Evaluation of the Dynamic Tube Method for Measuring Ammonia Emissions after Liquid Manure Application

Abstract

:1. Introduction

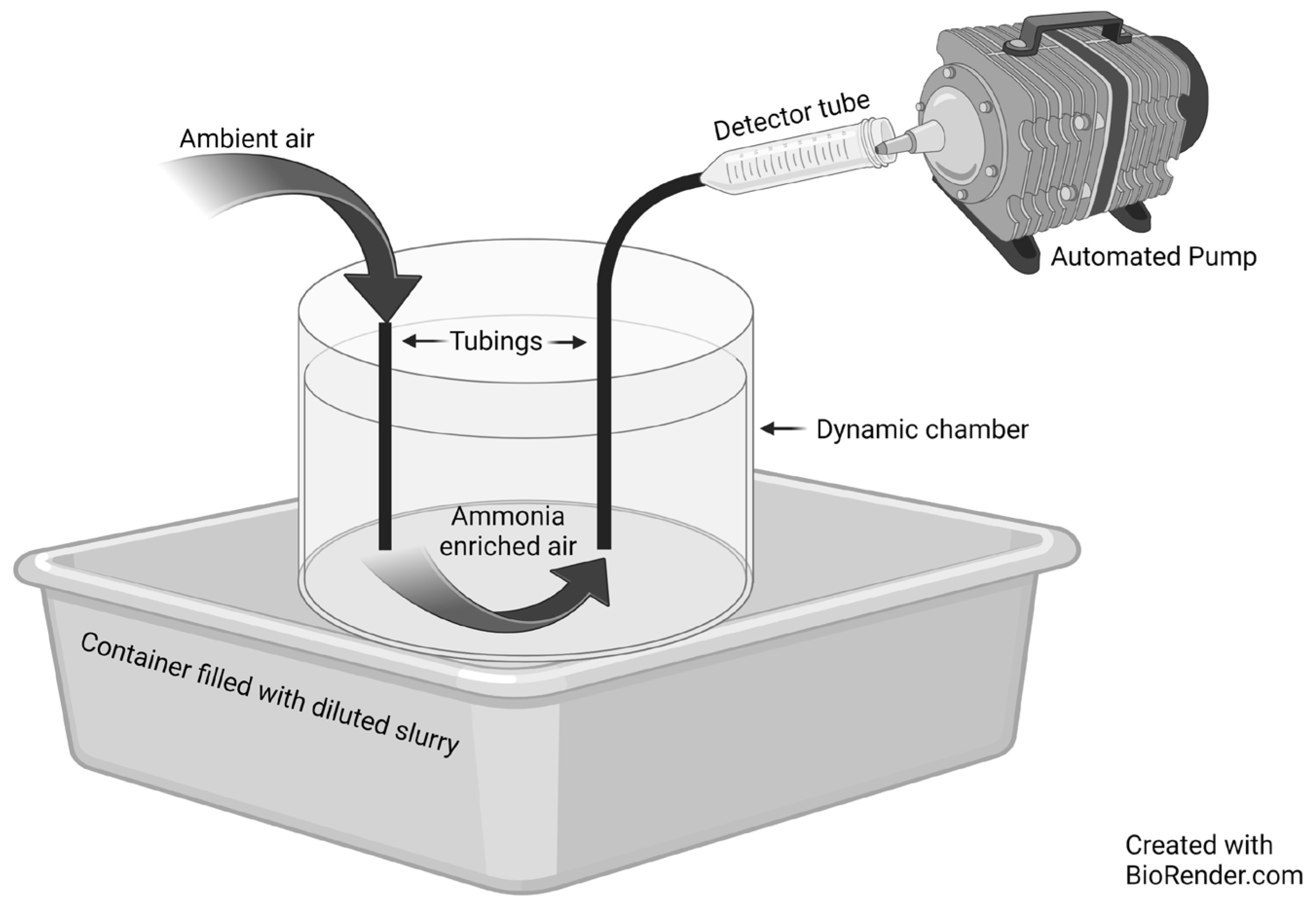

2. Materials and Methods

2.1. Constancy of the NH3 Concentration within the Chamber System

2.2. Assessment of the In-Field Chamber System Cleaning Procedure

2.3. Winter Wheat Field Trial to Estimate the Influence of Ubiquitous NH3 Concentration and Chamber System Contamination

2.4. Data Analyses

- No background subtraction regarding the raw flux calculation;

- Background subtraction based on UCS data to estimate the influence of the ubiquitous NH3 concentration;

- Background subtraction based on CCS data.

3. Results

3.1. Constancy of the NH3 Concentration within the Chamber System

3.2. Assessment of the In-Field Chamber System Cleaning Procedure

3.3. Influence of Ubiquitous NH3 Concentration and Chamber System Contamination

4. Discussion

4.1. Constancy of the NH3 Concentration within the Chamber System

4.2. Assessment of the In-Field Chamber System Cleaning Procedure

4.3. Influence of Ubiquitous NH3 Concentration and Chamber System Contamination

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sutton, M.A.; Oenema, O.; Erisman, J.W.; Leip, A.; van Grinsven, H.; Winiwarter, W. Too Much of a Good Thing. Nature 2011, 472, 159–161. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sommer, S.G.; Génermont, S.; Cellier, P.; Hutchings, N.J.; Olesen, J.E.; Morvan, T. Processes Controlling Ammonia Emission from Livestock Slurry in the Field. Europ. J. Agron. 2003, 19, 465–486. [Google Scholar] [CrossRef]

- Asman, W.A.H.; Sutton, M.A.; Schjorring, J.K. Ammonia: Emission, Atmospheric Transport and Deposition. New Phytol. 1998, 139, 27–48. [Google Scholar] [CrossRef]

- Ni, K.; Köster, J.R.; Seidel, A.; Pacholski, A. Field Measurement of Ammonia Emissions After Nitrogen Fertilization—A Comparison between Micrometeorological and Chamber Methods. Eur. J. Agron. 2015, 71, 115–122. [Google Scholar] [CrossRef]

- Lelieveld, J.; Evans, J.S.; Fnais, M.; Giannadaki, D.; Pozzer, A. The Contribution of Outdoor Air Pollution Sources to Premature Mortality on a Global Scale. Nature 2015, 525, 367–371. [Google Scholar] [CrossRef]

- Van Damme, M.; Clarisse, L.; Whitburn, S.; Hadji-Lazaro, J.; Hurtmans, D.; Clerbaux, C.; Coheur, P.-F. Industrial and Agricultural Ammonia Point Sources Exposed. Nature 2018, 564, 99–103. [Google Scholar] [CrossRef] [Green Version]

- Emmerling, C.; Krein, A.; Junk, J. Meta-Analysis of Strategies to Reduce NH3 Emissions from Slurries in European Agriculture and Consequences for Greenhouse Gas Emissions. Agronomy 2020, 10, 1633. [Google Scholar] [CrossRef]

- Liu, L.; Xu, W.; Lu, X.; Zhong, B.; Guo, Y.; Lu, X.; Zhao, Y.; He, W.; Wang, S.; Zhang, X.; et al. Exploring Global Changes in Agricultural Ammonia Emissions and Their Contribution to Nitrogen Deposition Since 1980. Proc. Natl. Acad. Sci. USA 2022, 119, e2121998119. [Google Scholar] [CrossRef]

- Webb, J.; Menzi, H.; Pain, B.F.; Misselbrook, T.H.; Dämmgen, U.; Hendriks, H.; Döhler, H. Managing Ammonia Emissions from Livestock Production in Europe. Environ. Pollut. 2005, 135, 399–406. [Google Scholar] [CrossRef]

- Webb, J.; Pain, B.; Bittman, S.; Morgan, J. The Impacts of Manure Application Methods on Emissions of Ammonia, Nitrous Oxide and on Crop Response—A Review. Agr. Ecosyst. Environ. 2010, 137, 39–46. [Google Scholar] [CrossRef]

- European Environment Agency. Air Pollution: National Emission Reduction; European Environment Agency: Copenhagen, Denmark, 2016. [Google Scholar]

- Pacholski, A. Calibrated Passive Sampling—Multi-Plot Field Measurements of NH3 Emissions with a Combination of Dynamic Tube Method and Passive Samplers. J. Vis. Exp. 2016, 109, e53273. [Google Scholar] [CrossRef] [Green Version]

- Leuning, R.; Freney, J.R.; Denmead, O.T.; Simpson, J.R. A Sampler for Measuring Atmospheric Ammonia Flux. Atmos. Environ. (1967) 1985, 19, 1117–1124. [Google Scholar] [CrossRef]

- Sherlock, R.R.; Freney, J.R.; Smith, N.P.; Cameron, K.C. Evaluation of a Sampler for Assessing Ammonia Losses from Fertilized Fields. Fertil. Res. 1989, 21, 61–66. [Google Scholar] [CrossRef]

- Sommer, S.G.; Misselbrook, T.H. A Review of Ammonia Emission Measured Using Wind Tunnels Compared with Micrometeorological Techniques. Soil Use Manag. 2016, 32, 101–108. [Google Scholar] [CrossRef]

- Roelcke, M.; Li, S.X.; Tian, X.H.; Gao, Y.J.; Richter, J. In Situ Comparisons of Ammonia Volatilization from N Fertilizers in Chinese Loess Soils. Nutr. Cycl. Agroecosyst. 2002, 62, 73–88. [Google Scholar] [CrossRef]

- Richter, J. Zur Methodik des Bodengashaushaltes. II. Ergebnisse und Diskussion. Z. Pflanzenernaehr. Bodenk. 1972, 132, 220–239. [Google Scholar] [CrossRef]

- Roelcke, M.A.P. Die Ammoniak-Volatilisation nach Ausbringung von Mineraldünger-Stickstoff in Carbonatreichen Chinesischen Löß-Ackerböden. Ph.D. Thesis, Braunschweig Technical University, Braunschweig, Germany, 1994. [Google Scholar]

- Pacholski, A.; Cai, G.; Nieder, R.; Richter, J.; Fan, X.; Zhu, Z.; Roelcke, M. Calibration of a Simple Method for Determining Ammonia Volatilization in the Field—Comparative Measurements in Henan Province, China. Nutr. Cycl. Agroecosyst. 2006, 74, 259–273. [Google Scholar] [CrossRef]

- Pacholski, A.; Cai, G.-X.; Fan, X.-H.; Ding, H.; Chen, D.; Nieder, R.; Roelcke, M. Comparison of Different Methods for the Measurement of Ammonia Volatilization After Urea Application in Henan Province, China. Z. Pflanzenernähr. Bodenk. 2008, 171, 361–369. [Google Scholar] [CrossRef]

- Gericke, D.; Pacholski, A.; Kage, H. Measurement of Ammonia Emissions in Multi-Plot Field Experiments. Biosyst. Eng. 2011, 108, 164–173. [Google Scholar] [CrossRef]

- Vandré, R.; Kaupenjohann, M. In Situ Measurement of Ammonia Emissions from Organic Fertilizers in Plot Experiments. Soil Sci. Soc. Am. J. 1998, 62, 467–473. [Google Scholar] [CrossRef]

- Ni, K.; Pacholski, A.; Kage, H. Ammonia Volatilization after Application of Urea to Winter Wheat Over 3 Years Affected by Novel Urease and Nitrification Inhibitors. Agric. Ecosyst. Environ. 2014, 197, 184–194. [Google Scholar] [CrossRef]

- Nyameasem, J.K.; Zutz, M.; Kluß, C.; Ten Huf, M.; Essich, C.; Buchen-Tschiskale, C.; Ruser, R.; Flessa, H.; Olfs, H.-W.; Taube, F.; et al. Impact of Cattle Slurry Application Methods on Ammonia Losses and Grassland Nitrogen Use Efficiency. Environ. Pollut. 2022, 315, 120302. [Google Scholar] [CrossRef] [PubMed]

- Quakernack, R.; Pacholski, A.; Techow, A.; Herrmann, A.; Taube, F.; Kage, H. Ammonia Volatilization and Yield Response of Energy Crops After Fertilization with Biogas Residues in a Coastal Marsh of Northern Germany. Agric. Ecosyst. Environ. 2012, 160, 66–74. [Google Scholar] [CrossRef]

- Seidel, A.; Pacholski, A.; Nyord, T.; Vestergaard, A.; Pahlmann, I.; Herrmann, A.; Kage, H. Effects of Acidification and Injection of Pasture Applied Cattle Slurry on Ammonia Losses, N2O Emissions and Crop N Uptake. Agric. Ecosyst. Environ. 2017, 247, 23–32. [Google Scholar] [CrossRef]

- Ten Huf, M.; Reinsch, T.; Zutz, M.; Essich, C.; Ruser, R.; Buchen-Tschiskale, C.; Flessa, H.; Olfs, H.-W. Effects of Liquid Manure Application Techniques on Ammonia Emission and Winter Wheat Yield. Agronomy 2023, 13, 472. [Google Scholar] [CrossRef]

- Wagner, C.; Nyord, T.; Vestergaard, A.V.; Hafner, S.D.; Pacholski, A.S. Acidification Effects on In Situ Ammonia Emissions and Cereal Yields Depending on Slurry Type and Application Method. Agriculture 2021, 11, 1053. [Google Scholar] [CrossRef]

- Freney, J.R.; Simpson, J.R.; Denmead, O.T. Volatilization of Ammonia. In Gaseous Loss of Nitrogen from Plant-Soil Systems; Freney, J.R., Simpson, J.R., Eds.; Springer: Dordrecht, The Netherlands, 1983; pp. 1–32. ISBN 978-90-481-8276-3. [Google Scholar]

- Sommer, S. Modelling Ammonia Volatilization from Animal Slurry Applied with Trail Hoses to Cereals. Atmos. Environ. 2000, 34, 2361–2372. [Google Scholar] [CrossRef]

- Denmead, O.T. Micrometeorological Methods for Measuring Gaseous Losses of Nitrogen in the Field. In Gaseous Loss of Nitrogen from Plant-Soil Systems; Freney, J.R., Simpson, J.R., Eds.; Springer: Dordrecht, The Netherlands, 1983; pp. 133–157. ISBN 978-90-481-8276-3. [Google Scholar]

| Detector Tube | Detection Range (ppm) | Default Stroke Number | Time per Stroke (s) |

|---|---|---|---|

| 0.25a | 0.25–3 | 10 | 4.5 |

| 2a | 2–30 | 5 | 6.5 |

| 5a | 5–70 | 10 | 4.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

ten Huf, M.; Olfs, H.-W. Evaluation of the Dynamic Tube Method for Measuring Ammonia Emissions after Liquid Manure Application. Agriculture 2023, 13, 1217. https://doi.org/10.3390/agriculture13061217

ten Huf M, Olfs H-W. Evaluation of the Dynamic Tube Method for Measuring Ammonia Emissions after Liquid Manure Application. Agriculture. 2023; 13(6):1217. https://doi.org/10.3390/agriculture13061217

Chicago/Turabian Styleten Huf, Martin, and Hans-Werner Olfs. 2023. "Evaluation of the Dynamic Tube Method for Measuring Ammonia Emissions after Liquid Manure Application" Agriculture 13, no. 6: 1217. https://doi.org/10.3390/agriculture13061217