Calibration of Collision Recovery Coefficient of Corn Seeds Based on High-Speed Photography and Sound Waveform Analysis

Abstract

:1. Introduction

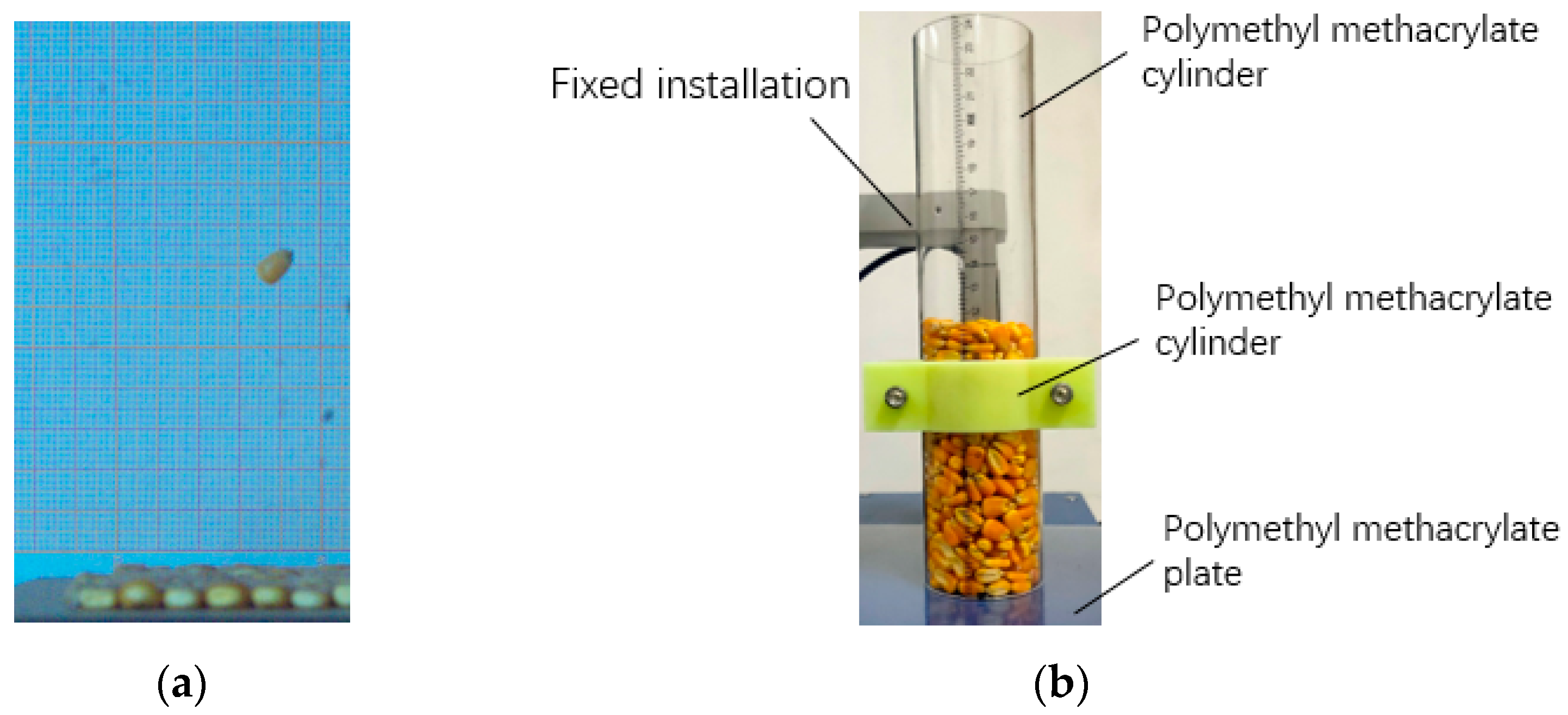

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

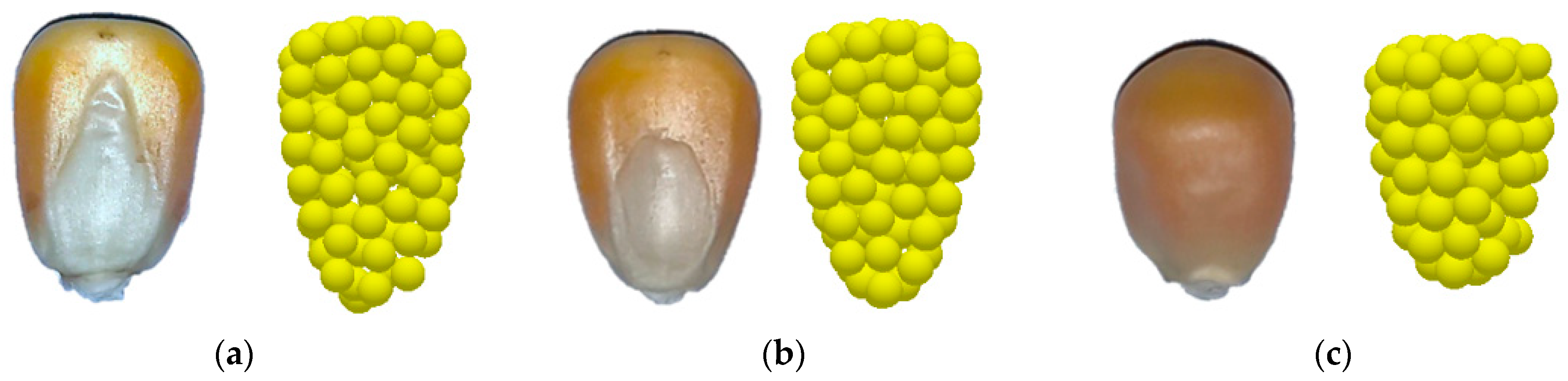

3.1. Determination of Intrinsic Parameters of Corn Seeds

3.1.1. Density and Moisture Content of Corn Seeds

3.1.2. Determination of Poisson’s Ratio and Shear Modulus

3.1.3. Determination of Characteristic Dimensions of Corn Seeds

3.2. Determination of Static and Rolling Friction Coefficient of Corn Seeds

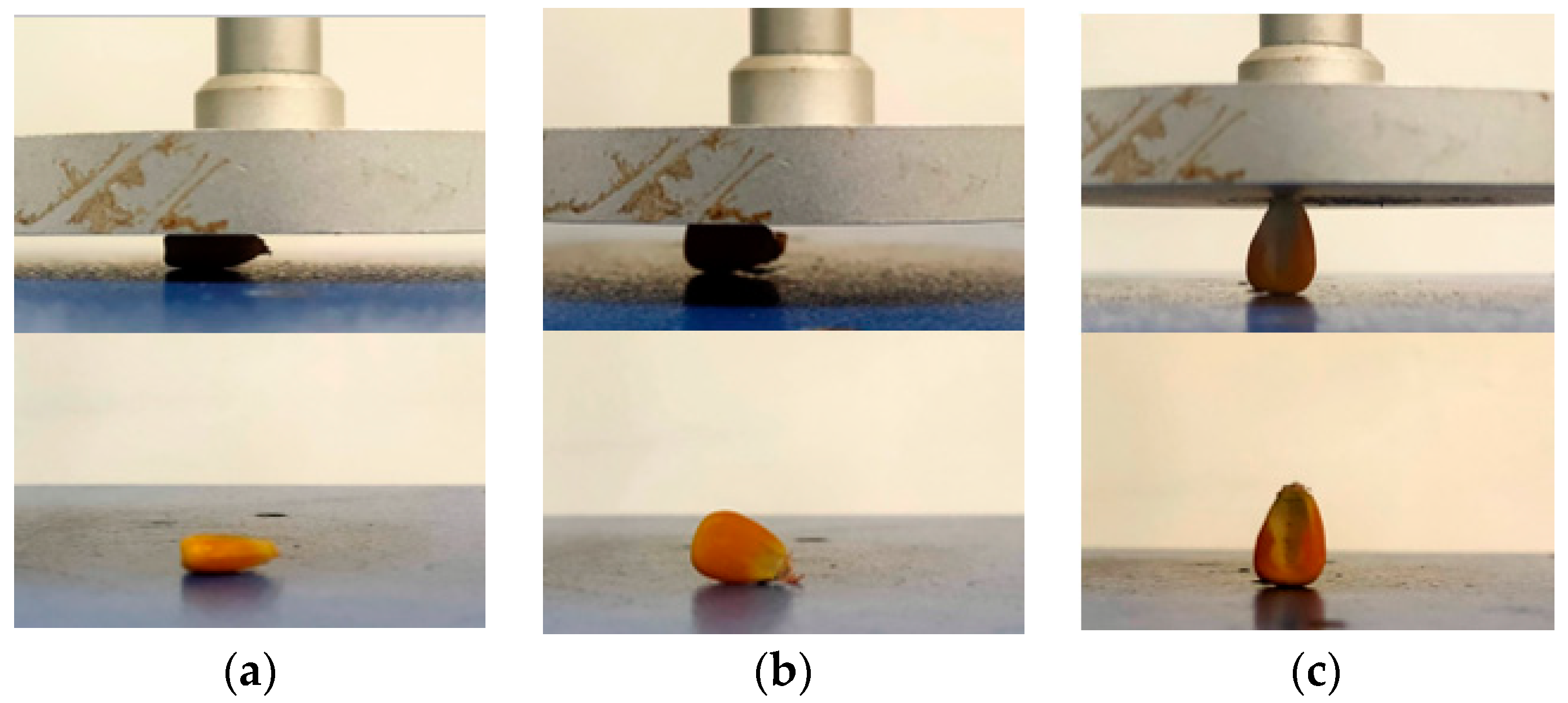

3.2.1. Static Friction Coefficient

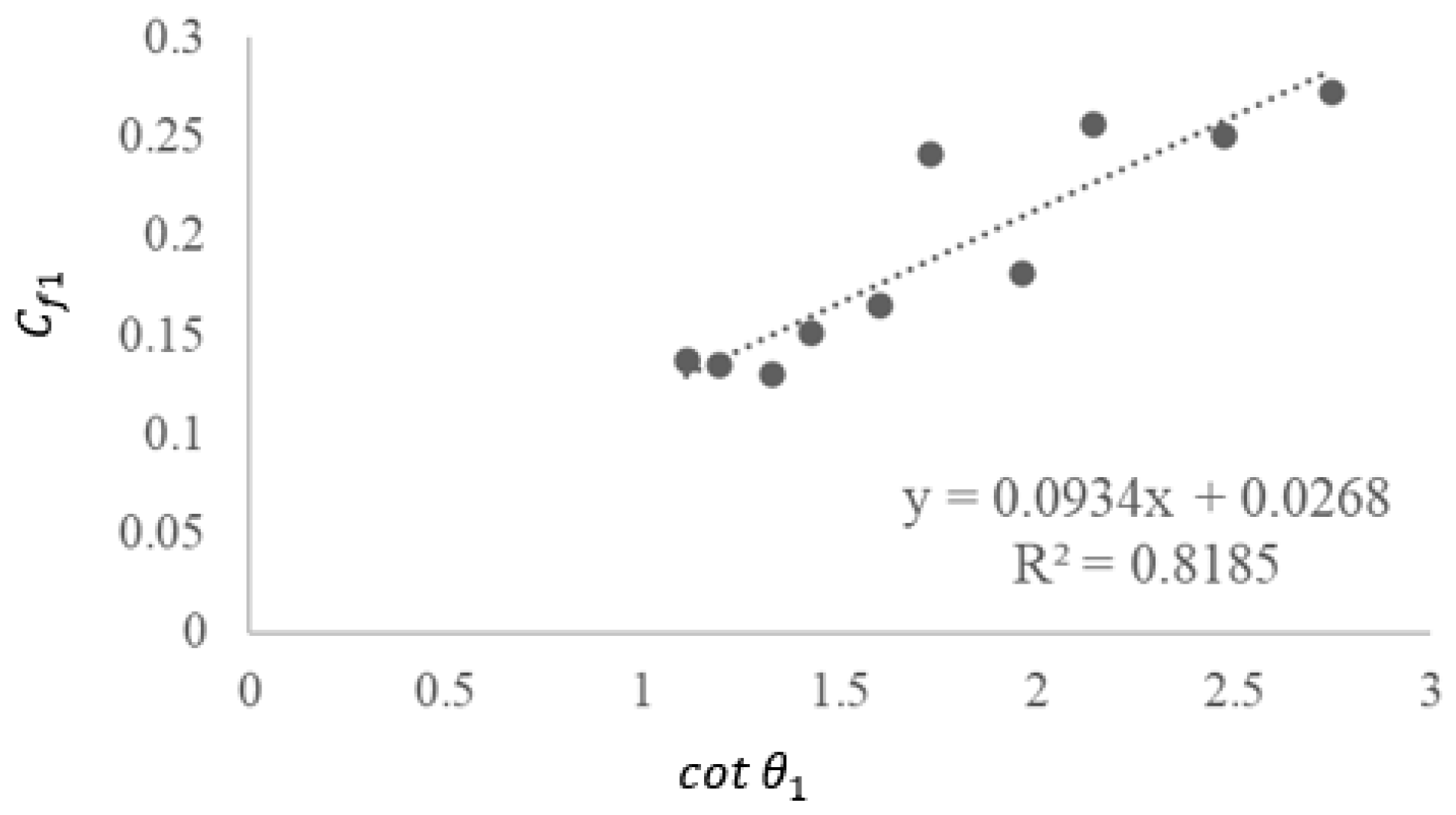

3.2.2. Rolling Friction Coefficient

3.3. Determination of Collision Recovery Coefficient of Corn Seeds

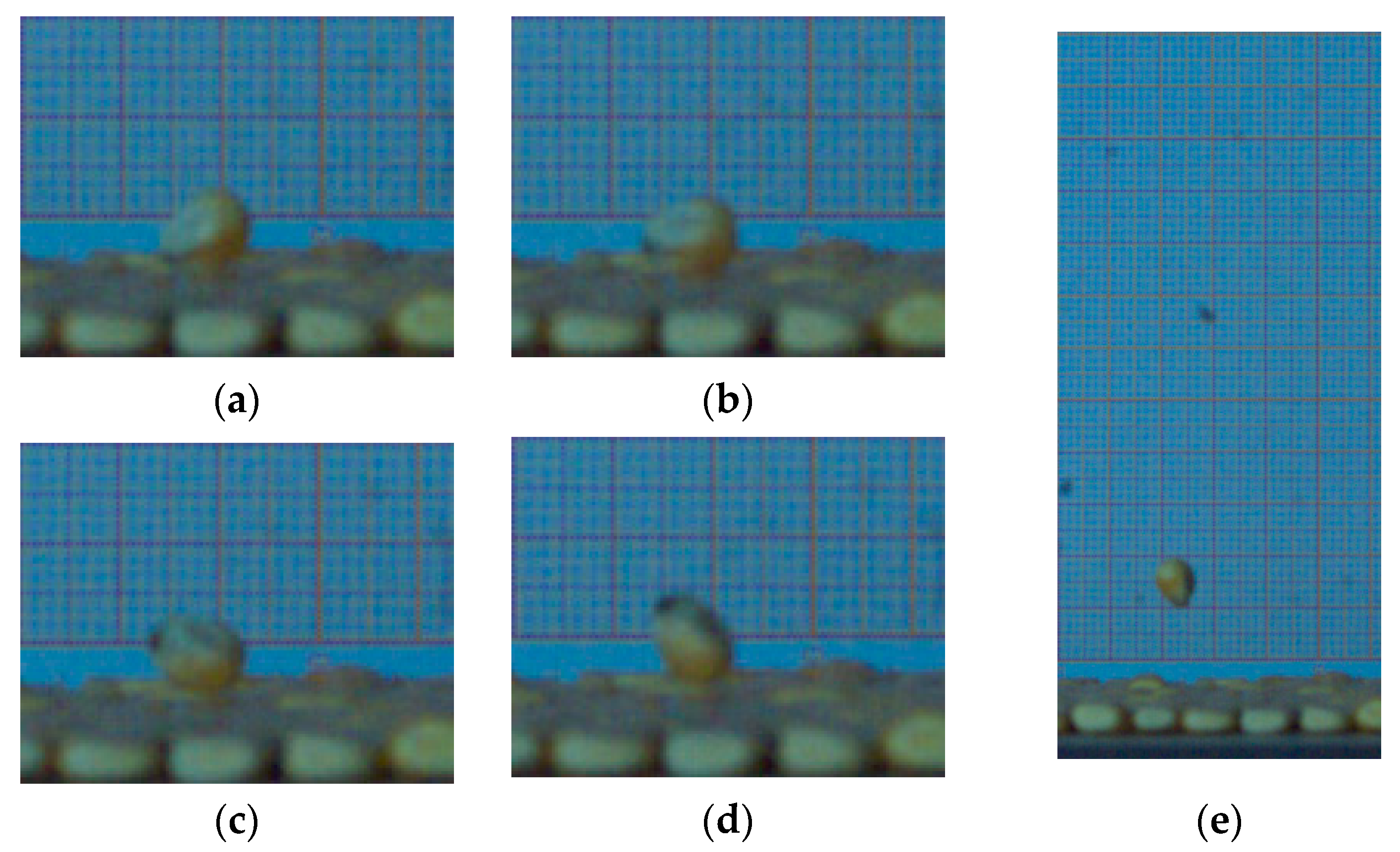

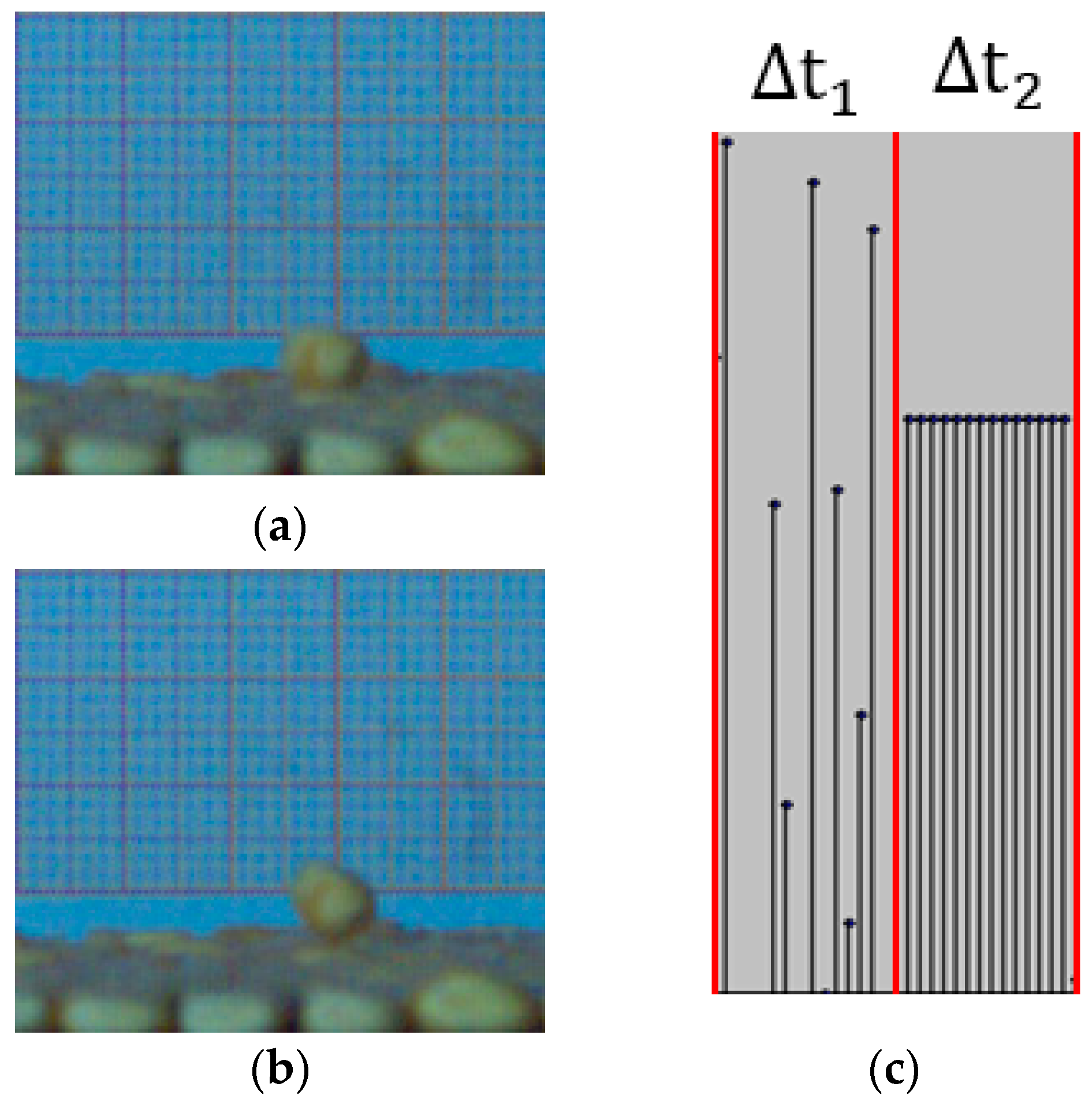

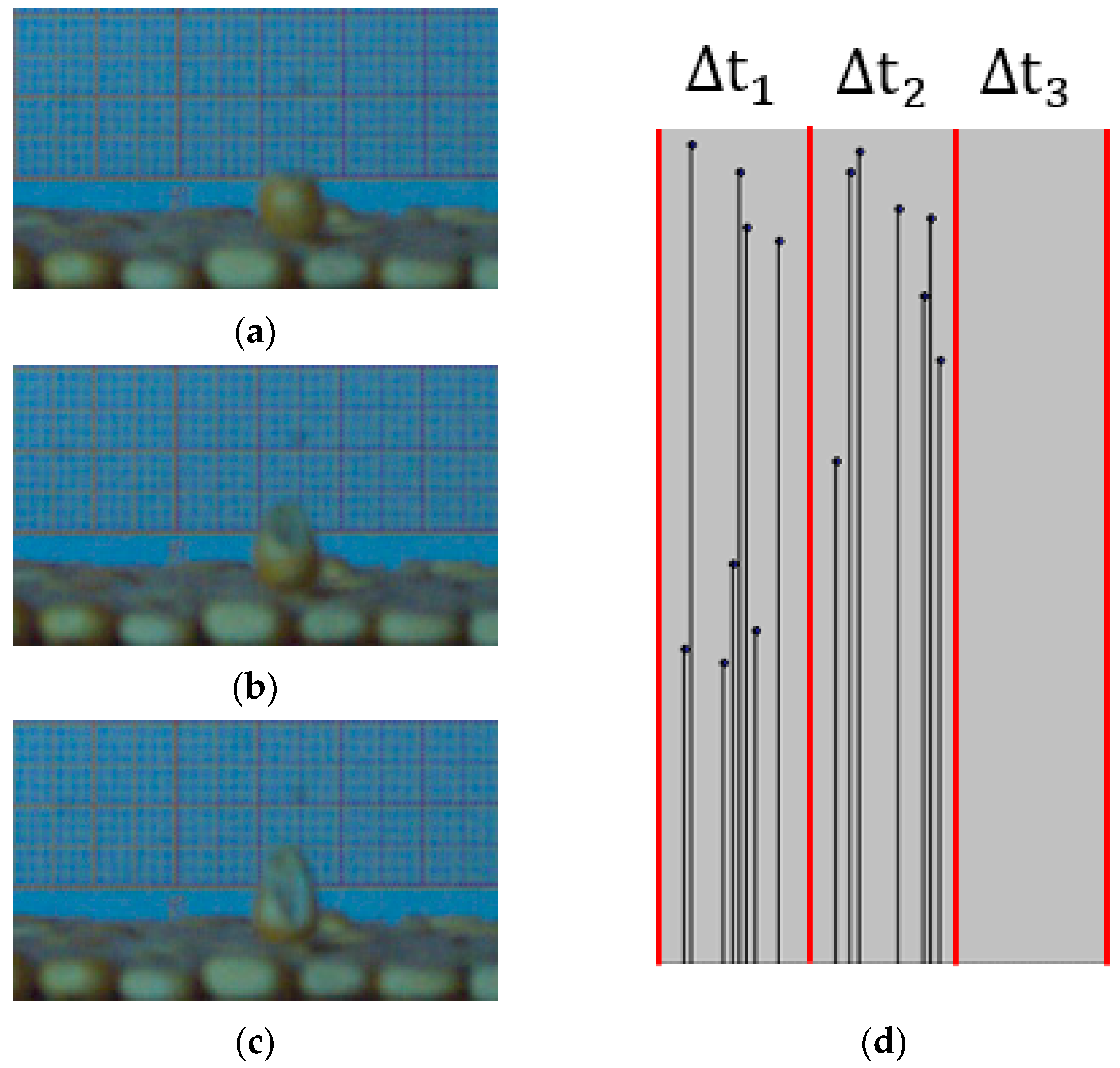

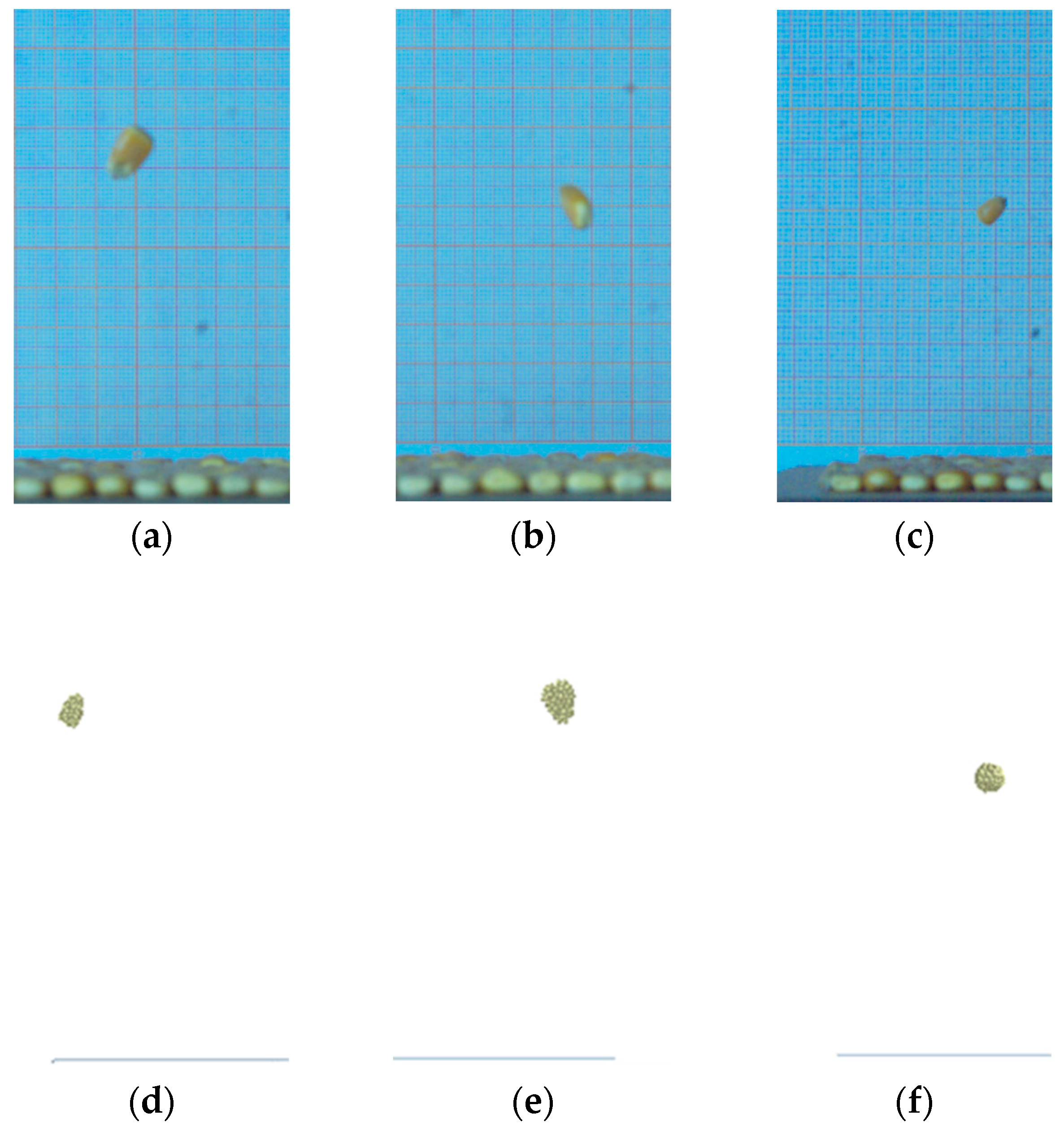

3.3.1. Multi-Point Collision of Corn Seeds

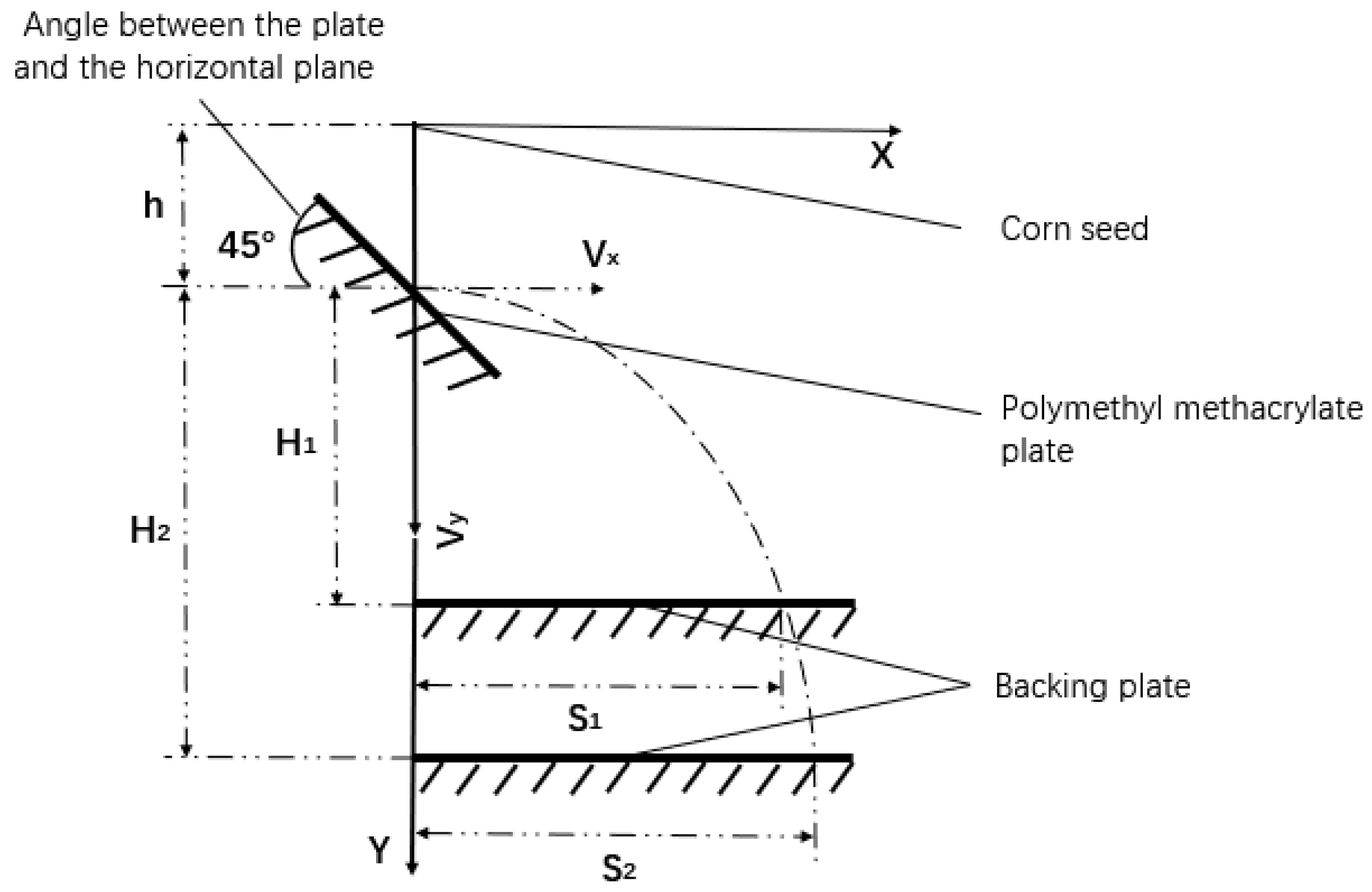

3.3.2. Test Principle of Collision Recovery Coefficient

3.4. Validation Test

3.4.1. Parameter Selection of Simulation Test

3.4.2. Plane Collision Test

3.4.3. Repose Angle Test

3.5. Discussion

- (1)

- The multi-point collision of corn seeds will reduce the rebound height of corn seeds, but the rebound height of corn seeds is affected by various factors, such as the collision angle between corn seeds and the falling posture of corn seeds. Therefore, the rebound height of corn seeds cannot be used as the basis for judging the multi-point collision between corn seeds.

- (2)

- After the collision between corn seeds, the more turns the corn seeds spin in the air, the lower the height of the corn seeds rebound.

- (3)

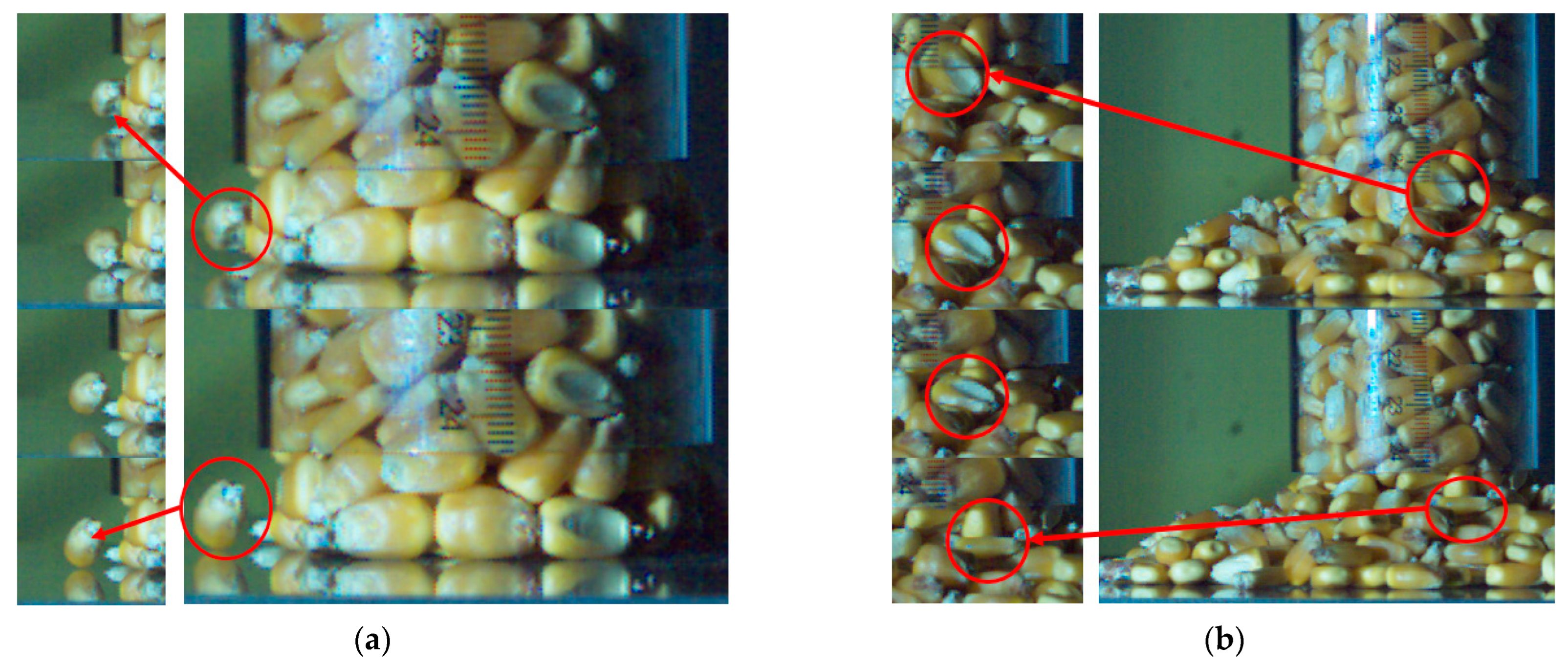

- When using the lifting method to conduct the repose angle test of corn seeds, the high-speed camera is used to shoot the test process. At the beginning of the experiment, when the cylinder was lifted, the corn seeds were dispersed in all directions after losing the barrier of the cylinder. Because no other object was around to block the corn seeds, they directly collided with the bottom surface to a small degree (Figure 19a). As the experiment continued, the corn seeds piled up on the bottom surface, and the seeds inside the cylinder came into contact with the fallen seeds. When the cylinder is lifted, the corn seeds in the original cylinder will mainly slide and roll due to the obstruction of the seeds below (Figure 19b).

4. Conclusions

- (1)

- According to the shape of the surfaces of corn seeds, they can be divided into three categories: flat, quasi-conical, and quasi-cylindrical. The number of flat, quasi-conical, and quasi-cylindrical corn seeds accounted for 77.9%, 15.4%, and 6.7%, respectively.

- (2)

- The sound waveform’s peak value after the corn seeds’ single-point collision is positive and remains stable in a specific time interval. The peak value of the sound waveform after the multi-point collision of corn seeds is zero and maintains a stable value within a specific time interval.

- (3)

- Through physical tests, the corn–corn rolling friction coefficient and corn–PMMA rolling friction coefficient were 0.0784 and 0.0934, respectively. The corn–corn static friction coefficient and corn–PMMA static friction coefficient were 0.32 and 0.445, respectively. The corn–corn collision recovery and corn–PMMA collision recovery coefficients were 0.28 and 0.62, respectively.

- (4)

- The measurements are verified by plane collision and repose angle tests. The relative errors between the simulation test and physical test of the two verification methods are less than 5%, which proves that the technique combining high-speed photography and sound waveform is reliable.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, K.; Xie, R.; Xue, J.; Sun, L.; Li, S. Comparison and analysis of maize grain commodity quality and mechanical harvest quality between China and the United States. Int. J. Agric. Biol. Eng. 2022, 15, 55–61. [Google Scholar] [CrossRef]

- Li, S.; Wang, K.; Xie, R.; Hou, P.; Ming, B.; Yang, X.; Han, D.; Wang, Y. Implementing higher population and full mechanization technologies to achieve high yield and high efficiency in maize production. Crops 2016, 4, 1–6. [Google Scholar]

- Ou, Y.; Fan, C.; Zhao, H.; Dong, J.; Jiao, Y. Present status and equipment research progress of maize full-mechanized production. J. Chin. Agric. Mech. 2022, 43, 207–214. [Google Scholar]

- Yang, L.; Yan, B.; Zhang, D.; Zhang, T.; Wang, Y.; Cui, T. Research Progress on Precision Planting Technology of Maize. Trans. Chin. Soc. Agric. Mach. 2016, 47, 38–48. [Google Scholar]

- Xu, Y.; Sun, Q.; Zhang, L.; Huang, W. Advances in discrete element methods for particulate materials. Adv. Mech. 2003, 33, 251–260. [Google Scholar]

- Zhu, H.; Zhou, Z.; Yang, R.; Yu, A. Discrete particle simulation of particulate systems: A review of major applications and findings. Chem. Eng. Sci. 2008, 63, 5728–5770. [Google Scholar] [CrossRef]

- Fleissner, F.; Gaugele, T.; Eberhard, P. Applications of the discrete element method in mechanical engineering. Multibody Syst. Dyn. 2007, 18, 81–94. [Google Scholar] [CrossRef]

- Zeng, Z.; Ma, X.; Cao, X.; Li, Z.; Wang, X. Critical Review of Applications of Discrete Element Method in Agricultural Engineering. Trans. Chin. Soc. Agric. Mach. 2021, 52, 1–20. [Google Scholar]

- Fu, H.; Wang, C.; Jin, C.; Yu, J. Development of digital design software platform AgriDEM for agricultural machinery parts. Trans. Chin. Soc. Agric. Eng. 2017, 33, 1–9. [Google Scholar]

- Martin, C.; Bouvard, D.; Shima, S. Study of particle rearrangement during powder compaction by the discrete element method. J. Mech. Phys. Solids 2003, 51, 667–693. [Google Scholar] [CrossRef]

- Wei, H.; Nie, H.; Li, Y.; Saxén, H.; He, Z.; Yu, Y. Measurement and simulation validation of DEM parameters of pellet, sinter and coke particles. Powder Technol. 2020, 364, 593–603. [Google Scholar] [CrossRef]

- Liu, C.; Chen, X.; Zhang, W.; Wang, S. Study on the calibration process of parallel bonding meso-structure parameter in PFC numerical simulation. Value Eng. 2017, 36, 204–207. [Google Scholar]

- Ma, Z.; Li, Y.; Xu, L. Summarize of particle movements research in agricultural engineering realm. Trans. Chin. Soc. Agric. Mach. 2013, 44, 22–29. [Google Scholar]

- Cui, T.; Liu, J.; Yang, L.; Zhang, D.; Zhang, R.; Lan, W. Experiment and simulation of rolling friction characteristic of corn seed based on high-speed photography. Trans. Chin. Soc. Agric. Eng. 2013, 29, 34–41. [Google Scholar]

- Han, Y.; Jia, F.; Tang, Y.; Liu, Y.; Zhang, Q. Influence of granular coefficient of rolling friction on accumulation characteristics. Acta Phys. Sin. 2014, 63, 4501–4507. [Google Scholar]

- Wang, Y.; Liang, Z.; Zhang, D.; Cui, T.; Shi, S.; Li, K.; Yang, L. Calibration method of contact characteristic parameters for corn seeds based on EDEM. Trans. Chin. Soc. Agric. Eng. 2016, 32, 36–42. [Google Scholar]

- Li, J.; Tong, J.; Hu, B.; Wang, H.; Mao, C.; Ma, Y. Calibration of parameters of interaction between clayey black soil with different moisture content and soil-engaging component in northeast China. Trans. Chin. Soc. Agric. Eng. 2019, 35, 130–140. [Google Scholar]

- Yu, Q.; Liu, Y.; Chen, X.; Sun, K.; Lai, Q. Calibration and experiment of simulation parameters for Panax notoginseng seeds based on DEM. Trans. Chin. Soc. Agric. Eng. 2020, 51, 123–132. [Google Scholar]

- Xing, J.; Zhang, R.; Wu, P.; Zhang, X.; Dong, X.; Chen, Y.; Ru, S. Parameter calibration of discrete element simulation model for latosol particles in hot areas of Hainan Province. Trans. Chin. Soc. Agric. Eng. 2020, 36, 158–166. [Google Scholar]

- Zhang, R.; Zhou, J.; Liu, H.; Shi, S.; Wei, G.; He, T. Determination of Interspecific Contact Parameters of Corn and Simulation Calibration of Discrete Element. Trans. Chin. Soc. Agric. Mach. 2022, 53, 69–77. [Google Scholar]

- Ding, X.; Li, K.; Hao, W.; Yang, Q.; Yan, F.; Cui, Y. Calibration of Simulation Parameters of Camellia oleifera Seeds Based on RSM and GA-BP-GA Optimization. Trans. Chin. Soc. Agric. Mach. 2023, 54, 139–150. [Google Scholar]

- Li, F.; Wang, P.; Wang, Y.; Ge, Y.; Tang, K.; Li, D. Calibration of Discrete Element Parameters of Corn Coated Seeds Based on Stacking Test. J. Agric. Sci. Technol. 2022, 24, 97–107. [Google Scholar]

- Joanna, W.; Marek, M.; Józef, H.; Jin, Y. Influence of grain shape and intergranular friction on material behavior in uniaxial compression: Experimental and DEM modeling. Powder Technol. Int. J. Sci. Technol. Wet Dry Part. Syst. 2012, 217, 435–442. [Google Scholar]

- Liu, W.; He, J.; Li, H.; Li, X.; Zheng, K.; Wei, Z. Calibration of simulation parameters for potato minituber based on EDEM. Trans. Chin. Soc. Agric. Mach. 2018, 49, 125–135. [Google Scholar]

- Zhong, J.; Tao, L.; Li, S.; Zhang, B.; Wang, J.; He, Y. Determination and interpretation of parameters of double-bud sugarcane model based on discrete element. Comput. Electron. Agric. 2022, 203, 107428. [Google Scholar] [CrossRef]

- Teng, G.; Jia, Z.; Zhou, K. A theoretical model for the coefficient of restitution calculation of point impact. Mach. Des. Res. 2007, 23, 14–15. [Google Scholar]

- Salot, C.; Gotteland, P.; Villard, P. Influence of relative density on granular materials behavior: DEM simulations of triaxial tests. Granul. Matter 2009, 11, 221–236. [Google Scholar] [CrossRef]

- Kozhar, S.; Dosta, M.; Antonyuk, S.; Heinrich, S.; Bröckel, U. DEM simulations of amorphous irregular shaped micrometer-sized titania agglomerates at compression. Adv. Powder Technol. 2015, 26, 767–777. [Google Scholar] [CrossRef]

- Wang, M.; Wang, W.; Yang, L.; Hou, M. Research of discrete element modeling method of maizekernel based on EDEM. J. Henan Agric. Univ. 2018, 52, 80–84. [Google Scholar]

- Jia, X.; Chen, X.; Li, X. Experiment research on instantaneous natural repose angle of granular slope under different granularity and stack form. Mod. Min. 2015, 31, 25–27. [Google Scholar]

- Feng, J.; Lin, J.; Li, S.; Zhou, J.; Zhou, Z. Calibration of discrete element parameters of particle in rotary solid state fermenters. Trans. Chin. Soc. Agric. Mach. 2015, 46, 208–213. [Google Scholar]

| Shape | Characteristic Dimensions | Mean Value (mm) |

|---|---|---|

| Flat | Wb1 | 8.21 |

| Wb2 | 7.77 | |

| Wb3 | 4.30 | |

| Hb0 | 12.77 | |

| Hb1 | 11.56 | |

| Hb2 | 11.50 | |

| Tb1 | 4.17 | |

| Tb2 | 4.29 | |

| Tb3 | 3.76 | |

| Quasi-conical | WZ1 | 7.80 |

| WZ2 | 7.21 | |

| WZ3 | 3.50 | |

| HZ | 5.07 | |

| TZ1 | 4.83 | |

| TZ2 | 3.10 | |

| TZ3 | 12.23 | |

| Quasi-cylindrical | WY1 | 7.05 |

| WY2 | 6.54 | |

| HY | 4.08 | |

| TY1 | 3.62 | |

| TY2 | 10.28 |

| Shape | Characteristic Dimensions | Mean Value (mm) |

|---|---|---|

| Flat | Wb1 | 8.14 |

| Wb2 | 7.83 | |

| Wb3 | 4.37 | |

| Hb0 | 12.71 | |

| Hb1 | 11.57 | |

| Hb2 | 11.45 | |

| Tb1 | 4.14 | |

| Tb2 | 4.29 | |

| Tb3 | 3.78 | |

| Quasi-conical | WZ1 | 7.76 |

| WZ2 | 7.20 | |

| WZ3 | 3.32 | |

| HZ | 5.02 | |

| TZ1 | 4.80 | |

| TZ2 | 3.04 | |

| TZ3 | 12.18 | |

| Quasi-cylindrical | WY1 | 7.05 |

| WY2 | 6.54 | |

| HY | 4.08 | |

| TY1 | 3.62 | |

| TY2 | 10.28 |

| Angle (°) | ||

|---|---|---|

| 20 | 2.747 | 0.273 |

| 22 | 2.475 | 0.251 |

| 25 | 2.145 | 0.257 |

| 27 | 1.963 | 0.181 |

| 30 | 1.732 | 0.241 |

| 32 | 1.600 | 0.165 |

| 35 | 1.428 | 0.151 |

| 37 | 1.327 | 0.131 |

| 40 | 1.192 | 0.135 |

| 42 | 1.111 | 0.137 |

| Angle (°) | ||

|---|---|---|

| 20 | 2.747 | 0.681 |

| 22 | 2.475 | 0.647 |

| 25 | 2.145 | 0.622 |

| 27 | 1.963 | 0.645 |

| 30 | 1.732 | 0.633 |

| 32 | 1.600 | 0.629 |

| 35 | 1.428 | 0.612 |

| 37 | 1.327 | 0.593 |

| 40 | 1.192 | 0.553 |

| 42 | 1.111 | 0.5 |

| Parameters | Value |

|---|---|

| Density of corn seed/(kg·m−3) | 1197 |

| Poisson’s ratio of corn seed | 0.4 |

| Shear modulus of corn seed/Pa | 1.36 × 108 |

| Normal Stiffness of corn seed/(N·m−3) | 3.54 × 109 |

| Shear stiffness of corn seed/(N·m−3) | 2.53 × 109 |

| Critical normal stress of corn seed/Pa | 1.1 × 107 |

| Critical shear stress of corn seed/Pa | 4.1 × 106 |

| Bonded disk radius/mm | 1 |

| Density of PMMA/(kg·m−3) | 1200 |

| Poisson’s ratio of PMMA | 0.35 |

| Shear modulus of PMMA/Pa | 1.30 × 109 |

| Corn–corn rolling friction coefficient | 0.0784 |

| Corn–PMMA rolling friction coefficient | 0.0934 |

| Corn–corn collision recovery coefficient | 0.28 |

| Corn–PMMA collision recovery coefficient | 0.62 |

| Corn–corn static friction coefficient | 0.32 |

| Corn–PMMA static friction coefficient | 0.445 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Zhang, W.; Xu, S.; Ma, F.; Du, Z.; Ma, Y.; Liu, J. Calibration of Collision Recovery Coefficient of Corn Seeds Based on High-Speed Photography and Sound Waveform Analysis. Agriculture 2023, 13, 1677. https://doi.org/10.3390/agriculture13091677

Li X, Zhang W, Xu S, Ma F, Du Z, Ma Y, Liu J. Calibration of Collision Recovery Coefficient of Corn Seeds Based on High-Speed Photography and Sound Waveform Analysis. Agriculture. 2023; 13(9):1677. https://doi.org/10.3390/agriculture13091677

Chicago/Turabian StyleLi, Xinping, Wantong Zhang, Shendi Xu, Fuli Ma, Zhe Du, Yidong Ma, and Jing Liu. 2023. "Calibration of Collision Recovery Coefficient of Corn Seeds Based on High-Speed Photography and Sound Waveform Analysis" Agriculture 13, no. 9: 1677. https://doi.org/10.3390/agriculture13091677

APA StyleLi, X., Zhang, W., Xu, S., Ma, F., Du, Z., Ma, Y., & Liu, J. (2023). Calibration of Collision Recovery Coefficient of Corn Seeds Based on High-Speed Photography and Sound Waveform Analysis. Agriculture, 13(9), 1677. https://doi.org/10.3390/agriculture13091677