Research Progress and Analysis on Comprehensive Utilization of Livestock and Poultry Biogas Slurry as Agricultural Resources

Abstract

:1. Introduction

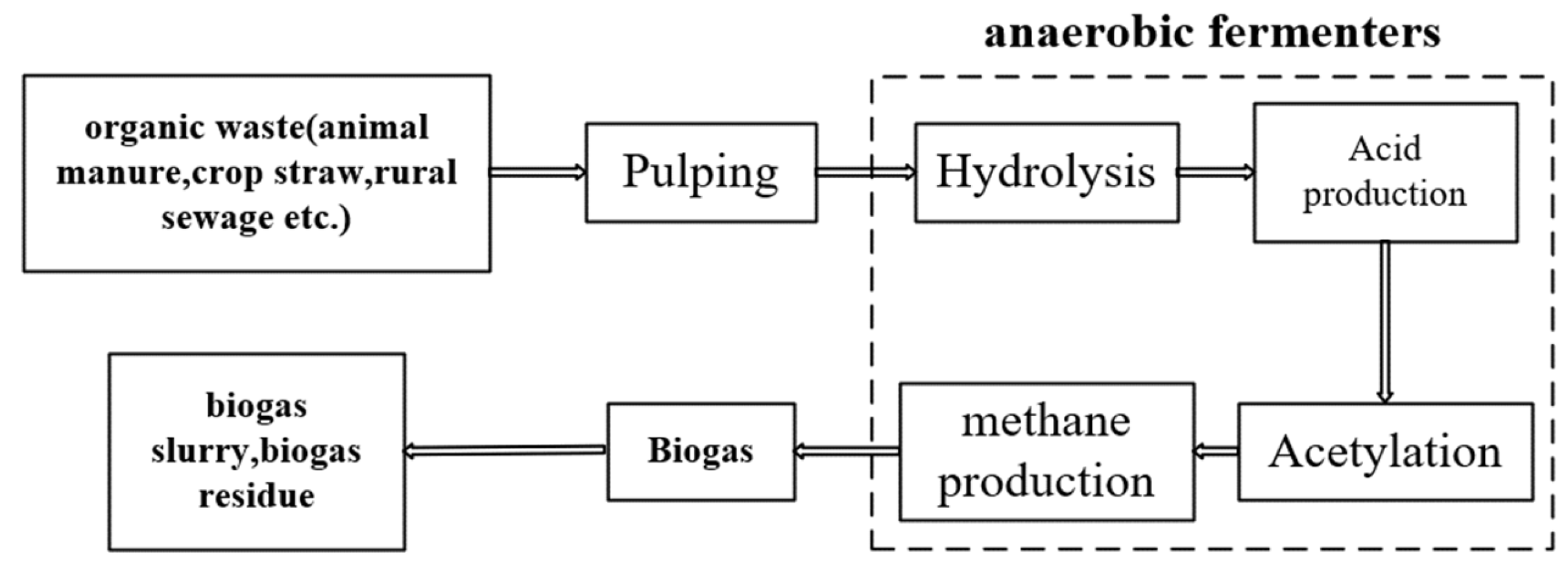

2. Production, Composition Analysis, and Filtration of Biogas Slurry

3. Agricultural Application of Biogas Slurry

3.1. The Impact on Crops

3.2. The Impact on Soil

3.3. The Impact on the Environment

4. Discussion

4.1. Irrigation Technology

4.2. Equipment

Environmental Risks

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.J. Analysis of the current situation of agriculture in China. Mod. Agric. Res. 2019, 11, 33–34. (In Chinese) [Google Scholar]

- Miyakita, T.; Ueda, A.; Futatsuka, M.; Inaoka, T.; Nagano, M.; Koyama, W. Noise exposure and hearing conservation for farmers of rural Japanese communities. J. Sound Vib. 2004, 277, 633–641. [Google Scholar]

- Li, Y.D. The experience and enlightenment of modern agricultural development in the Netherlands. Anhui Agric. Sci. Bull. 2009, 15, 34–36. (In Chinese) [Google Scholar]

- Zhang, K.; Li, X.; Zheng, D.; Zhang, L.; Zhu, G.F. Estimation of Global Irrigation Water Use by the Integration of Multiple Satellite Observations. Water Resour. Res. 2022, 58, 1029. [Google Scholar]

- Han, S.; Tian, F.; Gao, L. Current status and recent trend of irrigation water use in China. Irrig. Drain. 2020, 69, 25–35. [Google Scholar]

- Wang, H.X.; Liu, C.M.; Zhang, L. Water-saving agriculture in China: An overview. Adv. Agron. 2002, 75, 135–171. [Google Scholar]

- Scanlon, B.R.; Faunt, C.C.; Longuevergne, L.; Reedy, R.C.; Alley, W.M.; McGuire, V.L.; McMahon, P.B. Groundwater depletion and sustainability of irrigation in the US High Plains and Central Valley. Proc. Natl. Acad. Sci. USA 2012, 109, 9320–9325. [Google Scholar] [CrossRef]

- Molieleng, L.; Fourie, P.; Nwafor, I. Adoption of Climate Smart Agriculture by Communal Livestock Farmers in South Africa. Sustainability 2021, 13, 10468. [Google Scholar] [CrossRef]

- Sultan, B.; Gaetani, M. Agriculture in West Africa in the Twenty-First Century: Climate Change and Impacts Scenarios, and Potential for Adaptation. Front. Plant Sci. 2016, 7, 1262. [Google Scholar]

- Chen, J. Research on Sustainable Agricultural Development and Ecological Economic System Construction. Ph.D. Thesis, Xinjiang University, Xinjiang, China, 2008. (In Chinese). [Google Scholar]

- Shaibur, M.R.; Husain, H.; Arpon, S.H. Utilization of cow dung residues of biogas plant for sustainable development of a rural community. Curr. Res. Environ. Sustain. 2021, 3, 100026. [Google Scholar] [CrossRef]

- Bedana, D.; Kamruzzaman, M.; Rana, M.J.; Mustafi, B.A.A.; Talukder, R.K. Financial and functionality analysis of a biogas plant in Bangladesh. Heliyon 2022, 8, e10727. [Google Scholar] [CrossRef]

- Inban, G.; George, A.T.; Roula, I.L. Financial and economic appraisal of a biogas to electricity project. J. Clean. Prod. 2019, 214, 154–165. [Google Scholar]

- Munir, A.; Gul, J. Biogas technology adoption and household welfare perspectives for sustainable development. Energy Policy 2023, 181, 113728. [Google Scholar]

- Dagnall, S.P.; Hill, J.S.; Pegg, D.R. Resource mapping and analysis of farm livestock manures—Assessing the opportunities for biomass-to-energy schemes. Bioresour. Technol. 2000, 71, 225–234. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Duan, N.; Tsapekos, P.; Awasthi, M.K.; Liu, Z.; Mohammadi, A.; Angelidaki, I.; Tsang, D.C.W.; Zhang, Z.; Pan, J.; et al. A critical review on livestock manure biorefinery technologies: Sustainability, challenges, and future perspectives. Renew. Sustain. Energy Rev. 2021, 135, 110033. [Google Scholar] [CrossRef]

- Long, L.; Xu, F.Q.; Ge, X.M.; Li, Y.B. Improving the sustainability of organic waste management practices in the food-energy-water nexus: A comparative review of anaerobic digestion and composting. Renew. Sustain. Energy Rev. 2018, 89, 151–167. [Google Scholar]

- Xue, S.R.; Song, J.H.; Wang, X.J.; Shang, Z.Z.; Sheng, C.J.; Li, C.Y.; Zhu, Y.F.; Liu, J.Y. A systematic comparison of biogas development and related policies between China and Europe and corresponding insights. Renew. Sustain. Energy Rev. 2020, 117, 109474. [Google Scholar] [CrossRef]

- Raven, R.; Gregersen, K.H. Biogas plants in Denmark: Successes and setbacks. Renew. Sustain. Energy Rev. 2007, 11, 116–132. [Google Scholar] [CrossRef]

- Nielsen, M.E.B. Identifying Challenges and Drivers for Deployment of Centralized Biogas Plants in Denmark. Sustainability 2022, 14, 8021. [Google Scholar] [CrossRef]

- Henrik, B.L.; Sigurd, S.V. The influence of Industry 4.0 narratives on regional path development. Reg. Stud. Reg. Sci. 2022, 9, 82–92. [Google Scholar]

- Awasthi, M.K.; Sarsaiya, S.; Wainaina, S.T.; Rajendran, K.; Kumar, S.; Wang, Q.; Duan, Y.M.; Awasthi, S.; Pandey, A.; Chen, H.Y.; et al. A critical review of organic manure biorefinery models toward sustainable circular bioeconomy: Technological challenges, advancements, innovations, and future perspectives. Renew. Sustain. Energy Rev. 2019, 111, 115–131. [Google Scholar] [CrossRef]

- Roopnarain, A.; Rasheed, A.A. Current status, hurdles and future prospects of biogas digestion technology in Africa. Renew. Sustain. Energy Rev. 2017, 67, 1162–1179. [Google Scholar] [CrossRef]

- Halder, P.; Paul, N.; Joardder, M.U.H.; Khan, M.Z.H.; Sarker, M. Feasibility analysis of implementing anaerobic digestion as a potential energy source in Bangladesh. Renew. Sustain. Energy Rev. 2016, 65, 124–134. [Google Scholar] [CrossRef]

- Arshad, M.; Ansari, A.R.; Qadir, R.; Tahir, M.H.; Nadeem, A.; Mehmood, T.; Alhumade, H.; Khan, N. Green electricity generation from biogas of cattle manure: An assessment of potential and feasibility in Pakistan. Front. Energy Res. 2022, 10, 911485. [Google Scholar] [CrossRef]

- Pandey, P.; Pandey, A.; Yan, L.; Wang, D.; Pandey, V.; Meikap, B.C.; Huo, J.; Zhang, R.; Pandey, P.K. Dairy Waste and Potential of Small-Scale Biogas Digester for Rural Energy in India. Appl. Sci. 2021, 11, 10671. [Google Scholar] [CrossRef]

- Raheman, H. A mathematical model for fixed dome type biogas plant. Energy 2002, 27, 25–34. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, N.; Baredar, P.V.; Shukla, A. A review on biomass energy resources, potential, conversion and policy in India. Renew. Sustain. Energy Rev. 2015, 45, 530–539. [Google Scholar] [CrossRef]

- Khondoker, A.M.; Dil, B.R. Biogas adoption and elucidating its impacts in India: Implications for policy. Biomass Bioenergy 2019, 123, 166–174. [Google Scholar]

- Shivika, M.; Erik, O.A.; Shukla, P.R. Future biogas resource potential in India: A bottom-up analysis. Renew. Energy 2019, 141, 379–389. [Google Scholar]

- Tao, P.L.; Zhang, W.W.; Song, H.C.; Xiong, Z.W.; Wei, X.X. Current situation and development trend of comprehensive utilization of biogas fermentation. Energy Eng. 2001, 5, 9–11. (In Chinese) [Google Scholar]

- Hu, Z.P.; Hu, S.T. Pig-swamp-fruit “ecological agriculture model”. J. Nat. Resour. 2006, 4, 638–644. (In Chinese) [Google Scholar]

- Chen, Y.; Hu, W.; Feng, Y.; Sweeney, S. Status and prospects of rural biogas development in China. Renew. Sustain. Energy Rev. 2014, 39, 679–685. [Google Scholar] [CrossRef]

- Dong, Y.W.; Liang, D.; Li, D.Y.; Jin, H.M. Analysis of main nutrient content characteristics of biogas liquor. Jiangsu J. Agric. Sci. 2021, 5, 1206–1214. (In Chinese) [Google Scholar]

- Wang, J.H. Research on Biogas Fermentation Ecosystem and Comprehensive Utilization Technology of Residues. Master’s Thesis, China Agricultural University, Beijing, China, 2005. (In Chinese). [Google Scholar]

- Yang, Y.K. Development and Application of Integrated Device for Agricultural Gas-Fertilizer Co-Production and Fertilization of Residual Biogas Slurry. Master’s Thesis, Dalian University of Technology, Dalian, China, 2021. (In Chinese). [Google Scholar]

- Benginur, B.; Günnur, K. A review of the biogas digestate in agricultural framework. J. Mater. Cycles Waste Manag. 2020, 22, 1318–1327. [Google Scholar]

- Johnathon, P.S.; Yang, L.C.; Ge, X.M.; Wang, Z.W.; Li, Y.B. Beyond land application: Emerging technologies for the treatment and reuse of anaerobically digested agricultural and food waste. Waste Manag. 2015, 44, 94–115. [Google Scholar]

- Huang, H.Z. Research on the Analysis of Nutrients and Pollutants in Biogas Fertilizer. Fujian J. Agric. 2010, 1, 86–89. (In Chinese) [Google Scholar]

- Dong, Y.W.; Liang, D.; Li, D.Y.; Jin, H.M. Analysis of the Characteristics of Major Nutrient Contents in Biogas Slurry. Jiangsu Agric. Sci. 2021, 5, 1206–1214. (In Chinese) [Google Scholar]

- Stefaan, D.N.; Sleutel, S.; Hofman, G. Carbon mineralization from composts and food industry wastes added to soil. Nutr. Cycl. Agroecosystems 2003, 67, 13–20. [Google Scholar]

- Arunrat, N.; Sereenonchai, S.; Chaowiwat, W.; Wang, C.; Hatano, R. Carbon, Nitrogen and Water Footprints of Organic Rice and Conventional Rice Production over 4 Years of Cultivation: A Case Study in the Lower North of Thailand. Agronomy 2022, 12, 380. [Google Scholar] [CrossRef]

- Holka, M.; Kowalska, J.; Jakubowska, M. Reducing Carbon Footprint of Agriculture—Can Organic Farming Help to Mitigate Climate Change? Agriculture 2022, 12, 1383. [Google Scholar] [CrossRef]

- Leytem, A.; Bjorneberg, D. Changes in Soil Test Phosphorus and Phosphorus in Runoff from Calcareous Soils Receiving Manure, Compost, and Fertilizer Application with and without Alum. Soil Sci. 2009, 174, 445–455. [Google Scholar] [CrossRef]

- Möller, K.; Müller, T. Effects of anaerobic digestion on digestate nutrient availability and crop growth: A review. Eng. Life Sci. 2012, 12, 242–257. [Google Scholar] [CrossRef]

- Song, C.F.; Shan, S.D.; Zhang, M.X.; Wen, X.H. Concentration and composition of livestock and poultry breeding waste biogas slurry. Trans. Chin. Soc. Agric. Eng. 2010, 12, 256–259. (In Chinese) [Google Scholar]

- Ni, Z.Y.; Zhang, M.K. Chemical composition and bioavailability evaluation of nitrogen, phosphorus and potassium in biogas slurry. Chin. J. Soil Sci. 2017, 5, 1114–1118. (In Chinese) [Google Scholar]

- Shen, Q.; Shan, S.D.; Zhou, J.J.; Wang, Z.R. Determination and analysis of composition of pig manure fermented biogas slurry. China Biogas 2014, 32, 83–86. (In Chinese) [Google Scholar]

- Paula, A.; Clarisse, M.; Márcia, F.; Teresa, S.; Patrícia, P.; Joana, S.; Marie, C.M.; Cristina, C.Q. Sewage sludge, compost and other representative organic wastes as agricultural soil amendments: Benefits versus limiting factors. Waste Manag. 2015, 40, 44–52. [Google Scholar]

- Cao, R.K.; Chen, H.; Zhao, Y.Z. Current situation and new technology prospects for the utilization of biogas slurry resources. China Biogas 2015, 33, 42–50. (In Chinese) [Google Scholar]

- Liu, Y.; Dong, L.H.; Chen, X.F.; Liu, J.; Luo, X.; Cao, X.L.; Wu, L.F.; Wan, L.P. Design and analysis of biogas slurry micro-irrigation system based on graded filtration. J. Agric. Mech. Res. 2023, 45, 254–258. (In Chinese) [Google Scholar]

- Liang, K.Q.; Zhu, M.; Lin, X.J.; Sun, Y. Experimental study on pretreatment of biogas slurry by reverse osmosis concentration. China Biogas 2013, 31, 8–10+20. (In Chinese) [Google Scholar]

- Zhang, Z.Y.; Li, G.X.; Yuan, J.; Sun, Q.P.; Luo, Y.; Zhang, D.F. Filtration effect of corn straw filter material on fermented biogas slurry from pig manure. Chin. J. Environ. Eng. 2016, 10, 1985–1992. (In Chinese) [Google Scholar]

- Song, C.H. Study on Disposal of Anaerobic Digestion Residues. Ph.D. Thesis, Huazhong University of Science and Technology, Wuhan, China, 2007. (In Chinese). [Google Scholar]

- Fu, F.L.; Wang, Q. Removal of heavy metal ions from wastewaters: A review. J. Environ. Manag. 2011, 92, 407–418. [Google Scholar] [CrossRef]

- Shan, D.N.; Deng, S.B.; Zhao, T.N.; Wang, B.; Wang, Y.J.; Huang, L.; Yu, G.; Judy, W.; Mark, R.W. Preparation of ultrafine magnetic biochar and activated carbon for pharmaceutical adsorption and subsequent degradation by ball milling. J. Hazard. Mater. 2016, 305, 156–163. [Google Scholar] [CrossRef]

- Li, P.; Ma, D.; Guo, X.; Zhang, C.J.; Wang, X.; Li, Y.M.; Zhao, T.K. Study on filter material selection and suspended solids filtration pretreatment based on phosphorus retention in biogas slurry C. In Proceedings of the Environmental Engineering Technology Innovation and Application Sub-Forum of the 2019 Annual Conference of the Chinese Society of Environmental Science (Volume III), Xi’an, China, 24 August 2019; pp. 323–329+379. (In Chinese). [Google Scholar]

- Jiang, N.; Shang, R.; Heijman, S.G.J.; Rietveld, L.C. High-silica zeolites for adsorption of organic micro-pollutants in water treatment: A review. Water Res. 2010, 144, 145–161. [Google Scholar] [CrossRef] [PubMed]

- Wang, L. Study on Chemical Coagulation, Electrocoagulation-Nanofiltration Membrane Concentration Process for Pig Farm Biogas Slurry. Ph.D. Thesis, Zhejiang University, Zhejiang, China, 2016. (In Chinese). [Google Scholar]

- Chai, S.L.; John, R.; Mei, F.C. A review on application of flocculants in wastewater treatment. Process Saf. Environ. Prot. 2014, 92, 489–508. [Google Scholar]

- Wei, H.; Gao, B.; Ren, J.; Li, A.; Yang, H. Coagulation, flocculation in dewatering of sludge: A review. Water Res. 2018, 15, 608–631. [Google Scholar] [CrossRef] [PubMed]

- Alazaiza, M.Y.D.; Albahnasawi, A.; Ali, G.A.M.; Bashir, M.J.K.; Nassani, D.E.; Al Maskari, T.; Amr, S.S.A.; Abujazar, M.S.S. Application of Natural Coagulants for Pharmaceutical Removal from Water and Wastewater: A Review. Water 2022, 14, 140. [Google Scholar] [CrossRef]

- Khai, E.L.; Norhashimah, M.; Tjoon, T.T.; Beng, T.P. Development, characterization and the application of hybrid materials in coagulation, flocculation of wastewater: A review. Chem. Eng. J. 2012, 203, 370–386. [Google Scholar]

- Zhang, F.Z.; Yang, B.; Zhang, H.; Zhao, X.X.; Liu, J.H. Research progress on wastewater treatment by electrocoagulation. Ind. Water Treat. 2012, 32, 11–16. (In Chinese) [Google Scholar]

- Qasem, N.A.A.; Mohammed, R.H.; Lawal, D.U. Removal of heavy metal ions from wastewater: A comprehensive and critical review. NPJ Clean Water 2021, 4, 36. [Google Scholar] [CrossRef]

- Sergi, G.S.; Maria, M.S.G.E.; Jailson, V.D.M.; Carlos, A.M.H. Electrocoagulation and advanced electrocoagulation processes: A general review about the fundamentals, emerging applications and its association with other technologies. J. Electroanal. Chem. 2017, 801, 267–299. [Google Scholar]

- Bazrafshan, E.; Mohammadi, L.; Ansari, M.A.; Mahvi, A.H. Heavy metals removal from aqueous environments by electrocoagulation process- a systematic review. J. Environ. Health Sci. Eng. 2015, 26, 74. [Google Scholar] [CrossRef] [PubMed]

- Lü, L. Effects of Pig Manure Biogas Slurry Irrigation on Soil Quality and Growth of Four Vegetable Crops. Ph.D. Thesis, Yangzhou University, Yangzhou, China, 2022. (In Chinese). [Google Scholar]

- Yang, J.; Xu, X. Effects of applying biogas slurry on lettuce yield and soil quality. China Biogas 2013, 31, 51–54. (In Chinese) [Google Scholar]

- Xu, W.H.; Wang, Z.Y.; Quan, Y.M.; Ouyang, J.; Chen, C.F. Effect of biogas slurry on nitrate content and nutrient quality of lettuce and spinach. Rural. Ecol. Environ. 2003, 19, 34–37. (In Chinese) [Google Scholar]

- Tshikalange, B.; Ololade, O.; Jonas, C.; Bello, Z.A. Effectiveness of cattle dung biogas digestate on spinach growth and nutrient uptake. Heliyon 2022, 8, e09195. [Google Scholar] [CrossRef]

- Zheng, J.; Qi, X.Y.; Yang, S.H.; Shi, C.; Feng, Z.J. Effects and evaluation of biogas slurry, water integrated irrigation technology on the growth, yield and quality of tomatoes. Int. J. Agric. Biol. Eng. 2022, 15, 123–131. [Google Scholar] [CrossRef]

- Jothi, G.; Pugalendhi, S.; Poornima, K.; Rajendran, G. Management of root-knot nematode in tomato Lycopersicon esculentum, Mill, with biogas slurry. Bioresour. Technol. 2003, 89, 169–170. [Google Scholar] [CrossRef]

- Zhang, L.D.; Zhou, C.J.; He, G.L. Experimental study on the effect of biogas slurry in controlling citrus mites and aphids. Chin. Trop. Agric. 2010, 01, 63–64. (In Chinese) [Google Scholar]

- Cao, Y.; Wang, J.D.; Wu, H.S.; Yan, S.H.; Guo, D.J.; Wang, G.F.; Ma, Y. Soil chemical and microbial responses to biogas slurry amendment and its effect on Fusarium wilt suppression. Appl. Soil Ecol. 2016, 107, 116–123. [Google Scholar] [CrossRef]

- Li, N.; Chang, R.; Chen, S.; Lei, J.; Liu, Y.; Cui, W.; Chen, Q.; Wu, F. The role of the biogas slurry microbial communities in suppressing fusarium wilt of cucumber. Waste Manag. 2022, 151, 142–153. [Google Scholar] [CrossRef]

- Yu, F.; Li, X.; Ali, S.W.; Song, C.F.; Shan, S.; Luo, L. Use of Biogas Slurry for Enhancing Control of Phytopathogens. Pol. J. Environ. Stud. 2014, 23, 533–540. [Google Scholar]

- Barzee, T.; Edalati, A.; El-Mashad, H.M.; Wang, D.Y.; Scow, K.; Zhang, R.H. Digestate Biofertilizers Support Similar or Higher Tomato Yields and Quality Than Mineral Fertilizer in a Subsurface Drip Fertigation System. Front. Sustain. Food Syst. 2019, 3, 3389. [Google Scholar] [CrossRef]

- Liu, J.; Li, S.L.; Xia, Y.Z.; Sun, Z.Q. Effects of application mode and concentration of biogas liquor on the growth and quality of Chinese cabbage. J. Fujian Agric. For. Univ. 2014, 43, 80–84. [Google Scholar]

- Arunrat, N.; Sereenonchai, S.; Wang, C. Carbon footprint and predicting the impact of climate change on carbon sequestration ecosystem services of organic rice farming and conventional rice farming: A case study in Phichit province, Thailand. J. Environ. Manag. 2021, 289, 112458. [Google Scholar] [CrossRef] [PubMed]

- Haque, M.M.; Datta, J.; Ahmed, T.; Ehsanullah, M.; Karim, M.N.; Akter, M.S.; Iqbal, M.A.; Baazeem, A.; Hadifa, A.; Ahmed, S.; et al. Organic Amendments Boost Soil Fertility and Rice Productivity and Reduce Methane Emissions from Paddy Fields under Sub-Tropical Conditions. Sustainability 2021, 13, 3103. [Google Scholar] [CrossRef]

- Li, W.Y.; Dong, C.H. Research and benefit evaluation of application of biogas slurry in maize and rice production. Soil Science and Ecological Civilization (Volume 2). In Proceedings of the 13th National Congress of the Chinese Soil Society and the 11th Cross-Strait Soil Fertilizer Academic Exchange Symposium, Xi’an, China, 21–21 September 2016; pp. 231–236. (In Chinese). [Google Scholar]

- Tang, W.; Wu, J.; Sun, B.Y.; Yang, G.; Yang, Q. Effects of different application rates of biogas slurry on rice yield and quality. J. Agro-Environ. Sci. 2010, 29, 2268–2273. (In Chinese) [Google Scholar]

- Wu, H.S.; Guo, D.J.; Ma, Y.; Chang, Z.Z. Effects of pig manure biogas slurry application on soil ammonia volatilization, maize yield and quality. Chin. J. Eco-Agric. 2012, 20, 163–168. (In Chinese) [Google Scholar] [CrossRef]

- Muhmood, A.; Javid, S.; Ahmad, Z.A.; Majeed, A.; Rafique, R.A. Integrated use of bioslurry and chemical fertilizers for vegetable production. Pak. J. Agric. Sci. 2014, 51, 563–568. [Google Scholar]

- Huang, X.G.; Lin, D.Y.; Song, Y.K.; Ye, M.F. Study on the effect of biogas slurry irrigation on maize yield. China Biogas 2015, 33, 94–95. (In Chinese) [Google Scholar]

- Huang, H.Y.; Cao, J.L.; Chang, Z.Z.; Cao, Y. Effects of Application of Pig Manure Biogas Slurry on Yield and Nitrogen and Phosphorus Uptake of Rice and Wheat. Soil 2013, 45, 412–418. (In Chinese) [Google Scholar]

- Chen, Y.X.; Dong, H.M.; Tao, X.P.; Shang, B. Effect of biogas slurry irrigation of winter wheat on soil quality in pig farm. Chin. Agric. Sci. Bull. 2011, 27, 154–158. (In Chinese) [Google Scholar]

- Zheng, J.; Wang, Y.; Cai, H.J.; Wan, J.X.; Li, Z.J. Effects of different slurry irrigation methods on physiological indexes and soil nitrate content of maize. China Biogas 2014, 32, 62–66. (In Chinese) [Google Scholar]

- Wentzel, S.; Schmidt, R.; Piepho, H.; Semmler-Busch, U.; Joergensen, R.G. Response of soil fertility indices to long-term application of biogas and raw slurry under organic farming. Appl. Soil Ecol. 2015, 96, 99–107. [Google Scholar] [CrossRef]

- Thomas, T.U.; Edwin, S.; Markus, R.; Bernard, L.; Raine, G.J. CO2 evolution and N mineralization after biogas slurry application in the field and its yield effects on spring barley. Appl. Soil Ecol. 2009, 3, 297–302. [Google Scholar]

- Bian, B.; Zhou, L.J.; Li, L. Risk assessment of heavy metals in air, water, vegetables, grains, and related soils irrigated with biogas slurry in Taihu Basin. China. Environ. Sci. Pollut. Res. 2015, 22, 7794–7807. (In Chinese) [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Zhao, Z.; Xue, Z.; Li, D.; Wen, Z.; Ran, Y.; Mei, Z.; He, L. Comprehensive Risk Assessment of Applying Biogas Slurry in Peanut Cultivation. Front. Nutr. 2021, 8, 702096. [Google Scholar] [CrossRef]

- Cycoń, M.; Mrozik, A.; Piotrowska-Seget, Z. Antibiotics in the Soil Environment-Degradation and Their Impact on Microbial Activity and Diversity. Front. Microbiol. 2019, 10, 338. [Google Scholar] [CrossRef]

- Arunrat, N.; Kongsurakan, P.; Sereenonchai, S.; Hatano, R. Soil Organic Carbon in Sandy Paddy Fields of Northeast Thailand: A Review. Agronomy 2020, 10, 1061. [Google Scholar] [CrossRef]

- Huang, X.S.; Huang, Q.L.; Weng, B.Q.; Feng, D.Q.; Chen, Z.D.; Zhong, Z.M. Effects of different nitrogen levels of biogas slurry on the yield, quality, nitrogen utilization efficiency and distribution of nitrate nitrogen in soil profile of Pennisetum sinese Roxb. J. Agro-Environ. Sci. 2014, 33, 1652–1658. (In Chinese) [Google Scholar]

- Zeng, W.S.; Qiu, J.R.; Wang, D.H.; Wu, Z.Y.; He, L.T. Ultrafiltration concentrated biogas slurry can reduce the organic pollution of groundwater in fertigation. Sci. Total Environ. 2022, 810, 151294. [Google Scholar] [CrossRef]

- Möller, K.; Stinner, W.; Deuker, A. Effects of different manuring systems with and without biogas digestion on nitrogen cycle and crop yield in mixed organic dairy farming systems. Nutr. Cycl. Agroecosystems 2008, 82, 209–232. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y.; Shi, P.; Bi, Z.L.; Shan, Z.; Ren, L.J. The deep challenge of nitrate pollution in river water of China. Sci. Total Environ. 2020, 770, 144674. [Google Scholar] [CrossRef] [PubMed]

- Kazunori, M.; Khanh, C.H.; Kenichi, U.; Nam, S.T.; Chiem, H.N. Cattle biogas effluent application with multiple drainage mitigates methane and nitrous oxide emissions from a lowland rice paddy in the Mekong Delta, Vietnam. Agric. Ecosyst. Environ. 2021, 319, 107568. [Google Scholar]

| Aerobic Fermentation | Anaerobic Fermentation | ||||||

|---|---|---|---|---|---|---|---|

| Fermentation Method | Windrow Composting | Static Composting | Grooved Composting | Reactor Composting | USAB | USR | CSTR |

| Scope of application | Small and medium farms | Small and medium farms | Medium and large farms | Highly automated small and medium farms | Large- and medium-sized biogas digesters in warmer climates | Large- and medium-sized biogas digesters in warmer climates | Wide range of applications |

| Advantages | Manual or mechanical regular turning, simple operation, and low cost | Mechanical ventilation, simple operation, and low costs | Mechanical ventilation, simple operation, low cost, and short fermentation period | Insulation and energy-saving, easy odor control, and short fermentation cycle | Capable of handling high COD loads with a removal rate of over 90% | Suitable for processing high-solids and suspended solid materials, high gas production efficiency | Wide adaptability to feedstock, uniform temperature distribution inside the digester, and high gas |

| Disadvantages | Additional additives, prone to climate impact, and long fermentation period | Additional additives, prone to climate impact, and long fermentation period | Additional additives, multiple equipment requirements, and complex operations | Small individual processing capacity, higher cost | Poor impact resistance, suspended solid content needs to be controlled below 100 mg/L | The anaerobic digestion generates high levels of COD in the effluent | High construction costs, large volume digestion tanks, and long processing time |

| Fermented Raw Materials | ||||

|---|---|---|---|---|

| Pig Manure | Cow Manure | |||

| Before Fermentation | After Fermentation | Before Fermentation | After Fermentation | |

| NH4+ (mg/L) | 517 | 580 | 414 | 160 |

| NO3− (mg/L) | 310 | 62 | 310 | 31 |

| Soluble phosphorus (%) | 22.4 | 1.35 ± 0.03 | 20.7 | 3.52 ± 0.26 |

| Total Cu (mg/L) | 3.5 ± 0.1 | 0.7 ± 0.04 | 2.13 ± 0.3 | 1.9 ± 0.1 |

| Non-Concentrated Biogas Slurry Fertilizer | PH | Water-Insoluble Matter (mg, L) | The Death Rate of Ascaris Eggs, % | Total Arsenic (mg, L) | Total Chromium (Calculated as Hexavalent, (mg, L) | Total Cadmium (mg, L) | Total Lead (mg, L) | Total Mercury (mg, L) |

|---|---|---|---|---|---|---|---|---|

| Class Ⅰ | 5.5~8.5 | ≤50 | ≥95 | ≤0.3 | ≤1.3 | ≤0.04 | ≤1.2 | ≤0.4 |

| Class Ⅱ | 5.5~8.5 | ≤50 | ≥95 | ≤0.4 | ≤1.9 | ≤0.06 | ≤1.6 | ≤0.5 |

| Class Ⅲ | 5.5~8.5 | ≤50 | ≥95 | ≤10.0 | ≤50 | ≤3.0 | ≤50 | ≤5.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Zhang, Y.; Li, H. Research Progress and Analysis on Comprehensive Utilization of Livestock and Poultry Biogas Slurry as Agricultural Resources. Agriculture 2023, 13, 2216. https://doi.org/10.3390/agriculture13122216

Jiang Y, Zhang Y, Li H. Research Progress and Analysis on Comprehensive Utilization of Livestock and Poultry Biogas Slurry as Agricultural Resources. Agriculture. 2023; 13(12):2216. https://doi.org/10.3390/agriculture13122216

Chicago/Turabian StyleJiang, Yue, Yue Zhang, and Hong Li. 2023. "Research Progress and Analysis on Comprehensive Utilization of Livestock and Poultry Biogas Slurry as Agricultural Resources" Agriculture 13, no. 12: 2216. https://doi.org/10.3390/agriculture13122216