Development Status and Research Progress of a Tractor Electro-Hydraulic Hitch System

Abstract

:1. Introduction

2. Development Status of the Tractor Electro-Hydraulic Hitch System

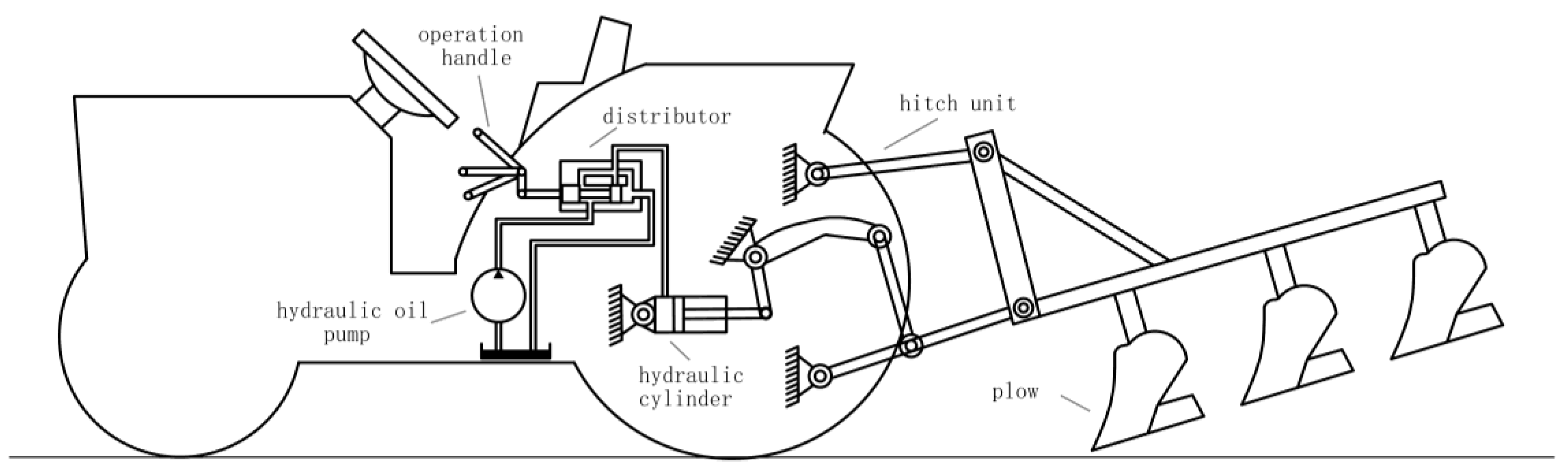

2.1. Basic Types of Hitch Systems

2.2. Development Status of the Electro-Hydraulic Hitch System in Foreign Countries

2.3. Development Status of the Electro-Hydraulic Hitch System in China

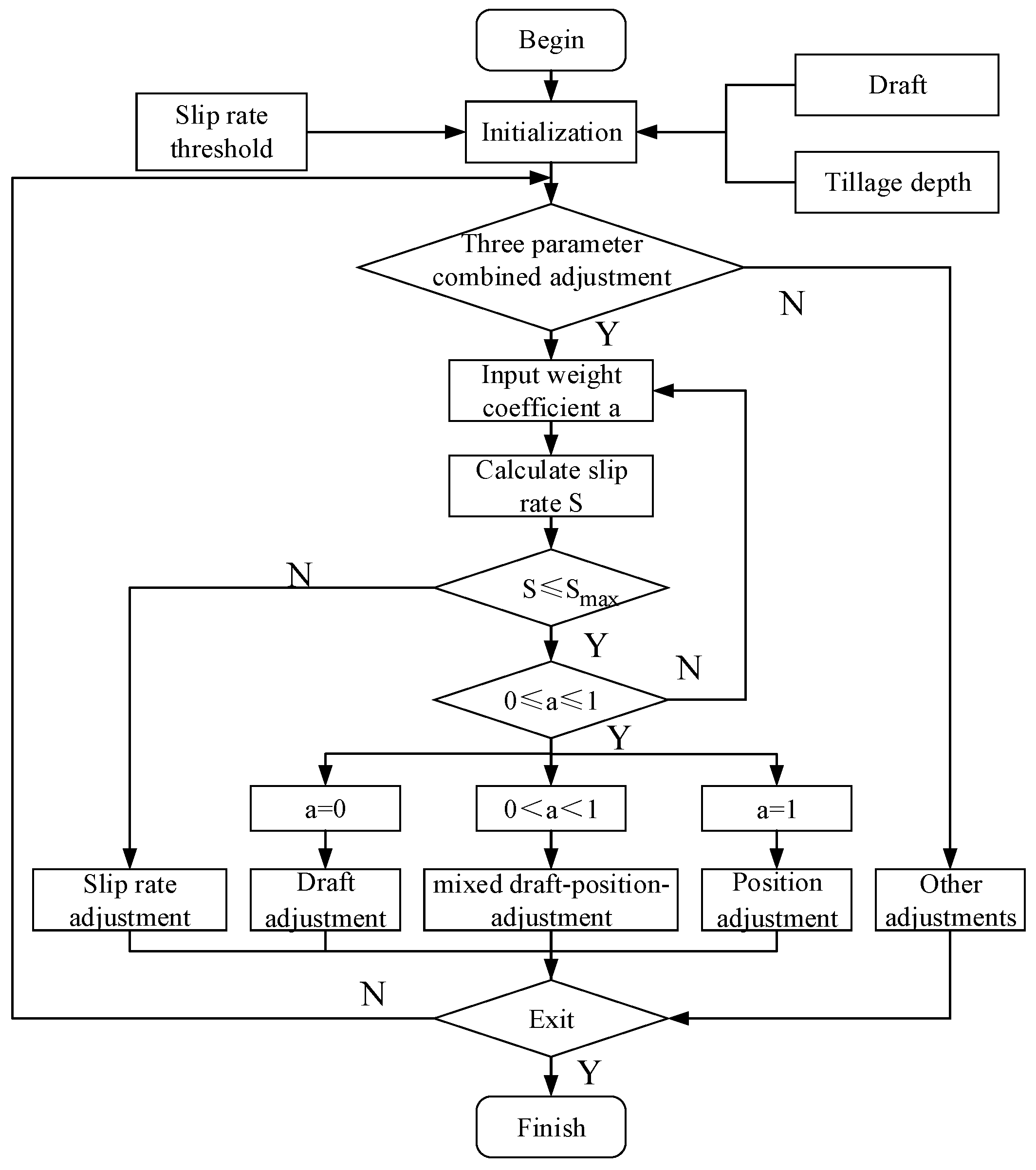

3. Research Progress into the Tillage Depth Adjustment Methods

3.1. Method of the Single Parameter Adjustment

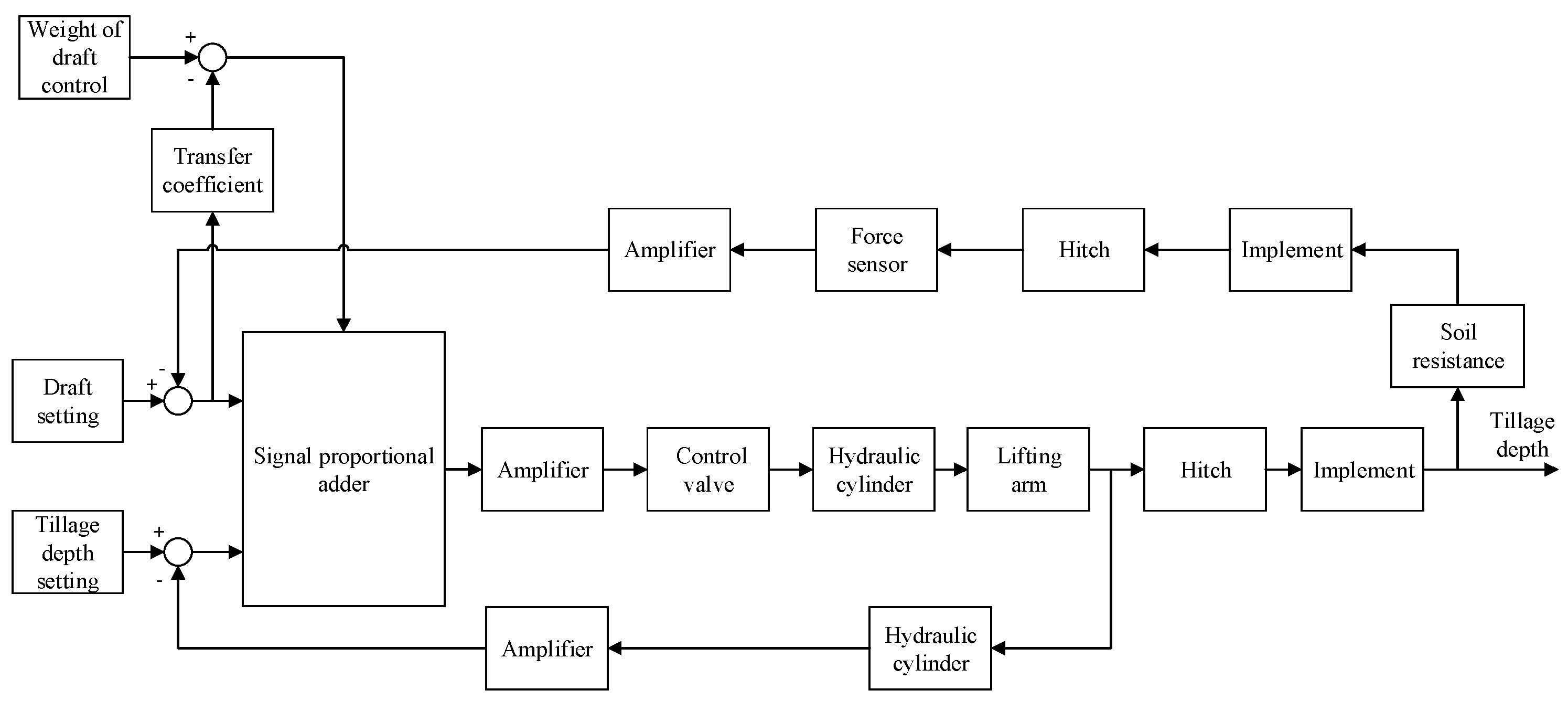

3.2. Method of the Mixed Draft-Position Adjustment

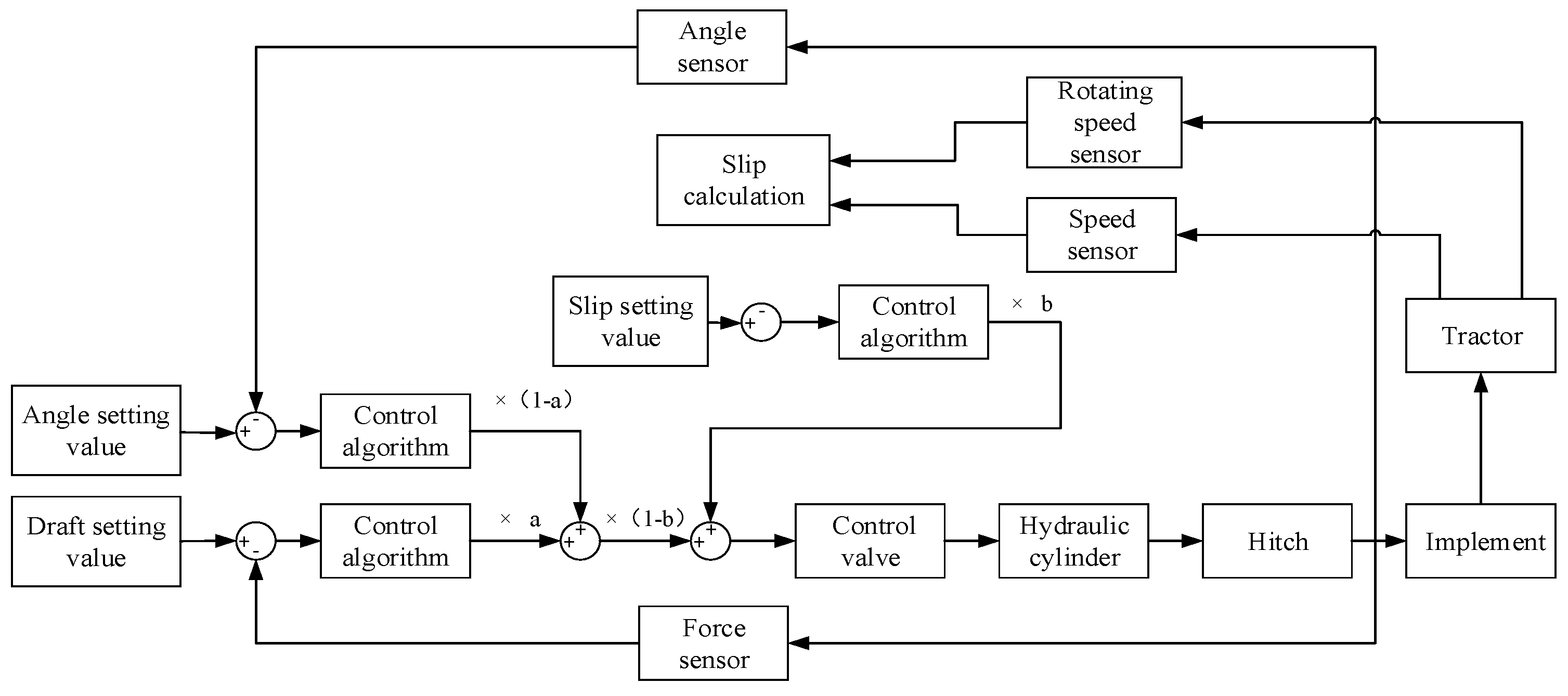

3.3. Method of the Mixed Draft-Position-Slip Adjustment

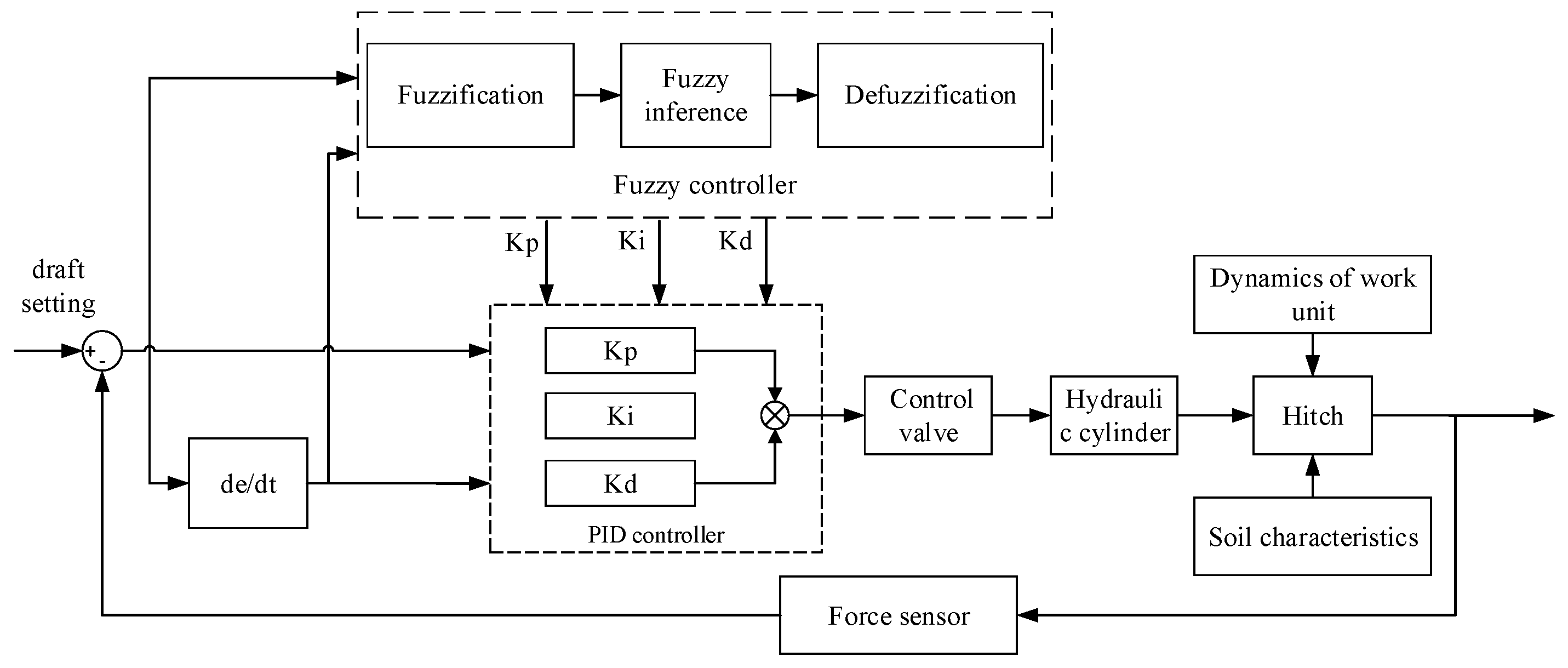

4. Research Progress of the Tillage Depth Control Algorithm

4.1. PID Control Algorithm of the Tillage Depth

4.2. Intelligent Control Algorithm of the Tillage Depth

5. Research Progress of Key Components of the Electro-Hydraulic Hitch System

5.1. Hydraulic Control Valve

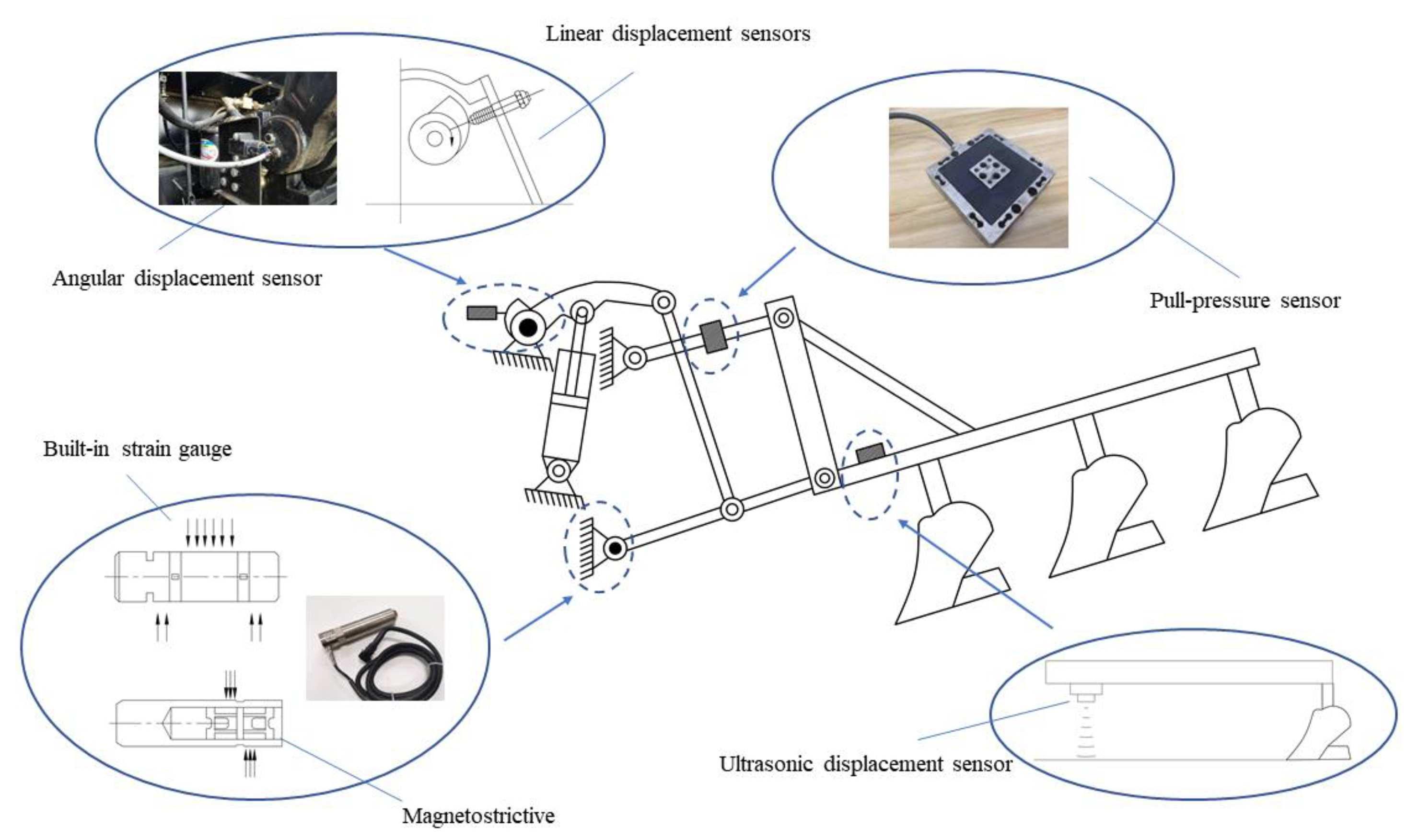

5.2. Sensor

5.2.1. Displacement Sensors

5.2.2. Draft Sensors

6. Conclusions and Prospects

- (1)

- The single-parameter adjustment method does not conform with the high-standard tillage quality requirements of modern precision agriculture. the coupling mechanism between the different adjustment parameters should be paid attention to in further research.

- (2)

- The integration of intelligent control algorithms can effectively improve the quality of work, but the impact of the different soil environments on the control system is not clear, and more field experiment tests will be required.

- (3)

- In terms of hardware, it is necessary to put forward higher design requirements for the key components of the electro-hydraulic hitch system. It is necessary to develop more intelligent control valves and strong anti-interference ability sensing elements.

6.1. Tillage Depth Adjustment Methods

6.2. Tillage Depth Control Algorithm

6.3. Key Components of the Electro-Hydraulic Hitch System

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kiropoulos, K.; Bibi, S.; Vakouftsi, F.; Pantzios, V. Precision agriculture investment return calculation tool. In Proceedings of the 17th International Conference on Distributed Computing in Sensor Systems (DCOSS), Pafos, Cyprus, 14–16 July 2021; IEEE: Electr Network, 2021; pp. 267–271. [Google Scholar]

- Gyarmati, G.; Mizik, T. The Present and Future of the Precision Agriculture, 2–4 June 2020; IEEE: Budapest, Hungary, 2020; pp. 593–596. [Google Scholar]

- Yang, X.; Shu, L.; Chen, J.N.; Ferrag, M.A.; Wu, J.; Nurellari, E.; Huang, K. A Survey on Smart Agriculture: Development Modes, Technologies, and Security and Privacy Challenges. IEEE-CAA J. Autom. Sin. 2021, 8, 273–302. [Google Scholar] [CrossRef]

- Bolfe, E.L.; Jorge, L.A.d.C.; Sanches, I.D.A.; Junior, A.L.; Costa, C.C.d.; Victoria, D.d.C.; Inamasu, R.Y.; Greog, C.R.; Ferreira, V.R.; Ramirez, A.R. Precision and digital agriculture: Adoption of technologies and perception of brazilian farmers. Agriculture 2020, 10, 653. [Google Scholar] [CrossRef]

- Anche, G.M.; Devika, K.B.; Subramanian, S.C. Robust Pitching Disturbance Force Attenuation for Tractor Considering Func-tional Constraints. IEEE Access 2020, 8, 86419–86432. [Google Scholar] [CrossRef]

- Shen, W.; Wang, J.H.; Huang, H.L.; He, J.Y. Fuzzy sliding mode control with state estimation for velocity control system of hydraulic cylinder using a new hydraulic transformer. Eur. J. Control 2019, 48, 104–114. [Google Scholar] [CrossRef]

- Sunusi, I.I.; Zhou, J.; Wang, Z.Z.; Sun, C.Y.; Ibrahim, I.E.; Opiyo, S.; Korohou, T.; Soomro, S.A.; Sale, N.A.; Olanrewaju, T.O. Intelligent tractors: Review of online traction control process. Comput. Electron. Agric. 2020, 170, 105176. [Google Scholar] [CrossRef]

- Aravind, K.R.; Raja, P.; Manuel, P.R. Task-based agricultural mobile robots in arable farming: A review. Span. J. Agric. Res. 2017, 15, e02R01. [Google Scholar] [CrossRef]

- Mamkagh, A.M. Effect of soil moisture, tillage speed, depth, ballast weight and, used implement on wheel slippage of the tractor: A review. Asian J. Adv. Agric. Res. 2019, 9, 1–7. [Google Scholar] [CrossRef]

- Mamkagh, A.M. Effect of tillage speed, depth, ballast weight and tire inflation pressure on the fuel consumption of the agricultural tractor: A review. J. Eng. Res. Rep. 2018, 3, 1–7. [Google Scholar] [CrossRef]

- Benkovic, R.; Sumanovac, L.; Jug, D.; Jug, I.; Japundzic-Palenkic, B.; Mirosavljevic, K.; Popijac, M.; Benkovic-Lacic, T. Influence of Aggregated Tillage Implements on Fuel Consumption and Wheel Slippage. Teh. Vjesn. Tech. Gaz. 2021, 28, 956–962. [Google Scholar]

- Mamkagh, A.M. Review of fuel consumption, draft force and ground speed measurements of the agricultural tractor during tillage operations. Asian J. Adv. Res. Rep. 2019, 3, 1–9. [Google Scholar] [CrossRef]

- Singha, P.S.; Kumar, A.; Sarkar, S.; Baishya, S.; Kumar, P. Development of Electro-Hydraulic Hitch Control System through Lower Link Draft Sensing of a Tractor. J. Sci. Ind. Res. 2022, 81, 384–392. [Google Scholar]

- Xu, J.K.; Li, R.C.; Li, Y.C.; Zhang, Y.S.; Sun, H.L.; Ding, X.K.; Ma, Y. Research on Variable-Universe Fuzzy Control Technology of an Electro-Hydraulic Hitch System. Processes 2021, 9, 1920. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Dai, D.; Wang, X.; Wang, S.M. Review of electro-hydraulic hitch system control method of automated tractors. Int. J. Agric. Biol. Eng. 2021, 14, 1–11. [Google Scholar] [CrossRef]

- Xiong, L.; Sun, S.L.; Xiao, M.T. Agricultural machinery automation and intelligent research and application. IOP Conf. Ser. Mater. Sci. Eng. 2018, 452, 042077. [Google Scholar] [CrossRef]

- Choudhary, R.; Rajarathnam, M.; Alekya, M.; Prithiv, H.K.; Selva, K.S. Agriculture automation system. J. Phys. Conf. Ser. 2020, 1706, 012089. [Google Scholar] [CrossRef]

- Kovacev, I.; Kosutic, S.; Jejcic, V.; Copec, K.; Pliestic, S. Impact of electronic-hydraulic hitch control on rational exploitation of tractor in ploughing. Strojarstvo 2008, 50, 287–294. [Google Scholar]

- Du, Q.L.; Chen, X.H. Design on control system for electro-hydraulic hitch equipment of tractor. Adv. Mater. Res. 2014, 945–949, 1513–1516. [Google Scholar] [CrossRef]

- Olson, D.J.; Cornell, C.R. Simulation of an electrohydraulic hitch control system on an agricultural tractor. SAE Trans. 1987, 96, 1253–1258. [Google Scholar] [CrossRef]

- Li, W.Z.; Xu, Q.C. Automobile and Tractor; China Agricultural Press: Beijing, China, 2008; pp. 149–150. [Google Scholar]

- Hobbs, J.; Hesse, H. Electronic/hydraulic hitch control for agricultural tractors. SAE Trans. 1980, 89, 3211–3219. [Google Scholar] [CrossRef]

- Xu, T.W. Research and Development of Electronically Controlled Hydraulic System for Medium and Small Tractor Suspension. Master’s Thesis, Qingdao Agricultural University, Qingdao, China, 2016. [Google Scholar]

- Han, C.H.; Gao, X.H. CAN bus technology and its application. Manuf. Autom. 2010, 32, 146–149. [Google Scholar]

- Scarlett, J.A. Integration of tractor engine, transmission and implement depth controls (Part2, Control Systems). J. Agric. Eng. Res. 1993, 54, 89–112. [Google Scholar] [CrossRef]

- Dwyer, M. The effect of draught control response on the performance of agricultural tractors. J. Agric. Eng. Res. 1969, 14, 295–312. [Google Scholar] [CrossRef]

- Jerzy, Z.; Zbigniew, Z. A functional model of a tractor working with mounted tools. J. Inn. Mong. Polytech. Univ. 2003, 22, 93–100. [Google Scholar]

- Kannakara, S.; Kushwaha, R.L.; Lague, C. Numerical modeling of soil stress and pressure distribution on a flat tillage tool using computational fluid dynamics. Biosyst. Eng. 2007, 97, 407–414. [Google Scholar]

- Bosch Rexroth Electronic-Hydraulic Hitch Control. Available online: https://dc-boschrexroth-cn.resource.bosch.com/media/cn/product/product_groups_1/mobile/mobile_systems/ehc_user_menu.pdf (accessed on 20 August 2022).

- Walvoil Hitch Control System. Available online: https://www.walvoil.com/allegati/catalogo/D1WWCB06_ENG.pdf (accessed on 20 August 2022).

- System Description-Hitch Control. Available online: https://assets.danfoss.com/documents/150036/AB152886482484en-000204.pdf (accessed on 20 August 2022).

- Zhan, K.; Zhang, L.Y.; Qin, W.Q. The simulation study of tractor-hanging farm implements tillage unit on microcomputer. J. Jilin Univ. Eng. Technol. Ed. 1990, 04, 81–88. [Google Scholar]

- Fang, C.L.; Wu, J.H. Theoretical and experimental study on electrohydraulic control of tractor suspension system. Trans. Chin. Soc. Agric. Mach. 1994, 03, 6–11. [Google Scholar]

- Xie, B. Study on Electrohydraulic Control Technology of Suspension System of Tractor Farm Tool Simulation Operation Unit. Master’s Thesis, China Agricultural University, Beijing, China, 2000. [Google Scholar]

- Xie, B.; Mao, E.R.; Tan, Y. Development of tractor electrohydraulic suspension system controller based on CAN bus. Mach. Tool Hydraul. 2006, 08, 185–187. [Google Scholar]

- Chen, M.J.; Lu, Z.X.; Yuan, Y.Y.; Wang, Q.M. Design of the position-adjust controller for electro-hydraulic hitch system of tractor. Mach. Electron. 2008, 11, 19–22. [Google Scholar]

- Zhan, C. Research on the Tractor Electric-Hydraulic Hitch Congtrol System Based on CAN Bus. Master’s Thesis, Nanjing Agricultural University, Nanjing, China, 2008. [Google Scholar]

- Lee, J.; Yamazaki, M.; Oida, A.; Nakashima, H.; Shimizu, H. Electro-hydraulic tillage depth control system for rotary implements mounted on agricultural tractor design and response experiments of control system. J. Terramech. 1998, 35, 229–238. [Google Scholar] [CrossRef]

- Lee, J.; Yamazaki, M.; Oida, A.; Nakashima, H.; Shimizu, H. Field performance of proposed foresight tillage depth control system for rotary implements mounted on an agricultural tractor. J. Terramech. 2000, 37, 99–111. [Google Scholar] [CrossRef]

- Xia, J.F.; Li, D.; Liu, G.Y.; Cheng, J.; Zhen, K.; Luo, C.M. Design and test of an electro-hydraulic monitoring device for hitch tillage depth based on measurement of tractor pitch angle. Trans. Chin. Soc. Agric. Mach. 2021, 52, 386–395. [Google Scholar]

- Hao, X.Y.; Wang, Y.L.; Xu, T.W.; Li, Z.M.; Zhang, J.; Geng, C. Modeling and simulation of tractor electronically controlled hydraulic suspension system based on AMESim. J. Qingdao Univ. Eng. Technol. Ed. 2018, 33, 125–129. [Google Scholar]

- Cheng, M.J. Research on Resistance-adjustment for Tractor Electro-hydraulic Hitch System Based on the Fuzzy Algorithm. Master’s Thesis, Nanjing Agricultural University, Nanjing, China, 2009. [Google Scholar]

- Wang, Q.M. The Research and Design of Electronic Hydraulic Control Technology of Hitch Control Unit for the Tractor. Master’s Thesis, Nanjing Agricultural University, Nanjing, China, 2008. [Google Scholar]

- Xu, H.; Lu, Z.X.; Song, Y.D. Force-position Adjustment Design of Tractor Hitch System Based on DSP. Appl. Mech. Mater. 2014, 462–463, 483–486. [Google Scholar] [CrossRef]

- Zhang, B.; Zhou, J. Research on prediction of traction resistance of tractor farming based on fuzzy neural network. J. Gansu Agric. Univ. 2020, 55, 213–220+228. [Google Scholar]

- Shang, G.G.; Peng, H.J.; Xia, Y. Study on auto-control method and simulation for tractor depth fuzzy control. Res. Agric. Mod. 2014, 35, 825–829. [Google Scholar]

- Zhao, J.J.; Zhu, Z.X.; Song, Z.H.; Zhou, R.J.; Wang, R.P.; Mao, E.R. Design of electro-hydraulic suspension proportional controller for heavy tractor. Trans. Chin. Soc. Agric. Mach. 2014, 45 (Suppl. S1), 10–16. [Google Scholar]

- Xu, H.; Lu, Z.X.; Song, Y.D. Study on force-position regulation of tractor electro-hydraulic hitch system. Acta. Agric. Zhejiangensis 2013, 25, 879–883. [Google Scholar]

- Guo, B. Research on Force-position Combined Control for Tractor Electronically Controlled Hydraulic Hitch System. Master’s Thesis, Nanjing Agricultural University, Nanjing, China, 2013. [Google Scholar]

- Li, M.S. Research on the Dynamic Performance of Electro-hydraulic Hitch System in Big-Power Tractor. Ph.D. Thesis, China Agricultural University, Beijing, China, 2013. [Google Scholar]

- Wang, S.Y.; Liu, Z.; Li, R.C.; Xu, J.K.; Liu, Y.J. Variable weight force-position mixed control of high-power tractor based on soil specific resistance. Trans. Chin. Soc. Agric. Mach. 2018, 49, 351–357. [Google Scholar]

- Ma, Y. Research on Tillage Depth Control Technology of Heavy Tractor Based on Variable Universe Fuzzy PID. Master’s Thesis, Shandong University of Science and Technology, Qingdao, China, 2019. [Google Scholar]

- Gao, L.L. Study of Electronic Control Technology for Tractor’s Hydraulic Hitch System. Master’s Thesis, Jiangsu University, Jiangsu, China, 2014. [Google Scholar]

- Mu, C.P. Research on Control Technology of Tillage Depth of Electro-Hydraulic Suspension System of Large Tractor. Master’s Thesis, Shandong University of Science and Technology, Qingdao, China, 2020. [Google Scholar]

- Bai, X.F.; Lu, Z.X.; Chang, J.X.; Li, H.; Zhou, W.W. Fuzzy control algorithm simulation of automatic control of tilling depth for tractor based on slip rate. Trans. Chin. Soc. Agric. Mach. 2012, 43 (Suppl. S1), 6–10. [Google Scholar]

- Yu, F.; Lin, Y. Vehicle System Dynamics; China Machine Press: Beijing, China, 2016; pp. 42–46. [Google Scholar]

- Li, C.J. Research on electro-hydraulic tillage depth control system based on PID control. Master’s Thesis, Southwest University, Chongqing, China, 2017. [Google Scholar]

- Shen, Z.F. Modeling and Simulation Analysis of Electronically Controlled Hydraulic Suspension System of Tractor. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2010. [Google Scholar]

- Wang, Z.Y. Dynamic Characteristics Analysis of Tractor Electronically Controlled Hydraulic Suspension System. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2012. [Google Scholar]

- Zhu, S.H.; Zhang, C. Study on PID control simulation of tractor electro-hydraulic hitch system. Mach. Des. Manuf. Eng. 2008, 21, 49–53. [Google Scholar]

- Li, D.; Ye, J.; Li, M.S.; Li, C.J.; Xu, H.G. Research on tillage depth regulation system based on integral-separated PID control. J. Southwest-China Norm. Univ. Nat. Sci. Ed. 2018, 43, 121–127. [Google Scholar]

- Zhou, M.K.; Xia, J.F. Development of a depth control system based on variable-gain single-neuron PID for rotary burying of stubbles. Agriculture 2022, 12, 30. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Xie, L.Y. Research on Plowing Depth Automatic Control for High-Power Tractor Electro-Hydraulic Hitch System. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2016. [Google Scholar]

- Pang, C.L.; Zong, B.H.; Er, Z.M. Fuzzy integrated control model and simulation test of tractor working unit. Trans. CSAE 2003, 4, 111–113. [Google Scholar]

- Lu, Z.X.; Guo, B.; Gao, Q. Fuzzy automatic control method and experimental study of tractor tillage depth. Trans. CSAE 2013, 29, 23–29. [Google Scholar]

- Soylu, S.; Arman, K. Fuzzy logic based automatic slip control system for agricultural tractors. J. Terramech. 2021, 95, 25–32. [Google Scholar] [CrossRef]

- Han, J.Y.; Xia, C.G.; Shang, G.G.; Gao, X. In-field experiment of electro-hydraulic tillage depth draft-position mixed control on tractor. IOP Conf. Ser. Mater. Sci. Eng. 2017, 274, 012028. [Google Scholar] [CrossRef]

- Tan, Y. Study on Performance of Hydraulic Suspension and Loading System of Tractor. Master’s Thesis, China Agricultural University, Beijing, China, 2004. [Google Scholar]

- Gao, X.; Sun, C.W.; Shi, J.Z.; Wang, Q. Research of fuzzy control method for electronic hydraulic hitch of tractor. Tractor Farm Transp. 2008, 35, 12–14. [Google Scholar]

- Shafaei, S.M.; Loghavi, M.; Kamgar, S. A practical effort to equip tractor-implement with fuzzy depth and draft control system. Eng. Agri. Environ. Food. 2019, 12, 191–203. [Google Scholar] [CrossRef]

- Li, M.S.; Zhao, J.J.; Zhu, Z.X.; Xie, B.; Chi, R.J.; Mao, E.R. Fuzzy PID adaptive control method for tractor electro-hydraulic suspension system. Trans. Chin. Soc. Agric. Mach. 2013, 44 (Suppl. S2), 295–300. [Google Scholar]

- Wang, P.Y. Study on the Technology of Adjusting the Plough Depth of Modern Agricultural Tractor Based on Variable Universe Fuzzy Control. Master’s Thesis, Shandong Agricultural University, Qingdao, China, 2020. [Google Scholar]

- Zhang, S.; Wu, Z.B.; Chen, J.; Li, Z.; Zhu, Z.X.; Song, Z.H.; Mao, E.R. Control method of driving wheel slip rate of high-power tractor for ploughing operation. Trans. CSAE 2020, 36, 47–55. [Google Scholar]

- Moradinejad, N. Electronic hitch control valve for Massey Ferguson 285 tractor. AMA-Agr. Mech. Asia Af. 2018, 49, 50–56. [Google Scholar]

- Zhang, S. Study on slip rate control of heavy tractor for ploughing based on sliding mode variable structure control. Ph.D. Thesis, China Agricultural University, Beijing, China, 2018. [Google Scholar]

- Liu, C.Q.; Hua, B.; Du, Y.F.; Li, Z.; Zhu, Z.X.; Mao, E.R. Dynamic pressure feedback correction method for tractor electro hydraulic hitch. Trans. Chin. Soc. Agric. Mach. 2020, 51 (Suppl. S1), 1–9. [Google Scholar]

- Zhao, H.P.; Zhou, J.J.; Bao, Q.Q.; Ma, H.C. Characteristic analysis of intelligent reversing valve based on high-speed on-off valve. Acta Armamentarii. 2022. [Google Scholar] [CrossRef]

- Li, M.S.; Zhu, Z.X.; Mao, E.R.; Song, Z.H.; Xie, B.; Li, C.L. Design of proportional raise valve in electro-hydraulic lifting mechanism of big-power tractor. Trans. Chin. Soc. Agric. Mach. 2012, 43, 31–35+89. [Google Scholar]

- Zhao, J.J.; Zhu, Z.X.; Song, Z.H.; Mao, E.R.; Liu, S.R.; Liu, D.L. Simulation and test of multi-way directional valve for heavy tractor electro-hydraulic hoist. Trans. Chin. Soc. Agric. Mach. 2014, 45 (Suppl. S1), 1–9. [Google Scholar]

- Hua, B.; Zhao, J.J.; Liu, C.Q.; Du, Y.F.; Mao, E.R.; Song, Z.H. Performance simulation and test of plug-in proportional raising valve of electro-hydraulic hitch for heavy tractor. Trans. CSAE 2019, 35, 109–117. [Google Scholar]

- Adamchuk, V.I.; Hummel, J.W.; Morgan, M.T.; Upadhyaya, S.K. On-the-go soil sensors for precision agriculture. Comput. Electron. Agric. 2004, 44, 71–91. [Google Scholar] [CrossRef]

- Li, Z.X. Research and design of operating depth measurement apparatus for farm implement. Trans. Chin. Soc. Agric. Mach. 2000, 31, 88–91. [Google Scholar]

- Mouazen, A.M.; Anthonis, J.; Saeys, W.; Ramon, H. An automatic depth control system for online measurement of spatial variation in soil compaction, Part 1: Sensor design for measurement of frame height variation from soil surface. Biosyst. Eng. 2004, 89, 139–150. [Google Scholar] [CrossRef]

- MacQueene, J.; Schwarz, P.; Nielsen, B. Development of the electronic draft control system for the ford New Holland 8210 tractor. SAE Trans. 1990, 99, 327–339. [Google Scholar]

- Chen, G.; Zhang, B.; Liu, P.; Ding, H. An adaptive analog circuit for LVDT’s nanometer measurement without losing sensitivity and range. IEEE Sens. J. 2015, 15, 2248–2254. [Google Scholar] [CrossRef]

- Cai, L.F. Research on the Plowing Depth Automatic Control of Tractor Hydraulic System Based on Electronic Control. Master’s Thesis, Jilin University, Changchun, China, 2016. [Google Scholar]

- Chethan, C.R.; Tewari, V.K.; Nare, B.; Kumar, S.P. Transducers for measurement of draft and torque of tractor-implement system—A review. Agric. Mech. Asia Afr. Lat. Am. 2018, 49, 81–87. [Google Scholar]

- Zhang, L.Y.; Zheng, X.; Qin, C.M.; He, X.C. Performance test and analysis of super-deep plow. J. Gansu Agric. Univ. 2016, 51, 156–160. [Google Scholar]

- Bentaher, H.; Hamza, E.; Kantchev, G.; Maalej, A.; Arnold, W. Three-point hitch-mechanism instrumentation for tillage power optimization. Biosyst. Eng. 2008, 100, 24–30. [Google Scholar] [CrossRef]

- Kumar, A.A.; Tewari, V.K.; Nare, B. Embedded digital draft force and wheel slip indicator for tillage research. Comput. Electron. Agric. 2016, 127, 38–49. [Google Scholar] [CrossRef]

- Raul, A.K.; Raheman, H.; Pansare, M.S.; Machavaram, R. Predicting the draught requirement of tillage implements in sandy clay loam soil using an artificial neural network. Biosyst. Eng. 2009, 104, 476–485. [Google Scholar] [CrossRef]

- Bhondave, B.; Ganesan, T.; Varma, N.; Renu, R.; Sabarinath, N. Design and development of electro hydraulics hitch control for agricultural tractor. SAE Int. J. Commer. Veh. 2017, 10, 405–410. [Google Scholar] [CrossRef]

- Gao, X.; Wang, Z.Y.; Pan, D.Y. Resistance regulation characteristic analysis of tractor rear hitch mounted hanging plough in multi-operative modes. J. Anhui Agric. Sci. 2012, 40, 14132–14135. [Google Scholar]

- Singh, C.D.; Singh, R.C. Computerized instrumentation system for monitoring the tractor performance in the field. J. Terramech. 2011, 48, 333–338. [Google Scholar] [CrossRef]

- Li, M.S.; Chi, R.J.; Mao, E.R.; Zhang, J.Y.; Liu, Y. Design of draft sensor in big-power tractor raiser based on magnetostriction. Trans. Chin. Soc. Agric. Mach. 2013, 44, 8–12+32. [Google Scholar]

- Li, R.C.; Guo, K.; Yang, J.R.; Xu, J.K.; Chi, Y.R. Magnetic circuit design and simulation of draft sensor in electro-hydraulic lifting mechanism of high-power tractor. Trans. Chin. Soc. Agric. Mach. 2017, 48, 358–367. [Google Scholar]

- Kheiralla, A.F.; Yahya, A.; Bardae, M.Z.; Ishak, W. Design and development of a three-point auto hitch dynamometer for an agricultural tractor. ASEAN J. Sci. Technol. Dev. 2003, 20, 271–288. [Google Scholar] [CrossRef]

- Al-Jalil, H.F.; Khdair, A.; Mukahal, W. Design and performance of an adjustable three-point hitch dynamometer. Soil Tillage Res. 2001, 62, 153–156. [Google Scholar] [CrossRef]

| Type | Layout Characteristics | Advantages | Disadvantages | Application of the Tractor |

|---|---|---|---|---|

| Split | Pumps, distributors (hydraulic control valves) and cylinders are installed at different locations | Flexible layout, Easier maintenance, Easy to be standardized | Complex connection pipeline, Easy to leak | Dongfanghong-75 (YTO, Luoyang, China) TN-55 (TT, Tianjin, China) M1304-R (LOVOL, Weifang, China) |

| Semi-split | Distributor (hydraulic control valve) and cylinder installed together, pump arranged separately | Compact structure | Inconvenient to fault check | TM130 (New Holland, WI, USA) 800 (CF, Changzhou, China) |

| Integral | Oil pump, distributor (hydraulic control valve) and oil cylinder are installed together | Compact structure, good sealing | Complex structure, big volume, Difficult to standardize | T8000 (New Holland, WI, USA) 35 (FS, Shanghai, China) |

| Model | Company | Type | Adjustment Mode | Maximum Lifting Force (kN) |

|---|---|---|---|---|

| M604-E | LOVOL | semi-split | Position, Draft, Mixed draft-position adjustment | ≥10.1 |

| LF1504 | YTO | semi-split | Position, Draft, Height, Mixed draft-position adjustment | ≥28 |

| M2204-R | LOVOL | split | Position, Height, adjustment | ≥39 |

| CFK1804 | Changfa | split | Position, Draft, Height, Mixed draft-position adjustment | ≥42 |

| Item | Position Adjustment | Draft Adjustment | Draft-Position Mixed Control | Draft-Position-Slip Mixed Control |

|---|---|---|---|---|

| Engine load stability | Bad | Best | Good | Best |

| Traction efficiency | Bad | Good | Good | Best |

| Operation quality on different soils | Good | Bad | Good | Best |

| Operation quality on rough surface | Bad | Good | Good | Best |

| Application | Shallow tillage | Deep tillage | All operation | All operation |

| Scheme | Structure | Control Mode | Features |

|---|---|---|---|

| 1 [75] | Rotary type | Motor control | Proportional valve, Single-acting |

| 2 [41,76,77] | plate design | Direct electromagnetic actuation | Proportional valve, Single-acting, With load sensitive |

| 3 [78] | threaded cartridge | Pilot control | Proportional valve, Single-acting, With load sensitive, With position feedback |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Lu, Z.; Song, Y.; Cheng, Z.; Jiang, C.; Qian, J.; Lu, Y. Development Status and Research Progress of a Tractor Electro-Hydraulic Hitch System. Agriculture 2022, 12, 1547. https://doi.org/10.3390/agriculture12101547

Sun X, Lu Z, Song Y, Cheng Z, Jiang C, Qian J, Lu Y. Development Status and Research Progress of a Tractor Electro-Hydraulic Hitch System. Agriculture. 2022; 12(10):1547. https://doi.org/10.3390/agriculture12101547

Chicago/Turabian StyleSun, Xiaoxu, Zhixiong Lu, Yue Song, Zhun Cheng, Chunxia Jiang, Jin Qian, and Yang Lu. 2022. "Development Status and Research Progress of a Tractor Electro-Hydraulic Hitch System" Agriculture 12, no. 10: 1547. https://doi.org/10.3390/agriculture12101547

APA StyleSun, X., Lu, Z., Song, Y., Cheng, Z., Jiang, C., Qian, J., & Lu, Y. (2022). Development Status and Research Progress of a Tractor Electro-Hydraulic Hitch System. Agriculture, 12(10), 1547. https://doi.org/10.3390/agriculture12101547