An Investigation on a Comprehensive Calibration Technique to Determine the Discrete Elemental Characteristics of Unrotted Sheep Dung at Varying Water Concentrations

Abstract

:1. Introduction

- (1)

- Establishment of two related mathematical models: Using the hollow cylinder lifting method, a moisture content–stacking angle model was established. A discrete element–stacking angle model was established using the EDEM 2022 simulation software, including Plackett–Burman testing, steepest ascent testing, and Box–Behnken experimental design.

- (2)

- Coupled mathematical model: By combining the moisture content–stacking angle model with the discrete element–stacking angle model, a moisture content–discrete element parameter model was constructed. This model can directly obtain key discrete element simulation parameters from the moisture content of unrotted sheep manure, providing an accurate mathematical model for the simulation of the mixing process of sheep manure in composting equipment.

- (3)

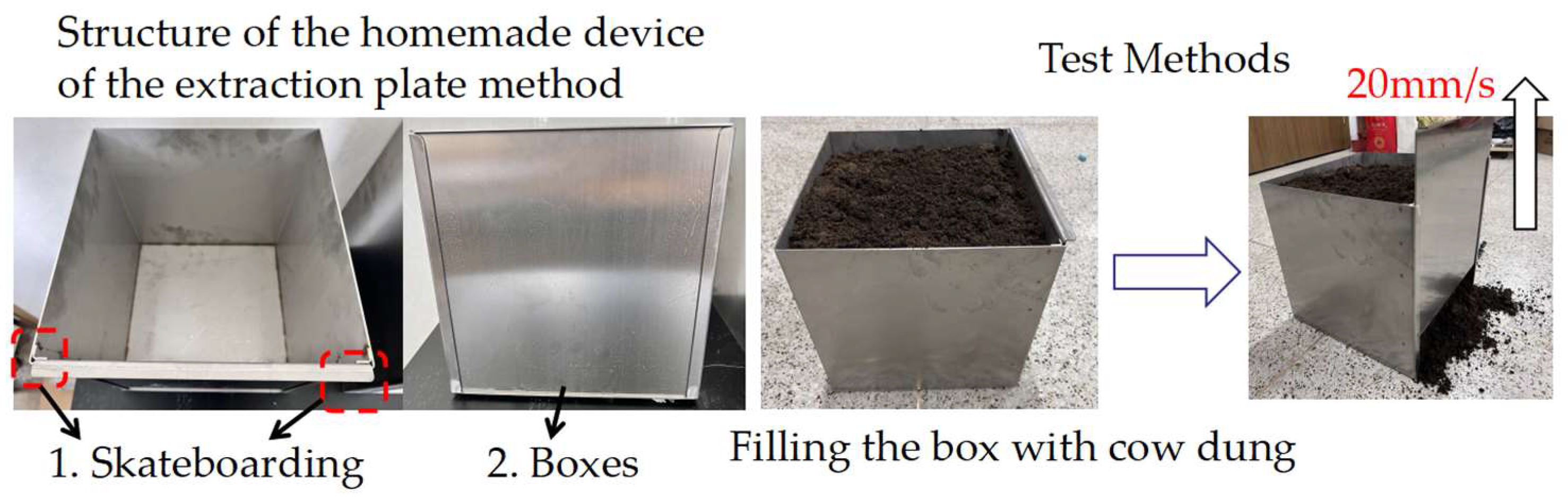

- Model validation: The reliability of the developed model was verified by pumping plate and funnel experiments, which confirmed its accuracy in calibrating the discrete element parameters of sheep manure.

- (4)

- Research contribution: The calibration method established in this study provides a flexible and effective way to optimize composting equipment. The mathematical model improves the accuracy of mechanical equipment simulation and helps to improve the design and operation of composting machinery.

2. Materials and Methods

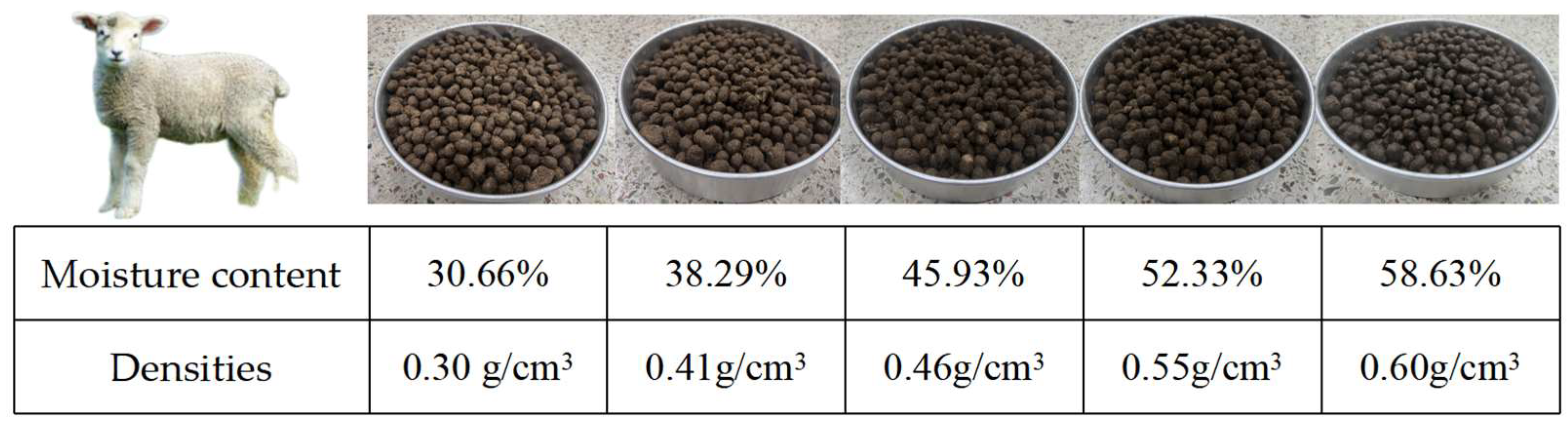

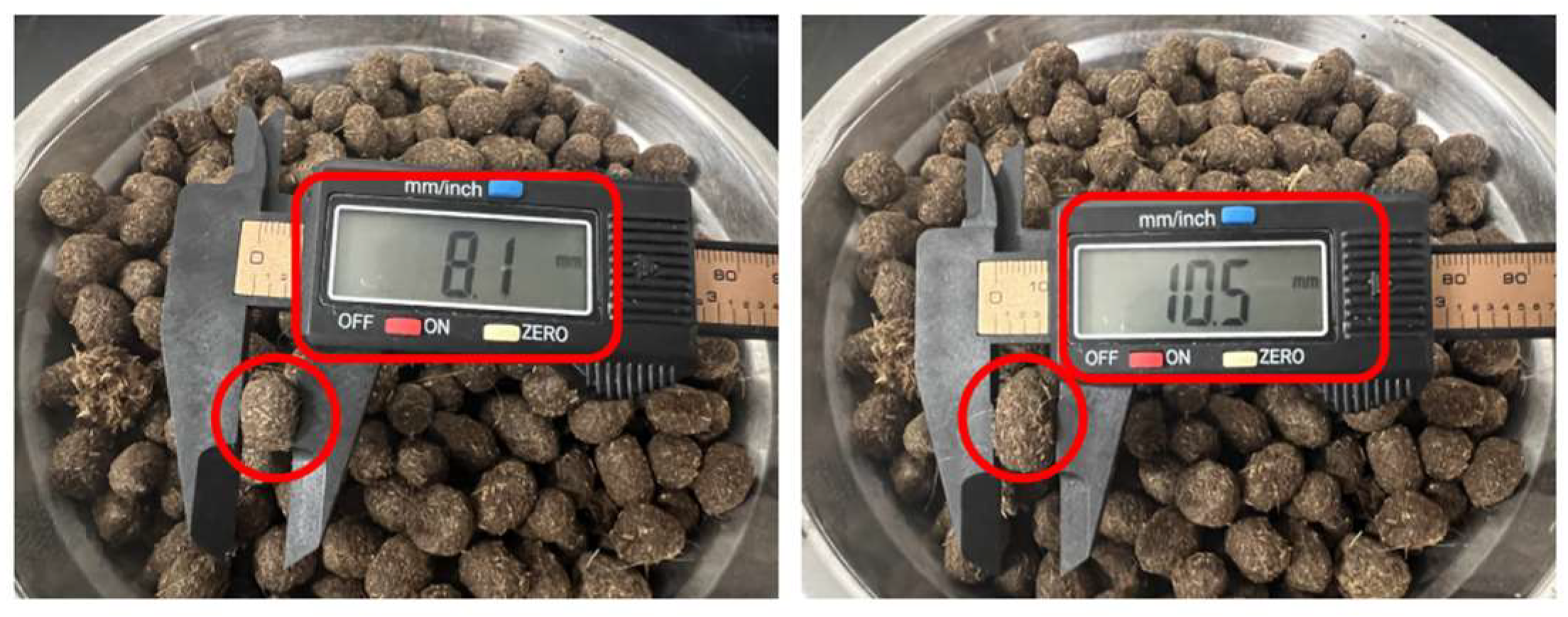

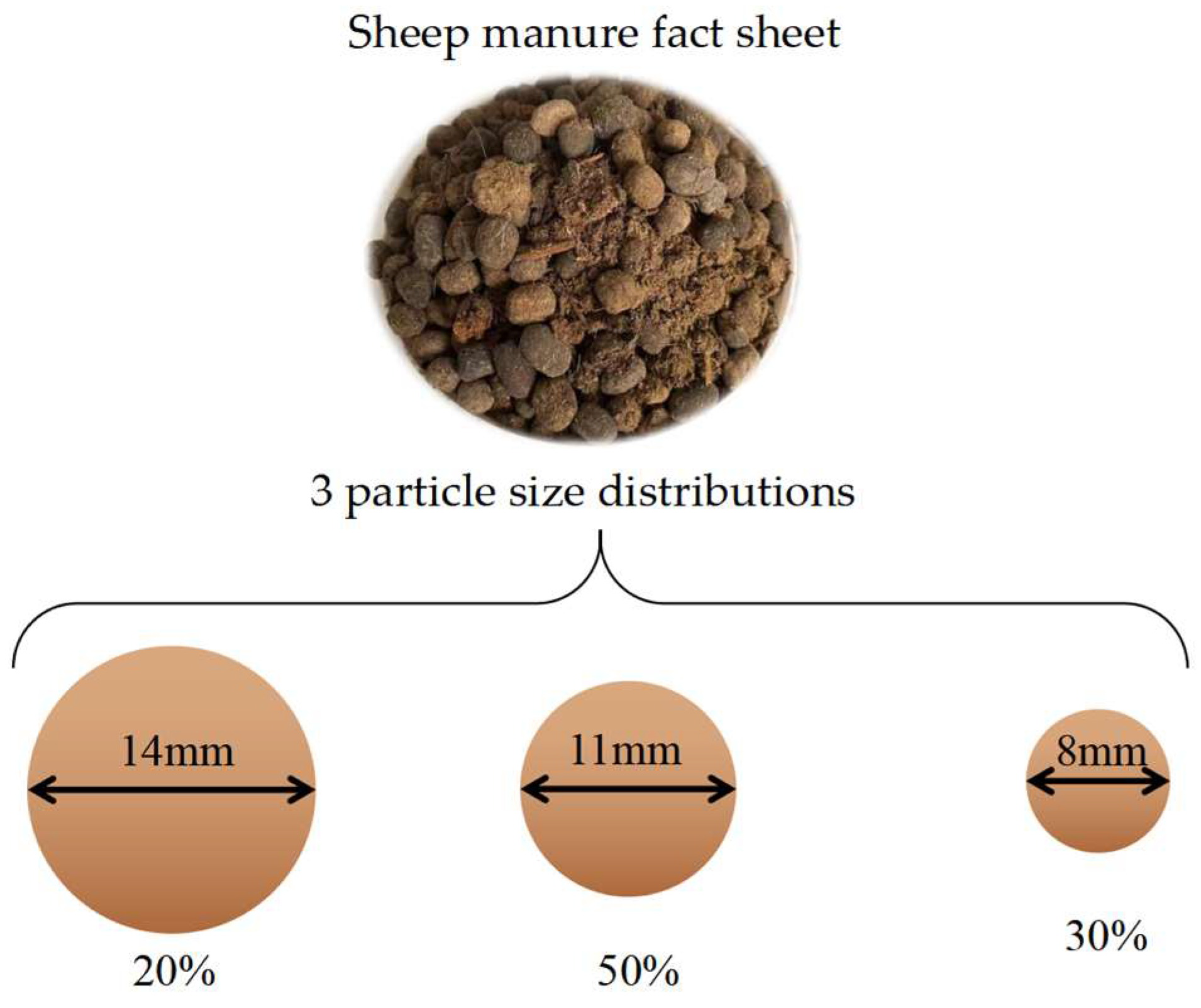

2.1. Test Material and Particle Size Distribution

2.2. Sheep Manure Stacking Angle Test and Moisture Content–Stacking Angle Model Construction

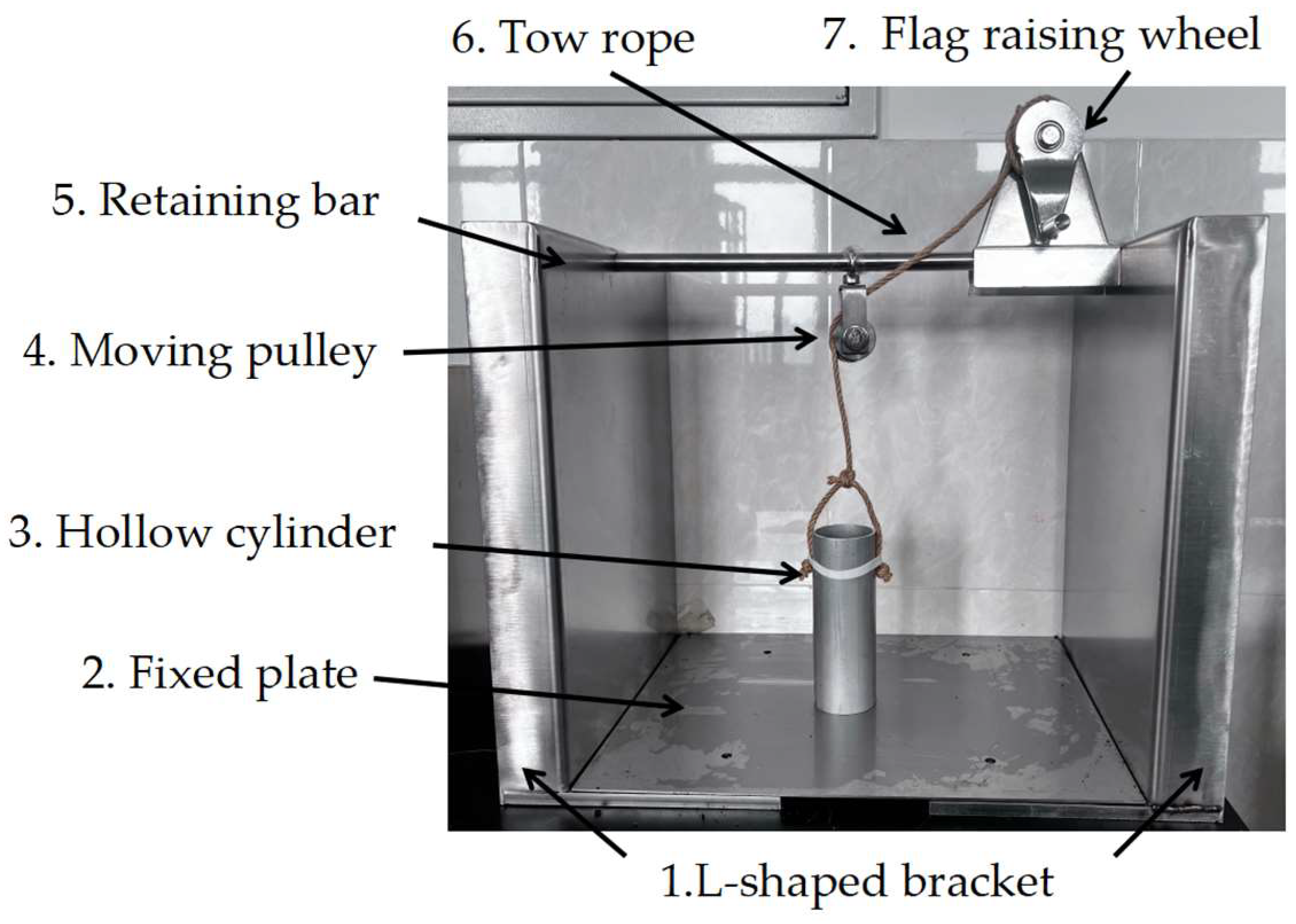

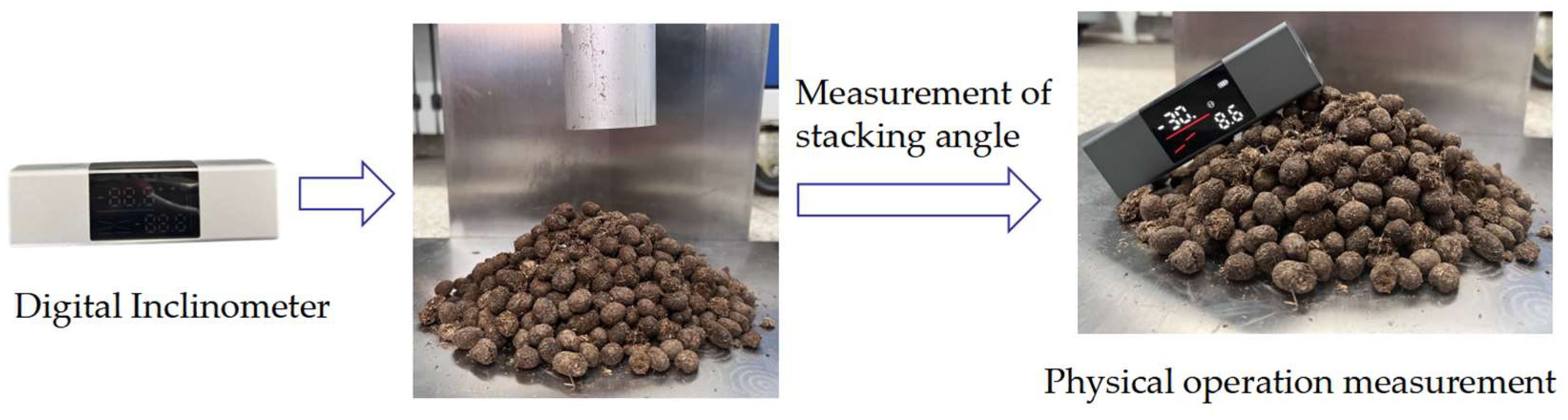

2.2.1. Sheep Manure Stacking Angle Test Device

2.2.2. Measurement of the Angle of Accumulation of Sheep Manure

2.3. Discrete Meta-Modeling of Sheep Manure

2.3.1. Selection of Contact Models

2.3.2. Setting the Simulated Particle Size

2.3.3. Selection of Discrete Element Simulation Parameters

2.4. Calibration of Discrete Element Parameters and Construction of Angle of Accumulation–Discrete Element Parameter Model for Sheep Manure

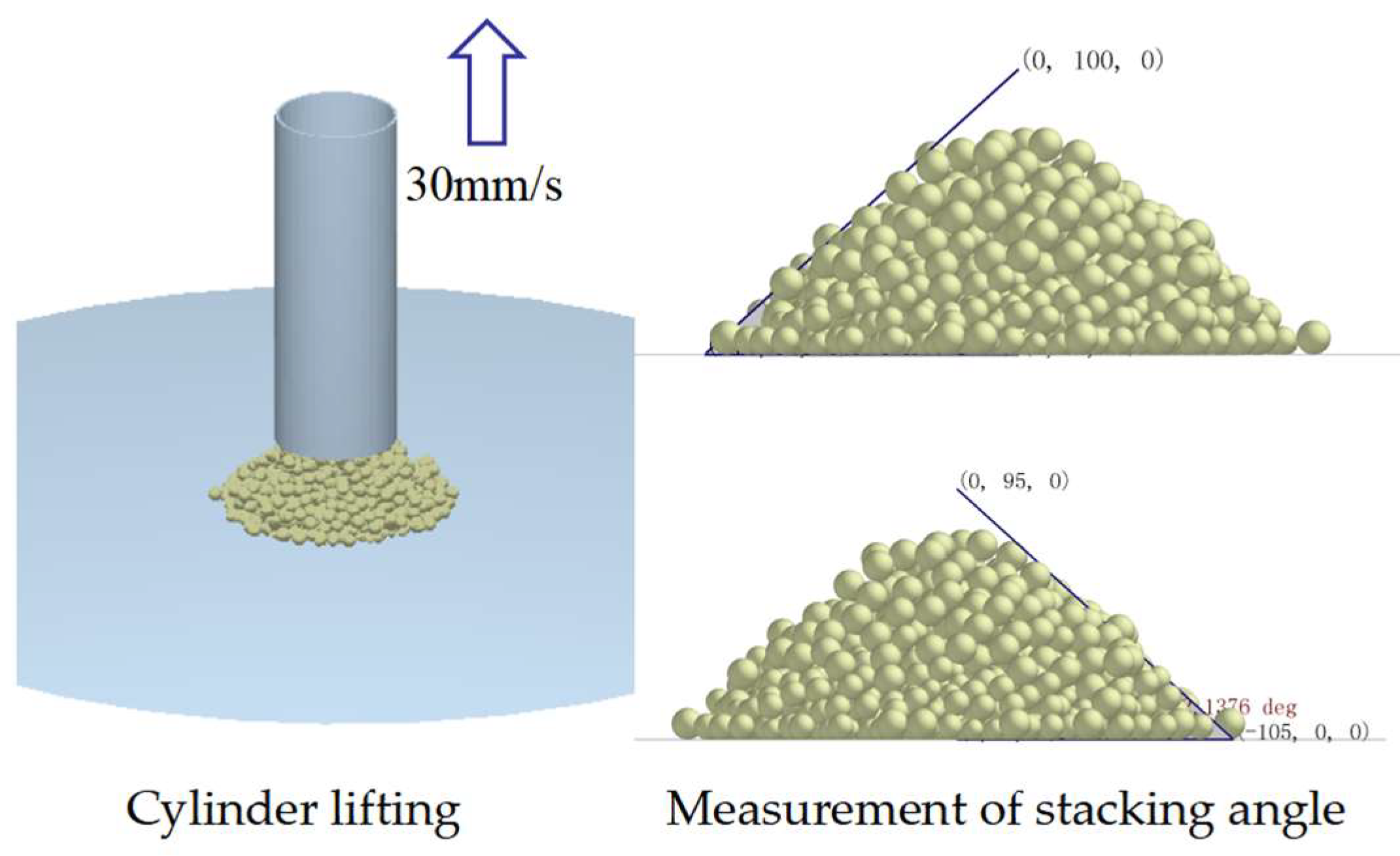

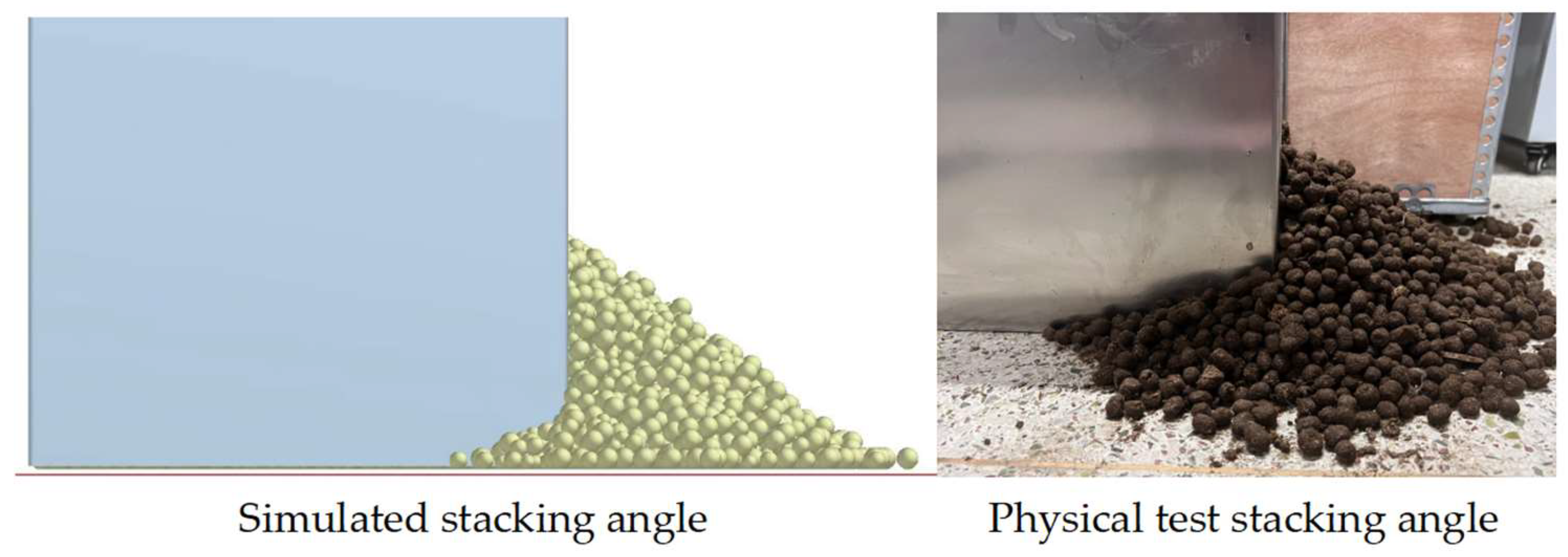

2.4.1. Simulated Angle of Repose for Measurement

2.4.2. Angle of Accumulation of Sheep Manure–Discrete Element Parameter Modeling

2.5. Sheep Manure Moisture Content–Discrete Element Parameter Modeling and Engineering Validation Test

3. Results

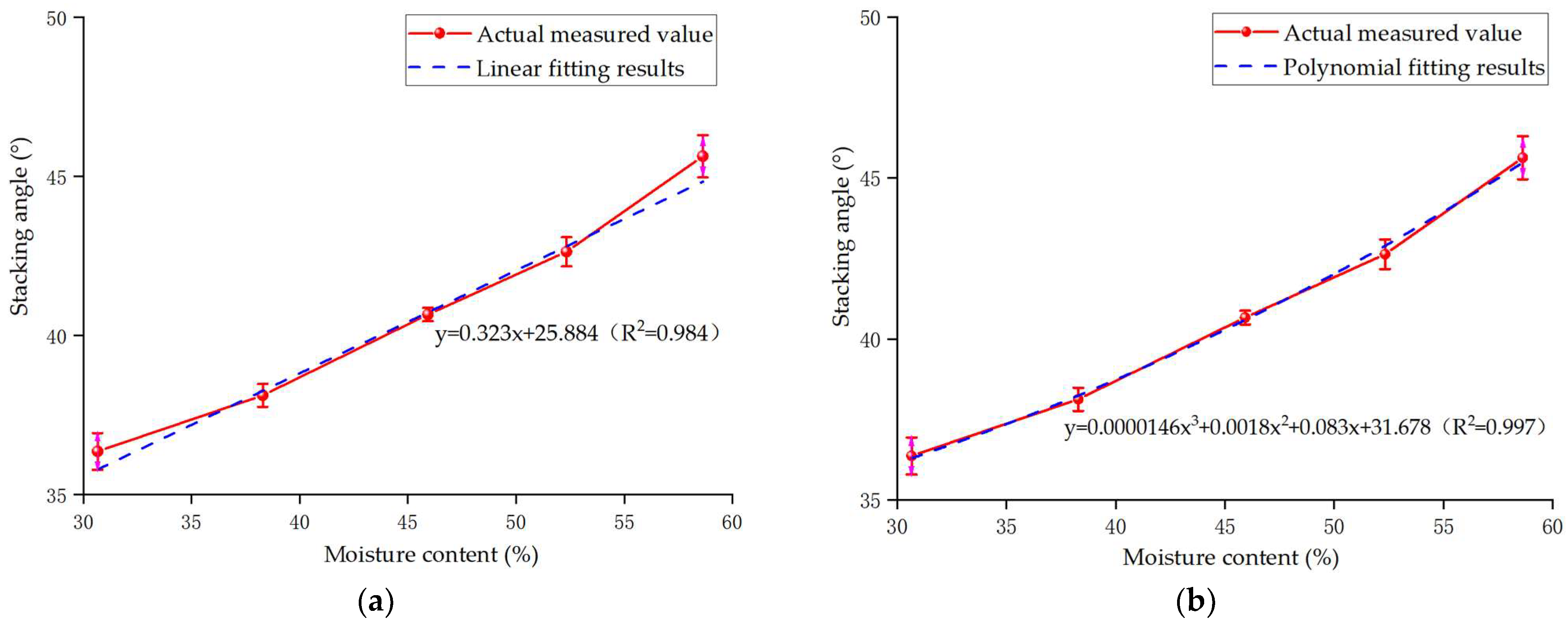

3.1. Water Content–Stacking Angle Modeling

3.2. Significance Parameter Screening Results and Analyses

3.3. Determination of Optimal Intervals for Discrete Element Parameters

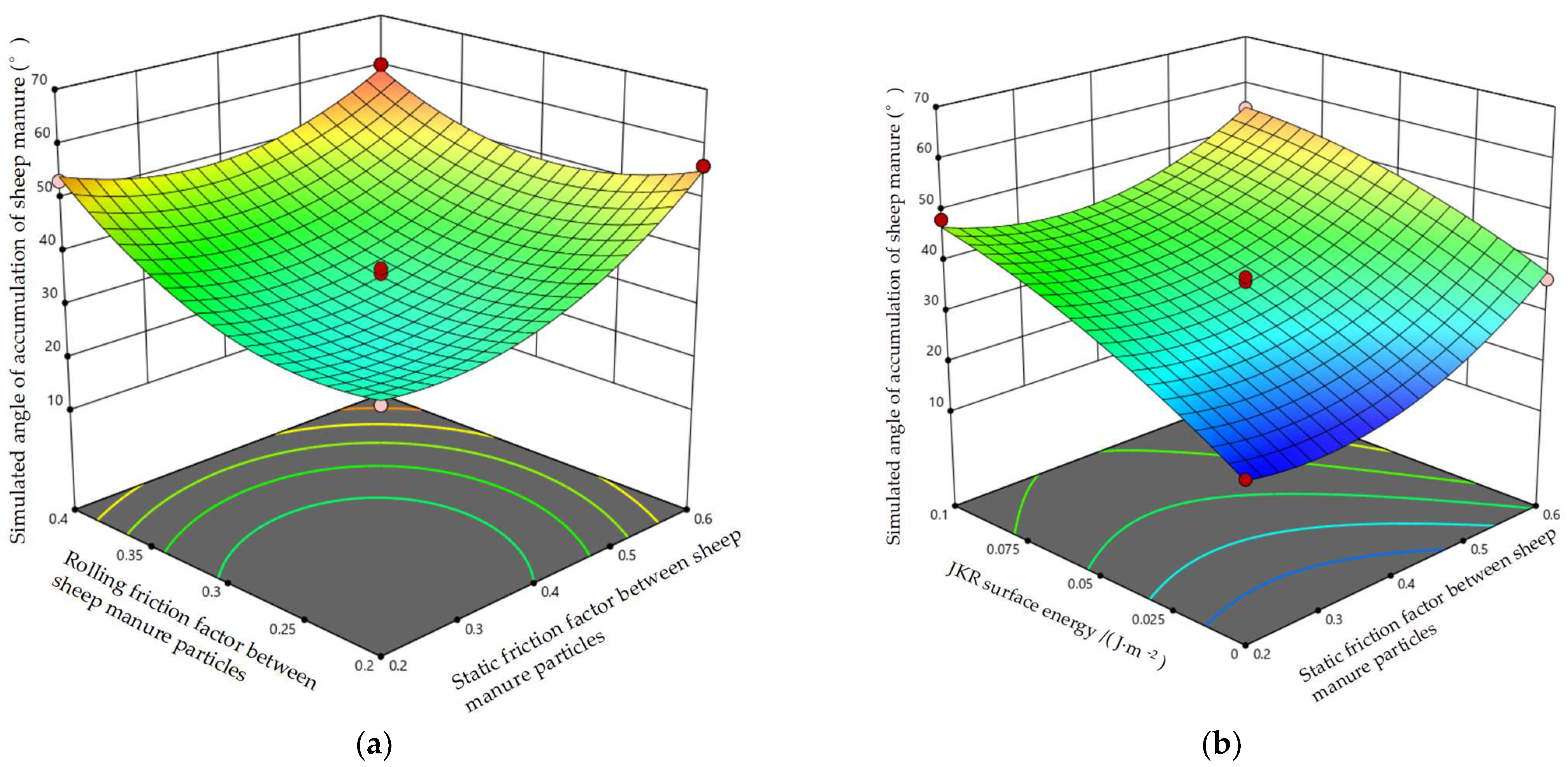

3.4. Stacking Angle–Discrete Element Parameter Modeling

3.5. Stacking Angle–Discrete Element Parametric Model Validation

3.6. Water Content–Discrete Element Parameter Model Construction and Validation

3.7. Parametric Modeling of Sheep Manure via Cylinder Lifting, Pumping Plate, and Funnel Methods

4. Discussion

5. Conclusions

- (1)

- The present work effectively established a comprehensive calibration procedure for the discrete element characteristics of unrotted sheep dung. By addressing the significant fluctuations in water content that previously hindered the accurate calibration of simulation parameters for composting processes, we developed a robust water content-stacking angle model using the cylinder-lifting technique. This model achieved an impressive correlation coefficient of 0.997, providing a reliable foundation for predicting the stacking angle based on varying water content levels, thereby enhancing the feasibility and precision of composting simulations.

- (2)

- Development and validation of discrete element models: we created three discrete element method (DEM) particle models using the Hertz–Mindlin with JKR bonding model, incorporating the particle size distribution of sheep manure. Comprehensive testing of JKR surface energy, including the Plackett–Burman test, the steepest ascent test, and the Box–Behnken test, identified it as one of the ten critical parameters. Further analysis confirmed JKR surface energy, rolling friction factor, and static friction factor as key parameters, leading to the development of a stacking angle–discrete element parameter model with a p-value below 0.0001 and a relative error of 3.46% or less. Validation of the comprehensive water content-discrete element parameter model, conducted using both the pumping plate and hopper methods, resulted in a relative error of 4.89% or less. These results demonstrate that the discrete element characteristics of sheep manure can be accurately predicted based on water content.

- (3)

- This study provides a reliable and universally applicable approach for estimating discrete element parameters in the simulation of sheep manure for composting operations. The model’s robustness and high accuracy make it a valuable tool for agricultural engineering, enabling more precise and efficient simulations. Future research should focus on further refining this model and evaluating its applicability to different types of organic waste, thus expanding its potential impact on composting and related fields. Additionally, examining the influence of other environmental and material factors could enhance the depth and accuracy of these simulations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, S.; Tong, M.; Cui, Y.; Wang, T.; Shi, C. Study on mixed compost of cattle dung and corn stalk biogas residue and its impact on environment. J. Chin. Agric. Mech. 2023, 44, 168–173. [Google Scholar]

- Zhou, H.; Di, L.; Hua, X.; Deng, T. The Addition of a Small Dose of Cinnamomum camphora Biomass Unexpectedly Enhanced Lignocellulose Degradation during the Compost of Stropharia rugosoannulata Cultivation Materials. Sustainability 2023, 15, 10483. [Google Scholar] [CrossRef]

- Wu, Y.; Luo, Z.; Qi, L.; Zhang, R.; Wang, Y. A Study of the Relationship between Initial Grape Yield and Soil Properties Based on Organic Fertilization. Agronomy 2024, 14, 861. [Google Scholar] [CrossRef]

- Li, Y.; Li, Q.; Ji, Z.; Andom, O.; Wang, X.; Guo, X.; Li, Z. Current Status and Spatiotemporal Evolution of Antibiotic Residues in Livestock and Poultry Manure in China. Agriculture 2023, 13, 1877. [Google Scholar] [CrossRef]

- Zhang, X.-A. Research on Nitrogen Loss and In-Situ Nitrogen Conservation in High Temperature Composting of Manure. Master’s Thesis, Chongqing Technology and Business University, Chongqing, China, 2018. [Google Scholar]

- Jiang, Y.; Zhang, Q.; Niu, J.; Wu, J. Pastoral Population Growth and Land Use Policy Has Significantly Impacted Livestock Structure in Inner Mongolia—A Case Study in the Xilinhot Region. Sustainability 2019, 11, 7208. [Google Scholar] [CrossRef]

- Aricha, H.; Simujide, H.; Wang, C.; Zhang, J.; Lv, W.; Jimisi, X.; Liu, B.; Chen, H.; Zhang, C.; He, L.; et al. Comparative Analysis of Fecal Microbiota of Grazing Mongolian Cattle from Different Regions in Inner Mongolia, China. Animals 2021, 11, 1938. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, P.; Wang, R.; Li, J.; Zhai, B.; Luo, X.; Yang, X. An Epidemiological Investigation and Drug-Resistant Strain Isolation of Nematodirus oiratianus in Sheep in Inner Mongolia, China. Animals 2023, 13, 30. [Google Scholar] [CrossRef]

- Wang, F. Design and Experiment of Small Composting Equipment for Fecal Matter of Livestock and Poultry Based on Heating by Aeration. Master’s Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2021. [Google Scholar]

- Li, L.-T.; Li, W.-M.; Sun, J.-M.; Fei, C.; Rao, Z.-X.; Huang, F.-Q. Research status and prospects of the resource utilization of organic waste in urban and rural areas. J. Agric. Resour. Environ. 2019, 36, 264–271. [Google Scholar]

- Zhao, C.; Wu, B.; Hao, W. Dynamic Changes in Physicochemical Properties and Microbial Community in Three Types of Recycled Manure Solids for Dairy Heifers. Agronomy 2024, 14, 1132. [Google Scholar] [CrossRef]

- Zając, M.; Skrajna, T. Effect of Composted Organic Waste on Miscanthus sinensis Andersson Energy Value. Energies 2024, 17, 2532. [Google Scholar] [CrossRef]

- Zhen, X.; Tan, C.; Li, Z. Humus Transformation and Compost Maturity Indexes in High-Temperature Composting of Livestock and Poultry Manure. J. Biobased Mater. Bioenergy 2022, 16, 329–335. [Google Scholar] [CrossRef]

- Lu, W.; Gao, Y.; Jian, L. Application effect of sheep manure on plant and soil. Acta Ecol. Anim. Domastici 2019, 40, 86–90. [Google Scholar]

- González, R.; Blanco, D.; Cascallana, J.G.; Carrillo-Peña, D.; Gómez, X. Anaerobic Co-Digestion of Sheep Manure and Waste from a Potato Processing Factory: Techno-Economic Analysis. Fermentation 2021, 7, 235. [Google Scholar] [CrossRef]

- Al-Suhaibani, N.; Selim, M.; Alderfasi, A.; El-Hendawy, S. Integrated Application of Composted Agricultural Wastes, Chemical Fertilizers and Biofertilizers as an Avenue to Promote Growth, Yield and Quality of Maize in an Arid Agro-Ecosystem. Sustainability 2021, 13, 7439. [Google Scholar] [CrossRef]

- Kureljušić, J.M.; Vesković Moračanin, S.M.; Đukić, D.A.; Mandić, L.; Đurović, V.; Kureljušić, B.I.; Stojanova, M.T. Comparative Study of Vermicomposting: Apple Pomace Alone and in Combination with Wheat Straw and Manure. Agronomy 2024, 14, 1189. [Google Scholar] [CrossRef]

- Cai, S.; Ma, Y.; Bao, Z.; Yang, Z.; Niu, X.; Meng, Q.; Qin, D.; Wang, Y.; Wan, J.; Guo, X. The Impacts of the C/N Ratio on Hydrogen Sulfide Emission and Microbial Community Characteristics during Chicken Manure Composting with Wheat Straw. Agriculture 2024, 14, 948. [Google Scholar] [CrossRef]

- Rodrigues, T.F.; Itkes, M.P.M.; Brogiato, G.; Marques, V.A.R.; Martins, V.; Villarraga, C.O.; Esposito, E. Agroecological Transformation: Implementation of an Agroforestry System in a Construction Debris Area Focusing on Vegetables Development through Microbial Treatments. Appl. Sci. 2024, 14, 4648. [Google Scholar] [CrossRef]

- Netthisinghe, A.; Woosley, P.; Strunk, W.; Agga, G.; Sistani, K. Composting Dairy Manure with Biochar: Compost Characteristics, Aminopyralid Residual Concentrations, and Phytotoxicity Effects. Agronomy 2024, 14, 952. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, H.; Jia, X.; Fang, Y.; Lin, C. Soil Fertility and Bacterial Community Composition in Response to the Composting of Biochar-Amended Chicken Manure. Agronomy 2024, 14, 886. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, B.; Wang, J.; Zhang, G.; Yue, Z.; Hu, L.; Yu, J.; Liu, Z. Effects of Different Agricultural Waste Composts on Cabbage Yield and Rhizosphere Environment. Agronomy 2024, 14, 413. [Google Scholar] [CrossRef]

- Su, L.; Ren, K.; Zhang, Y.; Zhang, L. Research on the Composting Technology of Cattle and Sheep Manure Based on Intelligent and Efficient Composting Equipment and the Evaluation Standard of Decomposition Degree. Fermentation 2024, 10, 328. [Google Scholar] [CrossRef]

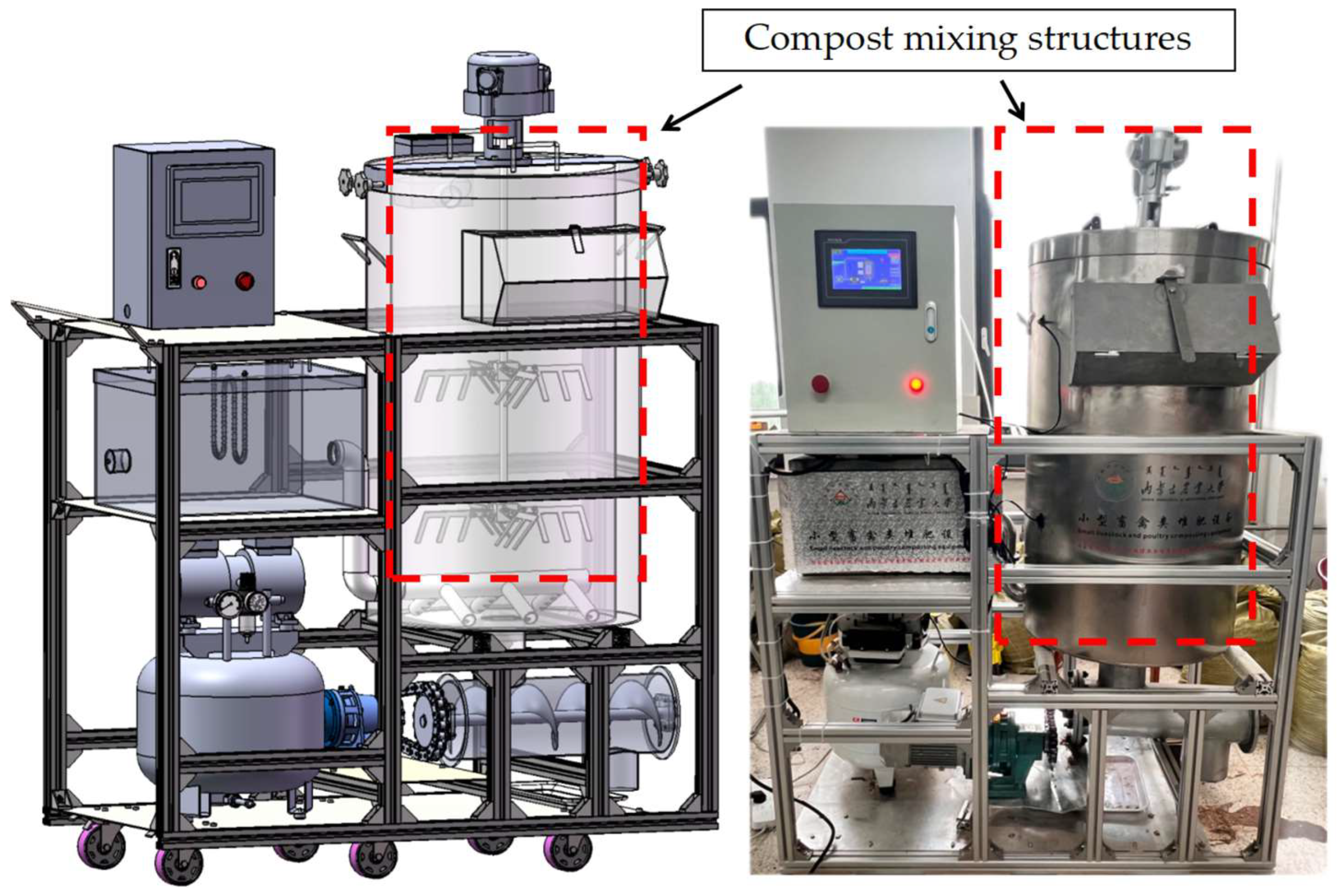

- Ren, K.; Su, L.; Zhang, Y.; He, X.; Cai, X. Optimization and Experiment of Livestock and Poultry Manure Composting Equipment with Vented Heating. Sustainability 2023, 15, 11353. [Google Scholar] [CrossRef]

- Ren, K.; Su, L.; Zhang, Y.; He, X.; Wu, H. Development and Evaluation of Cattle Dung Composting Equipment with Ventilation and Heating. Appl. Sci. 2023, 13, 8649. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, R.; Wang, B.; Chen, J.; Wang, X. Parameter Calibration of Discrete Element Model of Wine Lees Particles. Appl. Sci. 2024, 14, 5281. [Google Scholar] [CrossRef]

- Ma, X.; You, Y.; Yang, D.; Wang, D.; Hui, Y.; Li, D.; Wu, H. Calibration and Verification of Discrete Element Parameters of Surface Soil in Camellia Oleifera Forest. Agronomy 2024, 14, 1011. [Google Scholar] [CrossRef]

- Xu, T.; Fu, H.; Yu, J.; Li, C.; Wang, J.; Zhang, R. Determination of Ellipsoidal Seed–Soil Interaction Parameters for DEM Simulation. Agriculture 2024, 14, 376. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, M.; Jiang, X. A Review of Contact Models’ Properties for Discrete Element Simulation in Agricultural Engineering. Agriculture 2024, 14, 238. [Google Scholar] [CrossRef]

- Zhong, P.; Jia, W.; Yang, W.; He, J.; Zhang, E.; Yu, D.; Xu, Y.; Chen, J.; Peng, F.; Zeng, G.; et al. Calibration and Testing of Parameters for the Discrete Element Simulation of Soil Particles in Paddy Fields. Agriculture 2024, 14, 118. [Google Scholar] [CrossRef]

- Lei, X.; Wu, W.; Deng, X.; Li, T.; Liu, H.; Guo, J.; Li, J.; Zhu, P.; Yang, K. Determination of Material and Interaction Properties of Granular Fertilizer Particles Using DEM Simulation and Bench Testing. Agriculture 2023, 13, 1704. [Google Scholar] [CrossRef]

- Lenaerts, B.; Aertsen, T.; Tijskens, E.; De Ketelaere, B.; Ramon, H.; De Baerdemaeker, J.; Saeys, W. Simulation of grain-straw separation by discrete element modeling with bendable straw particles. Comput. Electron. Agric. 2014, 101, 24–33. [Google Scholar] [CrossRef]

- Jia, F.; Yao, L.; Han, Y. Simulation and optimal design of uniform plate of brown rice based on discrete element method. Trans. CSAE 2016, 32, 35–241. [Google Scholar]

- Li, H.; Li, Y.; Tang, Z. Numerical simulation and analysis of vibration screening based on EDEM. Trans. CSAE 2011, 27, 117–121. [Google Scholar]

- Jia, F.; Han, Y.; Liu, Y. Simulation prediction method of repose angle for rice particle material. Trans. Chin. Soc. Agric. Eng. 2014, 30, 254–260. [Google Scholar]

- Zheng, K.; He, J.; Li, H. Research on polyline soil breaking blade subsoiler based on subsoiling soil model using discrete element method. Trans. Chin. Soc. Agric. Mach. 2016, 47, 62–72. [Google Scholar]

- Yuan, Q.; Xu, L.; Xing, J. Parameter calibration of discrete element model of organic fertilizer particles for mechanical fertilization. Trans. CSAE 2018, 34, 21–27. [Google Scholar]

- Luo, S.; Yuan, Q.; Gouda, S. Parameters calibration of vermicomposting nursery substrate with discrete element method based on JKR contact model. Trans. Chin. Soc. Agric. Mach. 2018, 49, 343–350. [Google Scholar]

- Wang, L.; Fan, S.; Cheng, H. Calibration of contact parameters for pig manure based on EDEM. Trans. CSAE 2020, 36, 95–102. [Google Scholar]

- Wen, X.; Yuan, H.; Wang, G. Calibration method of friction coefficient of granular fertilizer by discrete element simulation. Trans. Chin. Soc. Agric. Mach. 2020, 51, 115–122, 142. [Google Scholar]

- Lin, J.; Luo, S.; Yuan, Q. Flow properties of vermicompost particle with different moisture contents. Trans. CSAE 2019, 35, 221–227. [Google Scholar]

- Han, S.; Qi, J.H.; Kan, Z. Parameters Calibration of Discrete Element for Deep Application of Bulk Manure in Xinjiang Orchard. Trans. Chin. Soc. Agric. Mach. 2021, 52, 101–108. [Google Scholar]

- Zhu, X.; Fu, S.; Li, X. General Method for Discrete Element Parameters Calibration of Goat Manure with Different Moisture Contents. Trans. Chin. Soc. Agric. Mach. 2022, 53, 34–41. [Google Scholar]

- Sun, Z.; Zhang, J.; Zhong, X.Z. Production of nitrate-rich compost from the solid fraction of dairy manure by a lab-scale composting system. Waste Manag. 2016, 51, 55–64. [Google Scholar] [CrossRef]

- Huang, Y.; Quan, L.; Hu, G. Calibration of discrete elemental contact parameters for a variety of materials with soils of different water content. China Agric. Sci. Technol. Her. 2024, 26, 98–109. [Google Scholar]

| Particle Size (d/mm) | Percentage Distribution (%) |

|---|---|

| [7, 10) | 31% |

| [10, 13] | 48% |

| (13, 16] | 21% |

| Materials | Density/(g·cm−3) | Poisson’s Ratio | Shear Modulus/MPa |

|---|---|---|---|

| Sheep manure | 0.30~0.60 a | 0.1~0.5 b | 1.00~10.00 b |

| Steels | 7.85 b | 0.30 b | 7.90 × 104 b |

| Parametric | Numerical Range |

|---|---|

| Interparticle coefficient of recovery for cow manure | 0.20~0.60 |

| Static friction factor between particles of cow manure | 0.20~1.00 |

| Rolling friction factor between cow manure particles | 0.20~0.60 |

| Coefficient of recovery of steel from cow dung | 0.10~0.80 |

| Static friction factor of cow manure steel | 0.20~0.80 |

| Rolling friction factor of cow manure steel | 0.20~1.00 |

| JKR surface energy/(J·m−2) | 0~0.20 |

| Parametric | Encodings | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| (A) Density of sheep manure/(g·cm−3) | 0.30 | 0.45 | 0.60 |

| (B) Poisson’s ratio in sheep manure | 0.10 | 0.30 | 0.50 |

| (C) Shear modulus of sheep manure/MPa | 1.00 | 5.50 | 10.00 |

| (D) Interparticle coefficient of recovery for sheep manure | 0.20 | 0.40 | 0.60 |

| (E) Static friction factor between particles of sheep manure | 0.20 | 0.60 | 1.00 |

| (F) Rolling friction factor between sheep manure particles | 0.2 | 0.40 | 0.60 |

| (G) Coefficient of recovery of steel from sheep manure | 0.20 | 0.50 | 0.80 |

| (H) Static friction factor of sheep manure steel | 0.20 | 0.60 | 1.00 |

| (J) Rolling friction factor of sheep manure steel | 0.20 | 0.60 | 1.00 |

| (K) JKR surface energy/(J·m−2) | 0 | 0.10 | 0.20 |

| Moisture content/% | 30.66 | 38.29 | 45.93 | 52.33 | 58.63 |

| Stacking angle/(°) | 36.36 | 38.12 | 40.66 | 42.63 | 45.63 |

| Standard deviation of stacking angle/(°) | 0.58 | 0.36 | 0.21 | 0.46 | 0.67 |

| Test No. | Considerations | Stacking Angle (°) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | ||

| 1 | 1 | −1 | 1 | −1 | 1 | 1 | 1 | −1 | −1 | −1 | 84.32 |

| 2 | 1 | −1 | 1 | 1 | −1 | −1 | −1 | 1 | −1 | 1 | 32.65 |

| 3 | 1 | 1 | 1 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 10.36 |

| 4 | −1 | 1 | 1 | −1 | −1 | −1 | 1 | −1 | 1 | 1 | 49.65 |

| 5 | −1 | −1 | −1 | −1 | 1 | 1 | −1 | 1 | 1 | 1 | 41.48 |

| 6 | 1 | 1 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | 27.93 |

| 7 | −1 | −1 | 1 | 1 | 1 | −1 | 1 | 1 | 1 | −1 | 28.49 |

| 8 | 1 | 1 | −1 | 1 | 1 | −1 | −1 | −1 | 1 | −1 | 40.33 |

| 9 | −1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | −1 | −1 | 27.98 |

| 10 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | 79.81 |

| 11 | −1 | 1 | −1 | 1 | −1 | 1 | 1 | 1 | −1 | −1 | 62.73 |

| 12 | 1 | −1 | −1 | 1 | −1 | 1 | 1 | −1 | 1 | 1 | 36.82 |

| Source of Variance | Effect (Scientific Phenomenon) | Mean Square and | p | Significance Number |

|---|---|---|---|---|

| A | −1.07 | 13.80 | 0.2260 | 8 |

| B | −1.07 | 13.72 | 0.2266 | 9 |

| C | −1.10 | 14.45 | 0.2212 | 7 |

| D | 1.79 | 38.27 | 0.1394 | 6 |

| E | 9.19 | 1012.92 | 0.0275 * | 3 |

| F | 11.98 | 1721.53 | 0.0211 * | 2 |

| G | −3.84 | 176.56 | 0.0657 | 4 |

| H | 1.05 | 13.29 | 0.2299 | 10 |

| I | 1.94 | 45.36 | 0.1284 | 5 |

| J | 13.92 | 2323.81 | 0.0182 * | 1 |

| Test No. | Considerations | Simulated Stacking Angle/ (°) | Relative Error/ % | ||

|---|---|---|---|---|---|

| JKR Surface Energy/(J·m−2) | Rolling Friction Factor between Sheep Manure Particles | Static Friction Factor between Particles of Sheep Manure | |||

| 1 | 0 | 0.20 | 0.20 | 25.32 | 37.73 |

| 2 | 0.05 | 0.30 | 0.40 | 37.69 | 7.30 |

| 3 | 0.10 | 0.40 | 0.60 | 50.36 | 23.86 |

| 4 | 0.15 | 0.50 | 0.80 | 56.12 | 38.02 |

| 5 | 0.20 | 0.60 | 1.00 | 63.29 | 55.66 |

| Level | (E) Interparticle Static Friction Factor | (F) Inter-Particle Rolling Friction Factor | (J) JKR Surface Energy/ (J·m−2) |

|---|---|---|---|

| −1 | 0.20 | 0.20 | 0 |

| 0 | 0.40 | 0.30 | 0.05 |

| +1 | 0.60 | 0.40 | 0.10 |

| Test No. | Considerations | Simulated Stacking Angle/(°) | ||

|---|---|---|---|---|

| E | F | J | ||

| 1 | −1 | 0 | 1 | 48.36 |

| 2 | 0 | 0 | 0 | 33.69 |

| 3 | 0 | 1 | 1 | 55.66 |

| 4 | 0 | 1 | −1 | 36.66 |

| 5 | −1 | 1 | 0 | 53.36 |

| 6 | 1 | −1 | 0 | 56.13 |

| 7 | 0 | 0 | 0 | 36.14 |

| 8 | 0 | −1 | −1 | 23.60 |

| 9 | 0 | 0 | 0 | 37.15 |

| 10 | 0 | −1 | −1 | 23.68 |

| 11 | 1 | 0 | −1 | 36.63 |

| 12 | −1 | −1 | 0 | 34.12 |

| 13 | 1 | 0 | 1 | 54.77 |

| 14 | 1 | 1 | 0 | 60.12 |

| 15 | −1 | 0 | −1 | 21.03 |

| Source of Variance | Mean Square and | Degrees of Freedom | Mean Square | p |

|---|---|---|---|---|

| Modeling | 2370.04 | 9 | 263.34 | <0.0001 ** |

| E | 322.33 | 1 | 322.33 | 0.0001 ** |

| F | 167.84 | 1 | 167.84 | 0.0005** |

| J | 681.87 | 1 | 681.87 | <0.0001 ** |

| EF | 58.14 | 1 | 58.14 | 0.0057 ** |

| EJ | 21.11 | 1 | 21.11 | 0.0386 * |

| FJ | 3.11 | 1 | 3.11 | 0.3337 |

| E2 | 160.95 | 1 | 160.95 | 0.0006 ** |

| F2 | 199.59 | 1 | 199.59 | 0.0004 ** |

| J2 | 22.28 | 4 | 22.28 | 0.0353 * |

| Residual | 13.60 | 5 | 2.72 | |

| Lost proposal | 7.26 | 3 | 3.63 | 0.3180 |

| Pure error | 6.33 | 2 | 2.11 | |

| Aggregate | 2383.63 | 14 |

| Source of Variance | Mean Square and | Degrees of Freedom | Mean Square | p |

|---|---|---|---|---|

| Modeling | 2366.92 | 8 | 106.24 | <0.0001 ** |

| E | 322.33 | 1 | 115.75 | <0.0001 ** |

| F | 253.74 | 1 | 91.12 | <0.0001 ** |

| J | 752.18 | 1 | 270.10 | <0.0001 ** |

| EF | 58.14 | 1 | 20.88 | 0.0038 ** |

| EJ | 21.11 | 1 | 7.58 | 0.0331 * |

| E2 | 205.72 | 1 | 73.87 | 0.0001 ** |

| F2 | 210.14 | 1 | 75.46 | 0.0001 ** |

| J2 | 33.35 | 4 | 11.98 | 0.0135 * |

| Residual | 16.71 | 5 | ||

| Lost proposal | 10.37 | 3 | 1.64 | 0.3476 |

| Pure error | 6.33 | 2 | ||

| Aggregate | 2383.63 | 14 |

| Moisture Content/ % | Static friction Factor between Particles of Sheep Manure | Rolling Friction Factor between Sheep Manure Particles | JKR Surface Energy/ (J·m−2) | Simulated Stacking Angle/ (°) | Relative Error/ % |

|---|---|---|---|---|---|

| 30.66 | 0.39 | 0.24 | 0.03 | 36.11 | 0.69 |

| 38.29 | 0.51 | 0.38 | 0.01 | 37.22 | 2.36 |

| 45.93 | 0.58 | 0.24 | 0.04 | 41.23 | 1.40 |

| 52.33 | 0.59 | 0.36 | 0.05 | 44.01 | 3.24 |

| 58.63 | 0.59 | 0.37 | 0.09 | 47.21 | 3.46 |

| Moisture Content/ % | Static Friction Factor between Particles of Sheep Manure | Rolling Friction Factor between Sheep Manure Particles | JKR Surface Energy/ (J·m−2) | Simulated Stacking Angle/ (°) | Relative Error/ % |

|---|---|---|---|---|---|

| 32.66 | 0.52 | 0.29 | 0.01 | 36.69 | 0.87 |

| 36.37 | 0.30 | 0.33 | 0.05 | 37.54 | 1.84 |

| 43.36 | 0.44 | 0.35 | 0.02 | 39.29 | 2.09 |

| 51.36 | 0.59 | 0.22 | 0.05 | 41.56 | 1.83 |

| 56.13 | 0.23 | 0.39 | 0.07 | 43.04 | 3.74 |

| Moisture Content/ % | Static Friction Factor between Particles of Sheep Manure | Rolling Friction Factor between Sheep Manure Particles | JKR Surface Energy/ (J·m−2) | Simulated Stacking Angle/ (°) | Relative Error/ % |

|---|---|---|---|---|---|

| 32.66 | 0.52 | 0.29 | 0.01 | 36.69 | 4.89 |

| 36.37 | 0.30 | 0.33 | 0.05 | 37.54 | 1.92 |

| 43.36 | 0.44 | 0.35 | 0.02 | 39.29 | 1.00 |

| 51.36 | 0.59 | 0.22 | 0.05 | 41.56 | 2.64 |

| 56.13 | 0.23 | 0.39 | 0.07 | 43.04 | 1.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Ren, K.; Li, Z.; Zhang, L. An Investigation on a Comprehensive Calibration Technique to Determine the Discrete Elemental Characteristics of Unrotted Sheep Dung at Varying Water Concentrations. Agriculture 2024, 14, 1762. https://doi.org/10.3390/agriculture14101762

Wang J, Ren K, Li Z, Zhang L. An Investigation on a Comprehensive Calibration Technique to Determine the Discrete Elemental Characteristics of Unrotted Sheep Dung at Varying Water Concentrations. Agriculture. 2024; 14(10):1762. https://doi.org/10.3390/agriculture14101762

Chicago/Turabian StyleWang, Jian, Kailin Ren, Zhe Li, and Longfei Zhang. 2024. "An Investigation on a Comprehensive Calibration Technique to Determine the Discrete Elemental Characteristics of Unrotted Sheep Dung at Varying Water Concentrations" Agriculture 14, no. 10: 1762. https://doi.org/10.3390/agriculture14101762