Calibration and Test of Contact Parameters between Chopped Cotton Stalks Using Response Surface Methodology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Materials

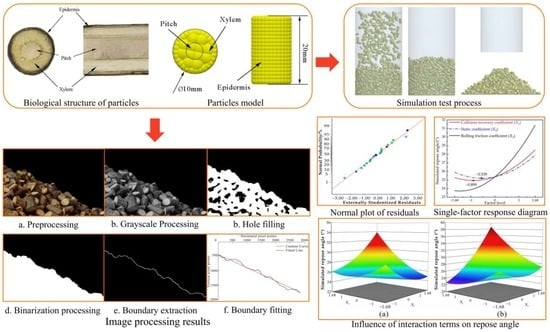

2.2. Simulation Contact Model Selection and Model Construction

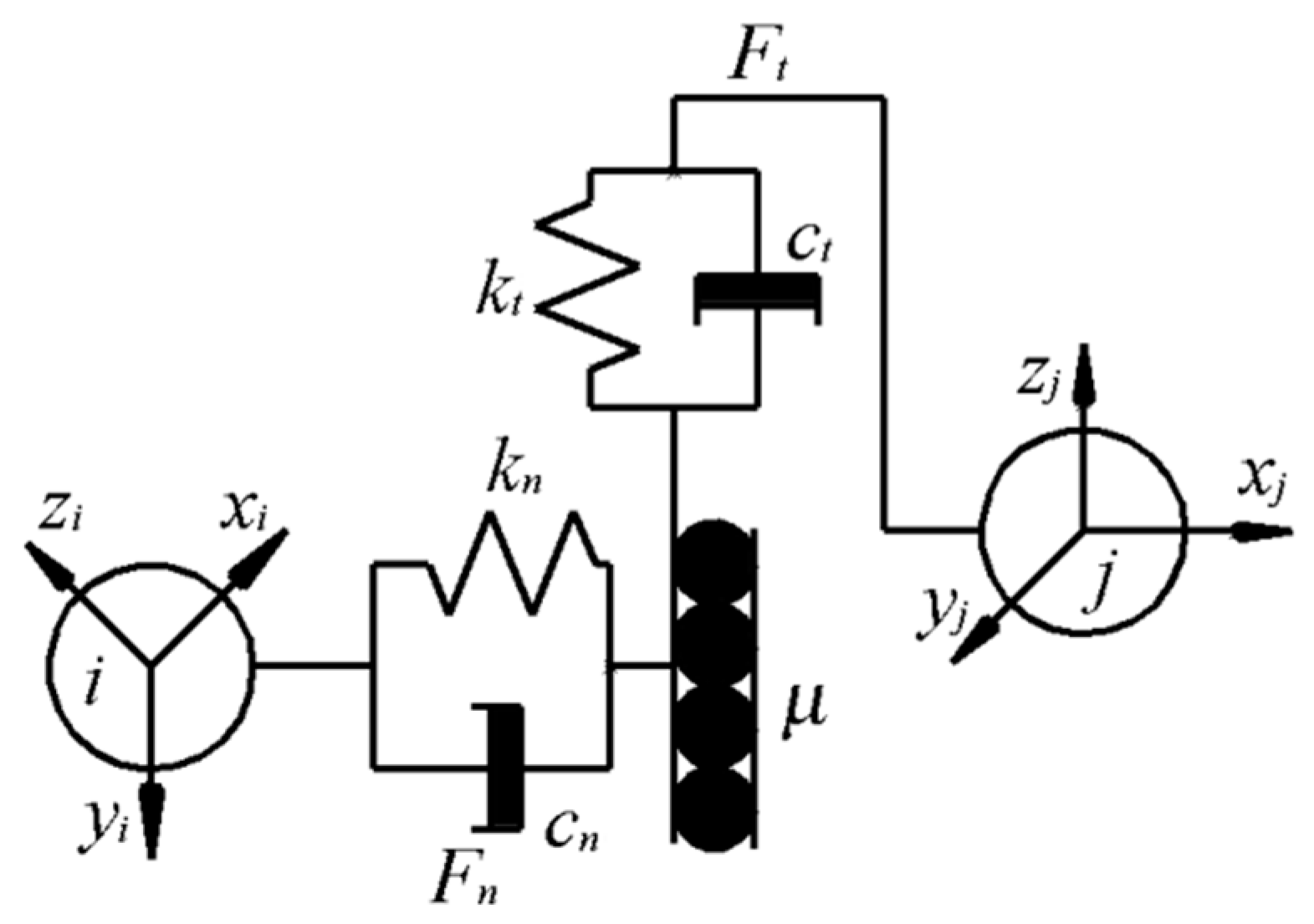

2.2.1. Simulation Contact Model Selection

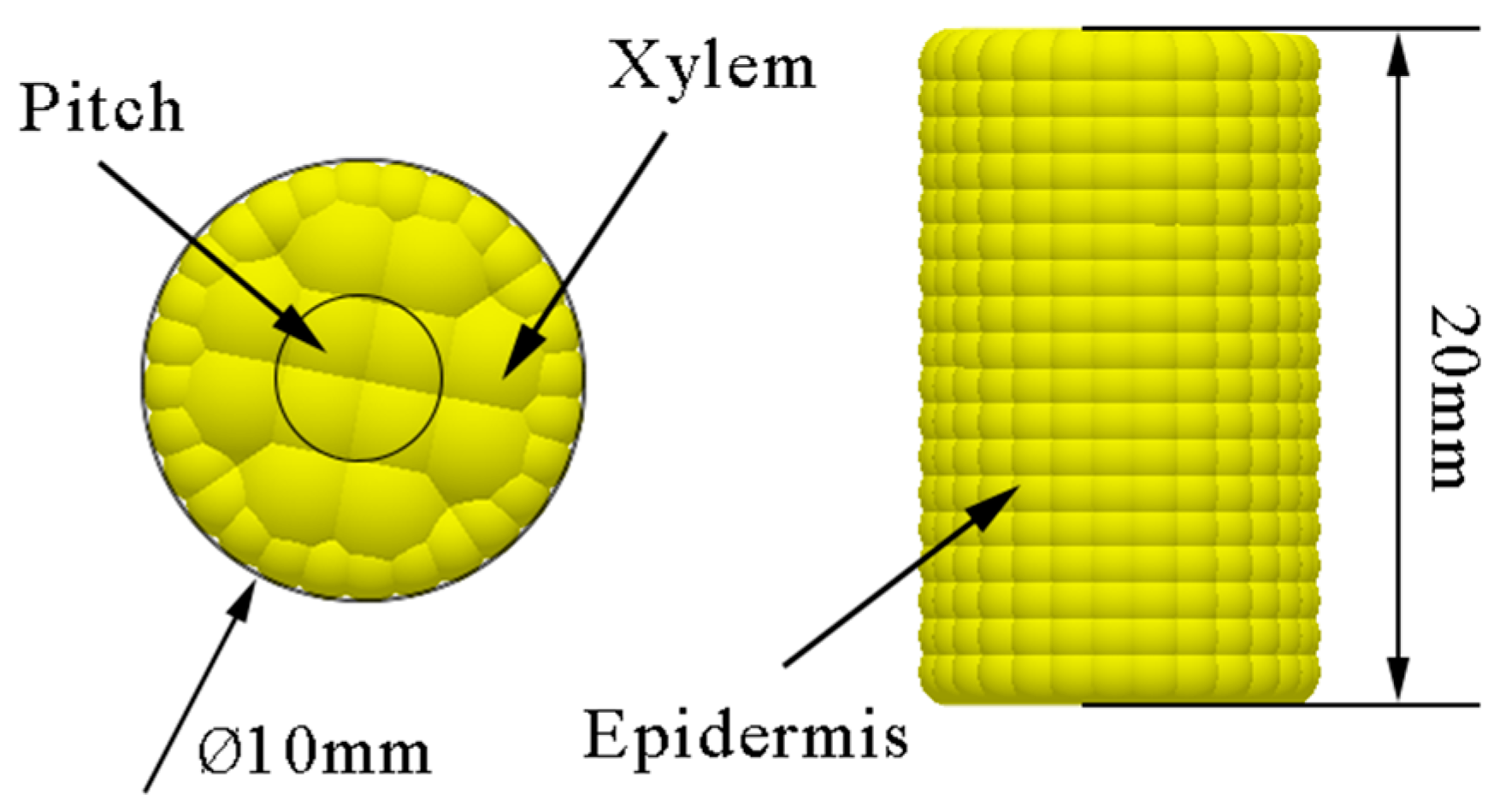

2.2.2. Discrete Element Model Construction of Cotton Stalk Particles

2.3. Experimental Determination of Some DEM Input Parameters

2.3.1. Cotton Stalk Density

2.3.2. Elastic Modulus and Poisson’s Ratio

2.3.3. Coefficient of Restitution

2.3.4. Static Friction Coefficient

2.3.5. Rolling Friction Coefficient

2.4. Physical Test of Repose Angle and DEM Simulation Test

2.4.1. Rolling Friction Coefficient

2.4.2. DEM Simulation Test

2.5. Determination of DEM Input Parameters and Test Scheme

2.5.1. Determination of DEM Input Parameters

2.5.2. Response Surface Test Design

2.6. Optimum Condition and Validation

3. Results and Discussion

3.1. Analysis of the Simulation Test Result of the Repose Angle

3.1.1. ANOVA and Model Construction

3.1.2. Single-Factor Effect Analysis

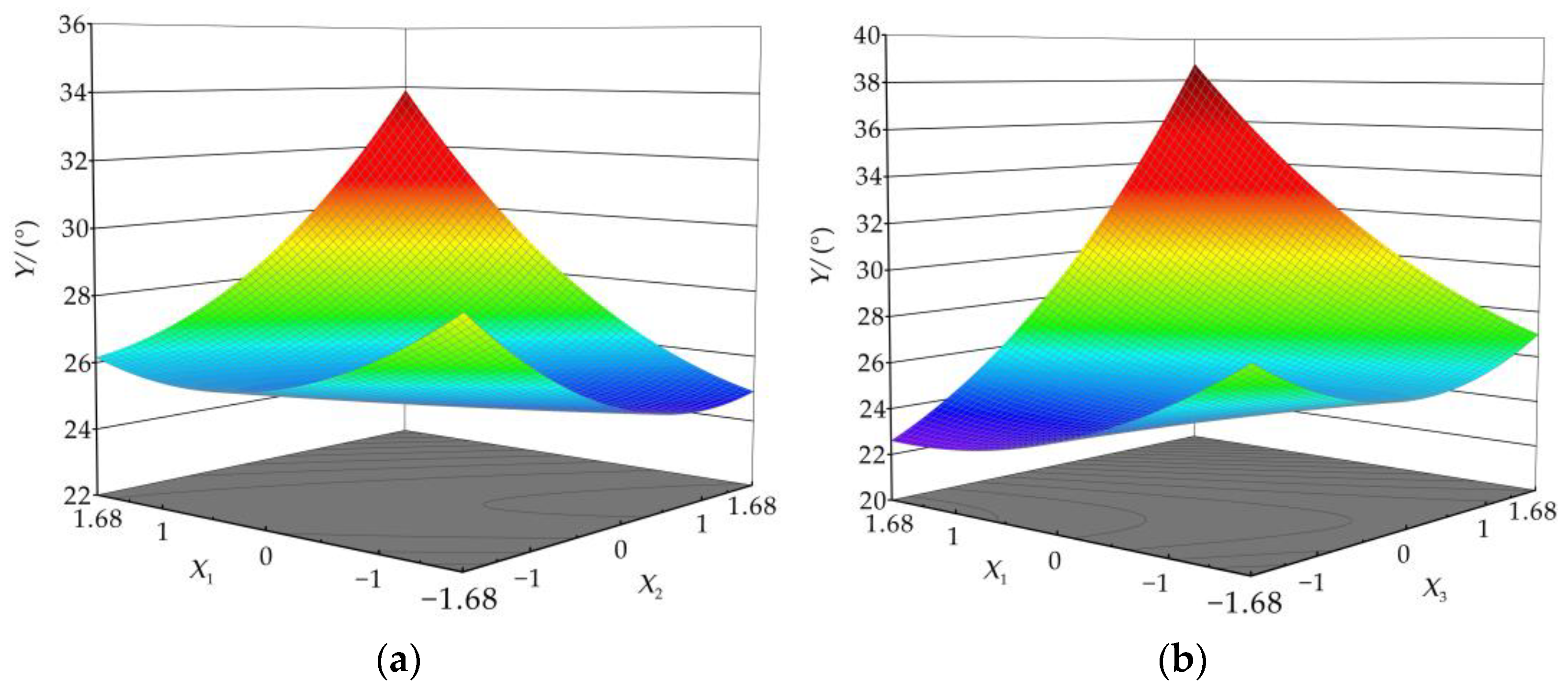

3.1.3. Interaction Effect Analysis

- Effect of interaction term X1X2 on the repose angle

- 2.

- Effect of interaction term X1X3 on repose angle

3.2. Determination of Optimal Parameter Combinations and Verification

4. Conclusions

- (1)

- The contact parameters between the cotton stalk particles and the contact material (steel) were measured by physical tests. The coefficient of restitution was 0.56, the static friction coefficient was 0.62, and the rolling friction coefficient was 0.16. As for the range of contact parameters between the cotton stalk particles, the coefficient of restitution ranged from 0.16 to 0.48, the static friction coefficient ranged from 0.45 to 0.65, and the rolling friction coefficient ranged from 0.10 to 0.20. The cylinder-lifting method was applied to test the repose angle of chopped cotton stalks, and the average value (26.45°) and the standard deviation (0.57°) of the repose angle of cotton stalk particles were obtained.

- (2)

- A central composite design test on the response surface methodology was constructed to conduct the simulation test of the repose angle, the second-order response model between contact parameters and repose angle. According to the results of ANOVA, all the figures indicate that the test factors had a high interpretation of the response value.

- (3)

- By analyzing the effects of single-factor and interaction factors on the repose angle, the extremely significant factors affecting the repose angle were the coefficient of restitution and rolling friction coefficient, while the static friction coefficient was the most significant factor. The coefficient of restitution interacted with the static friction coefficient and the rolling friction coefficient on the repose angle, and they had a significant effect on the repose angle.

- (4)

- The optimal combination of contact parameters was determined as follows: the coefficient of restitution was 0.45, the static friction coefficient was 0.47, and the rolling friction coefficient was 0.16. The verification test showed no significant difference between the simulated and physical test values, and the average relative error was 1.04%, indicating that the simulated values agreed well with the physical test values, verifying the authenticity of the simulation test and the reliability of the optimal combination of simulation parameters. The research provides a basis for the discrete element simulation study of cotton stalk motion in the separation process of cotton stalks and residual film and thus could be used for subsequent gas–solid coupling simulation research.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; He, H.; Zheng, X.; Zhang, J.; Li, W. Effect of cotton stalk returning to fields on residual film distribution in cotton fields under mulched drip irrigation in typical oasis area in Xinjiang. Trans. Chin. Soc. Agric. Eng. 2018, 34, 120–127. [Google Scholar]

- Zhang, D.; Yan, C.; Liu, H.; Wang, H.; Hu, W.; Qin, X.; Ma, X. The status and distribution characteristics of residual mulching film in Xinjiang, China. J. Integr. Agric. 2016, 15, 2639–2646. [Google Scholar] [CrossRef] [Green Version]

- Dai, J.; Dong, H. Intensive cotton farming technologies in China: Achievements, challenges and countermeasures. Field Crops Res. 2014, 155, 99–110. [Google Scholar] [CrossRef] [Green Version]

- Liu, E.; He, W.; Yan, C. ‘White revolution’ to ‘white pollution’—Agricultural plastic film mulch in China. Environ. Res. Lett. 2014, 9, 091001. [Google Scholar] [CrossRef] [Green Version]

- Zhang, D.; Ng, E.; Hu, W.; Wang, H.; Galaviz, P.; Yang, H.; Sun, W.; Li, C.; Ma, X.; Fu, B.; et al. Plastic pollution in croplands threatens long-term food security. Glob. Chang. Biol. 2020, 26, 3356–3367. [Google Scholar] [CrossRef]

- Liang, R.; Zhang, B.; Zhou, P.; Li, Y.; Meng, H.; Kan, Z. Power consumption analysis of the multi-edge toothed device for shredding the residual film and impurity mixture. Comput. Electron. Agric. 2022, 196, 106898. [Google Scholar] [CrossRef]

- Liang, R.; Zhang, B.; Zhou, P.; Li, Y.; Meng, H.; Kan, Z. Cotton length distribution characteristics in the shredded mixture of mechanically recovered residual films and impurities. Ind. Crop. Prod. 2022, 182, 114917. [Google Scholar] [CrossRef]

- Horabik, J.; Molenda, M. Parameters and contact models for DEM simulations of agricultural granular materials: A review. Biosyst. Eng. 2016, 147, 206–225. [Google Scholar] [CrossRef]

- Lenaerts, B.; De Ketelaere, B.; Tijskens, E.; Herman, R.; Baerdemaeker, J.D.; Aertsen, T.; Saeys, W. Simulation of grain-straw separation by discrete element modeling with bendable straw particles. Comput. Electron. Agric. 2014, 101, 24–33. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Li, R.; Wu, B.; Wu, Z.; Ding, Z. Determination of the coefficient of rolling friction of an irregularly shaped maize particle group using physical experiment and simulations. Particuology 2018, 38, 185–195. [Google Scholar] [CrossRef]

- Fang, W.; Wang, X.; Han, D.; Chen, X. Review of material parameter calibration method. Agriculture 2022, 12, 706. [Google Scholar] [CrossRef]

- Rackl, M.; Hanley, K. A methodical calibration procedure for discrete element models. Powder Technol. 2017, 307, 73–83. [Google Scholar] [CrossRef] [Green Version]

- Cunha, R.N.; Santos, K.G.; Lima, R.N.; Duarte, C.R.; Barrozo, M. Repose angle of monoparticles and binary mixture: An experimental and simulation study. Powder Technol. 2016, 303, 203–211. [Google Scholar] [CrossRef]

- Radvilaitė, U.; Ramírez-Gómez, Á.; Kačianauskas, R. Determining the shape of agricultural materials using spherical harmonics. Comput. Electron. Agric. 2016, 128, 160–171. [Google Scholar] [CrossRef]

- Kattenstroth, R.; Harms, H.H.; Lang, T. Systematic alignment of straw to optimise the cutting process in a combine’s straw chopper. In Proceedings of the 69th International Conference on Agricultural Engineering LAND TECHNIK AgEng, Hannover, Germany, 11–12 November 2011. [Google Scholar]

- Li, H.; Li, Y.; Gao, F.; Zhao, Z.; Xu, L. CFD-EDM simulation of material motion in air-and-screen cleaning device. Comput. Electron. Agric. 2012, 88, 111–119. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, X.; Wu, S.; Chen, C.; Wang, J.M.; Yuan, S.; Chen, B.; Li, P.; Xu, R. Numerical simulation of particle motion at cucumber straw grinding process based on EDEM. Int. J. Agric. Biol. Eng. 2020, 13, 227–235. [Google Scholar] [CrossRef]

- Ramírez-Gómez, Á.; Gallego, E.; Fuentes, J.M.; González-montellano, C.; Ayuga, F. Values for particle-scale properties of biomass briquettes made from agroforestry residues. Particuology 2014, 12, 100–106. [Google Scholar] [CrossRef]

- Fang, M.; Yu, Z.; Zhang, W.; Cao, J.; Liu, W. Friction coefficient calibration of corn stalk particle mixtures using plackett-burman design and response surface methodology. Powder Technol. 2022, 396, 731–742. [Google Scholar] [CrossRef]

- Ma, Y.; Song, C.; Xuan, C.; Wang, H.; Yang, S.; Wu, P. Parameters calibration of discrete element model for alfalfa straw compression simulation. Trans. Chin. Soc. Agric. Eng. 2020, 36, 22–30. [Google Scholar]

- Feng, J.; Lin, J.; Li, S.; Zhou, J.; Zhou, Z. Calibration of discrete element parameters of particle in rotary solid state fermenters. Trans. Chin. Soc. Agric. Machin. 2015, 46, 208–213. [Google Scholar]

- Liao, Y.; Wang, Z.; Liao, Q.; Wan, X.; Zhou, Y.; Liang, F. Calibration of discrete Element Model Parameters of Forage Rape Stalk at Early Pod Stage. Trans. Chin. Soc. Agric. Machin. 2020, 51, 236–243. [Google Scholar]

- Zhang, T.; Liu, F.; Zhao, M.; Ma, Q.; Wang, W.; Fan, Q.; Yan, P. Determination of corn stalk contact parameters and calibration of discrete element method simulation. J. Chin. Agric. Univer. 2018, 23, 120–127. [Google Scholar]

- Ma, Z.; Xu, L.; Li, Y. Discrete-element method simulation of agricultural particles’ motion in variable-amplitude screen box. Comput. Electron. Agric. 2015, 118, 92–99. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, J.; Chen, J. Modeling of flexible wheat straw by discrete element method and its parameter calibration. Int. J. Agric. Biol. Eng. 2018, 11, 42–46. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Xu, H.; Zhang, Y.; Yang, Y.; Zhao, H.; Yang, C.; He, Y.; Wang, K.; Liu, D. Discrete element modelling of citrus fruit stalks and its verification. Biosyst. Eng. 2020, 200, 400–414. [Google Scholar] [CrossRef]

- Zeng, Z.; Chen, Y. Simulation of straw movement by discrete element modelling of straw-sweep-soil interaction. Biosyst. Eng. 2019, 180, 25–35. [Google Scholar] [CrossRef]

- Guo, Q.; Zhang, X.; Xu, Y.; Li, P.; Chen, C.; Xie, H. Simulation and experimental study on cutting performance of tomato cane straw based on EDEM. J. Drain. Irrig. Machin. Eng. 2018, 36, 1017–1022. [Google Scholar]

- Quist, J.; Evertsson, C.M. Cone crusher modelling and simulation using DEM. Minerals Eng. 2016, 85, 92–105. [Google Scholar] [CrossRef]

- Sun, X.; Li, B.; Liu, Y.; Gao, X. Parameter measurement of edible sunflower exudates and calibration of discrete element simulation parameters. Processes 2022, 10, 185. [Google Scholar] [CrossRef]

- Paulick, M.; Morgeneyer, M.; Kwade, A. Review on the influence of elastic particle properties on DEM simulation results. Powder Technol. 2015, 283, 66–76. [Google Scholar] [CrossRef]

- Hertz, H. On the contact of elastic solids. J. Für Die Reine Und Angew. Math. (Crelles J.) 1880, 92, 156–171. [Google Scholar]

- Mindlin, R.D. Compliance of elastic bodies in contact. J. Appl. Mech. 1949, 16, 259–268. [Google Scholar] [CrossRef]

- Han, Y.; Jia, F.; Tang, Y.; Liu, Y.; Zhang, Q. Influence of granular coefficient of rolling friction on accumulation characteristics. Acta Phys. Sin. 2014, 63, 533–538. [Google Scholar]

- Liu, F.; Zhang, J.; Chen, J. Construction of visco-elasto-plasticity contact model of vibratory screening and its parameters calibration for wheat. Trans. Chin. Soc. Agric. Eng. 2018, 34, 37–43. [Google Scholar]

- Cabiscol, R.; Finke, J.H.; Kwade, A. Calibration and interpretation of DEM parameters for simulations of cylindrical tablets with multi-sphere approach. Powder Technol. 2017, 327, 232–245. [Google Scholar] [CrossRef]

- Wang, X.; Yu, J.; Lv, F.; Wang, Y.; Fu, W. A multi-sphere based modelling method for maize grain assemblies. Adv. Powder Technol. 2017, 28, 584–595. [Google Scholar] [CrossRef]

- Mcdowell, G.R.; Falagush, O.; Yu, H. A particle refinement method for simulating DEM of cone penetration testing in granular materials. Geotech. Lett. 2012, 2, 141–147. [Google Scholar] [CrossRef]

- ASTM D854–10; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2010.

- Mueller, P.; Antonyuk, S.; Stasiak, M.; Tomas, J.; Heinrich, S. The normal and oblique impact of three types of wet granules. Granul. Matter 2011, 13, 455–463. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, X.; Liang, R.; Li, J.; Wang, X.; Meng, H.; Kan, Z. Cotton stalk restitution coefficient determination tests based on the binocular high-speed camera technology. Int. J. Agric. Biol. Eng. 2022, 15, 181–189. [Google Scholar] [CrossRef]

- Castiglioni, C.A.; Drei, A.; Carydis, P.; Mouzakis, H. Experimental assessment of static friction between pallet and beams in racking systems. J. Build. Eng. 2016, 6, 203–214. [Google Scholar] [CrossRef]

- Zhang, B.; Liang, R.; Li, J.; Li, Y.; Meng, H.; Kan, Z. Test and Analysis on Friction Characteristics of Major Cotton Stalk Cultivars in Xinjiang. Agriculture 2022, 12, 906. [Google Scholar] [CrossRef]

- Cui, T.; Liu, J.; Yang, L.; Zhang, D.; Zhang, R.; Lan, W. Experiment and simulation of rolling friction characteristic of corn seed based on high-speed photography. Trans. Chin. Soc. Agric. Eng. 2013, 29, 34–41. [Google Scholar]

- Al-Hashemi, H.M.; Bukhary, A.H. Correlation between california bearing ratio (CBR) and angle of repose of granular soil. Electron. J. Geotech. Eng. 2016, 21, 5655–5660. [Google Scholar]

- Derakhshani, S.M.; Schott, D.L.; Lodewijks, G. Micro-macro properties of quartz sand: Experimental investigation and DEM simulation. Powder Technol. 2015, 269, 127–138. [Google Scholar] [CrossRef]

| DEM Parameter | Parameter Value | DEM Parameter | Parameter Value |

|---|---|---|---|

| Density of Cotton Stalk (g·cm−3) | 0.326 | Cotton Stalk-Steel coefficient of restitution | 0.56 |

| Elastic modulus of Cotton Stalk (Pa) | 4.34 × 109 | Cotton Stalk-Steel static friction coefficient | 0.62 |

| Poisson’s ratio of Cotton Stalk | 0.35 | Cotton Stalk-Steel rolling friction coefficient | 0.16 |

| Density of Steel (g·cm−3) | 7.85 | * Cotton Stalk-Cotton stalk coefficient of restitution | 0.16~0.48 |

| Elastic modulus of Steel (Pa) | 2.06 × 1011 | * Cotton Stalk-Cotton stalk static friction coefficient | 0.45~0.65 |

| Poisson’s ratio of Steel | 0.30 | * Cotton Stalk-Cotton stalk rolling friction coefficient | 0.10~0.20 |

| Level | X1 | X2 | X3 |

|---|---|---|---|

| −1.68 | 0.05 | 0.38 | 0.07 |

| −1 | 0.16 | 0.45 | 0.1 |

| 0 | 0.32 | 0.55 | 0.15 |

| 1 | 0.48 | 0.65 | 0.20 |

| 1.68 | 0.59 | 0.71 | 0.23 |

| Test No. | Coding | Response Value | Test No. | Coding | Response Value | ||||

|---|---|---|---|---|---|---|---|---|---|

| X1 | X2 | X3 | Y (°) | X1 | X2 | X3 | Y (°) | ||

| 1 | −1 | −1 | −1 | 25.52 ± 1.32 | 11 | 0 | −1.68 | 0 | 25.47 ± 1.23 |

| 2 | 1 | −1 | −1 | 23.43 ± 2.51 | 12 | 0 | 1.68 | 0 | 28.36 ± 1.14 |

| 3 | −1 | 1 | −1 | 25.28 ± 1.36 | 13 | 0 | 0 | −1.68 | 23.69 ± 1.46 |

| 4 | 1 | 1 | −1 | 25.64 ± 1.85 | 14 | 0 | 0 | 1.68 | 31.52 ± 2.65 |

| 5 | −1 | −1 | 1 | 27.96 ± 1.34 | 15 | 0 | 0 | 0 | 25.49 ± 1.28 |

| 6 | 1 | −1 | 1 | 30.3 ± 2.84 | 16 | 0 | 0 | 0 | 25.02 ± 1.25 |

| 7 | −1 | 1 | 1 | 25.68 ± 3.01 | 17 | 0 | 0 | 0 | 25.18 ± 1.64 |

| 8 | 1 | 1 | 1 | 33.76 ± 2.58 | 18 | 0 | 0 | 0 | 25.55 ± 0.87 |

| 9 | −1.68 | 0 | 0 | 25.61 ± 1.47 | 19 | 0 | 0 | 0 | 26.51 ± 1.84 |

| 10 | 1.68 | 0 | 0 | 28.26 ± 1.65 | 20 | 0 | 0 | 0 | 24.43 ± 1.91 |

| Source | Sum of Squares | Mean Square | F Value | p-Value |

|---|---|---|---|---|

| Model | 129.06 | 14.34 | 29.88 | <0.0001 ** |

| X1 | 12.66 | 12.66 | 26.37 | 0.0004 ** |

| X2 | 4.70 | 4.70 | 9.79 | 0.0107 * |

| X3 | 70.36 | 70.36 | 146.59 | <0.0001 ** |

| X1X2 | 8.38 | 8.38 | 17.47 | 0.0019 ** |

| X1X3 | 18.45 | 18.45 | 38.44 | 0.0001 ** |

| X2X3 | 0.078 | 0.078 | 0.16 | 0.6953 |

| X12 | 4.24 | 4.24 | 8.83 | 0.014 * |

| X22 | 4.13 | 4.13 | 8.60 | 0.015 * |

| X32 | 8.75 | 8.75 | 18.22 | 0.0016 ** |

| Residual | 4.80 | 0.48 | ||

| Lack of Fit | 2.41 | 0.48 | 1.01 | 0.4959 |

| Pure Error | 2.39 | 0.48 | ||

| Cor Total | 133.86 | |||

| Adeq Precision | 22.04 | |||

| R2= 0.9641, R2adj = 0.9319, R2Pred = 0.8216, C.V = 2.60% | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Chen, X.; Liang, R.; Wang, X.; Meng, H.; Kan, Z. Calibration and Test of Contact Parameters between Chopped Cotton Stalks Using Response Surface Methodology. Agriculture 2022, 12, 1851. https://doi.org/10.3390/agriculture12111851

Zhang B, Chen X, Liang R, Wang X, Meng H, Kan Z. Calibration and Test of Contact Parameters between Chopped Cotton Stalks Using Response Surface Methodology. Agriculture. 2022; 12(11):1851. https://doi.org/10.3390/agriculture12111851

Chicago/Turabian StyleZhang, Bingcheng, Xuegeng Chen, Rongqing Liang, Xinzhong Wang, Hewei Meng, and Za Kan. 2022. "Calibration and Test of Contact Parameters between Chopped Cotton Stalks Using Response Surface Methodology" Agriculture 12, no. 11: 1851. https://doi.org/10.3390/agriculture12111851

APA StyleZhang, B., Chen, X., Liang, R., Wang, X., Meng, H., & Kan, Z. (2022). Calibration and Test of Contact Parameters between Chopped Cotton Stalks Using Response Surface Methodology. Agriculture, 12(11), 1851. https://doi.org/10.3390/agriculture12111851