An Improved Multi-Objective Optimization Decision Method Using NSGA-III for a Bivariate Precision Fertilizer Applicator

Abstract

:1. Introduction

- The data utilized to build the prediction model of the fertilization rate is more consistent with the actual operation, eliminating outliers and using data segment modeling to effectively enhance the prediction accuracy of the model.

- The breakage rate is suggested as one of the optimization objectives to reduce the impairment level in the case of high fertilizer demands.

- NSGA-III is used to calculate the multi-objective optimization problem in this paper, so that the feasible solution has a more remarkable diversity and convergence.

2. Materials and Methods

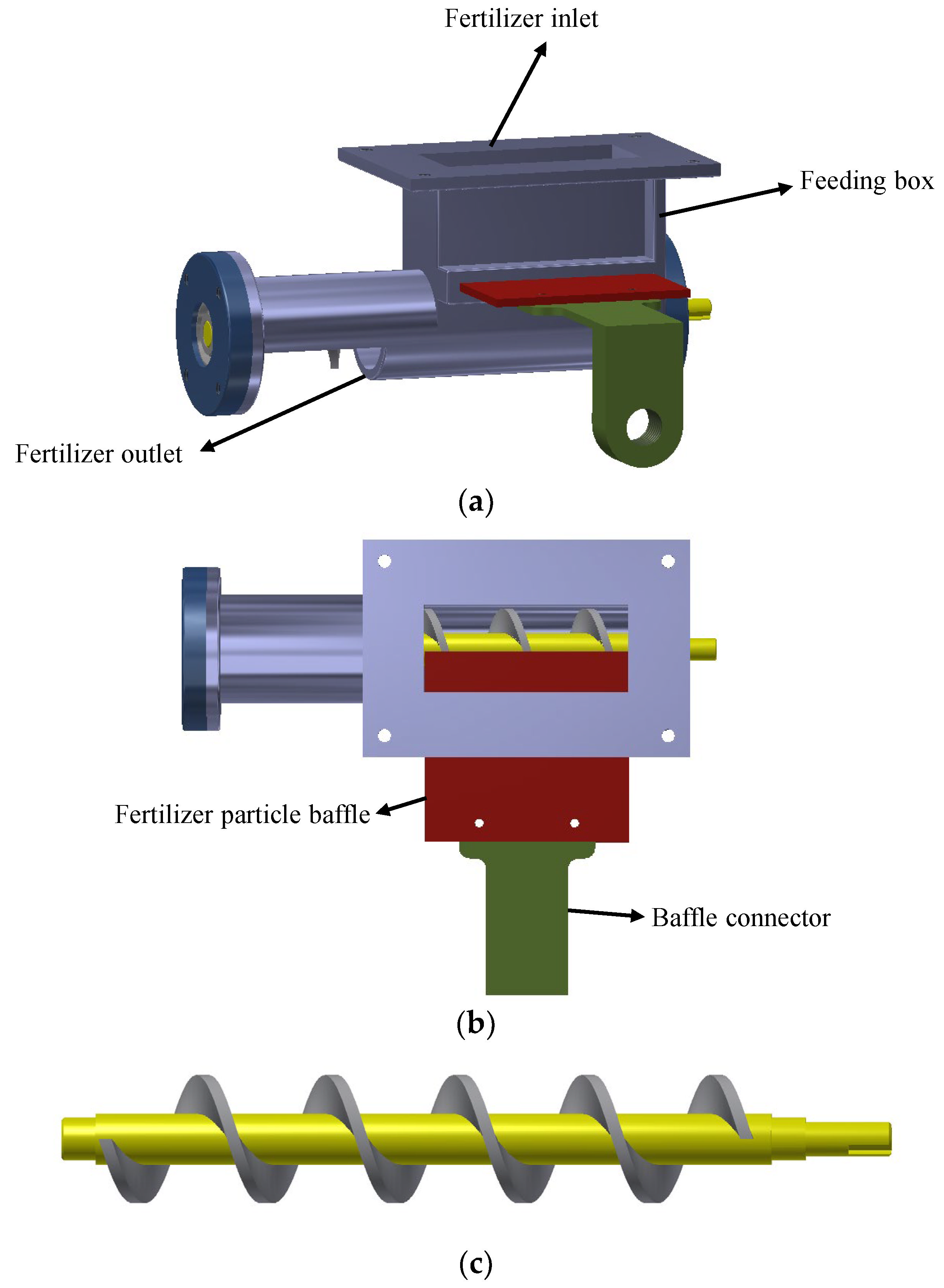

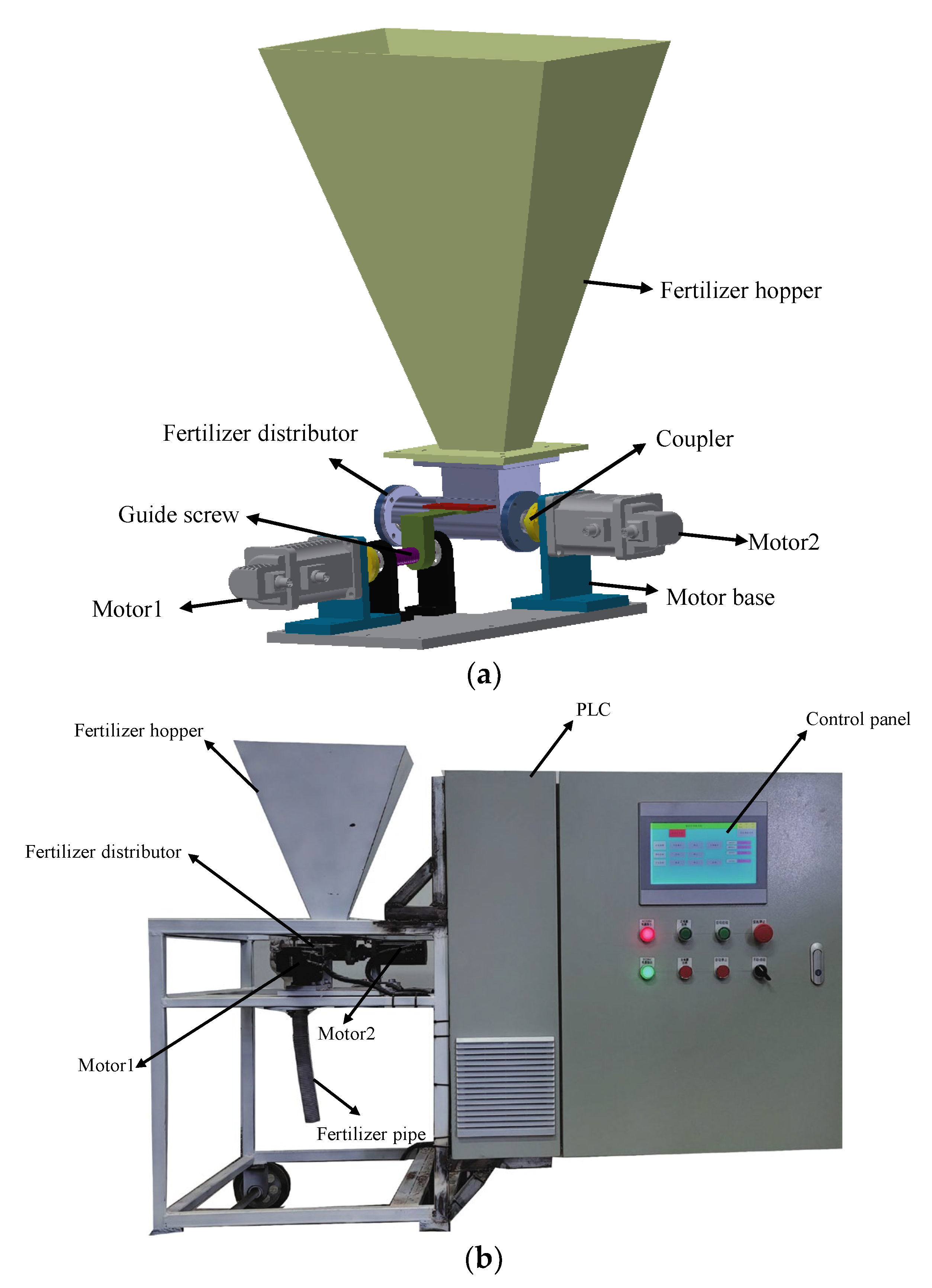

2.1. Design of the Variable Granular Fertilizer Applicator

2.2. Acquisition of the Fertilization Rate Data

2.3. Data Preprocessing

2.3.1. Outlier Test

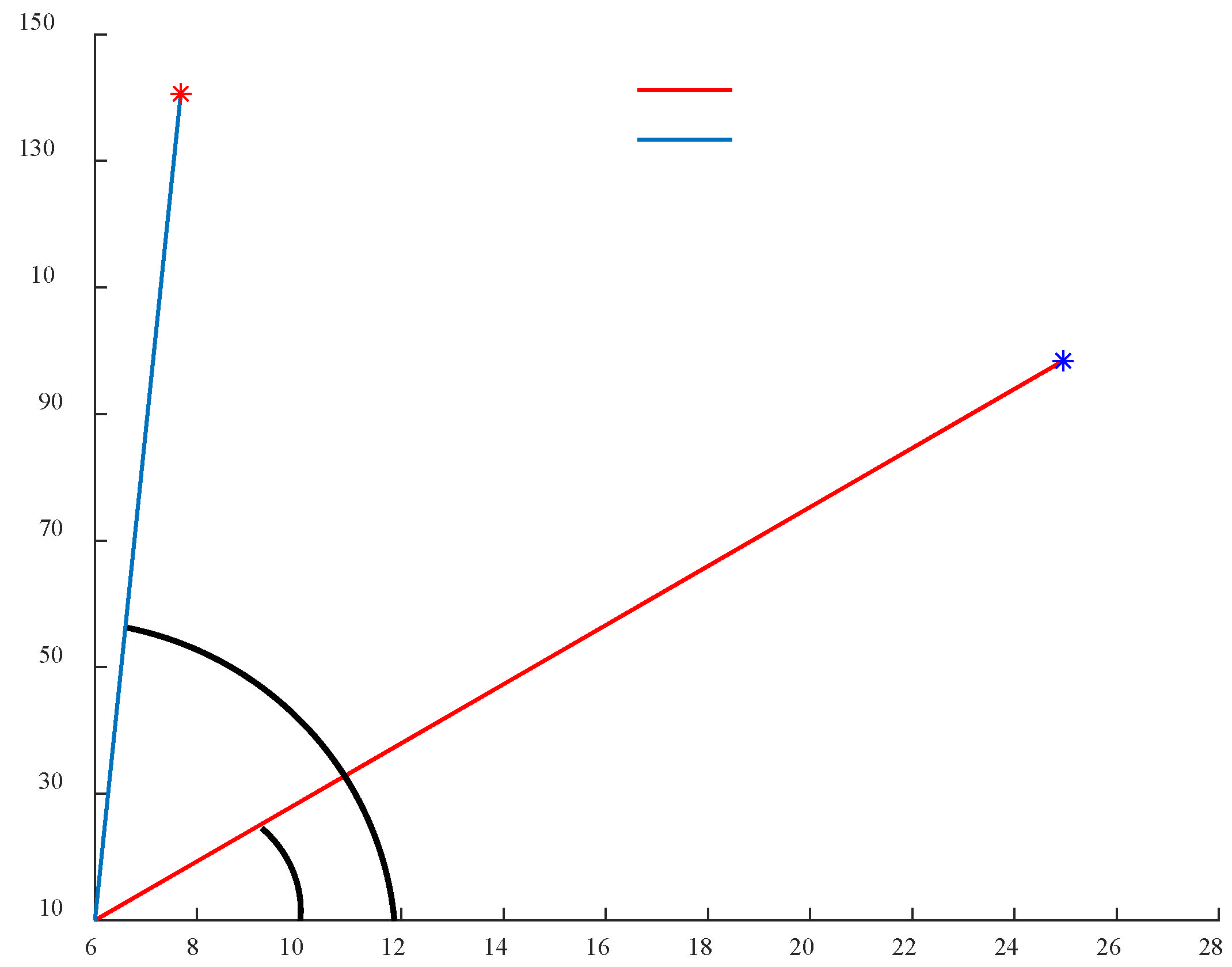

2.3.2. Data Segmentation

2.4. Establishment of the Fertilization Rate Prediction Model

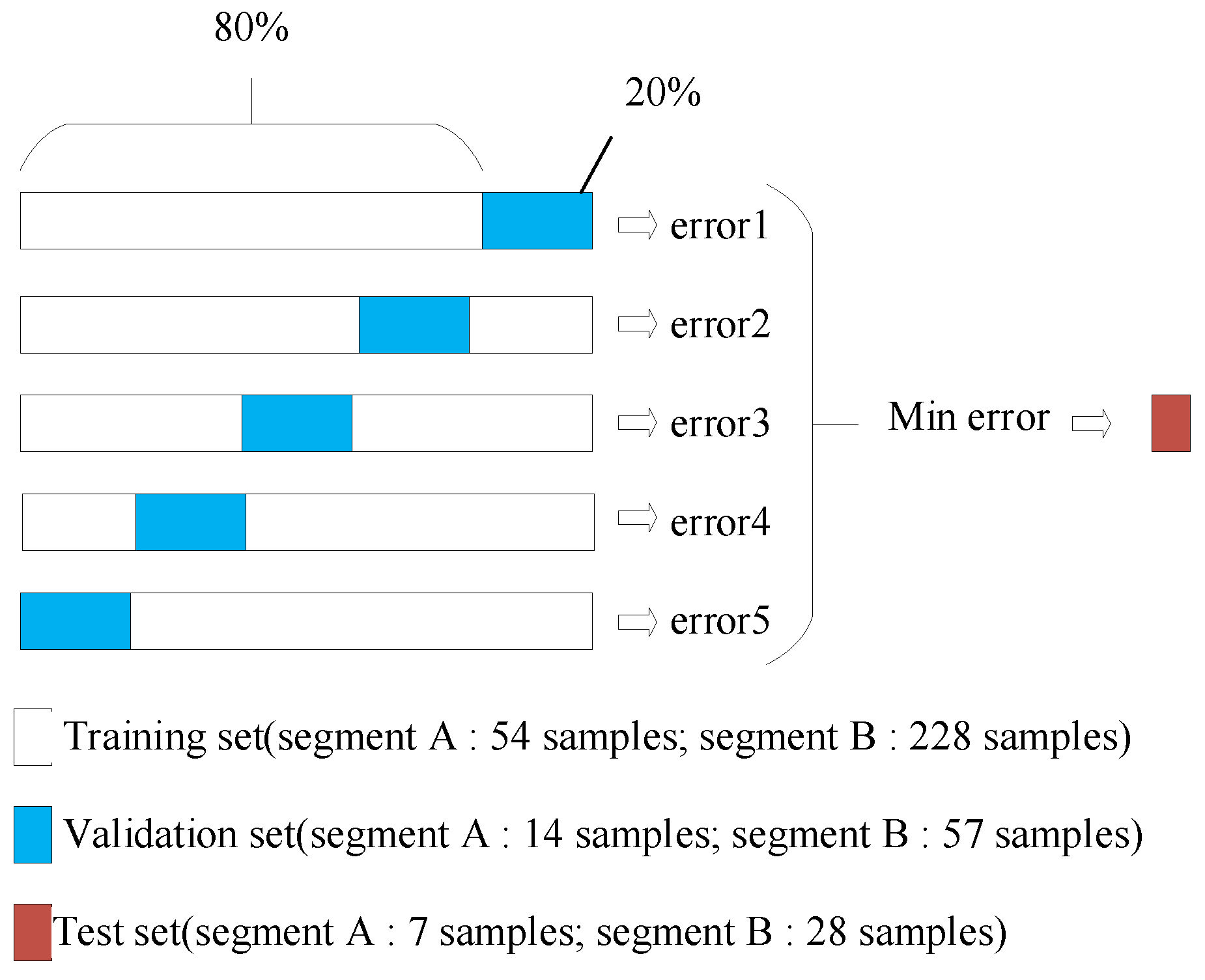

2.4.1. Dataset Partition and Performance Evaluation

2.4.2. Comparison of the Fertilization Rate Prediction Models

2.5. Modeling and Optimization of the Fertilization Decision

2.5.1. Objective Model

2.5.2. Multi-Objective Optimization Solution Based on NSGA-III

| Algorithm 1 Optimization of the fertilization decision based on NSGA-III |

|

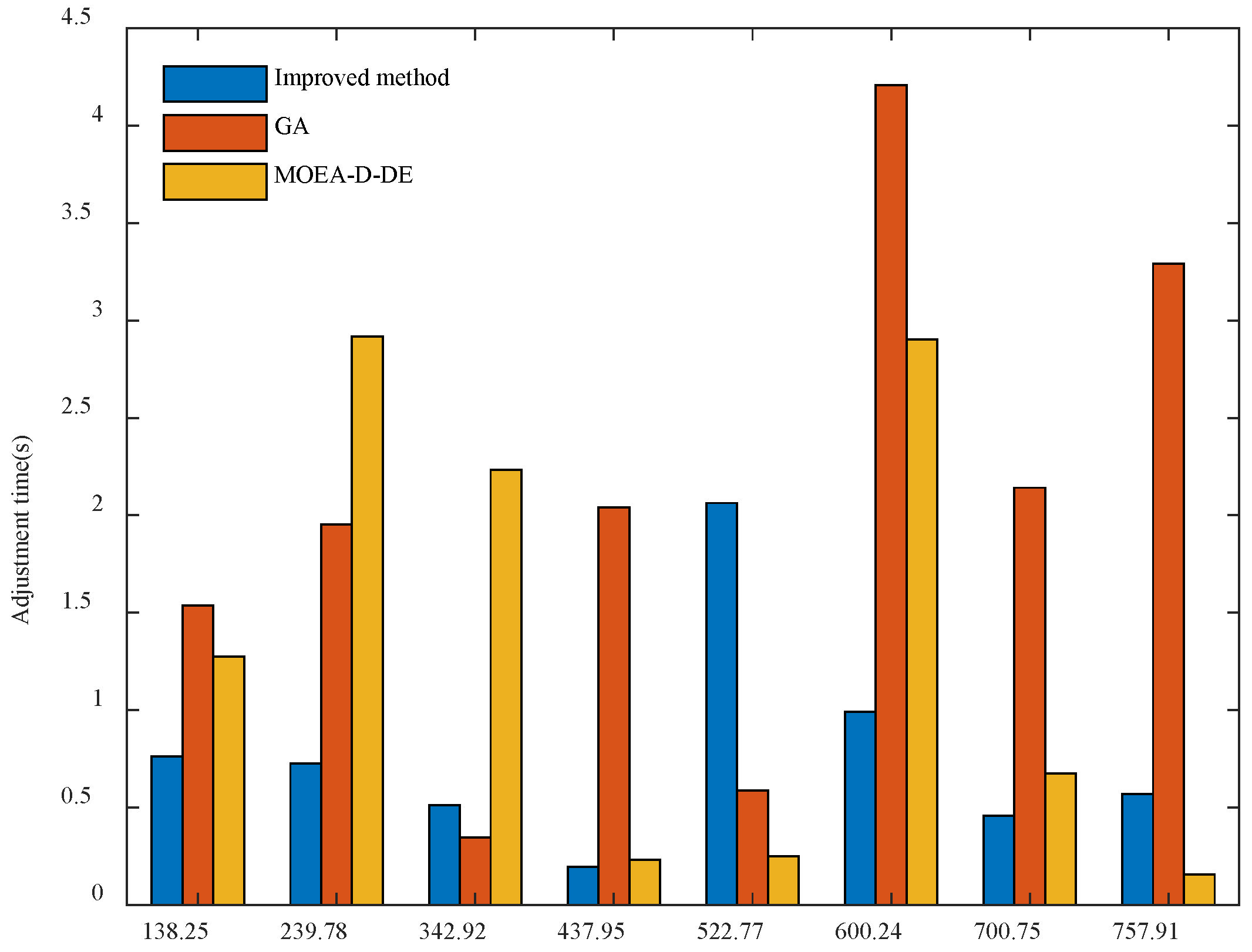

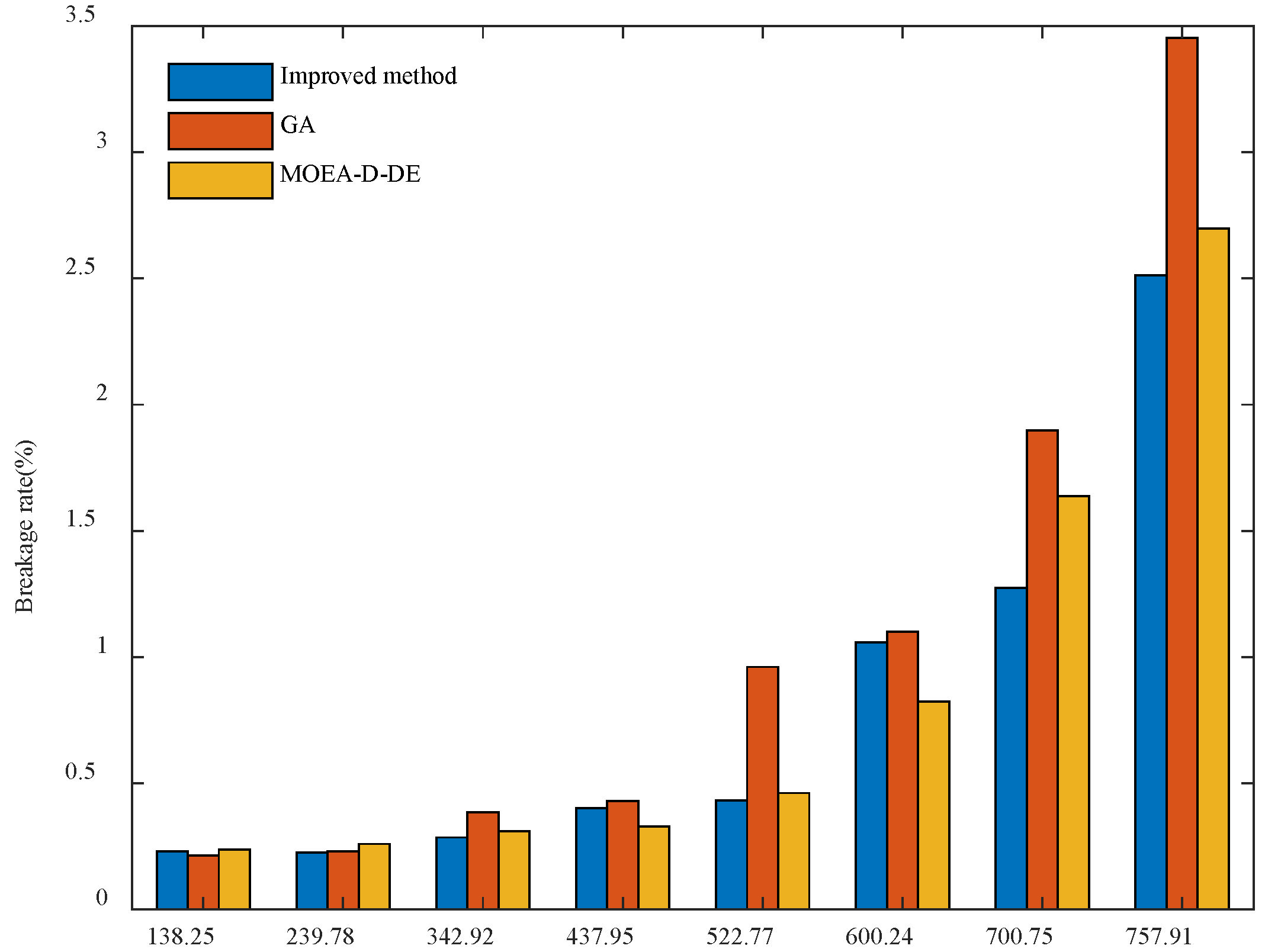

2.5.3. Performance Comparison of the Multi-Objective Optimization Results

2.6. Evaluation Criteria of the Fertilization Performance

2.6.1. Accuracy

2.6.2. Uniformity

2.6.3. Adjustment Time

2.6.4. Breakage Rate

3. Results and Discussion

3.1. Data Pretreatment Effect

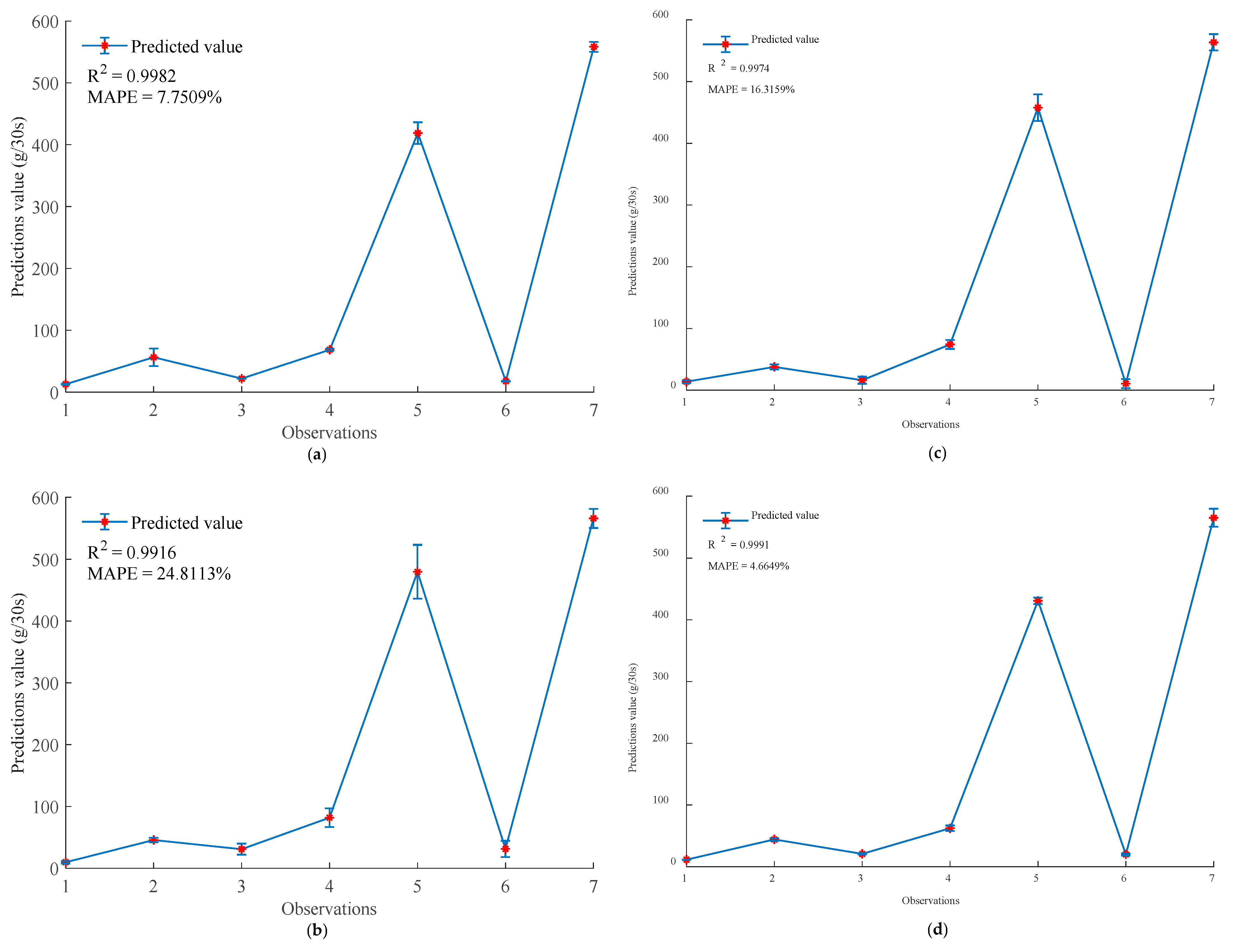

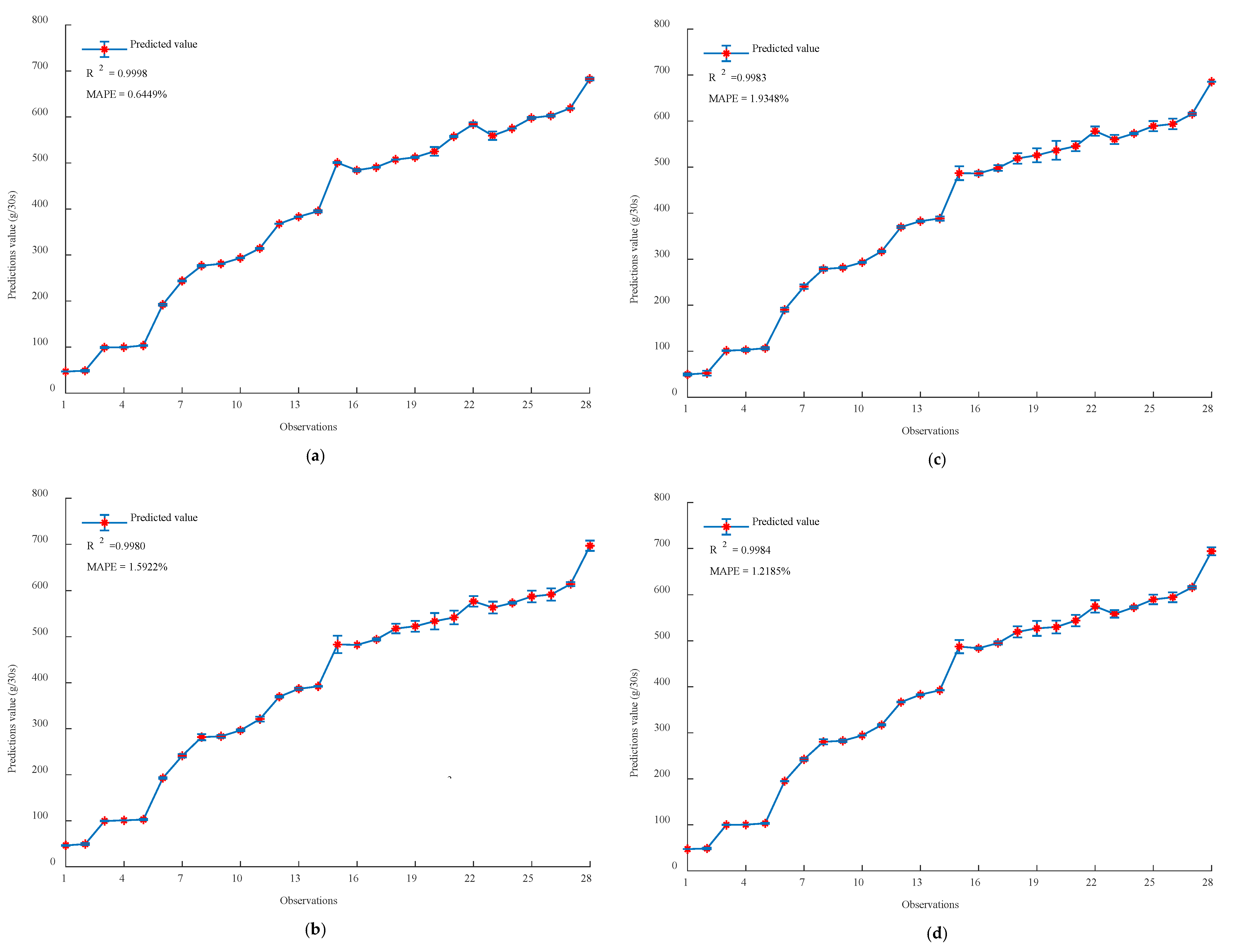

3.2. Performance of the Fertilization Rate Prediction Model

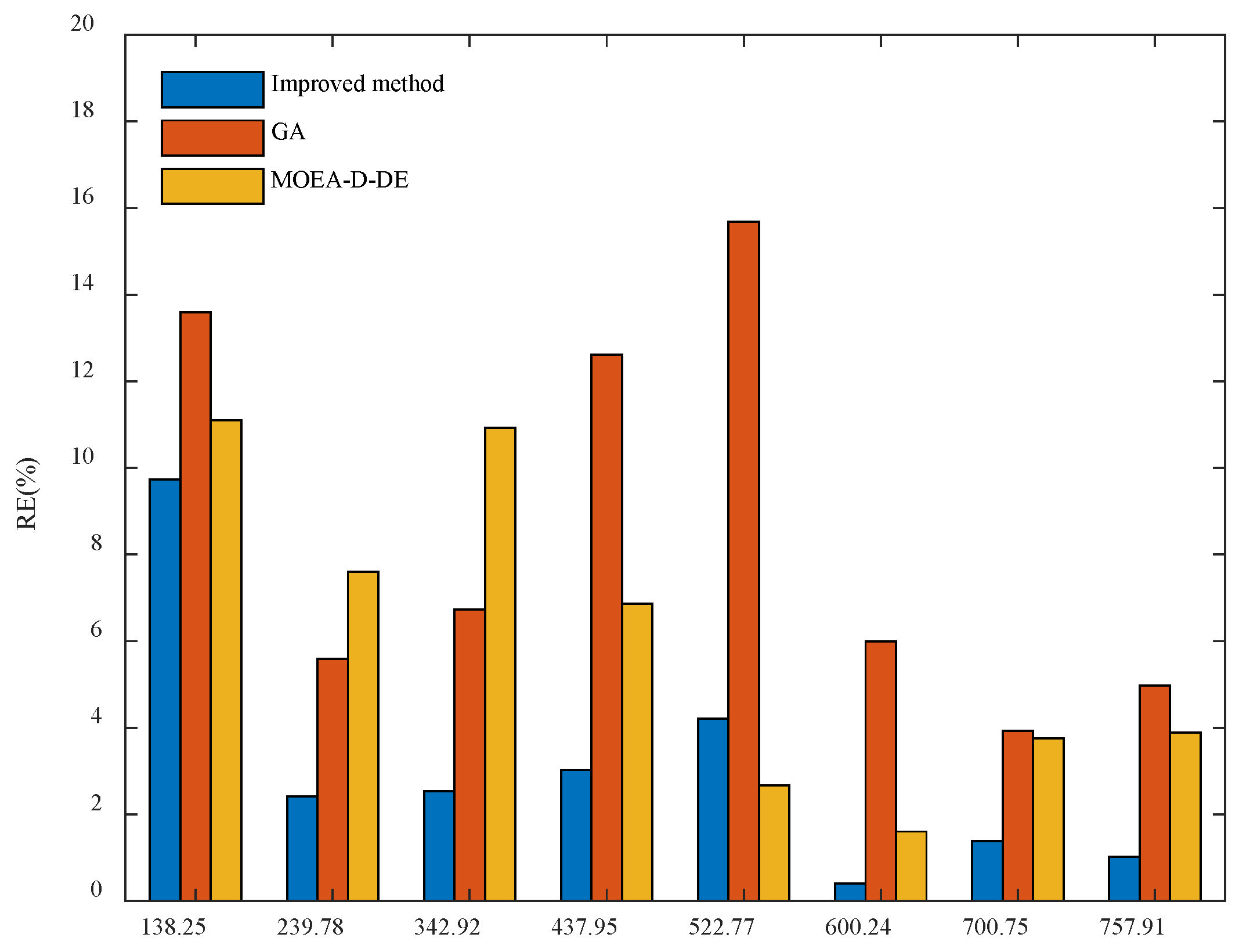

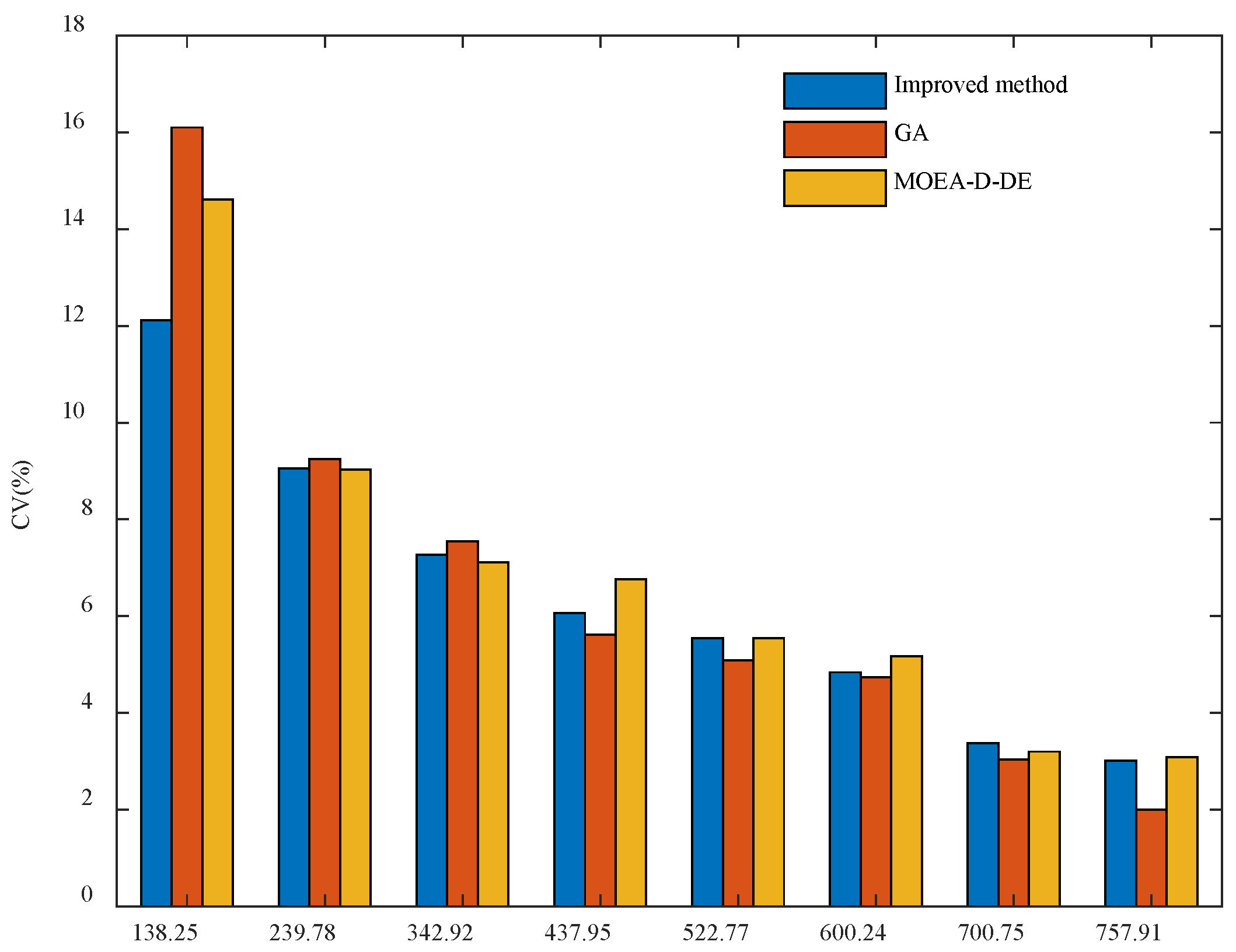

3.3. Performance of the Multi-Objective Optimization Based on NSGA-III

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bongiovanni, R.; Lowenberg-DeBoer, J. Precision agriculture and sustainability. Precis. Agric. 2004, 5, 359–387. [Google Scholar] [CrossRef]

- Tola, E.; Kataoka, T.; Burce, M.; Okamoto, H.; Hata, S. Granular fertiliser application rate control system with integrated output volume measurement. Biosyst. Eng. 2008, 101, 411–416. [Google Scholar] [CrossRef]

- Forouzanmehr, E.; Loghavi, M. Design, development and field evaluation of a map-based variable rate granular fertilizer application control system. Agric. Eng. Int. CIGR J. 2012, 14, 255–261. [Google Scholar] [CrossRef]

- Jafari, M.; Hemmat, A.; Sadeghi, M. Development and performance assessment of a DC electric variable-rate controller for use on grain drills. Comput. Electron. Agric. 2010, 73, 56–65. [Google Scholar] [CrossRef]

- Qi, J.; Tian, X.; Li, Y.; Fan, X.; Yuan, H.; Zhao, J.; Jia, H. Design and experiment of a subsoiling variable rate fertilization machine. Int. J. Agric. Biol. Eng. 2020, 13, 118–124. [Google Scholar] [CrossRef]

- Su, N.; Xu, T.S.; Song, L.T.; Wang, R.; Wei, Y.Y. Variable rate fertilization system with adjustable active feed-roll length. Int. J. Agric. Biol. Eng. 2015, 8, 19–26. [Google Scholar] [CrossRef]

- Shi, Y.Y.; Hu, Z.C.; Wang, X.C.; Odhiambo, M.O.; Sun, G.X. Fertilization strategy and application model using a centrifugal variable-rate fertilizer spreader. Int. J. Agric. Biol. Eng. 2018, 11, 41–48. [Google Scholar] [CrossRef]

- Sugirbay, A.M.; Zhao, J.; Nukeshev, S.O.; Chen, J. Determination of pin-roller parameters and evaluation of the uniformity of granular fertilizer application metering devices in precision farming. Comput. Electron. Agric. 2020, 179, 105835. [Google Scholar] [CrossRef]

- Liu, C.; Yuan, J.; Liu, J.; Li, C.; Zhou, Z.; Gu, Y. ARM and DSP-based bivariable fertilizing control system design and implementation. Trans. CSAM 2010, 41, 233–238. [Google Scholar]

- Zhang, J.Q.; Liu, G.; Luo, C.M.; Hu, H.; Huang, J.Y. MOEA/D-DE based bivariate control sequence optimization of a variable-rate fertilizer applicator. Comput. Electron. Agric. 2019, 167, 105063. [Google Scholar] [CrossRef]

- Yuan, J.; Liu, C.; Gu, Y.; Miao, Z. Bivariate fertilization control sequence optimization based on relevance vector machine. Trans. Chin. Soc. Agric. Mach. 2011, 42, 184–189. [Google Scholar]

- Zhang, J.Q.; Liu, G. Effects of control sequence optimisation on the performance of bivariate fertiliser applicator. Comput. Electron. Agric. 2022, 192, 106594. [Google Scholar] [CrossRef]

- Yuan, J.; Liu, C.L.; Li, Y.M.; Zeng, Q.B.; Zha, X.F. Gaussian processes based bivariate control parameters optimization of variable-rate granular fertilizer applicator. Comput. Electron. Agric. 2010, 70, 33–41. [Google Scholar] [CrossRef]

- Kartashov, O.O.; Chernov, A.V.; Polyanichenko, D.S.; Butakova, M.A. XAS Data Preprocessing of Nanocatalysts for Machine Learning Applications. Materials 2021, 14, 7884. [Google Scholar] [CrossRef]

- Khalil, A.; Salahuddin; Mashwani, W.K.; Shafiq, M.; Hassan, S.; Kumam, W. New advanced outliers detection tests. Commun. Stat.-Theory Methods 2021, 50, 1640–1655. [Google Scholar] [CrossRef]

- Guilizzoni, M.; Eizaguirre, P.M. Trend Lines and Japanese Candlesticks Applied to the Forecasting of Wind Speed Data Series. Forecasting 2022, 4, 165–181. [Google Scholar] [CrossRef]

- Gu, Y.; Yuan, J.; Liu, C. FIS-based method to generate bivariate control parameters regulation sequence for fertilization. Trans. Chin. Soc. Agric. Eng. 2011, 27, 134–139. [Google Scholar] [CrossRef]

- Wang, L.; Liao, Q.; Liao, Y.; Gao, L.; Xiao, W.; Chen, H. Effects of distributor types on fertilizing performance in an air-assisted applicator. Trans. Chin. Soc. Agric. Eng. 2021, 37, 24–34. [Google Scholar] [CrossRef]

- Deb, K.; Jain, H. An Evolutionary Many-Objective Optimization Algorithm Using Reference-Point-Based Nondominated Sorting Approach, Part I: Solving Problems With Box Constraints. IEEE Trans. Evol. Comput. 2014, 18, 577–601. [Google Scholar] [CrossRef]

- Jain, H.; Deb, K. An Evolutionary Many-Objective Optimization Algorithm Using Reference-Point Based Nondominated Sorting Approach, Part II: Handling Constraints and Extending to an Adaptive Approach. IEEE Trans. Evol. Comput. 2014, 18, 602–622. [Google Scholar] [CrossRef]

- Wang, C.; Ji, Z.C.; Wang, Y. Many-objective flexible job shop scheduling using NSGA-III combined with multi-attribute decision making. Mod. Phys. Lett. B 2018, 32, 1840110. [Google Scholar] [CrossRef]

- Yeganefar, A.; Niknam, S.A.; Asadi, R. The use of support vector machine, neural network, and regression analysis to predict and optimize surface roughness and cutting forces in milling. Int. J. Adv. Manuf. Technol. 2019, 105, 951–965. [Google Scholar] [CrossRef]

- Liang, W.; Wang, G.W.; Ning, X.J.; Zhang, J.L.; Li, Y.J.; Jiang, C.H.; Zhang, N. Application of BP neural network to the prediction of coal ash melting characteristic temperature. Fuel 2020, 260, 116324. [Google Scholar] [CrossRef]

- Ding, S.F.; Zhao, H.; Zhang, Y.N.; Xu, X.Z.; Nie, R. Extreme learning machine: Algorithm, theory and applications. Artif. Intell. Rev. 2015, 44, 103–115. [Google Scholar] [CrossRef]

- Tipping, M.E. Sparse Bayesian learning and the relevance vector machine. J. Mach. Learn. Res. 2001, 1, 211–244. [Google Scholar] [CrossRef]

- Jordan, M.I.; Mitchell, T.M. Machine learning: Trends, perspectives, and prospects. Science 2015, 349, 255–260. [Google Scholar] [CrossRef]

- Das, I.; Dennis, J.E. Normal-boundary intersection: A new method for generating the Pareto surface in nonlinear multicriteria optimization problems. SIAM J. Optim. 1998, 8, 631–657. [Google Scholar] [CrossRef]

- Beume, N.; Naujoks, B.; Emmerich, M. SMS-EMOA: Multiobjective selection based on dominated hypervolume. Eur. J. Oper. Res. 2007, 181, 1653–1669. [Google Scholar] [CrossRef]

- Zizler, E. Multiobjective optimization using evolutionary algorithms: A comparative study. Parallel Probl. Solving Nat. 1998, 1498, 292–301. [Google Scholar] [CrossRef]

- Zitzler, E.; Thiele, L. Multiobjective evolutionary algorithms: A comparative case study and the strength Pareto approach. IEEE Trans. Evol. Comput. 1999, 3, 257–271. [Google Scholar] [CrossRef] [Green Version]

- Tiwari, A.; Sharma, K.; Trivedi, M.K. NSGA-III-Based Time–Cost–Environmental Impact Trade-Off Optimization Model for Construction Projects. In Artificial Intelligence and Sustainable Computing; Springer: Singapore, 2022; pp. 11–25. [Google Scholar]

| Parameter | Group | Range | Step Size |

|---|---|---|---|

| Opening length | 23 | 6–12 mm | 0.5 |

| 12–16 mm | 1 | ||

| 16–28 mm | 2 | ||

| Rotational speed | 15 | 10–150 r min−1 | 10 |

| No. | Rotational Speed (r min−1) | Opening Length (mm) | Abnormal Data (g 30 s−1) | Replace Data (g 30 s−1) |

|---|---|---|---|---|

| 1 | 30 | 6.5 | 44 | 19 |

| 2 | 40 | 6 | 33 | 11 |

| 3 | 40 | 7 | 121 | 39 |

| 4 | 50 | 7 | 82 | 129 |

| 5 | 70 | 15 | 325 | 336 |

| 6 | 90 | 9 | 394 | 401 |

| 7 | 120 | 6 | 7 | 21 |

| 8 | 120 | 8 | 494 | 511 |

| 9 | 130 | 9 | 523 | 534 |

| 10 | 130 | 11.5 | 569 | 558 |

| 11 | 140 | 8.5 | 549 | 567 |

| 12 | 150 | 8.5 | 566 | 582 |

| 13 | 150 | 16 | 645 | 655 |

| Groups | Statistics | df | Sig. |

|---|---|---|---|

| A | 0.975 | 4 | 0.873 |

| B | 0.943 | 18 | 0.325 |

| Levene’s Test for Equality of Variances | t-Test for Equality of Means | 95% Confidence Interval | |||||||

|---|---|---|---|---|---|---|---|---|---|

| F | Sig. | t | df | Sig. (2-Tailed) | Mean Difference | Std. Error Difference | Lower | Upper | |

| Equal variances assumed | 95.199 | 0 | 7.49 | 20 | 0 | 1.19174 | 0.15911 | 0.85985 | 1.52364 |

| Equal variances not assumed | 3.207 | 3 | 0.049 | 1.19174 | 0.37156 | 0.00930 | 2.37419 | ||

| No. | Rotational Speed (r min−1) | Opening Length (mm) | Fertilization Rate Q (g 30 s−1) |

|---|---|---|---|

| 1 | 10 | 6 | 11.65 |

| 2 | 40 | 7 | 42.00 |

| 3 | 50 | 6.5 | 21.95 |

| 4 | 60 | 7 | 66.85 |

| 5 | 100 | 8 | 436.20 |

| 6 | 110 | 6 | 18.15 |

| 7 | 140 | 8 | 550.30 |

| No. | Rotational Speed (r min−1) | Opening Length (mm) | Fertilization Rate (g 30 s−1) | No. | Rotational Speed (r min−1) | Opening Length (mm) | Fertilization Rate (g 30 s−1) |

|---|---|---|---|---|---|---|---|

| 1 | 10 | 10 | 47.30 | 15 | 100 | 22 | 501.85 |

| 2 | 10 | 12 | 47.10 | 16 | 110 | 10 | 482.05 |

| 3 | 20 | 10.5 | 100.45 | 17 | 110 | 12 | 491.75 |

| 4 | 20 | 11.5 | 100.65 | 18 | 110 | 18 | 507.35 |

| 5 | 20 | 26 | 104.25 | 19 | 110 | 20 | 510.70 |

| 6 | 40 | 8.5 | 194.45 | 20 | 110 | 28 | 515.90 |

| 7 | 50 | 9.5 | 245.00 | 21 | 120 | 14 | 556.40 |

| 8 | 60 | 8.5 | 274.95 | 22 | 120 | 28 | 588.25 |

| 9 | 60 | 9 | 280.25 | 23 | 140 | 8 | 550.30 |

| 10 | 60 | 15 | 294.35 | 24 | 140 | 9 | 575.00 |

| 11 | 70 | 8 | 315.65 | 25 | 140 | 10.5 | 600.05 |

| 12 | 80 | 10 | 367.55 | 26 | 140 | 11 | 605.15 |

| 13 | 80 | 16 | 384.10 | 27 | 140 | 14 | 618.50 |

| 14 | 80 | 20 | 392.90 | 28 | 150 | 26 | 685.85 |

| Rotational Speed (r min−1) | Experimental Value (g 30 s−1) | Predict Value (g 30 s−1) | Relative Error (%) | ||

|---|---|---|---|---|---|

| Segment A | Segment B | Segment A | Segment B | ||

| 10 | 45.15 | 46.79 | 44.65 | 0.036323 | 0.011074 |

| 20 | 95.45 | 95.47 | 96.16 | 0.000210 | 0.007438 |

| 30 | 146.10 | 142.75 | 144.71 | 0.022930 | 0.009514 |

| 40 | 193.80 | 187.92 | 188.31 | 0.030341 | 0.028328 |

| 50 | 230.55 | 230.85 | 232.56 | 0.001301 | 0.008718 |

| 60 | 271.80 | 271.91 | 271.18 | 0.000405 | 0.002281 |

| 70 | 315.65 | 311.76 | 314.46 | 0.012324 | 0.00377 |

| 80 | 350.75 | 351.17 | 351.14 | 0.001197 | 0.001112 |

| 90 | 390.75 | 390.77 | 390.69 | 0.000051 | 0.000154 |

| 100 | 436.20 | 430.82 | 441.70 | 0.012334 | 0.012609 |

| 110 | 468.60 | 471.07 | 467.81 | 0.005271 | 0.001686 |

| 120 | 509.80 | 510.65 | 509.80 | 0.001667 | 0 |

| 130 | 520.40 | 548.19 | 519.84 | 0.053401 | 0.001076 |

| 140 | 550.30 | 581.87 | 559.38 | 0.057369 | 0.016500 |

| 150 | 573.95 | 609.67 | 575.37 | 0.062235 | 0.002474 |

| Average relative error | 0.019824 | 0.007116 | |||

| Algorithm | Before Segmentation | After Segmentation | ||||||

|---|---|---|---|---|---|---|---|---|

| 6–8 mm | 8–28 mm | 6–8 mm | 8–28 mm | |||||

| MAPE | MAPE | MAPE | MAPE | |||||

| SVM | 0.9789 | 23.4581% | 0.9833 | 16.7325% | 0.9991 | 4.6649% | 0.9984 | 1.2185% |

| BPNN | 0.9721 | 24.1568% | 0.9892 | 15.4239% | 0.9982 | 7.7509% | 0.9998 | 0.6449% |

| ELM | 0.9735 | 24.3684% | 0.9749 | 19.3415% | 0.9916 | 24.8113% | 0.9980 | 1.5922% |

| RVM | 0.9689 | 25.6428% | 0.9821 | 18.5963% | 0.9974 | 16.3159% | 0.9983 | 1.9348% |

| Mean value | 0.9734 | 24.4065% | 0.9824 | 17.5236% | 0.9966 | 13.3858% | 0.9986 | 1.3476% |

| Before Measurement (g) | After Measurement (g) | Error Amount (g) | Breakage Rate (%) | Average Breakage Rate (%) | |

|---|---|---|---|---|---|

| 100 | 626 | 621 | 5 | 0.80 | 0.69 |

| 362 | 360 | 2 | 0.55 | ||

| 410 | 407 | 3 | 0.73 | ||

| 125 | 660 | 648 | 12 | 1.82 | 1.87 |

| 469 | 460 | 9 | 1.92 | ||

| 638 | 626 | 12 | 1.88 | ||

| 150 | 529 | 510 | 19 | 3.59 | 3.5 |

| 510 | 489 | 21 | 4.12 | ||

| 679 | 660 | 19 | 2.80 |

| No. | Target Fertilizer Rate (kg ha−1) | Improved Method | GA | MOEA-D-DE | |||

|---|---|---|---|---|---|---|---|

| Rotational Speed (r min−1) | Opening Length (mm) | Rotational Speed (r min−1) | Opening Length (mm) | Rotational Speed (r min−1) | Opening Length (mm) | ||

| 1 | 138.25 | 33.9 | 7.65 | 23.07 | 9.33 | 25 | 8.79 |

| 2 | 239.78 | 40.92 | 9.22 | 40.64 | 13.56 | 45 | 15.09 |

| 3 | 342.92 | 59.75 | 10.33 | 59.57 | 12.9 | 63.73 | 10.25 |

| 4 | 437.95 | 78.82 | 9.91 | 92.57 | 17.32 | 79.18 | 9.75 |

| 5 | 522.77 | 92.61 | 14.38 | 108.29 | 18.59 | 95.01 | 9.21 |

| 6 | 600.24 | 104.54 | 17.79 | 114.53 | 9.47 | 106.36 | 15.5 |

| 7 | 700.75 | 123.18 | 18.78 | 133.34 | 11.79 | 125.01 | 16.96 |

| 8 | 757.91 | 138.5 | 17.55 | 148.42 | 18.29 | 135.01 | 16.90 |

| Algorithms | HV1 | HV2 | HV3 | HV4 | HV5 | Mean HV |

|---|---|---|---|---|---|---|

| NSGA-III | 0.2024 | 0.2381 | 0.1905 | 0.1986 | 0.1667 | 0.1993 |

| MOEA-D | 0.1824 | 0.2156 | 0.1852 | 0.1914 | 0.1629 | 0.1937 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dang, Y.; Ma, H.; Wang, J.; Zhou, Z.; Xu, Z. An Improved Multi-Objective Optimization Decision Method Using NSGA-III for a Bivariate Precision Fertilizer Applicator. Agriculture 2022, 12, 1492. https://doi.org/10.3390/agriculture12091492

Dang Y, Ma H, Wang J, Zhou Z, Xu Z. An Improved Multi-Objective Optimization Decision Method Using NSGA-III for a Bivariate Precision Fertilizer Applicator. Agriculture. 2022; 12(9):1492. https://doi.org/10.3390/agriculture12091492

Chicago/Turabian StyleDang, Yugong, Hongen Ma, Jun Wang, Zhigang Zhou, and Zhidong Xu. 2022. "An Improved Multi-Objective Optimization Decision Method Using NSGA-III for a Bivariate Precision Fertilizer Applicator" Agriculture 12, no. 9: 1492. https://doi.org/10.3390/agriculture12091492

APA StyleDang, Y., Ma, H., Wang, J., Zhou, Z., & Xu, Z. (2022). An Improved Multi-Objective Optimization Decision Method Using NSGA-III for a Bivariate Precision Fertilizer Applicator. Agriculture, 12(9), 1492. https://doi.org/10.3390/agriculture12091492