A Multi-Objective Optimization Method for a Tractor Driveline Based on the Diversity Preservation Strategy of Gradient Crowding

Abstract

1. Introduction

2. Optimization Model of Matching a Tractor Transmission System

2.1. Optimization of the Objective Function

2.2. Constraint of Transmission Ratio Optimization

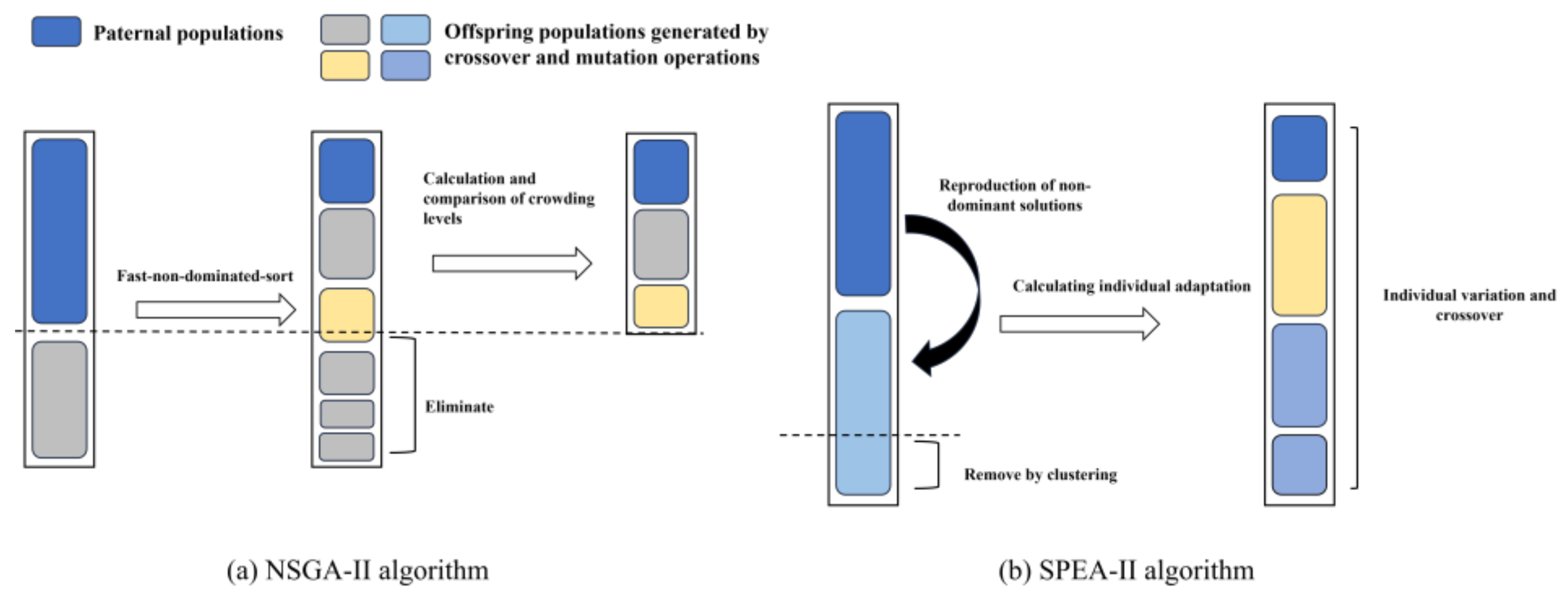

3. Multi-Objective Optimization Algorithm Based on Gradient Crowding

3.1. Gradient Crowding

3.2. Segmented Elite Strategy

3.3. Multi-Objective Optimization Algorithm for Gradient Crowding and Evaluation Metrics

4. Results and Discussion

4.1. Verification of Algorithm Optimization

4.2. Optimization Analysis of Matching Transmission Ratio

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chao, J.; Wang, Y.; Dong, W.; Yang, Y.; Zhai, Y. Research on transmission ratio distribution between gears of graded tractor driveline. Tract. Agric. Transp. Veh. 2016, 43, 28–33. [Google Scholar]

- AbdolMajid, M.; Gholamhossein, S.; Yousef, A.G.; Tarahom, M.G. The effect of the tractor driving system on its performance and fuel consumption. Energy 2020, 202, 117803. [Google Scholar]

- Zhang, S.L.; Wen, C.K.; Ren, W.; Luo, Z.H.; Xie, B.; Zhu, Z.X.; Chen, Z.J. A joint control method considering travel speed and slip for reducing energy consumption of rear wheel independent drive electric tractor in ploughing. Energy 2023, 263, 126008. [Google Scholar] [CrossRef]

- Sun, W.; Feng, Y.; Sun, H. Study on the optimization of the transmission system and reasonable matching with engine. Tract. Agric. Transp. Veh. 2000, 4, 23–29. [Google Scholar]

- Song, Q.; Ye, S.; Li, W.; Gao, P.; Li, Y.; Huang, Y. Research on the integrated shifting law of pure electric vehicle AMT based on a multi-objective genetic algorithm. J. Automot. Eng. 2017, 7, 44–51. [Google Scholar]

- Sheng, J.; Zhang, B.; Zhu, B.; Wang, M.; Jin, Q. Parameter optimization and experimental comparison of two-speed pure electric vehicle driveline. China Mech. Eng. 2019, 30, 763–770+776. [Google Scholar]

- Cheng, F. Multi-Objective Optimization of the Automotive Powertrain Based on Adaptive Maintenance Diversity Genetic Algorithm. Ph.D. Thesis, Jilin University, Changchun, China, 2011. [Google Scholar]

- Zhang, X.; Zhao, H.; Qian, L.; Zhang, B. Application of electric vehicle simulation software ADVISOR. Transp. Technol. Econ. 2004, 3, 40–43. [Google Scholar] [CrossRef]

- Wu, Y.; Ying, Y.; Li, B.; Li, Z. Secondary development and analysis of ADVISOR hybrid electric vehicle simulation software. Spec. Purp. Veh. 2022, 306, 15–18. [Google Scholar] [CrossRef]

- Hamilton, W.T.; Neises, T.W. Dispatch optimization of electric thermal energy storage within System Advisor Model. J. Energy Storage 2023, 61, 106786. [Google Scholar] [CrossRef]

- Cioroianu, C.C.; Marinescu, D.G.; Iorga, A.; Sibiceanu, A.R. Simulation of an electric vehicle model on the new WLTC test cycle using AVL CRUISE software. IOP Conf. Ser. Mater. Sci. Eng. 2017, 252, 012060. [Google Scholar] [CrossRef]

- Ma, J. A parameter matching study for electric sweeping vehicle power system based on AVL CRUISE. Int. J. Electr. Hybrid Veh. 2020, 12, 144–157. [Google Scholar] [CrossRef]

- Gong, B.; Ma, Y.; Song, G.; Guan, W.; Cai, Z. Simulation analysis of vehicle fuel consumption based on AVL_Cruise software. Automot. Pract. Technol. 2020, 45, 109–112. [Google Scholar] [CrossRef]

- He, R.; Liu, X.; He, Z. Research and development of optimal matching of the automobile powertrain system. J. Jiangsu Univ. Technol. 1997, 1, 37–41. [Google Scholar]

- Lei, Z. Parameter Matching and Simulation Optimization of Automotive Powertrain. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2010. [Google Scholar]

- Zhang, Z. Research on Speed Ratio Optimization and Gearshift Law of Automotive Driveline Based on NSGA-Ⅱ and NLPQL Algorithm. Ph.D. Thesis, Changchun University of Technology, Changchun, China, 2020. [Google Scholar] [CrossRef]

- Liu, T.; Guo, Y. Optimal matching analysis of automotive powertrain parameters based on compound shape method. Mech. Des. Manuf. 2008, 209, 201–203. [Google Scholar]

- Peng, P.; Xu, X.; Zeng, J. Research on the parameter matching of pure electric vehicle transmission systems based on motor efficiency. Mech. Des. Manuf. 2021, 364, 39–44. [Google Scholar] [CrossRef]

- Zheng, J.; Chen, J. Optimal design of power system speed ratio of a pure electric vehicle. Mech. Transm. 2019, 43, 79–82+93. [Google Scholar] [CrossRef]

- Zheng, J.; Chen, J.; Li, Y. Multi-objective genetic algorithm for optimizing pure electric vehicle power system parameters. Mod. Manuf. Eng. 2020, 477, 46–51. [Google Scholar] [CrossRef]

- Zheng, J.; Chen, J. Matching design and parameter influence analysis of pure electric vehicle power system. Mech. Electron. 2019, 37, 52–56+67. [Google Scholar]

- Nataraj, E.; Sarkar, P.; Raheman, H.; Upadhyay, G. Embedded digital display and warning system of velocity ratio and wheel slip for tractor operated active tillage implements. J. Terramechanics 2021, 97, 35–43. [Google Scholar] [CrossRef]

- Abdolhadi, Z.; Mohammad, M.; Mohammad, J. Auto-tuning PVT data using multi-objective optimization: Application of NSGA-II algorithm. Petroleum 2023, 20. [Google Scholar] [CrossRef]

- Mohammad, A.A.; Ashraf, E. Modified multi-objective evolutionary programming algorithm for solving project scheduling problems. Expert Syst. Appl. 2021, 183, 115338. [Google Scholar]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Liu, M.N.; Zhou, Z.L.; Xu, L.Y.; Zhao, J.H.; Yan, X.H. Multi-objective optimization and design of tractor trailer systems. Trans. Chin. Soc. Agric. Eng. 2017, 33, 62–68. (In Chinese) [Google Scholar]

- Krishnamurthy, K.V.; Zhang, Z. Biodiversity in the World; Chemical Industry Press: Beijing, China, 2006; pp. 97–98. [Google Scholar]

- Wang, L.; Ren, Y.; Qiu, Q.; Qiu, F. A review of research on performance evaluation metrics of multi-objective evolutionary algorithms. J. Comput. Sci. 2021, 44, 1590–1619. [Google Scholar]

- Qi, W. Research on MOEAs with Diversity Preservation Strategies Based on Gradient Congestion. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2008. [Google Scholar]

- Xiong, S.; Qi, W.; Zhang, L. MOEA of diversity retention strategy based on gradient congestion. J. Wuhan Univ. Technol. (Inf. Manag. Eng. Ed.) 2008, 5, 696–700. [Google Scholar]

- Lin, X.J.; Liu, H.L.; Li, J.Q.; Li, Q. Deep deterministic policy gradient algorithm for crowd-evacuation path planning. Comput. Ind. Eng. 2021, 161, 107621. [Google Scholar]

- Fu, S.; Li, Z.; Du, Y.; Mao, E.; Zhu, Z. Optimization of tractor transmission system matching based on improved NSGA-Ⅱ algorithm. J. Agric. Mach. 2018, 49, 349–357. [Google Scholar]

- Abdolmajid, M.; Ghoalmhossein, S.; Yousef, A.G.; Mohammad, K.; Mariusz, S. Investigating the effect of the tractor driving system type on soil compaction using different methods of ANN, ANFIS and step wise regression. Soil Tillage Res. 2022, 222, 1054444. [Google Scholar]

- Wen, C.K.; Li, R.C.; Zhao, C.J.; Chen, L.P.; Wang, M.H.; Yin, Y.X.; Meng, Z.J. An improved LSTM-based model for identifying high working intensity load segments of the tractor load spectrum. Comput. Electron. Agric. 2023, 210, 107879. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, J.; Wang, J.; Guo, Z.; Guo, F.; Xi, Z.; Xu, J. Tractor variable speed control strategy to improve fuel economy. J. Agric. Eng. 2020, 36, 82–89. [Google Scholar]

- Bao, M.; Ni, X.; Wang, Q.; Kang, S.; Peng, X.; Xu, G.; Zhao, X. Research on the shifting law of HMCVT based on tractor fuel economy. Mech. Transm. 2019, 43, 20–25. [Google Scholar] [CrossRef]

- Fu, S.H.; Li, Z.; Du, Y.F.; Mao, E.R.; Zhu, Z.X. Matching Optimization for Tractor Powertrain Based on Improved NSGA-Ⅱ Algorithm. Trans. Chin. Soc. Agric. Mach. 2018, 49, 349–357. (In Chinese) [Google Scholar]

- Li, Y.; Yu, X.M.; Liu, J.S. An opposition-based butterfly optimization algorithm with adaptive elite mutation in solving complex high-dimensional optimization problems. Math. Comput. Simul. 2023, 204, 498–528. [Google Scholar] [CrossRef]

- Liang, Z.P.; Zeng, J.Y.; Liu, L.; Zhu, Z.X. A many-objective optimization algorithm with mutation strategy based on variable classification and elite individual. Swarm Evol. Comput. 2021, 60, 100769. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, G.; Jin, Y.C.; Qian, F. Elitism-based transfer learning and diversity maintenance for dynamic multi-objective optimization. Inf. Sci. 2023, 636, 117927. [Google Scholar] [CrossRef]

- Liu, Q.; Xiong, S.; Zhan, M. High-dimensional objective scheduling optimization based on an improved elite strategy of PCA-NSGA II. Comput. Integr. Manuf. Syst. 2020, 26, 2474–2483. [Google Scholar] [CrossRef]

- Xie, C.; Li, K.; Liao, G. An improved NSGA2 algorithm with local differential search. Comput. Sci. 2013, 40, 235–238+273. [Google Scholar]

| Input: P, L Output: P | // Segment P by elite rating |

| 1: function Divide (P) 2: Divide P into Pi by Elite Level. 3: returen Pi 4: end function 5: for i = 1, 2, …, N do 6: Pi = Diversity-Prune(Pi, Li, P) 7: end for 8: P = Diversity-Prune(P, L) 9: end Procedure | // Reduce P by the number of limits per segment // function to exclude individuals when special treatment, only for the set of individuals of the specified segment // Reduce P by the total number of restrictions |

| Algorithm | NSGA-I | GC_NSGA-II | SPEA-II | GC_SPEA-II |

|---|---|---|---|---|

| Population size | 200 | 200 | 200 | 200 |

| Evolutionary algebra | 200 | 200 | 200 | 200 |

| Crossover probability | 1 | 1 | 1 | 1 |

| Mutation probability | 0.05 | 0.05 | 0.05 | 0.05 |

| Number of uniformly selected points at the front end of convergence | 500 | 500 | 500 | 500 |

| The pre-generation ratio of diversity random | 4 | 4 | ||

| Segmented strategy | 0.5, 0.4, 0.1 | 0.5, 0.4, 0.1 |

| Standard Test Functions | Algorithm | ||||

|---|---|---|---|---|---|

| ZDT1 | NSGA-II | 0.022912 | 0.007967 | 0.007611 | 0.955302 |

| GC_NSGA-II | 0.023032 | 0.008259 | 0.006376 | 0.771947 | |

| SPEA-II | 0.024342 | 0.007643 | 0.012948 | 1.694197 | |

| GC_SPEA-II | 0.019805 | 0.008127 | 0.008148 | 1.002563 | |

| ZDT2 | NSGA-II | 0.012369 | 0.007644 | 0.006560 | 0.858250 |

| GC_NSGA-II | 0.011480 | 0.007720 | 0.005724 | 0.741448 | |

| SPEA-II | 0.010460 | 0.007489 | 0.016042 | 2.142011 | |

| GC_SPEA-II | 0.005046 | 0.007541 | 0.007542 | 1.000210 | |

| ZDT3 | NSGA-II | 0.002024 | 0.011720 | 0.020567 | 1.754830 |

| GC_NSGA-II | 0.002127 | 0.011905 | 0.021290 | 1.788401 | |

| SPEA-II | 0.003303 | 0.011691 | 0.028947 | 2.475952 | |

| GC_SPEA-II | 0.002726 | 0.012225 | 0.022220 | 1.817520 | |

| ZDT4 | NSGA-II | 0.000473 | 0.007389 | 0.00680 | 0.920091 |

| GC_NSGA-II | 0.000185 | 0.007634 | 0.005503 | 0.720860 | |

| SPEA-II | 0.000238 | 0.007284 | 0.010673 | 1.465305 | |

| GC_SPEA-II | 0.000181 | 0.007400 | 0.008518 | 1.151056 | |

| ZDT6 | NSGA-II | 0.000473 | 0.007389 | 0.006799 | 0.920091 |

| GC_NSGA-II | 0.000185 | 0.007634 | 0.005503 | 0.720860 | |

| SPEA-II | 0.000238 | 0.007284 | 0.010673 | 1.465305 | |

| GC_SPEA-II | 0.000181 | 0.007400 | 0.008518 | 1.151056 |

| Indicators | ||

|---|---|---|

| Engine | Model | WP6G180E330 |

| Calibrated power (kW) | 132.5 | |

| ) | 2200 | |

| ) | <235 | |

| Driveline | Central drive ratio | 6.125 |

| Final Drive Ratio | 6.40 | |

| Speed | Number of gears | 32(F) + 32(R) |

| ) | 2.28–39.8 | |

| Machine parameter | Rated tractive force (kN) | 57 |

| Machine quality (kg) | 8144 | |

| Service mass (kg) | 8319 | |

| Gear Partition | Gear | Gear Name | Before Optimization | NSGA-II | SPEA-II | GC_NSGA-II |

|---|---|---|---|---|---|---|

| Low gear | 1 | Forward L-I | 298.93 | 290.539 | 238.377 | 287.742 |

| 2 | Forward L-II | 248.11 | 241.145 | 198.647 | 229.116 | |

| 3 | Forward L-III | 209.25 | 203.271 | 165.494 | 190.772 | |

| 4 | Forward L-IV | 173.68 | 171.640 | 137.820 | 159.082 | |

| 5 | Forward M-I | 191.47 | 189.216 | 151.937 | 175.377 | |

| 6 | Forward M-II | 158.92 | 157.049 | 126.108 | 149.280 | |

| 7 | Forward M-III | 134.03 | 132.452 | 106.357 | 129.168 | |

| 8 | Forward M-IV | 111.25 | 109.940 | 88.280 | 109.952 | |

| 9 | Forward H-I | 132.71 | 131.147 | 105.309 | 127.864 | |

| 10 | Forward H-II | 110.15 | 108.853 | 87.407 | 108.838 | |

| 11 | Forward H-III | 82.89 | 81.914 | 65.776 | 83.794 | |

| 12 | Forward H-IV | 77.102 | 76.194 | 61.183 | 80.180 | |

| 13 | Forward S-I | 97.45 | 96.303 | 77.329 | 101.341 | |

| 14 | Forward S-II | 80.88 | 79.928 | 64.181 | 84.109 | |

| 15 | Forward S-III | 68.21 | 67.407 | 54.127 | 70.933 | |

| 16 | Forward S-IV | 56.62 | 55.953 | 44.930 | 58.881 | |

| high grade | 17 | Forward L-I | 90.155 | 89.094 | 71.541 | 93.755 |

| 18 | Forward L-II | 74.828 | 73.947 | 59.378 | 77.816 | |

| 19 | Forward L-III | 63.108 | 62.365 | 50.078 | 65.628 | |

| 20 | Forward L-IV | 52.379 | 51.762 | 41.564 | 54.470 | |

| 21 | Forward M-I | 57.746 | 46.951 | 45.823 | 60.052 | |

| 22 | Forward M-II | 47.929 | 38.970 | 38.033 | 49.843 | |

| 23 | Forward M-III | 40.422 | 32.866 | 32.076 | 42.036 | |

| 24 | Forward M-IV | 33.550 | 27.278 | 26.623 | 34.890 | |

| 25 | Forward H-I | 40.023 | 32.541 | 31.759 | 41.621 | |

| 26 | Forward H-II | 33.218 | 27.008 | 26.359 | 34.544 | |

| 27 | Forward H-III | 28.016 | 22.779 | 22.232 | 29.135 | |

| 28 | Forward H-IV | 23.253 | 18.906 | 18.452 | 24.181 | |

| 29 | Forward S-I | 29.39 | 23.896 | 23.322 | 30.563 | |

| 30 | Forward S-II | 24.39 | 19.831 | 19.354 | 25.364 | |

| 31 | Forward S-III | 20.57 | 16.725 | 16.323 | 21.391 | |

| 32 | Forward S-IV | 17.07 | 13.879 | 13.546 | 17.752 |

| Indicators | Before Optimization | NSGA-II (Mean ± S.D.) | SPEA-II (Mean ± S.D.) | GC_NSGA-II (Mean ± S.D.) |

|---|---|---|---|---|

| The loss rate of driving power (%) | 36.21 | 22.06 ± 0.31 | 20.19 ± 0.52 | 21.14 ± 0.44 |

| The loss rate of specific fuel consumption (%) | 11.37 | 6.29 ± 0.33 | 8.62 ± 0.21 | 4.23 ± 0.36 |

| ) | 31.73 | 32.13 ± 0.45 | 34.33 ± 0.23 | 30.20 ± 0.51 |

| ) | 2.30 | 2.71 ± 0.60 | 2.87 ± 0.43 | 2.76 ± 0.14 |

| The climbing gradient of the first gear of the transport gear (%) | 44.03 | 39.57 ± 0.11 | 38.07 ± 0.26 | 45.07 ± 0.39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, F.; Yuan, F.; Lu, Z. A Multi-Objective Optimization Method for a Tractor Driveline Based on the Diversity Preservation Strategy of Gradient Crowding. Agriculture 2023, 13, 1324. https://doi.org/10.3390/agriculture13071324

Chang F, Yuan F, Lu Z. A Multi-Objective Optimization Method for a Tractor Driveline Based on the Diversity Preservation Strategy of Gradient Crowding. Agriculture. 2023; 13(7):1324. https://doi.org/10.3390/agriculture13071324

Chicago/Turabian StyleChang, Feilong, Fahui Yuan, and Zhixiong Lu. 2023. "A Multi-Objective Optimization Method for a Tractor Driveline Based on the Diversity Preservation Strategy of Gradient Crowding" Agriculture 13, no. 7: 1324. https://doi.org/10.3390/agriculture13071324

APA StyleChang, F., Yuan, F., & Lu, Z. (2023). A Multi-Objective Optimization Method for a Tractor Driveline Based on the Diversity Preservation Strategy of Gradient Crowding. Agriculture, 13(7), 1324. https://doi.org/10.3390/agriculture13071324