Design of and Experiment on a Cleaning Mechanism of the Pneumatic Single Seed Metering Device for Coated Hybrid Rice

Abstract

:1. Introduction

2. Overall Structure and Design of the Seed Cleaning Mechanism

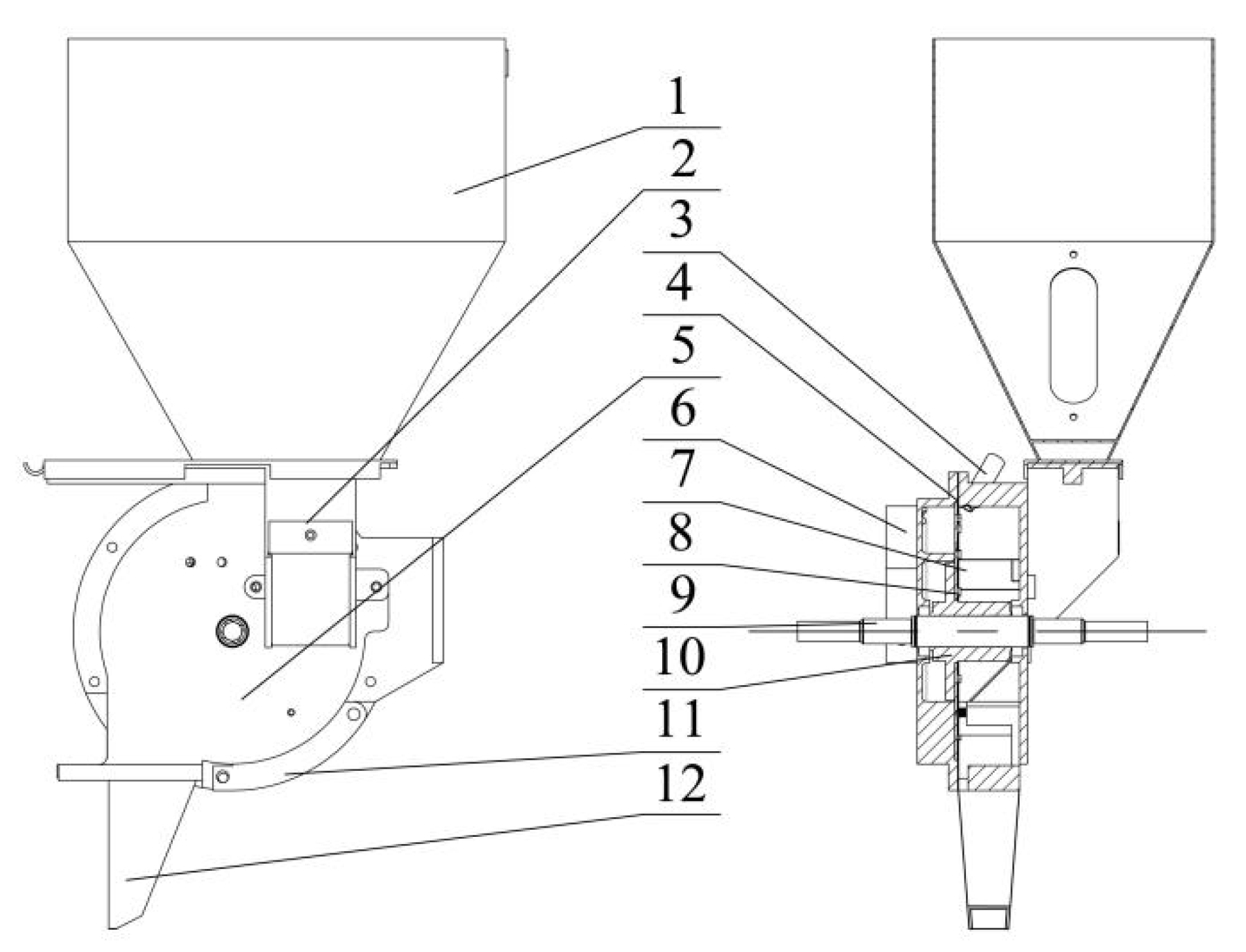

2.1. The Overall Structure of the Seed Meter

2.2. The Design of the Seed Cleaning Mechanism

2.2.1. Theoretical Analysis

2.2.2. Structural Design of Seed Cleaning Mechanism

3. Simulation Analysis of Nozzle Structure Flow Field

3.1. Nozzle Structure Parameters

3.2. Simulation Model Construction

3.3. Simulation Results and Analysis

4. Test and Analysis

4.1. Test Materials and Methods

4.1.1. Coating Treatment of Rice Seeds

4.1.2. Test Device

4.1.3. Evaluation Indicators

4.1.4. Test Design

4.2. Results and Analysis

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Farooq, M.; Siddique, K.H.M.; Rehman, H.; Aziz, T.; Lee, D.; Wahid, A. Rice direct seeding: Experiences, challenges and opportunities. Soil Tillage Res. 2011, 111, 87–98. [Google Scholar] [CrossRef]

- Xing, H.; Wang, Z.M.; Luo, X.W.; Cao, X.M.; Liu, C.B.; Zang, Y. General structure design and field experiment of pneumatic rice direct-seeder. Int. J. Agric. Biol. Eng. 2017, 10, 31–42. [Google Scholar] [CrossRef]

- Luo, X.W.; Jiang, E.C.; Wang, Z.M.; Tang, X.R.; Li, J.H.; Chen, W.T. Precision rice hill-drop drilling machine. Trans. Chin. Soc. Agric. Eng. 2008, 24, 52–56. [Google Scholar]

- Rao, A.N.; Brainard, D.C.; Kumar, V.; Ladha, J.K.; Johnson, D.E. Preventive weed management in direct-seeded rice: Targeting the weed seedbank. Adv. Agron. 2017, 144, 45–142. [Google Scholar] [CrossRef]

- Weerakoon, W.M.W.; Mutunayake, M.M.P.; Bandara, C.; Rao, A.N.; Bhandari, D.C.; Ladha, J.K. Direct-seeded rice culture in Sri Lanka: Lessons from farmers. Field Crops Res. 2011, 121, 53–63. [Google Scholar] [CrossRef]

- Zhang, M.H.; Wang, Z.M.; Luo, X.W.; Zang, Y.; Yang, W.W.; Xing, H.; Wang, B.L.; Dai, Y.Z. Review of precision rice hill-drop drilling technology and machine for paddy. Int. J. Agric. Biol. Eng. 2018, 11, 1–11. [Google Scholar] [CrossRef]

- Fu, W.; Zhang, Z.Y.; Zang, Y.; Luo, X.W.; Zeng, S.; Wang, Z.M. Development and experiment of rice hill-drop drilling machine for dry land based on proportional speed regulation. Int. J. Agric. Biol. Eng. 2017, 10, 77–86. [Google Scholar] [CrossRef]

- Zheng, T.X.; Tang, X.R.; Luo, X.W.; Li, G.X.; Wang, Z.M.; Shu, S.F.; Chen, W.T. Effects of different irrigation methods on production of precision hill-direct-seeding super rice. Trans. Chin. Soc. Agric. Eng. 2010, 26, 52–55. [Google Scholar] [CrossRef]

- Pandey, S.; Velasco, L. Trends in crop establishment methods in Asia and research issues. In Rice Is Life: Scientific Perspectives for the 21st Century, Proceedings of the World Rice Research Conference, Tsukuba, Japan, 4–7 November 2004; International Rice Research Institute: Manila, Philippines, 2005; pp. 178–181. [Google Scholar]

- Yang, L.; Yan, B.X.; Yu, Y.M.; He, X.T.; Liu, Q.W.; Liang, Z.J.; Yin, X.W.; Zhang, D.X. Global overview of research progress and development of precision maize planters. Int. J. Agric. Biol. Eng. 2016, 9, 9–26. [Google Scholar] [CrossRef]

- Liao, Y.T.; Wang, L.; Liao, Q.X. Design and test of an inside-filling pneumatic precision centralized seed-metering device for rapeseed. Int. J. Agric. Biol. Eng. 2017, 10, 56–62. [Google Scholar] [CrossRef]

- St jack, D.; Hesterman, D.C.; Guzzomi, A.L. Precision metering of Santalum spicatum (Australian Sandalwood) seeds. Biosyst. Eng. 2013, 115, 171–183. [Google Scholar] [CrossRef]

- Zhang, G.Z.; Zang, Y.; Luo, X.W.; Wang, Z.M.; Zhang, Q.; Zhang, S.S. Design and indoor simulated experiment of pneumatic rice seed metering device. Int. J. Agric. Biol. Eng. 2015, 8, 10–18. [Google Scholar] [CrossRef]

- Li, Y.H.; Yang, L.; Zhang, D.X.; Cui, T.; He, X.T.; Hu, H. Design and Test of Double-side Cleaning Mechanism for Air-suction Maize Seed-metering Device. Trans. Chin. Soc. Agric. Eng. 2021, 52, 29–39. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Liu, L.J.; Zhao, J.H.; Cui, W. Design and Experiment on Plant Seeding Device for Vegetable Seeding Seeder. Trans. Chin. Soc. Agric. Eng. 2018, 49, 83–91. [Google Scholar] [CrossRef]

- QI, B.; Zhang, D.X.; Liu, Q.W.; Yang, L.; Shi, S.; Cui, T. Design and experiment of cleaning performance in a centralized pneumatic metering device for maize. Trans. Chin. Soc. Agric. Eng. 2015, 31, 20–27. [Google Scholar]

- Lai, Q.H.; Sun, K.; Yu, Q.X.; Qin, W. Design and experiment of a six-row air-blowing centralized precision seed-metering device for panax notoginseng. Int. J. Agric. Biol. Eng. 2020, 13, 111–122. [Google Scholar] [CrossRef]

- Wang, B.L.; Na, Y.; Liu, J.; Wang, Z.M. Design and evaluation of vacuum central drum seed metering device. Appl. Sci. 2022, 12, 2159. [Google Scholar] [CrossRef]

- Wang, J.W.; Qi, X.; Xu, C.S.; Wang, Z.M.; Jiang, Y.M.; Tang, H. Design Evaluation and Performance Analysis of the Inside-Filling Air-Assisted High-Speed Precision Maize Seed-Metering Device. Sustainability 2021, 13, 5483. [Google Scholar] [CrossRef]

- Xiong, D.Y.; Wu, M.L.; Xie, W.; Liu, R.; Luo, H.F. Design and Experimental Study of the General Mechanical Pneumatic Combined Seed Metering Device. Appl. Sci. 2021, 16, 7223. [Google Scholar] [CrossRef]

- Ding, L.; Yang, L.; Liu, S.R.; Yan, B.X.; He, X.T.; Zhang, D.X. Design of air suction high speed precision maize seed metering device with assistant seed filling plate. Trans. Chin. Soc. Agric. Mach. 2018, 34, 1–11. [Google Scholar] [CrossRef]

- Cui, T.; Han, D.D.; Yin, X.W.; Li, K.H.; Xiao, L.L.; Yang, L.; Zhang, D.X. Design and experiment of inside-filling air-blowing maize precision seed metering device. Trans. Chin. Soc. Agric. Eng. 2017, 33, 8–16. [Google Scholar] [CrossRef]

- Sibendu, S.; Anita, L.R.; Douglas, E.L.; Suresh, K.A. Effect of nozzle orifice geometry on spray, combustion, and emission characteristics under diesel engine conditions. Fuel 2021, 229, 3–13. [Google Scholar] [CrossRef]

- Cao, C.M.; Qin, K.; Wang, A.M.; Sun, Y.; Zhou, M.; Li, W.Y. Design and experiment on rice hill seeder with air-blowing special hole and scoop-wheel. Trans. Chin. Soc. Agric. Mach. 2015, 46, 66–72. [Google Scholar] [CrossRef]

- Brown, A.R.; Ettefagh, K.A.; Todd, D.A.; Cole, P.S.; Egan, J.M.; Foil, D.H.; Lacey, E.P.; Cech, N.B. Bacterial efflux inhibitors are widely distributed in land plants. J. Ethnopharmacol. 2020, 267, 113533. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.Q.; Cheng, X.; Peng, L.L.; Li, M.S. Aerodynamic shape of transition curve for truncated mountainous terrain model in wind field simulation. J. Wind. Eng. Ind. Aerodyn. 2018, 178, 80–90. [Google Scholar] [CrossRef]

- Kangsopa, J.; Hynes, R.K.; Siri, B. Lettuce seeds pelleting: A new bilayer matrix for lettuce (Lactuca sativa) seeds. Seed. Sci. Technol. 2018, 46, 521–531. [Google Scholar] [CrossRef]

- Afzal, I.; Javed, T.; Amirkhani, M.; Taylor, A.G. Modern Seed Technology: Seed Coating Delivery Systems for Enhancing Seed and Crop Peformance. Agriculture 2020, 10, 526. [Google Scholar] [CrossRef]

- Hou, Z.F.; Zhang, X.W.; Chen, Z.; Dai, N.Z.; Dai, N.Z.; Ma, X.J.; Liu, M. Design and Experiment of Identification and Detection System for Pelleted Coated Seed. Trans. Chin. Soc. Agric. Mach. 2022, 53, 62–69. [Google Scholar] [CrossRef]

- GB/T 6973-2005; Single (Precise) Test Method. National Standards of the People’s Republic of China: Beijing, China, 2005.

- Xing, H.; Wang, Z.M.; Luo, X.W.; He, S.Y.; Zang, Y. Mechanism modeling and experimental analysis of seed throwing with rice pneumatic seed metering device with adjustable seeding rate. Comput. Electron. Agric. 2020, 178, 105697. [Google Scholar] [CrossRef]

- Zang, Y.; He, S.Y.; Wang, Z.M.; Liu, S.C.; Wang, X.G.; Wen, Z.Q. Design of pneumatic single seed metering device for coated hybrid rice. Trans. Chin. Soc. Agric. Eng. 2021, 37, 10–18. [Google Scholar] [CrossRef]

- Han, D.D.; Zhang, D.X.; Jing, H.R.; Yang, L.; Cui, T.; Ding, Y.Q.; Wang, Z.D.; Wang, Y.X.; Zhang, T.L. DEM-CFD coupling simulation and optimization of an inside-filling air-blowing maize precision seed-metering device. Comput. Electron. Agric. 2018, 150, 426–438. [Google Scholar] [CrossRef]

| Coding | Factor | ||

|---|---|---|---|

| Rotation Speed of Sucking Plate A/r·min−1 | Negative Pressure B/kPa | Cleaning Pressure C/kPa | |

| −1 | 20 | 1.0 | 0.1 |

| 0 | 30 | 1.4 | 0.2 |

| 1 | 40 | 1.8 | 0.3 |

| Test Number | Test Factors | Test Results | ||||

|---|---|---|---|---|---|---|

| A | B | C | Qualified Index | Missing Index | Multiple Index | |

| 1 | 0 | 0 | 0 | 86.41% | 6.5% | 7.09% |

| 2 | 1 | −1 | 0 | 76.60% | 21.31% | 2.08% |

| 3 | 0 | 1 | −1 | 75.82% | 2.52% | 21.66% |

| 4 | 0 | 0 | 0 | 84.76% | 7.16% | 8.08% |

| 5 | 0 | 0 | 0 | 84.15% | 9.69% | 6.15% |

| 6 | −1 | 0 | −1 | 84.37% | 7.88% | 7.88% |

| 7 | 1 | 1 | 0 | 86.99% | 5.57% | 7.74% |

| 8 | −1 | −1 | 0 | 76.07% | 21.65% | 2.29% |

| 9 | 0 | 0 | 0 | 83.95% | 9.47% | 6.58% |

| 10 | 0 | −1 | −1 | 80.09% | 12.56% | 7.35% |

| 11 | 0 | 0 | 0 | 84.29% | 8.77% | 6.94% |

| 12 | −1 | 0 | 1 | 66.67% | 31.02% | 2.31% |

| 13 | −1 | 1 | 0 | 85.22% | 4.03% | 10.75% |

| 14 | 1 | 0 | −1 | 77.65% | 7.12% | 15.23% |

| 15 | 0 | −1 | 1 | 54.47% | 44.36% | 1.17% |

| 16 | 1 | 0 | 1 | 74.72% | 23.54% | 1.74% |

| 17 | 0 | 1 | 1 | 81.99% | 13.62% | 4.39% |

| Source | Qualified Index | Missing Index | Multiple Index | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SS | df | F | p-Value * | SS | df | F | p-Value | SS | df | F | p-Value | |

| Model | 1100.88 | 9 | 143.37 | <0.0001 | 1945.56 | 9 | 55.07 | <0.0001 | 418.64 | 9 | 17.66 | 0.0005 |

| A | 1.65 | 1 | 1.93 | 0.2073 | 6.20 | 1 | 1.58 | 0.2493 | 1.58 | 1 | 0.60 | 0.4634 |

| B | 228.87 | 1 | 268.26 | <0.0001 | 687.09 | 1 | 175.05 | <0.0001 | 125.22 | 1 | 47.55 | 0.0002 |

| C | 200.80 | 1 | 235.36 | <0.0001 | 849.96 | 1 | 216.54 | <0.0001 | 225.89 | 1 | 85.78 | <0.0001 |

| AB | 0.38 | 1 | 0.45 | 0.5236 | 0.88 | 1 | 0.23 | 0.6496 | 1.96 | 1 | 0.74 | 0.4169 |

| AC | 54.54 | 1 | 63.92 | <0.0001 | 11.29 | 1 | 288 | 0.1337 | 15.68 | 1 | 5.95 | 0.0447 |

| BC | 252.65 | 1 | 296.13 | <0.0001 | 107.12 | 1 | 27.29 | 0.0012 | 30.75 | 1 | 11.68 | 0.0112 |

| A2 | 0.56 | 1 | 0.66 | 0.4429 | 16.40 | 1 | 4.18 | 0.0802 | 10.15 | 1 | 0.0904 | 0.0904 |

| B2 | 41.14 | 1 | 48.23 | 0.0002 | 34.16 | 1 | 8.70 | 0.0214 | 0.38 | 1 | 0.7159 | 0.7159 |

| C2 | 303.75 | 1 | 356.02 | <0.0001 | 212.16 | 1 | 54.05 | 0.0002 | 7.96 | 1 | 0.1257 | 0.1257 |

| Residual | 5.97 | 7 | 27.48 | 7 | 18.43 | 7 | ||||||

| Lack of fit | 2.01 | 3 | 0.68 | 0.6099 | 19.42 | 3 | 3.21 | 0.1446 | 16.36 | 3 | 0.0228 | 0.0228 |

| Error | 3.96 | 4 | 8.06 | 4 | 2.07 | 4 | ||||||

| Total | 1106.85 | 16 | 1973.04 | 16 | 437.08 | 16 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, S.; Zang, Y.; Huang, Z.; Tao, W.; Xing, H.; Qin, W.; Jiang, Y.; Wang, Z. Design of and Experiment on a Cleaning Mechanism of the Pneumatic Single Seed Metering Device for Coated Hybrid Rice. Agriculture 2022, 12, 1239. https://doi.org/10.3390/agriculture12081239

He S, Zang Y, Huang Z, Tao W, Xing H, Qin W, Jiang Y, Wang Z. Design of and Experiment on a Cleaning Mechanism of the Pneumatic Single Seed Metering Device for Coated Hybrid Rice. Agriculture. 2022; 12(8):1239. https://doi.org/10.3390/agriculture12081239

Chicago/Turabian StyleHe, Siyu, Ying Zang, Zishun Huang, Wanyan Tao, He Xing, Wei Qin, Youcong Jiang, and Zaiman Wang. 2022. "Design of and Experiment on a Cleaning Mechanism of the Pneumatic Single Seed Metering Device for Coated Hybrid Rice" Agriculture 12, no. 8: 1239. https://doi.org/10.3390/agriculture12081239

APA StyleHe, S., Zang, Y., Huang, Z., Tao, W., Xing, H., Qin, W., Jiang, Y., & Wang, Z. (2022). Design of and Experiment on a Cleaning Mechanism of the Pneumatic Single Seed Metering Device for Coated Hybrid Rice. Agriculture, 12(8), 1239. https://doi.org/10.3390/agriculture12081239