Abstract

The purpose of this research was to collect efficacy data on biological, biochemical, and chemical fungicide seed treatments on hemp (Cannabis sativa L.) to mitigate damping-off and enhance field stand establishment. Seed treatments were evaluated in fields in New York (NY), North Dakota (ND), and Virginia (VA) and at two planting dates in each state in 2020. A single seed lot of a dual-purpose (fiber + grain) cultivar (‘Anka’) was treated using a laboratory-scale rotary pan coater. Five biological, two biochemical, and four chemical seed treatments were tested. A laboratory germination test revealed that seed treatments did not exhibit phytotoxicity when compared to the non-treated control. A laboratory bioassay with naturally infested soil was used to assess the preliminary activity of seed treatments for protection against damping-off. The biochemical seed treatment Ultim® (active ingredient; organic copper) performed as well as the chemical treatments Apron XL® + Maxim® 4FS and Mertect® 340F in preventing damping-off whereas the biological treatments did not differ from the non-treated control in terms of disease incidence. In all field tests, biological seed treatments did not improve plant stands compared to the non-treated control. Biochemical seed treatments Prudent 44® with Nutrol® (active ingredient; phosphite) and Ultim®, along with chemical seed treatments, had acceptable efficacy and improved stand establishment compared to the non-treated control across field locations. Based on efficacy results from laboratory and field trials, the copper seed treatment has potential for both conventional and organic hemp production.

1. Introduction

There is a renewed interest in the commercial production of hemp (Cannabis sativa L.) in the United States (US) following the passage of the 2018 US Farm Bill that removed the crop from Schedule I of the Controlled Substances Act [1,2]. C. sativa L. is most often associated with its production of psychoactive terpenophenolic cannabinoids, specifically, Δ-9-tetrahydrocannabiol (THC) [3,4]. However, industrial hemp with <0.3% THC is grown for fiber, grain, and hempseed oil or for use as a nutraceutical primarily for cannabidiol (CBD) production [2,3,5]. Hemp grown for grain and fiber is normally direct-seeded in the field, whereas cannabinoid hemp is often grown in a greenhouse or transplanted to the field [6]. Several recent publications reported numerous pest and disease problems associated with the production of hemp [7,8,9]. Damping-off, along with powdery mildew, Botrytis grey mold, and multiple leaf spot diseases, were all cited as impediments to commercial hemp production [9,10,11,12,13]. In addition, seedlings started in the greenhouse often have poor root development that leads to increased susceptibility to pathogens and biotic stresses when transplanted into the field.

Damping-off is specifically identified as a major problem in both field and greenhouse production in the US and Canada [8,14,15,16,17]. The primary pathogens responsible for damping-off in several studies were identified as Pythium sp., Fusarium sp., and Rhizoctonia [8,14,16,17]. The US restrictions placed on hemp in the 1930s limited research and no pesticides were developed for disease control. Seed treatments are urgently needed for efficient early season pest management, including the control of damping-off caused by soil associated pathogens. Currently, pelleting, film coating, and encrusting are coating technologies used in the seed industry as delivery systems for plant protectants [18]. However, the hard, waxy surface of hemp seeds necessitates film coating formulations for uniform seed treatment application. Organically approved treatments would be ideal so that they could be used in both conventional and organic production systems. Significant advances were made in recent decades in the application of biopesticides as seed treatments that have resulted in increased efficacy and more consistent disease control [19].

Biopesticides comprise two main categories, namely microbial-based products that are either composed of microorganisms and the second category, which are biochemicals. Biochemical products include minerals, plant and microbial extracts, enzymes, and organic acids [20]. Several studies showed that biological seed treatments (BCA) that use Trichoderma and Bacillus species alone or in combination suppressed disease development and improved plant growth [21,22,23]. Corn (Zea mays) seed coated with Trichoderma atroviride had greater emergence and efficacy against two Fusarium pathogens in greenhouse and field studies, and Trichoderma applications also enhanced plant defense and germination when applied to cucumbers (Cucumis sativus L.) [24,25]. Zaim et al. [26] demonstrated that a combination of B. subtilis and T. harzianum applied as seed treatments on chickpea suppressed disease development caused by F. oxysporum f. sp. ciceris by 93% and enhanced plant growth. A combination of B. subtilis and T. asperellum applied as seed treatments on tomato were effective in controlling Pythium aphanidermatum [23]. Biological control of damping-off with a commercial formulation of Clonostachys rosea applied as a combination of seed treatment and soil drench was as effective as mefenoxam in reducing disease in seedlings of American ginseng (Panax quinquefolius) [27]. However, a commercial formulation of Trichoderma harzianum was ineffective in this same study.

Biochemical seed treatments may be derived from minerals and elements, including copper and phosphorus. Phosphites are widely studied in agriculture, and phosphites as an alternative for the management of plant disease were reviewed in [28,29]. Phosphites, also known as phosphonates, are derived from phosphorus acid (H3PO3) and are commonly combined with potassium, sodium, calcium, or ammonia. Phosphites exhibit systemic movement in the plant and move in both the xylem and phloem. Phosphites have demonstrated efficacy for a broad range of plant pathogens (oomycetes, fungi, bacteria, and nematodes) in studies conducted on specific crops and applied with different application technologies. Inorganic copper compounds were used for over a century as seed treatments for the control of plant pathogens, and this was reviewed by Leukel (1936) [30]. The early copper seed treatments were composed of copper sulfate, copper carbonate, or copper hydroxide and formulated as dusts. Because inorganic copper treatments could cause seed injury (phytotoxicity), they were largely replaced with synthetic fungicides [31]. The chemical synthetic seed treatment fungicides mefenoxam and fludioxonil are labeled on a wide range of crops [32,33]. Mefenoxam is effective against Pythium, while fludioxonil controls soil-borne fungi, including Fusarium and Rhizoctonia. The efficacy of these chemical seed treatments has not been reported on hemp.

Currently, there are neither registered organic controls nor chemical pesticides approved for use on hemp in the US. The purpose of this research was to evaluate a number of biological, biochemical, and chemical seed treatments for the management of damping-off caused by several pathogens (Pythium, Fusarium, and Rhizoctonia) to enhance stand establishment.

2. Materials and Methods

2.1. Seed, Seed Treatments, and Laboratory Seed Treatment Testing

Seed of a single hemp seed lot (cv’Anka’, a monoecious dual purpose-fiber and grain variety) was acquired from UniSeeds, Cobden, ON, Canada. The seed lot was first sized by seed width to remove small seeds (<7.5/64 inch, or <3 mm). Seeds were treated at Cornell AgriTech, Geneva, NY, USA, using a laboratory-scale rotary pan coater, R-6 (Universal Coating Systems, Independence, OR, USA). Seed treatments and active ingredients are listed in Table 1. The 20CU_2697LQ from ABM (now Agrauxine Corp.), Van Wert, OH, USA, contained T. atroviride at a concentration of 2.6 × 109 colony forming units (cfu)/mL. AmplitudeTM, B. amyloliquefaciens strain F727, containing 1.0 × 109 cfu/mL, was provided by Marrone Bio Innovations, Davis, CA, USA. Bio Seed contained five biologicals at 1.0 × 108 cfu for each species and was provided by Ag Biotech, Lakeville, NY, USA. Phyter from Endo Plant Health, Oakville, ON, Canada, consisted of C. rosea at 1.0 × 109 cfu/mL. Varnimo contained 1.0 × 109 B. amyloliquefaciens cfu/g, and KaPre Embrella, Prudent 44® and Nutrol® were provided by LidoChem Inc, Hazlet, NJ, USA. Ultim®, a copper hydroxide formulation, was obtained from Germains, Gilroy, CA, USA. All chemical fungicides were acquired from Syngenta, Greensboro, NC, USA. EnVigor, an organic-based, multi-functional seed coating polymer from Agrauxine, was used as the seed treatment binder for all treatments except for the Ultim® seed treatment.

Table 1.

Seed treatments were applied to the Anka hemp seed lot with a laboratory-scale rotary pan coater.

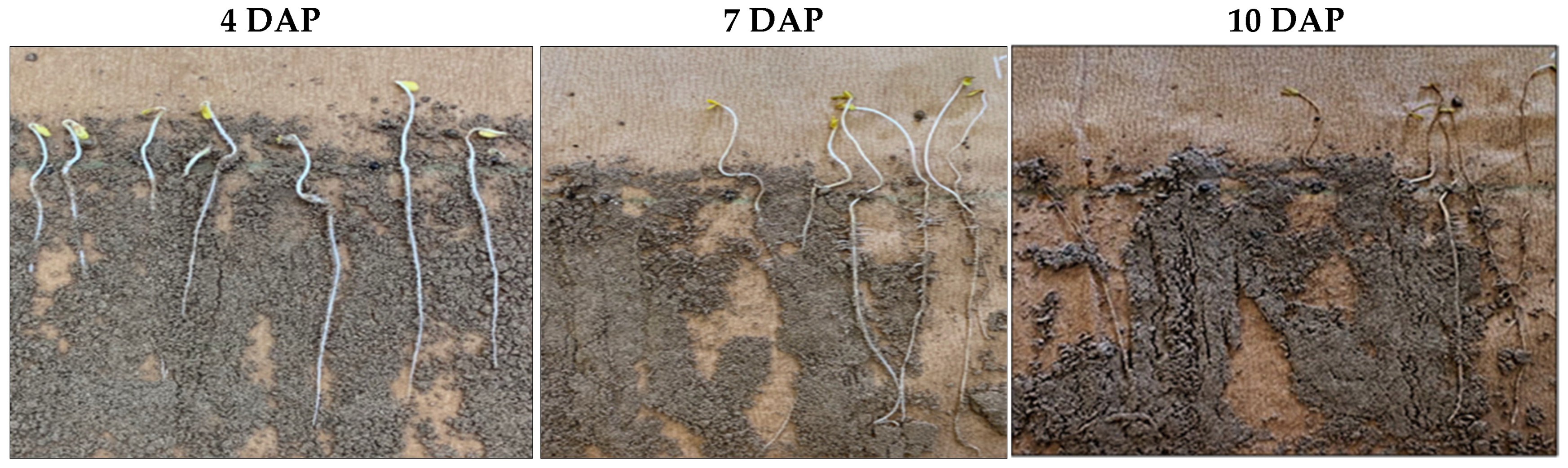

A preliminary roll-towel soil bioassay was conducted to test the germination and efficacy of the seed treatments. Field soil (Arkport fine sandy loam) was obtained from an East Ithaca, NY, field location and contained the damping-off pathogen P. aphanidermatum (Figure 1). The soil media used for the bioassay was composed of (by weight) 10% of the field soil thoroughly mixed with 90% sand. Twenty-five seeds were placed linearly, 6 cm from the edge of the moistened towels. A straight-edge shield was placed 4 cm from the edge of the towel, allowing the seeds to be covered with 2 cm of soil, simulating in-furrow planting depth. Using 100 g of the prepared soil media and a #10 sieve, the soil was evenly shaken over the seeds and towel surface, then covered with a third towel and folded. Four replicates were prepared using a roll-towel protocol [34], and germination results were scored on days 4 and 7 with a final count on day 10 (DAP) (Figure 1).

Figure 1.

Soil bioassay naturally infested with Pythium aphanidermatum. Ratings were recorded 4, 7 and 10 days after planting (DAP).

Germination test criteria were adopted from the Association of Official Seed Analysts (AOSA) manual [34], and germination was counted as a positive score when the seedling radical was at least 2mm in length. For final counts, seedlings were only considered viable when they met AOSA standards of healthy roots, hypocotyl, epicotyl, the presence of at least ½ of cotyledon tissue, and no disease presence. Seedlings were scored as normal, abnormal, or dead. Seeds were germinated in a Percival germinator (Percival Scientific, Inc., model I36LL, Perry, IA, USA) set at 15/25 °C, night 10 h, day 14 h, with light provided during the day period. The alternating 15/25 °C was selected based on the average diurnal soil temperatures on June 1st in Geneva, NY, USA [35]. In addition, a rolled towel germination test was conducted without soil to assess seed treatment phytotoxicity. Seedlings were scored as normal, abnormal, or dead after 7 days, and the germination test was also conducted in the same Percival germinator at 15/25 °C, night 14 h, day 10 h, with light provided during the day period.

2.2. Field Trials

Trial locations, planting dates, and the dates of final seedling counts were recorded, and soil types are shown in Table 2 and Table 3. All planting sites were tilled prior to planting. In NY, 100 seeds were sown per plot with four replications for both trials with a push planter. The first trial in NY was planted on 12 June. The soil was an Arkport fine sandy loam. The second trial in NY (Hudson/Collamer silt loam soil) was sown on 26 June. North Dakota trials were planted on 20 June and 29 July into fine and firm seedbeds with a Bearden/Perella silty clay loam soil. The field was conventionally prepared for a small-seeded crop. Seeding in ND was performed using a 6-row (spaced at 30 cm), 3-point mounted planter with double disk openers with twin-vee packer wheels. The center four-planter rows were sown with 100 seeds placed at a 20 mm depth with a row length of 3.05 m. The first site in VA (Dothan/Norfolk sandy loam soil), planted at the Southern Piedmont Agricultural Research and Extension Center, was established with a forage seeder on 10 April. Four replications were planted on each experimental plot, each plot containing two 6.1 m-long rows containing 100 seeds per row. The second trial was also seeded with four replications of 100 seeds in VA (Duffield/Ernst complex fine loam soil) and was planted with a walk-behind cone seeder adapted for two rows. The second site was seeded on 4 October following several spring plantings that failed due to flooding. The plots were tilled, and the soil was allowed to settle for a week before planting.

Table 2.

Trial locations, planting and final stand count dates, and soil types at each location.

Table 3.

Trial GPS locations, and addresses.

Stand counts were recorded starting at day 7 and continued every 5–7 days for 3–4 weeks at each location. Stand counts were based on the above ground emergence of the cotyledons and used to estimate the percentage emergence for each measurement event. In addition, plants were evaluated for disease incidence via visual inspection for signs and symptoms of pathogen development. After final counts, samples were destructively harvested at some locations and examined for root rot. Samples with signs of disease were evaluated for pathogens at each location.

2.3. Field Pathogen Diagnosis

Diseased seedlings from field trials in Ithaca, NY, were collected while conducting stand counts and taken to the Bergstrom laboratory located at Cornell University for identification. Samples were surface sterilized for 1 min each in 70% ethanol, 90% hypochlorite, and sterile distilled water. Tissue was then plated on potato dextrose agar (PDA) with the addition of streptomycin and neomycin and an oomycete selective agar (combination of pea and rye B agar) [36]. Plates were incubated at room temperature with a light cycle of 12 h of UV-light and 12 h of darkness for 3–5 days until colonies could be isolated. Once isolated into a pure culture, samples were identified morphologically and via sequencing of the ITS rDNA region. Genomic DNA was extracted using a DNeasy Plant Mini Kit (Qiagen), followed by PCR amplification of the ITS rDNA region using the universal ITS primers ITS1 and ITS4 and the PCR method of White et al., 1990 [37]. The PCR fragments were purified using a Monarch PCR and DNA clean-up kit (New England Biolabs), and Sanger sequenced using Big Dye Terminator Cycle Sequencing and Clean-up Kits (Applied Biosystems, Inc., Waltham, MA, USA), followed by analysis on an ABI 3730XL DNA analyzer. The resulting sequence data were further processed using GeneStudio Sequence Analysis Software (GeneStudio, Inc., Suwanee, GA, USA), followed by sequence best match identification using NCBI BLAST [38].

Seedlings from North Dakota trials were carefully washed to remove soil that was attached to the roots. Entire plants were examined with a dissecting microscope (80× magnification) to observe general symptoms such as lack of roots, injuries, and discolored tissue. When a pathogen was suspected, tissues (roots and stems were cut lengthwise, leaves were cut into small pieces) were placed on temporary wet mounts and viewed on a compound microscope (400× magnification). Slides were examined for the presence of fungal structures (hyphae, spores) and bacterial streaming. Suspect arthropod-pest afflicted tissues were examined by an entomological diagnostician to confirm the cause. No disease was observed in trials located in Virginia.

2.4. Statistical Analysis

All seedling data from the trials were evaluated for normality, homoscedasticity, and goodness of fit, along with the generation of histograms of the distribution of residuals and normal probability plots, using JMP Pro Version 15 SAS Institute Inc., Cary, NC, USA, 1989–2021. All data (including a soil bioassay; Table 4) were subjected to arcsine square root transformation and evaluated for normality, homoscedasticity, and goodness of fit using the same procedures described above. Non-transformed percent emerged seedlings data had normal distributions in all trials across locations, and transformation did not improve normality or tests of goodness of fit. Therefore, non-transformed raw data were used to determine statistical differences in the percentage of emerged seedlings. Analysis of variance was assessed, and a comparison of means was conducted with Tukey’s procedure using JMP Pro 15 at a significance level of α = 0.05.

Table 4.

Percent germination test results (Normal seedlings, Abnormal seedlings and Dead) and Soil Bioassay results for percent viable seedlings (4 Day, 7 Day, 10 Day).

3. Results

3.1. Seed, Seed Treatments, and Laboratory Seed Treatment Testing

Normal, abnormal, and dead seedlings were counted in roll towel germination tests. No differences in any germination parameters were observed for biological, biochemical, and chemical seed treatments (#9–12, Table 1, Table 4 and Table 5) when compared to the non-treated control (Table 4). Results from the soil bioassay showed that only Ultim, an organic copper treatment and chemical seed treatments (Apron XL + Maxim 4FS and in combination with Mertect 340 F [rates presented in Table 1, Table 4 and Table 5]) reduced damping-off compared to the non-treated control and other treatments after 7 and 10 days. Varnimo and Prudent + Nutrol showed some efficacy after 7 days; however, after 10 days, they were not significantly better than the non-treated control.

Table 5.

Final stand counts (% emerged seedlings/plants) in two trials of hemp seed treatments across three locations in 2020.

3.2. Field Trials

Conditions were dry with above average air temperatures for the first trial in NY planted on 12 June. The second trial in NY (Hudson/Collamer silt loam soil) was sown on 26 June and was again planted under dry conditions, followed by a hot and dry period. Soil temperatures were greater than 16 and 21 °C for the North Dakota trials for the two seeding dates, respectively, and rainfall 7 days post-planting was 9.6 mm and 0.0 mm for seeding dates 20 June and 29 July, respectively. Although rainfall was minimal 7 days post-planting, soil water status was adequate for seed germination for both seeding dates due to rainfall occurring 7 days before planting.

Weather conditions were cool and damp at planting for the first site in VA, followed by >5 cm of rain 24–30 h after planting. For the second trial in VA (Duffield/Ernst complex fine loam soil), soil conditions were favorable, but seeding depth was inconsistent, and there was little rainfall after planting.

Overall, the % of final emerged seedling counts measured for the two trials established at different locations and planting dates (Table 3, Table 4 and Table 5) ranged from 9–58%. The highest percentage of final emerged seedling counts were observed in ND and the lowest in VA (Table 5). Trials in all three states had consistent seedling counts for both planting dates. New York trials ranged from 28–46% and 21–41% in the first and second planting dates, while ND ranged from 30–58% and 26–41%, respectively. Virginia with the lowest stand counts ranged from 10–21% in the first trial and 9–25% in the second planting.

In five of the six seed treatment trials, most chemical seed treatments (#9–12, Table 1 and Table 5) generally had higher stand counts than the biological seed treatments (#2–6, Table 1 and Table 5). No differences were observed among seed treatments in the second trial conducted in VA. Apron XL/Maxim 4FS applied at the 1X and 2X rates, and the biopesticides phosphite and Ultim seed treatments had greater stand counts than the non-treated controls at E. Ithaca (Table 5). At the second location in NY, only Apron XL + Maxim 4FS 2X rate had better stands than the non-treated control (Table 5). The Ultim seed treatment (#7, Table 5) was consistent across all locations and in most trials performed as well as the chemical seed treatments (#9–12, Table 5).

3.3. Pathogen Diagnosis

Pathogens and/or diseased plants were observed and diagnosed in trials located in NY and ND; however, no samples were collected from either VA trial. For trials in NY, species of the damping-off pathogens Pythium, Fusarium, and Rhizoctonia were detected in plants sampled at East Ithaca (Table 6 and Figure 2). Due to dry conditions, no observations of diseased roots and/or seedlings were obtained in the second NY trial. Rhizoctonia was positively identified to species from samples treated with Amplitude in the first trial in ND and also from the control, Apron XL Max ½X rate, and Apron Max XL 2X rates in the second trial. Ulocladium and Fusarium were found in the Bio Seed treatment and Apron Max XL ½X rate plots in trial 1 in ND (Table 7).

Table 6.

Sample and positive identification of pathogens present on hemp seedlings in Ithaca, NY.

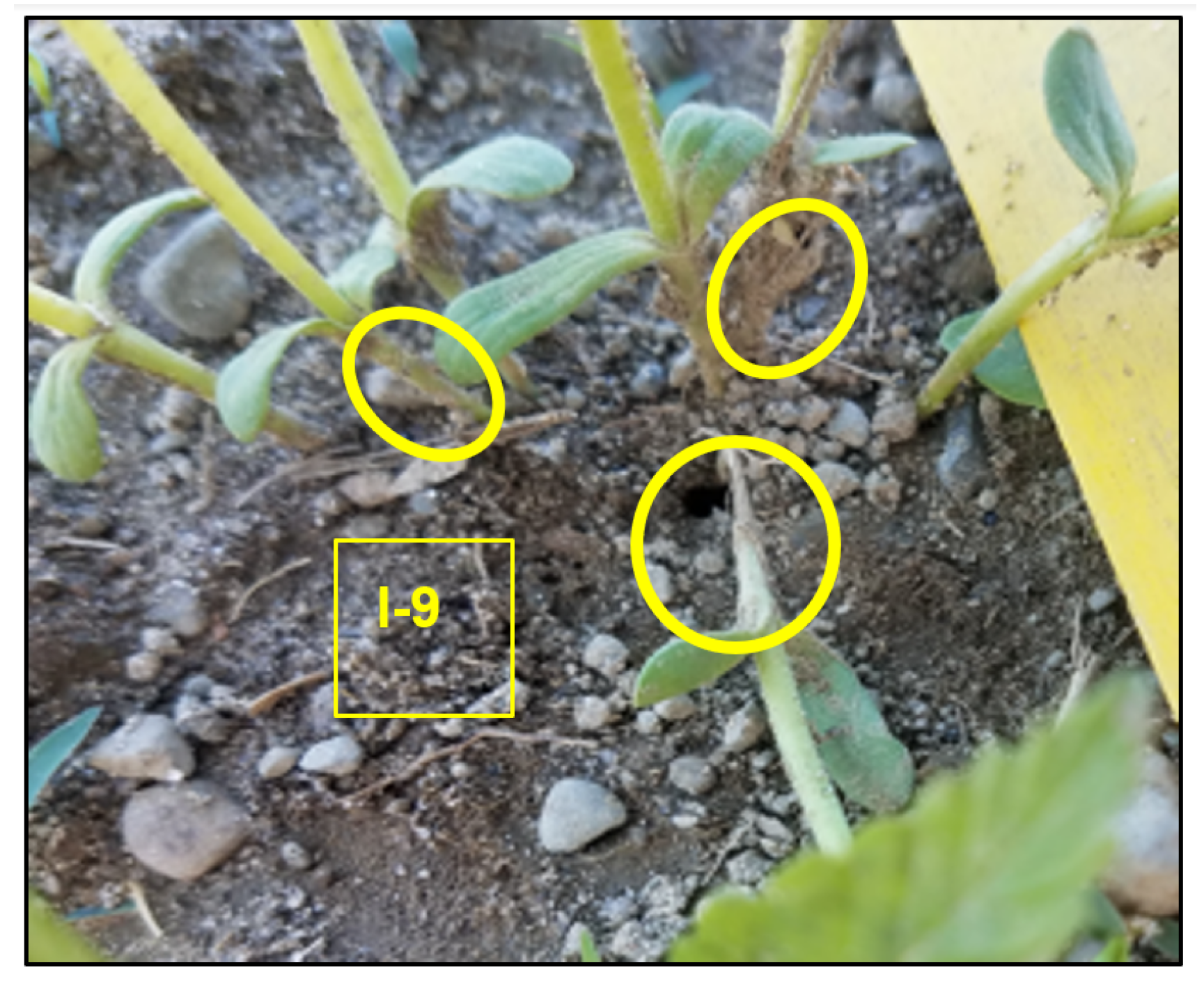

Figure 2.

Pathogens were observed on seedlings from treatments 1, 3, 4 and 5 and 9 (Table 1 and Table 6). Damping-off pathogens were identified as P. aphanidermatum, F. equiseti, F. solani, F. oxysporum, R. solani, Mucor, and Trichoderma species (Table 6) and the presence of bacterial species was also identified on hemp seedlings from trial 1 in NY. Pathogen tests were conducted in the Bergstrom lab, Cornell University.

Table 7.

Sample and positive identification of pathogens present on hemp seedlings in Prosper, ND.

4. Discussion

High quality seed is the foundation for optimal stand establishment and the successful production of any crop. Moreover, seed quality is especially important for hemp as a new commercial crop with seed produced by a developing hemp seed industry. Currently, the seed of most fiber and grain varieties are imported into the US, and seed lots may be of low quality. Research at Cornell AgriTech’s Seed Science and Technology program tested germination of 23 commercial hemp seed lots, and germination ranged from 29 to 94% in 2018 [39]. The minimum AOSCA standard for hemp is 80% germination [40], and only 13 of 23 lots tested in 2018 had greater than 80% germination. The germination of a hemp seed lot can be improved by post-harvest seed conditioning [41]. Small-sized seeds of three hemp varieties had a lower percentage of germination and produced seedlings with lower dry weight than larger sized seeds [42]. Thus, removing the small-sized seeds effectively upgraded seed lot quality. In this study, a commercial seed lot of ‘Anka’ was used, and approximately 10% of the seed lot was removed, resulting in the non-treated control with 89% germination (Table 1).

There are several important factors and conditions needed for the efficacy of biological control agents (BCA), starting with proper formulation and seed coating application technology [43,44]. The BCA used in this investigation were from commercial sources, so our assumption was that all the BCA were properly formulated. Envigor, a commercial seed treatment binder, was tested in preliminary experiments and the CFU (colony forming units) recovered from hemp seeds treated with a commercial mixture of Trichoderma spp. or Bacillus amyloliquefaciens remained high. Therefore, the lack of efficacy was not attributed to BCA formulation or seed coating technology. The environment in the soil bioassay created severe disease pressure resulting in <10% seedling survival after 10 days (Table 4). There are several mechanisms responsible for disease management in BCA, including mycoparasitism [45]. The biocontrol organism may need to achieve a critical population and produce its antifungal metabolites on roots in advance of pathogen growth in order to provide protection to the plant or enhance plant defense. In addition, hemp seedlings may be extremely susceptible to soil-borne pathogens, rendering these agents difficult to control. Further investigation is warranted to explore BCA efficacy and mechanisms in relation to damping-off on hemp seedlings.

Arguably, biochemical seed treatments have greater utility and flexibility than BCA seed treatments as they do not contain living organisms that must remain viable during the seed treatment process and post-treatment storage. Therefore, biochemical seed treatment preparation, application, and storage are less complicated than BCA and thus more similar to the application of chemical seed treatments [18]. A phosphite seed treatment, Prudent 44 in combination with Nutrol, was included in this study (Table 1). Prudent 44 contains 57% by wt. urea phosphite and 15% by wt. ammonium phosphite [46]. Nutrol is monopotassium phosphate and is registered with the US EPA (Environmental Protection Agency), and Nutrol, when combined with Prudent, has expanded efficacy [47]. Since phosphites do not exist in nature, formulations containing phosphites are not approved for organic labelling. Prudent 44 with Nutrol provided some level of protection in the soil bioassay (Table 4) and two (Table 5-Trial 1 of New York and Virginia) of the six field tests. A commercial phosphite formulation (AG3) was applied as a seed soak, controlled damping-off caused by Pythium spp. in Cucumis sativus [48]. Phosphite applied as a seed treatment to corn reduced the mycelial growth of two Fusarium species [49].

Collectively, phosphites demonstrated potential as a hemp seed treatment, although efficacy was generally less than copper or the chemical fungicide seed treatments. Ultim treatment was performed as well as the chemical treatments at all locations and was the only treatment that was not significantly different from the chemical treatments in the soil bioassay (Table 4 and Table 5). Soil type and planting conditions significantly influenced hemp stand establishment and growth; however, chemical seed treatments and Ultim were able to improve overall stand establishment at most locations. Currently, the registrant for the chemical seed treatments was not supportive of registering their materials for commercial use on hemp. The active component in Ultim is copper hydroxide, a patented formulation that is approved for organic use [50]. Collectively, the organic copper seed treatment has potential for both conventional and organic hemp production. Moreover, results from this study provide the foundation for seed treatment research on Cannabis sativa grown for other uses. For example, Ultim, the organic copper treatment evaluated in this study, and other organic copper seed treatments were found to be effective in controlling damping-off in the soil bioassay on a CBD (cannabidiol) variety of hemp [51].

Author Contributions

The first author H.M. contributed to the experimental design, data collection and analysis, writing of the original draft, and revisions of the manuscript. The second author, M.A., assisted with planting field trials, data analysis, and preparation of the manuscript. The third author, M.L., conducted laboratory bioassays and assisted with planting and data collection in the field. The fourth, B.J., fifth, J.F., and sixth, C.J., authors were involved in the establishment and collection of data for field trials conducted in ND and VA. The seventh, K.M., eighth, J.S., and ninth, G.C.B., authors were responsible for plant pathogen identification for trials in NY. The last author, A.T., served as the principal investigator and was involved with all aspects of experiments, including experimental design and with the preparation and revisions of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the IR4 and NYS EDS 90512. This material is based upon work that is supported by the United States Hatch Funds under Multi-state Project W-4168 under accession number 1007938.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors thank company registrants for contributing their seed treatment formulations and expertise in conducting this research: Agrauxine, Ag Biotech, Endo Plant Health, Germains, LidoChem, Marrone Bio Innovations, and Syngenta. We also thank Incotec (Salinas, CA) for seed treatment binders and film coating technology.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mead, A. Legal and regulatory issues governing cannabis and Cannabis-derived products in the United States. Front. Plant Sci. 2019, 10, 697. [Google Scholar] [CrossRef] [PubMed]

- Cherney, J.H.; Small, E. Industrial hemp in North America: Production, politics and potential. Agronomy 2016, 6, 58. [Google Scholar] [CrossRef] [Green Version]

- VanDolah, H.J.; Bauer, B.A.; Mauck, K.F. Clinicians’ guide to cannabidiol and hemp oils. Mayo Clin. Proc. 2019, 94, 1840–1851. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Piluzza, G.; Delogu, G.; Cabras, A.; Marceddu, S.; Bullitta, S. Differentiation between fiber and drug types of hemp (Cannabis sativa L.) from a collection of wild and domesticated accessions. Genet. Resour. Crop Evol. 2013, 60, 2331–2342. [Google Scholar] [CrossRef]

- Iseger, T.A.; Bossong, M.G. A systematic review of the antipsychotic properties of cannabidiol in humans. Schizophr. Res. 2015, 162, 153–161. [Google Scholar] [CrossRef] [PubMed]

- Adesina, I.; Bhowmik, A.; Sharma, H.; Shahbazi, A. A review on the current state of knowledge of growing conditions, agronomic soil health practices and utilities of hemp in the United States. Agriculture 2020, 10, 129. [Google Scholar] [CrossRef] [Green Version]

- Thiessen, L.D.; Schappe, T.; Cochran, S.; Hicks, K.; Post, A.R. Surveying for potential diseases and abiotic disorders of industrial hemp (Cannabis sativa) production. Plant Health Prog. 2020, 21, 321–332. [Google Scholar] [CrossRef]

- Punja, Z.K. Emerging diseases of Cannabis sativa and sustainable management. Pest Manag. Sci. 2021, 77, 3857–3870. [Google Scholar] [CrossRef]

- Bakro, F.; Wielgusz, K.; Bunalski, M.; Jedryczka, M. An overview of pathogen and insect threats to fiber and oilseed hemp (Cannabis sativa L.) and methods for their biocontrol. Integr. Control Oilseed Crops IOBC-WPRS Bull. 2018, 136, 9–20. [Google Scholar]

- McPartland, J.M. A review of Cannabis diseases. J. Int. Hemp Assoc. 1996, 3, 19–23. [Google Scholar]

- Marin, M.V.; Coburn, J.; Desaeger, J.; Peres, N.A. First Report of Cercospora Leaf Spot Caused by Cercospora cf. flagellaris on 2 Industrial Hemp in Florida. Plant Dis. 2020, 104, 1536. [Google Scholar] [CrossRef]

- Tang, L.; Song, X.; Zhang, L.; Wang, J.; Zhang, S. First Report of Leaf Spot on Industrial Hemp (Cannabis sativa L.) Caused by Alternaria alternata in China. Plant Dis. 2021, 105, 3294. [Google Scholar] [CrossRef] [PubMed]

- Szarka, D.; Bernadette, A.; Julie, B.; Dixon, E.; Schardl, C.L.; Gauthier, N. First report of hemp leaf spot caused by a Bipolaris species on hemp (Cannabis sativa) in Kentucky. Plant Health Prog. 2020, 21, 82–84. [Google Scholar] [CrossRef]

- Beckerman, J.; Nisonson, H.; Albright, N.; Creswell, T. First report of Pythium aphanidermatum crown and root rot of industrial hemp in the United States. Plant Dis. 2017, 101, 1038. [Google Scholar] [CrossRef]

- Beckerman, J.; Stone, J.; Ruhl, G.; Creswell, T. First report of Pythium ultimum crown and root rot of industrial hemp in the United States. Plant Dis. 2018, 102, 2045. [Google Scholar] [CrossRef]

- Hu, J.; Masson, R. First report of crown and root rot caused by Pythium aphanidermatum on industrial hemp (Cannabis sativa) in Arizona. Plant Dis. 2021, 105, 2736. [Google Scholar] [CrossRef]

- McGehee, C.S.; Apicella, P.; Raudales, R.; Berkowitz, G.; Ma, Y.; Durocher, S.; Lubell, J. First report of root rot and wilt caused by Pythium myriotylum on hemp (Cannabis sativa) in the United States. Plant Dis. 2019, 103, 3288. [Google Scholar] [CrossRef]

- Afzal, I.; Javed, T.; Amirkhani, M.; Taylor, A.G. Modern seed technology: Seed coating delivery systems for enhancing seed and crop performance. Agriculture 2020, 10, 526. [Google Scholar] [CrossRef]

- Harman, G. Biological Seed Treatments. Preprints 2021. [Google Scholar] [CrossRef]

- Samada, L.H.; Tambunan, U.S.F. Biopesticides as promising alternatives to chemical pesticides: A review of their current and future status. OnLine J. Biol. Sci. 2020, 20, 66–76. [Google Scholar] [CrossRef]

- Ramírez-Cariño, H.F.; Guadarrama-Mendoza, P.C.; Sánchez-López, V.; Cuervo-Parra, J.A.; Ramírez-Reyes, T.; Dunlap, C.A.; Valadez-Blanco, R. Biocontrol of Alternaria alternata and Fusarium oxysporum by Trichoderma asperelloides and Bacillus paralicheniformis in tomato plants. Antonie Van Leeuwenhoek 2020, 113, 1247–1261. [Google Scholar] [CrossRef] [PubMed]

- Pastrana, A.M.; Basallote-Ureba, M.J.; Aguado, A.; Akdi, K.; Capote, N. Biological control of strawberry soil-borne pathogens Macrophomina phaseolina and Fusarium solani, using Trichoderma asperellum and Bacillus spp. Phytopathol. Mediterr. 2016, 55, 109–120. [Google Scholar]

- Kipngeno, P.; Losenge, T.; Maina, N.; Kahangi, E.; Juma, P. Efficacy of Bacillus subtilis and Trichoderma asperellum against Pythium aphanidermatum in tomatoes. Biol. Control 2015, 90, 92–95. [Google Scholar] [CrossRef]

- Coninck, E.; Scauflaire, J.; Gollier, M.; Liénard, C.; Foucart, G.; Manssens, G.; Munaut, F.; Legrève, A. Trichoderma atroviride as a promising biocontrol agent in seed coating for reducing Fusarium damping-off on maize. J. Appl. Microbiol. 2020, 129, 637–651. [Google Scholar] [CrossRef]

- Szczech, M.; Nawrocka, J.; Felczyński, K.; Małolepsza, U.; Sobolewski, J.; Kowalska, B.; Maciorowski, R.; Jas, K.; Kancelista, A. Trichoderma atroviride TRS25 isolate reduces downy mildew and induces systemic defence responses in cucumber in field conditions. Sci. Hortic. 2017, 224, 17–26. [Google Scholar] [CrossRef]

- Zaim, S.; Bekkar, A.A.; Belabid, L. Efficacy of Bacillus subtilis and Trichoderma harzianum combination on chickpea Fusarium wilt caused by F. oxysporum f. sp. ciceris. Arch. Phytopathol. Plant Prot. 2018, 51, 217–226. [Google Scholar] [CrossRef]

- Rahman, M.; Zamir, K.; Punja, Z.K. Biological control of damping-off on American ginseng (Panaxquinquefolius) by Clonostachysrosea f. catenulata (Gliocladium catenulatum). Can. J. Plant Pathol. 2007, 29, 203–207. [Google Scholar] [CrossRef]

- Yáñez-Juárez, M.G.; López-Orona, C.A.; Felipe Ayala-Tafoya, F.; Leopoldo Partida-Ruvalcaba, L.; Velázquez-Alcaraz, T.J.; Medina-López, R. Phosphites as alternative for the management of phytopathological problems. Rev. Mex. Fitopatol. 2018, 36, 79–94. [Google Scholar]

- Havlin, J.L.; Schlegel, A.J. Review of Phosphite as a Plant Nutrient and Fungicide. Soil Syst. 2021, 5, 52. [Google Scholar] [CrossRef]

- Leukel, R.W. The Present Status of Seed Treatment, with Special Reference to Cereals. Bot. Rev. 1936, 2, 498–527. [Google Scholar] [CrossRef]

- Russell, P. A century of fungicide evolution. J. Agric. Sci. 2005, 143, 11–25. [Google Scholar] [CrossRef]

- Syngenta-US. Available online: https://www.syngenta-us.com/seed-treatment/apron-xl (accessed on 15 November 2021).

- Syngenta-US. Available online: https://www.syngenta-us.com/seed-treatment/maxim-4fs (accessed on 15 November 2021).

- AOSA. Rules for testing seeds. Principles and procedures. Assn. Off. Seed Anal. 2014, 1, 6–25. [Google Scholar]

- Taylor, A.G.; Amirkhani, M. Effects of Stress on Snap Bean Germination. New York State Vegetable Growers Association, Empire State Producers Expo 2022. Available online: https://nysvga.org/expo/proceedings/ (accessed on 20 April 2022).

- Smart, C.D.; Mayton, H.; Mizubuti, E.S.G.; Willmann, M.R.; Fry, W.E. Environmental and genetic factors influencing self-fertility in Phytophthora infestans. Phytopathology 2000, 90, 987–994. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- White, T.J.; Bruns, T.; Lee, S.; Taylor, J. Amplification and Direct Sequencing of Fungal Ribosomal RNA Genes for Phylogenetics. In PCR Protocols: A Guide to Methods and Applications; Innis, M.A., Gelfand, D.H., Sninsky, J.J., White, T.J., Eds.; Academic Press: San Diego, CA, USA, 1990; pp. 315–322. [Google Scholar]

- Altschul, S.F.; Gish, W.; Miller, W.; Myers, E.W.; Lipman, D.J. Basic local alignment search tool. J. Mol. Biol. 1990, 215, 403–410. [Google Scholar] [CrossRef]

- Taylor, A.G.; Loos, M.; Amirkhani, M. Hemp Seed Coating Technology, Certification Standards and Seed Quality. 2018. Available online: https://cpb-us-e1.wpmucdn.com/blogs.cornell.edu/dist/a/7491/files/2017/04/Taylor-Seed-Quality-Handout-Cornell-Hemp-Field-Day-2018_08_13-22pt7t0.pdf (accessed on 12 December 2021).

- Association of Official Seed Certifying Agencies. Hemp Seed Standards; AOSCA: Moline, IL, USA, 2020. [Google Scholar]

- Taylor, A.G.; Cornell University, Geneva, New York, NY, USA; Loos, M.; Cornell University, Geneva, New York, NY, USA. Personal communication, 2021.

- Mi, R.; Taylor, A.G.; Smart, L.B.; Mattson, N.S. Developing Production Guidelines for Baby Leaf Hemp (Cannabis sativa L.) as an Edible Salad Green: Cultivar, Sowing Density and Seed Size. Agriculture 2020, 10, 617. [Google Scholar] [CrossRef]

- Darby, H.; Bruce, J.; Gupta, A. Hemp Greenhouse Seed Treatment Evaluation. Northwest Crops & Soils Program. 2018; p. 323. Available online: https://scholarworks.uvm.edu/nwcsp/323 (accessed on 20 November 2021).

- Harman, G.; Khadka, R.; Doni, F.; Uphoff, N. Benefits to Plant Health and Productivity from Enhancing Plant Microbial Symbionts. Front. Plant Sci. 2021, 11, 610065. [Google Scholar] [CrossRef]

- Pimentel, M.F.; Arnao, E.; Warner, A.J.; Rocha, L.F.; Subedi, A.; Elsharif, N.; Chilvers, M.I.; Matthiesen, R.; Robertson, A.E.; Bradley, C.; et al. Reduction of Pythium Damping-off in Soybean by Biocontrol Seed Treatment. Plant Dis. 2022. [Google Scholar] [CrossRef] [PubMed]

- LidoChem Inc. Prudent 44-Newsom Seed. Available online: https://www.pnfertilizers.com/wp-content/uploads/2019/01/Prudent44CaseLabelGHS053015.pdf (accessed on 22 December 2021).

- LidoChem Inc. Nutrol. Available online: https://www.pnfertilizers.com/wp-content/uploads/2019/01/Nutrol-booklet-label-111615.pdf (accessed on 20 February 2022).

- Abbasi, P.A.; Lazarovits, G. Seed treatment with phosphonate (AG3) suppresses Pythium damping-off of cucumber seedlings. Plant Dis. 2006, 90, 459–464. [Google Scholar] [CrossRef] [Green Version]

- Borin, R.G.; Possenti, J.C.; dos Santos Rey, M.; Bernardi, C.; Mazaro, S.M. Phosphites associated to fungicides for diseases control and sanity in corn seeds. Braz. J. Appl. Technol. Agric. Sci. 2017, 10, 83–92. [Google Scholar]

- Germain Seed Technology, Inc. Anti-Fungal Seed Treatment Formulations, Treated Seeds, and Methods. U.S. Patent 10,233,134 B2, 19 March 2019.

- Taylor, A.G.; Cornell University, Geneva, New York, NY, USA; Loos, M.; Cornell University, Geneva, New York, NY, USA. Personal communication, 2022.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).