Methodology of Analyzing Maize Density Loss in Smallholder’s Fields and Potential Optimize Approach

Abstract

:1. Introduction

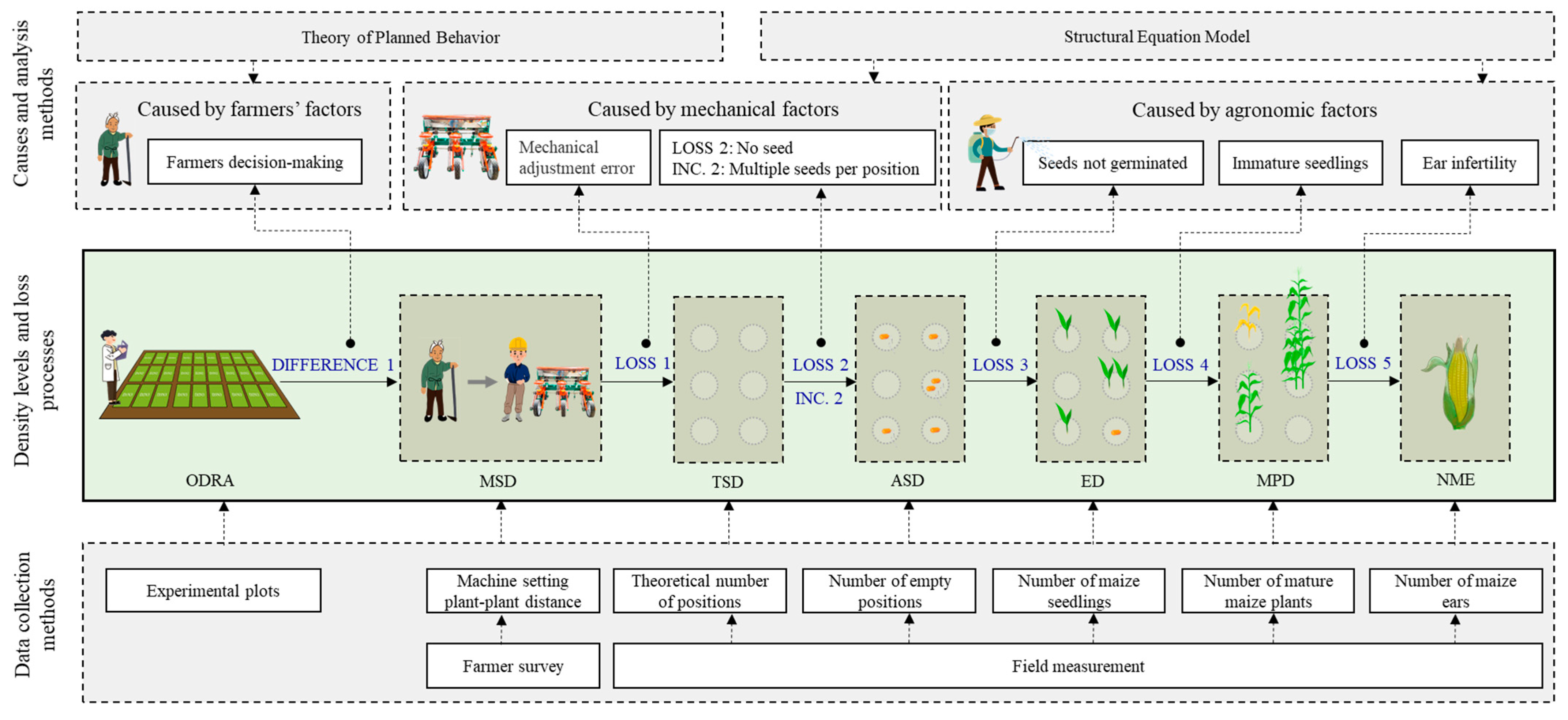

2. Materials and Methods

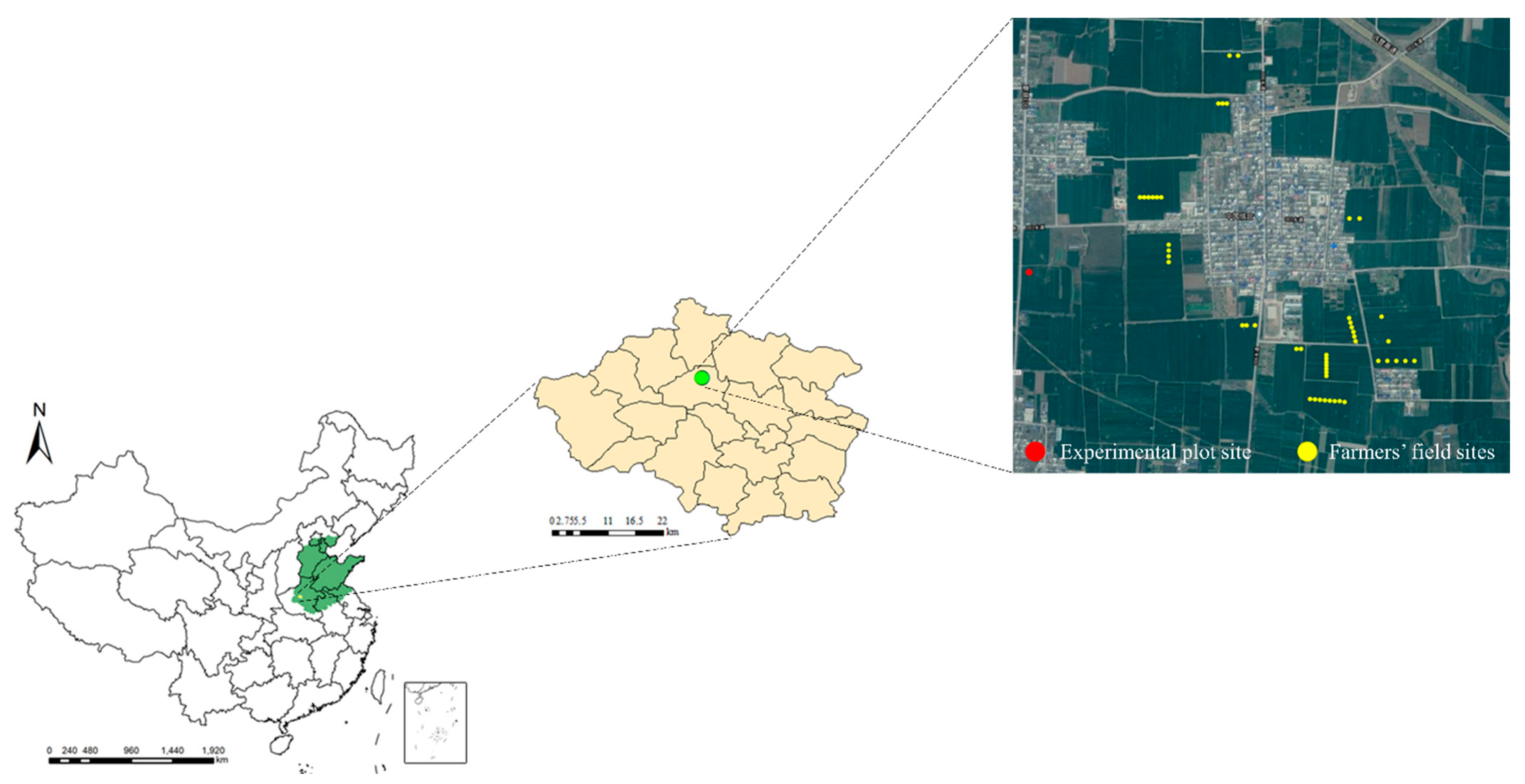

2.1. Study Area 0′27″

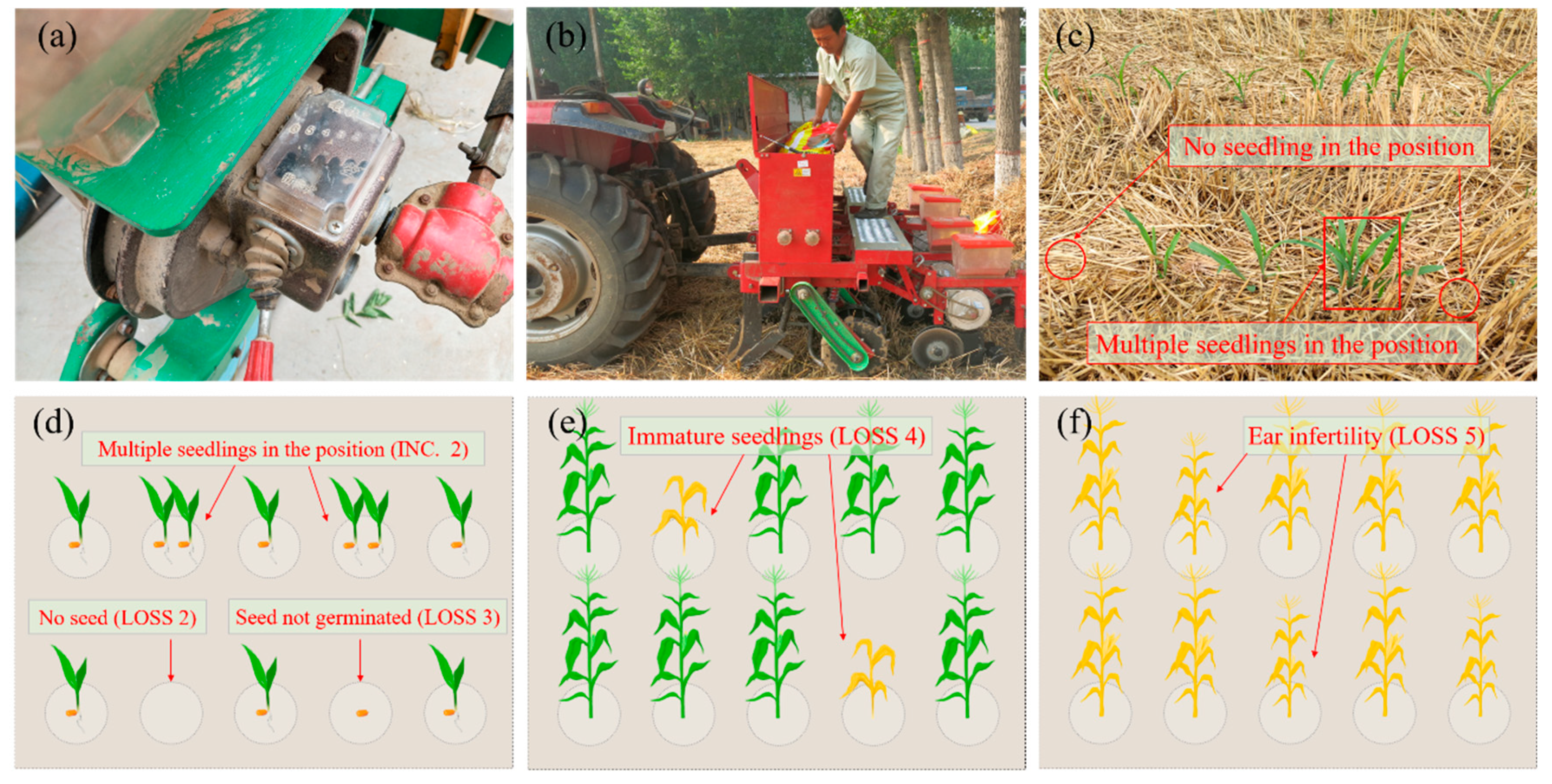

2.2. Measurement Methods of Density Loss and Data Collection

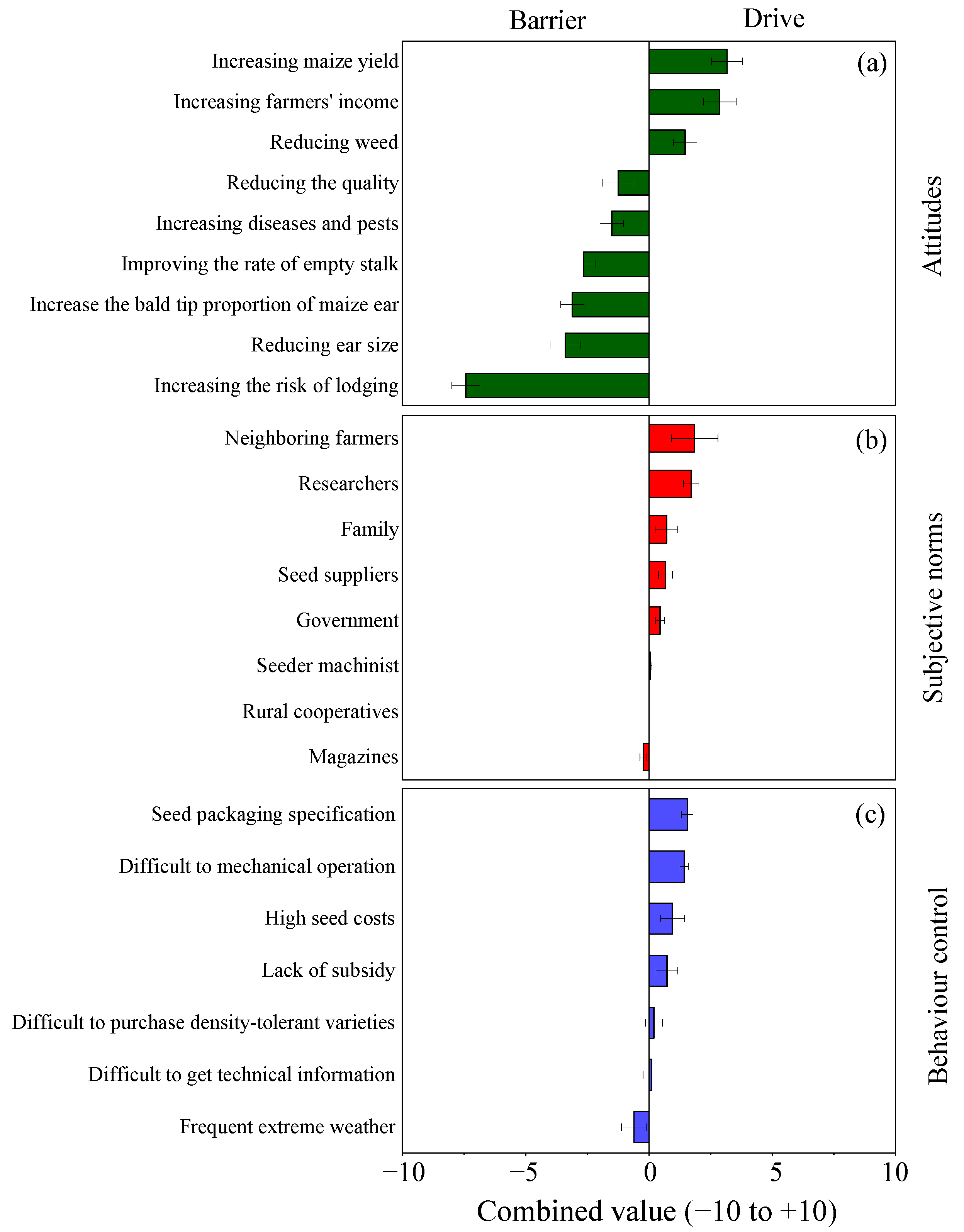

2.3. Theory of Planned Behavior

2.4. Statistical Analysis

3. Results

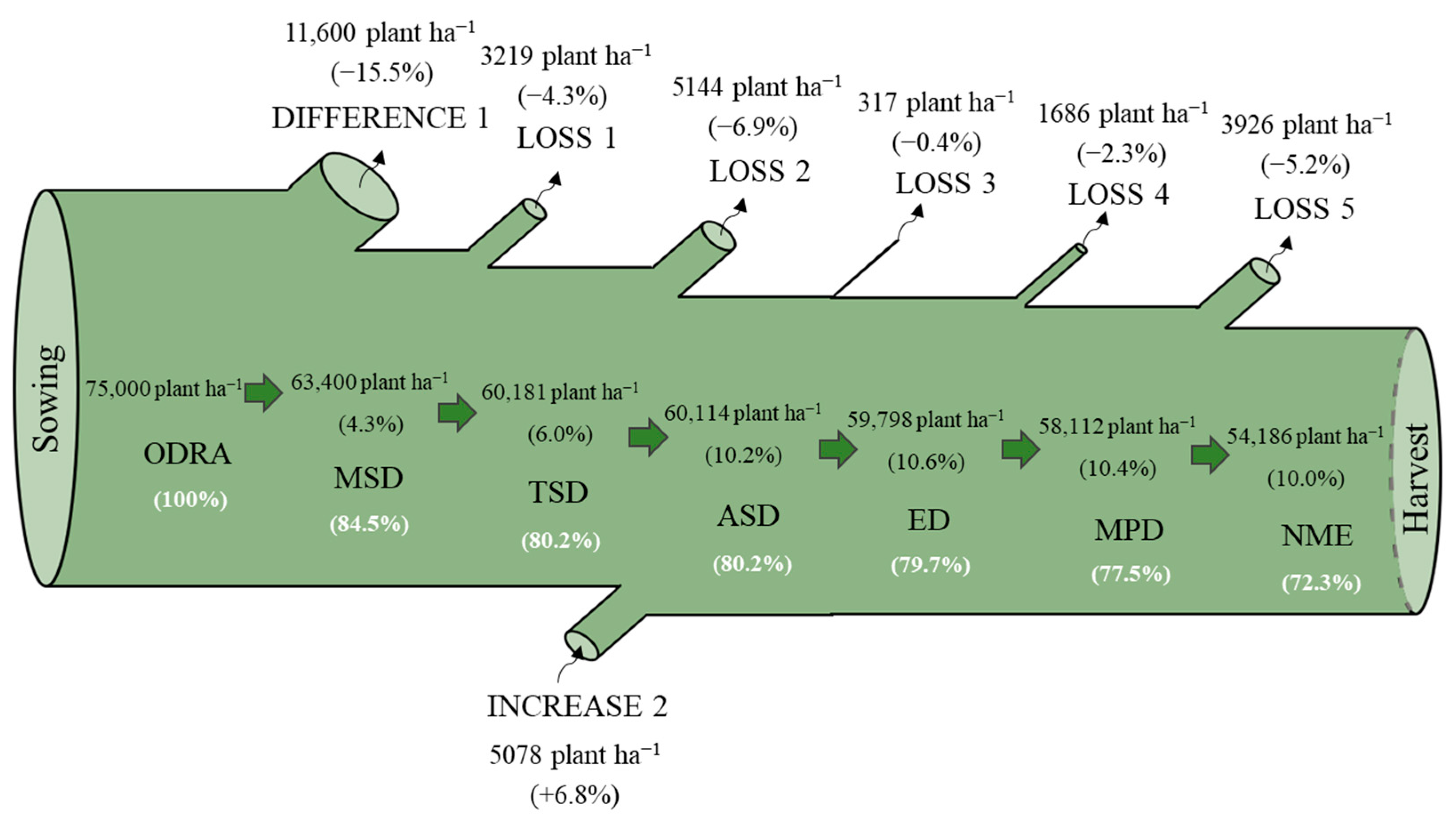

3.1. Sowing Density Difference Caused by Farmer Factors and Other Causes

3.2. Density Loss Caused by Mechanical Factors and Agronomic Factors

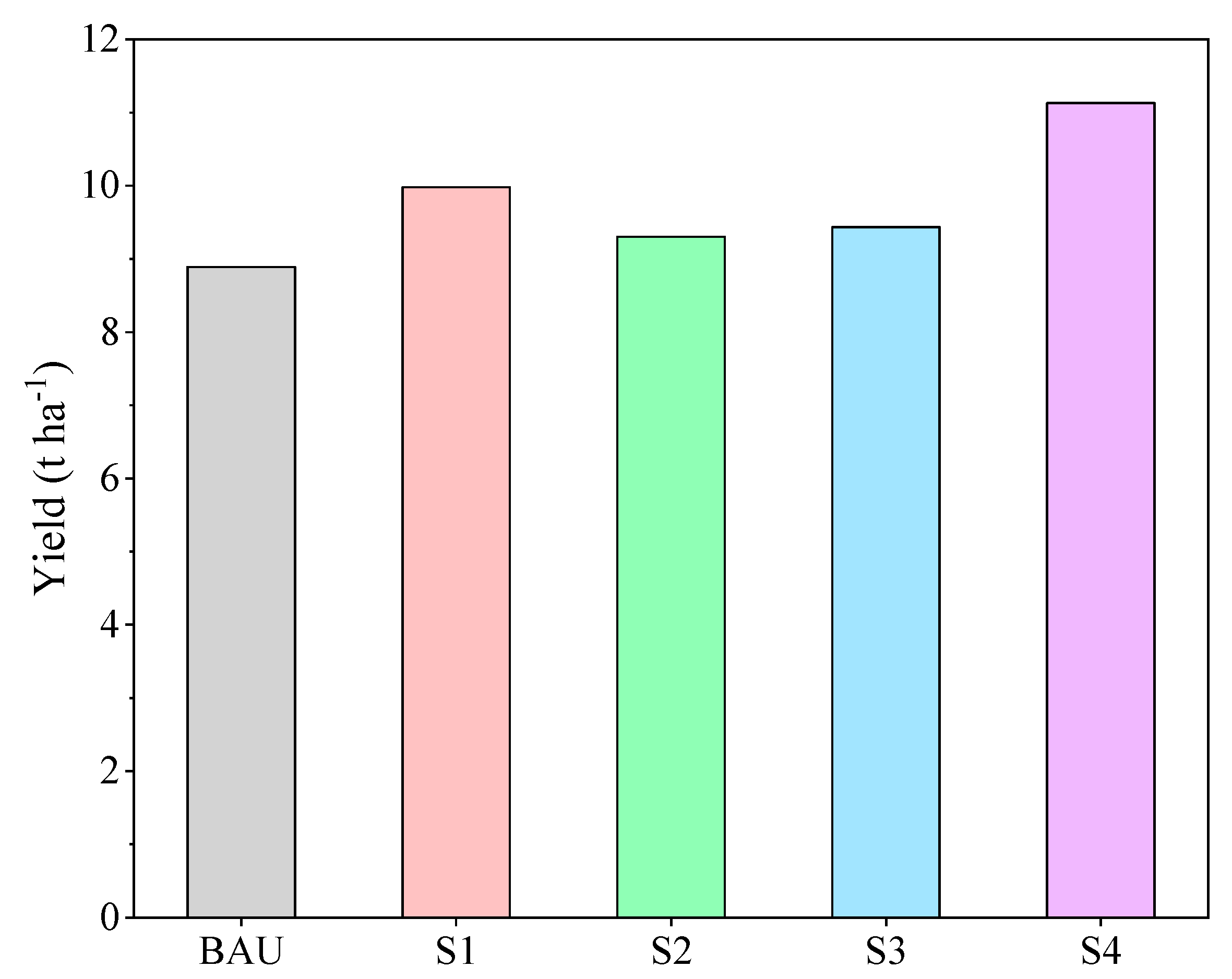

3.3. Effects of Density Loss on Yield and Scenario Analysis Results

4. Discussion

4.1. Systematic Methodology of Analyzing the Primary Causes for Density Difference and Loss

4.2. Density Difference between Agronomists and Smallholders

4.3. Density Loss Caused by Mechanical and Agronomic Factors

4.4. Potential Optimization Approach of Reducing Density Loss

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, W.; Liu, C.; Wang, K.; Xie, R.; Ming, B.; Wang, Y.; Zhang, G.; Liu, G.; Zhao, R.; Fan, P.; et al. Adjusting maize plant density to different climatic conditions across a large longitudinal distance in China. Field Crops Res. 2017, 212, 126–134. [Google Scholar] [CrossRef]

- Ray, D.K.; Ramankutty, N.; Mueller, N.D.; West, P.C.; Foley, J.A. Recent patterns of crop yield growth and stagnation. Nat. Commun. 2012, 3, 1293. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Chen, X.; Meng, Q.; Yang, H.; van Wart, J. Estimating maize yield potential and yield gap with agro-climatic zones in China distinguish irrigated and rainfed conditions. Agric. For. Meteorol. 2017, 239, 108–117. [Google Scholar] [CrossRef]

- Meng, Q.; Hou, P.; Wu, L.; Chen, X.; Cui, Z.; Zhang, F. Understanding production potentials and yield gaps in intensive maize production in China. Field Crops Res. 2013, 143, 91–97. [Google Scholar] [CrossRef] [Green Version]

- Ray, D.K.; Gerber, J.S.; MacDonald, G.K.; West, P.C. Climate variation explains a third of global crop yield variability. Nat. Commun. 2015, 6, 5989. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Z.; Yang, X.; Lin, X.; Hubbard, K.G.; Lv, S.; Wang, J. Narrowing the agronomic yield gaps of maize by improved soil, cultivar, and agricultural management practices in different climate zones of Northeast China. Earth Interact. 2016, 20, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Ren, H.; Li, Z.; Cheng, Y.; Zhang, J.; Liu, P.; Li, R.; Yang, Q.; Dong, S.; Zhang, J.; Zhao, B. Narrowing yield gaps and enhancing nitrogen utilization for summer maize (Zea mays L.) by combining the effects of varying nitrogen fertilizer input and planting density in DSSAT simulations. Front. Plant Sci. 2020, 11, 1787. [Google Scholar] [CrossRef]

- National Bureau of Statistics. Main Data Bulletin of the Third National Agricultural Census. Beijing. 2017. Available online: http://www.stats.gov.cn/ (accessed on 7 January 2021).

- Mueller, N.D.; Gerber, J.S.; Johnston, M.; Ray, D.K.; Ramankutty, N.; Foley, J.A. Closing yield gaps through nutrient and water management. Nature 2012, 490, 254–257. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Cao, G.; Li, X.; Zhang, H.; Wang, C.; Liu, Q.; Chen, X.; Cui, Z.; Shen, J.; Jiang, R.; et al. Closing yield gaps in China by empowering smallholder farmers. Nature 2016, 537, 671–674. [Google Scholar] [CrossRef]

- Chen, G.; Cao, H.; Liang, J.; Ma, W.; Guo, L.; Zhang, S.; Jiang, R.; Zhang, H.; Goulding, K.W.T.; Zhang, F. Factors affecting nitrogen use efficiency and grain yield of summer maize on smallholder farms in the North China Plain. Sustainability 2018, 10, 363. [Google Scholar] [CrossRef] [Green Version]

- Sun, H.; Zhang, X.; Wang, E.; Chen, S.; Shao, L.; Qin, W. Assessing the contribution of weather and management to the annual yield variation of summer maize using APSIM in the North China Plain. Field Crops Res. 2016, 194, 94–102. [Google Scholar] [CrossRef]

- Timlin, D.J.; Fleisher, D.H.; Kemanian, A.R.; Reddy, V.R. Plant density and leaf area index effects on the distribution of light transmittance to the soil surface in maize. Agron. J. 2014, 106, 1828–1837. [Google Scholar] [CrossRef]

- Ren, B.; Liu, W.; Zhang, J.; Dong, S.; Liu, P.; Zhao, B. Effects of plant density on the photosynthetic and chloroplast characteristics of maize under high-yielding conditions. Sci. Nat. 2017, 104, 12. [Google Scholar] [CrossRef]

- Han, K.; Yin, F.; Liu, P. Planting density and N application rate balance maize agronomic and environmental effect. Nutr. Cycl. Agroecosyst. 2020, 117, 337–349. [Google Scholar] [CrossRef]

- Li, J.; Wu, M.; Wang, K.; Ming, B.; Chang, X.; Wang, X.; Yang, Z.; Xie, R.; Li, S. Identifying ways to narrow maize yield gaps based on plant density experiments. Agronomy 2020, 10, 281. [Google Scholar] [CrossRef] [Green Version]

- Sher, A.; Khan, A.; Cai, L.J.; Irfan Ahmad, M.; Asharf, U.; Jamoro, S.A. Response of maize grown under high plant density; Performance, issues and management—A critical review. Adv. Crop Sci. Technol. 2017, 5, 275. [Google Scholar] [CrossRef] [Green Version]

- Li, T.; Liu, J.; Wang, S.; Zhang, Y.; Zhan, A.; Li, S. Maize yield response to nitrogen rate and plant density under film mulching. Agron. J. 2018, 110, 996–1007. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Xing, S.; Zhang, Q.; Zhang, F.; Ma, W. Causes of maize density loss in farmers’ fields in Northeast China. J. Integr. Agric. 2019, 18, 1680–1689. [Google Scholar] [CrossRef]

- Huang, X.; Yang, W.; Wang, W.; Li, Z.; Chen, L. Design and experiment of straw shifting anti-blocking maize seed drill. Int. Agric. Eng. J. 2018, 27, 166–175. [Google Scholar]

- Tabakovic, M.; Simic, M.; Stanisavljevic, R.; Milivojevic, M.; Secanski, M.; Postic, D. Effects of shape and size of hybrid maize seed on germination and vigour of different genotypes. Chil. J. Agric. Res. 2020, 80, 381–392. [Google Scholar] [CrossRef]

- Chapwanya, M.; Matusse, A.; Dumont, Y. On synergistic co-infection in crop diseases. The case of the maize lethal necrosis disease. Appl. Math. Model. 2021, 90, 912–942. [Google Scholar] [CrossRef]

- Lu, H.; Hu, L.; Zheng, W.; Yao, S.; Qian, L. Impact of household land endowment and environmental cognition on the willingness to implement straw incorporation in China. J. Clean. Prod. 2020, 262, 121479. [Google Scholar] [CrossRef]

- Kamanga, B.C.G.; Waddington, S.R.; Robertson, M.J.; Giller, K.E. Risk analysis of maize-legume crop combinations with smallholder farmers varying in resource endowment in central Malawi. Exp. Agric. 2010, 46, 1–21. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Li, X.; Gong, T.; Zhang, H. Life cycle assessment of wheat-maize rotation system emphasizing high crop yield and high resource use efficiency in Quzhou County. J. Clean. Prod. 2014, 68, 56–63. [Google Scholar] [CrossRef]

- FAO. World Reference Base for Soil Resources 2014 International Soil Classification System; FAO: Rome, Italy, 2015; ISBN 9789251083697. [Google Scholar]

- Assefa, Y.; Prasad, P.V.V.; Carter, P.; Hinds, M.; Bhalla, G.; Schon, R.; Jeschke, M.; Paszkiewicz, S.; Ciampitti, I.A. Yield Responses to Planting Density for US Modern Corn Hybrids: A Synthesis—Analysis. Crop Sci. 2016, 56, 2802–2817. [Google Scholar] [CrossRef]

- Zhao, Y.; Huang, Y.; Li, S.; Chu, X.; Ye, Y. Improving the growth, lodging and yield of different density-resistance maize by optimising planting density and nitrogen fertilisation. Plant Soil Environ. 2020, 66, 453–460. [Google Scholar] [CrossRef]

- Ajzen, I. The theory of planned behavior. Org. Behav. Hum. Decis. Proc. 1991, 50, 179–211. [Google Scholar] [CrossRef]

- Hijbeek, R.; Pronk, A.A.; van Ittersum, M.K.; Verhagen, A.; Ruysschaert, G.; Bijttebier, J.; Zavattaro, L.; Bechini, L.; Schlatter, N.; Ten Berge, H.F.M. Use of organic inputs by arable farmers in six agro-ecological zones across Europe: Drivers and barriers. Agric. Ecosyst. Environ. 2019, 275, 42–53. [Google Scholar] [CrossRef]

- Schipanski, M.E.; Smith, R.G.; Gareau, T.L.P.; Jabbour, R.; Lewis, D.B.; Barbercheck, M.E.; Mortensen, D.A.; Kaye, J.P. Mul-tivariate relationships influencing crop yields during the transition to organic management. Agric. Ecosyst. Environ. 2014, 189, 119–126. [Google Scholar] [CrossRef]

- Li, J.; Xie, R.Z.; Wang, K.R.; Ming, B.; Guo, Y.Q.; Zhang, G.Q.; Li, S.K. Variations in maize dry matter, harvest index, and grain yield with plant density. Agron. J. 2015, 107, 829–834. [Google Scholar] [CrossRef]

- Assefa, Y.; Carter, P.; Hinds, M.; Bhalla, G.; Schon, R.; Jeschke, M.; Paszkiewicz, S.; Smith, S.; Ciampitti, I.A. Analysis of long term study indicates both agronomic optimal plant density and increase maize yield per plant contributed to yield gain. Sci. Rep. 2018, 8, 4937. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, T.; Hou, Y.; Meng, T.; Ma, Y.; Tan, M.; Zhang, F.; Oenema, O. Replacing synthetic fertilizer by manure requires adjusted technology and incentives: A farm survey across China. Resour. Conserv. Recycl. 2021, 168, 105301. [Google Scholar] [CrossRef]

- Assefa, B.T.; Chamberlin, J.; Reidsma, P.; Silva, J.V.; van Ittersum, M.K. Unravelling the variability and causes of small-holder maize yield gaps in Ethiopia. Food Secur. 2020, 12, 83–103. [Google Scholar] [CrossRef] [Green Version]

- Anbessa, F.; Abraham, T.; Ashagre, H. Performance of maize (Zea mays L.) influenced by NPSB blended fertilizer rates and plant population on yield and economic analysis at Bako. Green Farm. 2020, 11, 111–117. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, X.; Lin, X.; Hubbard, K.G.; Lv, S.; Wang, J. Maize yield gaps caused by non-controllable, agronomic, and socioeconomic factors in a changing climate of Northeast China. Sci. Total Environ. 2016, 541, 756–764. [Google Scholar] [CrossRef]

- Sher, A.; Khan, A.; Ashraf, U.; Liu, H.H.; Li, J.C. Characterization of the effect of increased plant density on canopy morphology and stalk lodging risk. Front. Plant Sci. 2018, 9, 1047. [Google Scholar] [CrossRef]

- Shao, H.; Shi, D.; Shi, W.; Ban, X.; Chen, Y.; Ren, W.; Chen, F.; Mi, G. The impact of high plant density on dry matter remobilization and stalk lodging in maize genotypes with a different stay-green degree. Arch. Agron. Soil Sci. 2020, 67, 504–518. [Google Scholar] [CrossRef]

- Robertson, D.J.; Julias, M.; Lee, S.Y.; Cook, D.D. Maize stalk lodging: Morphological determinants of stalk strength. Crop Sci. 2017, 57, 926–934. [Google Scholar] [CrossRef] [Green Version]

- Shi, D.; Li, Y.; Zhang, J.; Liu, P.; Zhao, B.; Dong, S. Increased plant density and reduced N rate lead to more grain yield and higher resource utilization in summer maize. J. Integr. Agric. 2016, 15, 2515–2528. [Google Scholar] [CrossRef] [Green Version]

- Ma, D.; Xie, R.; Liu, X.; Niu, X.; Hou, P.; Wang, K.; Lu, Y.; Li, S. Lodging-related stalk characteristics of maize varieties in China since the 1950s. Crop Sci. 2014, 54, 2805–2814. [Google Scholar] [CrossRef]

- Wang, Q.; Xue, J.; Zhang, G.; Chen, J.; Xie, R.; Ming, B.; Hou, P.; Wang, K.; Li, S. Nitrogen split application can improve the stalk lodging resistance of maize planted at high density. Agriculture 2020, 10, 364. [Google Scholar] [CrossRef]

- Rossini, M.A.; Maddonni, G.A.; Otegui, M.E. Inter-plant competition for resources in maize crops grown under contrasting nitrogen supply and density: Variability in plant and ear growth. Field Crops Res. 2011, 121, 373–380. [Google Scholar] [CrossRef]

- Piao, L.; Qi, H.; Li, C.; Zhao, M. Optimized tillage practices and row spacing to improve grain yield and matter transport efficiency in intensive spring maize. Field Crops Res. 2016, 198, 258–268. [Google Scholar] [CrossRef]

- Seilsepour, M.; Jafari, P.; Molahoseini, H. The effects of drought stress and plant density on yield and some agronomic traits of maize (Sc301). Res. Agric. Sci. 2007, 2, e12–e13. [Google Scholar]

- Ciampitti, I.A.; Murrell, S.T.; Camberato, J.J.; Tuinstra, M.; Xia, Y.; Friedemann, P.; Vyn, T.J. Physiological dynamics of maize nitrogen uptake and partitioning in response to plant density and nitrogen stress factors: II. Reproductive phase. Crop Sci. 2013, 53, 2588–2602. [Google Scholar] [CrossRef]

- Oury, V.; Tardieu, F.; Turc, O. Ovary apical abortion under water deficit is caused by changes in sequential development of ovaries and in silk growth rate in maize. Plant Physiol. 2016, 171, 986–996. [Google Scholar]

- Knappenberger, T.; Koller, K. Simulation of germination and emergence of corn to gain information for sitespecific drilling. Bulletin of University of Agricultural Sciences and Veterinary Medicine Cluj-Napoca. Agriculture 2008, 65, 147–152. [Google Scholar]

- Zhao, X.; Mei, P.; Zhang, F.; Wu, F.; Xue, H.; Zhang, J.; Huang, R.; Tang, B.; Li, C. Effects of seed grading on growth and yield of summer maize under no-tilling precision sowing conditions. Bangladesh J. Bot. 2016, 45S, 803–810. [Google Scholar]

- Zhao, P.; Cao, G.; Zhao, Y.; Zhang, H.; Chen, X.; Li, X.; Cui, Z. Training and organization programs increases maize yield and nitrogen-use efficiency in smallholder agriculture in China. Agron. J. 2016, 108, 1944–1950. [Google Scholar] [CrossRef]

- Kamran, M.; Cui, W.; Ahmad, I.; Meng, X.; Zhang, X.; Su, W.; Chen, J.; Ahmad, S.; Fahad, S.; Han, Q.; et al. Effect of paclobutrazol, a potential growth regulator on stalk mechanical strength, lignin accumulation and its relation with lodging resistance of maize. Plant Growth Regul. 2018, 84, 317–332. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, Z.; Wang, C.; Jiao, X.; Kong, Z.; Jiang, W.; Zhang, D.; Ma, W.; Zhang, F. Methodology of Analyzing Maize Density Loss in Smallholder’s Fields and Potential Optimize Approach. Agriculture 2021, 11, 480. https://doi.org/10.3390/agriculture11060480

An Z, Wang C, Jiao X, Kong Z, Jiang W, Zhang D, Ma W, Zhang F. Methodology of Analyzing Maize Density Loss in Smallholder’s Fields and Potential Optimize Approach. Agriculture. 2021; 11(6):480. https://doi.org/10.3390/agriculture11060480

Chicago/Turabian StyleAn, Zhichao, Chong Wang, Xiaoqiang Jiao, Zhongliang Kong, Wei Jiang, Dong Zhang, Wenqi Ma, and Fusuo Zhang. 2021. "Methodology of Analyzing Maize Density Loss in Smallholder’s Fields and Potential Optimize Approach" Agriculture 11, no. 6: 480. https://doi.org/10.3390/agriculture11060480