Core Technologies of Sugarcane Chopper Harvester Extractor: A Critical Review

Abstract

1. Introduction

2. Research Ideas

- (i)

- Research on material characteristics: The development of a cleaning scheme and the establishment of an appropriate cleaning speed range are foundational for the structural design of impurity exhaust fans. Sugarcane leaves are classified as flexible flake materials, which are prevalent in the realm of agricultural material cleaning. The cleaning process predominantly employs the principle of gas–solid two-phase flow to facilitate the entry and removal of impurities. The CFD-DEM coupling method is widely utilized to address these dynamics, with the prerequisite of conducting parameter determination. Given the limitations inherent in this approach, several scholars have proposed innovative methods to overcome these challenges, thereby paving the way for further mechanistic research. This discussion will delve into these advancements and their implications for the design and optimization of impurity exhaust fans.

- (ii)

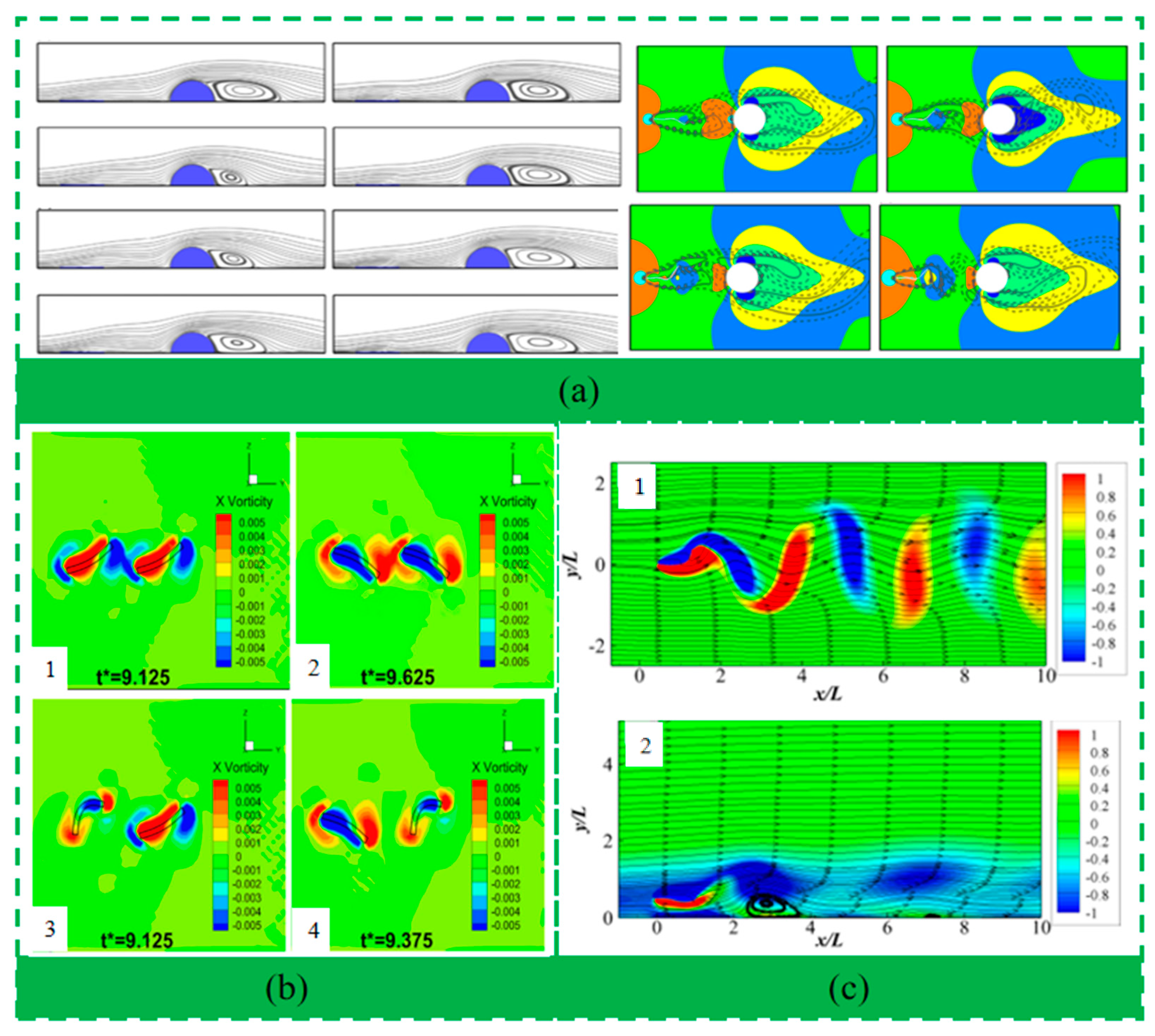

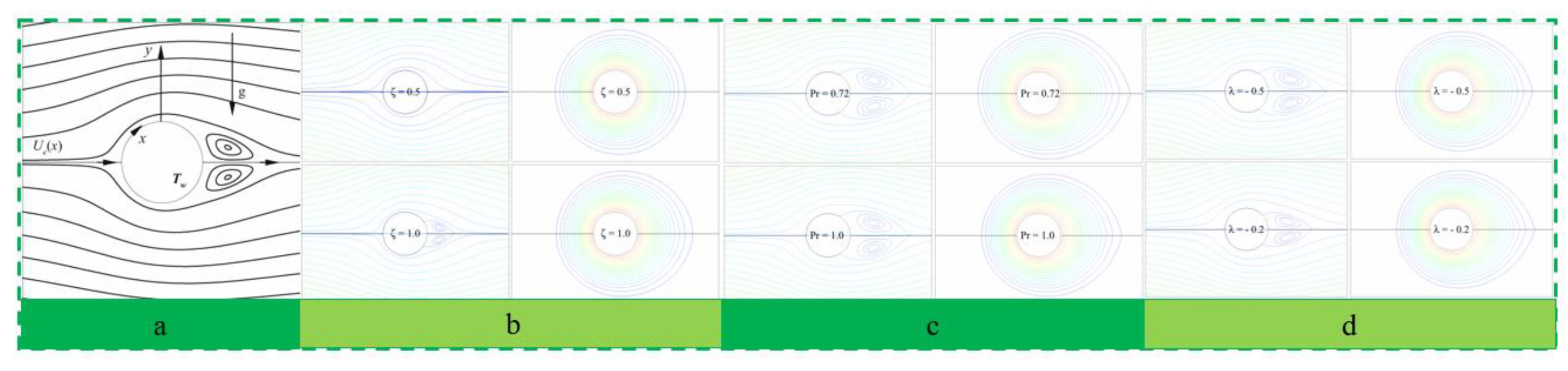

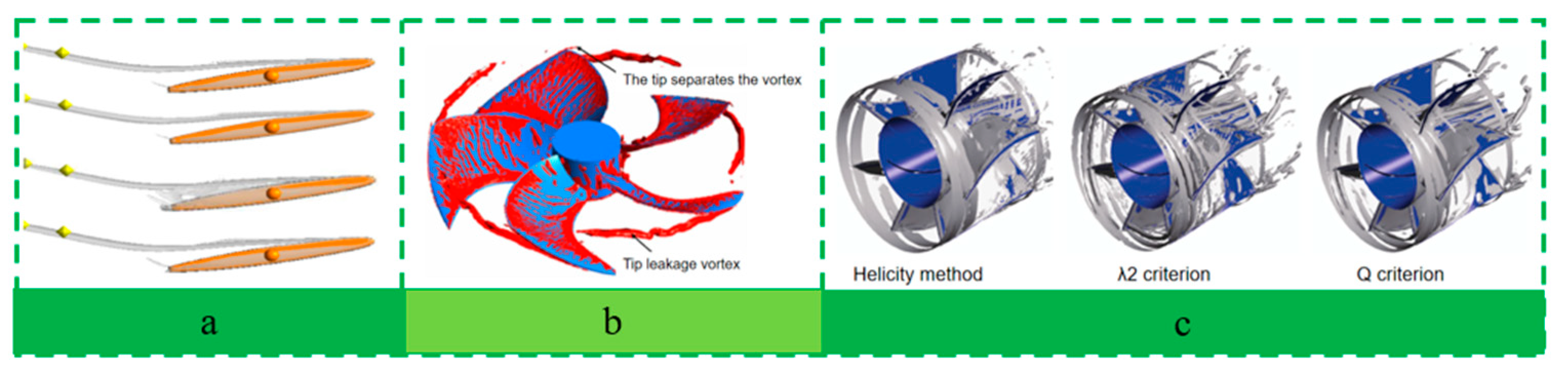

- Mechanistic research on impurity emission: The impurity exhaust fan, a quintessential piece of fluid machinery, has received less mechanistic investigation compared to other fluid machinery such as industrial fans and aero engines, and it lacks a robust theoretical foundation. The foundation for defining the operating conditions and establishing optimal usage parameters for fluid machinery is a comprehensive understanding of its fluid mechanical characteristic curves. The flow state is an essential research subject in the optimization process of fluid machinery, with the boundary layer flow separation phenomenon being a key research focus. When examining the performance mechanisms of fluid machinery, eddy identification technology emerges as a principal investigative tool. The third segment of this study, which pertains to the structural and operational parameters of the fan, is informed and directed by the insights gained from mechanistic research. This approach ensures that the design and operational strategies for the impurity exhaust fan are grounded in a thorough understanding of its fluid dynamics and performance characteristics.

- (iii)

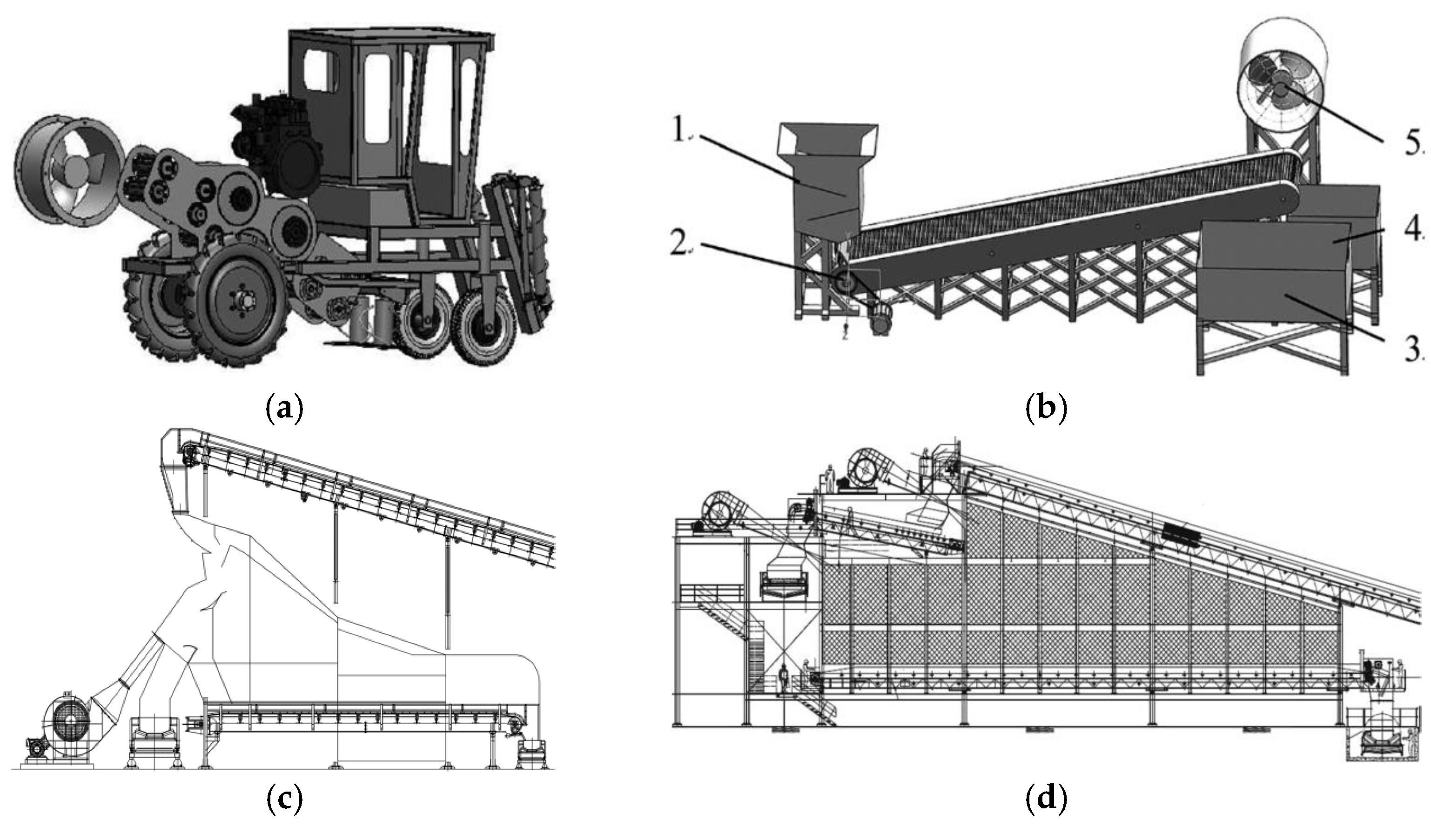

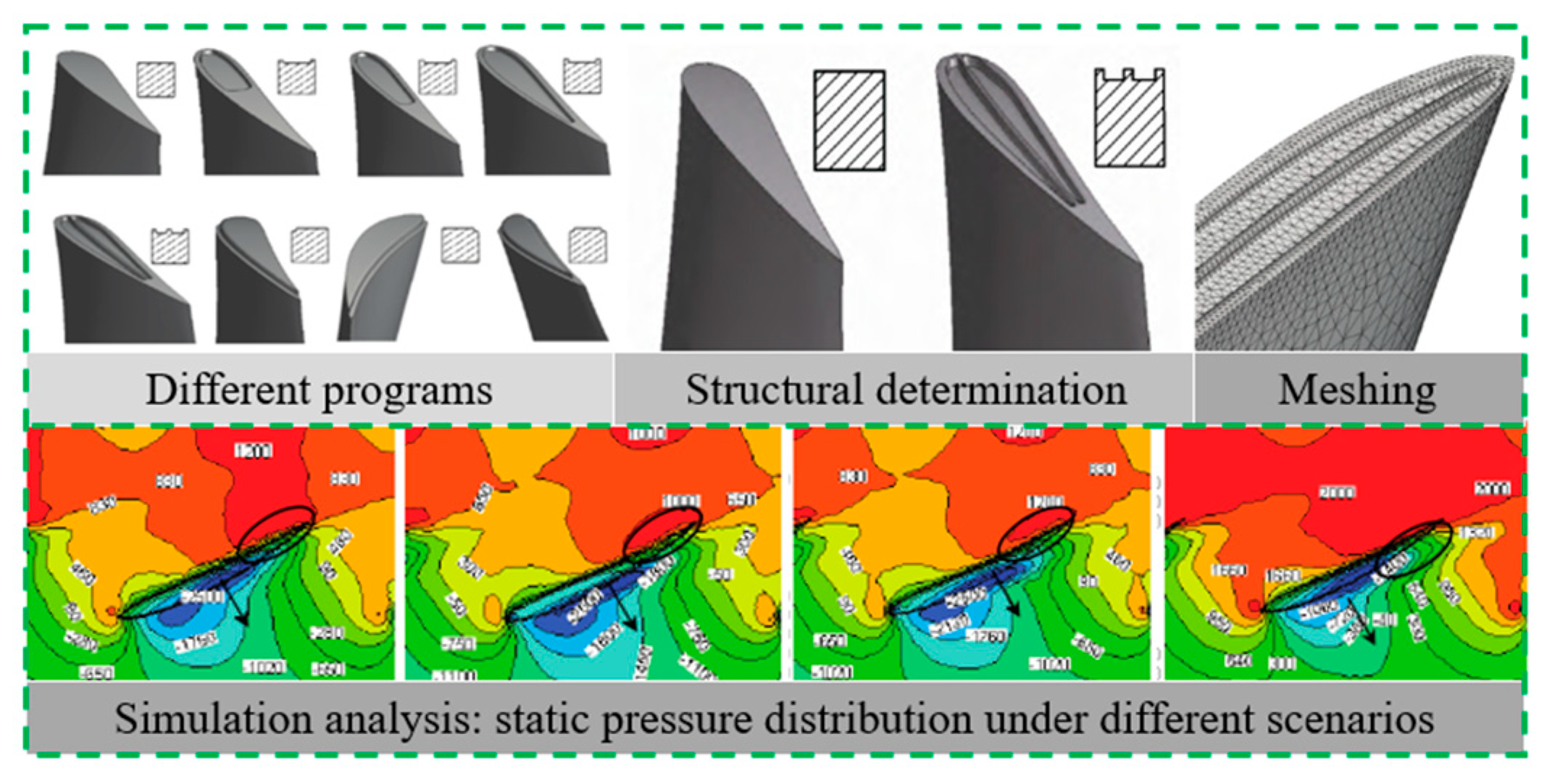

- Investigation of fan structure and operating parameters: This study synthesizes the significant impact of the impurity exhaust fan’s structure and operating parameters on its impurity removal efficiency. The analysis is conducted from three perspectives: operating mode, structural parameters, and airflow field. The research on structural parameters primarily encompasses structural optimization, investigation of the airflow field, and comparative assessments of performance before and after structural modifications. The overarching goal of these investigations is to minimize the impurity content.

3. Material Characteristics

3.1. Material Research Methodology

3.2. Problems of Retention and New Approaches

4. Mechanism of Impurity Removal

5. Structure and Parameter Optimization

5.1. Mode of Operation

5.2. Structural Parameters

6. Conclusions and Recommendations

6.1. Research Status and Problems

6.2. Research Development and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Q.; Mo, J.; Li, T.; Ou, Y.-G. Current situation of sugarcane planter and its key technical issues in China. Sugarcane Canesugar 2011, 5, 52–58. [Google Scholar]

- Wei, F.; Wei, J.; Du, G. Analysis of the development status and countermeasures of mechanization of sugarcane production. China Agric. Inf. 2015, 11, 148–149. [Google Scholar]

- Liu, X.; Zhang, C.; Zheng, C. Policy Development and Enlightenment of Brazilian Sugar Industry. In Proceedings of the 15th Symposium of the Sugarcane Committee of the Crop Science Society of China, Haikou, China, 1 August 2014; pp. 238–244. [Google Scholar]

- Zhang, H.; Luo, J.; Yang, Y.; Lin, Z. An Analysis of the Labor Force in the Sugarcane Region of Guangxi. Sugarcane Canesugar 2011, 4, 87–90. [Google Scholar]

- Tan, J.; Yang, S. Research on the development of mechanization of sugarcane production in Guangxi. J. South Agric. Sci. 2018, 391, 194–199. [Google Scholar] [CrossRef]

- Zhang, Z. Ministry of Agriculture: Implement the No. 1 Document of the Central Committee to improve the level of agricultural mechanization. South China Agric. Mach. 2016, 2, 4. [Google Scholar]

- Wang, W. Research on the Trend of China’s Three Rural Policies since the 21st Century: A Review and Prospect of 14 “Central No. 1 Documents”. Jiangxi Soc. Sci. 2017, 7, 51–58. [Google Scholar]

- Chen, W. Changes and future trends of the “three rural” policies in the No. 1 document of the Central Committee. Rural Econ. 2017, 8, 13–19. [Google Scholar]

- Mo, J.; Liu, Q. Discussion on mechanization technology of sugarcane harvesting in China. Agric. Mech. Res. 2013, 3, 12–18. [Google Scholar] [CrossRef]

- Tang, X. Effect of Leaf Stripping Drum Speed on Sugarcane Leaf Stripping Machine with Spring Leaf Stripping Element. Mach. Tool Hydraul. 2018, 46, 29–33. [Google Scholar] [CrossRef]

- Xie, F.; Ou, Y.; Liu, Q.; Feng, J.; Huang, S. High-speed photographic analysis of internal logistics and impurity removal in a whole straw sugarcane harvester. J. Agric. Mech. Res. 2015, 37, 203–206. [Google Scholar] [CrossRef]

- Wen, X.; Yang, J. Analysis of the current situation and problems of impurity removal devices in sugarcane harvesting machinery in China. Agric. Mach. Use Maint. 2019, 2, 80. [Google Scholar] [CrossRef]

- Shao, K.; Niu, Z.; Yu, C.; Wu, W. Determination and analysis of suspension velocity of aquatic pellet feed. Rev. Agric. Sci. Technol. 2022, 24, 120–129. [Google Scholar] [CrossRef]

- Kang, J.; Zhang, H.; Zhang, G.; Du, H.; Peng, Q.; Song, Y. Aerodynamic Characteristics of Residual Film Materials and Test of Membrane Miscellaneous Separation Device. Chin. J. Agric. Mach. 2020, 41, 167–172. [Google Scholar] [CrossRef]

- Hu, C.; Fang, X.; Shi, Y. Design and test of pneumatic fertilization device in paddy field. Chin. J. Agric. Mech. Chem. 2022, 43, 14–19+32. [Google Scholar] [CrossRef]

- Yuan, C.; Ou, Y.; Liu, Q.; Huang, Z. Suspension properties of a sliced sugarcane mixture. Jiangsu Agric. Sci. 2017, 45, 166–168. [Google Scholar] [CrossRef]

- Wang, F.; Yang, G.; Ke, W.; Ma, S. Studies on suspension property of sugarcane components. IFAC-PapersOnLine 2018, 51, 526–531. [Google Scholar] [CrossRef]

- Wen, X.; Yang, W.; Guo, W.; Zeng, B. Calibration and verification of simulation parameters of discrete element discharge of segmented sugarcane harvester. Chin. J. Agric. Mech. 2020, 41, 12. [Google Scholar] [CrossRef]

- Guo, W.; Yang, W.; Wen, X.; Yang, J.; Mo, J.; Zeng, B.; Nong, H. Research on simulation modeling method of impurity discharge of segmented sugarcane harvester. Agric. Mech. Res. 2020, 8, 6–12. [Google Scholar] [CrossRef]

- Huang, S.; Yang, W.; Yang, J.; Liang, L. Study on finite element modeling method of sugarcane stem-cane leaf system. Agric. Mech. Res. 2018, 40, 19–23. [Google Scholar] [CrossRef]

- Pu, M.; Wu, J. Modeling of sugarcane flexible body model based on ADAMS. J. Syst. Simul. 2009, 7, 1930–1932. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, F.; Zhao, M.; Ma, Q.; Wang, W.; Fan, Q.; Yan, P. Determination of physical parameters of corn straw contact and calibration of discrete element simulation. J. China Agric. Univ. 2018, 23, 120–127. [Google Scholar] [CrossRef]

- Liu, W.; He, J.; Li, H.; Li, X.; Zheng, K.; Wei, Z. Parameter calibration of micro-potato simulation based on discrete elements. Trans. CSAM 2018, 49, 125–135. [Google Scholar] [CrossRef]

- Zewdu, A.D. Aerodynamic properties of tef grain and straw material. Biosyst. Eng. 2007, 98, 304–309. [Google Scholar] [CrossRef]

- Khir, R.; Pan, Z.; Atungulu, G.G.; Thompson, J.F. Characterization of physical and aerodynamic properties of walnuts. Trans. ASABE 2014, 57, 53–61. [Google Scholar] [CrossRef]

- Vogel, S. Drag and reconfiguration of broad leaves in high winds. J. Exp. Botany. 1989, 40, 941–948. [Google Scholar] [CrossRef]

- Zhang, K.; Fu, H. Resistance characteristics of three-dimensional virtual canopy based on lattice-Boltzmann method. J. Donghua Univ. (Nat. Sci. Ed.) 2019, 45, 306–312. [Google Scholar]

- Yang, H.; Fu, H. Numerical Simulation and Experimental Study of Tree Canopy Flow Resistance Characteristics. J. Cent. South Univ. (Nat. Sci. Ed.) 2016, 47, 4292–4300. [Google Scholar] [CrossRef]

- Jin, Y.; Li, J.; Lin, P.; Wu, J. Numerical Simulation of Coupling of Fiber and Airflow. J. Text. Res. 2015, 36, 152–157. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, P.; Hu, X. Study on the filament motion and joint forming mechanism in the pneumatic yarn splicing process. Text. Res. J. 2016, 86, 2000–2012. [Google Scholar] [CrossRef]

- Rojas, R.; Hayashi, K.; Seta, T.; Tomiyama, A. Numerical simulation of flows about a stationary and a free-falling cylinder using immersed boundary-finite difference lattice Boltzmann method. J. Comput. Multi. Flow 2013, 5, 27–41. [Google Scholar] [CrossRef]

- Xia, Z.; Connington, K.; Rapaka, S.; Yue, P.; Feng, J.J.; Chen, S. Flow patterns in the sedimentation of an elliptical particle. J. Fluid Mech. 2009, 249, 249–272. [Google Scholar] [CrossRef]

- Hua, R.; Zhu, L.; Lu, X. Dynamics of fluid flow over a circular flexible plate. J. Fluid Mech. 2014, 759, 56–72. [Google Scholar] [CrossRef]

- Tang, C.; Lu, X. Self-propulsion of a three-dimensional flapping flexible plate. J. Hydrodyn. Ser. B 2016, 28, 1–9. [Google Scholar] [CrossRef]

- Wu, J.; Shu, C.; Zhao, N. Numerical study of flow control via the interaction between a circular cylinder and a flexible plate. J. Fluid. Struct. 2014, 49, 594–613. [Google Scholar] [CrossRef]

- Luo, Y.; Wu, T.H.; Qi, D. Lattice-Boltzmann lattice-spring simulations of flexibility and inertial effects on deformation and cruiing reversal of self-propelled flexible swimming bodies. Comput. Fluids 2017, 87, 87–102. [Google Scholar] [CrossRef]

- Wang, L.; Tian, F. Numerical simulation of flow over a parallel cantilevered flag in the vicinity of a rigid wall. Phys. Rev. E 2019, 99, 053111. [Google Scholar] [CrossRef]

- Connell, B.S.H.; Yue, D.K.P. Flapping dynamics of a flag in a uniform stream. J. Fluid Mech. 2007, 581, 33–67. [Google Scholar] [CrossRef]

- Kim, H.; Kang, S.; Kim, D. Dynamics of a flag behind a bluff body. J. Fluid. Struct. 2017, 71, 1–14. [Google Scholar] [CrossRef]

- Kim, D.; Cossé, J.; Cerdeira, C.H.; Gharib, M. Flapping dynamics of an inverted flag. J. Fluid Mech. 2013, 736, R1. [Google Scholar] [CrossRef]

- Zhang, K. Principles of Fluid Mechanics; China Machine Press: Beijing, China, 2000. [Google Scholar]

- Han, J. Surge analysis and preventive measures of mine axial flow fan. Min. Equip. 2020, 1, 100–101. [Google Scholar]

- Zhang, P. Optimization Design of Structural Parameters of Axial Fan; Yanshan University: Qinhuangdao, China, 2016. [Google Scholar]

- Yang, M.; Yang, Q. A review on the modeling of wind speed-power characteristic curves of wind turbines. Electr. Power Autom. Equip. 2018, 38, 34–43. [Google Scholar] [CrossRef]

- Ye, X.; Zhang, J.; Li, C. Simulation of blade tip grooving effect on performance of twin-stage variable-pitch axial fan. J. Syst. Simul. 2018, 30, 1511–1519. [Google Scholar] [CrossRef]

- Wangsawijaya, D.D.; Hutchins, N. Investigation of unsteady secondary flows and large-scale turbulence in heterogeneous turbulent boundary layers. J. Fluid Mech. 2022, 934, 440. [Google Scholar] [CrossRef]

- Mehmood, A.; Shah, B.H.; Usman, M.; Raza, I. Calculation of flow separation in a retarded boundary-layer over a moving continuous sheet. Phys. Scr. 2021, 96, 12. [Google Scholar] [CrossRef]

- Hanif, H. A computational approach for boundary layer flow and heat transfer of fractional Maxwell fluid. Math. Comput. Simulat. 2022, 191, 1–13. [Google Scholar] [CrossRef]

- Loper, D.E. Turbulent boundary-layer flow beneath a vortex. Part 1. Turbulent Bödewadt flow. J. Fluid Mech. 2020, 892, A12. [Google Scholar] [CrossRef]

- Schrichtin, X.Y.; Kestin, J. Boundary Layer Theory; McGraw-Hill: New York, NY, USA, 1961. [Google Scholar]

- Wen, S. Microfluidic Boundary Layer Theory and Its Application; Metallurgical Industry Press: Beijing, China, 2002. [Google Scholar]

- Qu, X.; Zhang, Y.; Lu, X.; Zhu, J.; Zhang, Y. Unsteady fluidic oscillators for active controlling boundary layer separation in an ultra-high-lift low-pressure turbine. Aerosp. Sci. Technol. 2021, 119, 1071300. [Google Scholar] [CrossRef]

- Nepal, C.R.; Rahman, T.; Parvin, S. Boundary-Layer Separations of Mixed Convection Flow Past an Isothermal Circular Cylinder. Int. J. Appl. Comput. Math. 2019, 5, 3. [Google Scholar] [CrossRef]

- Guo, C.; Huang, X.; Qiu, B.; Feng, X. Application and evaluation of eddy criterion in eddy current analysis of wing end clearance. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2018, 46, 23–28. [Google Scholar] [CrossRef]

- Liu, G.; Wang, L.; Liu, X. Numerical study on the effect of bladelet winglets on the aerodynamic performance and noise characteristics of axial fans. J. Xi’an Jiaotong Univ. 2020, 54, 104–112. [Google Scholar] [CrossRef]

- Zhao, B.; Xie, Y.; Liao, W.; Han, L.; Fu, Y.; Huang, Z. Applicability analysis of the second-generation vortex identification method in the internal flow field of mixed-flow pumps. J. Mech. Eng. 2020, 56, 216–223. [Google Scholar] [CrossRef]

- Wang, C. Analysis and Control of Flow Characteristics of Three-Dimensional Hydrofoil Blade Top Gap. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2019. [Google Scholar]

- Wang, B.; Wu, Y. Vortex dynamics mechanism of unsteady flow at the tip of a diffused blade grid. Acta Aeronaut. Sin. 2020, 41, 246–262. [Google Scholar] [CrossRef]

- Yan, H.; Liu, Y.; Li, Q.; Lu, L. Turbulence characteristics in corner separation in a highly loaded linear compressor cascade. Aerosp. Sci. Technol. 2018, 75, 139–154. [Google Scholar] [CrossRef]

- Wang, H.; Li, S.; Ma, F.; Li, Z. Pneumatic design of impurity removal fan for small sugarcane harvester. Agric. Mech. Res. 2015, 37, 103–107. [Google Scholar] [CrossRef]

- Zeng, L.; Cao, Y.; Zhong, X.; Wang, W.; Huang, W. Design of sugarcane stem and leaf separator. South China Agric. Mach. 2021, 52, 36–38+44. [Google Scholar]

- dos Santos Penteado Soares, C.C.; Okuno, F.M.; Garbellini Duft, D.; Carvalho, D.J.; Morandi, J.; Guizelini Júnior, P.C.; Trez, C.R.; Eduardo, P.; Mantelatto Lima Verde Leal, M.R. Commercial Sugarcane Dry Cleaning Systems in Brazil: Progress and Challenges. BioEnergy Res. 2019, 12, 920–929. [Google Scholar] [CrossRef]

- Zhong, J.; Li, S.; Ma, F.; He, Y.; Pan, Y.; Sun, T.; Li, Z. Stress-strain and model analysis on impurity removal fan based on fluid-structure interaction. J. Agric. Mech. Res. 2017, 39, 6. [Google Scholar] [CrossRef]

- Xing, H.; Ma, S.; Wang, F.; Bai, J.; Hu, J. Structure optimization and experiment of sugarcane chopper harvester extractor. Trans. CSAE 2020, 36, 67–75. [Google Scholar] [CrossRef]

- Ye, X.; Li, P.; Li, C. Numerical study on the effect of blade top slotting on the performance of axial fans. Chin. J. Electr. Eng. 2015, 35, 652–659. [Google Scholar] [CrossRef]

- Ye, X.; Li, P.; Li, C. Study on the performance and vibration characteristics of axial fans under double-groove blade top structure. J. Mech. Eng. 2015, 51, 167–174. [Google Scholar] [CrossRef]

- Xing, H.; Ma, S.; Li, W.; Wang, F.; Bai, J.; Hu, J. Improving the performance of a sugarcane harvester extractor using design changes validated by computational fluid dynamic modelling and experiment. Biosystems Eng. 2022, 218, 124–138. [Google Scholar] [CrossRef]

- Xing, H.; Ma, S.; Mo, J.; Zeng, B.; Liang, W.; Li, W.; Wang, F.; Bai, J.; Ding, Z. Optimization and experiment of parameters for the impeller structure of extractor in a sugarcane chopper harvester. Trans. CSAE 2021, 37, 12–19. [Google Scholar] [CrossRef]

- Zhang, X. Study on the Influence of Blade Shape on the Performance of Axial Fan. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2021. [Google Scholar]

- Huang, H.; Lu, Y. Research on Effect of Blade Tip Clearance and Installation Position of Guide Vane on Flow Field of Axial-flow Fan. Fluid Mach. 2018, 46, 34–39. [Google Scholar]

- Shen, J.; Wang, B.; Li, K. Simulation study on the influence of shallow structure parameters on the performance of axial fans. Low Temp. Superconduct. 2019, 2, 91–95. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Ma, S.; Zhou, B.; Li, W.; Huo, P.; Qian, J. Core Technologies of Sugarcane Chopper Harvester Extractor: A Critical Review. Agriculture 2024, 14, 1730. https://doi.org/10.3390/agriculture14101730

Li W, Ma S, Zhou B, Li W, Huo P, Qian J. Core Technologies of Sugarcane Chopper Harvester Extractor: A Critical Review. Agriculture. 2024; 14(10):1730. https://doi.org/10.3390/agriculture14101730

Chicago/Turabian StyleLi, Weiqing, Shaochun Ma, Baocheng Zhou, Wenzhi Li, Peng Huo, and Jun Qian. 2024. "Core Technologies of Sugarcane Chopper Harvester Extractor: A Critical Review" Agriculture 14, no. 10: 1730. https://doi.org/10.3390/agriculture14101730

APA StyleLi, W., Ma, S., Zhou, B., Li, W., Huo, P., & Qian, J. (2024). Core Technologies of Sugarcane Chopper Harvester Extractor: A Critical Review. Agriculture, 14(10), 1730. https://doi.org/10.3390/agriculture14101730