Evolution and Modelling of the Moisture Diffusion in Walnuts during the Combination of Hot Air and Microwave–Vacuum Drying

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Preparation

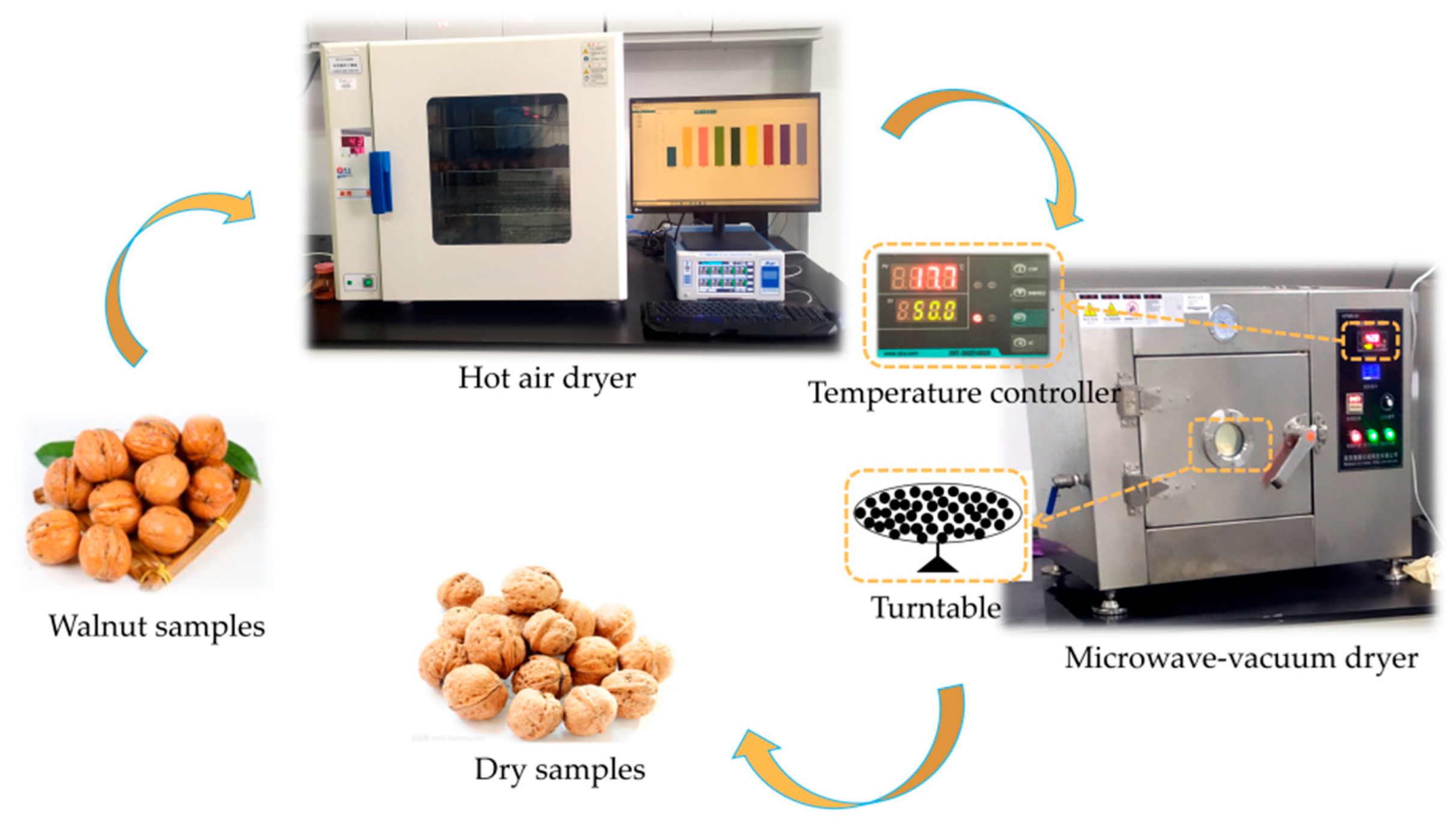

2.2. Drying Equipment

2.3. Drying Experiments

2.4. Drying Characteristic Parameters

2.5. Effective Moisture Diffusivity

2.6. Statistical Analysis

3. Results and Discussion

3.1. Drying Characteristics

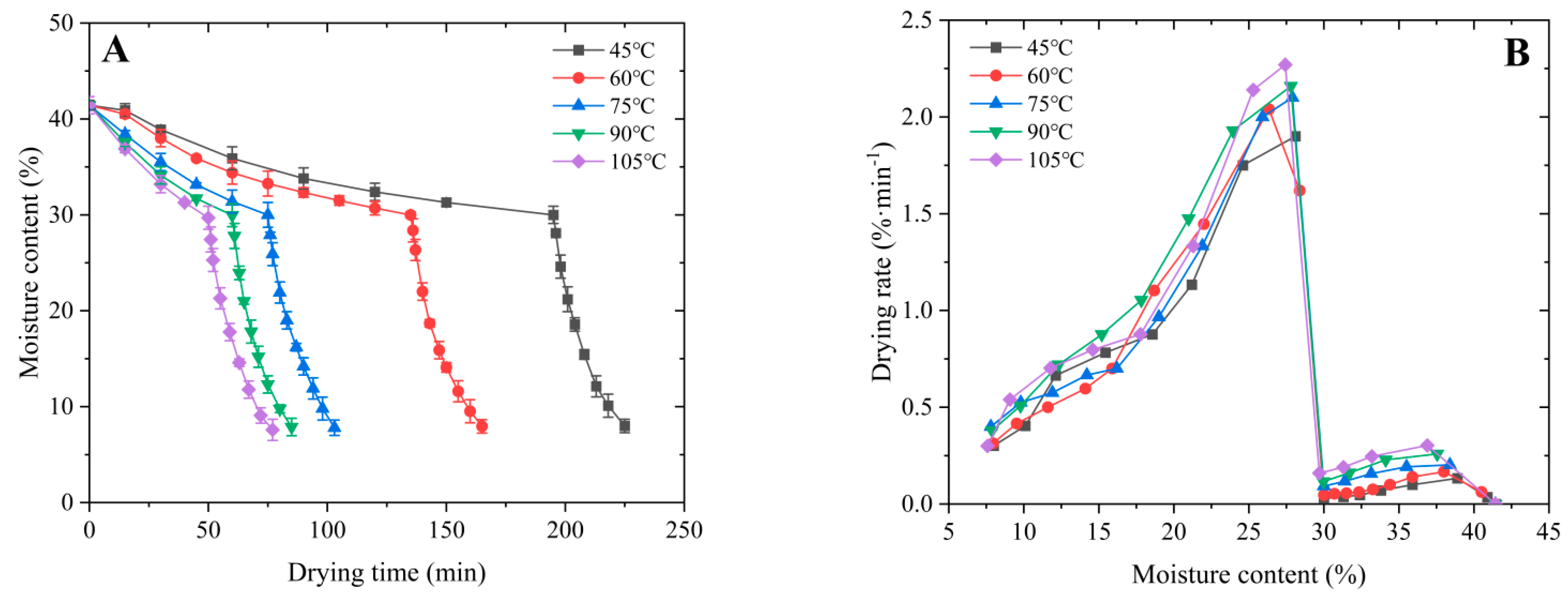

3.1.1. Effect of Hot Air Temperature on Drying Characteristics

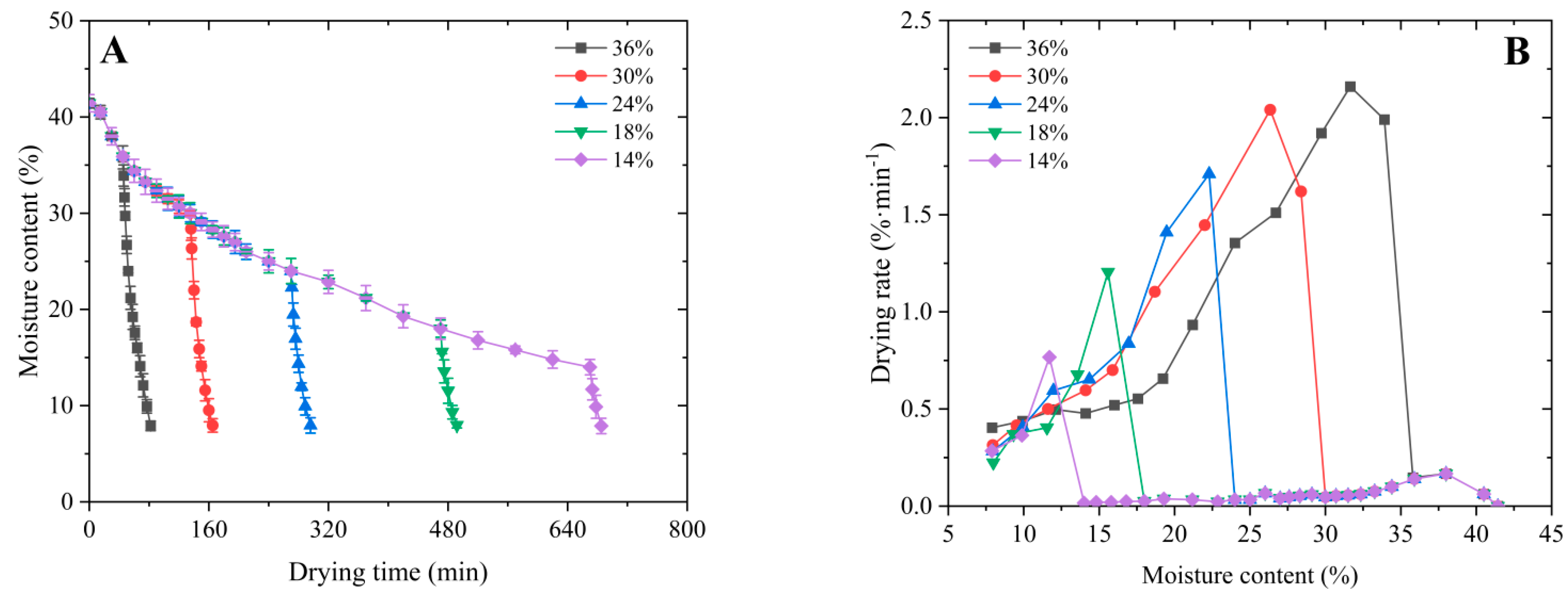

3.1.2. Effect of Moisture Content at the Transition Point on Drying Characteristics

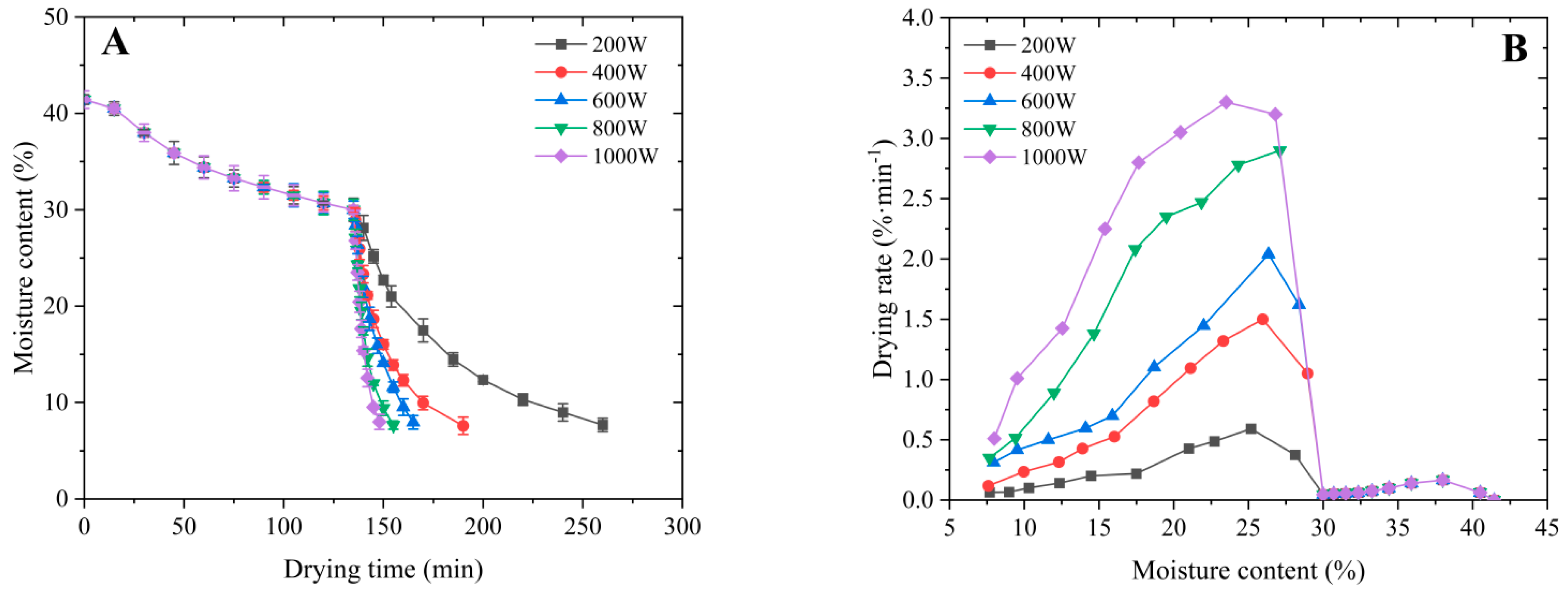

3.1.3. Effect of Microwave Power on Drying Characteristics

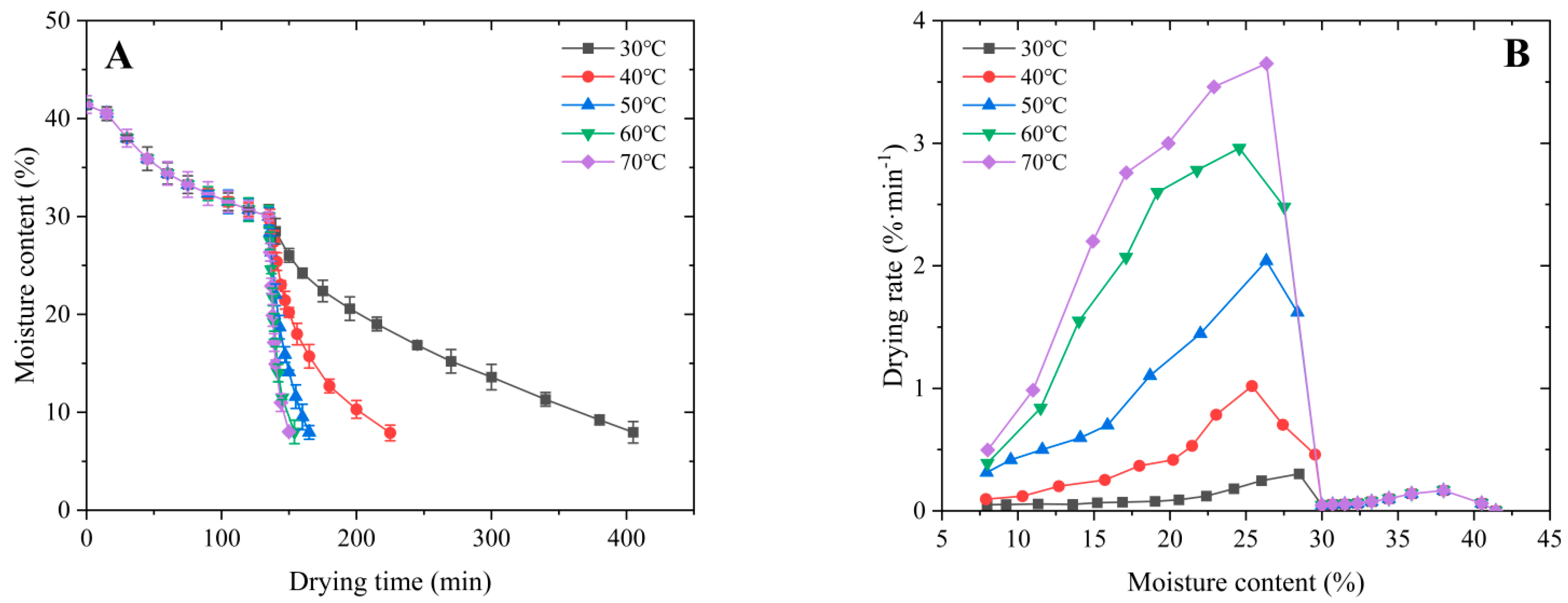

3.1.4. Effect of Microwave–Vacuum Thermostatic Temperature on Drying Characteristics

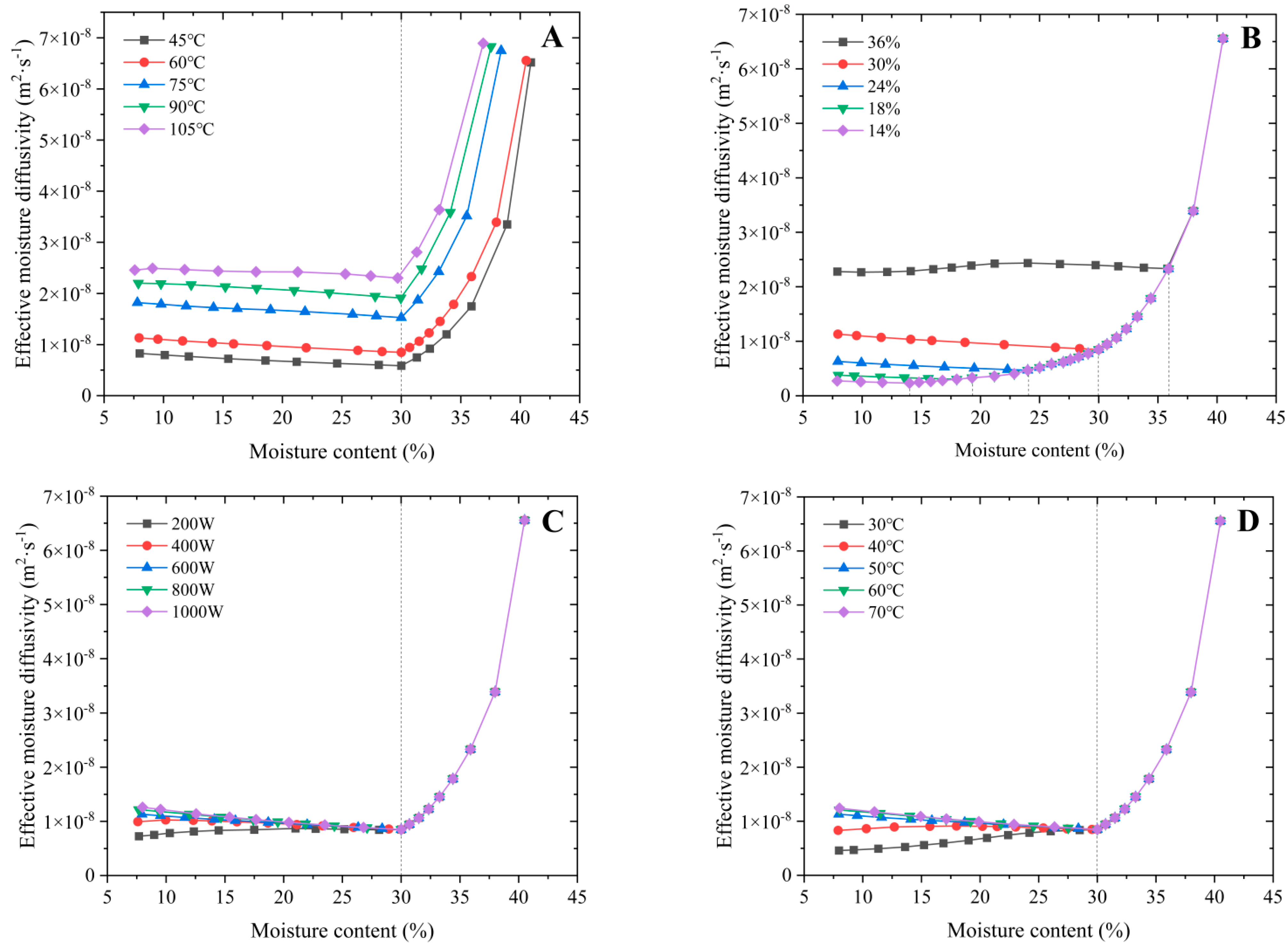

3.2. Effective Moisture Diffusivity

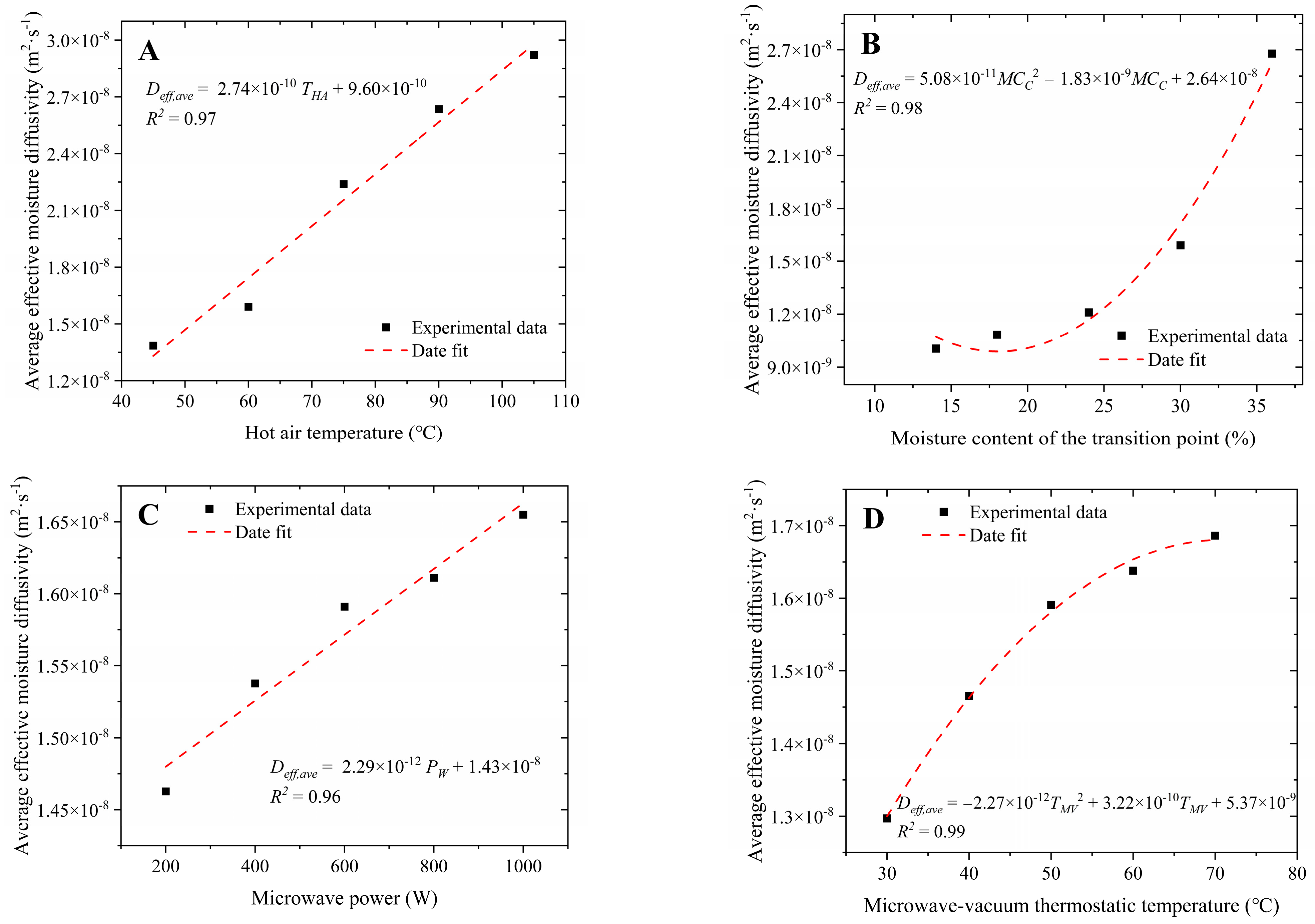

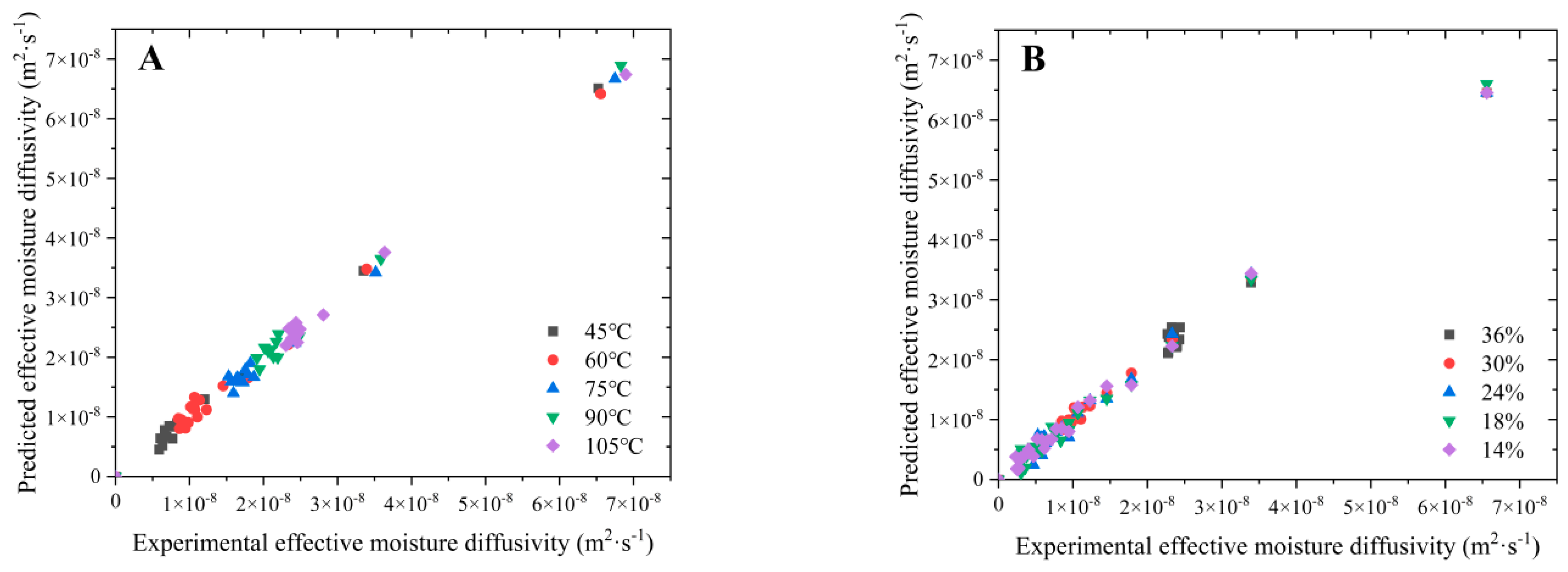

3.3. Model Development for Effective Moisture Diffusivity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Erfani, A.; Pirouzifard, M.K.; Almasi, H.; Gheybi, N.; Pirsa, S. Application of cellulose plate modified with encapsulated cinnamomum zelanicum essential oil in active packaging of walnut kernel. Food Chem. 2022, 381, 132246. [Google Scholar] [CrossRef] [PubMed]

- Man, X.L.; Li, L.; Zeng, Y.; Tang, Y.R.; Yang, J.L.; Fan, X.W.; Zhang, Y.C.; Zhang, H.; Su, G.G.; Wang, J.P. Mechanical impact characteristics of hollow shell granule based on continuous damage theory. Powder Technol. 2023, 429, 118946. [Google Scholar] [CrossRef]

- Liu, M.Z.; Li, C.H.; Cao, C.M.; Wang, L.Q.; Li, X.P.; Che, J.; Yang, H.M.; Zhang, X.W.; Zhao, H.Y.; He, G.Z.; et al. Walnut fruit processing equipment: Academic insights and perspectives. Food Eng. Rev. 2021, 13, 822–857. [Google Scholar] [CrossRef]

- Fu, M.; Qu, Q.; Yang, X.; Zhang, X. Effect of intermittent oven drying on lipid oxidation, fatty acids composition and antioxidant activities of walnut. LWT-Food Sci. Technol. 2016, 65, 1126–1132. [Google Scholar] [CrossRef]

- Mao, Y.X.; Wang, P.H.; Wu, Y.; Hou, L.X.; Wang, S.J. Effects of various radio frequencies on combined drying and disinfestation treatments for in-shell walnuts. LWT-Food Sci. Technol. 2021, 144, 111246. [Google Scholar] [CrossRef]

- Qu, Q.; Yang, X.; Fu, M.; Chen, Q.; Zhang, X.; He, Z.; Qiao, X. Effects of three conventional drying methods on the lipid oxidation, fatty acids composition, and antioxidant activities of walnut (Juglans regia L.). Dry. Technol. 2016, 34, 822–829. [Google Scholar] [CrossRef]

- Zhou, X.; Gao, H.; Mitcham, E.J.; Wang, S. Comparative analyses of three dehydration methods on drying characteristics and oil quality of in-shell walnuts. Dry. Technol. 2018, 36, 477–490. [Google Scholar] [CrossRef]

- Chen, C.; Pan, Z.L. Postharvest processing of tree nuts: Current status and future prospects-A comprehensive review. Compr. Rev. Food Sci. Food Saf. 2022, 21, 1702–1731. [Google Scholar] [CrossRef]

- Dolgun, G.K.; Aktas, M.; Dolgun, E.C. Infrared convective drying of walnut with energy-exergy perspective. J. Food Eng. 2021, 306, 110638. [Google Scholar] [CrossRef]

- Zhu, D.Q.; Ma, J.; Jiang, R.; Yuan, J.H.; Wang, C.X.; Zhu, H. Parameter optimization of hickory nut drying by phased varying power microwave. Trans. CSAE 2016, 32, 268–274. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, W.P.; Venkitasamy, C.; Khir, R.; McHugh, T.; Pan, Z.L. Walnut structure and its influence on the hydration and drying characteristics. Dry. Technol. 2019, 38, 975–986. [Google Scholar] [CrossRef]

- Chen, C.; Upadhyaya, S.; Khir, R.; Pan, Z.L. Simulation of walnut drying under hot air heating using a nonequilibrium multiphase transfer model. Dry. Technol. 2020, 40, 987–1001. [Google Scholar] [CrossRef]

- Shen, L.Y.; Wang, L.; Zheng, C.Y.; Liu, C.H.; Zhu, Y.; Liu, H.; Liu, C.; Shi, Y.K.; Zheng, X.Z.; Xu, H. Continuous microwave drying of germinated brown rice: Effects of drying conditions on fissure and color, and modeling of moisture content and stress inside kernel. Dry. Technol. 2020, 39, 669–697. [Google Scholar] [CrossRef]

- Shen, L.Y.; Zhu, Y.; Liu, C.H.; Wang, L.; Liu, H.; Kamruzzaman, M.; Liu, C.; Zhang, Y.P.; Zheng, X.Z. Modelling of moving drying process and analysis of drying characteristics for germinated brown rice under continuous microwave drying. Biosyst. Eng. 2020, 195, 64–88. [Google Scholar] [CrossRef]

- Chen, A.Q.; Achkar, G.E.; Liu, B.; Bennacer, R. Experimental study on moisture kinetics and microstructure evolution in apples during high power microwave drying process. J. Food Eng. 2020, 29, 110362. [Google Scholar] [CrossRef]

- Zielinska, M.; Markowski, M.; Zielinska, D. The effect of freezing on the hot air and microwave vacuum drying kinetics and texture of whole cranberries. Dry. Technol. 2019, 37, 1714–1730. [Google Scholar] [CrossRef]

- Cuccurullo, G.; Metallo, A.; Corona, O.; Cinquanta, L. Comparing different processing methods in apple slice drying. part 1. performance of microwave, hot air and hybrid methods at constant temperatures. Biosyst. Eng. 2019, 188, 331–344. [Google Scholar] [CrossRef]

- Ishibashi, R.; Numata, T.; Tanigawa, H.; Tsuruta, T. In-situ measurements of drying and shrinkage characteristics during microwave vacuum drying of radish and potato. J. Food Eng. 2022, 323, 110988. [Google Scholar] [CrossRef]

- Gonzalez-Cavieres, L.; Pérez-Won, M.; Tabilo-Munizaga, G.; Jara-Quijada, E.; Díaz-Alvarez, R.; Lemus-Mondaca, R. Advances in vacuum microwave drying (VMD) systems for food products. Trends Food Sci. Technol. 2021, 116, 626–638. [Google Scholar] [CrossRef]

- Song, Z.L.; Jing, C.M.; Yao, L.S.; Zhao, X.Q.; Sun, J.; Wang, W.L.; Mao, Y.P.; Ma, C.Y. Coal slime hot air/microwave combined drying characteristics and energy analysis. Fuel Process Technol. 2016, 156, 491–499. [Google Scholar] [CrossRef]

- Zhou, Y.H.; Staniszewska, I.; Liu, Z.L.; Zielinska, D.; Xiao, H.W.; Pan, Z.L.; Nowak, K.W.; Zielinska, M. Microwave-vacuum-assisted drying of pretreated cranberries: Drying kinetics, bioactive compounds and antioxidant activity. LWT-Food Sci. Technol. 2021, 146, 111464. [Google Scholar] [CrossRef]

- Figiel, A. Drying kinetics and quality of beetroots dehydrated by combination of convective and vacuum-microwave methods. J. Food Eng. 2010, 98, 461–470. [Google Scholar] [CrossRef]

- Hu, Q.G.; Zhang, M.; Mujumdar, A.S.; Xiao, G.N.; Sun, J.C. Drying of edamames by hot air and vacuum microwave combination. J. Food Eng. 2006, 77, 977–982. [Google Scholar] [CrossRef]

- Wu, H.H.; Zhu, D.Z.; Zhang, X.X.; Bian, H.; Wang, D.Y.; Zhu, Y.Z. Optimization of processing parameters for microwave vacuum puffing of duck breast after hot-air dehydration. Food Sci. 2017, 38, 267–273. [Google Scholar] [CrossRef]

- Kaveh, M.; Abbaspour-Gilandeh, Y.; Nowacka, M. Optimisation of microwave-rotary drying process and quality parameters of terebinth. Biosyst. Eng. 2021, 208, 113–130. [Google Scholar] [CrossRef]

- Hassini, L.; Azzouz, S.; Peczalski, R.; Belghith, A. Estimation of potato moisture diffusivity from convective drying kinetics with correction for shrinkage. J. Food Eng. 2007, 79, 47–56. [Google Scholar] [CrossRef]

- Thuwapanichayanan, R.; Prachayawarakorn, S.; Kunwisawa, J.; Soponronnarit, S. Determination of effective moisture diffusivity and assessment of quality attributes of banana slices during drying. LWT-Food Sci. Technol. 2011, 44, 1502–1510. [Google Scholar] [CrossRef]

- Khan, M.I.H.; Kumar, C.; Joardder, M.U.H.; Karim, M.A. Determination of appropriate effective diffusivity for different food materials. Dry. Technol. 2017, 35, 335–346. [Google Scholar] [CrossRef]

- Bal, L.M.; Kar, A.; Satya, S.; Naik, S.N. Drying kinetics and effective moisture diffusivity of bamboo shoot slices undergoing microwave drying. Int. J. Food Sci. Technol. 2010, 45, 2321–2328. [Google Scholar] [CrossRef]

- Dadalı, G.; Apar, K.D.; Ozbek, B. Estimation of effective moisture diffusivity of okra for microwave drying. Dry. Technol. 2007, 25, 1445–1450. [Google Scholar] [CrossRef]

- Zeng, Y.; Mao, B.Q.; Jia, F.G.; Han, Y.L.; Li, G.R. Modelling of grain breakage of in a vertical rice mill based on dem simulation combining particle replacement model. Biosyst. Eng. 2022, 215, 32–48. [Google Scholar] [CrossRef]

- Chen, C.; Venkitasamy, C.; Zhang, W.P.; Khir, R.; Upadhyaya, S.; Pan, Z.L. Effective moisture diffusivity and drying simulation of walnuts under hot air. Int. J. Heat Mass Transf. 2020, 150, 119283. [Google Scholar] [CrossRef]

- Xu, W.X.; Song, C.F.; Li, Z.F.; Song, F.H.; Hu, S.G.; Li, J.; Zhu, G.Y.; Raghauan, G.S.V. Temperature gradient control during microwave combined with hot air drying. Biosyst. Eng. 2018, 169, 175–187. [Google Scholar] [CrossRef]

- Nguyen, T.V.L.; Nguyen, Q.D.; Nguyen, P.B.D.; Tran, B.L.; Huynh, P.T. Effects of drying conditions in low-temperature microwaveassisted drying on bioactive compounds and antioxidant activity of dehydrated bitter melon (Momordica charantia L.). Food Sci. Nutr. 2020, 8, 3826–3834. [Google Scholar] [CrossRef]

- Ye, J.H.; Xu, C.; Zhang, C.; Zhu, H.C.; Huang, K.M.; Li, Q.; Wang, J.; Zhou, L.; Wu, Y.Y. A hybrid ale/implicit function method for simulating microwave heating with rotating objects of arbitrary shape. J. Food Eng. 2021, 302, 110551. [Google Scholar] [CrossRef]

- Vera, C.M.; Vizcarra, M.G. Concentration-dependent moisture diffusion coefficient estimation in peas drying considering shrinkage: An observer approach. Biosyst. Eng. 2022, 218, 256–273. [Google Scholar] [CrossRef]

- Perazzini, H.; Leonel, A.; Perazzini, M.T.B. Energy of activation, instantaneous energy consumption, and coupled heat and mass transfer modeling in drying of sorghum grains. Biosyst. Eng. 2021, 210, 181–192. [Google Scholar] [CrossRef]

- Wang, H. Effects of different drying methods on drying kinetics, physicochemical properties, microstructure, and energy consumption of potato (Solanum tuberosum L.) cubes. Dry. Technol. 2020, 39, 418–431. [Google Scholar] [CrossRef]

- Li, L.; Mao, B.Q.; Zeng, Y.; Tang, Y.R.; Man, X.L.; Fan, X.W.; Zhang, Y.C.; Zhang, H. Experimental study on crack irregularity of hollow shell particle under impact loading. Powder Technol. 2023, 427, 118704. [Google Scholar] [CrossRef]

- Dak, M.; Pareek, N.K. Effective moisture diffusivity of pomegranate arils under going microwave-vacuum drying. J. Food Eng. 2014, 122, 117–121. [Google Scholar] [CrossRef]

- Crank, J. The Mathematics of Diffusion; Oxford University Press Inc.: Oxford, UK, 1975. [Google Scholar]

- Hassan-Beygi, S.R.; Aghbashlo, M.; Kianmehr, M.H.; Massah, J. Drying characteristics of walnut (Juglans regia L.) during convection drying. Int. Agrophys. 2009, 23, 129–135. [Google Scholar] [CrossRef]

- Shi, J.L.; Pan, Z.L.; McHugh, T.H.; Wood, D.; Hirschberg, E.; Olson, D. Drying and quality characteristics of fresh and sugarinfused blueberries dried with infrared radiation heating. LWT-Food Sci. Technol. 2008, 41, 1962–1972. [Google Scholar] [CrossRef]

- Ekezie, F.G.C.; Sun, D.W.; Han, Z.; Cheng, J.H. Microwave-assisted food processing technologies for enhancing product quality and process efficiency: A review of recent developments. Trends Food Sci. Technol. 2018, 67, 58–69. [Google Scholar] [CrossRef]

- Chen, C.; Pan, Z.L. Heat and moisture transfer studies on walnuts during hot air drying in a fixed-bed column dryer. Appl. Therm. Eng. 2021, 199, 117554. [Google Scholar] [CrossRef]

- Lu, Y.J.; Ren, G.Y.; Duan, X.; Zhang, L.D.; Ling, Z.Z. Moisture migration properties and quality changes of fresh in-shell peanuts during hot air drying. Food Sci. 2020, 41, 86–92. [Google Scholar] [CrossRef]

- Sharma, P.; Xiao, H.W.; Zhang, Q.; Sutar, P.P. Intermittent high-power short-time microwave-vacuum treatment combined with steam impingement for effective microbial decontamination of black pepper (piper nigrum). J. Food Eng. 2023, 343, 111373. [Google Scholar] [CrossRef]

- Ma, X.T.; Luo, G.Y.; Li, Z.F.; Raghavan, G.S.V.; Chen, H.Y.; Song, C.F. Microwave power control scheme for potatoes based on dielectric loss factor feedback. J. Food Eng. 2020, 288, 110134. [Google Scholar] [CrossRef]

- Luo, G.Y.; Song, C.F.; Hongjie, P.; Li, Z.F.; Xu, W.X.; Raghavan, G.S.V.; Chen, H.Y.; Jin, G.Y. Optimization of the microwave drying process for potato chips based on the measurement of dielectric properties. Dry. Technol. 2019, 37, 1329–1339. [Google Scholar] [CrossRef]

- Moreno, Á.H.; Aguirre, Á.J.; Maqueda, R.H.; Jiménez, G.J.; Miño, C.T. Effect of temperature on the microwave drying process and the viability of amaranth seeds. Biosyst. Eng. 2022, 215, 49–66. [Google Scholar] [CrossRef]

- Raponi, F.; Moscetti, R.; Chakravartula, S.S.N.; Fidaleo, M.; Massantini, R. Monitoring the hot-air drying process of organically grown apples (cv. gala) using computer vision. Biosyst. Eng. 2021, 223, 1–13. [Google Scholar] [CrossRef]

- Yu, H.M.; Li, H.Y.; Zhang, X.Y.; Wang, H.Y.; Sun, Y. Drying kinetic model of microwave coupled with hot air drying of straw-based nutrient seedling-growing bowl tray. Trans. CSAM 2020, 51, 339–348. [Google Scholar] [CrossRef]

- Chen, C.; Venkitasamy, C.; Zhang, W.P.; Deng, L.Z.; Meng, X.Y.; Pan, Z.L. Effect of step-down temperature drying on energy consumption and product quality of walnuts. J. Food Eng. 2020, 285, 110105. [Google Scholar] [CrossRef]

- Saravacos, G.D.; Maroulis, Z.B. Food Process Engineering Operations; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar] [CrossRef]

- Jiang, C.; Wan, F.; Zang, Z.; Zhang, Q.; Ma, G.; Huang, X. Effect of an ultrasound pre-treatment on the characteristics and quality of far-infrared vacuum drying with cistanche slices. Foods 2022, 11, 866. [Google Scholar] [CrossRef]

- Xiao, A.; Ding, C. Effect of electrohydrodynamic (EHD) on drying kinetics and quality characteristics of shiitake mushroom. Foods 2022, 11, 1303. [Google Scholar] [CrossRef] [PubMed]

- Mujumdar, A.S. Handbook of Industrial Drying, 4th ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar] [CrossRef]

| Test No. | Hot Air Temperature (°C) | Moisture Content at the Transition Point (%) | Microwave Power (W) | Microwave–Vacuum Thermostatic Temperature (°C) |

|---|---|---|---|---|

| 1 | 45 | 30 | 600 | 50 |

| 2 | 60 | 30 | 600 | 50 |

| 3 | 75 | 30 | 600 | 50 |

| 4 | 90 | 30 | 600 | 50 |

| 5 | 105 | 30 | 600 | 50 |

| 6 | 60 | 36 | 600 | 50 |

| 7 | 60 | 30 | 600 | 50 |

| 8 | 60 | 24 | 600 | 50 |

| 9 | 60 | 18 | 600 | 50 |

| 10 | 60 | 14 | 600 | 50 |

| 11 | 60 | 30 | 200 | 50 |

| 12 | 60 | 30 | 400 | 50 |

| 13 | 60 | 30 | 600 | 50 |

| 14 | 60 | 30 | 800 | 50 |

| 15 | 60 | 30 | 1000 | 50 |

| 16 | 60 | 30 | 600 | 30 |

| 17 | 60 | 30 | 600 | 40 |

| 18 | 60 | 30 | 600 | 50 |

| 19 | 60 | 30 | 600 | 60 |

| 20 | 60 | 30 | 600 | 70 |

| Test No. | HAD Stage | MVD Stage | MCE | tT | DRAVG | ||

|---|---|---|---|---|---|---|---|

| tHAD | DRHAD | tMVD | DRMVD | ||||

| 1 | 195 ± 4 | 0.064 ± 0.001 | 30 ± 1 | 0.976 ± 0.006 | 7.99 ± 0.5 | 225 ± 5 | 0.516 ± 0.006 |

| 2 | 135 ± 4 | 0.085 ± 0.001 | 30 ± 1 | 0.971 ± 0.006 | 7.95 ± 0.5 | 165 ± 4 | 0.579 ± 0.006 |

| 3 | 75 ± 3 | 0.152 ± 0.001 | 28 ± 1 | 1.030 ± 0.008 | 7.80 ± 0.5 | 103 ± 4 | 0.669 ± 0.006 |

| 4 | 60 ± 3 | 0.191 ± 0.001 | 25 ± 1 | 1.138 ± 0.008 | 7.88 ± 0.5 | 85 ± 3 | 0.759 ± 0.006 |

| 5 | 50 ± 3 | 0.225 ± 0.001 | 27 ± 1 | 1.120 ± 0.008 | 7.58 ± 0.5 | 77 ± 3 | 0.758 ± 0.006 |

| 6 | 45 ± 3 | 0.125 ± 0.001 | 37 ± 1 | 1.032 ± 0.008 | 7.90 ± 0.5 | 82 ± 3 | 0.862 ± 0.006 |

| 7 | 135 ± 4 | 0.085 ± 0.001 | 30 ± 1 | 0.971 ± 0.006 | 7.95 ± 0.5 | 165 ± 4 | 0.528 ± 0.006 |

| 8 | 270 ± 5 | 0.068 ± 0.001 | 26 ± 1 | 0.842 ± 0.006 | 7.95 ± 0.5 | 296 ± 5 | 0.304 ± 0.005 |

| 9 | 470 ± 6 | 0.061 ± 0.001 | 22 ± 1 | 0.576 ± 0.006 | 7.98 ± 0.5 | 492 ± 6 | 0.164 ± 0.004 |

| 10 | 670 ± 8 | 0.054 ± 0.001 | 15 ± 0.5 | 0.472 ± 0.005 | 7.89 ± 0.5 | 685 ± 8 | 0.100 ± 0.004 |

| 11 | 135 ± 4 | 0.085 ± 0.001 | 125 ± 3 | 0.268 ± 0.004 | 7.68 ± 0.5 | 260 ± 5 | 0.181 ± 0.004 |

| 12 | 135 ± 4 | 0.085 ± 0.001 | 55 ± 2 | 0.741 ± 0.006 | 7.59 ± 0.5 | 190 ± 4 | 0.430 ± 0.006 |

| 13 | 135 ± 4 | 0.085 ± 0.001 | 30 ± 1 | 0.971 ± 0.006 | 7.95 ± 0.5 | 165 ± 4 | 0.528 ± 0.006 |

| 14 | 135 ± 4 | 0.085 ± 0.001 | 20 ± 1 | 1.746 ± 0.01 | 7.66 ± 0.5 | 155 ± 4 | 0.915 ± 0.006 |

| 15 | 135 ± 4 | 0.085 ± 0.001 | 13 ± 0.5 | 2.193 ± 0.01 | 7.99 ± 0.5 | 148 ± 4 | 1.077 ± 0.008 |

| 16 | 135 ± 4 | 0.085 ± 0.001 | 270 ± 4 | 0.114 ± 0.004 | 7.96 ± 0.5 | 405 ± 6 | 0.102 ± 0.008 |

| 17 | 135 ± 4 | 0.085 ± 0.001 | 90 ± 2 | 0.450 ± 0.005 | 7.89 ± 0.5 | 225 ± 5 | 0.286 ± 0.005 |

| 18 | 135 ± 4 | 0.085 ± 0.001 | 30 ± 1 | 0.971 ± 0.006 | 7.95 ± 0.5 | 165 ± 4 | 0.528 ± 0.006 |

| 19 | 135 ± 4 | 0.085 ± 0.001 | 19 ± 0.5 | 0.196 ± 0.004 | 7.99 ± 0.5 | 154 ± 4 | 0.967 ± 0.006 |

| 20 | 135 ± 4 | 0.085 ± 0.001 | 15 ± 0.5 | 2.365 ± 0.01 | 8.01 ± 0.5 | 150 ± 4 | 1.082 ± 0.008 |

| Test No. | Deff,ave | A | B | C | D | R2 | RSS |

|---|---|---|---|---|---|---|---|

| 1 | 1. 386 × 10−8 | 7.83 × 10−12 | −4.69 × 10−10 | 8.40 × 10−9 | −3.62 × 10−8 | 0.944 | 9.120 × 10−17 |

| 2 | 1.591 × 10−8 | 7.69 × 10−12 | −4.52 × 10−10 | 7.90 × 10−9 | −2.98 × 10−8 | 0.957 | 8.530 × 10−17 |

| 3 | 2.239 × 10−8 | 9.12 × 10−12 | −5.19 × 10−10 | 8.79 × 10−9 | −2.63 × 10−8 | 0.951 | 1.239 × 10−16 |

| 4 | 2.636 × 10−8 | 1.00 × 10−11 | −5.67 × 10−10 | 9.57 × 10−9 | −2.59 × 10−8 | 0.960 | 1.427 × 10−16 |

| 5 | 2.922 × 10−8 | 9.79 × 10−12 | −5.43 × 10−10 | 9.01 × 10−9 | −1.92 × 10−8 | 0.951 | 1.977 × 10−16 |

| 6 | 2.679 × 10−8 | 6.59 × 10−12 | −4.14 × 10−10 | 7.86 × 10−9 | −2.08 × 10−8 | 0.820 | 3.399 × 10−16 |

| 7 | 1.591 × 10−8 | 7.69 × 10−12 | −4.52 × 10−10 | 7.90 × 10−9 | −2.98 × 10−8 | 0.957 | 1.427 × 10−16 |

| 8 | 1.210 × 10−8 | 6.87 × 10−12 | −3.97 × 10−10 | 7.01 × 10−9 | −3.10 × 10−8 | 0.963 | 1.515 × 10−16 |

| 9 | 1.083 × 10−8 | 6.42 × 10−12 | −3.67 × 10−10 | 6.53 × 10−9 | −3.12 × 10−8 | 0.960 | 1.767 × 10−16 |

| 10 | 1.005 × 10−8 | 6.17 × 10−12 | −3.51 × 10−10 | 6.31 × 10−9 | −3.17 × 10−8 | 0.958 | 1.919 × 10−16 |

| 11 | 1. 463 × 10−8 | 7.86 × 10−12 | −4.71 × 10−10 | 8.58 × 10−9 | −3.78 × 10−8 | 0.958 | 1.512 × 10−16 |

| 12 | 1.538 × 10−8 | 7.74 × 10−12 | −4.58 × 10−10 | 8.12 × 10−9 | −3.22 × 10−8 | 0.956 | 1.507 × 10−16 |

| 13 | 1.591 × 10−8 | 7.69 × 10−12 | −4.52 × 10−10 | 7.90 × 10−9 | −2.98 × 10−8 | 0.957 | 1.427 × 10−16 |

| 14 | 1.611 × 10−8 | 7.80 × 10−12 | −4.58 × 10−10 | 7.94 × 10−9 | −2.85 × 10−8 | 0.956 | 1.450 × 10−16 |

| 15 | 1.655 × 10−8 | 7.88 × 10−12 | −4.63 × 10−10 | 8.02 × 10−9 | −2.88 × 10−8 | 0.958 | 1.353 × 10−16 |

| 16 | 1.297 × 10−8 | 7.38 × 10−12 | −4.40 × 10−10 | 8.15 × 10−9 | −3.96 × 10−8 | 0.954 | 1.791 × 10−16 |

| 17 | 1.465 × 10−8 | 7.50 × 10−12 | −4.37 × 10−10 | 7.84 × 10−9 | −3.51 × 10−8 | 0.958 | 1.493 × 10−16 |

| 18 | 1.591 × 10−8 | 7.69 × 10−12 | −4.52 × 10−10 | 7.90 × 10−9 | −2.98 × 10−8 | 0.957 | 1.427 × 10−16 |

| 19 | 1.638 × 10−8 | 7.96 × 10−12 | −4.72 × 10−10 | 8.29 × 10−9 | −3.12 × 10−8 | 0.958 | 1.380 × 10−16 |

| 20 | 1.687 × 10−8 | 8.02 × 10−12 | −7.74 × 10−10 | 8.25 × 10−9 | −3.03 × 10−8 | 0.960 | 1.290 × 10−16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Man, X.; Li, L.; Fan, X.; Zhang, H.; Lan, H.; Tang, Y.; Zhang, Y. Evolution and Modelling of the Moisture Diffusion in Walnuts during the Combination of Hot Air and Microwave–Vacuum Drying. Agriculture 2024, 14, 190. https://doi.org/10.3390/agriculture14020190

Man X, Li L, Fan X, Zhang H, Lan H, Tang Y, Zhang Y. Evolution and Modelling of the Moisture Diffusion in Walnuts during the Combination of Hot Air and Microwave–Vacuum Drying. Agriculture. 2024; 14(2):190. https://doi.org/10.3390/agriculture14020190

Chicago/Turabian StyleMan, Xiaolan, Long Li, Xiuwen Fan, Hong Zhang, Haipeng Lan, Yurong Tang, and Yongcheng Zhang. 2024. "Evolution and Modelling of the Moisture Diffusion in Walnuts during the Combination of Hot Air and Microwave–Vacuum Drying" Agriculture 14, no. 2: 190. https://doi.org/10.3390/agriculture14020190

APA StyleMan, X., Li, L., Fan, X., Zhang, H., Lan, H., Tang, Y., & Zhang, Y. (2024). Evolution and Modelling of the Moisture Diffusion in Walnuts during the Combination of Hot Air and Microwave–Vacuum Drying. Agriculture, 14(2), 190. https://doi.org/10.3390/agriculture14020190