Carbon Footprint of a Typical Crop–Livestock Dairy Farm in Northeast China

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Area

2.2. Calculation of Carbon Emissions Equivalent

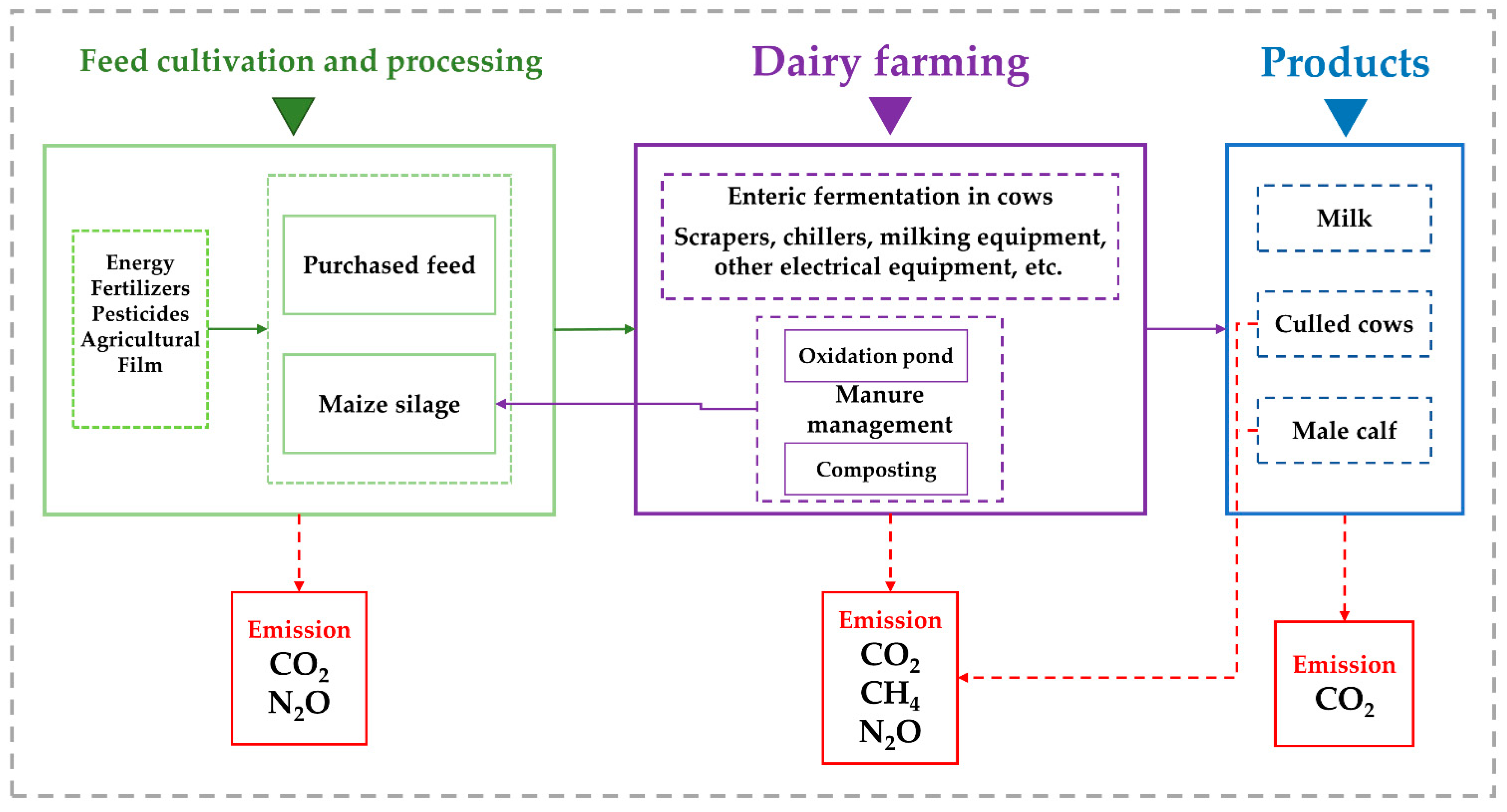

2.2.1. Functional Unit and System Boundaries

2.2.2. Methodology for Calculating Carbon Emissions Equivalent

2.2.3. Sensitivity Analysis

2.3. Allocation of Carbon Emissions Equivalent

2.4. Data Acquisition

2.5. Emission-Reduction Scenarios

3. Results and Discussion

3.1. Carbon Footprint of Typical Dairy Farms in Northeast China

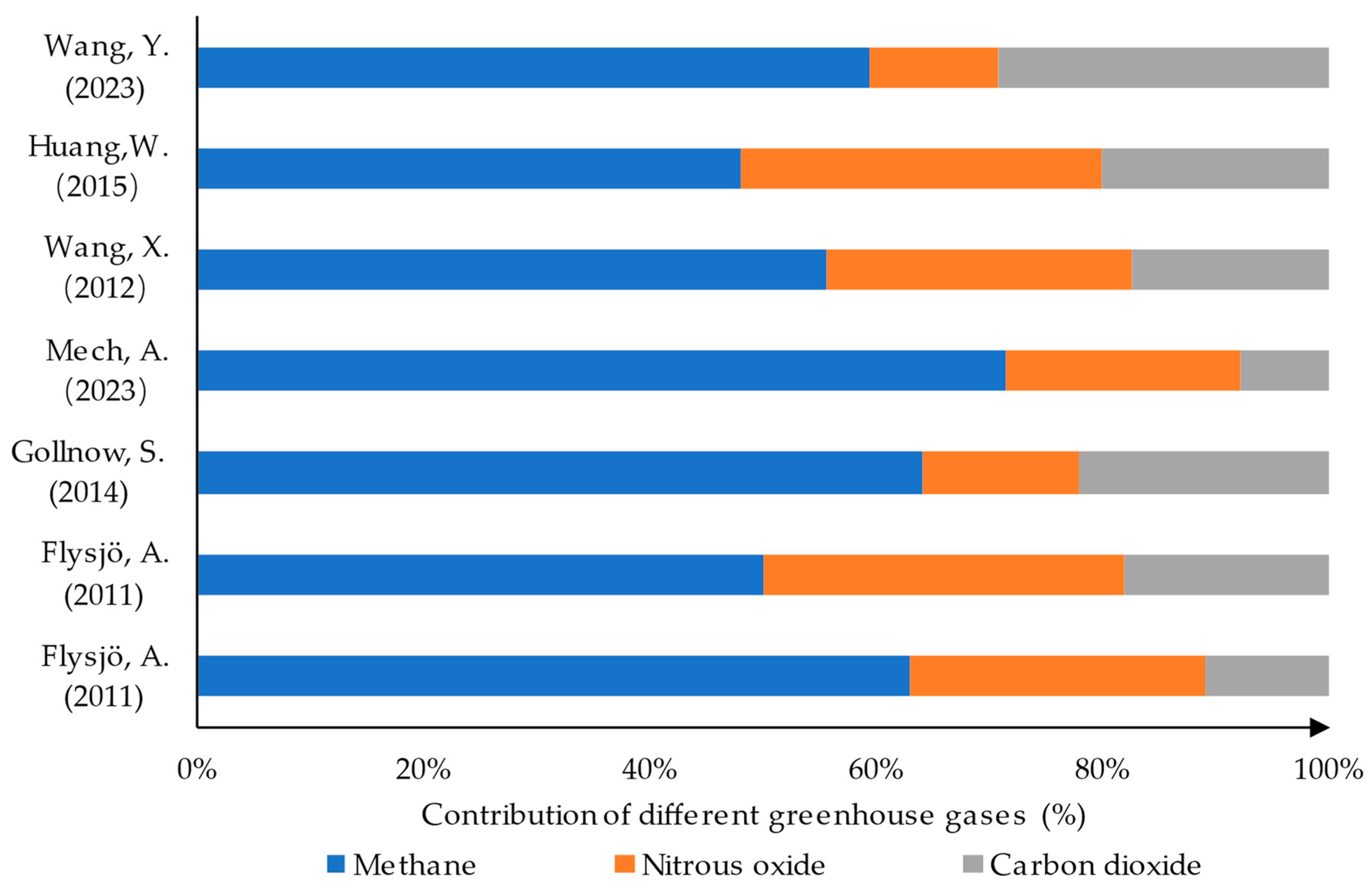

3.2. Contribution of Different Greenhouse Gases to the System

3.3. Results of the Sensitivity Analysis

3.4. Comparison of Carbon Footprints of Two Production Systems

3.4.1. Comparison of the Carbon Footprints of Stockbreeding and Non-Stockbreeding Systems

3.4.2. Comparison of Carbon Footprints of Stockbreeding and Non-Stockbreeding Systems in China and Abroad

3.5. Net-Zero Pathway for a Typical Cattle Farm in the Northeast China

4. Conclusions

- (1)

- In the milk-production system, the emission equivalent of the enteric fermentation of dairy cows was 5135.1 t CO2-eq, which accounted for 38.2% of the total emissions of the system and accounted for the largest share of the total emissions; the emission equivalent of the manure management was 3947.4 t CO2-eq, which accounted for 29.4% of the total emissions of the system; and the emission equivalent of the dairy farm’s energy consumption was 2989.5 t CO2-eq, which accounted for 22.3%.

- (2)

- In the milk-production system, the CH4 emission equivalent was 8074.8 t CO2-eq, accounting for 60.1% of the total system emission, which was the largest GHG contribution in the system. In total, 1785.8 t CO2-eq of N2O emission equivalent accounted for 13.3% of the total system emission, and the indirect emission of CO2 was 3568.9 t CO2-eq, which accounted for 26.6% of the total system emission.

- (3)

- Assuming that the silage maize in this study’s seeding system is a purchased feed, this would increase emissions from transporting silage maize by 187.2 t CO2-eq. Assuming that the organic fertilizer in this study’s seeding system is a purchased fertilizer with the same amount of nitrogen, this would increase emissions from fertilizer production and transport by about 400 t CO2-eq. On the dairy farms in the study, the seeding model reduced carbon emissions from the production and transport of fertilizer at least once a year for the cattle farm and reduced carbon emissions associated with feed production and transport by at least around 1000 t.

- (4)

- Compared with the baseline scenario, emission reduction scenarios 1 to 4 reduced carbon dioxide emissions by 9%, 20%, 42%, and 61%, respectively. However, with the current technology, the maximum emission reduction scenario is still unable to achieve the “net-zero” target, and there are still 4677 t carbon emissions directly and indirectly per year. Due to the cold climate in the northeast region, the anaerobic digestion technology, which has the characteristics of carbon emission reduction and energy offset, is difficult to operate efficiently, and its carbon-offsetting capacity is limited. Improvements in fertilizer application would still require the farm to emit 4000 t of carbon dioxide per year. To achieve the “net zero” goal, the farm needs to increase the offsetting role of its clean energy alternatives to achieve the goal of offsetting 7000 t of carbon per year.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, X.L.; Shi, B.Y.; Wang, S.; Yin, C.B.; Fang, L.N. Mitigating environmental impacts of milk production via integrated maize silage planting and dairy cow breeding system: A case study in China. J. Clean. Prod. 2021, 309, 127343. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). FAO Statistical Databases. 2019. Available online: https://www.fao.org/faostat/zh/#home (accessed on 1 July 2023).

- Herrero, M.; Henderson, B.; Havlik, P.; Thornton, P.K.; Conant, R.T.; Smith, P.; Wirsenius, S.; Hristov, A.N.; Gerber, P.; Gill, M.; et al. Greenhouse gas mitigation potentials in the livestock sector. Nat. Clim. Chang. 2016, 6, 452–461. [Google Scholar] [CrossRef]

- Basset-Mens, C.; Ledgard, S.; Boyes, M. Eco-efficiency of intensification scenarios for milk production in New Zealand. Ecol. Econ. 2009, 68, 1615–1625. [Google Scholar] [CrossRef]

- Fan, X.; Chang, J.; Ren, Y.; Wu, X.; Du, Y.Y.; Xu, R.H.; Liu, D.; Chang, S.X.; Meyerson, L.A.; Peng, C.H.; et al. Recoupling Industrial Dairy Feedlots and Industrial Farmlands Mitigates the Environmental Impacts of Milk Production in China. Environ. Sci. Technol. 2018, 52, 3917–3925. [Google Scholar] [CrossRef] [PubMed]

- Guerci, M.; Knudsen, M.T.; Bava, L.; Zucali, M.; Schönbach, P.; Kristensen, T. Parameters affecting the environmental impact of a range of dairy farming systems in Denmark, Germany and Italy. J. Clean. Prod. 2013, 54, 133–141. [Google Scholar] [CrossRef]

- Zheng, Y.H.; Wei, J.G.; Li, J.; Feng, S.F.; Li, Z.F.; Jiang, G.M.; Lucas, M.; Wu, G.L.; Ning, T.Y. Anaerobic fermentation technology increases biomass energy use efficiency in crop residue utilization and biogas production. Renew. Sustain. Energy Rev. 2012, 16, 4588–4596. [Google Scholar] [CrossRef]

- Eggelston, S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. (Eds.) 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies (IGES): Kanagawa, Japan, 2006. [Google Scholar]

- van Boxmeer, E.; Modernel, P.; Viets, T. Environmental and economic performance of Dutch dairy farms on peat soil. Agric. Syst. 2021, 193, 103243. [Google Scholar] [CrossRef]

- Cortés, A.; Feijoo, G.; Fernández, M.; Moreira, M.T. Pursuing the route to eco-efficiency in dairy production: The case of Galician area. J. Clean. Prod. 2021, 285, 124861. [Google Scholar] [CrossRef]

- Ledgard, S.F.; Falconer, S.J.; Abercrombie, R.; Philip, G.; Hill, J.P. Temporal, spatial, and management variability in the carbon footprint of New Zealand milk. J. Dairy Sci. 2020, 103, 1031–1046. [Google Scholar] [CrossRef]

- Styles, D.; Gonzalez-Mejia, A.; Moorby, J.; Foskolos, A.; Gibbons, J. Climate mitigation by dairy intensification depends on intensive use of spared grassland. Glob. Chang. Biol. 2018, 24, 681–693. [Google Scholar] [CrossRef]

- Chen, L.; Ling, H.; Xu, Z.; Wang, F. Research on the math of the combustion oil consumption of the farm transport machineries. J. Zhejiang Univ. 2003, 29, 185–187. [Google Scholar]

- Qu, S.; Yang, Y.T.; Wang, Z.H.; Zou, J.P.; Xu, M. Great Divergence Exists in Chinese Provincial Trade-Related CO2 Emission Accounts. Environ. Sci. Technol. 2020, 54, 8527–8538. [Google Scholar] [CrossRef] [PubMed]

- FAO. Greenhouse Gas Emissions from the Dairy Sector. Available online: https://milk.procon.org/wp-content/uploads/sites/44/ghg-emissions-from-dairy-sector-fao-2010.pdf (accessed on 1 July 2023).

- International Dairy Federation. A Common Carbon Footprint approach for the Dairy Sector—The lDF Guide to Standard Life Cycle Assessment Methodology. Available online: https://www.fil-idf.org/wp-content/uploads/2016/09/Bulletin479-2015_A-common-carbon-footprint-approach-for-the-dairy-sector.CAT.pdf (accessed on 1 July 2023).

- Huang, W.; Dong, H.; Zhu, Z.; Liu, C.; Tao, X.; Wang, Y. Research Progress and Analysis of Carbon Footprint of Livestock Products. Sci. Agric. Sin. 2015, 48, 93–111. [Google Scholar]

- Wang, X.; Liang, D.; Wang, X.; Peng, S.; Zheng, J. Estimation of greenhouse gas emissions from dairy farming systems based on LCA. Trans. Chin. Soc. Agric. Eng. 2012, 28, 179–184. [Google Scholar]

- Gollnow, S.; Lundie, S.; Moore, A.D.; McLaren, J.; van Buuren, N.; Stahle, P.; Christie, K.; Thylmann, D.; Rehl, T. Carbon footprint of milk production from dairy cows in Australia. Int. Dairy J. 2014, 37, 31–38. [Google Scholar] [CrossRef]

- Flysjö, A.; Henriksson, M.; Cederberg, C.; Ledgard, S.; Englund, J.E. The impact of various parameters on the carbon footprint of milk production in New Zealand and Sweden. Agric. Syst. 2011, 104, 459–469. [Google Scholar] [CrossRef]

- Mech, A.; Devi, G.L.; Sivaram, M.; Sirohi, S.; Dhali, A.; Kolte, A.P.; Malik, P.K.; Veeranna, R.K.; Niketha, L.; Bhatta, R. Assessment of carbon footprint of milk production and identification of its major determinants in smallholder dairy farms in Karnataka, India. J. Dairy Sci. 2023, 106, 8847–8860. [Google Scholar] [CrossRef]

- Mills, J.A.N.; Kerbreab, E.; Yates, C.M.; Crompton, L.A.; Cammell, S.B.; Dhanoa, M.S.; Agnew, R.E.; France, J. Alternative approaches to predicting methane emissions from dairy cows. J. Anim. Sci. 2003, 81, 3141–3150. [Google Scholar] [CrossRef]

- GB 10205-2009; Monoammonium Phosphate and Diammonium Phosphate. General Administration of Quality Supervision, Inspection and Quarantine, National Administration of Standardization: Beijing, China, 2009.

- Li, Z.J.; Sui, P.; Wang, X.L.; Yang, X.L.; Long, P.; Cui, J.X.; Yan, L.L.; Chen, Y.Q. Comparison of net GHG emissions between separated system and crop-swine integrated system in the North China Plain. J. Clean. Prod. 2017, 149, 653–664. [Google Scholar] [CrossRef]

- Chen, X.; Wang, X. Accounting Framework of Carbon Footprint on Integrated Cropping- Breeding Farming System: A Case on Maize-Cow-Recycling Manure Model. Sci. Agric. Sin. 2023, 56, 314–332. [Google Scholar]

- Costa, M.P.; Schoeneboom, J.C.; Oliveira, S.A.; Viñas, R.S.; de Medeiros, G.A. A socio-eco-efficiency analysis of integrated and non-integrated crop-livestock-forestry systems in the Brazilian Cerrado based on LCA. J. Clean. Prod. 2018, 171, 1460–1471. [Google Scholar] [CrossRef]

- de Figueiredo, E.B.; Jayasundara, S.; Bordonal, R.D.; Berchielli, T.T.; Reis, R.A.; Wagner-Riddle, C.; La Scala, N. Greenhouse gas balance and carbon footprint of beef cattle in three contrasting pasture-management systems in Brazil. J. Clean. Prod. 2017, 142, 420–431. [Google Scholar] [CrossRef]

- Thanh Hai, L.; Tran, Q.B.; Tra, V.T.; Nguyen, T.P.T.; Le, T.N.; Schnitzer, H.; Braunegg, G.; Le, S.; Hoang, C.T.; Nguyen, X.C.; et al. Integrated farming system producing zero emissions and sustainable livelihood for small-scale cattle farms: Case study in the Mekong Delta, Vietnam. Environ. Pollut. 2020, 265, 114853. [Google Scholar] [CrossRef] [PubMed]

- Dunfield, P.; knowles, R.; Dumont, R.; Moore, T.R. Methane production and consumption in temperate and subarctic peat soils: Response to temperature and pH. Soil Biol. Biochem. 1993, 25, 321–326. [Google Scholar] [CrossRef]

| Production Stage | Emission Source | Direct Emissions | Indirect Emissions |

|---|---|---|---|

| feed production | organic fertilizer application | N2O | N2O |

| fertilizer | |||

| agricultural film | CO2 | ||

| pesticides | CO2 | ||

| fossil fuels | CO2 | ||

| livestock and poultry farming | enteric fermentation (lactating cows, breeding cows, calves, dry cows) | CH4 | |

| purchased feed | CO2 | ||

| manure management and integrated use | liquid manure | CH4, N2O | N2O |

| solid manure composting | CH4, N2O | N2O | |

| solid manure as bedding | N2O | ||

| farm management | use of agricultural machinery (diesel) | CO2 | |

| energy use (diesel, petrol, electricity, coal) | CO2 |

| Projects | Unit | Lactating Cow | Dry Cow | Young Bull | Breeding Cattle | Calf |

|---|---|---|---|---|---|---|

| annual stock | head | 1029 | 118 | 431 | 253 | 371 |

| daily intake | kg DM | 25.5 | 15.5 | 13.3 | 8.5 | 5 |

| percentage of crude protein in the diet | % | 16.3 | 14.6 | 13.76 | 15.85 | 20 |

| daily milk production per cow | kg/head/day | 39 | 0 | 0 | 0 | 0 |

| Projects | Unit | Value |

| maize feed consumption | t | 2100 |

| maize silage consumption | t | 12,000 |

| soya meal consumption | t | 520 |

| Products | Unit | Value |

| annual raw milk production | t | 13,000 |

| protein content in raw milk from dairy farms | % | 3.35 |

| fat content in raw milk from dairy farms | % | 4.45 |

| Manure Management | Energy Substitution | Ruminant Emissions Reduction | |||

|---|---|---|---|---|---|

| Sewers | Solid Waste | ||||

| Scenario 1 | minimum cost | pharmacist | |||

| Scenario 2 | improved manure management only | pharmacist | mulch compost | ||

| Scenario 3 | new energy scenarios | pharmacist | mulch compost | solar energy substitution | |

| Scenario 4 | maximum emission-reduction scenarios | laminating, recovering natural gas | mulch compost | solar energy substitution | feed-side improvements |

| Emission Sector | Emission Source | Direct Emissions | Indirect Emissions | Emission Equivalent (t CO2-eq) |

|---|---|---|---|---|

| enteric fermentation in cows | enteric fermentation (CH4) | 5135.1 | 0 | 5135.1 |

| manure management | manure management (CH4) | 2939.7 | 0 | 2939.7 |

| manure management (N2O) | 698.8 | 308.9 | 1007.7 | |

| manure field consumption | manure field application (N2O) | 363.0 | 73.8 | 436.8 |

| feed production and processing | nitrogen fertilizer field application (N2O) | 293.60 | 47.7 | 341.3 |

| fertilizer production (CO2) | 0 | 63.5 | 63.5 | |

| pesticide production (CO2) | 0 | 37.3 | 37.3 | |

| machine operation (CO2) | 0 | 75.7 | 75.7 | |

| feed transport (CO2) | 0 | 402.9 | 402.9 | |

| dairy farm energy consumption (diesel/electricity) | energy consumption in dairy farm (CO2) | 0 | 2989.5 | 2989.5 |

| total system emissions (unallocated) | 9430.2 | 3999.3 | 13,429.5 | |

| total emissions from milk production (after allocation) | 8958.7 | 3799.3 | 12,758.0 |

| Emission Segment | Emission Source | Direct Emission | Indirect Emissions | Emission Equivalent (t CO2-eq) |

|---|---|---|---|---|

| enteric fermentation in cows | enteric fermentation (CH4) | 5135.0 | 0 | 5135.0 |

| manure management | manure management (CH4) | 137.5 | 0 | 137.5 |

| manure management (N2O) | 639.5 | 0 | 639.5 | |

| manure field consumption | manure field application (N2O) | 453.3 | 1.7 | 455 |

| dairy farm energy consumption (diesel/electricity) | dairy farm energy consumption (CO2) | 0 | 5194.9 | 5194.9 |

| total system emissions (unallocated) | 6365.3 | 5196.6 | 11,561.9 | |

| total emissions from milk production (after allocation) | 6047.0 | 4936.8 | 10,983.8 |

| Emission Segment | Emission Source | Direct Emission | Indirect Emissions | Emission Equivalent (t CO2-eq) |

|---|---|---|---|---|

| enteric fermentation in cows | enteric fermentation (CH4) | 365.3 | 0 | 365.3 |

| manure management | manure management (CH4) | 6181.0 | 0 | 6181.0 |

| manure management (N2O) | 50.0 | 1.9 | 51.9 | |

| manure field consumption | manure field application (N2O) | 1.9 | 0.2 | 2.1 |

| feed production and processing | pesticide production (CO2) | 0 | 66.0 | 66.0 |

| machinery operations (CO2) | 0 | 75.2 | 75.2 | |

| dairy farm energy consumption (diesel/electricity) | dairy farm energy consumption (CO2) | 0 | 1742.2 | 1742.2 |

| total system emissions (unallocated) | 6598.2 | 1885.5 | 8483.7 | |

| total emissions from milk production (after allocation) | 6268.3 | 1791.2 | 8059.5 |

| Scenario | Feeding | Enteric Fermentation | Manure Management | Fertilization of Farmland | Total Emissions |

|---|---|---|---|---|---|

| Stockbreeding system (this study) | 920.7 | 5135.1 | 3947.4 | 436.8 | 13,429.5 |

| Non-stockbreeding system | 1585.3 | 5135.1 | 3947.4 | 1358.6 | 15,015.9 |

| Emission Segment | Emission Source | Baseline Scenario | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 |

|---|---|---|---|---|---|---|

| enteric fermentation in cows | enteric fermentation (CH4) | 5135.1 | 5135.1 | 5135.1 | 5135.1 | 3081.1 |

| manure management | manure management (CH4) | 2939.7 | 2204.8 | 1102.4 | 1102.4 | 0.0 |

| direct emissions of manure management (N2O) | 698.8 | 524.1 | 262.1 | 262.1 | 698.8 | |

| indirect emissions of manure management (N2O) | 308.9 | 231.7 | 115.8 | 115.8 | 308.9 | |

| manure field consumption | direct emissions from field application of manure (N2O) | 363 | 181.5 | 181.5 | 181.5 | 181.5 |

| indirect emissions from field application of manure (N2O) | 73.8 | 36.9 | 36.9 | 36.9 | 36.9 | |

| feed production and processing | direct emissions from field application of nitrogen fertilizers (N2O) | 293.6 | 293.6 | 293.6 | 293.6 | 293.6 |

| indirect emissions from field application of nitrogen fertilizers (N2O) | 47.7 | 47.7 | 47.7 | 47.7 | 47.7 | |

| fertilizer production (CO2) | 63.5 | 63.5 | 63.5 | 63.5 | 63.5 | |

| pesticide production (CO2) | 37.3 | 37.3 | 37.3 | 37.3 | 37.3 | |

| machine operation (CO2) | 75.7 | 75.7 | 75.7 | 75.7 | 75.7 | |

| transport of feed and fertilizer (CO2) | 402.9 | 402.9 | 402.9 | 402.9 | 402.9 | |

| dairy farm energy consumption (diesel/electricity) | energy consumption on dairy farms (CO2) | 2989.5 | 2989.5 | 2989.5 | 0.0 | 0.0 |

| total system emissions | 13,429.5 | 12,224.3 | 10,744 | 7754.5 | 5227.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Liu, S.; Xie, Q.; Ma, Z. Carbon Footprint of a Typical Crop–Livestock Dairy Farm in Northeast China. Agriculture 2024, 14, 1696. https://doi.org/10.3390/agriculture14101696

Wang Y, Liu S, Xie Q, Ma Z. Carbon Footprint of a Typical Crop–Livestock Dairy Farm in Northeast China. Agriculture. 2024; 14(10):1696. https://doi.org/10.3390/agriculture14101696

Chicago/Turabian StyleWang, Yurong, Shule Liu, Qiuju Xie, and Zhanyun Ma. 2024. "Carbon Footprint of a Typical Crop–Livestock Dairy Farm in Northeast China" Agriculture 14, no. 10: 1696. https://doi.org/10.3390/agriculture14101696