Application of Agri-Food By-Products in the Food Industry

Abstract

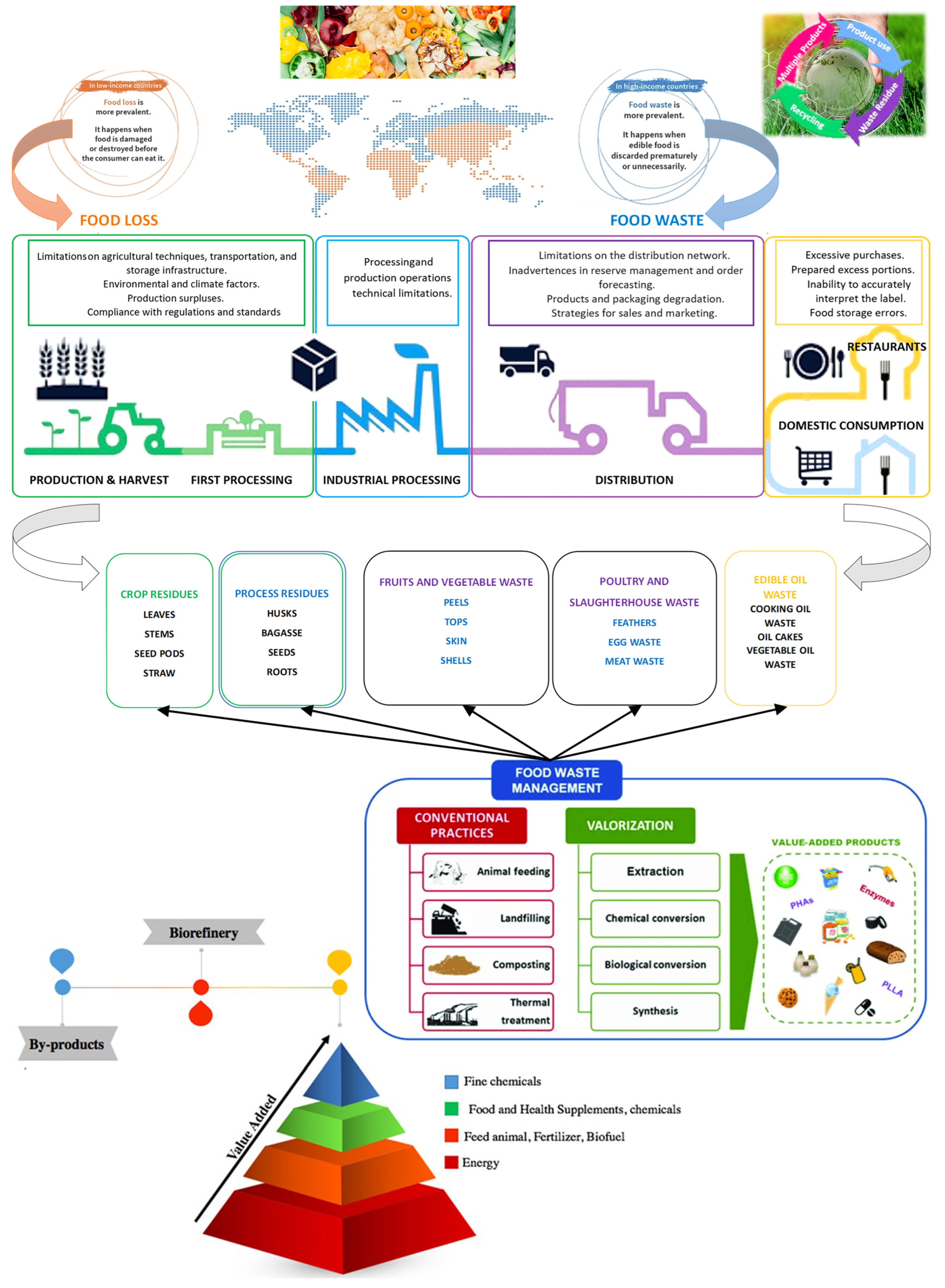

1. Introduction

2. Agri-Food By-Products and Their Properties

2.1. Some Examples of Agri-Food By-Products

2.2. Nutritional Composition and Potential Health Benefits of Using Agri-Food By-Products in Food Products

2.2.1. Dietary Fiber

2.2.2. Phenolic Compounds

2.2.3. Carotenoids and Tocopherols

2.2.4. Proteins

2.2.5. Organic Acids

3. Approaches in the Application of Agri-Food By-Products in the Food Industry

3.1. Incorporation of By-Products into Various Food Products, Such as Bakery Goods, Meat Products, and Beverages

3.2. Technological Applications of Food By-Products in Bakery Formulations

3.3. Technological Applications of Food By-Products in Dairy Formulations

3.4. Technological Applications of Food By-Products in Meat Products

3.5. Technological Applications of Food By-Products in the Beverage Industry

4. Environmental and Economic Benefits of Reducing Food Waste and Utilizing Agri-Food By-Products

5. Future Directions and Challenges

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- EEA. Circular Economy in Europe—Developing the Knowledge Base: Report 2; European Environment Agency: København, Denmark, 2016. [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). Food Wastage Footprint. In Food and Agriculture Organization of the United Nations (FAO). 2013. Available online: http://www.fao.org/nr/sustainability/food-loss-and-waste/en/ (accessed on 26 June 2023).

- Cara, G.I.; Topa, D.; Puiu, I.; Jitareanu, G. Biochar a Promising Strategy for Pesticide-Contaminated Soils. Agriculture 2022, 12, 1579. [Google Scholar] [CrossRef]

- Comunian, T.A.; Silva, M.P.; Souza, C.J.F. The Use of Food By-Products as a Novel for Functional Foods: Their Use as Ingredients and for the Encapsulation Process. Trends Food Sci. Technol. 2021, 108, 269–280. [Google Scholar] [CrossRef]

- Berenguer, C.V.; Andrade, C.; Pereira, J.A.M.; Perestrelo, R.; Câmara, J.S. Current challenges in the sustainable valorisation of agri-food wastes: A review. Processes 2022, 11, 20. [Google Scholar] [CrossRef]

- Carpentieri, S.; Larrea-Wachtendorff, D.; Donsì, F.; Ferrari, G. Functionalization of pasta through the incorporation of bioactive compounds from agri-food by-products: Fundamentals, opportunities, and drawbacks. Trends Food Sci. Technol. 2022, 122, 49–65. [Google Scholar] [CrossRef]

- Isah, S.; Ozbay, G. Valorization of food loss and wastes: Feedstocks for biofuels and valuable chemicals. Front. Sustain. Food Syst. 2020, 4, 82. [Google Scholar] [CrossRef]

- Torres-León, C.; Ramírez-Guzman, N.; Londoño-Hernandez, L.; Martinez-Medina, G.A.; Díaz-Herrera, R.; Navarro-Macias, V.; Alvarez-Pérez, O.B.; Picazo, B.; Villarreal-Vázquez, M.; Ascacio-Valdes, J.; et al. Food Waste and Byproducts: An Opportunity to Minimize Malnutrition and Hunger in Developing Countries. Front. Sustain. Food Syst. 2018, 2, 52. [Google Scholar] [CrossRef]

- Khorairi, A.; Sofian-Seng, A.N.S.; Othaman, N.S.; Abdul Rahman, R.; Mohd Razali, H.; Lim, N.S.; Wan Mustapha, S.J. A Review on Agro-Industrial Waste as Cellulose and Nanocellulose Source and Their Potentials in Food Applications. Food Rev. Int. 2023, 39, 663–688. [Google Scholar] [CrossRef]

- Marcillo-Parra, V.; Tupuna-Yerovi, D.S.; Gonzalez, Z.; Ruales, J. Encapsulation of Bioactive Compounds from Fruit and Vegetable By-Products for Food Application-A Review. Trends Food Sci. Technol. 2021, 116, 11–23. [Google Scholar] [CrossRef]

- Saini, A.; Panesar, P.S.; Bera, M.B. Valorization of fruits and vegetables waste through green extraction of bioactive compounds and their nanoemulsions-based delivery system. Bioresour. Bioprocess. 2019, 6, 26. [Google Scholar] [CrossRef]

- Tiwari, A.; Khawas, R. Food waste and Agro by-products: A step towards food sustainability. In Innovation in the Food Sector through the Valorization of Food and Agro-Food By-Products; IntechOpen: London, UK, 2021. [Google Scholar]

- Plasek, B.; Lakner, Z.; Kasza, G.; Temesi, Á. Consumer Evaluation of the Role of Functional Food Products in Disease Prevention and the Characteristics of Target Groups. Nutrients 2019, 12, 69. [Google Scholar] [CrossRef]

- Bharat Helkar, P.; Sahoo, A.K. Review: Food Industry by-Products Used as a Functional Food Ingredients. Int. J. Waste Resour. 2016, 6, 3. [Google Scholar] [CrossRef]

- WFPUSA. Difference between Food Waste vs Food Loss: Examples & Answers. 2023. Available online: https://www.wfpusa.org/articles/food-loss-vs-food-waste-primer (accessed on 26 June 2023).

- Available online: https://www.researchgate.net/publication/355241289_Progress_in_the_Valorization_of_Fruit_and_Vegetable_Wastes_Active_Packaging_Biocomposites_By-products_and_Innovative_Technologies_Used_for_Bioactive_Compound_Extraction (accessed on 26 June 2023).

- Socas-Rodríguez, B.; Álvarez-Rivera, G.; Valdés, A.; Ibáñez, E.; Cifuentes, A. Food By-Products and Food Wastes: Are They Safe Enough for Their Valorization? Trends Food Sci. Technol. 2021, 114, 133–147. [Google Scholar] [CrossRef]

- Kumari, B.; Tiwari, B.K.; Hossain, M.B.; Brunton, N.P.; Rai, D.K. Recent Advances on Application of Ultrasound and Pulsed Electric Field Technologies in the Extraction of Bioactives from Agro-Industrial by-Products. Food Bioproc. Technol. 2018, 11, 223–241. [Google Scholar] [CrossRef]

- Cecilia, J.A.; García-Sancho, C.; Maireles-Torres, P.J.; Luque, R. Industrial Food Waste Valorization: A General Overview. In Biorefinery; Springer International Publishing: Cham, Switzerland, 2019; pp. 253–277. [Google Scholar]

- Sadh, P.K.; Duhan, S.; Duhan, J.S. Agro-Industrial Wastes and Their Utilization Using Solid State Fermentation: A Review. Bioresour. Bioprocess. 2018, 5, 1. [Google Scholar] [CrossRef]

- Reguengo, L.M.; Salgaço, M.K.; Sivieri, K.; Maróstica Júnior, M.R. Agro-Industrial by-Products: Valuable Sources of Bioactive Compounds. Food Res. Int. 2022, 152, 110871. [Google Scholar] [CrossRef]

- Hussain, S.; Jõudu, I.; Bhat, R. Dietary Fiber from Underutilized Plant Resources—A Positive Approach for Valorization of Fruit and Vegetable Wastes. Sustainability 2020, 12, 5401. [Google Scholar] [CrossRef]

- De Los, Á.; Fernández, M.; Espino, M.; Gomez, F.J.V.; Silva, M.F. Novel Approaches Mediated by Tailor-Made Green Solvents for the Extraction of Phenolic Compounds from Agro-Food Industrial by-Products. Food Chem. 2018, 239, 671–678. [Google Scholar] [CrossRef]

- Jiménez-Moreno, N.; Esparza, I.; Bimbela, F.; Gandía, L.M.; Ancín-Azpilicueta, C. Valorization of Selected Fruit and Vegetable Wastes as Bioactive Compounds: Opportunities and Challenges. Crit. Rev. Environ. Sci. Technol. 2020, 50, 2061–2108. [Google Scholar] [CrossRef]

- Kaderides, K.; Goula, A.M.; Konstantinos, G. A Process for Turining Pomegranate Peels into a Valuable Food Ingredient Using Ultrasound Assisted Extraction and Encapsulation. Innov. Food Sci. Emerg. Technol. 2015, 31, 204–215. [Google Scholar] [CrossRef]

- Barreira, J.C.M.; Arraibi, A.A.; Ferreira, I.C.F.R. Bioactive and Functional Compounds in Apple Pomace from Juice and Cider Manufacturing: Potential Use in Dermal Formulations. Trends Food Sci. Technol. 2019, 90, 76–87. [Google Scholar] [CrossRef]

- Rabetafika, H.N.; Bchir, B.; Blecker, C.; Richel, A. Fractionation of Apple By-Products as Source of New Ingredients: Current Situation and Perspectives. Trends Food Sci. Technol. 2014, 40, 99–114. [Google Scholar] [CrossRef]

- Zema, D.A.; Calabrò, P.S.; Folino, A.; Tamburino, V.; Zappia, G.; Zimbone, S.M. Valorisation of Citrus Processing Waste: A Review. Waste Manag. 2018, 80, 252–273. [Google Scholar] [CrossRef] [PubMed]

- Shea, O.; Arendt, N.; Gallagher, E.K. Dietary Fibre and Phytochemical Characteristics of Fruit and Vegetable By-Products and Their Recent Applications as Novel Ingredients in Food Products. Innov. Food Sci. Emerg. Technol. 2012, 16, 1–10. [Google Scholar] [CrossRef]

- Bordiga, M.; Travaglia, F.; Locatelli, M. Valorisation of Grape Pomace: An Approach That Is Increasingly Reaching Its Maturity-A Review. Int. J. Food Sci. Technol. 2019, 54, 933–942. [Google Scholar] [CrossRef]

- Yu, J.; Ahmedna, M. Functional Components of Grape Pomace: Their Composition, Biological Properties and Potential Applications. Int. J. Food Sci. Technol. 2013, 48, 221–237. [Google Scholar] [CrossRef]

- Zheng, Y.; Lee, C.; Yu, C.; Cheng, Y.-S.; Simmons, C.W.; Zhang, R.; Jenkins, B.M.; VanderGheynst, J.S. Ensilage and Bioconversion of Grape Pomace into Fuel Ethanol. J. Agric. Food Chem. 2012, 60, 11128–11134. [Google Scholar] [CrossRef]

- Minjares-Fuentes, R.; Femenia, A.; Garau, M.C.; Meza-Velasquez, L.A.; Simal, S.; Rossello, C. Ultrasoundassisted Extraction of Pectins from Grape Pomace Using Citric Acid: A Response Surface Methodology Approach. Carbohydr. Polym. 2014, 106, 179–189. [Google Scholar] [CrossRef]

- Yi, C.; Shi, J.; Kramer, J.; Xue, S.; Jiang, Y.; Zhang, M.; Ma, Y.; Pohorly, J. Fatty Acid Composition and Phenolic Antioxidants of Winemaking Pomace Powder. Food Chem. 2009, 114, 570–576. [Google Scholar] [CrossRef]

- Islam, M.R.; Kamal, M.M.; Kabir, M.R.; Hasan, M.M.; Haque, A.R.; Hasan, S.M.K. Phenolic Compounds and Antioxidants Activity of Banana Peel Extracts: Testing and Optimization of Enzyme-Assisted Conditions. Meas. Food 2023, 10, 100085. [Google Scholar] [CrossRef]

- Pelissari, F.M.; Sobral, P.J.D.A.; Menegalli, F.C. Isolation and Characterization of Cellulose Nano-Fibers from Banana Peels. Cellulose 2014, 21, 417–432. [Google Scholar] [CrossRef]

- Ballesteros-Vivas, D.; Alvarez-Rivera, G.; Medina, S.J.M.; Del Pilar Sánchez Camargo, A.; Ibánez, E.; Parada-Alfonso, F.; Cifuentes, A. An Integrated Approach for the Valorization of Mango Seed Kernel: Efficient Extraction Solvent Selection, Photochemical Profiling and Anti-Proliferative Activity Assessment. Food Res. Int. 2019, 126, 108616. [Google Scholar] [CrossRef]

- Kim, H.; Kim, H.; Mosaddik, A.; Gyawali, R.; Ahn, K.S.; Cho, S.K. Induction of Apoptosis by Ethanolic Extract of Mango Peel and Comparative Analysis of the Chemical Constitutes of Mango Peel and Flesh. Food Chem. 2012, 133, 416–422. [Google Scholar] [CrossRef] [PubMed]

- Ajila, C.; Naidu, K.; Bhat, S.; Rao, U. Bioactive Compounds and Antioxidant Potential of Mango Peel Extract. Food Chem. 2007, 105, 982–988. [Google Scholar] [CrossRef]

- Sójka, M.; Kołodziejczyk, K.; Milala, J.; Abadias, M.; Viñas, I.; Guyot, S.; Baron, A. Composition and Properties of the Polyphenolic Extracts Obtained from Industrial Plum Pomaces. J. Funct. Foods 2015, 12, 168–178. [Google Scholar] [CrossRef]

- Valle, D.; Camara, M.; Torija, M. Chemical Characterization of Tomato Pomace. J. Sci. Food Agric. 2006, 86, 1232–1236. [Google Scholar] [CrossRef]

- Chantaro, P.; Devahastin, S.; Chiewchan, N. Production of Antioxidant High Dietary Fiber Powder from Carrot Peels. Lebenson. Wiss. Technol. 2008, 41, 1987–1994. [Google Scholar] [CrossRef]

- Benitez, V.; Molla, E.; Martın-Cabrejas, M.A.; Aguilera, Y.; Lopez-Andreu, F.J.; Terry, L.A.; Esteban, R.M. The Impact of Pasteurization and Sterilization on Bioactive Compounds of Onion By-Products. Food Bioprocess Technol. 2013, 6, 1979–1989. [Google Scholar] [CrossRef]

- Regueiro, J.; Simal-Gandara, J.; Rodrigues, A.S.; Almeida, D. Increasing the Addedvalue of Onions as a Source of Antioxidant Flavonoids: A Critical Review. Crit. Rev. Food Sci. Nutr. 2014, 54, 1050–1062. [Google Scholar]

- Gómez, M.; Martinez, M.M. Fruit and Vegetable By-Products as Novel Ingredients to Improve the Nutritional Quality of Baked Goods. Crit. Rev. Food Sci. Nutr. 2018, 58, 2119–2135. [Google Scholar] [CrossRef]

- Vulić, J.J.; Ćebović, T.N.; Čanadanović-Brunet, J.M.; Ćetković, G.S.; Čanadanović, V.M.; Djilas, S.M.; Tumbas Šaponjac, V.T. In Vivo and in Vitro Antioxidant Effects of Beetroot Pomace Extracts. J. Funct. Foods 2014, 6, 168–175. [Google Scholar] [CrossRef]

- Albishi, T.; John, J.A.; Al-Khalifa, A.S.; Shahidi, F. Phenolic Content and Antioxidant Activities of Selected Potato Varieties and Their Processing By-Products. J. Funct. Foods 2013, 5, 590–600. [Google Scholar] [CrossRef]

- Friedman, M. Chemistry and Anticarcinogenic Mechanisms of Glycoalkaloids Produced by Eggplants, Potatoes, and Tomatoes. J. Agric. Food Chem. 2015, 63, 3323–3337. [Google Scholar] [CrossRef]

- Ncobela, C.N.; Kanengoni, A.T.; Hlatini, V.A.; Thomas, R.S.; Chimonyo, M. A Review of the Utility of Potato By-Products as a Feed Resource for Smallholder Pig Production. Anim. Feed Sci. Technol. 2017, 227, 107–117. [Google Scholar] [CrossRef]

- Salim, N.S.M.; Singh, A.; Raghavan, V. Potential Utilization of Fruit and Vegetable Wastes for Food through Drying or Extraction Techniques. Nov. Tech. Nutr. Food Sci. 2017, 1, 1–12. [Google Scholar] [CrossRef]

- Ayala-Zavala, J.F.; Vega-Vega, V.; Rosas-Domínguez, C.; Palafox-Carlos, H.; Villa-Rodriguez, J.A.; Siddiqui, M.W.; Dávila-Aviña, J.E.; González-Aguilar, G.A. Agro-Industrial Potential of Exotic Fruit Byproducts as a Source of Food Additives. Food Res. Int. 2011, 44, 1866–1874. [Google Scholar] [CrossRef]

- Dimou, C.; Karantonis, H.C.; Skalkos, D.; Koutelidakis, A.E. Valorization of Fruits By-Products to Unconventional Sources of Additives, Oil, Biomolecules and Innovative Functional Foods. Curr. Pharm. Biotechnol. 2019, 20, 776–786. [Google Scholar] [CrossRef]

- Alexandre, E.M.C.; Castro, L.M.G.; Moreira, S.A.; Pintado, M.; Saraiva, J.A. Comparison of Emerging Technologies to Extract High-Added Value Compounds from Fruit Residues: Pressure- and Electro-Based Technologies. Food Eng. Rev. 2017, 9, 190–212. [Google Scholar] [CrossRef]

- Rezende, E.S.V.; Lima, G.C.; Naves, M.M.V. Dietary Fibers as Beneficial Microbiota Modulators: A Proposed Classification by Prebiotic Categories. Nutrition 2021, 89, 111217. [Google Scholar] [CrossRef]

- Nawirska, A.; Kwaśniewska, M. Dietary Fibre Fractions from Fruit and Vegetable Processing Waste. Food Chem. 2005, 91, 221–225. [Google Scholar] [CrossRef]

- Dhillon, G.S.; Kaur, S.; Brar, S.K. Perspective of Apple Processing Wastes as Low-Cost Substrates for Bioproduction of High Value Products: A Review. Renew. Sustain. Energy Rev. 2013, 27, 789–805. [Google Scholar] [CrossRef]

- Navarro-González, I.; García-Valverde, V.; García-Alonso, J.; Periago, M.J. Chemical Profile, Functional and Antioxidant Properties of Tomato Peel Fiber. Food Res. Int. 2011, 44, 1528–1535. [Google Scholar] [CrossRef]

- Jayalaxmi, B.; Vijayalakshmi, D.; Kapale, M. Extraction of Total Polyphenols and Dietary Fiber from Mango Peel-As Potential Sources of Natural Phytonutrients. Int. J. Curr. Microbiol. Appl. Sci. 2018, 7, 1196–1205. [Google Scholar] [CrossRef]

- Pacheco, M.T.; Moreno, F.J.; Villamiel, M. Chemical and Physicochemical Characterization of Orange By-Products Derived from Industry. J. Sci. Food Agric. 2019, 99, 868–876. [Google Scholar] [CrossRef]

- Venkatanagaraju, E.; Bharathi, N.; Hema Sindhuja, R.; Roy Chowdhury, R.; Sreelekha, Y. Extraction and Purification of Pectin from Agro-Industrial Wastes. In Pectins—Extraction, Purification, Characterization and Applications; IntechOpen: London, UK, 2020. [Google Scholar]

- Ayo, J.A.; Kajo, N. Effect of Soybean Hulls Supplementation on the Quality of Acha Based Biscuits. Agric. Biol. J. N. Am. 2016, 6, 49–56. [Google Scholar]

- Sęczyk, Ł.; Świeca, M.; Dziki, D.; Anders, A.; Gawlik-Dziki, U. Antioxidant, Nutritional and Functional Characteristics of Wheat Bread Enriched with Ground Flaxseed Hulls. Food Chem. 2017, 214, 32–38. [Google Scholar] [CrossRef]

- Averilla, J.N.; Oh, J.; Kim, H.J.; Kim, J.S.; Kim, J.-S. Potential Health Benefits of Phenolic Compounds in Grape Processing By-Products. Food Sci. Biotechnol. 2019, 28, 1607–1615. [Google Scholar] [CrossRef]

- Iannone, A.; Sapone, V.; Di Paola, L.; Cicci, A.; Bravi, M. Extraction of Anthocyanins from Grape (Vitis Vinifera) Skins Employing Natural Deep Eutectic Solvents (NaDES). Chem. Eng. Trans. 2021, 87, 469–474. [Google Scholar]

- Belovic, M.; Torbica, A.; Pajic-Lijakovic, I.; Mastilovic, J. Development of Lowcalorie Jams with Increased Content of Natural Dietary Fibre Made from Tomato Pomace. Food Chem. 2017, 237, 1226–1233. [Google Scholar] [CrossRef]

- Serna-Cock, L.; García-Gonzales, E.; Torres-León, C. Agro-Industrial Potential of the Mango Peel Based on Its Nutritional and Functional Properties. Food Rev. Int. 2016, 32, 364–376. [Google Scholar] [CrossRef]

- Kohajdová, Z.; Karovičová, J.; Kuchtová, V.; Lauková, M. Utilisation of Beetroot Powder for Bakery Applications. Chem. Pap. 2018, 72, 1507–1515. [Google Scholar] [CrossRef]

- Mattos, G.N.; Tonon, R.V.; Furtado, A.A.L.; Cabral, L.M.C. Grape By-Product Extracts against Microbial Proliferation and Lipid Oxidation: A Review: Grape by-Products with Antimicrobial and Antioxidant Potential. J. Sci. Food Agric. 2017, 97, 1055–1064. [Google Scholar] [CrossRef] [PubMed]

- Huc-Mathis, D.; Journet, C.; Fayolle, N.; Bosc, V. Emulsifying Properties of Food By-Products: Valorizing Apple Pomace and Oat Bran. Colloids Surf. A Physicochem. Eng. Asp. 2019, 568, 84–91. [Google Scholar] [CrossRef]

- Juarez-Garcia, E.; Agama-Acevedo, E.; Sáyago-Ayerdi, S.G.; Rodríguez-Ambriz, S.L.; Bello-Pérez, L.A. Composition, Digestibility and Application in Breadmaking of Banana Flour. Plant Foods Hum. Nutr. 2006, 61, 131–137. [Google Scholar] [CrossRef]

- Sendra, E.; Fayos, P.; Lario, Y.; Fernández-López, J.; Sayas-Barberá, E.; Pérez-Alvarez, J.A. Incorporation of Citrus Fibers in Fermented Milk Containing Probiotic Bacteria. Food Microbiol. 2008, 25, 13–21. [Google Scholar] [CrossRef] [PubMed]

- Satari, B.; Karimi, K. Citrus Processing Wastes: Environmental Impacts, Recent Advances, and Future Perspectives in Total Valorization. Resour. Conserv. Recycl. 2018, 129, 153–167. [Google Scholar] [CrossRef]

- Singh, V.K.; Das, S.; Dubey, N.K. Nutritional Oils for Food and Their Quality Improvement Using Genetically Modified Organisms (GMOs). In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Del Rio, D.; Rodriguez-Mateos, A.; Spencer, J.P.E.; Tognolini, M.; Borges, G.; Crozier, A. Dietary (Poly)Phenolics in Human Health: Structures, Bioavailability, and Evidence of Protective Effects against Chronic Diseases. Antioxid. Redox Signal. 2013, 18, 1818–1892. [Google Scholar] [CrossRef]

- Acosta-Estrada, B.A.; Gutiérrez-Uribe, J.A.; Serna-Saldívar, S.O. Bound Phenolics in Foods, a Review. Food Chem. 2014, 152, 46–55. [Google Scholar] [CrossRef]

- Omre, P.K.; Singh, S.; Singh, S. Waste Utilization of Fruits and Vegetables—A Review. South Asian J. Food Technol. Environ. 2018, 4, 605–615. [Google Scholar] [CrossRef]

- Ayala-Zavala, J.F.; Rosas-Domínguez, C.; Vega-Vega, V.; González-Aguilar, G.A. Antioxidant Enrichment and Antimicrobial Protection of Fresh-Cut Fruits Using Their Own Byproducts: Looking for Integral Exploitation. J. Food Sci. 2010, 75, R175–R181. [Google Scholar] [CrossRef]

- Yu, M.; Gouvinhas, I.; Rocha, J.; Barros, A.I.R.N.A. Phytochemical and Antioxidant Analysis of Medicinal and Food Plants towards Bioactive Food and Pharmaceutical Resources. Sci. Rep. 2021, 11, 10041. [Google Scholar] [CrossRef]

- Teixeira, A.; Baenas, N.; Dominguez-Perles, R.; Barros, A.; Rosa, E.; Moreno, D.A.; Garcia-Viguera, C. Natural Bioactive Compounds from Winery by-Products as Health Promoters: A Review. Int. J. Mol. Sci. 2014, 15, 15638–15678. [Google Scholar] [CrossRef]

- Nieto, J.A.; Santoyo, S.; Prodanov, M.; Reglero, G.; Jaime, L. Valorisation of Grape Stems as a Source of Phenolic Antioxidants by Using a Sustainable Extraction Methodology. Foods 2020, 9, 604. [Google Scholar] [CrossRef] [PubMed]

- Barros, A.; Gouvinhas, I.; Machado, N.; Pinto, J.; Cunha, M.; Rosa, E.; Domínguez-Perles, R. New Grape Stems-Based Liqueur: Physicochemical and Phytochemical Evaluation. Food Chem. 2016, 190, 896–903. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Moreno, M.J.; Raposo, R.; Cayuela, J.M.; Zafrilla, P.; Piñeiro, Z.; Moreno-Rojas, J.M.; Mulero, J.; Puertas, B.; Giron, F.; Guerrero, R.F.; et al. Valorization of Grape Stems. Ind. Crops Prod. 2015, 63, 152–157. [Google Scholar] [CrossRef]

- Goula, A.M.; Lazarides, H.N. Integrated Processes Can Turn Industrial Food Waste into Valuable Food By-Products and/or Ingredients: The Cases of Olive Mill and Pomegranate Wastes. J. Food Eng. 2015, 167, 45–50. [Google Scholar] [CrossRef]

- Singh, B.; Singh, J.P.; Kaur, A.; Singh, N. Phenolic Composition, Antioxidant Potential and Health Benefits of Citrus Peel. Food Res. Int. 2020, 132, 109114. [Google Scholar] [CrossRef]

- González-Montelongo, R.; Gloria Lobo, M.; González, M. Antioxidant Activity in Banana Peel Extracts: Testing Extraction Conditions and Related Bioactive Compounds. Food Chem. 2010, 119, 1030–1039. [Google Scholar] [CrossRef]

- Lafka, T.-I.; Sinanoglou, V.; Lazos, E.S. On the Extraction and Antioxidant Activity of Phenolic Compounds from Winery Wastes. Food Chem. 2007, 104, 1206–1214. [Google Scholar] [CrossRef]

- Szabo, K.; Mitrea, L.; Călinoiu, L.F.; Teleky, B.-E.; Martău, G.A.; Plamada, D.; Pascuta, M.S.; Nemeş, S.-A.; Varvara, R.-A.; Vodnar, D.C. Natural Polyphenol Recovery from Apple-, Cereal-, and Tomato-Processing by-Products and Related Health-Promoting Properties. Molecules 2022, 27, 7977. [Google Scholar] [CrossRef]

- Rojas-García, A.; Rodríguez, L.; Cádiz-Gurrea, M.d.l.L.; García-Villegas, A.; Fuentes, E.; Villegas-Aguilar, M.d.C.; Palomo, I.; Arráez-Román, D.; Segura-Carretero, A. Determination of the Bioactive Effect of Custard Apple By-Products by in Vitro Assays. Int. J. Mol. Sci. 2022, 23, 9238. [Google Scholar] [CrossRef]

- Asma, U.; Morozova, K.; Ferrentino, G.; Scampicchio, M. Apples and Apple By-Products: Antioxidant Properties and Food Applications. Antioxidants 2023, 12, 1456. [Google Scholar] [CrossRef]

- Ben-Othman, S.; Jõudu, I.; Bhat, R. Bioactives from Agri-Food Wastes: Present Insights and Future Challenges. Molecules 2020, 25, 510. [Google Scholar] [CrossRef] [PubMed]

- Meléndez-Martínez, A.J.; Mandić, A.I.; Bantis, F.; Böhm, V.; Borge, G.I.A.; Brnčić, M.; Bysted, A.; Cano, M.P.; Dias, M.G.; Elgersma, A.; et al. A Comprehensive Review on Carotenoids in Foods and Feeds: Status Quo, Applications, Patents, and Research Needs. Crit. Rev. Food Sci. Nutr. 2022, 62, 1999–2049. [Google Scholar] [CrossRef]

- Saini, R.K.; Nile, S.H.; Park, S.W. Carotenoids from Fruits and Vegetables: Chemistry, Analysis, Occurrence, Bioavailability and Biological Activities. Food Res. Int. 2015, 76 Pt 3, 735–750. [Google Scholar] [CrossRef] [PubMed]

- Rivera-Madrid, R.; Carballo-Uicab, V.M.; Cárdenas-Conejo, Y.; Aguilar-Espinosa, M.; Siva, R. Overview of Carotenoids and Beneficial Effects on Human Health. In Carotenoids: Properties, Processing and Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–40. [Google Scholar]

- Rudra, S.G.; Hanan, E.; Sagar, V.R.; Bhardwaj, R.; Basu, S.; Sharma, V. Manufacturing of Mayonnaise with Pea Pod Powder as a Functional Ingredient. J. Food Meas. Charact. 2020, 14, 2402–2413. [Google Scholar] [CrossRef]

- Tiwari, S.; Upadhyay, N.; Singh, A.K.; Meena, G.S.; Arora, S. Organic Solvent-Free Extraction of Carotenoids from Carrot Bio-Waste and Its Physico-Chemical Properties. J. Food Sci. Technol. 2019, 56, 4678–4687. [Google Scholar] [CrossRef]

- Nour, V.; Ionica, M.E.; Trandafir, I. Bread Enriched in Lycopene and Other Bioactive Compounds by Addition of Dry Tomato Waste. J. Food Sci. Technol. 2015, 52, 8260–8267. [Google Scholar] [CrossRef]

- Santanna, V.; Christiano, F.D.P.; Marczak, L.D.F.; Tessaro, I.C.; Thys, R.C. The Effect of the Incorporation of Grape Marc Powder in Fettuccini Pasta Properties. LWT-Food Sci. Technol. 2014, 58, 497–501. [Google Scholar] [CrossRef]

- Sharma, R.; Oberoi, H.S.; Dhillon, G.S. Agro-Industrial Wastes as Feedstock for Enzyme Production: Apply and Exploit the Emerging and Valuable Use Options of Waste Biomass; Dhillon, G.S., Kaur, S., Eds.; Academic Press: Cambridge, MA, USA; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Swain, M.R.; Ray, R.C.; Patra, J.K. Citric Acid: Microbial Production and Applications in Food and Pharmaceutical Industries. In Citric Acid: Synthesis, Properties, and Applications; Vargas, D.A., Medina, J.V., Eds.; Nova Science Publishers: Hauppauge, NY, USA, 2011; pp. 1–22. [Google Scholar]

- Dhillon, G.S.; Brar, S.K.; Verma, M.; Tyagi, R.D. Enhanced Solid-State Citric Acid Bio-Production Using Apple Pomace Waste through Surface Response Methodology: Enhanced Solid-State Citric Acid Bio-Production. J. Appl. Microbiol. 2011, 110, 1045–1055. [Google Scholar] [CrossRef]

- Prabha, M.S.; Rangaiah, G.S. Citric Acid Production Using Ananas Comosus and Its Waste with the Effect of Alcohols. Int. J. Curr. Microbiol. Appl. 2014, 3, 747–754. [Google Scholar]

- Ibrahim, S.A.; Fidan, H.; Aljaloud, S.O.; Stankov, S.; Ivanov, G. Application of Date (Phoenix dactylifera L.) Fruit in the Composition of a Novel Snack Bar. Foods 2021, 10, 918. [Google Scholar] [CrossRef] [PubMed]

- Coman, V.; Teleky, B.-E.; Mitrea, L.; Martău, G.A.; Szabo, K.; Călinoiu, L.-F.; Vodnar, D.C. Bioactive Potential of Fruit and Vegetable Wastes. Adv. Food Nutr. Res. 2020, 91, 157–225. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, P.; Indrani, D.; Singh, R.P. Effect of Dried Pomegranate (Punica granatum) Peel Powder (DPPP) on Textural, Organoleptic and Nutritional Characteristics of Biscuits. Int. J. Food Sci. Nutr. 2014, 65, 827–833. [Google Scholar] [CrossRef]

- Ajila, C.M.; Leelavathi, K.; Prasada Rao, U.J.S. Improvement of Dietary Fiber Content and Antioxidant Properties in Soft Dough Biscuits with the Incorporation of Mango Peel Powder. J. Cereal Sci. 2008, 48, 319–326. [Google Scholar] [CrossRef]

- Martins, Z.E.; Pinho, O.; Ferreira, I.M.P.L.V.O. Food Industry By-Products Used as Functional Ingredients of Bakery Products. Trends Food Sci. Technol. 2017, 67, 106–128. [Google Scholar] [CrossRef]

- Meral, R.; Köse, Y.E. The Effect of Bread-Making Process on the Antioxidant Activity and Phenolic Profile of Enriched Breads. Qual. Assur. Saf. Crops Foods 2019, 11, 171–181. [Google Scholar] [CrossRef]

- Hussain, M.I.; Farooq, M.; Syed, Q.A. Nutritional and Biological Characteristics of the Date Palm Fruit (Phoenix dactylifera L.)-A Review. Food Biosci. 2020, 34, 100509. [Google Scholar] [CrossRef]

- Romero-Lopez, M.R.; Osorio-Diaz, P.; Bello-Perez, L.A.; Tovar, J.; Bernardino-Nicanor, A. Fiber Concentrate from Orange (Citrus sinensis L.) Bagase: Characterization and Application as Bakery Product Ingredient. Int. J. Mol. Sci. 2011, 12, 2174–2186. [Google Scholar] [CrossRef]

- Rupasinghe, H.; Wang, L.; Huber, G.; Pitts, N. Effect of Baking on Dietary Fibre and Phenolics of Muffins Incorporated with Apple Skin Powder. Food Chem. 2008, 107, 1217–1224. [Google Scholar] [CrossRef]

- Ramírez-Maganda, J.; Blancas-Benítez, F.J.; Zamora-Gasga, V.M.; García-Magaña, M.d.L.; Bello-Pérez, L.A.; Tovar, J.; Sáyago-Ayerdi, S.G. Nutritional Properties and Phenolic Content of a Bakery Product Substituted with a Mango (Mangifera Indica) ‘Ataulfo’ Processing by-Product. Food Res. Int. 2015, 73, 117–123. [Google Scholar] [CrossRef]

- Bajerska, J.; Mildner-Szkudlarz, S.; Górnaś, P.; Seglina, D. The Effects of Muffins Enriched with Sour Cherry Pomace on Acceptability, Glycemic Response, Satiety and Energy Intake: A Randomized Crossover Trial: The Effects of Muffins Enriched with Sour Cherry Pomace in a Crossover Trial. J. Sci. Food Agric. 2016, 96, 2486–2493. [Google Scholar] [CrossRef]

- Jeddou, K.B.; Bouaziz, F.; Zouari-Ellouzi, S.; Chaari, F.; Ellouz-Chaabouni, S.; Ellouz-Ghorbel, R.; Nouri-Ellouz, O. Improvement of Texture and Sensory Properties of Cakes by Addition of Potato Peel Powder with High Level of Dietary Fiber and Protein. Food Chem. 2017, 217, 668–677. [Google Scholar] [CrossRef] [PubMed]

- Kırbaş, Z.; Kumcuoglu, S.; Tavman, S. Effects of Apple, Orange and Carrot Pomace Powders on Gluten-Free Batter Rheology and Cake Properties. J. Food Sci. Technol. 2019, 56, 914–926. [Google Scholar] [CrossRef] [PubMed]

- Krishnan, R.; Dharmaraj, U.; Sai Manohar, R.; Malleshi, N.G. Quality Characteristics of Biscuits Prepared from Finger Millet Seed Coat Based Composite Flour. Food Chem. 2011, 129, 499–506. [Google Scholar] [CrossRef]

- Alongi, M.; Melchior, S.; Anese, M. Reducing the Glycemic Index of Short Dough Biscuits by Using Apple Pomace as a Functional Ingredient. Lebenson. Wiss. Technol. 2019, 100, 300–305. [Google Scholar] [CrossRef]

- Colantuono, A.; Ferracane, R.; Vitaglione, P. In Vitro Bioaccessibility and Functional Properties of Polyphenols from Pomegranate Peels and Pomegranate Peels-Enriched Cookies. Food Funct. 2016, 7, 4247–4258. [Google Scholar] [CrossRef]

- Theagarajan, R.; Narayanaswamy, L.M.; Dutta, S.; Moses, J.A.; Chinnaswamy, A. Valorisation of Grape Pomace (Cv. Muscat) for Development of Functional Cookies. Int. J. Food Sci. Technol. 2019, 54, 1299–1305. [Google Scholar] [CrossRef]

- de Toledo, N.M.V.; Nunes, L.P.; da Silva, P.P.M.; Spoto, M.H.F.; Canniatti-Brazaca, S.G. Influence of Pineapple, Apple and Melon by-Products on Cookies: Physicochemical and Sensory Aspects. Int. J. Food Sci. Technol. 2017, 52, 1185–1192. [Google Scholar] [CrossRef]

- Servili, M.; Rizzello, C.G.; Taticchi, A.; Esposto, S.; Urbani, S.; Mazzacane, F.; Di Maio, I.; Selvaggini, R.; Gobbetti, M.; Di Cagno, R. Functional Milk Beverage Fortified with Phenolic Compounds Extracted from Olive Vegetation Water, and Fermented with Functional Lactic Acid Bacteria. Int. J. Food Microbiol. 2011, 147, 45–52. [Google Scholar] [CrossRef]

- Issar, K.; Sharma, P.C.; Gupta, A. Utilization of Apple Pomace in the Preparation of Fiber-Enriched Acidophilus Yoghurt: Utilization of Apple Pomace Fiber in Yoghurt. J. Food Process. Preserv. 2017, 41, e13098. [Google Scholar] [CrossRef]

- Aliakbarian, B.; Casale, M.; Paini, M.; Casazza, A.A.; Lanteri, S.; Perego, P. Production of a Novel Fermented Milk Fortified with Natural Antioxidants and Its Analysis by NIR Spectroscopy. Lebenson. Wiss. Technol. 2015, 62, 376–383. [Google Scholar] [CrossRef]

- Chouchouli, V.; Kalogeropoulos, N.; Konteles, S.J.; Karvela, E.; Makris, D.P.; Karathanos, V.T. Fortification of Yoghurts with Grape (Vitis Vinifera) Seed Extracts. Lebenson. Wiss. Technol. 2013, 53, 522–529. [Google Scholar] [CrossRef]

- Marchiani, R.; Bertolino, M.; Belviso, S.; Giordano, M.; Ghirardello, D.; Torri, L.; Piochi, M.; Zeppa, G. Yogurt Enrichment with Grape Pomace: Effect of Grape Cultivar on Physicochemical, Microbiological and Sensory Properties: Grape Skin Flour and Yogurt Quality. J. Food Qual. 2016, 39, 77–89. [Google Scholar] [CrossRef]

- Lucera, A.; Costa, C.; Marinelli, V.; Saccotelli, M.; Del Nobile, M.; Conte, A. Fruit and Vegetable By-Products to Fortify Spreadable Cheese. Antioxidants 2018, 7, 61. [Google Scholar] [CrossRef]

- Shan, B.; Cai, Y.-Z.; Brooks, J.D.; Corke, H. Potential Application of Spice and Herb Extracts as Natural Preservatives in Cheese. J. Med. Food 2011, 14, 284–290. [Google Scholar] [CrossRef]

- Felix da Silva, D.; Matumoto-Pintro, P.T.; Bazinet, L.; Couillard, C.; Britten, M. Effect of Commercial Grape Extracts on the Cheese-Making Properties of Milk. J. Dairy Sci. 2015, 98, 1552–1562. [Google Scholar] [CrossRef]

- Abid, Y.; Azabou, S.; Jridi, M.; Khemakhem, I.; Bouaziz, M.; Attia, H. Storage Stability of Traditional Tunisian Butter Enriched with Antioxidant Extract from Tomato Processing By-Products. Food Chem. 2017, 233, 476–482. [Google Scholar] [CrossRef] [PubMed]

- Çam, M.; Erdoğan, F.; Aslan, D.; Dinç, M. Enrichment of Functional Properties of Ice Cream with Pomegranate By-Products: Enrichment of Ice Cream. J. Food Sci. 2013, 78, C1543–C1550. [Google Scholar] [CrossRef]

- Younis, K.; Ahmad, S.; Malik, M.A. Mosambi Peel Powder Incorporation in Meat Products: Effect on Physicochemical Properties and Shelf Life Stability. Appl. Food Res. 2021, 1, 100015. [Google Scholar] [CrossRef]

- Gibson, C. Sensory Evaluation of Meat of Broiler Poultry Birds Fed with Tomato-Supplemented Feed. Am. Sci. Res. J. Eng. Technol. Sci. 2018, 47, 145–150. [Google Scholar]

- Shahidi, F.; Chandrasekara, A. Millet Grain Phenolics and Their Role in Disease Risk Reduction and Health Promotion: A Review. J. Funct. Foods 2013, 5, 570–581. [Google Scholar] [CrossRef]

- Tekgül, Y.; Baysal, T. Comparative Evaluation of Quality Properties and Volatile Profiles of Lemon Peels Subjected to Different Drying Techniques. J. Food Process Eng. 2018, 41, e12902. [Google Scholar] [CrossRef]

- Ergezer, H.; Serdaroğlu, M. Antioxidant Potential of Artichoke (Cynara scolymus L.) Byproducts Extracts in Raw Beef Patties during Refrigerated Storage. J. Food Meas. Charact. 2018, 12, 982–991. [Google Scholar] [CrossRef]

- Andrés, A.I.; Petrón, M.J.; Adámez, J.D.; López, M.; Timón, M.L. Food By-Products as Potential Antioxidant and Antimicrobial Additives in Chill Stored Raw Lamb Patties. Meat Sci. 2017, 129, 62–70. [Google Scholar] [CrossRef]

- Bryant, C.; Barnett, J. Consumer Acceptance of Cultured Meat: A Systematic Review. Meat Sci. 2018, 143, 8–17. [Google Scholar] [CrossRef]

- Amofa-Diatuo, T.; Anang, D.M.; Barba, F.J.; Tiwari, B.K. Development of New Apple Beverages Rich in Isothiocyanates by Using Extracts Obtained from Ultrasound-Treated Cauliflower by-Products: Evaluation of Physical Properties and Consumer Acceptance. J. Food Compost. Anal. 2017, 61, 73–81. [Google Scholar] [CrossRef]

- Wedamulla, N.E.; Fan, M.; Choi, Y.-J.; Kim, E.-K. Citrus Peel as a Renewable Bioresource: Transforming Waste to Food Additives. J. Funct. Foods 2022, 95, 105163. [Google Scholar] [CrossRef]

- Combest, S.; Warren, C.; Patterson, M. Upcycling Brewers’ Spent Grain: The Development of Muffins and Biomarker Response after Consuming Muffins for 8-Weeks in Healthy Adults from Randomized-Controlled Trial. Curr. Dev. Nutr. 2020, 4, 4140745. [Google Scholar] [CrossRef]

- Bianchi, F.; Tolve, R.; Rainero, G.; Bordiga, M.; Brennan, C.S.; Simonato, B. Technological, Nutritional and Sensory Properties of Pasta Fortified with Agro-industrial By-products: A Review. Int. J. Food Sci. Technol. 2021, 56, 4356–4366. [Google Scholar] [CrossRef]

- Cuomo, F.; Trivisonno, M.C.; Iacovino, S.; Messia, M.C.; Marconi, E. Sustainable Re-Use of Brewer’s Spent Grain for the Production of High Protein and Fibre Pasta. Foods 2022, 11, 642. [Google Scholar] [CrossRef]

- Ginindza, A.; Solomon, W.K.; Shelembe, J.S.; Nkambule, T.P. Valorisation of Brewer’s Spent Grain Flour (BSGF) through Wheat-Maize-BSGF Composite Flour Bread: Optimization Using D-Optimal Mixture Design. Heliyon 2022, 8, e09514. [Google Scholar] [CrossRef] [PubMed]

- Bertagnolli, S.M.M.; Silveira, M.L.R.; Fogaça, A.d.O.; Umann, L.; Penna, N.G. Bioactive Compounds and Acceptance of Cookies Made with Guava Peel Flour. Food Sci. Technol. 2014, 34, 303–308. [Google Scholar] [CrossRef]

- Boff, J.M.; Strasburg, V.J.; Ferrari, G.T.; de Oliveira Schmidt, H.; Manfroi, V.; de Oliveira, V.R. Chemical, Technological, and Sensory Quality of Pasta and Bakery Products Made with the Addition of Grape Pomace Flour. Foods 2022, 11, 3812. [Google Scholar] [CrossRef] [PubMed]

- Ungureanu-Iuga, M.; Dimian, M.; Mironeasa, S. Development and Quality Evaluation of Gluten-Free Pasta with Grape Peels and Whey Powders. Lebenson. Wiss. Technol. 2020, 130, 109714. [Google Scholar] [CrossRef]

- Begum, T.; Islam, Z.K.; Rana Siddiki, M.S.; Habib, R.; Rashid, H.U. Preparation of Fermented Beverage from Whey-Based Watermelon (Citrullus Lanatus) Juice. J. Dairy. Foods Home Sci. 2019, 38, 301–306. [Google Scholar] [CrossRef]

- Marchiani, R.; Bertolino, M.; Ghirardello, D.; McSweeney, P.L.H.; Zeppa, G. Physicochemical and Nutritional Qualities of Grape Pomace Powder-Fortified Semi-Hard Cheeses. J. Food Sci. Technol. 2016, 53, 1585–1596. [Google Scholar] [CrossRef]

- Gaglio, R.; Barbaccia, P.; Barbera, M.; Restivo, I.; Attanzio, A.; Maniaci, G.; Di Grigoli, A.; Francesca, N.; Tesoriere, L.; Bonanno, A.; et al. The Use of Winery By-Products to Enhance the Functional Aspects of the Fresh Ovine “Primosale” Cheese. Foods 2021, 10, 461. [Google Scholar] [CrossRef]

- Mercadante, A.Z.; Capitani, C.D.; Decker, E.A.; Castro, I.A. Effect of Natural Pigments on the Oxidative Stability of Sausages Stored under Refrigeration. Meat Sci. 2010, 84, 718–726. [Google Scholar] [CrossRef]

- Huda, A.; Parveen, S.; Sajad, A.R.; Akhter, R.; Hassan, M. Effect of Incorporation of Apple Pomace on the Physico-Chemical, Sensory and Textural Properties of Mutton Nuggets. Int. J. Adv. Res. 2004, 2, 974–983. [Google Scholar]

- Tremlova, B.; Havlova, L.; Benes, P.; Zemancova, J.; Buchtova, H.; Tesikova, K.; Dordevic, S.; Dordevic, D. Vegetarian “Sausages” with the Addition of Grape Flour. Appl. Sci. 2022, 12, 2189. [Google Scholar] [CrossRef]

- Liu, H.; Xu, X.; Cui, H.; Xu, J.; Yuan, Z.; Liu, J.; Li, C.; Li, J.; Zhu, D. Plant-Based Fermented Beverages and Key Emerging Processing Technologies. Food Rev. Int. 2022, 38, 1–20. [Google Scholar] [CrossRef]

- García-Lomillo, J.; González-SanJosé, M.L.; Del Pino-García, R.; Rivero-Pérez, M.D.; Muñiz-Rodríguez, P. Antioxidant and Antimicrobial Properties of Wine Byproducts and Their Potential Uses in the Food Industry. J. Agric. Food Chem. 2014, 62, 12595–12602. [Google Scholar] [CrossRef] [PubMed]

- Gasiński, A.; Kawa-Rygielska, J.; Mikulski, D.; Kłosowski, G.; Głowacki, A. Application of White Grape Pomace in the Brewing Technology and Its Impact on the Concentration of Esters and Alcohols, Physicochemical Parameteres and Antioxidative Properties of the Beer. Food Chem. 2022, 367, 130646. [Google Scholar] [CrossRef]

- Pérez-Bibbins, B.; Torrado-Agrasar, A.; Salgado, J.M.; Oliveira, R.P.d.S.; Domínguez, J.M. Potential of Lees from Wine, Beer and Cider Manufacturing as a Source of Economic Nutrients: An Overview. Waste Manag. 2015, 40, 72–81. [Google Scholar] [CrossRef] [PubMed]

- Al-Obadi, M.; Ayad, H.; Pokharel, S.; Ayari, M.A. Perspectives on Food Waste Management: Prevention and Social Innovations. Sustain. Prod. Consum. 2022, 31, 190–208. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Food Waste Index Report 2021; United Nations Environment Programme: Nairobi, Kenya, 2021; ISBN 978-92-807-3868-1. [Google Scholar]

- Carmona-Cabello, M.; Garcia, I.L.; Leiva-Candia, D.; Dorado, M.P. Valorization of Food Waste Based on Its Composition through the Concept of Biorefinery. Curr. Opin. Green Sustain. Chem. 2018, 14, 67–79. [Google Scholar] [CrossRef]

- The World Counts. 2023. Available online: https://www.theworldcounts.com/challenges/people-and-poverty/hunger-and-obesity/food-waste-statistics (accessed on 20 June 2023).

- Elgarahy, A.M.; Eloffy, M.G.; Alengebawy, A.; El-Sherif, D.M.; Gaballah, M.S.; Elwakeel, K.Z.; El-Qelish, M. Sustainable Management of Food Waste; Pre-Treatment Strategies, Techno-Economic Assessment, Bibliometric Analysis, and Potential Utilizations: A Systematic Review. Environ. Res. 2023, 225, 115558. [Google Scholar] [CrossRef]

- Pérez-Marroquín, X.A.; Estrada-Fernández, A.G.; García-Ceja, A.; Aguirre-Álvarez, G.; León-López, A. Agro-Food Waste as an Ingredient in Functional Beverage Processing: Sources, Functionality, Market and Regulation. Foods 2023, 12, 1583. [Google Scholar] [CrossRef]

- Alara, O.R.; Abdurahman, N.H.; Ukaegbu, C.I. Extraction of Phenolic Compounds: A Review. Curr. Res. Food Sci. 2021, 4, 200–214. [Google Scholar] [CrossRef]

- Dey, G.; Sireswar, S. Tailoring Functional Beverages from Fruits and Vegetables for Specific Disease Conditions-Are We There Yet? Crit. Rev. Food Sci. Nutr. 2021, 61, 2034–2046. [Google Scholar] [CrossRef]

- Santagata, R.; Zucaro, A.; Viglia, S.; Ripa, M.; Tian, X.; Ulgiati, S. Assessing the Sustainability of Urban Eco-Systems through Emergy-Based Circular Economy Indicators. Ecol. Indic. 2020, 109, 105859. [Google Scholar] [CrossRef]

- Dahiya, S.; Kumar, A.N.; Shanthi Sravan, J.; Chatterjee, S.; Sarkar, O.; Mohan, S.V. Food Waste Biorefinery: Sustainable Strategy for Circular Bioeconomy. Bioresour. Technol. 2018, 248, 2–12. [Google Scholar] [CrossRef]

- Galali, Y.; Omar, Z.A.; Sajadi, S.M. Biologically Active Components in By-Products of Food Processing. Food Sci. Nutr. 2020, 8, 3004–3022. [Google Scholar] [CrossRef]

- Capanoglu, E.; Nemli, E.; Tomas-Barberan, F. Novel Approaches in the Valorization of Agricultural Wastes and Their Applications. J. Agric. Food Chem. 2022, 70, 6787–6804. [Google Scholar] [CrossRef] [PubMed]

- Gómez-García, R.; Campos, D.A.; Aguilar, C.N.; Madureira, A.R.; Pintado, M. Valorisation of Food Agro-Industrial by-Products: From the Past to the Present and Perspectives. J. Environ. Manag. 2021, 299, 113571. [Google Scholar] [CrossRef] [PubMed]

| Industry | Product | Incorporated Agri-Food By-Product | Nutritional Value | References |

|---|---|---|---|---|

| Bakery | Bread | Mango peel powder Green banana powder Pea powder Chickpea powder Banana peel powder | Increased dietary fiber and carotenoid content Increased polyphenol content and antioxidant properties Increased protein, dietary fiber, mineral, antioxidant activity and β-carotene contents Increased protein, resistant starch and dietary fiber content | Srivastava et al. [104] Ajila et al. [105] Martins et al. [106] Meral et al. [107] |

| Cookies | Watermelon rind powder | Increased dietary fiber Decreased glycemic index Increased phenolic content and the antioxidant activity | Hussain et al. [108] | |

| Muffins | Orange bagasse Apple skin powder Sour cherry pomace Strawberry, raspberry pomace Goji berry by-product | Increased dietary fiber Increased antioxidant capacity Increased total phenolic content Decreased glycemic index Increase satiety Regulate long-term energy balance | Romero-Lopez et al. [109] Rupasinghe et al. [110] Ramírez-Maganda et al. [111] Bajerska et al. [112] | |

| Snack | Date fruit paste Figs fruit paste | Increased protein Increased dietary fiber Rich in thiamin, Ca, Mg, Zn | Ibrahim et al. [102] | |

| Cake | Potato peel powder Apple, orange, and carrot pomace | Increased protein content Increased dietary fiber content Increased fiber content Increased viscosity Increased fiber, protein, carbohydrates, and sensory acceptability Increased phenolic compounds and antioxidant capacity Increased total anthocyanins | Jeddou et al. [113] Kirbas et al. [114] | |

| Biscuits | Finger millet seed coat matter Legume flour (chickpea flour, pigeon pea, mung bean flour and cowpea flour) Apple pomace Grape pomace Apple, melon by-products | Increased protein, dietary fiber and calcium contents Increased fiber and phenolic compounds Decreased dialyzed glucose Increased fiber, phenolic compounds and antioxidant capacity Increased anthocyanins, phenolic and antioxidant capacity Increased fiber content | Krishnan et al. [115] Alongi et al. [116] Colantuono et al. [117] Theagarajan et al. [118] de Toledo et al. [119] | |

| Dairy | Dairy beverage | Olive vegetable water | Increased antioxidant activity Source of phenols | Servili et al. [120] |

| Fermented milk | Apple pomace Wine pomace extract Grape marc flour Wine pomace extract and flour | Source of protein Probiotic protection Texturizing agent Source of fiber Source of phenols Increased antioxidant capacity Colorant agent | Issar et al. [121] Aliakbarian et al. [122] | |

| Yogurt | Grape seed extract Grape skin flour | Texturizing agent Increased phenols content Colorant agent Yogurt’s syneresis level was considerably reduced Maintained textural and gelling formation | Chouchouli et al. [123] Marchiani et al. [124] | |

| Cheese | Peer/apple stones Orange by-products Pomegranate peel Tomato peel Grape seed Grape pomace Wine pomace, skin and seed extract | Increased phenols content Probiotic protection Texturizing agent Increased antioxidant capacity Increased antimicrobial capacity | Lucera et al. [125] Shan et al. [126] Da Silva et al. [127] | |

| Butter | Tomato peel | Increased antioxidant capacity | Abid et al. [128] | |

| Ice cream | Pomegranate peel | Texturizing agent Increased phenols content Increased antioxidant capacity Colorant agent | Cam et al. [129] | |

| Meat | Chicken meat Patties Chickens thigh | Mosambi peel powder | Increased antioxidant capacity Anti-bacterial agent Increased microflora | Younis et al. [130] Gibson [131] |

| Pork ground Meatballs Sausages | Tomato peel Grape seed | Increased antioxidant capacity | Shahidi [132] | |

| Shrimp Tuna | Pomegranate peel | Increased antioxidant capacity Anti-bacterial agent Enhanced meat flavor and color | Tekgül and Baysal [133] | |

| Beef meatballs, Sausages | Pomegranate peel Orange peel | Increased antioxidant capacity Anti-bacterial agent | Ergezer [134] | |

| Lamb meat Patties | Tomato pomace Grape pomace Olive pomace Tomato pamace Pomegranate pomace | Increased antioxidants Anti-bacterial agent | Andrés et al. [135] Bryant and Barnett [136] | |

| Beverage | Apple juice | Pomegranate peel | Increased antioxidant capacity Anti-bacterial agent Enhanced juice flavor and color | Amofa-Diatuo et al. [137] |

| Carrot juice | Orange pulp and peel | Increased antioxidant capacity | Wedamulla et al. [138] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rațu, R.N.; Veleșcu, I.D.; Stoica, F.; Usturoi, A.; Arsenoaia, V.N.; Crivei, I.C.; Postolache, A.N.; Lipșa, F.D.; Filipov, F.; Florea, A.M.; et al. Application of Agri-Food By-Products in the Food Industry. Agriculture 2023, 13, 1559. https://doi.org/10.3390/agriculture13081559

Rațu RN, Veleșcu ID, Stoica F, Usturoi A, Arsenoaia VN, Crivei IC, Postolache AN, Lipșa FD, Filipov F, Florea AM, et al. Application of Agri-Food By-Products in the Food Industry. Agriculture. 2023; 13(8):1559. https://doi.org/10.3390/agriculture13081559

Chicago/Turabian StyleRațu, Roxana Nicoleta, Ionuț Dumitru Veleșcu, Florina Stoica, Alexandru Usturoi, Vlad Nicolae Arsenoaia, Ioana Cristina Crivei, Alina Narcisa Postolache, Florin Daniel Lipșa, Feodor Filipov, Andreea Mihaela Florea, and et al. 2023. "Application of Agri-Food By-Products in the Food Industry" Agriculture 13, no. 8: 1559. https://doi.org/10.3390/agriculture13081559

APA StyleRațu, R. N., Veleșcu, I. D., Stoica, F., Usturoi, A., Arsenoaia, V. N., Crivei, I. C., Postolache, A. N., Lipșa, F. D., Filipov, F., Florea, A. M., Chițea, M. A., & Brumă, I. S. (2023). Application of Agri-Food By-Products in the Food Industry. Agriculture, 13(8), 1559. https://doi.org/10.3390/agriculture13081559