A Co-Simulation Virtual Reality Machinery Simulator for Advanced Precision Agriculture Applications

Abstract

1. Introduction

2. Related Study

- Digital model (DM): a digital representation without automated data exchange between the entity and virtual model.

- Digital shadow (DS): a digital representation with automated information flow in one direction. This information flows from the entity to the virtual representation, meaning a change in the entity is reflected in the virtual representation.

- Digital twin (DT): a digital representation with automated bi-directional information flow. The digital twin has a virtual representation, reflecting any changes in the physical entity’s state.

- Energy consumption analysis: analyze the energy consumption of the physical system;

- Optimization/update: allows to find the optimal parameters for the operation of a system;

- Behavior analysis user operation guide: analyze human-fabricated operations and provide feedback;

- Technology integration: bring together different already deployed technologies under the same umbrella to control and visualize operations more easily.

3. Materials and Methods

- The main requirements of the simulation;

- Virtual tractor design;

- Virtual implements;

- Simulation platform;

- Experimental test.

3.1. The Main Requirements of the Simulation

- Dynamics of the vehicle similar to an agricultural tractor;

- Monitoring tractor forces exchanged with the ground;

- Replication of engine behavior and related fuel consumption;

- Simulation of the main pillars of precision agriculture (PA);

- Driving position layout;

- Operating conditions.

3.1.1. Dynamics of the Vehicle

- The dynamic behavior of the agricultural tractor as it is subjected to linear and angular accelerations;

- The lateral and longitudinal stability of the vehicle when working on slopes or with drawbar force;

- The vertical, lateral, and longitudinal forces that each tire exchanges with the ground.

3.1.2. Monitoring Tractor Forces Exchanged with the Ground

- The algorithms relating to the forward resistance of an implement [33], i.e., the traction force at the drawbar.

3.1.3. Replication of Engine Behavior and Related Fuel Consumption

3.1.4. Simulation of the Main Pillars of Precision Agriculture

- Calculation of guidelines for the tractor, automatic guidance;

- Actuation signal to the operators based on a position in the field provided by the GNSS signal;

- ISOBUS implement.

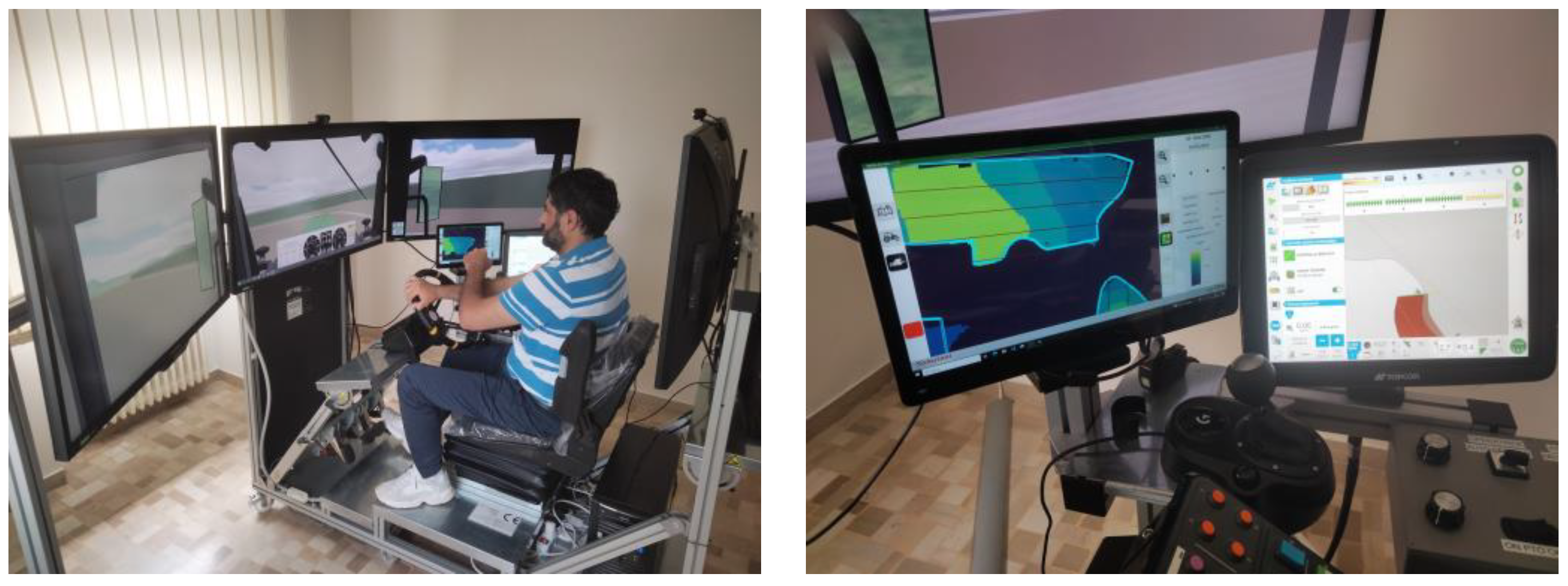

3.1.5. Driving Position Layout

- Engine data: power, torque, fuel consumption;

- PTO settings;

- Torque to the wheels and adherent weight;

- GPS data and view of the auto guidance tractor guidelines;

- Implement settings (type, width, sections, etc.);

- Prescription maps to verify the work performed by the operator.

3.1.6. Operating Conditions

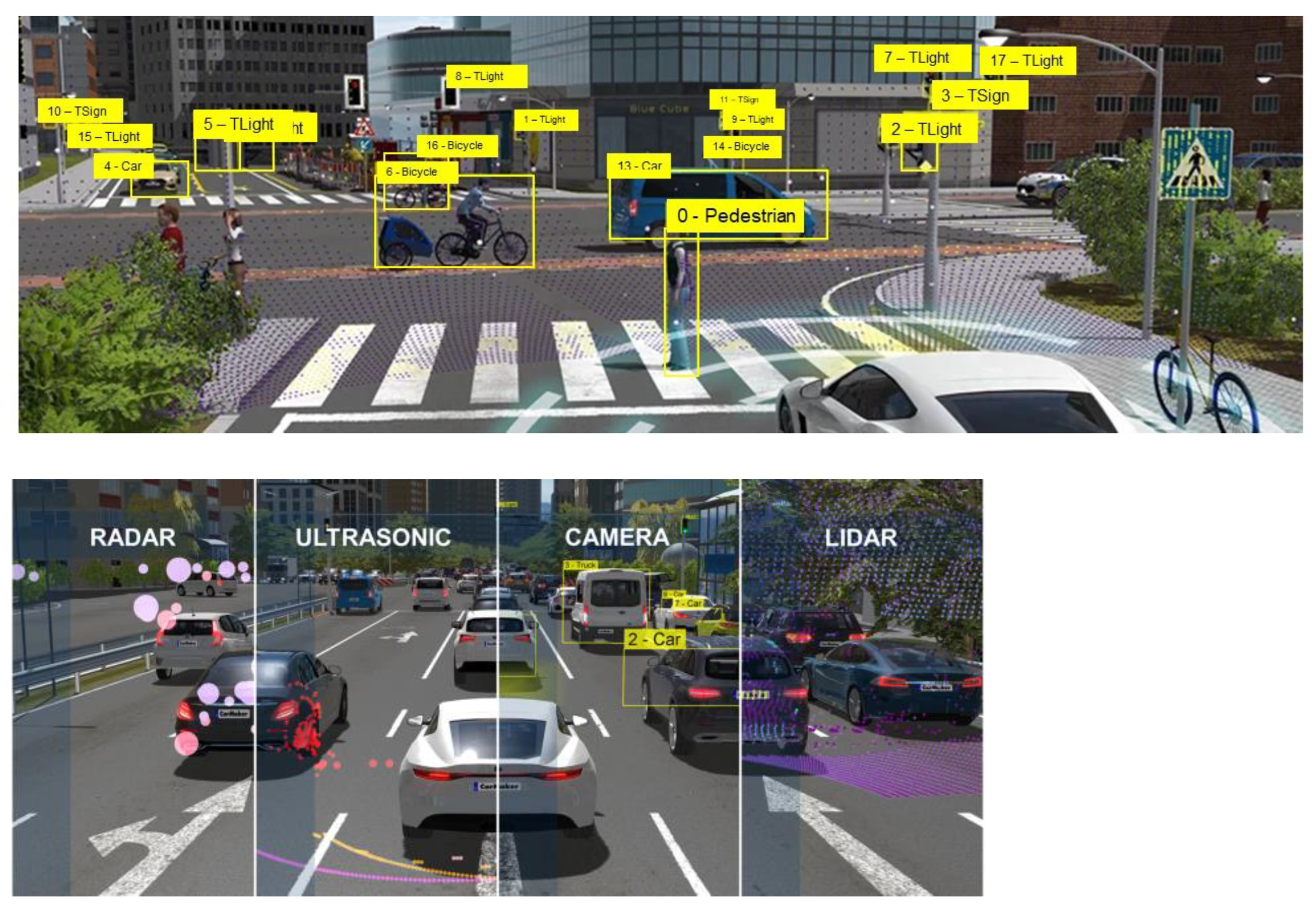

- The simulation of transfer or transport on paved roads in a mainly suburban road environment;

- Transfer or processing on agricultural land: the environment will be brown-colored land with borders represented by farm roads, country roads (“white”) or ditches.

- The ability to simulate nighttime or poor visibility environments.

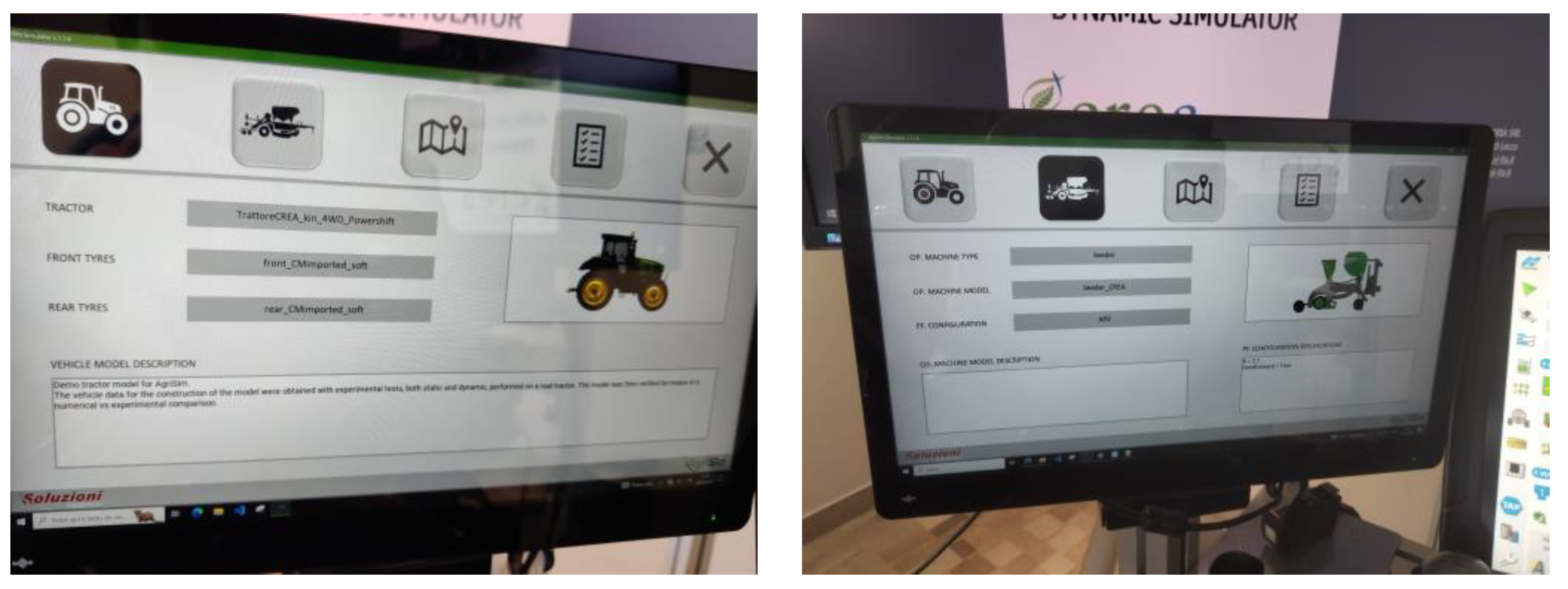

3.2. Virtual Tractor Design

- MFWD open-field-type tractor with rear axle rigid, front axle and cab suspended;

- Engine maximum power: 130 CV (96 kW) @ 2100 min−1 and maximum torque of 600 Nm @ 1600 min−1;

- Engine capacity: 4.5 L, inline-4 cylinders;

- Curb weight: 6200 kg; maximum admissible mass: 9500 kg;

- Wheelbase: 2.58 m; front width track 1.95 mm; rear width track 1.85 mm;

- Four wheels, not isodiametric; front tires: 540/65 R24; rear tires: 600/65 R38;

- Possibility of working by two- (rear) or four-wheel drive;

- Maximum forward speed: 65 km h−1;

- Steering system: no simulation of the correct steering wheel force was required, only a generic activation effort as feedback for the driver;

- Simulated driveline in three modes: 1. mechanical; 2. power shift (able to change without disconnecting the engine torque); 3. continuously variable transmission ((CVT) obtained as a 99 gears automatic). CREA has provided the transmission characteristics of point 1 and 2.

- Brakes: there are two brake pedals (one for the right and one for the left wheels only), close and connectable. The two pedals can be connected mechanically. When connected, the force measurement on the pedal is required (max. 60 kg). The CREA has provided the correlation curves between the load on the pedal and the tractor’s deceleration [32].

3.3. The Virtual Implements

3.3.1. The Seeder

3.3.2. The Fertilizer

3.3.3. The Sprayer

3.4. Simulation Platform

3.4.1. Vehicle Dynamics Simulation Platform

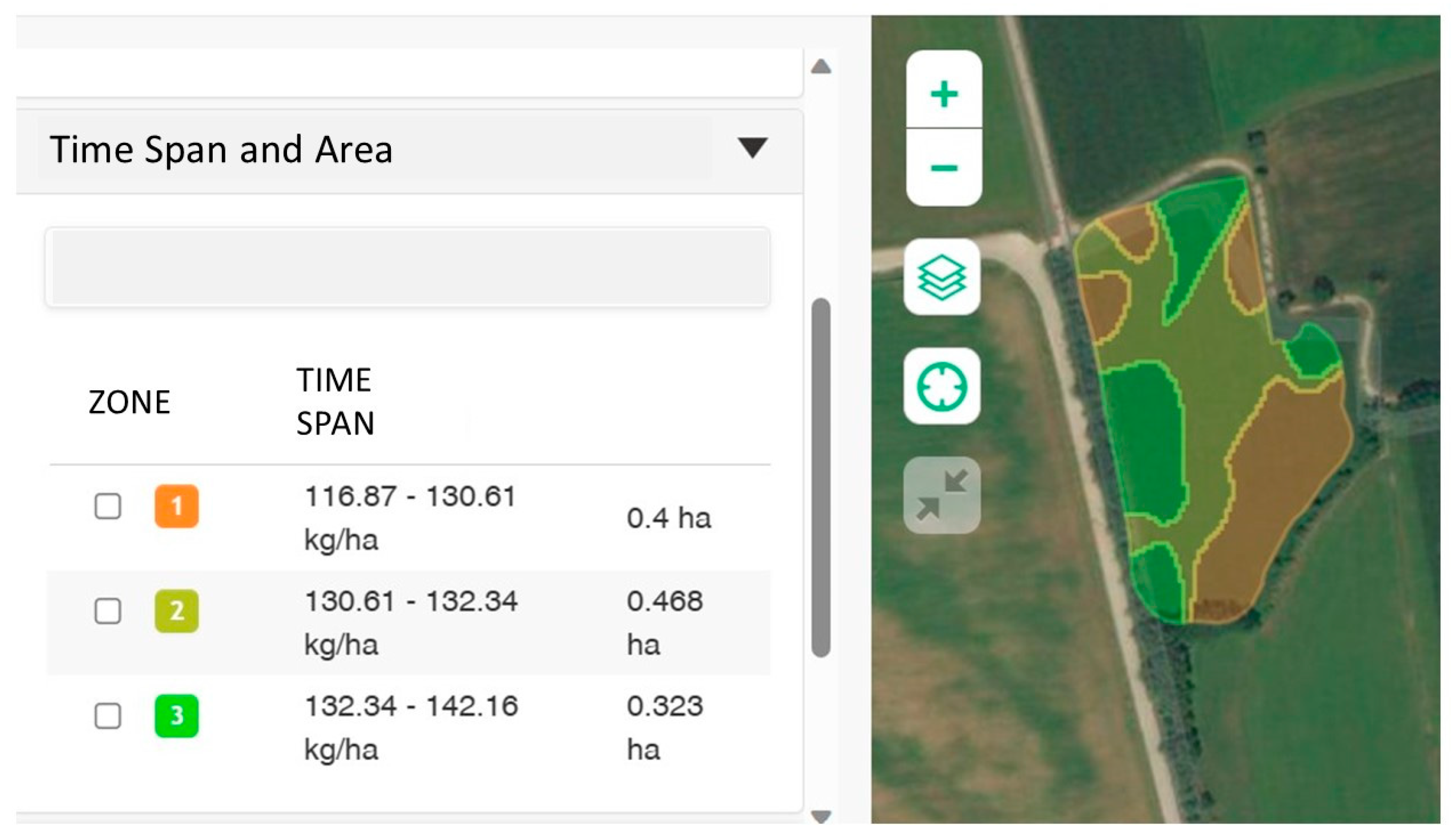

3.4.2. Precision Farming Simulation Platform

- Simulation setting;

- Simulation run;

- Data post-processing.

- Actual distribution map (which should be compared with the prescription map, if any, to obtain the distribution error);

- Actual trajectory followed by the tractor;

- Time history of the flow rate of each implement distributor;

- Time history of the total mass of product spread on the field.

3.5. Experimental Test

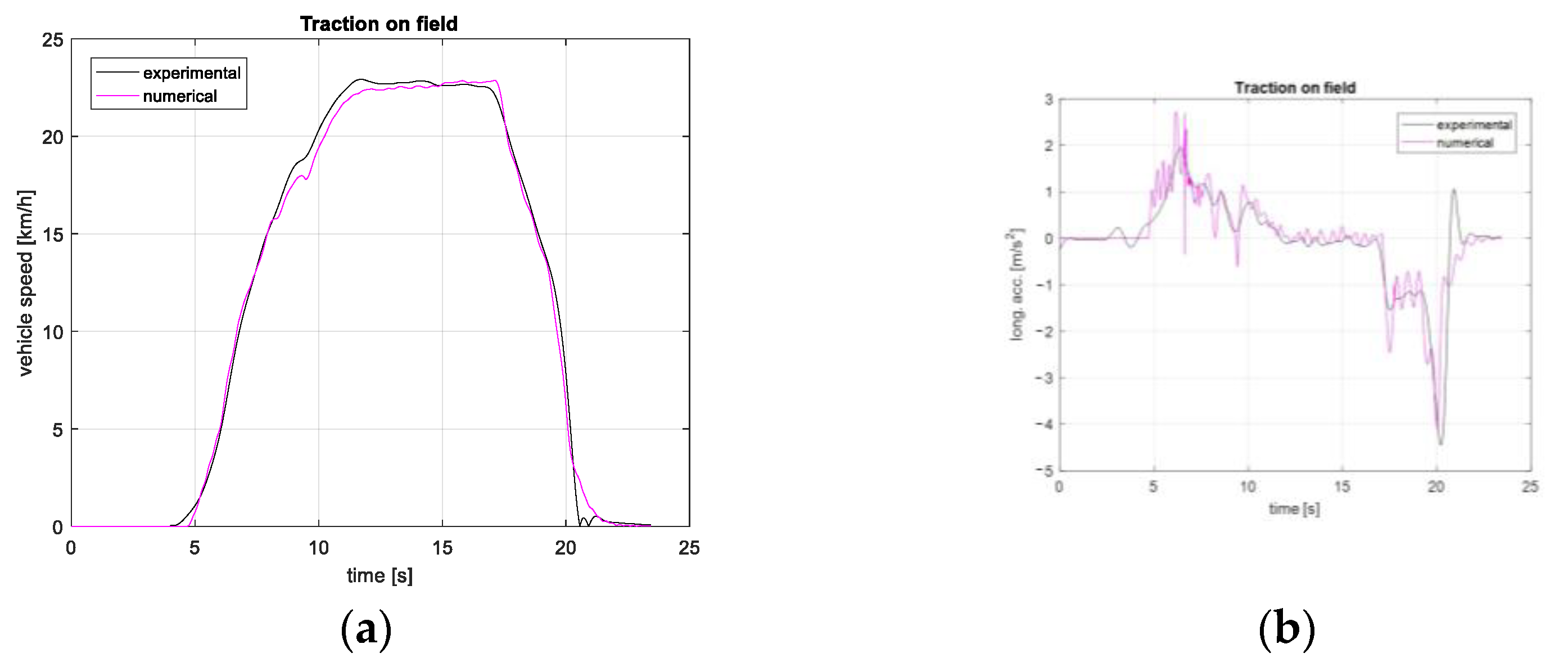

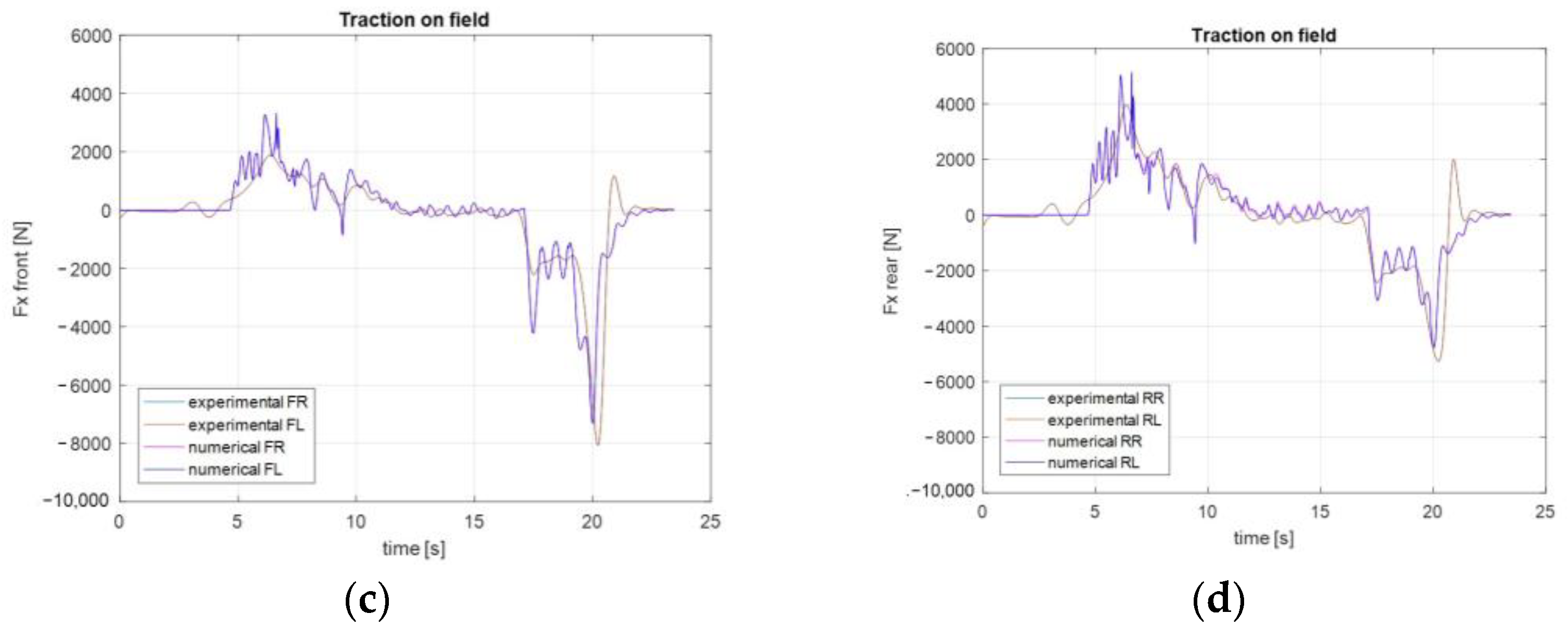

3.5.1. Vehicle Dynamics

- Characterization Maneuver on the tarmac:

- ○

- Acceleration and brake, useful to collect tire data and compare numerical and experimental results in longitudinal dynamics;

- ○

- Coast down, useful to characterize both the aerodynamic and rolling resistance on the tarmac;

- ○

- Steering pad, useful to compare numerical and experimental results in lateral dynamics.

- Characterization Maneuver on the field:

- ○

- Acceleration and brake, useful to collect tire data and compare numerical and experimental results in longitudinal dynamics;

- ○

- Coast down, useful to characterize the rolling resistance on the field.

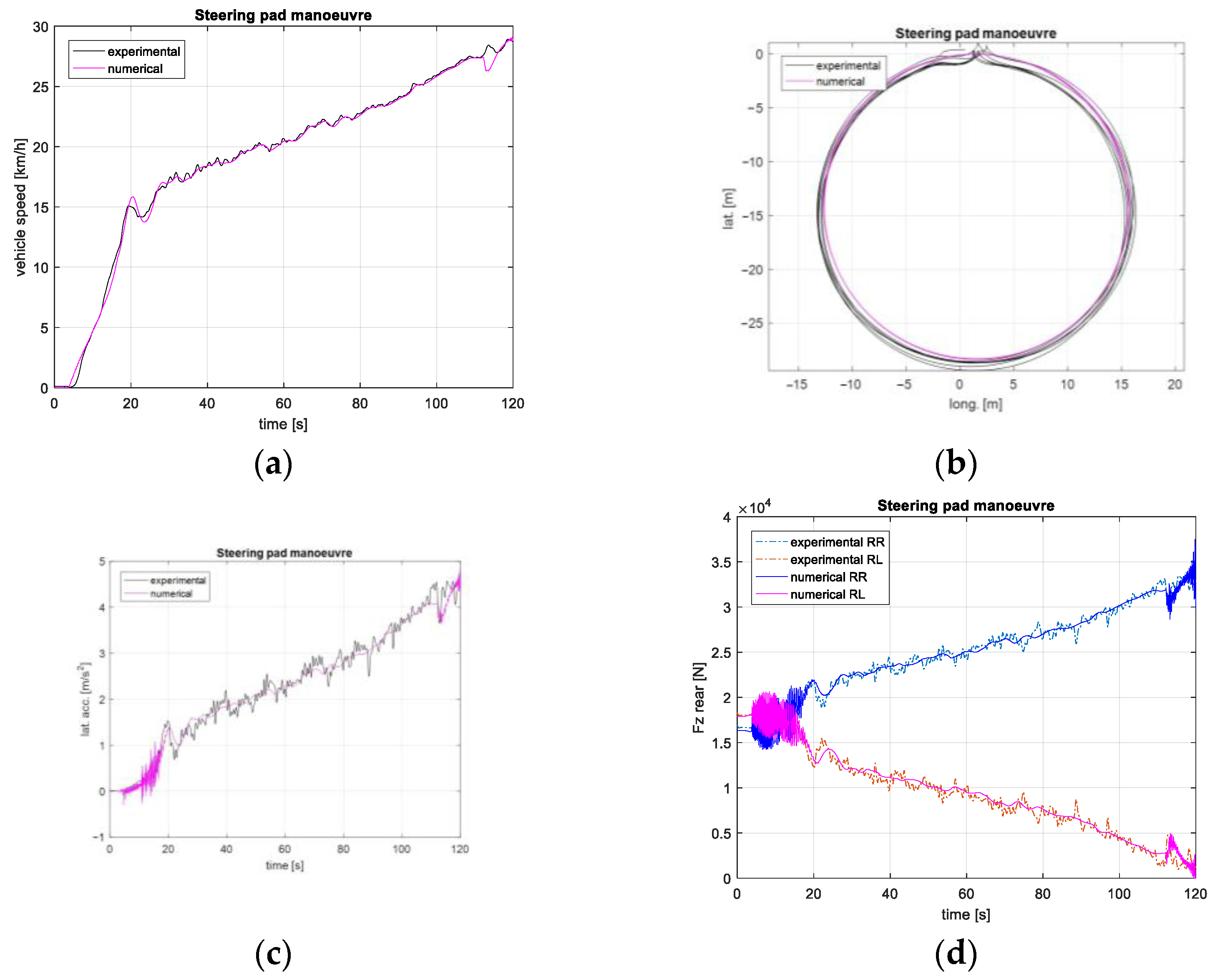

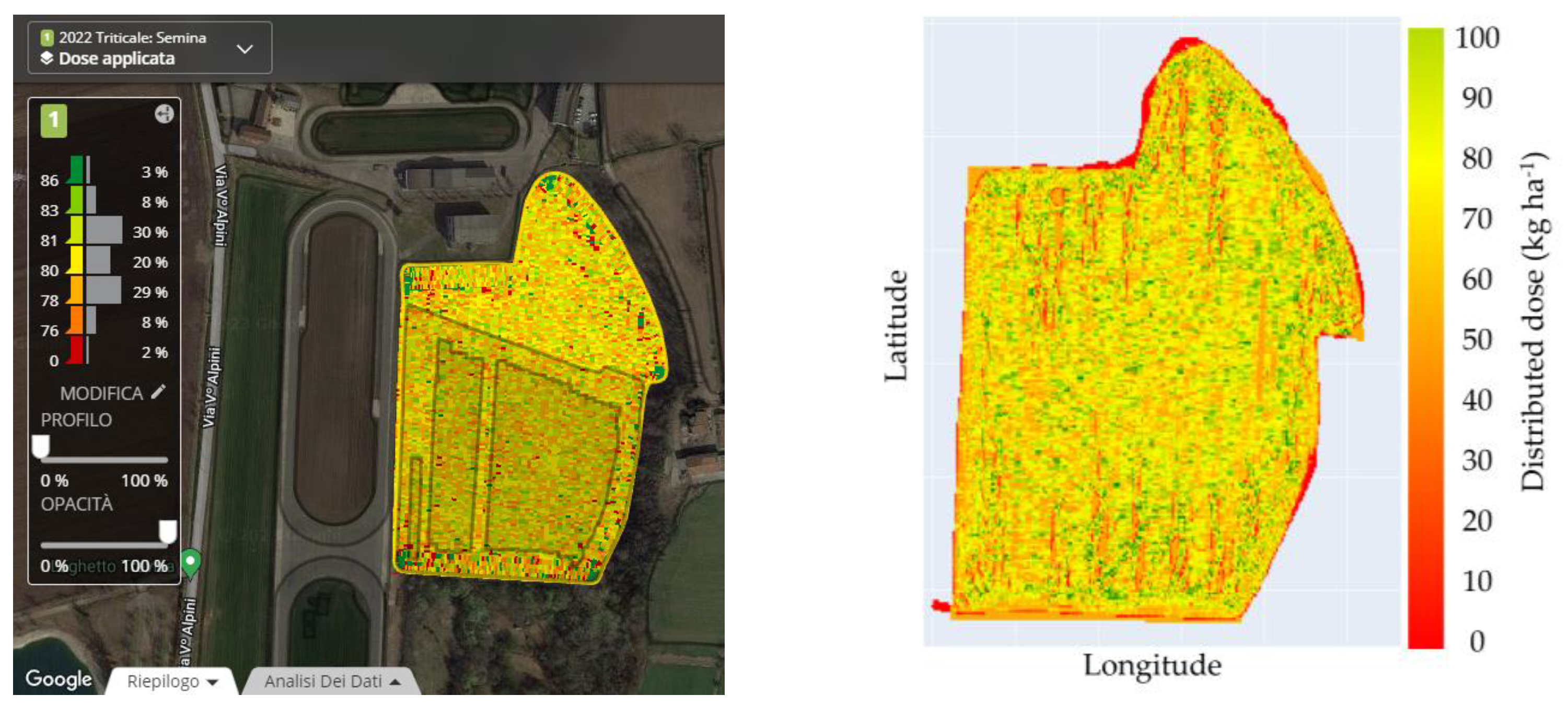

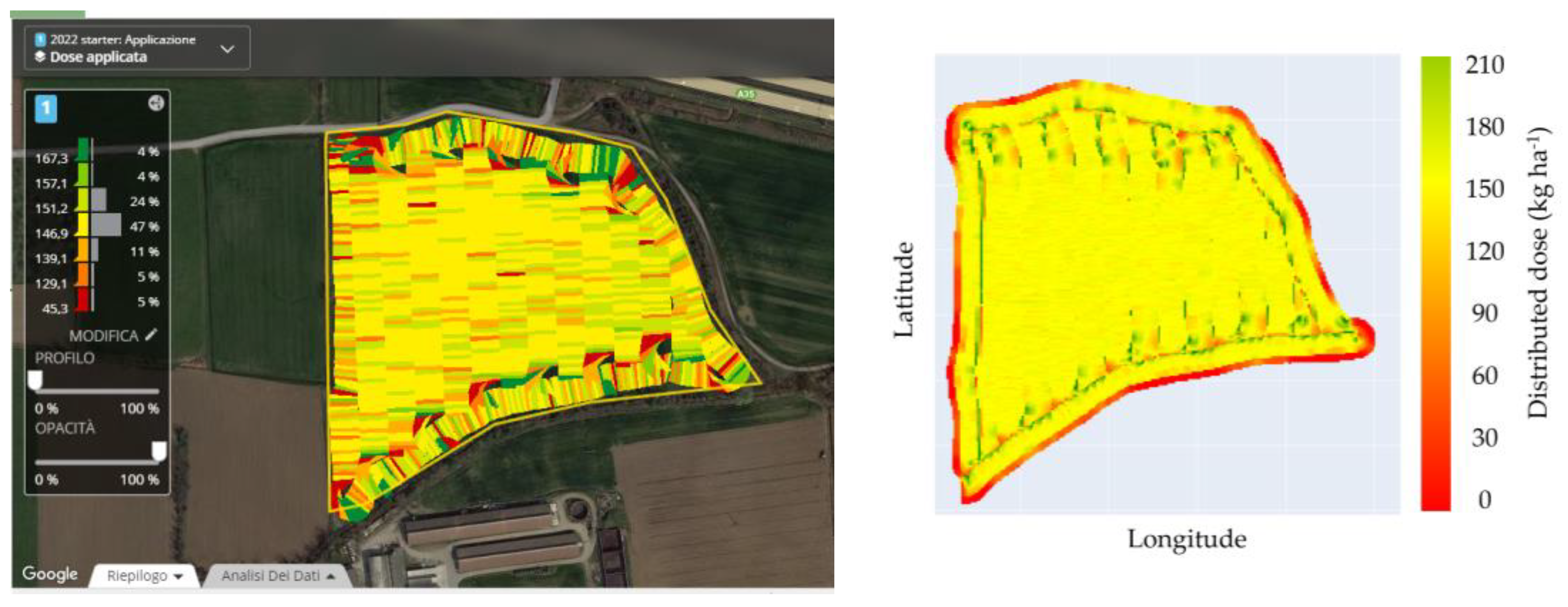

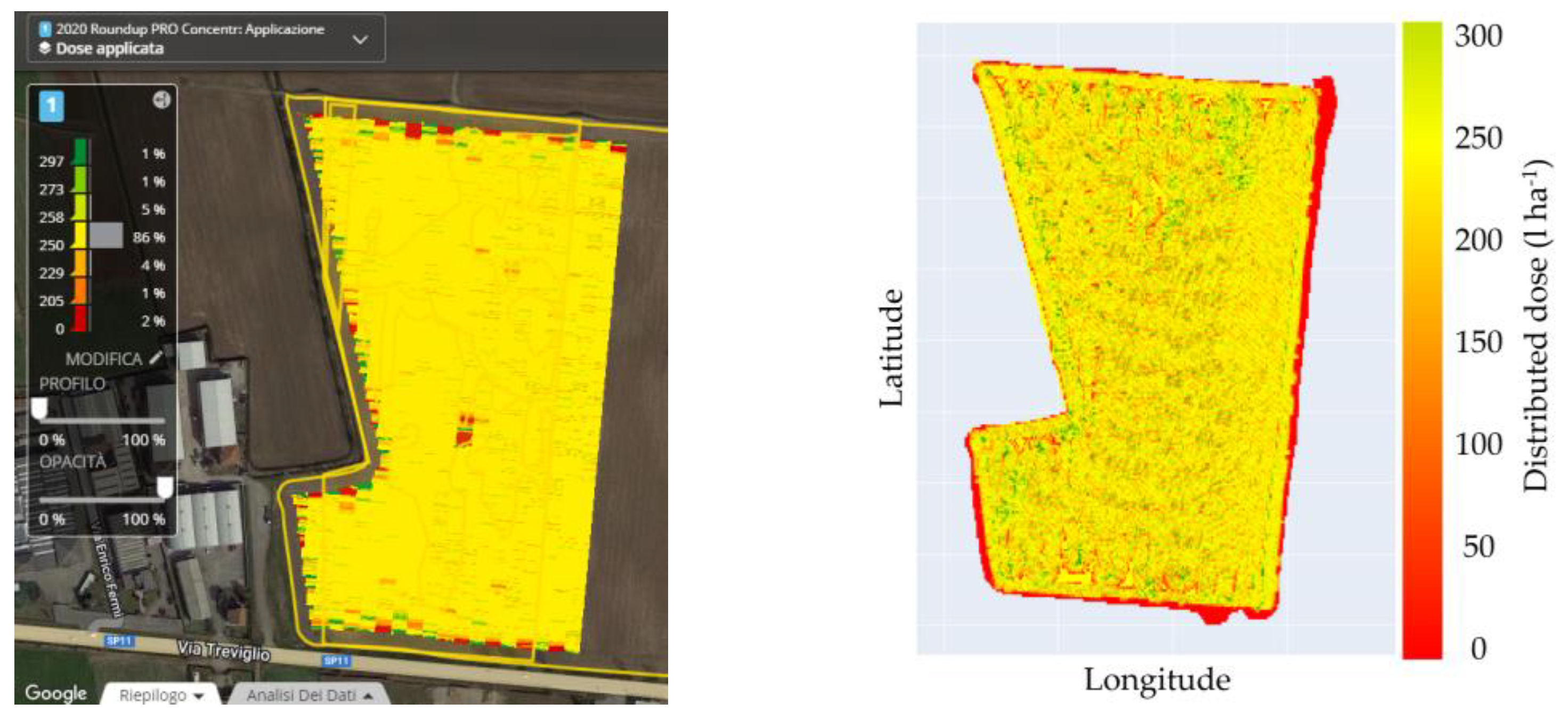

3.5.2. Precision Agriculture

4. Results

4.1. The Designed Simulator

4.1.1. The Driving Position Layout

4.1.2. The Virtual Machines

4.1.3. The Operating Conditions

4.1.4. The Co-Simulation Software

4.2. Vehicle Dynamics

4.3. The Experimental Test

5. Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gebbers, R.; Adamchuk, V.I. Precision agriculture and food security. Science 2010, 327, 828–831. [Google Scholar] [CrossRef]

- Pierce, F.J.; Nowak, P. Aspects of precision agriculture. Adv. Agron. 1999, 67, 1–85. [Google Scholar] [CrossRef]

- Olson, K.D. Precision agriculture: Current economic and environmental issues. In Proceedings of the Sixth Joint Conference, Minneapolis, MN, USA, 31 August–2 September 1998; pp. 213–220. [Google Scholar]

- Wolfert, S.; Goense, D.; Sørensen, C.A.G. A future internet collaboration platform for safe and healthy food from farm to fork. In Proceedings of the 2014 Annual SRII Global Conference, San Jose, CA, USA, 23–25 April 2014; pp. 266–273. [Google Scholar] [CrossRef]

- Zarco Tejada, P.J.; Hubbard, N.; Loudjani, P. Precision Agriculture: An Opportunity for E.U. Farmers Potential Support with the CAP 2014–2020; Joint Research Centre (JRC) of the European Commission, Monitoring Agriculture Resources (MARS) Unit H04: Brussels, Belgium, 2014. [Google Scholar]

- Balafoutis, A.; Beck, B.; Fountas, S.; Vangeyte, J.; Wal, T.V.d.; Soto, I.; Gómez-Barbero, M.; Barnes, A.; Eory, V. Precision Agriculture Technologies Positively Contributing to GHG Emissions Mitigation, Farm Productivity and Economics. Sustainability 2017, 9, 1339. [Google Scholar] [CrossRef]

- Van Evert, F.K.; Gaitán-Cremaschi, D.; Fountas, S.; Kempenaar, C. Can Precision Agriculture Increase the Profitability and Sustainability of the Production of Potatoes and Olives? Sustainability 2017, 9, 1863. [Google Scholar] [CrossRef]

- Stoorvogel, J.J.; Kooistra, L.; Bouma, J. Managing Soil Variability at Different Spatial Scales as a basis for precision agriculture. In Soil-Specific Farming Precision Agriculture, 1st ed.; Lal, R., Stewart, B.A., Eds.; CRC Press: Boca Raton, FL, USA, 2015; pp. 37–72. [Google Scholar] [CrossRef]

- Miller, N.; Griffin, T.; Bergtold, J. Kansas Farms’ Sequence of Information-Intensive Precision Agriculture Technology Adoption in Bundles; Kansas State University Department of Agricultural Economics: Manhattan, KS, USA, 2016. [Google Scholar]

- Bucci, G.; Bentivoglio, D.; Finco, A.; Belletti, M. Exploring the impact of innovation adoption in agriculture: How and where Precision Agriculture Technologies can be suitable for the Italian farm system? IOP Conf. Ser. Earth Environ. Sci. 2019, 275, 012004. [Google Scholar] [CrossRef]

- Miller, N.J.; Griffin, T.W.; Ciampitti, I.A.; Sharda, A. Farm adoption of embodied knowledge and information intensive precision agriculture technology bundles. Precis. Agric. 2019, 20, 348–361. [Google Scholar] [CrossRef]

- Haapala, H.E.S. Speeding up innovation in agricultural. It. J. Agric. Eng. 2013, 44, 137–139. [Google Scholar] [CrossRef][Green Version]

- Brambilla, M.; Romano, E.; Toscano, P.; Cutini, M.; Biocca, M.; Ferré, C.; Comolli, R.; Bisaglia, C. From Conventional to Precision Fertilization: A Case Study on the Transition for a Small-Medium Farm. Agri. Eng. 2021, 3, 29. [Google Scholar] [CrossRef]

- Caffaro, F.; Cavallo, E. The Effects of Individual Variables, Farming System Characteristics and Perceived Barriers on Actual Use of Smart Farming Technologies: Evidence from the Piedmont Region, Northwestern Italy. Agriculture 2019, 9, 111. [Google Scholar] [CrossRef]

- Cutini, M.; Romano, E.; Assirelli, A.; Bisaglia, C.; Brambilla, M. Evaluation of Precision Sprayer Technologies Practical Application. In AIIA 2022: Biosystems Engineering towards the Green Deal; Lecture Notes in Civil Engineering; Springer Nature: Cham, Switzerland, 2023; pp. 509–516. [Google Scholar] [CrossRef]

- Lee, H.G.; Chung, S.; Lee, W.H. Presence in virtual golf simulators: The effects of presence on perceived enjoyment, perceived value, and behavioral intention. New Media Soc. 2013, 15, 930–946. [Google Scholar] [CrossRef]

- Milgram, P.; Kishino, F. A taxonomy of mixed reality visual displays. IEICE Trans. Inf. Syst. 1994, 77, 1321–1329. [Google Scholar]

- Bevilacqua, R.; Maranesi, E.; Riccardi, G.R.; Di Donna, V.; Pelliccioni, P.; Luzi, R.; Lattanzio, F.; Pelliccioni, G. Non-immersive virtual reality for rehabilitation of the older people: A systematic review into efficacy and effectiveness. J. Clin. Med. 2019, 8, 1882. [Google Scholar] [CrossRef]

- Olstam, J.; Espié, S. Combination of autonomous and controlled vehicles in driving simulator scenarios. In Proceedings of the RSS, Rome, Italy, 7–9 November 2007. [Google Scholar]

- Swanson, K.S.; Brown, A.A.; Brennan, S.N.; LaJambe, C.M. Extending driving simulator capabilities toward hardware-in-the-loop testbeds and remote vehicle interfaces. In Proceedings of the 2013 IEEE Intelligent Vehicles Symposium Workshops (IV Workshops), Gold Coast, QLD, Australia; 2013; pp. 115–120. [Google Scholar] [CrossRef]

- Fathy, H.K.; Folip, Z.S.; Hagena, J.; Stein, J.L. Review of hardware-in-the-loop simulation and its prospects in the automotive area. In Modeling and Simulation for Military Applications Bellingham; SPIE: Washington, DC, USA, 2006; Volume 6228, pp. 117–136. [Google Scholar] [CrossRef]

- Onesti, P. Combination of Human- and Hardware-in-the-Loop Testing Reduces Development Time. ATZ Autotechnol. 2009, 9, 32–37. [Google Scholar] [CrossRef]

- Krepelka, M.; Vrany, J. Synthesizing Vehicle Speed-Related Features with Neural Networks. Vehicles 2023, 5, 40. [Google Scholar] [CrossRef]

- Piromalis, D.; Kantaros, A. Digital Twins in the Automotive Industry: The Road toward Physical-Digital Convergence. Appl. Syst. Innov. 2022, 5, 65. [Google Scholar] [CrossRef]

- Ibrahim, M.; Rassõlkin, A.; Vaimann, T.; Kallaste, A. Overview on Digital Twin for Autonomous Electrical Vehicles Propulsion Drive System. Sustainability 2022, 14, 601. [Google Scholar] [CrossRef]

- Purcell, W.; Neubauer, T. Digital Twins in Agriculture: A State-of-the-art review. Smart Agric. Technol. 2023, 3, 100094. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Tsolakis, N.; Bechtsis, D.; Bochtis, D. AgROS: A Robot Operating System Based Emulation Tool for Agricultural Robotics. Agronomy 2019, 9, 403. [Google Scholar] [CrossRef]

- Verdouw, C.; Tekinerdogan, B.; Beulens, A.; Wolfert, S. Digital twins in smart farming. Agric. Syst. 2021, 189, 103046. [Google Scholar] [CrossRef]

- MIPAAF. Consultazione Pubblica Linee Guida per Agricoltura di Precisione. (Public Consultation on Precision Farming Guidelines). 2016. Available online: https://www.politicheagricole.it/flex/cm/pages/ServeBLOB.php/L/IT/IDPagina/10349 (accessed on 6 March 2013).

- Pylianidis, C.; Osinga, S.; Athanasiadis, I.N. Introducing digital twins to agriculture. Comput. Electron. Agric. 2021, 184, 105942. [Google Scholar] [CrossRef]

- OECD Code 2:2020; OECD Standard Code for the Official Testing of Agricultural and Forestry Tractor Performance. OECD: Paris, France, 2020.

- ASAE D497.7 Mar2011 (R2020); Agricultural Machinery Management Data. American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2011.

- Kim, C.; Lee, H.; Park, Y.; Myung, C.-L.; Park, S. Study on the Criteria for the Determination of the Road Load Correlation for Automobiles and an Analysis of Key Factors. Energies 2016, 9, 575. [Google Scholar] [CrossRef]

- IS 14785:2000; Determination of Road-Load Constants by Coast Down Test Method. Bureau of Indian Standards: New Delhi, India, 2000; Reaffirmed 2005.

- Leo, E.; Maroni, C.; Pezzola, E. On Road and on Field Agricultural Tractor Tires on Board Identification. In Proceedings of the JSAE Annual Congress, Yokohama, Japan, 24–26 May 2023. [Google Scholar]

| Conceptual | Thematic | Farming Operation | Farming Type * |

|---|---|---|---|

| Human in the loop Digital Model | Machinery Management Farm Management Logistic farming | Fertilizing Spraying Seeding Weeding | Arable |

| Worked Area (ha) | Distributed Dose (kg ha−1) | Forward Speed (km h−1) | Productivity (ha h−1) | Fuel Consumption (l h−1) | |

|---|---|---|---|---|---|

| Experimental | 4.5 | 81 | 4.8 | 1.4 | 11.7 |

| Simulated | 4.5 | 79 | 5.0 | 1.6 | 11.8 |

| Worked Area (ha) | Distributed Dose (kg ha−1) | Forward Speed (km h−1) | Productivity (ha h−1) | Fuel Consumption (l h−1) | |

|---|---|---|---|---|---|

| Experimental | 8.4 | 149 | 11 | 24.3 | 4.6 |

| Simulated | 8.4 | 149 | 11 | 23.4 | 4.2 |

| Worked Area (ha) | Distributed Dose (kg ha−1) | Forward Speed (km h−1) | Productivity (ha h−1) | Fuel Consumption (l h−1) | |

|---|---|---|---|---|---|

| Experimental | 7.5 | 249.9 | 8.3 | 6.6 | 5.2 * |

| Simulated | 7.5 | 249 | 8.5 | 7.4 | 8.5 ** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cutini, M.; Bisaglia, C.; Brambilla, M.; Bragaglio, A.; Pallottino, F.; Assirelli, A.; Romano, E.; Montaghi, A.; Leo, E.; Pezzola, M.; et al. A Co-Simulation Virtual Reality Machinery Simulator for Advanced Precision Agriculture Applications. Agriculture 2023, 13, 1603. https://doi.org/10.3390/agriculture13081603

Cutini M, Bisaglia C, Brambilla M, Bragaglio A, Pallottino F, Assirelli A, Romano E, Montaghi A, Leo E, Pezzola M, et al. A Co-Simulation Virtual Reality Machinery Simulator for Advanced Precision Agriculture Applications. Agriculture. 2023; 13(8):1603. https://doi.org/10.3390/agriculture13081603

Chicago/Turabian StyleCutini, Maurizio, Carlo Bisaglia, Massimo Brambilla, Andrea Bragaglio, Federico Pallottino, Alberto Assirelli, Elio Romano, Alessandro Montaghi, Elisabetta Leo, Marco Pezzola, and et al. 2023. "A Co-Simulation Virtual Reality Machinery Simulator for Advanced Precision Agriculture Applications" Agriculture 13, no. 8: 1603. https://doi.org/10.3390/agriculture13081603

APA StyleCutini, M., Bisaglia, C., Brambilla, M., Bragaglio, A., Pallottino, F., Assirelli, A., Romano, E., Montaghi, A., Leo, E., Pezzola, M., Maroni, C., & Menesatti, P. (2023). A Co-Simulation Virtual Reality Machinery Simulator for Advanced Precision Agriculture Applications. Agriculture, 13(8), 1603. https://doi.org/10.3390/agriculture13081603