Quality and Fertility Assessments of Municipal Solid Waste Compost Produced from Cleaner Development Mechanism Compost Projects: A Case Study from Uganda

Abstract

:1. Introduction

2. Materials and Methods

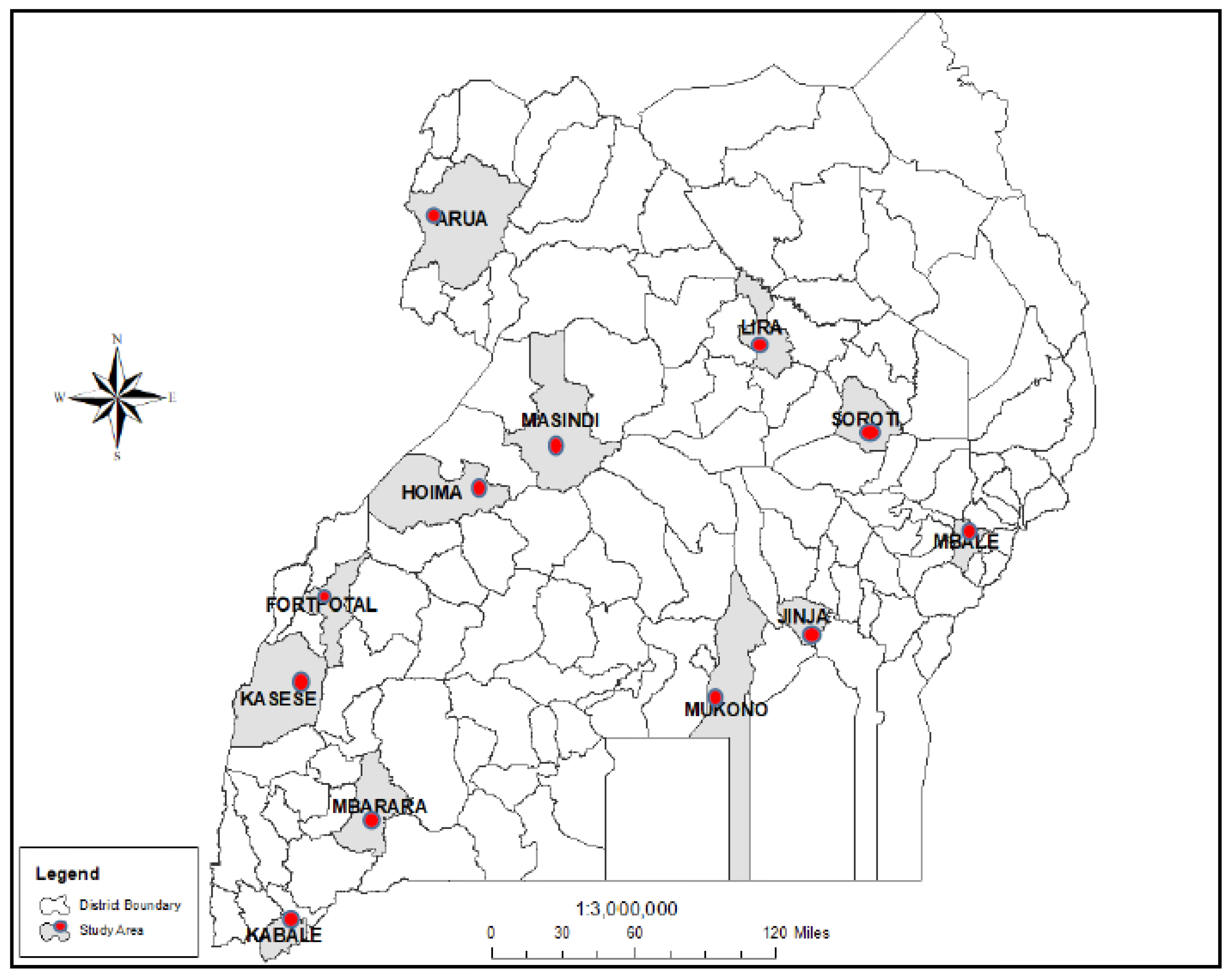

2.1. Study Areas

2.2. Composting Mechanisms at the CDM Plants

2.3. Collection, Preparation, and Chemical Analyses of Samples

2.4. Methods of Analysis

2.4.1. Indices for Compost Quality

2.4.2. Statistical Analysis

3. Results and Discussion

3.1. MSWC Quality

3.1.1. Macronutrients

3.1.2. Secondary Nutrients

3.1.3. Heavy Metal Contamination in MSWC

3.1.4. Fertility Index and Clean Index

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, X. Life Cycle Assessment (LCA) of Five Municipal Solid Waste Management Systems (MSWMS): A Case Study of Nanjing, China; Doctoral Dissertation, Master’s Thesis of Science, Norwich Research Park; University of East Anglia: Norwich, UK, 2012; pp. 1–48. Available online: https://pdfs.semanticscholar.org/ff80/a0fd04868b9cdcadcac48bcc31fcb6fd3951.pdf (accessed on 19 May 2020).

- Banna, F.M.; Bhada-Tata, P.; Ho, R.; Kaza, S.; Lee, M. Results-based Financing for Municipal Solid Waste. Main Report (English) in Urban Development Series Knowledge; World Bank Group: Washington, WA, USA, 2014; Volume 2, pp. 1–84. [Google Scholar]

- Ziraba, A.K.; Haregu, T.N.; Mberu, B. A review and framework for understanding the potential impact of poor solid waste management on health in developing countries. Arch. Public Health 2016, 74, 55. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- UNHABITAT. Towards achieving SDG 11 in Uganda: Making Cities and Human Settlements Inclusive, Liveable, Safe, Resilient, Productive and Sustainable. Available online: https://unhabitat.org/sites/default/files/documents/2019-05/un-habitat_country_programme_document_2016-_2021_-_uganda.pdf (accessed on 2 February 2022).

- Okot-Okumu, J. Solid Waste Management in African Cities-East Africa in Waste Management-An Integrated Vision; IntechOpen: Kampala, Uganda, 2012; Available online: http://www.intechopen.com/books/waste-management-an-integrated-vision/solid-waste-management-in-african-cities-east-africa (accessed on 2 February 2022).

- Oosterveer, P.; Van Vliet, B. Environmental Systems and Local Actors: Decentralizing Environmental Policy in Uganda. Environ. Manag. 2010, 45, 284–295. [Google Scholar] [CrossRef] [Green Version]

- Rogger, C.; Beaurain, F.; Schmidt, T.S. Composting projects under the Clean Development Mechanism: Sustainable contribution to mitigate climate change. Waste Manag. 2011, 31, 138–146. [Google Scholar] [CrossRef] [PubMed]

- Komakech, A.J.; Banadda, N.E.; Kinobe, J.R.; Kasisira, L.; Sundberg, C.; Gebresenbet, G.; Vinnerås, B. Characterization of municipal waste in Kampala, Uganda. J. Air Waste Manag. Assoc. 2014, 64, 340–348. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Komakech, A.; Zurbrügg, C.; Miito, G.; Wanyama, J.; Vinnerås, B. Environmental impact from vermicomposting of organic waste in Kampala, Uganda. J. Environ. Manag. 2016, 181, 395–402. [Google Scholar] [CrossRef] [PubMed]

- Luske, B. Reduced GHG Emissions Due to Compost Production and Compost Use in Egypt. Comparing Two Scenarios; Louis Bolk Instituut: Bunnik, The Netherlands, 2010; pp. 1–30. [Google Scholar]

- Saha, J.; Panwar, N.; Singh, M. An assessment of municipal solid waste compost quality produced in different cities of India in the perspective of developing quality control indices. Waste Manag. 2010, 30, 192–201. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S. Composting of municipal solid waste. Crit. Rev. Biotechnol. 2011, 31, 112–136. [Google Scholar] [CrossRef] [PubMed]

- Mutairi, S.O.; Ghoneim, A.M.; Modaihsh, A.S.; Mahjoub, M.O.; Abdel-Aziz, R.A. The characterization and composting of the municipal solid waste of Riyadh city, Saudi Arabia. Waste Manag. Environ. VII 2014, 180, 283–292. [Google Scholar]

- Tibihika, P.D.; Okurut, T.; Lugumira, J.S.; Akello, C.; Muganga, G.; Tumuhairwe, J.B.; Nsereko, M.; Kiguli, D.; Mugambwa, R. Characteristics of municipal fresh solid wastes from the selected large urban centres in Uganda: Implication for re-use and soil amendment strategies. J. Air Waste Manag. Assoc. 2021, 71, 923–933. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.; Stowell, A. Sustainable Financing and Policy: Models for Municipal Composting (Urban development series, Knowledge Papers 24). Available online: https://openknowledge.worldbank.org/handle/10986/26286 (accessed on 14 April 2021).

- Mandal, P.; Chaturvedi, M.; Bassin, J.K.; Vaidya, A.N.; Gupta, R.K. Qualitative assessment of municipal solid waste compost by indexing method. Int. J. Recycl. Org. Waste Agric. 2014, 3, 133–139. [Google Scholar] [CrossRef] [Green Version]

- Chrysargyris, A.; Tzortzakis, N. Municipal solid wastes and mineral fertilizer as an eggplant transplant medium. J. Soil Sci. Plant Nutr. 2015, 15, 11–23. [Google Scholar] [CrossRef] [Green Version]

- Shweta, C. Valuable black gold as a result of utilization of municipal solid waste. Recent Res. Sci. Technol. 2014, 6, 241–244. [Google Scholar]

- Jodar, J.R.; Ramos, N.; Carreira, J.A.; Pacheco, R.; Fernández-Hernández, A. Quality assessment of compost prepared with municipal solid waste. Open Eng. 2017, 7, 221–227. [Google Scholar] [CrossRef]

- Nsimbe, P.; Mendoza, H.; Wafula, S.T.; Ndejjo, R. Factors Associated with Composting of Solid Waste at Household Level in Masaka Municipality, Central Uganda. J. Environ. Public Health 2018, 2018, 1284234. [Google Scholar] [CrossRef] [PubMed]

- Jalal, S.Y.; Hanna, N.S.; Shekha, Y.A. The effects of Insects on the Physicochemical Characteristics During Composting. Iraqi J. Sci. 2019, 2019, 2426–2432. [Google Scholar] [CrossRef]

- He, X.-T.; Logan, T.J.; Traina, S.J. Physical and Chemical Characteristics of Selected U.S. Municipal Solid Waste Composts. J. Environ. Qual. 1995, 24, 543–552. [Google Scholar] [CrossRef]

- Eggerth, L.; Diaz, L.; Chang, M.; Iseppi, L. Chapter 12 Marketing of composts. Biogranulation Technol. Wastewater Treat. 2007, 8, 325–355. [Google Scholar]

- Uganda National Bureau of Standards. Organic Fertilizer—Specification, US 1584.2017. Available online: https://members.wto.org/crnattachments/2017/TBT/UGA/17_1082_00_e.pdf (accessed on 14 April 2021).

- Uganda Bureau of Statistics. Uganda Census of Agriculture 2008/2009. Crop. Area Prod. Rep. 2010, 4, 1–178. [Google Scholar]

- Bary, A.I.; Sullivan, D.M.; Cogger, C.G. Fertilizing with Manure and Other Organic Amendments. Available online: https://s3.wp.wsu.edu/uploads/sites/411/2016/07/Paper_FertManure2016.pdf (accessed on 14 April 2021).

- Brinton, W.; Bonhotal, J.; Fiesinger, T. Compost Sampling for Nutrient and Quality Parameters: Variability of Sampler, Timing and Pile Depth. Compos. Sci. Util. 2012, 20, 141–149. [Google Scholar] [CrossRef]

- Okalebo, J.R.; Gathua, K.W.; Woomer, P.L. Laboratory Methods of Soil and Plant Analysis: A working Manual; TSBF Programme. Soil Sci. Soc. East Afr. Tech. Publ. 1993, 1, 88. [Google Scholar]

- Okalebo, J.R.; Gathua, K.W.; Woomer, P.L. Laboratory methods of soil and plant analysis: A working manual second edition. Sacred Afr. Nairobi. 2002, 21, 25–26. [Google Scholar]

- Nelson, D.W.; Sommers, L.E. Total Carbon, Organic Carbon, and Organic Matter. In Methods of Soil Analysis: Part 3 Chemical Methods; Sparks, D.L., Ed.; Soil Science Society of America: Madison, WI, USA, 1996; Volume 5, pp. 961–1010. [Google Scholar]

- Hendershot, W.H.; Lalande, H. Ion Exchange and Exchangeable Cations in Soil Sampling and Methods of Analysis; Carter, M.R., Ed.; Lewis Publishers, CRC Press: Cambridge, UK, 1993. [Google Scholar]

- Walkley, A.J.; Black, I.A. Estimation of soil organic carbon by the chromic acid titration method. Soil Sci. 1934, 37, 29–38. [Google Scholar] [CrossRef]

- Horwitz, W.; Latimer, G.W. Official Methods of Analysis of AOAC International; AOAC International: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Schrenk, W. Analytical Atomic Spectroscopy in Modern Analytical Chemistry [Internet]; Springer Science & Business Media: Manhattan, KS, USA, 2012. [Google Scholar]

- Lane, E.A.; Canty, M.J.; More, S.J. Cadmium exposure and consequence for the health and productivity of farmed ruminants. Res. Vet. Sci. 2015, 101, 132–139. [Google Scholar] [CrossRef]

- World Health Organization. Exposure to Lead: A Major Public Health Concern. 2010. Available online: https://www.who.int/ipcs/features/cadmium.pdf (accessed on 27 August 2021).

- Anderson, M.J.; Gorley, R.N.; Clarke, K.R. PERMANOVA+ for PRIMER: Guide to Software and Statistical Methods; PRIMER-E Ltd.: Plymouth, UK, 2008; p. 214. [Google Scholar]

- Ye, J.; Zhang, R.; Nielsen, S.; Joseph, S.D.; Huang, D.; Thomas, T. A Combination of Biochar–Mineral Complexes and Compost Improves Soil Bacterial Processes, Soil Quality, and Plant Properties. Front. Microbiol. 2016, 7, 372. [Google Scholar] [CrossRef]

- Rutaro, K.; Malinga, G.M.; Lehtovaara, V.J.; Opoke, R.; Valtonen, A.; Kwetegyeka, J.; Nyeko, P.; Roininen, H. The fatty acid composition of edible grasshopper Ruspolia differens (Serville) (Orthoptera: Tettigoniidae) feeding on diversifying diets of host plants. Èntomol. Res. 2018, 48, 490–498. [Google Scholar] [CrossRef]

- Vyas, P.B. Assessment of municipal solid waste compost characterization and compliance. I Control. Pollut. 2011, 27, 87–91. [Google Scholar]

- Rahman, M.M.; Bhuiyan, M.; Rouf, M.; Sarker, R.; Rashid, M.H. Quality Assessment of Municipal Solid Waste Compost. Acta Chem. Malays. 2020, 4, 33–39. [Google Scholar] [CrossRef]

- WCA Environment Ltd. Review of Scientific Literature on Compost Produced from Food and Garden Organic Waste in Final Report to New South Wales Environment Protection Authority; WCA Environment Ltd.: Faringdon, UK, 2019; pp. 1–35. [Google Scholar]

- Standards Association of Australia. Composts, Soil Conditioners and Mulches; Standards Australia International Ltd.: Sydney, Australia, 2012; Volume 4, pp. 1–74. [Google Scholar]

- The African Organization for Standardization (ARSO). African Standard WD-ARS; The African Organization for Standardization (ARSO): Waknaghat, India, 2018; pp. 1–25. [Google Scholar]

- Mkhabela, M.; Warman, P. The influence of municipal solid waste compost on yield, soil phosphorus availability and uptake by two vegetable crops grown in a Pugwash sandy loam soil in Nova Scotia. Agric. Ecosyst. Environ. 2005, 106, 57–67. [Google Scholar] [CrossRef]

- Bazrafshan, E.; Zarei, A.; Mostafapour, F.K.; Poormollae, N.; Mahmoodi, S.; Zazouli, M.A. Maturity and Stability Evaluation of Composted Municipal Solid Wastes. Health Scope 2016, 5, e33202. [Google Scholar] [CrossRef] [Green Version]

- Rawat, M.; Ramanathan, A.; Kuriakose, T. Characterisation of Municipal Solid Waste Compost (MSWC) from Selected Indian Cities—A Case Study for Its Sustainable Utilisation. J. Environ. Prot. 2013, 4, 163–171. [Google Scholar] [CrossRef] [Green Version]

- Zaha, C.; Dumitrescu, L.; Manciulea, I. Correlations between composting conditions and characteristics of compost as biofertilizer. Bulletin of the Transilvania University of Brasov. Eng. Sci. Ser. I 2013, 6, 51. [Google Scholar]

- Sharma, A.; Ganguly, R.; Gupta, A.K. Spectral characterization and quality assessment of organic compost for agricultural purposes. Int. J. Recycl. Org. Waste Agric. 2019, 8, 197–213. [Google Scholar] [CrossRef] [Green Version]

- Sayara, T.; Basheer-Salimia, R.; Hawamde, F.; Sánchez, A. Recycling of organic wastes through composting: Process performance and compost application in agriculture. Agronomy 2020, 10, 1838. [Google Scholar] [CrossRef]

- Silva, M.T.; Menduíña, A.M.; Seijo, Y.C.; Viqueira, F.D. Assessment of municipal solid waste compost quality using standardized methods before preparation of plant growth media. Waste Manag. Res. 2007, 25, 99–108. [Google Scholar] [CrossRef]

- Sultana, M.; Jahiruddin, M.; Islam, M.R.; Rahman, M.M.; Abedin, M.A.; Solaiman, Z.M. Nutrient Enriched Municipal Solid Waste Compost Increases Yield, Nutrient Content and Balance in Rice. Sustainability 2021, 13, 1047. [Google Scholar] [CrossRef]

- Sullivan, D.M.; Bary, A.I.; Miller, R.O.; Brewer, L.J. Interpreting Compost Analyses; Oregon State University: Corvallis, OR, USA, 2018. [Google Scholar]

- Kihara, J.; Bolo, P.; Kinyua, M.; Rurinda, J.; Piikki, K. Micronutrient deficiencies in African soils and the human nutritional nexus: Opportunities with staple crops. Environ. Geochem. Health 2020, 42, 3015–3033. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ayari, F.; Hamdi, H.; Jedidi, N.; Gharbi, N.; Kossai, R. Heavy metal distribution in soil and plant in municipal solid waste compost amended plots. Int. J. Environ. Sci. Technol. 2010, 7, 465–472. [Google Scholar] [CrossRef] [Green Version]

- Yüksel, O. Influence of municipal solid waste compost application on heavy metal content in soil. Environ. Monit. Assess. 2015, 187, 313. [Google Scholar] [CrossRef]

- Guerra, F.; Trevizam, A.R.; Fior, R.C.; Muraoka, T. Cadmium phytoavailability in soils and evaluation of extractant effectiveness using an isotope technique. Sci. Agric. 2014, 71, 410–415. [Google Scholar] [CrossRef] [Green Version]

- Mukai, S.; Oyanagi, W. Evaluation on maturity and stability of organic fertilisers in semi-arid Ethiopian Rift Valley. Sci. Rep. 2021, 11, 4035. [Google Scholar] [CrossRef] [PubMed]

- Barčauskaitė, K.; Žydelis, R.; Mažeika, R. Screening of chemical composition and risk index of different origin composts produced in Lithuania. Environ. Sci. Pollut. Res. 2020, 27, 24480–24494. [Google Scholar] [CrossRef] [PubMed]

- Nyakaana, J.B. Solid Waste Management in Urban Centers: The Case of Kampala City—Uganda. East Afr. Geogr. Rev. 1997, 19, 33–43. [Google Scholar] [CrossRef]

| Compost Plant | pH | Electrical Conductivity (µs/cm) | Organic Matter (%) | Organic Carbon (%) | C:N Ratio | Total N (%) | Total P (%) | Total K (%) | Calcium (%) | Magnesium (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| Arua | 8.9 ± 0.15 | 3779 ± 85.24 | 7.8 ± 0.43 | 4.1 ± 0.18 | 12.9 ± 0.32 | 0.3 ± 0.04 | 0.3 ± 0.10 | 0.8 ± 0.05 | 2.1 ± 0.14 | 0.4 ± 0.00 |

| Hoima | 9.4 ± 0.32 | 4841 ± 50.01 | 13.8 ± 0.27 | 7.4 ± 0.90 | 14.0 ± 0.00 | 0.5 ± 0.06 | 0.2 ± 0.01 | 1.3 ± 0.02 | 2.1 ± 0.03 | 0.5 ± 0.00 |

| Fort Portal | 9.6 ± 0.18 | 4427 ± 652.12 | 10.2 ± 1.19 | 5.7 ± 1.04 | 10.5 ± 1.03 | 0.5 ± 0.05 | 0.4 ± 0.02 | 1.8 ± 0.20 | 1.3 ± 0.10 | 0.6 ± 0.04 |

| Jinja | 8.9 ± 0.15 | 4925 ± 115 | 21.3 ± 1.00 | 11.8 ± 1.17 | 23.8 ± 1.59 | 0.5 ± 0.02 | 0.3 ± 0.01 | 1.5 ± 0.17 | 2.1 ± 0.11 | 0.5 ± 0.02 |

| Kabale | 9.3 ± 0.08 | 2867 ± 141.71 | 15.6 ± 1.10 | 8.6 ± 1.40 | 15.9 ± 0.77 | 0.5 ± 0.06 | 0.2 ± 0.04 | 0.8 ± 0.05 | 1.2 ± 0.00 | 0.4 ± 0.01 |

| Mbarara | 9.6 ± 0.06 | 9511 ± 505.2 | 28.6 ± 1.56 | 15.7 ± 2.07 | 26.3 ± 0.57 | 0.6 ± 0.07 | 0.4 ± 0.03 | 2.3 ± 0.17 | 3.0 ± 0.16 | 0.9 ± 0.04 |

| Kasese | 9.2 ± 0.16 | 5577 ± 395.19 | 14.3 ± 1.23 | 8.3 ± 0.88 | 14.5 ± 2.37 | 0.6 ± 0.04 | 0.5 ± 0.03 | 1.4 ± 0.02 | 2.1 ± 0.28 | 0.7 ± 0.03 |

| Mbale | 8.9 ± 0.39 | 4097 ± 453.91 | 16.3 ± 1.12 | 9.7 ± 0.55 | 23.2 ± 4.62 | 0.4 ± 0.10 | 0.3 ± 0.02 | 0.8 ± 0.02 | 3.2 ± 0.09 | 0.7 ± 0.08 |

| Masindi | 9.6 ± 0.20 | 5124 ± 351.61 | 12.6 ± 2.01 | 6.8 ± 1.69 | 13.3 ± 2.49 | 0.5 ± 0.03 | 0.2 ± 0.03 | 2.3 ± 0.04 | 2.7 ± 0.04 | 0.8 ± 0.02 |

| Mukono | 9.3 ± 0.07 | 3230 ± 1498.23 | 17.5 ± 3.52 | 10.1 ± 2.25 | 16.8 ± 2.78 | 0.6 ± 0.04 | 0.3 ± 0.01 | 0.9 ± 0.57 | 2.4 ± 0.10 | 0.5 ± 0.02 |

| Soroti | 9.0 ± 0.23 | 2888 ± 272.52 | 10.1 ± 0.65 | 6.1 ± 0.49 | 15.3 ± 0.47 | 0.4 ± 0.02 | 0.2 ± 0.02 | 0.7 ± 0.06 | 1.4 ± 0.09 | 0.4 ± 0.05 |

| Lira | 8.3 ± 0.48 | 5148 ± 256.07 | 14.1 ± 1.78 | 7.9 ± 1.12 | 20.9 ± 3.96 | 0.4 ± 0.02 | 0.8 ± 0.60 | 0.8 ± 0.06 | 0.7 ± 0.04 | 0.3 ± 0.02 |

| Average | 9.2 | 4701.2 | 15.2 | 8.5 | 17.2 | 0.5 | 0.3 | 1.3 | 2.0 | 0.6 |

| Maximum | 9.6 | 9511 | 28.6 | 15.7 | 26.3 | 0.6 | 0.8 | 2.3 | 3.2 | 0.9 |

| Minimum | 8.3 | 2867.3 | 7.8 | 4.1 | 10.5 | 0.3 | 0.2 | 0.7 | 0.7 | 0.3 |

| UNBS | 6–10 | 5000 | - | 12 | 12–15 | 1 | - | - | - | - |

| Pseudo-F (11, 24) | 7.76 | 1.76 | 2.62 | 1.36 | 2.54 | 2.60 | 2.81 | 4.99 | 2.60 | 2.81 |

| p value | 0.001 | 0.123 | 0.024 | 0.246 | 0.026 | 0.032 | 0.009 | 0.003 | 0.027 | 0.019 |

| Compost Plant | Boron (mg/kg) | Copper (mg/kg) | Iron (mg/kg) | Manganese (%) | Zinc (mg/kg) | Lead (mg/kg) | Cadmium (mg/kg) | Chromium (mg/kg) |

|---|---|---|---|---|---|---|---|---|

| Arua | 10.6 ± 0.61 | 58.8 ± 10.37 | 8826.2 ± 300.7 | 0.02 ± 0.006 | 409.2 ± 8.8 | 12.8 ± 1.97 | 0.04 ± 0.07 | 10.0 ± 0.2 |

| Hoima | 13.7 ± 1.58 | 53.4 ± 9.4 | 23,208.3 ± 1690.8 | 0.05 ± 0.009 | 553.3 ± 117.19 | 13.3 ± 3.53 | Not detected | 11.0 ± 1.65 |

| Fort Portal | 12.8 ± 0.65 | 46.7 ± 7.14 | 12,780.0 ± 4429.5 | 0.07 ± 0.004 | 272.8 ± 23.80 | 9.8 ± 6.7 | Not detected | 15.9 ± 4.25 |

| Jinja | 21.6 ± 8.64 | 139.5 ± 23.1 | 32,925.3 ± 8250 | 0.12 ± 0.015 | 605.3 ± 0.58 | 33.5 ± 18.11 | 0.77 ± 0.15 | 13.5 ± 2.93 |

| Kabale | 54.6 ± 70.5 | 55.0 ± 9.3 | 15,630.0 ± 2671.1 | 0.07 ± 0.003 | 384.2 ± 190.7 | 16.0 ± 2.61 | 0.30 ± 0.52 | 10.5 ± 0.83 |

| Mbarara | 25.8 ± 3.22 | 33.5 ± 10.17 | 6362.5 ± 1282.76 | 0.42 ± 0.33 | 301.2 ± 10.79 | 12.6 ± 4.6 | Not detected | 10.9 ± 2.23 |

| Kasese | 15.2 ± 1.37 | 50.7 ± 11.9 | 9884.7 ± 291.21 | 0.05 ± 0.01 | 400.7 ± 17.21 | 16.4 ± 8.67 | 0.07 ± 0.12 | 13.0 ± 0.63 |

| Mbale | 16.8 ± 1.66 | 56.6 ± 0.26 | 15,773.3 ± 1037.7 | 0.08 ± 0.01 | 429.0 ± 15.6 | 15.8 ± 6.78 | Not detected | 7.9 ± 0.56 |

| Masindi | 15.3 ± 2.21 | 39.0 ± 5.66 | 34,591.7 ± 1983.1 | 0.06 ± 0.01 | 444.3 ± 23.8 | 13.9 ± 3.87 | 0.07 ± 0.12 | 11.5 ± 1.36 |

| Mukono | 19.8 ± 0.59 | 94.1 ± 6.34 | 12,770.0 ± 331.51 | 0.06 ± 0.02 | 516.7 ± 8.5 | 24.8 ± 10.9 | 0.27 ± 0.25 | 11.2 ± 1.97 |

| Soroti | 12.5 ± 0.64 | 50.5 ± 8.7 | 15,676.7 ± 610.44 | 0.05 ± 0.01 | 1088.7 ± 68.16 | 5.8 ± 0.49 | Not detected | 6.7 ± 1.8 |

| Lira | 20.4 ± 8.99 | 51.4 ± 9.7 | 17,353.3 ± 13,009.6 | 0.03 ± 0.002 | 335.5 ± 289.5 | 9.0 ± 0.06 | 0.10 ± 0.1 | 3.7 ± 0.66 |

| Average | 19.9 | 60.8 | 17,148.5 | 0.1 | 478.8 | 15.3 | 0.13 | 10.5 |

| Maximum | 54.6 | 139.5 | 34,591.7 | 0.42 | 1088.7 | 33.5 | 0.77 | 15.9 |

| Minimum | 10.6 | 33.5 | 6362.5 | 0.02 | 272.8 | 5.8 | Not detected | 3.7 |

| UNBS | - | 300 | - | - | - | 100 | 5 | 50 |

| F | 0.969 | 0.991 | 13.811 | 3.695 | 13.811 | 2.922 | 4.556 | 8.256 |

| p values | 0.499 | 0.481 | <0.001 | 0.004 | <0.001 | 0.014 | 0.001 | <0.001 |

| Arua | Hoima | Fort Portal | Jinja | Kabale | Mbarara | Kasese | Mbale | Masindi | Mukono | Soroti | Lira | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fertility Index | 2.2 | 2.1 | 2.5 | 2.2 | 2.0 | 2.9 | 2.7 | 2.1 | 2.1 | 2.5 | 1.9 | 2.2 |

| Clean Index | 4.7 | 4.6 | 4.9 | 3.8 | 4.4 | 4.9 | 4.9 | 4.7 | 4.9 | 4.6 | 4.6 | 4.7 |

| Compost Class | RU-1 | RU-1 | RU-1 | RU-1 | RU-1 | RU-1 | RU-1 | RU-1 | RU-1 | RU-1 | RU-1 | RU-1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kabasiita, J.K.; Opolot, E.; Malinga, G.M. Quality and Fertility Assessments of Municipal Solid Waste Compost Produced from Cleaner Development Mechanism Compost Projects: A Case Study from Uganda. Agriculture 2022, 12, 582. https://doi.org/10.3390/agriculture12050582

Kabasiita JK, Opolot E, Malinga GM. Quality and Fertility Assessments of Municipal Solid Waste Compost Produced from Cleaner Development Mechanism Compost Projects: A Case Study from Uganda. Agriculture. 2022; 12(5):582. https://doi.org/10.3390/agriculture12050582

Chicago/Turabian StyleKabasiita, Juliet Kiiza, Emmanuel Opolot, and Geoffrey Maxwell Malinga. 2022. "Quality and Fertility Assessments of Municipal Solid Waste Compost Produced from Cleaner Development Mechanism Compost Projects: A Case Study from Uganda" Agriculture 12, no. 5: 582. https://doi.org/10.3390/agriculture12050582

APA StyleKabasiita, J. K., Opolot, E., & Malinga, G. M. (2022). Quality and Fertility Assessments of Municipal Solid Waste Compost Produced from Cleaner Development Mechanism Compost Projects: A Case Study from Uganda. Agriculture, 12(5), 582. https://doi.org/10.3390/agriculture12050582