Design and Motion Process of Air-Sieve Castor Cleaning Device Based on Discrete Element Method

Abstract

:1. Introduction

2. Materials and Methods

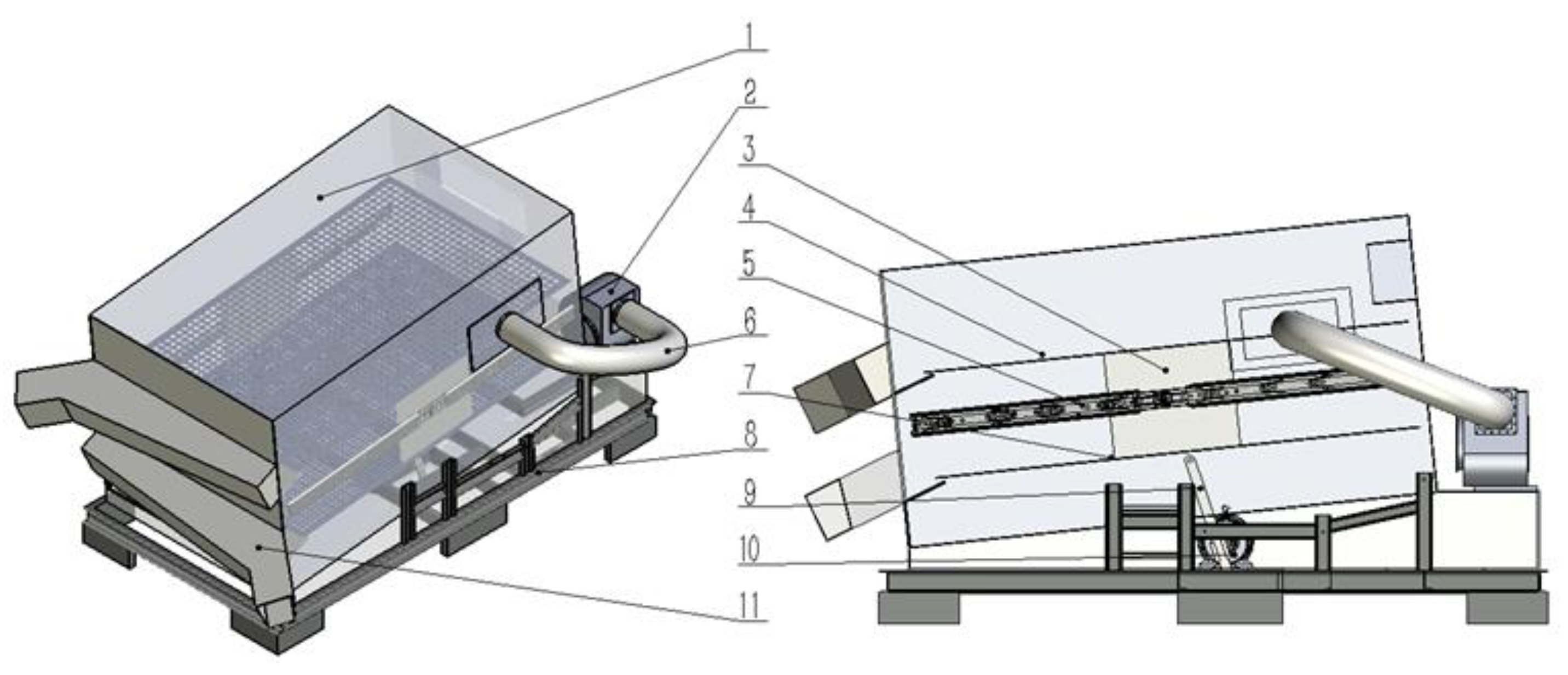

2.1. Cleaning Device and Working Principle

2.2. Design of Cleaning Device Parameters

2.2.1. Determination of Castor Parameters

- Content determination of castor shelling mixture

- 2.

- Determination of characteristic parameters of materials

- 3.

- Determination of friction coefficient and recovery coefficient

2.2.2. Design of Vibrating Sieve

2.2.3. Design of Cleaning Room

2.2.4. Design of Discharge Port

2.3. Material Movement Process of Cleaning

2.3.1. Movement Analysis of Materials without Airflow

2.3.2. Movement Analysis of Materials under the Action of Airflow

2.4. Optimization of Structural Parameters of the Cleaning Device

2.4.1. Modeling Castor Shelling Mixture

2.4.2. Cleaning Device Area Division

2.4.3. Setting before Simulation

2.4.4. Determination of Test Indicators

2.5. Optimization and Test of Operation Parameters in the Cleaning Process

2.5.1. Airflow Parameter Setting

2.5.2. Multi-Factor Experimental Design

- Test-level coding table

- 2.

- Test scheme design

2.5.3. Single Objective Parameter Optimization

2.5.4. Multi-Objective Parameter Optimization

2.5.5. Preparation of the Cleaning Test

3. Results and Discussion

3.1. The Results of Multivariate Experiments

3.1.1. Significance Analysis of Sieving Efficiency

3.1.2. Significance Analysis of Loss Rate

3.2. Optimization Results of the Cleaning Device Structural Parameters

3.2.1. Influence of Different Sieve Hole Arrangements on Cleaning Efficiency

- Analysis of cleaning effect

- 2.

- Distribution of the two-chambered castor capsule

- 3.

- Analysis of average velocity in the Z-axis direction

- 4.

- Analysis of average displacement

3.2.2. Influence of Different Sieve Hole Diameters on Cleaning Efficiency

- Analysis of cleaning effect

- 2.

- Distribution of the two-chambered castor capsule

- 3.

- Analysis of average velocity

- 4.

- Analysis of average displacement

3.2.3. Influence of Different Inclination Angles on Cleaning Efficiency

- Analysis of cleaning effect

- 2.

- Distribution of the two-chambered castor capsule

- 3.

- Analysis of average velocity

- 4.

- Analysis of average displacement

3.3. Optimization of Operating Parameters and Analysis of Test Results

4. Conclusions

- (1)

- The air-sieve-type cleaning device for castor shelling mixture is designed. The width of the cleaning sieve is determined to be 600 mm, and the length is determined to be 960 mm. The distance between the upper and lower vibrating sieves is 200 mm; the diameter of the upper sieve hole is 14 mm; and the diameter of the lower sieve hole is 8 mm.

- (2)

- The results of the single-factor simulations show that the sieving efficiency and the loss rate are 98.23% and 2.39%, respectively, for the square sieve hole arrangement. The sieving efficiencies for the triangular sieve hole arrangement are 96.70% and 96.71%, respectively. The sieving efficiency and the loss rate of the 14 mm sieve hole diameter are obtained, which are 98.23% and 2.39%, respectively. The sieving efficiency of 15 mm and 16 mm is 96.64% and 96.69%, respectively. The analysis of each sieve surface inclination shows that the sieving efficiency is between 94.0–99.5%, and the loss rate is between 0.5–3.0%. The optimal combination of structural parameters can be obtained as a square distribution of sieve holes, a 14 mm sieve hole diameter, and an 8° sieve surface inclination angle.

- (3)

- The parameter combinations of the maximum sieving efficiency, the minimum loss rate, and the optimal cleaning effect of the castor shelling mixture are obtained by parameter optimization, respectively. The three-parameter combinations are tested. The results show that the sieving efficiency of the first combination is 94.68%, with a loss rate of 7.13%. The sieving efficiency of the second combination is 95.21%, with a loss rate of 6.09%. The sieving efficiency of the third combination is 93.15%, with a loss rate of 6.94%. The impurity rate of the castor seed is less than 1%, which can meet the design requirements.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Pari, L.; Suardi, A.; Stefanoni, W.; Latterini, F.; Palmieri, N. Environmental and Economic Assessment of Castor Oil Supply Chain: A Case Study. Sustainability 2020, 12, 6339. [Google Scholar] [CrossRef]

- Yao, L.; Cao, Y.; Li, C.; Fang, Z. Dynamics Property of Air-and-Screen Cleaning Mechanism of Castor Hulling. J. Agric. Mech. Res. 2014, 36, 70–73. [Google Scholar] [CrossRef]

- Xu, L.; Li, Y.; Li, Y.; Chai, X.; Qiu, J. Research Progress on Cleaning Technology and Device of Grain Combine Harvester. Trans. Chin. Soc. Agric. Mach. 2019, 50, 1–16. [Google Scholar] [CrossRef]

- Gebrehiwot, M.G.; De Baerdemaeker, J.; Baelmans, M. Effect of a cross-flow opening on the performance of a centrifugal fan in a combine harvester: Computational and experimental study. Biosyst. Eng. 2010, 105, 247–256. [Google Scholar] [CrossRef]

- Yang, R.; Chen, D.; Zha, X.; Pan, Z.; Shang, S. Optimization Design and Experiment of Ear-Picking and Threshing Devices of Corn Plot Kernel Harvester. Agriculture 2021, 11, 904. [Google Scholar] [CrossRef]

- Wang, L.; Yu, Y.; Zhang, S.; Feng, X.; Song, L. Bionic design and performance test of maize grain cleaning screen through earthworm motion characteristics. Int. J. Agric. Biol. Eng. 2021, 14, 12–21. [Google Scholar] [CrossRef]

- Gao, Y.; Song, L.; Wang, L.; Wang, H.; Li, Y. Behavior of maize grains on the three-dimensional translational vibrating sieve. Powder Technol. 2022, 412, 117999. [Google Scholar] [CrossRef]

- Xiao, J.; Tong, X. Characteristics and efficiency of a new vibrating screen with a swing trace. Particuology 2013, 11, 601–606. [Google Scholar] [CrossRef]

- Li, Z.; Liang, J.; Jia, P.; Tong, X. Parameter optimization and mechanism research of double-layer variable screen surface vibrating screen. Part. Sci. Technol. 2022, in press. [Google Scholar] [CrossRef]

- Ma, Z.; Han, M.; Li, Y.; Gao, H.; Lu, E.; Chandio, F.A.; Ma, K. Motion of cereal particles on variable-amplitude sieve as determined by high-speed image analysis. Comput. Electron. Agric. 2020, 174, 105465. [Google Scholar] [CrossRef]

- Ma, Z.; Li, Y.; Xu, L. Discrete-element method simulation of agricultural particles’ motion in variable-amplitude screen box. Comput. Electron. Agric. 2015, 118, 92–99. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, Z.; Chen, N.; Chen, D. Numerical Simulation and Experiment of Airflow Field of Cleaning Room under Action of Conical Fan. Trans. Chin. Soc. Agric. Mach. 2019, 50, 91–100. [Google Scholar] [CrossRef]

- Xu, Z.; Li, Y.; Wan, L.; Ma, X.; Song, J.; Huang, J. Optimising the design of ball racks to improve the sorting efficiency of vibrating screen seed cleaners using discrete element method modeling and experiment. Biosyst. Eng. 2023, 225, 99–117. [Google Scholar] [CrossRef]

- Shen, G.; Chen, Z.; Wu, X.; Li, Z.; Tong, X. Stepwise shape optimization of the surface of a vibrating screen. Particuology 2021, 58, 26–34. [Google Scholar] [CrossRef]

- Li, H.; Wan, X.; Wang, H.; Jiang, Y.; Liao, Q. Design and Experiment on Integrated Longitudinal Axial Flow Threshing and Separating Device of Rape Combine Harvester. Trans. Chin. Soc. Agric. Mach. 2017, 48, 108–116. [Google Scholar] [CrossRef]

- Aldoshin, N.; Lylin, N. Improving the design of the grain combine harvester cleaner. Russ. Agric. Sci. 2018, 44, 108–111. [Google Scholar] [CrossRef]

- Wang, L.; Duan, L.; Zheng, Z.; Cui, Y.; Li, Y.; Zhao, H. Optimization and Experiment on Driving Mechanism of Vibrating Screen with Three Translations and Two Rotations. Trans. Chin. Soc. Agric. Mach. 2018, 49, 138–145. [Google Scholar] [CrossRef]

- Wan, X.; Liao, Q.; Xu, Y.; Yuan, J.; Li, H. Design and Evaluation of Cyclone Separation Cleaning Devices Using a Conical Sieve for Rape Combine Harvesters. Appl. Eng. Agric. 2018, 34, 677–686. [Google Scholar] [CrossRef]

- Wan, X.; Shu, C.; Xu, Y.; Yuan, J.; Li, H.; Liao, Q. Design and experiment on cylinder sieve with different rotational speed in cleaning system for rape combine harvesters. Trans. Chin. Soc. Agric. Eng. 2018, 34, 27–35. [Google Scholar] [CrossRef]

- Gao, L.; Zhao, X.; Yang, D.; Jiao, W.; Zhang, X.; Liu, D. Development and performance test on pneumatic cleaning-circulatory device of soybean thresher. Trans. Chin. Soc. Agric. Eng. 2013, 28, 22–27. [Google Scholar] [CrossRef]

- Fan, C.; Cui, T.; Zhang, D.; Yang, L.; Tian, C.; Zhong, X. Design and Experiment of Double-layered Reverse Cleaning Device for Axial Flow Combine Harvester. Trans. Chin. Soc. Agric. Mach. 2018, 49, 239–248. [Google Scholar] [CrossRef]

- Wang, Z.; Lü, P.; Chen, N.; Li, H.; Liu, Z.; Chen, D. Design and Experiment on Axial-flow Differential-speed Threshing-Separating-Cleaning Unit. Trans. Chin. Soc. Agric. Mach. 2016, 47, 53–61. [Google Scholar] [CrossRef]

- Liao, Q.; Xu, Y.; Yuan, J.; Wan, X.; Jiang, Y. Design and Experiment on Combined Cutting and Throwing Longitudinal Axial Flow Threshing and Separating Device of Rape Combine Harvester. Trans. Chin. Soc. Agric. Mach. 2019, 50, 140–150. [Google Scholar] [CrossRef]

- Tabatabaifar, A.; Persson, S. Layer Breakup and Particle Movement on a Chaffer Sieve. Trans. ASAE 1995, 38, 1305–1313. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Z.; Chen, J.; Xu, L. Nonlinear motion law of material on air-and-screen cleaning mechanism. Trans. Chin. Soc. Agric. Eng. 2007, 23, 142–147. [Google Scholar] [CrossRef]

- Wang, L.; Chai, J.; Wang, H.; Wang, Y. Design and performance of a countersunk screen in a maize cleaning device. Biosyst. Eng. 2021, 209, 300–314. [Google Scholar] [CrossRef]

- Li, Y.; Fan, H.; Xu, Y.; Cui, T.; Su, Y.; Qiao, M.; Han, S.; Qian, J.; Zheng, Z. CFD-DEM investigation of particle dispersion degree on a novel vibrating screen. Powder Technol. 2022, 404, 117497. [Google Scholar] [CrossRef]

- Du, W.; Huang, H.; Fan, Q. Application of ANSYS in the Flow Field in the Cleaning Device of a Rape’s Combine Harvester. J. Agric. Mech. Res. 2007, 10, 174–175. [Google Scholar] [CrossRef]

- Chu, K.; Wang, B.; Xu, D.; Chen, Y.; Yu, A. CFD–DEM simulation of the gas–solid flow in a cyclone separator. Chem. Eng. Sci. 2011, 66, 834–847. [Google Scholar] [CrossRef]

- Li, Y.; Xu, L.; Liang, Z. Simulation and Experiment of Airflow Field in Cleaning Device with Double Outlets and Four Ducts. J. Agric. Mech. Res. 2018, 40, 7–12. [Google Scholar] [CrossRef]

- Xu, L.; Yu, L.; Li, Y.; Ma, Z.; Wang, C. Numerical Simulation of Internal Flow Field in Centrifugal Fan with Double Outlet and Multi-duct. Trans. Chin. Soc. Agric. Mach. 2014, 45, 78–86. [Google Scholar] [CrossRef]

- Li, H.; Li, Y.; Tang, Z.; Xu, L. Numerical Simulation of Material Motion on Vibrating Screen of Air-and-screen Cleaning Device Based on CFD-DEM. Trans. Chin. Soc. Agric. Mach. 2012, 43, 79–84. [Google Scholar] [CrossRef]

- Jiang, E.; Sun, Z.; Pan, Z.; Wang, L. Numerical Simulation Based on CFD-DEM and Experiment of Grain Moving Laws in Inertia Separation Chamber. Trans. Chin. Soc. Agric. Mach. 2014, 45, 117–122. [Google Scholar] [CrossRef]

- Li, J.; Webb, C.; Pandiella, S.S.; Campbell, G.M. Discrete particle motion on sieves—A numerical study using the DEM simulation. Powder Technol. 2003, 133, 190–202. [Google Scholar] [CrossRef]

- Davoodi, A.; Bengtsson, M.; Hulthén, E.; Evertsson, C. Effects of screen decks’ aperture shapes and materials on screening efficiency. Miner. Eng. 2019, 139, 105699. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, C.; Yan, J. A virtual experiment showing single particle motion on a linearly vibrating screen-deck. Min. Sci. Technol. 2010, 20, 276–280. [Google Scholar] [CrossRef]

- Jiang, H.; Duan, C.; Wu, J.; Zhao, Y.; Liu, C.; Luo, Z.; Dong, L.; Zhang, B.; Wang, Z.; Zhang, C. Kinematics characteristics of the vibrating screen with rigid-flexible screen rod and the behavior of moist coal particles during the dry deep screening process. Powder Technol. 2017, 319, 92–101. [Google Scholar] [CrossRef]

- Feng, X.; Gong, Z.; Wang, L.; Yu, Y.; Liu, T.; Song, L. Behavior of maize particle penetrating a sieve hole based on the particle centroid in an air-screen cleaning unit. Powder Technol. 2021, 385, 501–516. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Xia, H.; Tong, X. Performance optimization of the elliptically vibrating screen with a hybrid MACO-GBDT algorithm. Particuology 2021, 56, 193–206. [Google Scholar] [CrossRef]

- Xia, X.; Gou, L.; Zhang, Z.; Wang, L.; Guo, Y.; Jing, W. Collaborative optimization of linear vibrating screen screening efficiency and dynamic response stability based on coupled DEM-MBK simulation. Particuology 2023, 78, 49–61. [Google Scholar] [CrossRef]

- Zhao, L.; Zhao, Y.; Liu, C.; Li, J.; Dong, H. Simulation of the screening process on a circularly vibrating screen using 3D-DEM. Min. Sci. Technol. 2011, 21, 677–680. [Google Scholar] [CrossRef]

- Zhao, L.; Zhao, Y.; Bao, C.; Hou, Q.; Yu, A. Optimisation of a circularly vibrating screen based on DEM simulation and Taguchi orthogonal experimental design. Powder Technol. 2017, 310, 307–317. [Google Scholar] [CrossRef]

- Qiao, J.; Duan, C.; Jiang, H.; Zhao, Y.; Chen, J.; Huang, L.; Wen, P.; Wu, J. Research on screening mechanism and parameters optimization of equal thickness screen with variable amplitude based on DEM simulation. Powder Technol. 2018, 331, 296–309. [Google Scholar] [CrossRef]

- Dong, K.; Esfandiary, A.H.; Yu, A. Discrete particle simulation of particle flow and separation on a vibrating screen: Effect of aperture shape. Powder Technol. 2017, 314, 195–202. [Google Scholar] [CrossRef]

- Dong, K.; Yu, A.; Brake, I. DEM simulation of particle flow on a multi-deck banana screen. Miner. Eng. 2009, 22, 910–920. [Google Scholar] [CrossRef]

- Dong, H.; Liu, C.; Zhao, Y.; Zhao, L. Influence of vibration mode on the screening process. Int. J. Min. Sci. Technol. 2013, 23, 95–98. [Google Scholar] [CrossRef]

| Material | Sieve Type | Cleaning Mode | Impurity Content/% | Cleaning Efficiency/% | Loss Rate/% | Reference |

|---|---|---|---|---|---|---|

| Rape | conical sieve | Airflow-Sieve rotation | 88.99% | 4.86% | [18] | |

| Rape | Cylinder sieve | Airflow-Sieve rotation | 84.4% | 5.9% | [19] | |

| Soybean | Single-layer vibrating sieve | Airflow-Sieve vibration | 0.70% | 0.30–0.32% | [20] | |

| Corn | Double-layer vibrating sieve | Airflow-Sieve vibration | 0.73% | 0.45% | [21] | |

| Rice | Double-layer vibrating sieve | Airflow-Sieve vibration | 0.38% | 1.57% | [22] | |

| Rape | Concave sieve | Airflow | 91.97% | 6.13% | [23] |

| Method | Study Target | Main Conclusion | References |

|---|---|---|---|

| EDEM Fluent | Cyclone separator | The strength of particle-wall interaction increases with the increase in the solid load ratio in the cyclone separator. | [29] |

| Fluent | Fish scale sieve | It is beneficial to improve the cleaning efficiency when the front and middle airflow velocity of the sieve reaches the maximum. | [30] |

| Fluent | Centrifugal fan | The airflow velocity of the upper outlet and the edge of the impeller is larger, and the pressure of the impeller channel increases gradually along the radial direction. | [31] |

| ANSYS | Air-sieve cleaning device | It is helpful to improve the cleaning effect of the material when the wind speed at the outlet of the fan increases within a certain range. | [32] |

| EDEM Fluent | The cleaning room of the seed harvester | The increase in gas velocity at the entrance of the cleaning room is helpful in improving the cleaning performance, but it will aggravate the gas turbulence at the rear of the cleaning room. | [33] |

| Study Target | Main Conclusion | References |

|---|---|---|

| Circular vibrating sieve plate | The sieving efficiency was highest when the vibration amplitude, throw index, and sieve angle were 3–3.5 mm, 2.7, and 15°, respectively. | [41,42] |

| Single-layer equal-thickness sieve | The factors affecting the sieving efficiency were ejection angle, inclination, amplitude, and center amplitude. | [43] |

| Single-layer vibrating sieve | The elongation of the sieve hole increases the percentage of material passing through the sieve. | [44] |

| Banana sieve | The sieving performance can be improved by reducing the vibration frequency and tilt angle. | [45] |

| Single-layer vibrating sieve | The sieving efficiency of circular vibration is the highest among linear, circular, and elliptical vibration modes. | [46] |

| Component | Length/mm | Width/mm | Height/mm |

|---|---|---|---|

| Castor seeds | 8.11 | 6.27 | 11.89 |

| Castor shells | 7.51 | 5.07 | 15.89 |

| Two-chambered castor capsule | 15.62 | 9.05 | 16.04 |

| Component | Quality/g | Suspension Velocity/m·s−1 | Poisson’s Ratio | Elastic Modulus /MPa | Density /kg·m−3 |

|---|---|---|---|---|---|

| Castor seeds | 0.31 | 7.46 | 0.25 | 42.56 | 1094.75 |

| Castor shells | 0.04 | 2.48 | 0.25 | 50.62 | 674.73 |

| Two-chambered castor capsule | 0.84 | 13.69 | 0.25 | 44 | 1021.32 |

| Category | Static Friction Coefficient | Dynamic Friction Coefficient | Collision Recovery Coefficient |

|---|---|---|---|

| Two-chambered castor capsule—Two-chambered castor capsule | 0.60 | 0.03 | 0.30 |

| Two-chambered castor capsule—Castor seeds | 0.60 | 0.03 | 0.20 |

| Two-chambered castor capsule—Castor shells | 0.67 | 0.04 | 0.17 |

| Two-chambered castor capsule—Q235 steel | 0.40 | 0.02 | 0.43 |

| Castor seeds—Castor seeds | 0.35 | 0.02 | 0.19 |

| Castor seeds—Castor shells | 0.63 | 0.03 | 0.24 |

| Castor seeds—Q235 steel | 0.31 | 0.01 | 0.52 |

| Castor shells—Castor shells | 0.74 | 0.05 | 0.25 |

| Castor shells—Q235 steel | 0.53 | 0.03 | 0.24 |

| Parameters | Numerical Value |

|---|---|

| Velocity Magnitude(m/s) | 14 |

| X-Component of Flow Direction (m) | 0.60403 |

| Y-Component of Flow Direction (m) | 0.22106 |

| Z-Component of Flow Direction (m) | −0.77026 |

| Turbulent Intensity (%) | 5 |

| Turbulent Viscosity Ratio | 10 |

| Factor | A: Amplitude/mm | B: Vibration Frequency/Hz | C: Transverse Angle/° | |

| Level | −1 | 7 | 6 | 40 |

| 0 | 8 | 7 | 50 | |

| 1 | 9 | 8 | 60 | |

| Test Number | A: Amplitude/mm | B: Vibration Frequency/Hz | C: Transverse Angle/° | Y1: Sieving Efficiency/% | Y2: Loss Rate/% |

|---|---|---|---|---|---|

| 1 | 8 | 7 | 50 | 96.96 | 4.22 |

| 2 | 8 | 8 | 60 | 94.53 | 5.48 |

| 3 | 8 | 8 | 40 | 94.87 | 4.11 |

| 4 | 7 | 8 | 50 | 96.48 | 2.03 |

| 5 | 7 | 6 | 50 | 96.11 | 5.84 |

| 6 | 7 | 7 | 60 | 96.21 | 3.05 |

| 7 | 8 | 6 | 60 | 94.98 | 6.92 |

| 8 | 9 | 8 | 50 | 93.65 | 5.67 |

| 9 | 8 | 7 | 50 | 97.11 | 4.87 |

| 10 | 8 | 6 | 40 | 98.51 | 4.94 |

| 11 | 7 | 7 | 40 | 95.93 | 2.51 |

| 12 | 9 | 7 | 60 | 93.14 | 5.98 |

| 13 | 8 | 7 | 50 | 96.46 | 4.16 |

| 14 | 9 | 7 | 40 | 95.65 | 2.59 |

| 15 | 8 | 7 | 50 | 95.82 | 5.13 |

| 16 | 8 | 7 | 50 | 96.87 | 3.24 |

| 17 | 9 | 6 | 50 | 96.17 | 5.57 |

| Source | Sum of Squares | Degree of Freedom | Mean Square | F Value | p Value | Significance |

|---|---|---|---|---|---|---|

| Model | 25.77 | 9 | 2.86 | 10.39 | 0.0027 | ** |

| A-amplitude | 4.68 | 1 | 4.68 | 16.98 | 0.0045 | ** |

| B-vibration frequency | 4.87 | 1 | 4.87 | 17.66 | 0.004 | ** |

| C-transverse angle | 4.65 | 1 | 4.65 | 16.87 | 0.0045 | ** |

| AB | 2.09 | 1 | 2.09 | 7.57 | 0.0284 | * |

| AC | 1.95 | 1 | 1.95 | 7.06 | 0.0326 | * |

| BC | 2.54 | 1 | 2.54 | 9.23 | 0.0189 | * |

| A2 | 2.47 | 1 | 2.47 | 8.96 | 0.0201 | * |

| B2 | 0.32 | 1 | 0.32 | 1.16 | 0.3169 | |

| C2 | 1.76 | 1 | 1.76 | 6.37 | 0.0396 | * |

| Residual | 1.93 | 7 | 0.28 | |||

| Lack of fit | 0.85 | 3 | 0.28 | 1.05 | 0.4632 | |

| Error | 1.08 | 4 | 0.27 | |||

| Total | 27.7 | 16 |

| Source | Sum of Squares | Degree of Freedom | Mean Square | F Value | p Value | Significance |

|---|---|---|---|---|---|---|

| Model | 29.31 | 9 | 3.26 | 9.2 | 0.004 | ** |

| A-amplitude | 5.09 | 1 | 5.09 | 14.37 | 0.0068 | ** |

| B-vibration frequency | 4.47 | 1 | 4.47 | 12.63 | 0.0093 | ** |

| C-transverse angle | 6.62 | 1 | 6.62 | 18.71 | 0.0035 | ** |

| AB | 3.82 | 1 | 3.82 | 10.8 | 0.0134 | * |

| AC | 2.03 | 1 | 2.03 | 5.74 | 0.0478 | * |

| BC | 0.093 | 1 | 0.093 | 0.26 | 0.624 | |

| A2 | 1.99 | 1 | 1.99 | 5.63 | 0.0493 | * |

| B2 | 5.49 | 1 | 5.49 | 15.51 | 0.0056 | ** |

| C2 | 0.045 | 1 | 0.045 | 0.13 | 0.7323 | |

| Residual | 2.48 | 7 | 0.35 | |||

| Lack of fit | 0.32 | 3 | 0.11 | 0.2 | 0.8942 | |

| Error | 2.16 | 4 | 0.54 | |||

| Total | 31.79 | 16 |

| Indicator | Type-1 | Type-2 | Type-3 |

|---|---|---|---|

| Sieving efficiency (%) | 98.23 | 96.70 | 96.71 |

| Loss rate (%) | 2.39 | 2.96 | 2.50 |

| Indicator | 14 mm Sieve Hole Diameter | 15 mm Sieve Hole Diameter | 16 mm Sieve Hole Diameter |

|---|---|---|---|

| Sieving efficiency (%) | 98.23 | 96.64 | 96.69 |

| Loss rate (%) | 2.39 | 4.32 | 3.41 |

| Parameter Combination | A: Amplitude/mm | B: Vibration Frequency/Hz | C: Transverse Angle/° | Y1: Sieving Efficiency/% | Y2: Loss Rate/% | Y3: Impurity Rate/% |

|---|---|---|---|---|---|---|

| 1 | 8.43 | 6 | 40 | 94.68 | 7.13 | 0.68 |

| 2 | 7 | 7.76 | 40.81 | 95.21 | 6.09 | 0.52 |

| 3 | 9 | 6.16 | 40 | 93.15 | 6.94 | 0.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, J.; Liu, X.; Zhu, H.; Ma, Z.; Tang, Z.; Yu, Y.; Jin, J.; Wang, W. Design and Motion Process of Air-Sieve Castor Cleaning Device Based on Discrete Element Method. Agriculture 2023, 13, 1130. https://doi.org/10.3390/agriculture13061130

Hou J, Liu X, Zhu H, Ma Z, Tang Z, Yu Y, Jin J, Wang W. Design and Motion Process of Air-Sieve Castor Cleaning Device Based on Discrete Element Method. Agriculture. 2023; 13(6):1130. https://doi.org/10.3390/agriculture13061130

Chicago/Turabian StyleHou, Junming, Xu Liu, Hongjie Zhu, Zhi Ma, Ziyuan Tang, Yachen Yu, Jiuyu Jin, and Wei Wang. 2023. "Design and Motion Process of Air-Sieve Castor Cleaning Device Based on Discrete Element Method" Agriculture 13, no. 6: 1130. https://doi.org/10.3390/agriculture13061130