Enhancing Biogas Production of Corn Stover by Biogas Slurry Reflux Based on Microfiltration Membrane Filtration and Biochar Adsorption

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Filtration Experiment of Biogas Slurry with a Microfiltration Membrane

2.3. Biochar Adsorption Experiment of Biogas Slurry Filtered by a Microfiltration Membrane

2.4. Anaerobic Digestion Experiment with Biogas Slurry Be Refluxed

2.5. Analytical Methods

3. Results

3.1. Effects of the Microfilter Membrane System on SS, COD, and Ammonia Nitrogen Conditions in Biogas Slurry

3.1.1. Impact of the Microfilter Membrane System on the SS Characteristics in Biogas Slurry

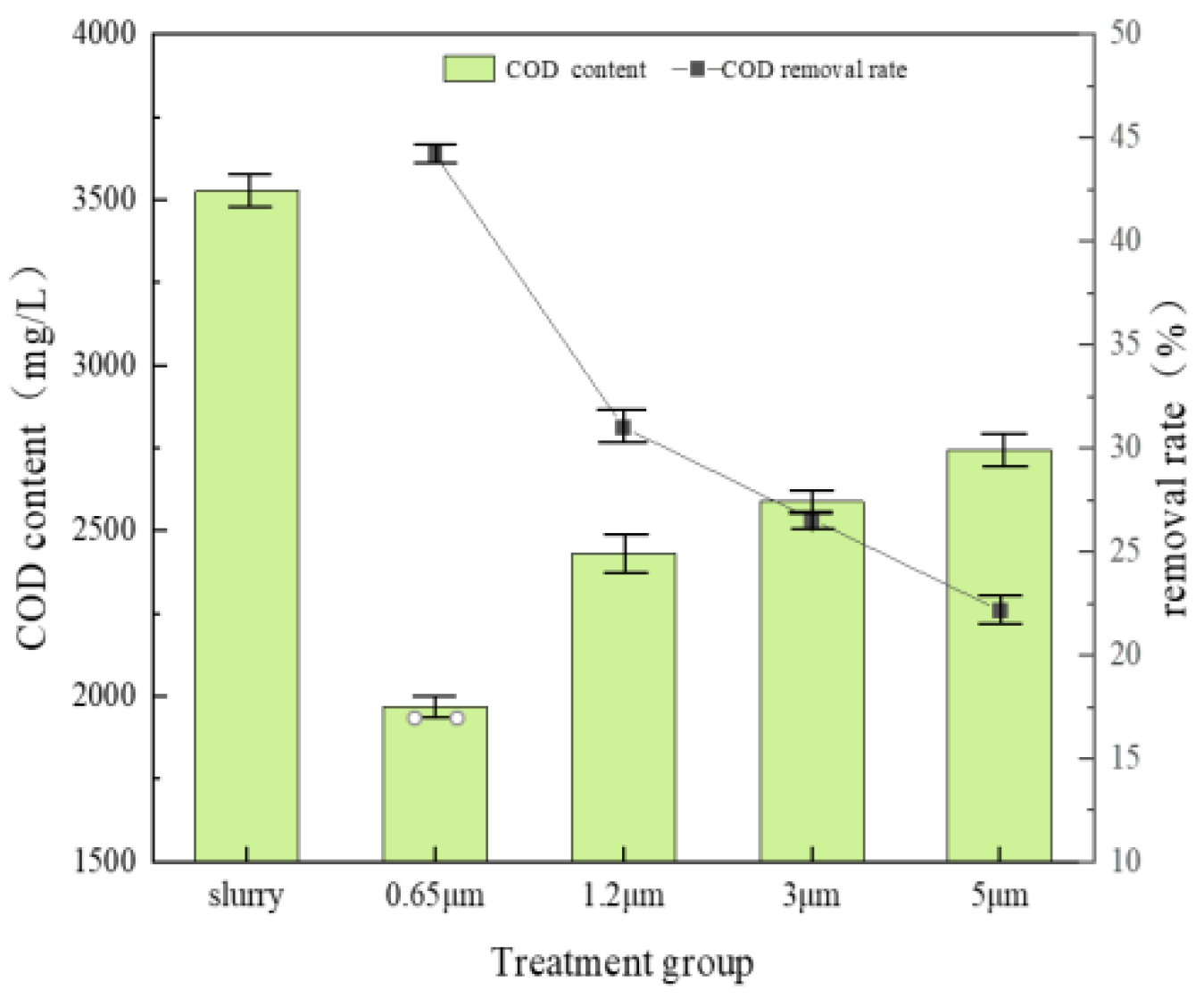

3.1.2. Impact of the Microfilter Membrane System on COD Characteristics in Biogas Slurry

3.1.3. Effect of the Microfilter Membrane Filter on NH4+-N Contents in Biogas Slurry

3.2. Effects of Biochar Absorption on SS, COD, and NH4+-N of Biogas Slurry Retentate

3.2.1. Effects of Biochar Addition on SS of Biogas Slurry Retentate

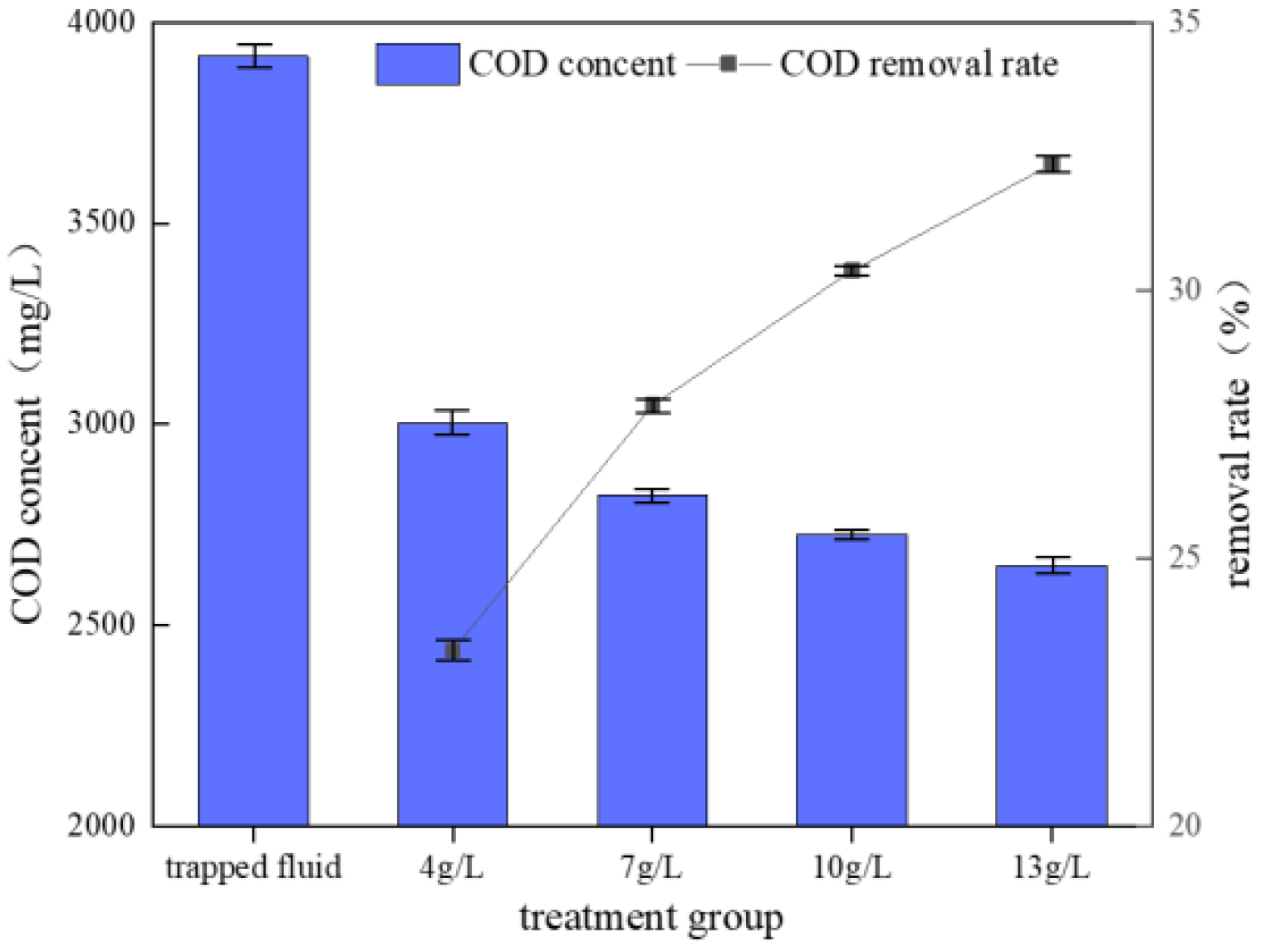

3.2.2. Effects of Biochar Addition on COD of Biogas Slurry Retentate

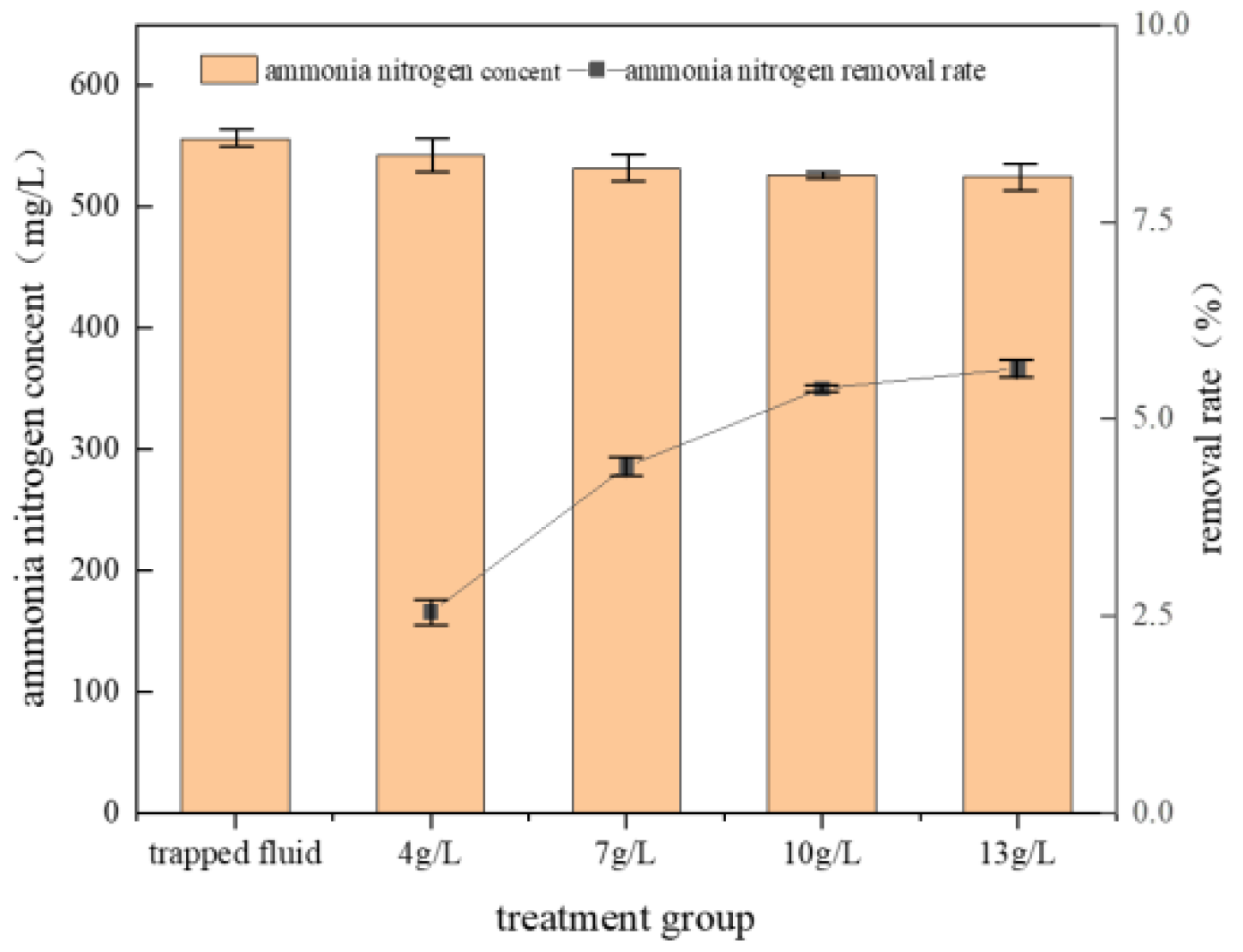

3.2.3. Effects of Biochar Addition on NH4+-N of Biogas Slurry Retentate

3.3. Effect of Biogas Slurry Reflux on the AD Process

3.3.1. Effect of Reflux on Ammonia Nitrogen during the AD Process

3.3.2. Effect of Reflux on the Volatile Fatty Acid Content during AD

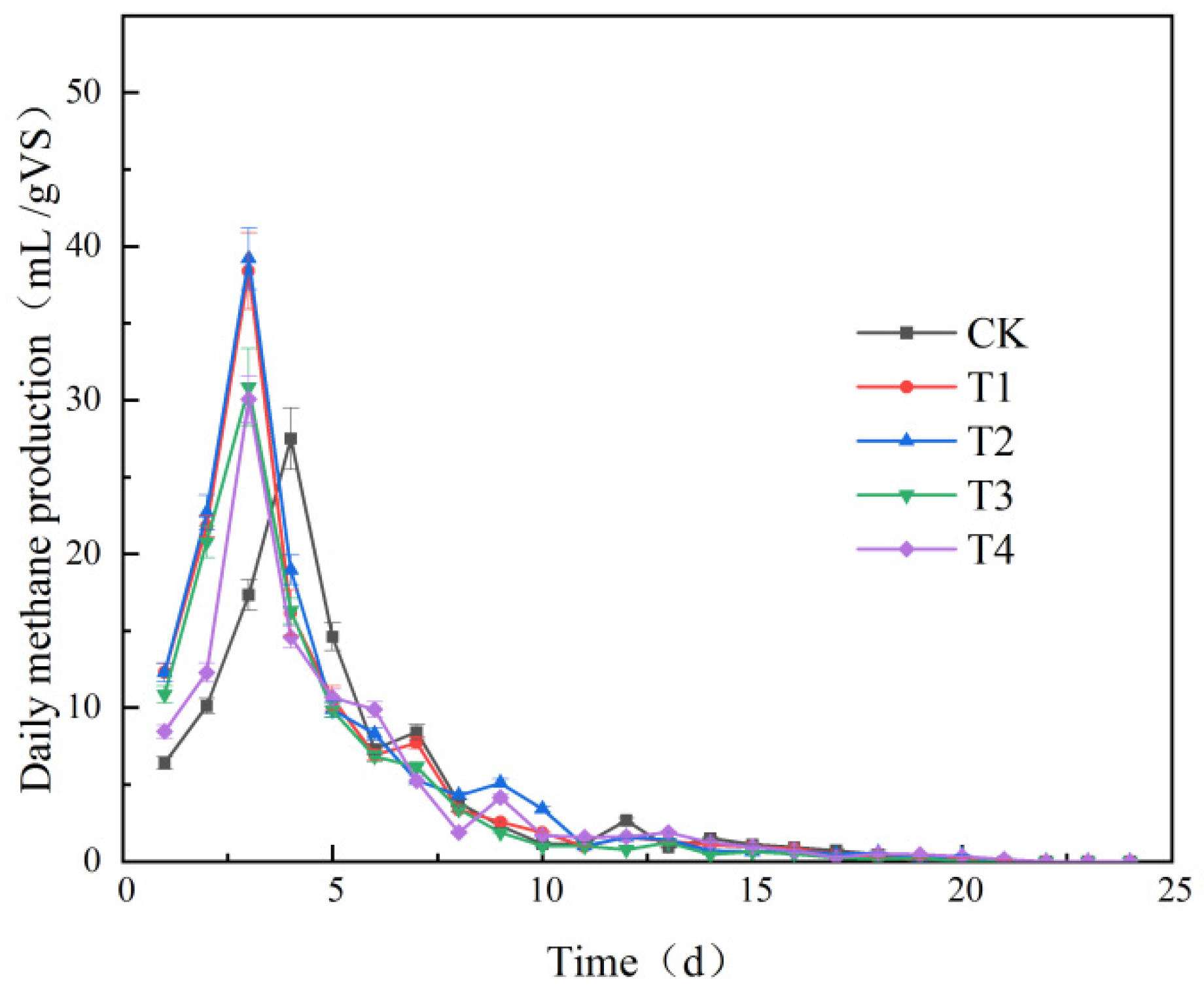

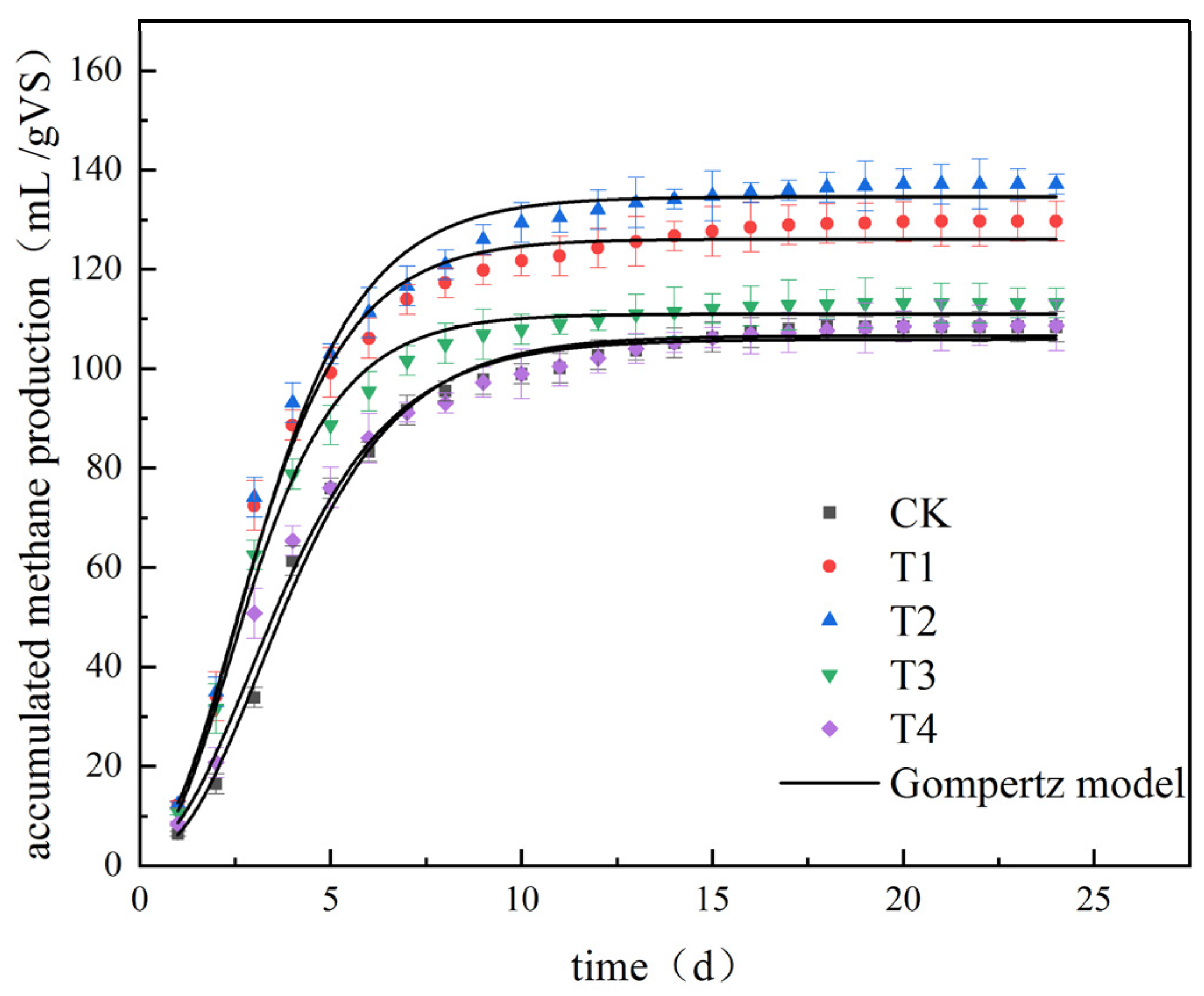

3.3.3. Effect of Reflux on Methanogenic Performance during AD

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- O’kelly, B. Consolidation properties of a dewatered municipal sewage sludge. Can. Geotech. J. 2005, 42, 1350–1358. [Google Scholar] [CrossRef] [Green Version]

- Chang, Y.; Zhao, H.; Sun, L.; Cui, J.; Liu, J.; Tang, Q.; Du, F.; Liu, X.; Yao, D. Resource Utilization of Biogas Waste as Fertilizer in China Needs More Inspections Due to the Risk of Heavy Metals. Agriculture 2022, 12, 72. [Google Scholar] [CrossRef]

- Song, Y.; Wang, G.; Li, R.; Chen, G. Research progress of biogas slurry treatment and resource utilization. Trans. Chin. Soc. Agric. Eng. 2021, 37, 237–250. [Google Scholar]

- Shi, L.; Liu, J.; Wei, Y.; Li, B.; Xue, Y.; Bi, Z. Current Status of Resource Utilization of Biogas Slurry in Agriculture. Chin. Agriculural Sci. Bull. 2019, 35, 109–117. [Google Scholar]

- Lai, X.; Wu, J.; Wang, J.; Xu, M.; Meng, X.; Mao, X.; Li, Y. The Long-term Effects of Biogas Slurry on Soil Properties and Potential Risks of Heavy Metals in Soils. J. Soil Water 2018, 32, 359–364+370. [Google Scholar]

- Sui, H.; Chen, X.; Qin, N.; Wang, G.; Xu, K.; Ai, P. Effects of Drip Irrigation with Biogas Slurry on Yield and Quality of Tomato and Physical and Chemical Properties of Soil. Shandong Agric. Sci. 2016, 48, 80–84. [Google Scholar]

- Xue, S.; Qiu, L.; Guo, X.; Yao, Y. Effect of liquid digestate recirculation on biogas production and enzyme activities for anaerobic digestion of corn straw. Water Sci. Technol. 2020, 82, 144–156. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, M.; Yan, S.; Yong, X.; Zhang, X.; Awasthi, M.K.; Xi, Y.; Zhou, J. Effects of hydrochar and biogas slurry reflux on methane production by mixed anaerobic digestion of cow manure and corn straw. Chemosphere 2022, 310, 136876. [Google Scholar] [CrossRef]

- Yang, J.; Wang, D.; Luo, Z.; Zeng, W. Influence of reflux ratio on the anaerobic digestion of pig manure in leach beds coupled with continuous stirred tank reactors. Waste Manag. 2019, 97, 115–122. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, W.; Yuan, X.; Li, Q.; Yang, Z. Effect of Slurry Recirculation on Methane Production of Cotton Stalk and Its microflora. China Biogas. 2018, 1, 19–25. [Google Scholar]

- Xiao, H.; Xu, X.; Zhu, X.; Zhou, W. Application of membrane technology for volume reduction of biogas slurry. Trans. Chin. Soc. Agric. Eng. 2020, 36, 226–236. [Google Scholar]

- Yin, F.; Zhan, Y.; Yue, C.; Hu, X.; Zhu, Z.; Dong, H. Research progress on membrane technology for treatment of husbandry biogas slurry and wastewater. J. Agro-Environ. Sci. 2021, 40, 2335–2341. [Google Scholar]

- Hu, C.L.; Zhang, D.; Dai, L. Research progress of inhibitory effects of ammonia in an anaerobic digestion system. Environ. Eng. 2016, 34, 23–27. [Google Scholar]

- APHA. Standard Methods for the Examination of Water and Wastewater, 18th ed.; American Public Health Association: Washington, DC, USA, 1998. [Google Scholar]

- Chen, Z.; Zhang, R.; Chen, S. Effects of peg on pore formation of polyether sulfone microporous membranes. Acta Polym. Sin. 2005, 4, 566–570. [Google Scholar]

- Dong, H.B.; Xu, Y.Y.; Zhu, L.P.; Yi, Z.; Zhu, B.K. Structure control and properties of ultrafiltration/microfiltration membranes. J. Funct. Mater. 2008, 39, 1941–1945. [Google Scholar]

- Szwast, M.; Szwast, Z.; Grądkowski, M.; Piątkiewicz, W. Modelling of postproduction suspensions concentration processes by “Batch” membrane microfiltration. Chem. Process Eng. Inz. Chem. Proces. 2013, 34, 313–325. [Google Scholar] [CrossRef]

- Xu, Y.; Zou, D.; Xiong, J. Microfiltration membrane materials and techniques. J. Clin. Rehabil. Tissue Eng. Res. 2011, 15, 2949–2952. [Google Scholar]

- Camilleri-Rumbau, M.S.; Norddahl, B.; Wei, J.; Christensen, K.V.; Søtoft, L.F. Microfiltration and ultrafiltration as a post-treatment of biogas plant digestates for producing concentrated fertilizers. Desalin. Water Treat. 2015, 55, 1639–1653. [Google Scholar] [CrossRef]

- Ni, C.; Zheng, X.; Zhang, Y.; Zhang, X.; Li, Y. Multifunctional porous materials with simultaneous high water flux, antifouling and antibacterial performances from ionic liquid grafted polyethersulfone. Polymer 2021, 212, 123183. [Google Scholar] [CrossRef]

- Wei, Y.; Sun, X.; Chu, R.; Chen, N. Process parameters of biogas slurry concentrating by membrane method. China Biogas 2020, 38, 60–65. [Google Scholar]

- Fan, K.; Zhou, G.; Yang, H.; Jun, H.U.; Hou, Z. Ultrafiltration membranes prepared from polyethersulfone-grafted-poly (N-vinyl-pyrrolidone) synthesized via simultaneous irradiation in homogenous phase and their anti-fouling performance. J. Radiat. Res. Radiat. Process. 2018, 36, 020301-1–020301-8. [Google Scholar]

- Zhang, X.; Zhao, W.; Zhao, C. Progress in Functionalized Polyethersulfone Membranes. J. Funct. Polym. 2021, 34, 114–143. [Google Scholar]

- Wang, M.; Wang, G.; Qian, L.; Yong, X.; Wang, Y.; An, W.; Jia, H.; Zhou, J. Biochar production using biogas residue and their adsorption of ammonium nitrogen and chemical oxygen demand in wastewater. Biomass Convers. Biorefin. 2021. [Google Scholar] [CrossRef]

- Zheng, Y.; Yu, Q.; Wang, H.; Wang, Y.; He, N.; Shen, L.; Li, Q. Preparation of biochars from biogas residue and adsorption of ammonia-nitrogen in biogas slurry. Ciesc J. 2014, 65, 1856–1861. [Google Scholar]

- Yuxiu, Z.H.; Xiaoshan, M.E.; Yawei, W.A.; Dawei, Y.U.; Yuansong, W.E. Research progress of ammonia inhibition and counter measures during anaerobic digestion of livestock wastes. Chin. J. Environ. Eng. 2018, 12, 985–998. [Google Scholar]

- Zhang, B.; Zhao, H.; Hairu, Y.U.; Chen, D.; Xue, L.I.; Changming, G.E.; Renzhe, P.; Cui, Z. Evaluation of Biogas Production Performance of Corn Straw by Anaerobic Digestion. Environ. Sci. Technol. 2016, 39, 70–74. [Google Scholar]

- Cheng, H.; Jing, Z.; Zhang, Z.; Tang, H. Ammonia inhibition and its regulation strategy during anaerobic digestion. Appl. Chem. Ind. 2020, 49, 1308–1312. [Google Scholar]

- Li, H.; Cao, F.; Wang, Y. The effect of different acetic acid accumulation on the methanogenic population and methane production in dry mesophilic anaerobic digestion. Energy Sources Part A-Recovery Util. Environ. Eff. 2016, 38, 1678–1684. [Google Scholar] [CrossRef]

- Shin, D.C.; Kim, I.T.; Jung, J.; Jeong, Y.; Lee, Y.E.; Ahn, K.H. Increasing Anaerobic Digestion Efficiency Using Food-Waste-Based Biochar. Fermentation 2022, 8, 282. [Google Scholar] [CrossRef]

- Pan, J.; Ma, J.; Zhai, L.; Liu, H. Enhanced methane production and syntrophic connection between microorganisms during semi-continuous anaerobic digestion of chicken manure by adding biochar. J. Clean. Prod. 2019, 240, 118178. [Google Scholar] [CrossRef]

- Wang, S.; Shi, F.; Li, P.; Yang, F.; Pei, Z.; Yu, Q.; Zuo, X.; Liu, J. Effects of rice straw biochar on methanogenic bacteria and metabolic function in anaerobic digestion. Sci. Rep. 2022, 12, 6971. [Google Scholar] [CrossRef]

| Raw Material | Total Carbon a (TC) (%) | Total Nitrogen a (TN) (%) | C/N | Total Solid (TS) (%) | Volatile Solid (VS) (%) |

|---|---|---|---|---|---|

| Biogas slurry | 32.4 ± 0.35 | 0.66 ± 0.08 | 49.09 ± 0.72 | 3.68 ± 0.41 | 1.32 ± 0.33 |

| Corn stover | 42.67 ± 0.09 | 0.98 ± 0.11 | 43.54 ± 0.78 | 89.69 ± 0.26 | 86.37 ± 0.16 |

| Biochar | 47.56 ± 0.82 | 0.96 ± 0.06 | 49.08 ± 0.52 | 98.97 ± 0.06 | 98.89 ± 0.43 |

| Inoculum | 33.36 ± 0.29 | 2.52 ± 0.33 | 13.29 ± 0.21 | 3.54 ± 0.15 | 1.12 ± 0.44 |

| Kinetic Parameters of Cumulative Methane Production | ||||||

|---|---|---|---|---|---|---|

| Treatment Group | Ym (ML g−1 VS) | Rm (mL d−1 g−1 VS) | λ(d) | R2 | Ya (mL g−1 VS) | Ra (mL d−1 g−1 VS) |

| CK | 106.57 ± 0.74 | 19.84 ± 0.89 | 1.16 ± 0.13 | 0.9924 | 108.44 ± 2.98 | 27.50 ± 2.51 |

| T1 | 126.71 ± 0.95 | 24.67 ± 1.39 | 0.40 ± 0.17 | 0.9858 | 129.68 ± 3.56 | 38.40 ± 2.01 |

| T2 | 135.15 ± 0.85 | 24.56 ± 1.33 | 0.37 ± 0.18 | 0.9864 | 137.14 ± 3.55 | 39.21 ± 2.15 |

| T3 | 111.33 ± 0.56 | 23.17 ± 1.12 | 0.45 ± 0.14 | 0.9912 | 113.19 ± 2.03 | 30.85 ± 3.12 |

| T4 | 106.22 ± 0.82 | 20.63 ± 1.22 | 0.66 ± 0.14 | 0.9928 | 108.70 ± 4.06 | 30.07 ± 1.57 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, X.; Qu, J.; Huang, Y.; Liu, W.; Sun, Y. Enhancing Biogas Production of Corn Stover by Biogas Slurry Reflux Based on Microfiltration Membrane Filtration and Biochar Adsorption. Agriculture 2022, 12, 2040. https://doi.org/10.3390/agriculture12122040

Su X, Qu J, Huang Y, Liu W, Sun Y. Enhancing Biogas Production of Corn Stover by Biogas Slurry Reflux Based on Microfiltration Membrane Filtration and Biochar Adsorption. Agriculture. 2022; 12(12):2040. https://doi.org/10.3390/agriculture12122040

Chicago/Turabian StyleSu, Xiaohong, Jingbo Qu, Yan Huang, Wei Liu, and Yong Sun. 2022. "Enhancing Biogas Production of Corn Stover by Biogas Slurry Reflux Based on Microfiltration Membrane Filtration and Biochar Adsorption" Agriculture 12, no. 12: 2040. https://doi.org/10.3390/agriculture12122040