Optimization and Test of Structural Parameters of Flat Hob Chopper

Abstract

:1. Introduction

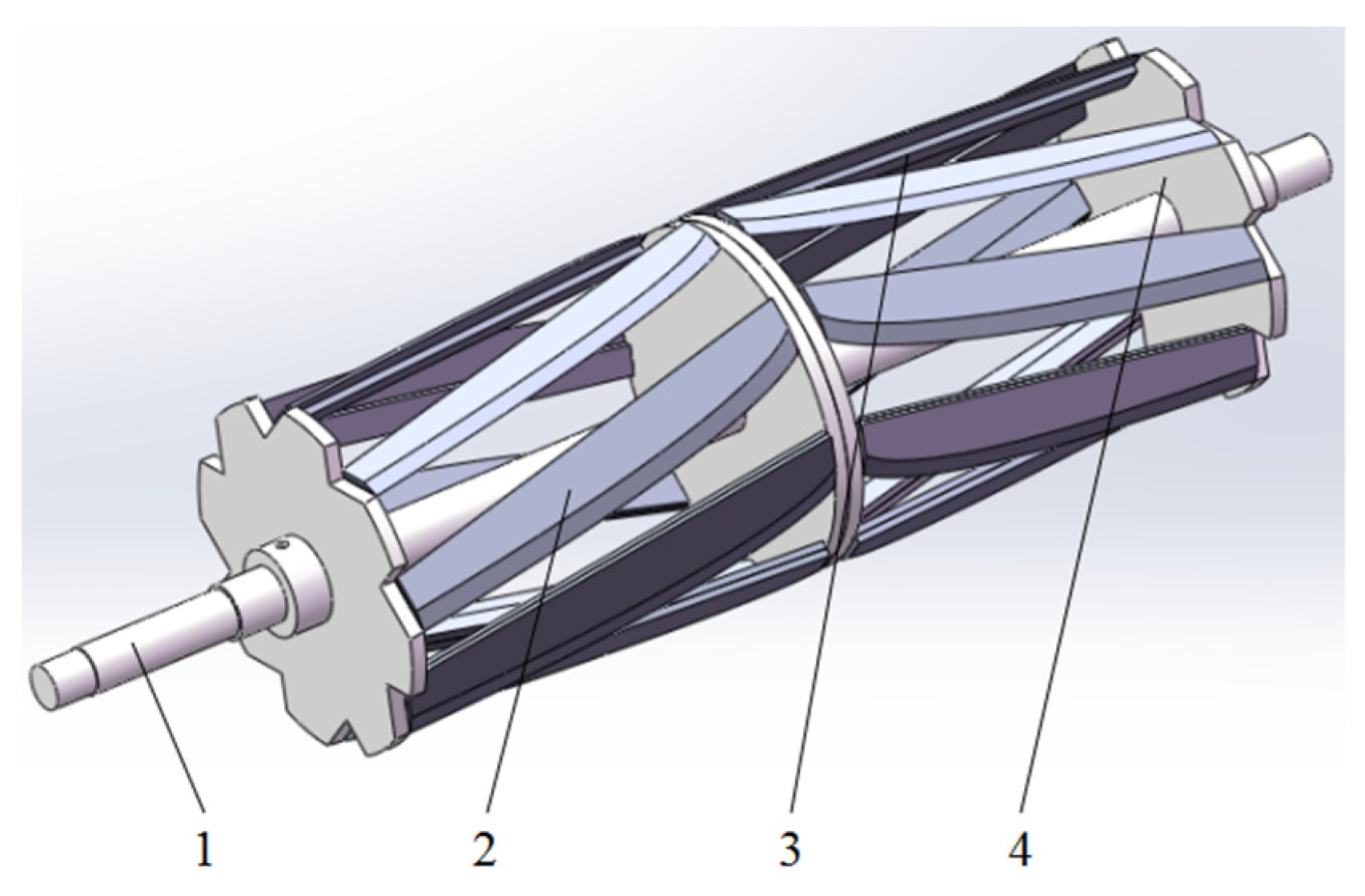

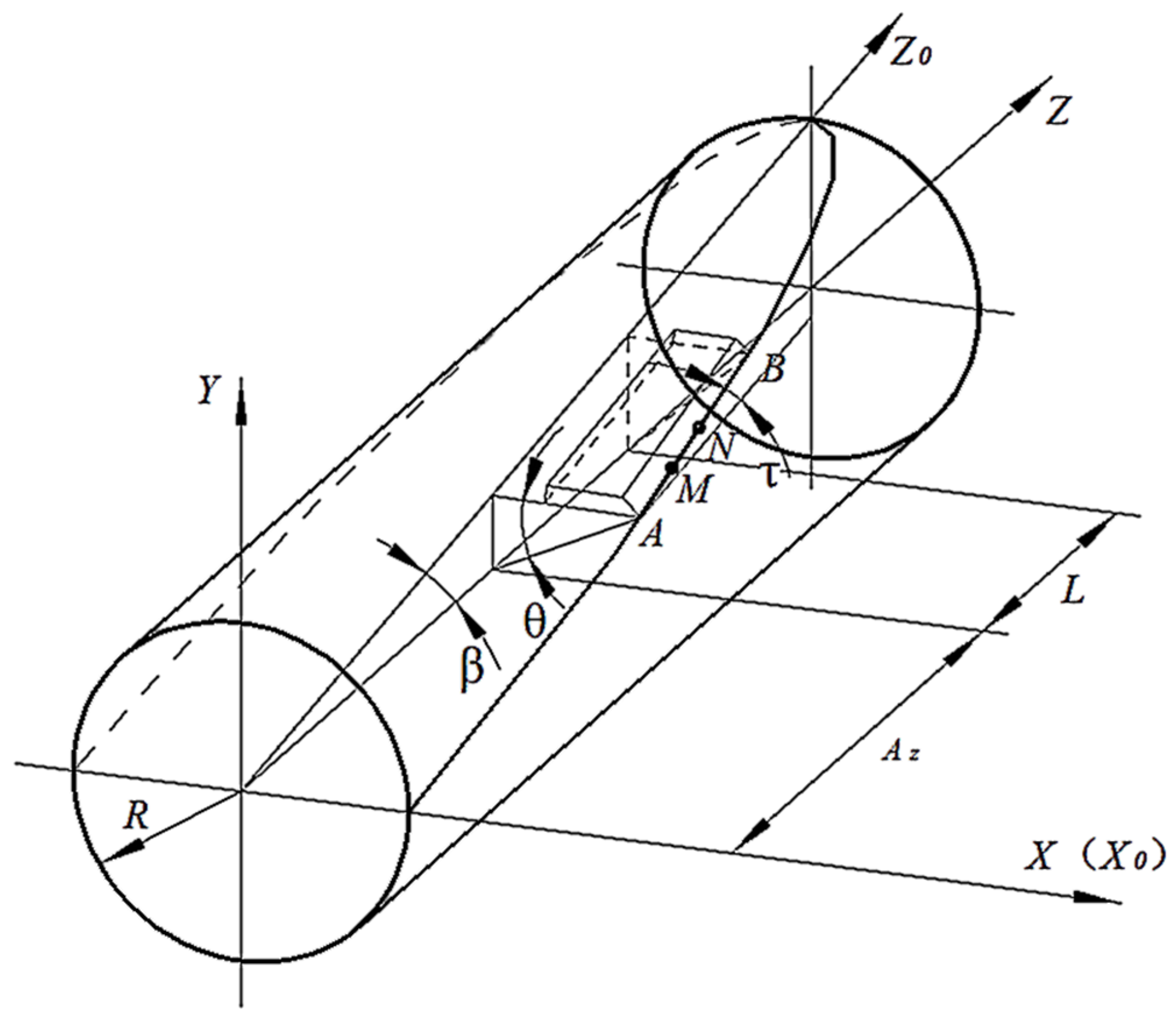

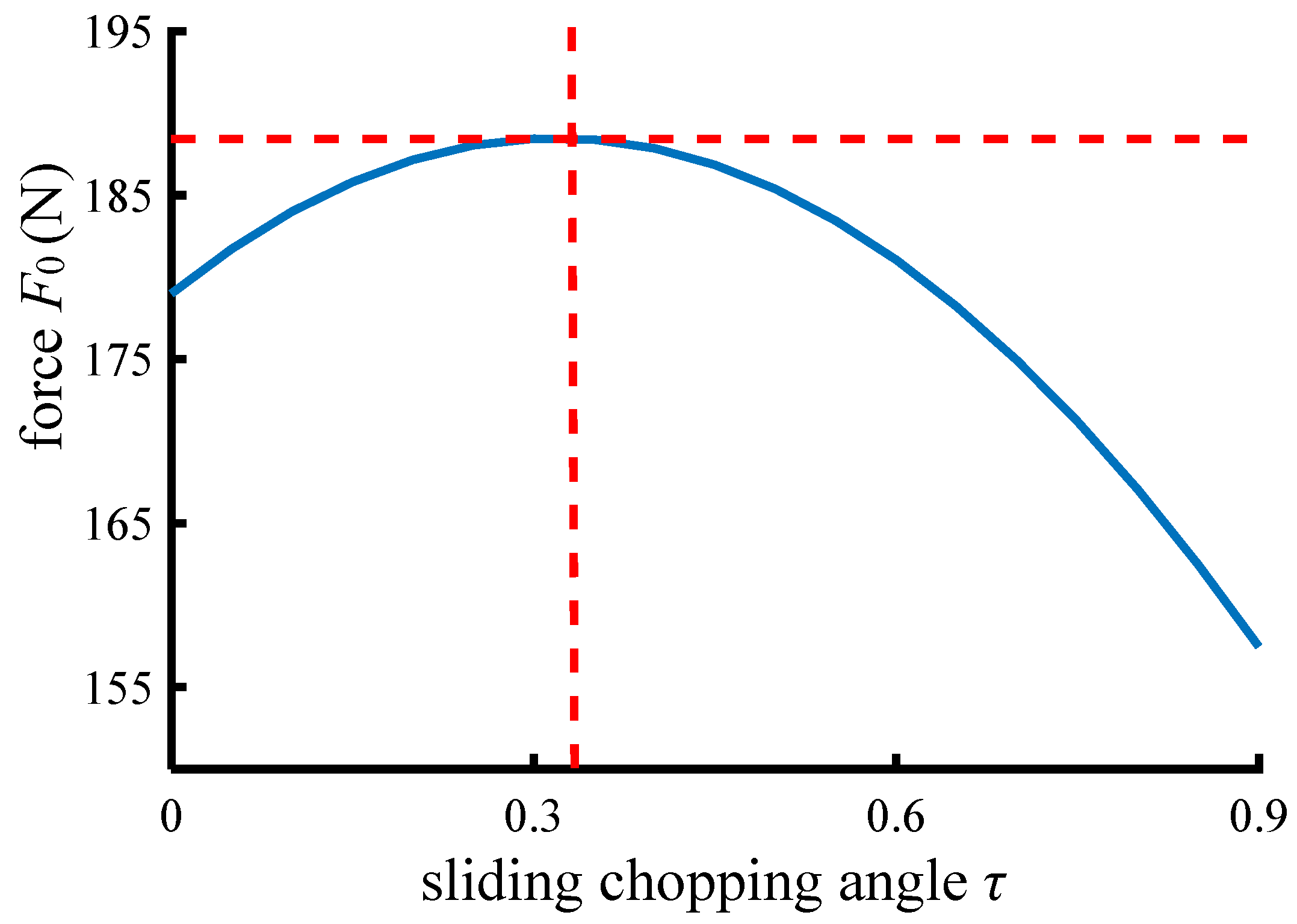

2. Establishment of Optimization Mathematical Model

2.1. Objective Function

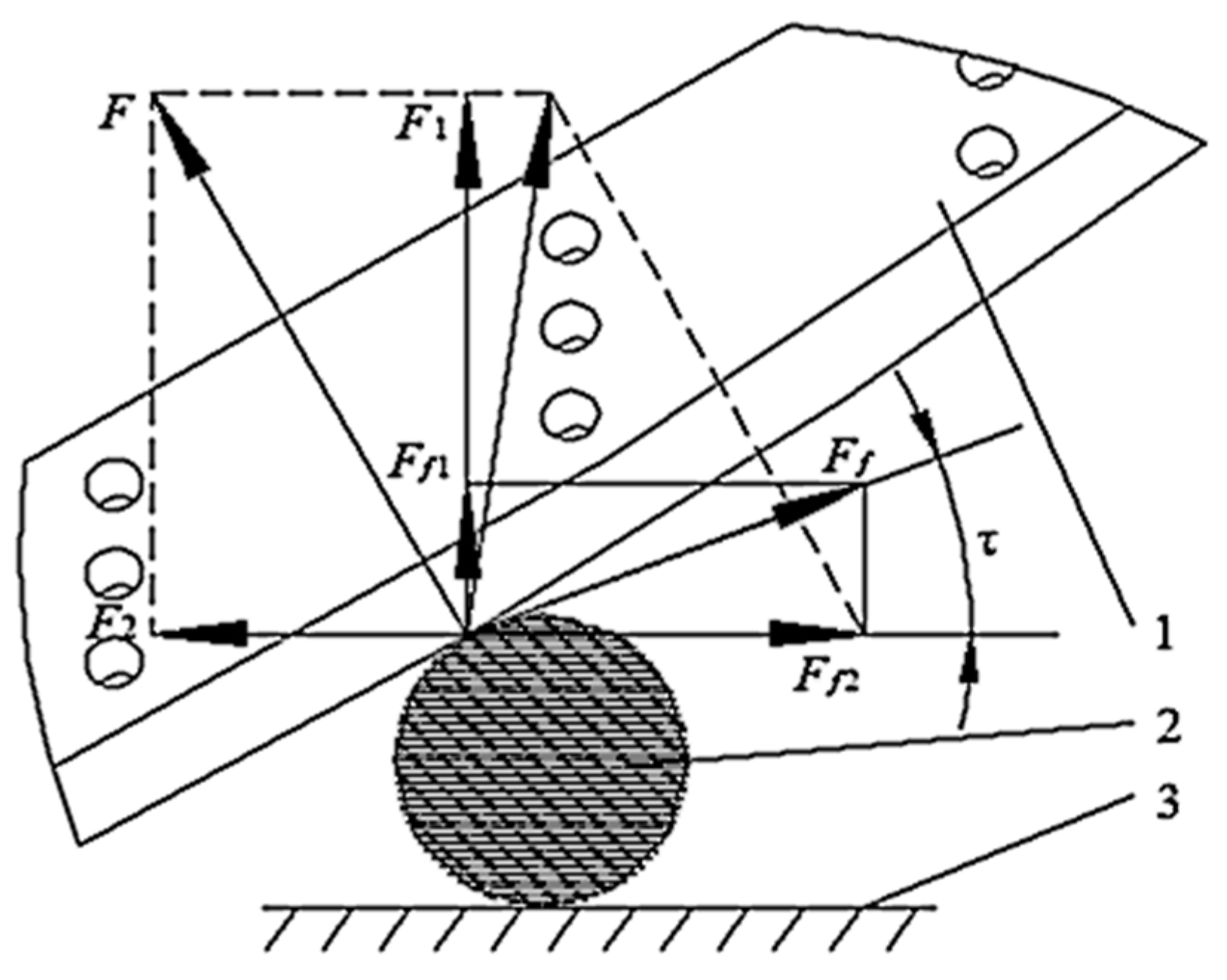

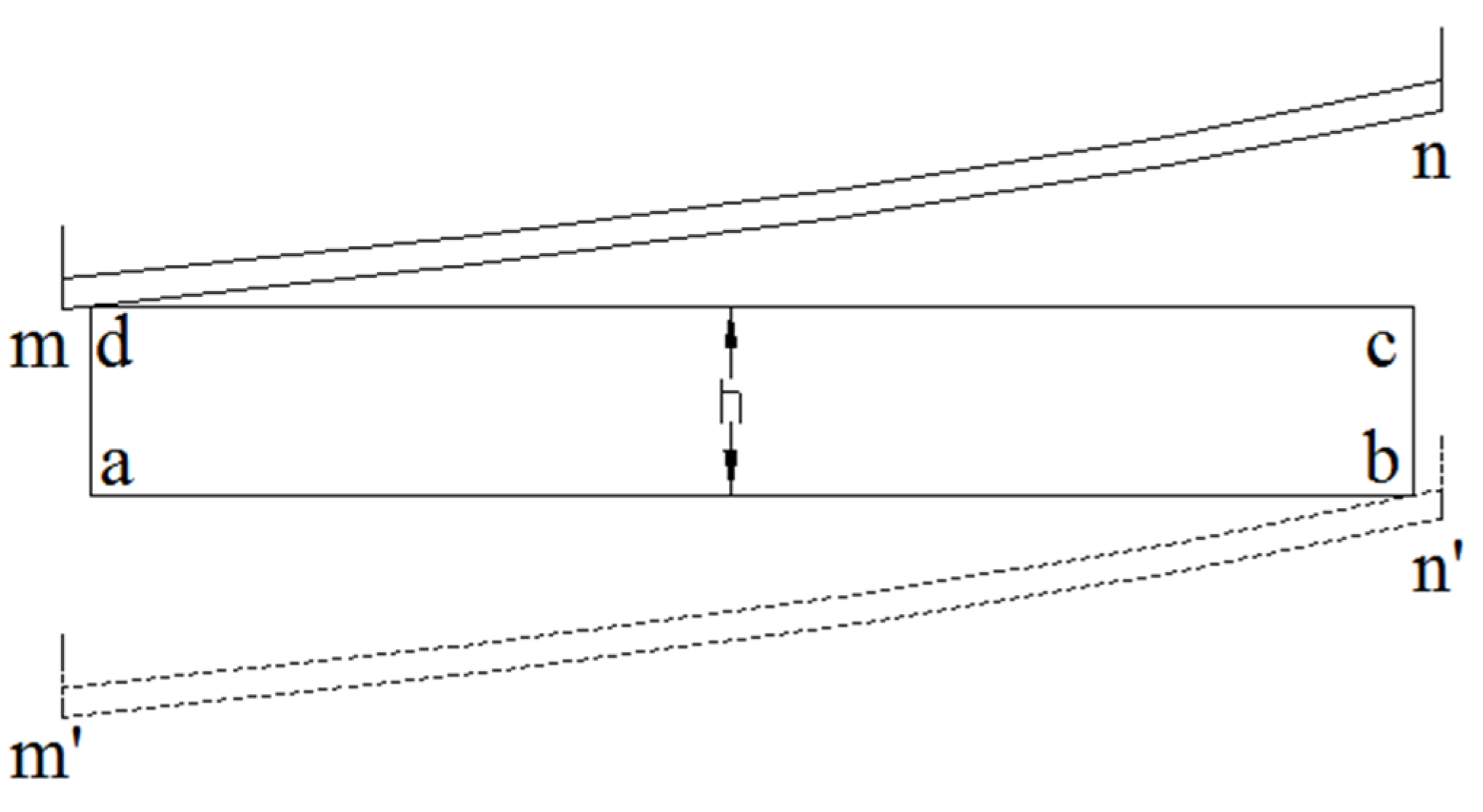

2.2. Constraint Condition

2.2.1. Continuity of Chopping Motion

2.2.2. Stability of Chopping Motion

3. Using MATLAB to Optimize Calculation

4. Validation of Optimization Results

4.1. Verification by Software Analysis

4.2. Verification by Bench Test

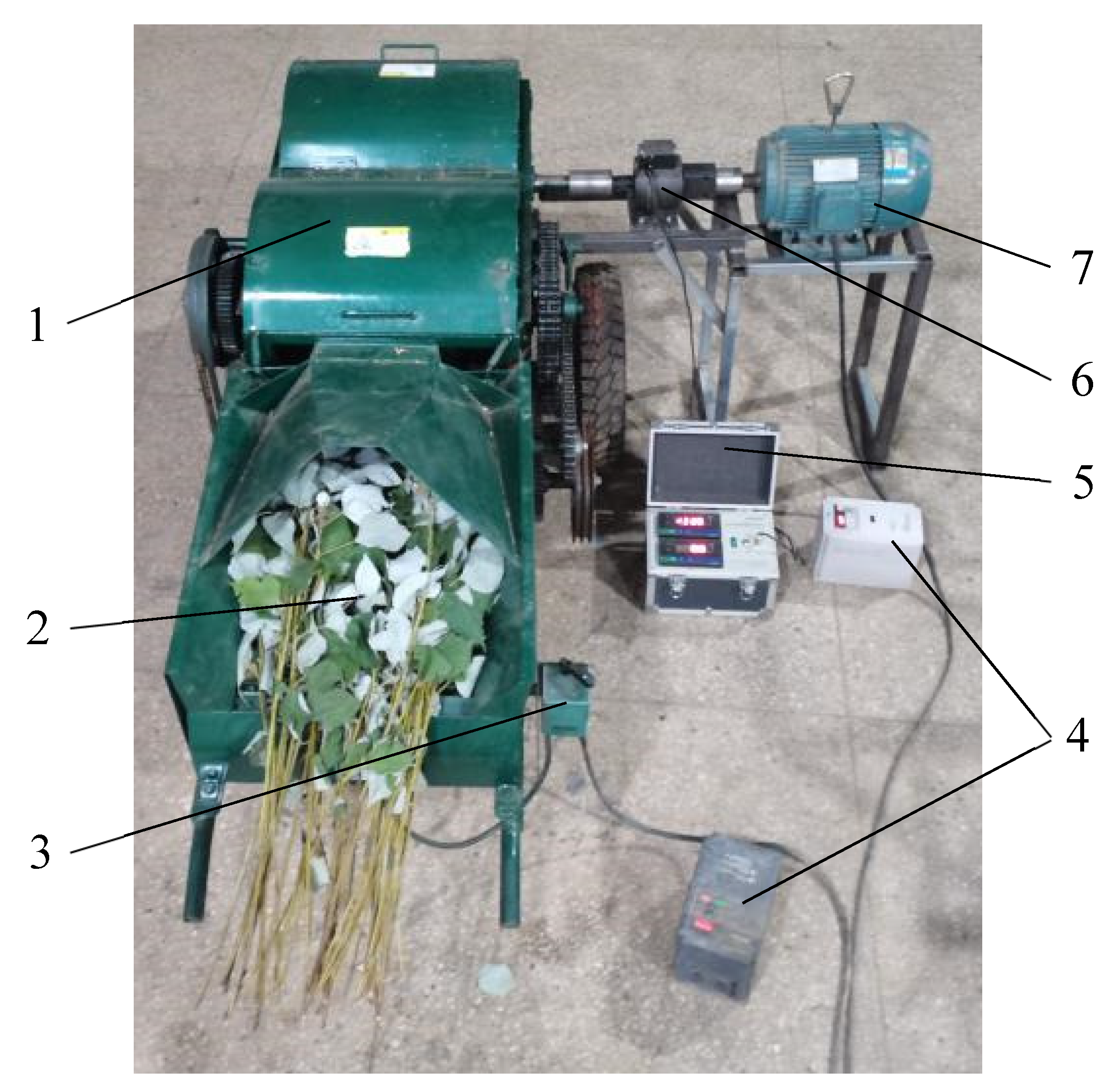

4.2.1. Test Materials and Equipment

4.2.2. Test Method

4.2.3. Test Index

4.2.4. Test Results and Analysis

- (1)

- The standard grass length rate (average value) of chopped ramie stalk by the chopper before and after the optimization of structural parameters is 92.96% and 92.84%, respectively, which are very close, indicating that the optimization of structural parameters basically has no influence on the chopping effect of the chopper.

- (2)

- After optimizing the structural parameters, the chopping power of the chopper is reduced by 22.25% compared with that before optimization, indicating the chopping power of bench test decreased significantly.

- (3)

- The standard deviation of the two test indexes of the chopper after structural parameter optimization is less than that before optimization, indicating that the working performance of the chopper after structural parameter optimization is more stable.

5. Discussion

- (1)

- The existing research on the power consumption of the chopper basically focuses on the working parameters of the chopper, the curve and shape of the chopper blade, and the installation parameters of the chopper on the machines and tools. However, this paper creatively considers the chopping power consumption of the chopper from the perspective of the structural parameters of the chopper (the installation form of the chopper blade on the knife roll), breaks the solidification thinking of the existing research, and provides a new idea and method to reduce the power consumption of the chopper.

- (2)

- The reason why the chopping power reduction in the bench test (22.25%) is lower than the software analysis value (25.50%) may be that other parts of the machine cause power loss, but the overall chopping power reduction in the bench test is obvious, which is basically close to the software analysis value, indicating that the optimization result is accurate and reliable.

6. Conclusions

- (1)

- When the coordinate value of point A on the blade edge line in the Z axis is 0.7 m, the included angle between the blade bottom and the cutter roll axis is 6°. When the radius of the chopper is 0.11 m, the chopper can obtain the theoretical minimum chopping power.

- (2)

- The software analysis results show that the chopper after the structural parameter optimization has more uniform stress, less impact vibration, and more stable chopping movement. The chopping power of the chopper after the optimization of structural parameters is approximately 25.50% lower than before the optimization, and the optimization effect is remarkable.

- (3)

- The bench test results show that the standard grass length rates of chopped ramie stalk by the chopper before and after the optimization of structural parameters were extremely close to each other. This demonstrates that the optimization of structural parameters basically has no influence on the chopping effect and quality of the chopper. After the optimization of structural parameters, the chopping power of the chopper is reduced by 22.25% compared with that before the optimization, which is close to the software analysis value, indicating that the optimization result is accurate and reliable. The standard deviation of the two test indexes of the chopper after structural parameter optimization is less than before optimization, indicating that the working performance of the chopper following structural parameter optimization is more stable.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Che, G.; Wan, L.; Zhang, W. Solid design and experiment of forage harvester. Trans. Chin. Soc. Agric. Mach. 2010, 41, 82–86. [Google Scholar]

- Zhang, Y.; Diao, P.; Du, R. Design and test of stalk chopping and conveying device for corn combine reaping both stalk and spike. Trans. Chin. Soc. Agric. Mach. 2016, 47, 208–214. [Google Scholar]

- Jiang, Y.; Liao, Y.; Liao, Q. Design and experiment on cylinder-type chopping device of harvester for fodder rapeseed in winter and spring. Trans. Chin. Soc. Agric. Mach. 2019, 50, 102–111. [Google Scholar]

- Wan, Q.; Wang, D.; Wang, G. Design and experiment of self-propelled grass silage combined bagging machine. Trans. Chin. Soc. Agric. Eng. 2014, 30, 30–37. [Google Scholar]

- Li, B.; Wang, S.; Yang, B. Force analysis of two kinds of moving blades on chopper. Trans. Chin. Soc. Agric. Mach. 2005, 36, 49–52. [Google Scholar]

- Lin, G.; Ji, J.; Mao, J. Research and analysis of power consumption on flywheel-type cutterhead for dry forage. Trans. Chin. Soc. Agric. Mach. 1997, 28, 70–74. [Google Scholar]

- Guo, Y. Effect of fly-wheel cutterhead with different curve edges on cutting energy consumption. J. Jilin Agric. Univ. 2003, 25, 107–110. [Google Scholar]

- Deng, C.; Chen, F.; Deng, C. Design of small straw chopper. J. Agric. Mech. Res. 2011, 33, 141–143. [Google Scholar]

- Tian, K.; Li, X.; Zhang, B. Design and Test Research on Cutting Blade of Corn Harvester Based on Bionic Principle. Appl. Bionics Biomech. 2017, 2017, 6953786. [Google Scholar] [CrossRef] [Green Version]

- Jin, T.; Shun, X.; Chen, D. Design of a Bionic Blade for Vegetable Chopper. J. Bionic Eng. 2017, 14, 163–171. [Google Scholar]

- Jia, H.; Wang, Z.; Ma, C. Chopping and throwing mechanism of corn straw. Trans. Chin. Soc. Agric. Mach. 2003, 34, 96–99. [Google Scholar]

- Jia, H.; Ma, C. Study on chopping and throwing parameters of the chopping knife with curved surface and straight edge. Trans. Chin. Soc. Agric. Mach. 2002, 33, 41–43. [Google Scholar]

- Jamshidpouya, M.; Najafi, G.; Hashjin, T.T. Design fabrication and evaluation of electric forage chopper with adjustable helix angle. J. Agric. Sci. Technol. 2018, 20, 923–938. [Google Scholar]

- Hu, J.; Ma, S.; Wang, F. Design and Development of Sugarcane Top Chopper and its Field Performance. Sugar Tech 2021, 23, 1192–1198. [Google Scholar] [CrossRef]

- Xue, Z.; Fu, J.; Chen, Z. Optimization experiment on parameters of chopping device of forage maize harvester. J. Jilin Univ. Eng. Technol. Ed. 2020, 50, 739–748. [Google Scholar]

- Johnson, P.C.; Clementson, C.L.; Mathanker, S.K. Cutting energy characteristics of miscanthus x giganteus stems with varying oblique angle and cutting speed. Biosyst. Eng. 2012, 112, 42–48. [Google Scholar] [CrossRef]

- Fang, M.; Bie, Z.; Yu, Z. Experimental study on cutting performance of discutter chaff cutter. Trans. Chin. Soc. Agric. Mach. 2020, 41, 67–72. [Google Scholar]

- Ge, Y.; Jiang, Y.; Li, Y. Design and test for hob-type chopped roller of green fed harvester. IOP Conf. Ser. Mater. Sci. Eng. 2018, 382, 032061. [Google Scholar] [CrossRef]

- Thangdee, D.; Thangdee, S. The effect of blade type and speed to the bananas plant chopping machine. IOP Conf. Ser. Earth Environ. Sci. 2019, 301, 012012. [Google Scholar] [CrossRef]

- Yang, A.; Wu, M.; Lv, J. Design and experiment on chopping system of forage ramie harvester. J. Agric. Sci. Technol. Res. 2020, 22, 110–118. [Google Scholar]

- Liu, P.; He, J.; Li, Y. Design and experiment of double rollers maize stalk chopping device with different rotation speeds. Trans. Chin. Soc. Agric. Mach. 2020, 36, 69–79. [Google Scholar]

- Zhou, J. The Influence of the Relative Position between Paired Blades on the Cutting Quality of Billet Combine Harvester; South China Agricultural University: Guangzhou, China, 2017. [Google Scholar]

- Li, J. Cattail Chopped Structure Optimization Design; Yunnan Agricultural University: Kunming, China, 2016. [Google Scholar]

- Chinese Academy of Agricultural Mechanization Sciences. Agricultural Machinery Design Manual; China Agricultural Machinery Science and Technology Press: Beijing, China, 2007. [Google Scholar]

- Sun, J. Mechanical Optimization Design; China Machine Press: Beijing, China, 2003. [Google Scholar]

- Xu, X. The Design and Key Components Simulation of the New Ramie Decorticator; Chinese Academy of Forestry: Beijing, China, 2018. [Google Scholar]

- Li, B. Research on the One-Sheet Hyperboloid Cylindrical Cutter with Flat Surface and Straight Edge; China Agricultural University: Guangzhou, China, 2005. [Google Scholar]

- Yuan, X.; Teng, Z.; Tao, D. Optimal worm transmission design based on MATLAB. J. Hunan Agric. Univ. Nat. Sci. 2007, 33, 101–104. [Google Scholar]

- Zhou, M.; Zhang, L.; Chen, Y. Structural optimization for rack of boat-type tractor based on sensitivity analysis. Trans. Chin. Soc. Agric. Eng. 2016, 32, 54–60. [Google Scholar]

- Tao, D.; Sun, S.; Lu, Y. Optimization design of gear transmission box for tiller. Trans. Chin. Soc. Agric. Mach. 2001, 32, 118–120. [Google Scholar]

- Wu, M.; Guan, C.; Tang, C. Optimization of rotary-cultivated ditch mechanism of type 2BYF-6 no-till rape combine seeder. J. Hunan Agric. Univ. Nat. Sci. 2008, 34, 735–738. [Google Scholar]

- Deng, C.; Xiang, J.; Tao, D. Optimize on Working Parameters Crank Rolling Velocity and Radius of the Vibration Sieve about Cereal Cleaning Windmill. J. Hunan Agric. Univ. Nat. Sci. 2013, 29, 250–257. [Google Scholar]

- Su, J.; Ruan, S.; Wang, Y. Matlab Engineering Mathematics; Electronic Industry Press: Beijing, China, 2005. [Google Scholar]

| Az (m) | Β (°) | R (m) | |

|---|---|---|---|

| Before optimization | 1.4 | 5 | 0.15 |

| After optimization | 0.7 | 6 | 0.11 |

| Power (W) | |||||

|---|---|---|---|---|---|

| Minimum Value | Maximum Value | Mean Value | Median | Mode | |

| Before optimization | 2386 | 2448 | 2404 | 2398 | 2386 |

| After optimization | 1776 | 1822 | 1795 | 1793 | 1776 |

| Decreased degree | 25.57% | 25.57% | 25.33% | 25.23% | 25.57% |

| Number of Tests | Weight of the Sample (g) | Weight of the Unqualified (g) | Standard Grass Length Rate (%) | Mean Value of Standard Grass Length Rate (%) | Standard Deviation of Standard Grass Length Rate | |

|---|---|---|---|---|---|---|

| Before optimization | 1 | 136.34 | 10.14 | 92.56 | 92.96 | 0.13 |

| 2 | 142.13 | 10.07 | 92.91 | |||

| 3 | 153.85 | 9.83 | 93.61 | |||

| 4 | 139.67 | 10.22 | 92.68 | |||

| 5 | 144.62 | 10.09 | 93.02 | |||

| After optimization | 1 | 143.17 | 10.67 | 92.55 | 92.84 | 0.08 |

| 2 | 149.96 | 9.96 | 93.36 | |||

| 3 | 148.41 | 10.58 | 92.87 | |||

| 4 | 145.56 | 10.42 | 92.84 | |||

| 5 | 138.94 | 10.28 | 92.60 |

| Number of Tests | Chopping Torque (N•m) | Mean Value of Chopping Torque (N•m) | Standard Deviation of Chopping Torque | Chopping Power (KW) | Decreased Degree Chopping Power (%) | |

|---|---|---|---|---|---|---|

| Before optimization | 1 | 83.88 | 85.03 | 8.51 | 7.55 | 22.25 |

| 2 | 81.80 | |||||

| 3 | 88.38 | |||||

| 4 | 82.46 | |||||

| 5 | 88.63 | |||||

| After optimization | 1 | 65.91 | 66.11 | 4.33 | 5.87 | |

| 2 | 68.91 | |||||

| 3 | 67.83 | |||||

| 4 | 64.83 | |||||

| 5 | 63.08 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, A.; Xiang, W.; Yan, B.; Duan, Y.; Lv, J.; Wu, M. Optimization and Test of Structural Parameters of Flat Hob Chopper. Agriculture 2022, 12, 824. https://doi.org/10.3390/agriculture12060824

Yang A, Xiang W, Yan B, Duan Y, Lv J, Wu M. Optimization and Test of Structural Parameters of Flat Hob Chopper. Agriculture. 2022; 12(6):824. https://doi.org/10.3390/agriculture12060824

Chicago/Turabian StyleYang, Anming, Wei Xiang, Bo Yan, Yiping Duan, Jiangnan Lv, and Mingliang Wu. 2022. "Optimization and Test of Structural Parameters of Flat Hob Chopper" Agriculture 12, no. 6: 824. https://doi.org/10.3390/agriculture12060824

APA StyleYang, A., Xiang, W., Yan, B., Duan, Y., Lv, J., & Wu, M. (2022). Optimization and Test of Structural Parameters of Flat Hob Chopper. Agriculture, 12(6), 824. https://doi.org/10.3390/agriculture12060824