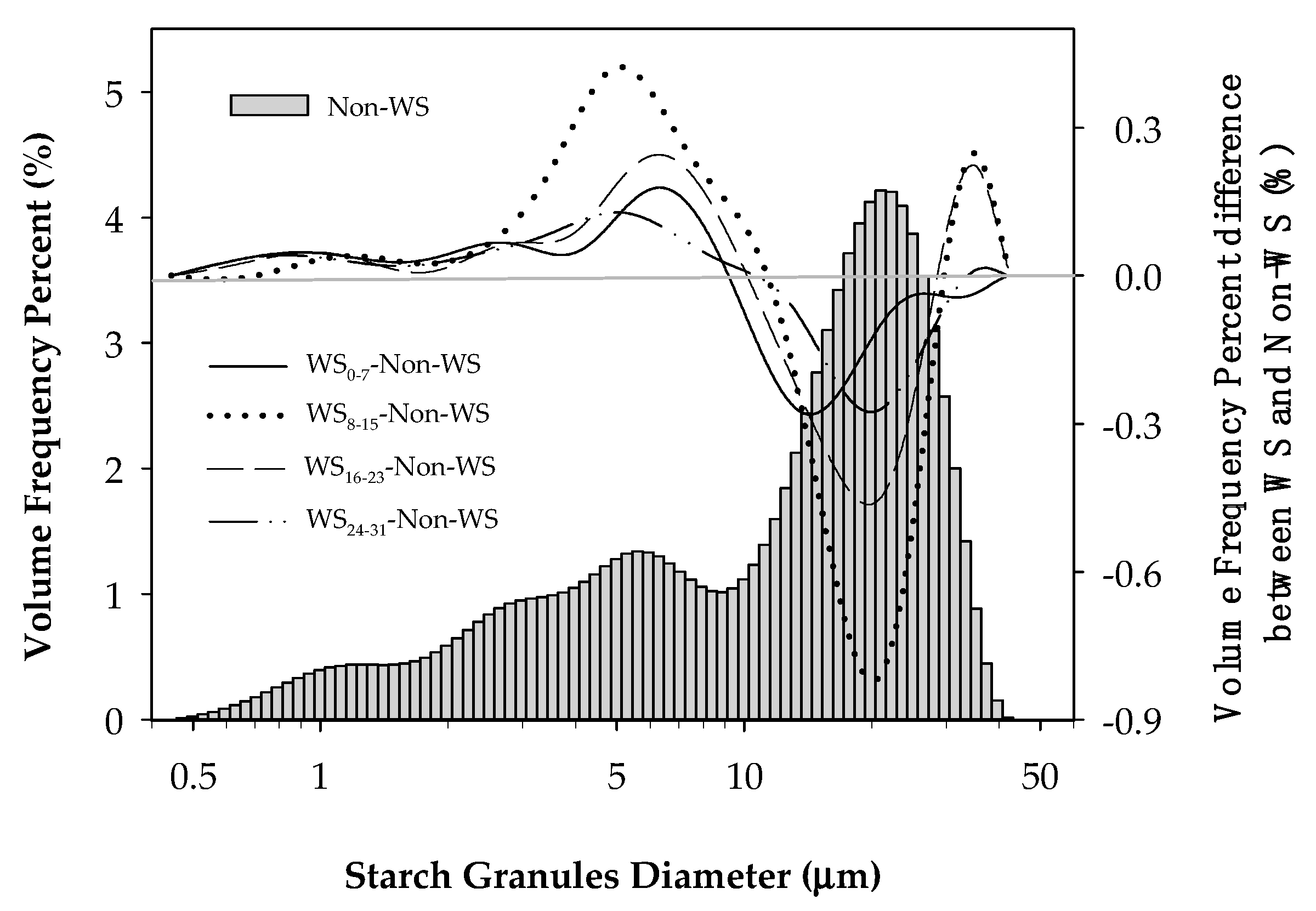

3.2. Effect of Post-Anthesis WS Treatments on the Volume Distribution of Starch Granules in Mature Wheat Grains

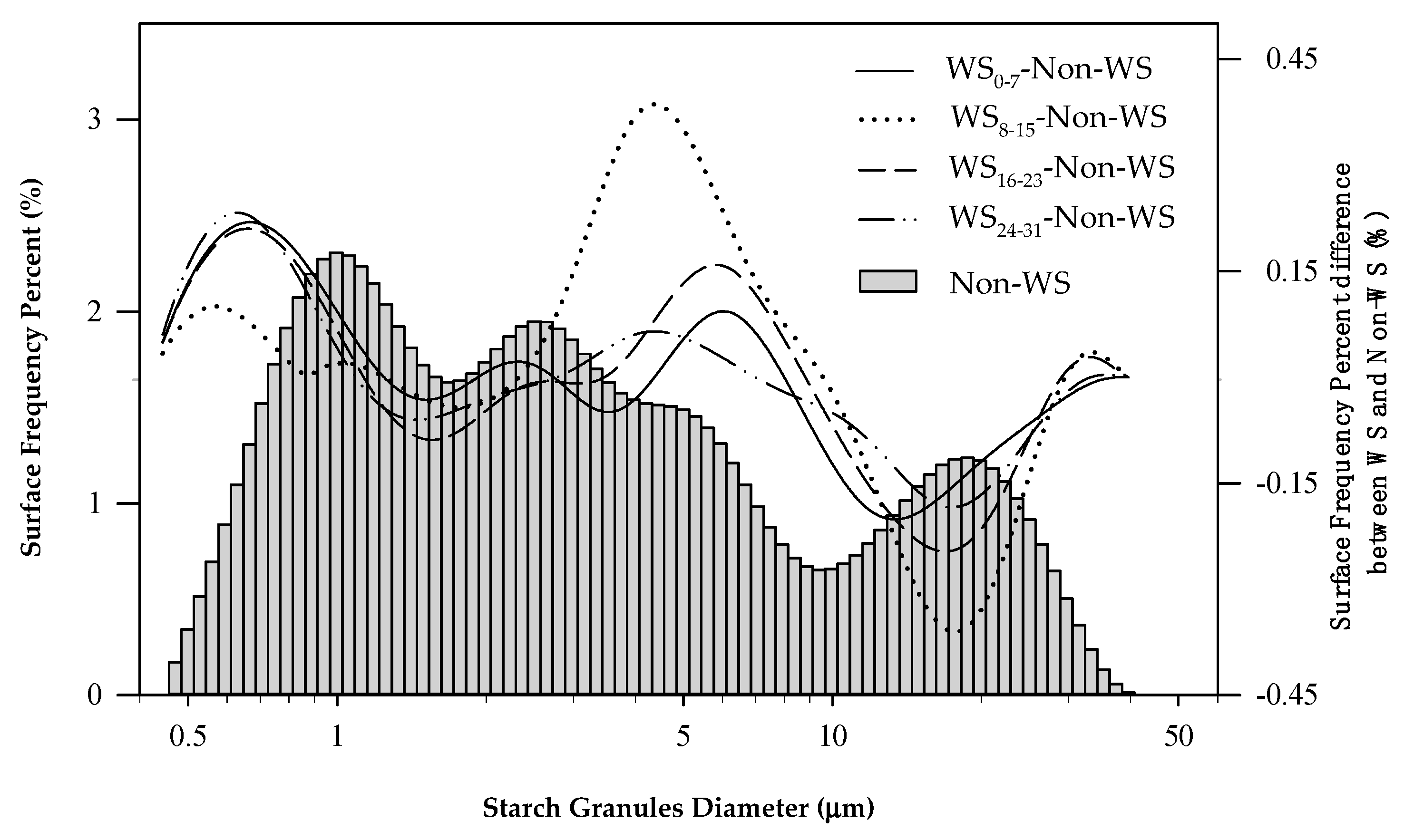

3.3. Effect of Post-Anthesis WS Treatments on the Surface area Distribution of Starch Granules in Mature Wheat Grains

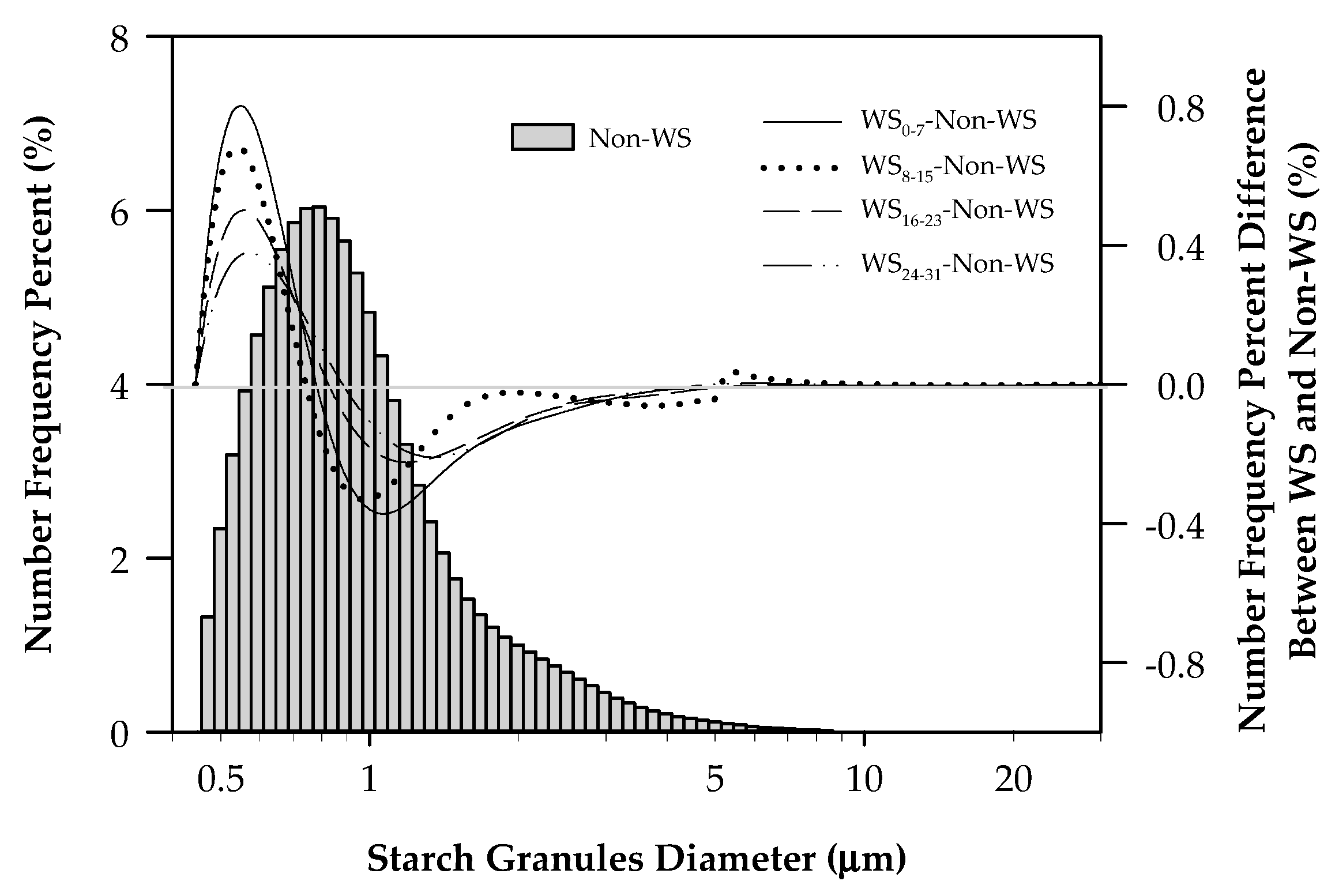

3.4. Effect of Post-Anthesis WS Treatments on the Number Distribution of Starch Granules in Mature Wheat Grains

3.5. Relationship between the Starch Content and Starch Pasting Characteristics of Wheat under Post-Anthesis WS Treatments

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bechtel, D.B.; Zayas, I.; Kaleikau, L.; Pomeranz, Y. Size-distribution of wheat starch granules during endosperm development. Cereal Chem. 1990, 67, 59–63. [Google Scholar]

- Morell, M.; Rahman, S.; Abrahams, S.; Appels, R. The biochemistry and molecular biology of starch synthesis in cereals. Funct. Plant Biol. 1995, 22, 647–660. [Google Scholar] [CrossRef]

- Salman, H.; Blazek, J.; Lopez-Rubio, A.; Gilbert, E.P.; Hanley, T.; Copeland, L. Structure–function relationships in A and B granules from wheat starches of similar amylose content. Carbohydr. Polym. 2009, 75, 420–427. [Google Scholar] [CrossRef]

- Srichuwong, S.; Jane, J.-L. Physicochemical properties of starch affected by molecular composition and structures: A Review. Food Sci. Biotechnol. 2007, 16, 663–674. [Google Scholar]

- Pérez, S.; Bertoft, E. The molecular structures of starch components and their contribution to the architecture of starch granules: A comprehensive review. Starch Stärke 2010, 62, 389–420. [Google Scholar] [CrossRef]

- Zhang, B.; Li, X.; Liu, J.; Xie, F.; Chen, L. Supramolecular structure of A-and B-type granules of wheat starch. Food Hydrocoll. 2013, 31, 68–73. [Google Scholar] [CrossRef]

- Zhang, C.; Jiang, D.; Liu, F.; Cai, J.; Dai, T.; Cao, W. Starch granules size distribution in superior and inferior grains of wheat is related to enzyme activities and their gene expressions during grain filling. J. Cereal Sci. 2010, 51, 226–233. [Google Scholar] [CrossRef]

- Shinde, S.V.; Nelson, J.E.; Huber, K.C. Soft Wheat Starch Pasting Behavior in Relation to A- and B-type Granule Content and Composition. Cereal Chem. 2003, 80, 91–98. [Google Scholar] [CrossRef]

- Raeker, M.Ö.; Gaines, C.S.; Finney, P.L.; Donelson, T. Granule size distribution and chemical composition of starches from 12 soft wheat cultivars. Cereal Chem. 1998, 75, 721–728. [Google Scholar] [CrossRef]

- Gerits, L.R.; Pareyt, B.; Delcour, J.A. Wheat starch swelling, gelatinization and pasting: Effects of enzymatic modification of wheat endogenous lipids. LWT Food Sci. Technol. 2015, 63, 361–366. [Google Scholar] [CrossRef]

- Yan, Z.; Jinfeng, D.; Jianmin, S.; Gavin, H.S.; Yongxin, P.; Chunyan, L.; Xinkai, Z.; Wenshan, G. Grain yield, starch content and activities of key enzymes of waxy and non-waxy wheat (Triticum aestivum L.). Sci. Rep. 2018, 8, 4548. [Google Scholar]

- Meredith, P. Large and small starch granules in wheat–are they really different? Starch Stärke 1981, 33, 40–44. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Sharma, L.; Kaur, M. Effect of granule size on physicochemical, morphological, thermal and pasting properties of native and 2-octenyl-1-ylsuccinylated potato starch prepared by dry heating under different pH conditions. LWT-Food Sci. Technol. 2015, 61, 224–230. [Google Scholar] [CrossRef]

- Guo, Q.; He, Z.; Xia, X.; Qu, Y.; Zhang, Y. Effects of Wheat Starch Granule Size Distribution on Qualities of Chinese Steamed Bread and Raw White Noodles. Cereal Chem. 2014, 91, 623–630. [Google Scholar] [CrossRef]

- Li, W.; Gao, J.; Wu, G.; Zheng, J.; Ouyang, S.; Luo, Q.; Zhang, G. Physicochemical and structural properties of A- and B-starch isolated from normal and waxy wheat: Effects of lipids removal. Food Hydrocoll. 2016, 60, 364–373. [Google Scholar] [CrossRef]

- Kaur, A.; Shevkani, K.; Katyal, M.; Singh, N.; Ahlawat, A.K.; Singh, A.M. Physicochemical and rheological properties of starch and flour from different durum wheat varieties and their relationships with noodle quality. J. Food Sci. Technol. 2016, 53, 2127–2138. [Google Scholar] [CrossRef]

- Panozzo, J.; Eagles, H. Cultivar and environmental effects on quality characters in wheat. I. Starch. Aust. J. Agric. Res 2000, 51, 629–636. [Google Scholar] [CrossRef]

- Wang, X.; Cai, J.; Liu, F.; Jin, M.; Yu, H.; Jiang, D.; Cao, W. Pre-anthesis high temperature acclimation alleviates the negative effects of post-anthesis heat stress on stem stored carbohydrates remobilization and grain starch accumulation in wheat. J. Cereal Sci. 2012, 55, 331–336. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, Z.; Yin, Y.; Cai, R.; Yan, S.; Li, W. Starch content and granule size distribution in grains of wheat in relation to post-anthesis water deficits. J. Agron. Crop. Sci. 2010, 196, 1–8. [Google Scholar] [CrossRef]

- Ni, Y.; Wang, Z.; Yin, Y.; Li, W.; Yan, S.; Cai, T. Starch granule size distribution in wheat grain in relation to phosphorus fertilization. J. Agric. Sci. 2010, 150, 45–52. [Google Scholar] [CrossRef]

- Xiong, F.; Yu, X.; Zhou, L.; Zhang, J.; Jin, Y.; Li, D.; Wang, Z. Effect of nitrogen fertilizer on distribution of starch granules in different regions of wheat endosperm. Crop. J. 2014, 2, 46–54. [Google Scholar] [CrossRef]

- Li, W.; Yan, S.; Yin, Y.; Wang, Z. Starch granule size distribution in wheat grain in relation to shading after anthesis. J. Agric. Sci. 2010, 148, 183–189. [Google Scholar] [CrossRef]

- Li, H.; Cai, J.; Jiang, D.; Liu, F.; Dai, T.; Cao, W. Carbohydrates accumulation and remobilization in wheat plants as influenced by combined waterlogging and shading stress during grain filling. J. Agron. Crop. Sci. 2013, 199, 38–48. [Google Scholar] [CrossRef]

- Burkey, K.O.; Wells, R. Effects of natural shade on soybean thylakoid membrane composition. Photosynth. Res. 1996, 50, 149–158. [Google Scholar] [CrossRef]

- Huang, Q.; Liu, H.; Chen, R. Effects of shade on photosynthetic characteristics in Chieh-qua. Acta Hortic. 2004, 659, 799–804. [Google Scholar]

- Dai, Z.; Yin, Y.; Wang, Z. Starch granule size distribution from seven wheat cultivars under different water regimes. Cereal Chem. 2009, 86, 82–87. [Google Scholar] [CrossRef]

- Zhang, C. Research on Characteristics and Physiological Mechanism for Formation of Starch Granule Size Distribution in Wheat Grain Agricultural College; Nanjing Agricultural University: Nanjing, China, 2010. [Google Scholar]

- Wardlaw, I.F.; Moncur, L. The response of wheat to high temperature following anthesis. I. the rate and duration of kernel filling. Funct. Plant. Biol. 1995, 22, 391–397. [Google Scholar] [CrossRef]

- Yu, X.; Yu, H.; Zhang, J.; Shao, S.; Zhou, L.; Xiong, F.; Wang, Z. Comparison of endosperm starch granule development and physicochemical properties of starches from waxy and non-waxy wheat. Int. J. Food Prop. 2015, 18, 2409–2421. [Google Scholar] [CrossRef]

- Zhou, Q.; Huang, M.; Huang, X.; Xin, H.; Jing, L.; Xiao, W.; Jian, C.; Tingbo, D.; Weixing, C.; Dong, J. Effect of post-anthesis waterlogging on biosynthesis and granule size distribution of starch in wheat grains. Plant. Physiol. Biochem. 2018, 132, 222–228. [Google Scholar] [CrossRef]

| Treatment | Content (%) | Accumulation Account (mg/plant) | Peak Viscosity (cP) | Trough Viscosity (cP) | Final Viscosity (cP) | Pasting Temperature (°C) | ||

|---|---|---|---|---|---|---|---|---|

| Amylose | Amylopectin | Amylose | Amylopectin | |||||

| Non-WS | 14.4 d | 46.5 a | 326.9 a | 1055.6 a | 3195 c | 2320 a | 4213 a | 72.3 b |

| WS0–7 | 15 b | 45.6 b | 316.5 b | 962.2 b | 3663 b | 2108 b | 3960 b | 72.8 b |

| WS8–15 | 16 a | 37.4 d | 300.8 c | 703.1 e | 3988 a | 1916 d | 3492 c | 76.8 a |

| WS16–23 | 15.4 b | 42.7 c | 297.2 c | 824.1 d | 3653 b | 2040 c | 3978 b | 75.3 a |

| WS24–31 | 14.9 c | 44.5 b | 311.4 b | 930.1 c | 3187 c | 2206 ab | 4050 ab | 73.5 ab |

| Treatments | Mean Grain Size (μm) | Volume Frequency Percent of Different Kinds Starch Granules (%) | PA/PB | ||||

|---|---|---|---|---|---|---|---|

| B1-type | B2-type | B3-type | A1-type | A2-type | |||

| Non-WS | 15.03 a | 5.16 d | 10.61 d | 0.249 d | 57.31 a | 4.93 c | 1.65 a |

| WS0–7 | 14.68 b | 5.84 a | 11.34 b | 0.254 c | 54.3 c | 4.8 d | 1.45 b |

| WS8–15 | 14.19 d | 5.47 c | 11.61a | 0.268 a | 49.51 d | 5.88 a | 1.24 d |

| WS16–23 | 14.6 c | 5.76 b | 11.16 c | 0.263 b | 52.36 c | 5.82 b | 1.39 c |

| WS24–31 | 14.65 b | 5.75 b | 11.25 b | 0.257 c | 54.45 b | 4.93 c | 1.47 b |

| Treatments | Surface Area m2 g−1 | Surface Frequency Percent of Different Kinds Starch Granules (%) | ||||

|---|---|---|---|---|---|---|

| B1-type | B2-type | B3-type | A1-type | A2-type | ||

| Non-WS | 0.659 d | 31.47 d | 26.79 b | 22.59 e | 18.33 a | 0.81 b |

| WS0–7 | 0.689 c | 34.00 a | 26.68 b | 22.84 d | 15.72 c | 0.76 c |

| WS8–15 | 0.765 a | 33.56 c | 27.03 a | 24.55 a | 14.33 d | 0.93 a |

| WS16–23 | 0.717 b | 33.64 b | 26.16 c | 24.04 b | 15.25 c | 0.91 a |

| WS24–31 | 0.691 c | 33.72 b | 26.41 b | 23.03 c | 16.06 b | 0.79 b |

| Treatments | Number × 1010 g−1 | Number Frequency Percent of Different Kinds Starch Granules (%) | ||||

|---|---|---|---|---|---|---|

| B1-type | B2-type | B3-type | A1-type | A2-type | ||

| Non-WS | 6.63 e | 85.43 d | 12.54 a | 1.86 a | 0.145 a | 0.017 b |

| WS0-7 | 7.39 b | 86.03 a | 12.13 c | 1.72 c | 0.135 c | 0.006 c |

| WS8-15 | 8.45 a | 85.94 b | 12.27 b | 1.65 c | 0.133 d | 0.018 a |

| WS16-23 | 7.22 c | 85.9 b | 12.13 c | 1.83 b | 0.138 c | 0.006 c |

| WS24-31 | 7.06 d | 85.86 c | 11.95 d | 1.73 c | 0.141 b | 0.006 c |

| Peak Viscosity | Trough Viscosity | Final Viscosity | Pasting Temperature | |

|---|---|---|---|---|

| Amylose content | 0.890 * | −0.982 ** | −0.943 * | 0.958 * |

| Amylopectin content | −0.782 | 0.882 * | 0.946 * | −0.967 ** |

| Starch content of grain | −0.752 | 0.892 * | 0.935 * | −0.957 * |

| Amylose/Amylopectin | 0.822 | −0.909 * | −0.962 ** | 0.964 ** |

| Mean grain size of starch granules | −0.816 | 0.938 * | 0.959 ** | −0.903 * |

| Mean grain size of B-type starch granules | 0.795 | −0.932 * | −0.839 | 0.817 |

| Mean grain size of A-type starch granules | −0.924 * | 0.983 ** | 0.878 | −0.943 * |

| PA/PB | −0.865 | 0.976 ** | 0.933 * | −0.911 * |

| Number (×1010 g−1) | 0.883 * | −0.944 * | −0.993 ** | 0.919 * |

| Surface area (m2 g−1) | 0.852 | −0.954 * | −0.956 * | 0.971 ** |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Wang, Z.; Zhuo, Q.; Zhang, B.; Wang, F.; Jiang, D. Starch Granule Size Distribution and Pasting Characteristic Response to Post-Anthesis Combined Stress of Waterlogging and Shading. Agriculture 2020, 10, 384. https://doi.org/10.3390/agriculture10090384

Li H, Wang Z, Zhuo Q, Zhang B, Wang F, Jiang D. Starch Granule Size Distribution and Pasting Characteristic Response to Post-Anthesis Combined Stress of Waterlogging and Shading. Agriculture. 2020; 10(9):384. https://doi.org/10.3390/agriculture10090384

Chicago/Turabian StyleLi, Huawei, Zongshuai Wang, Qicui Zhuo, Bin Zhang, Fahong Wang, and Dong Jiang. 2020. "Starch Granule Size Distribution and Pasting Characteristic Response to Post-Anthesis Combined Stress of Waterlogging and Shading" Agriculture 10, no. 9: 384. https://doi.org/10.3390/agriculture10090384

APA StyleLi, H., Wang, Z., Zhuo, Q., Zhang, B., Wang, F., & Jiang, D. (2020). Starch Granule Size Distribution and Pasting Characteristic Response to Post-Anthesis Combined Stress of Waterlogging and Shading. Agriculture, 10(9), 384. https://doi.org/10.3390/agriculture10090384