Multi-Span Greenhouse Energy Saving by External Insulation: System Design and Implementation

Abstract

:1. Introduction

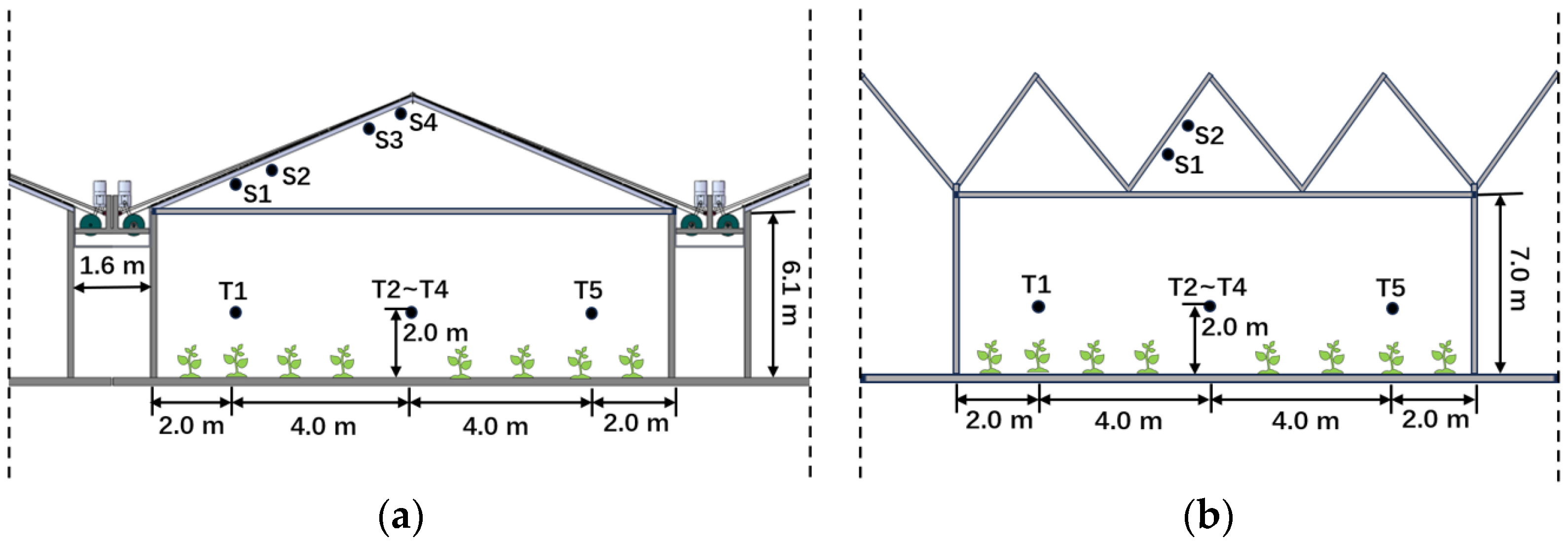

2. Materials and Methods

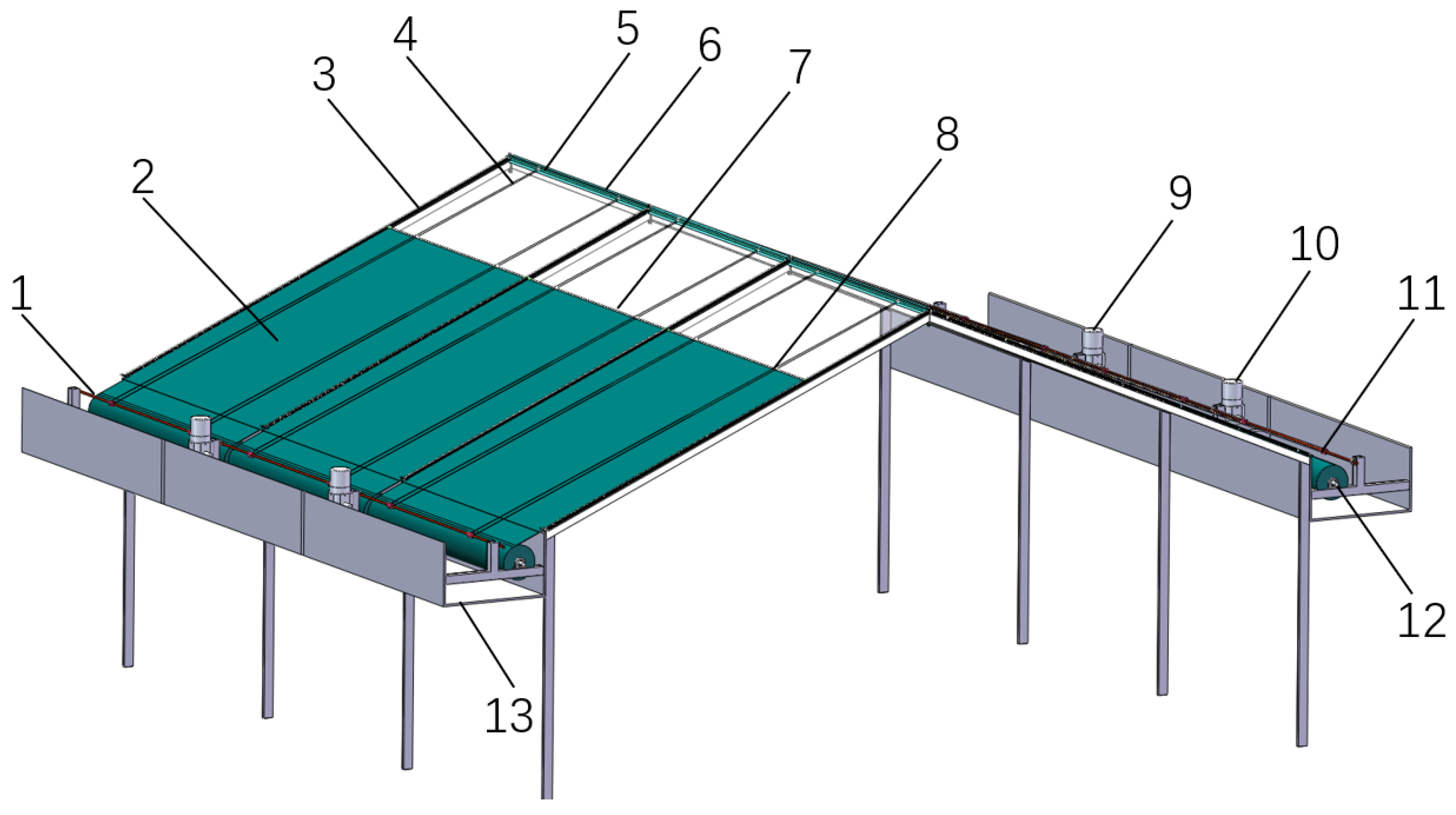

2.1. Overall Design and Working Method

2.2. Thermal Blanket

2.3. Critical Components Design

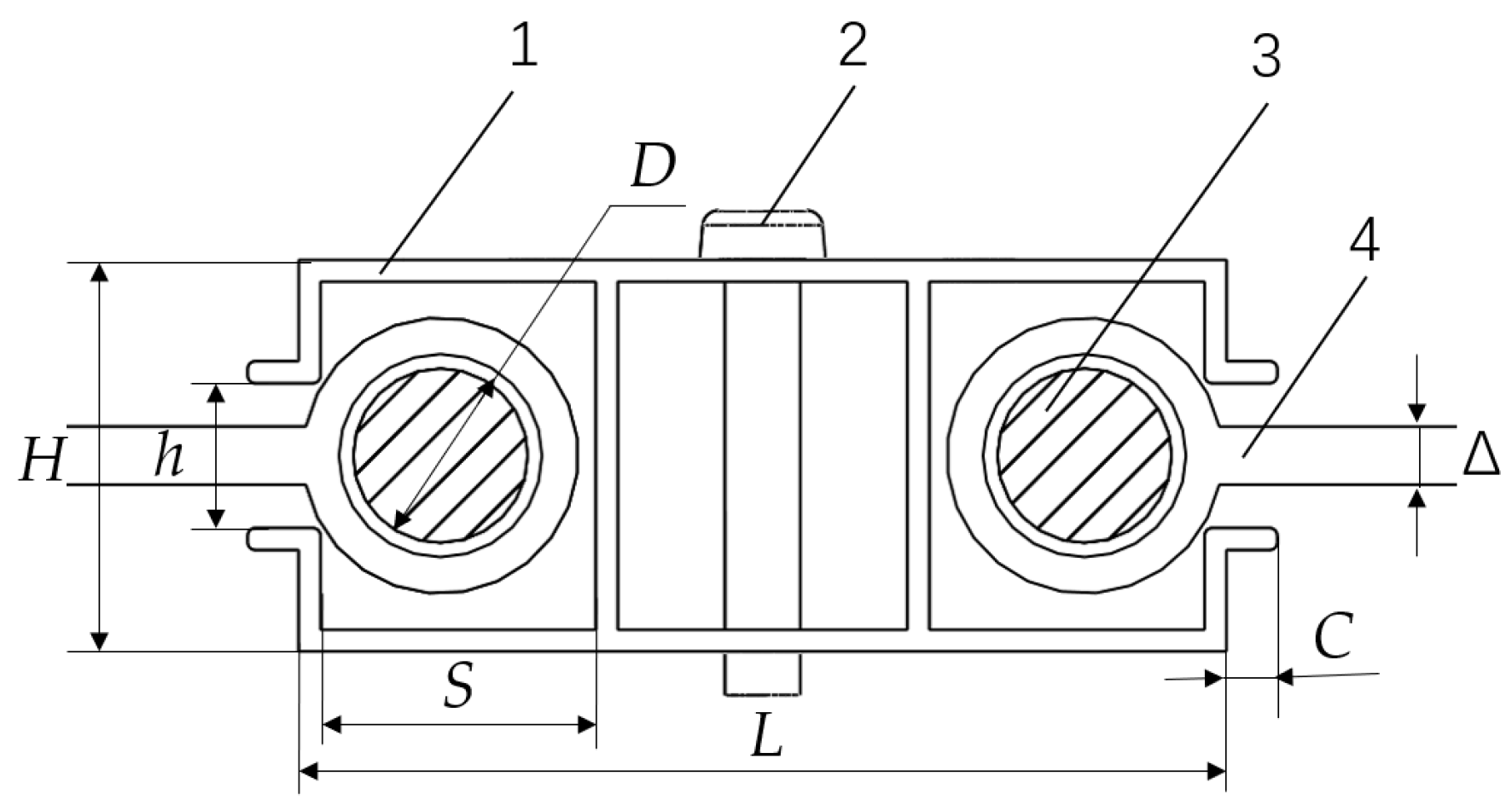

2.3.1. Seal Structure

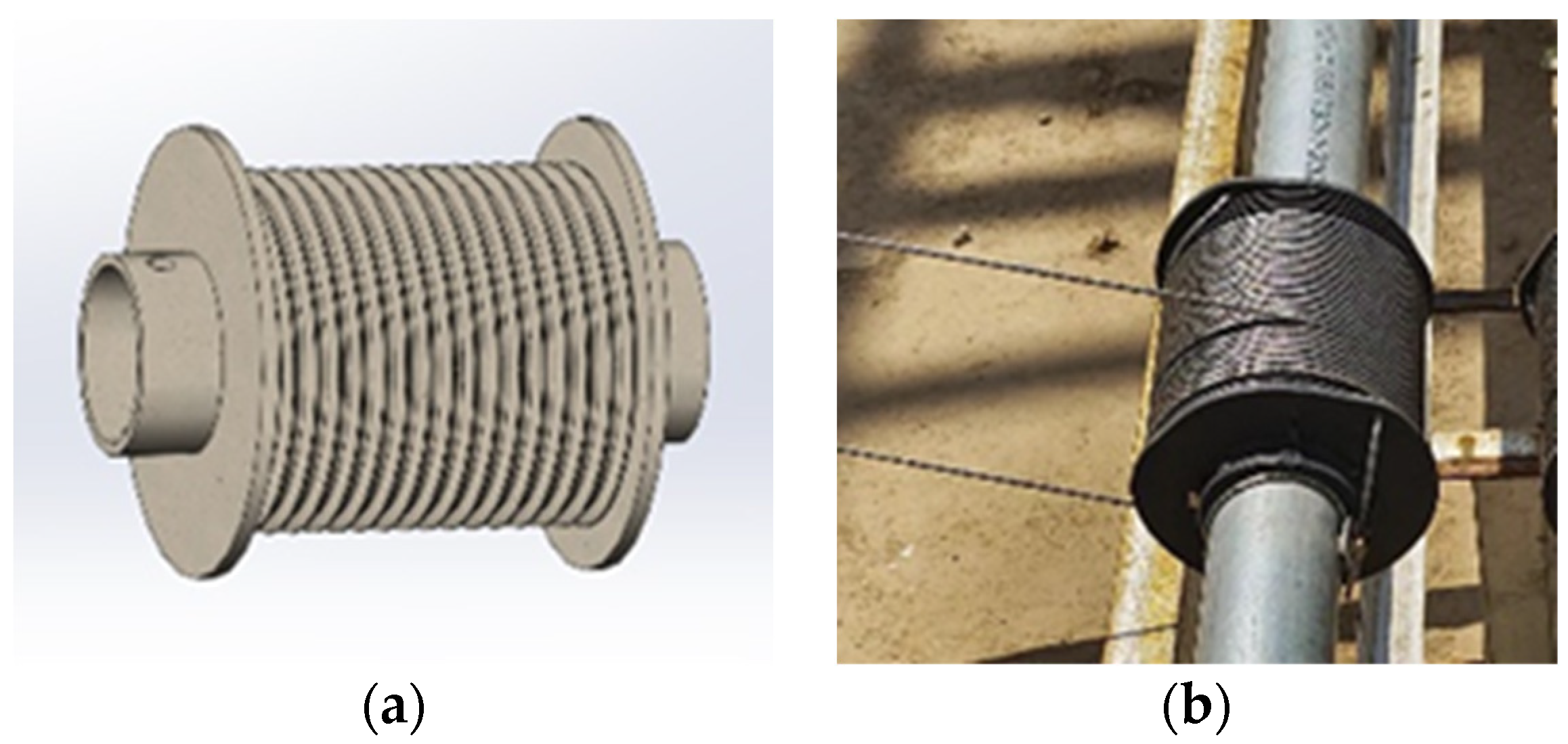

2.3.2. Traction Rope Transmission Mechanism

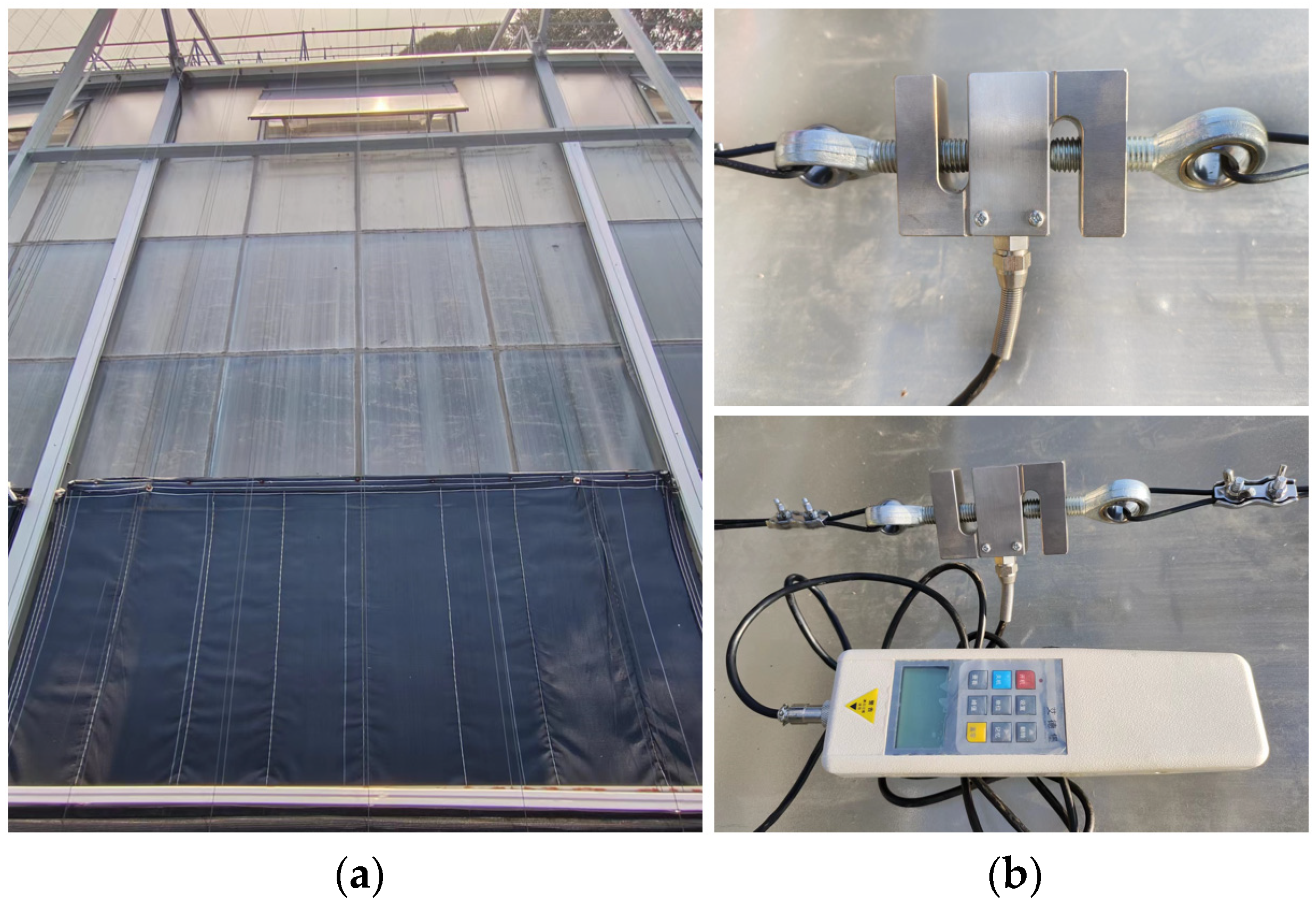

2.4. Experiment and Methods

3. Results

3.1. Traction Rope Tension

3.2. Operation Time

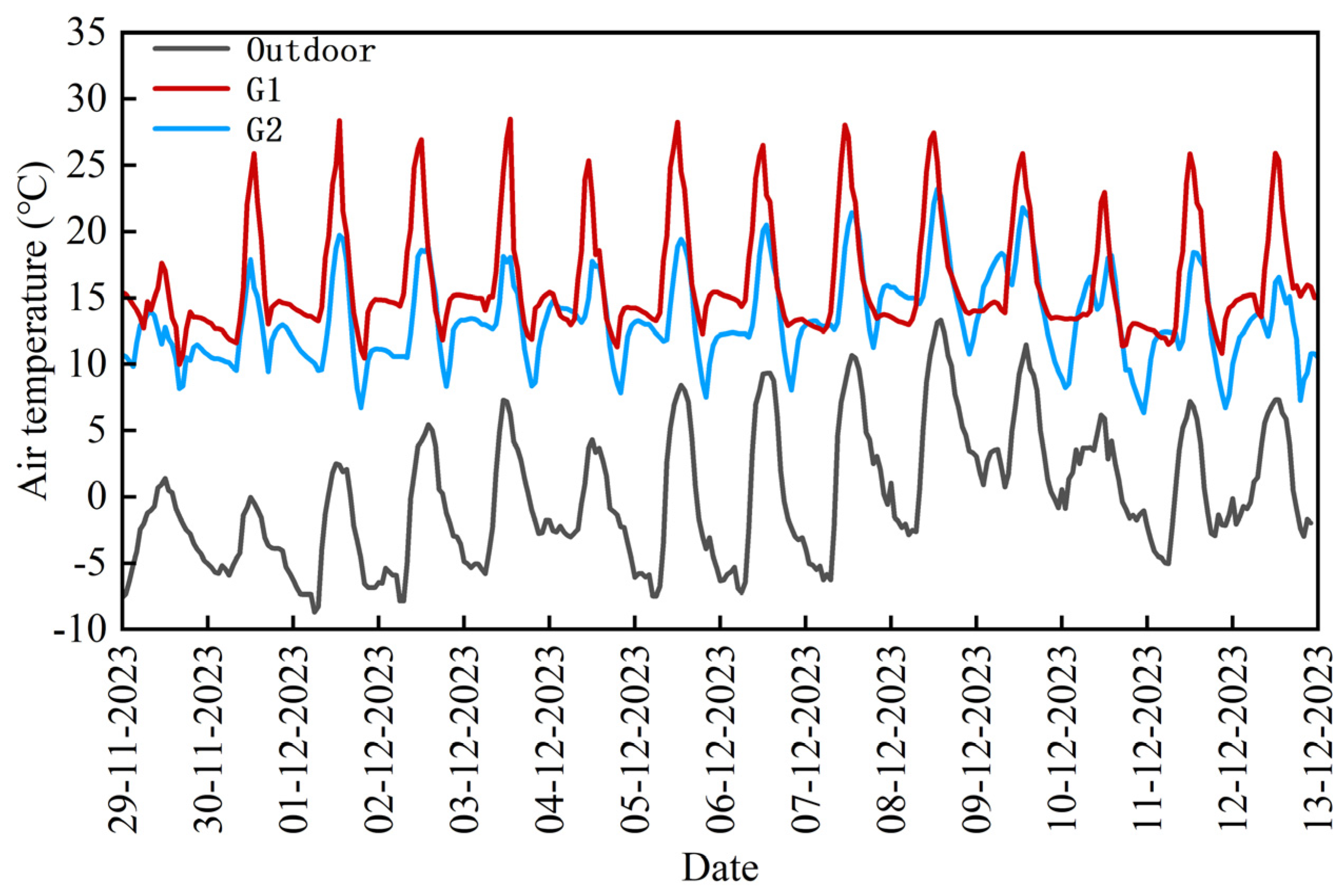

3.3. Greenhouse Air Temperature

3.3.1. Indoor Temperature Analysis

3.3.2. Typical Weather Temperature Changes

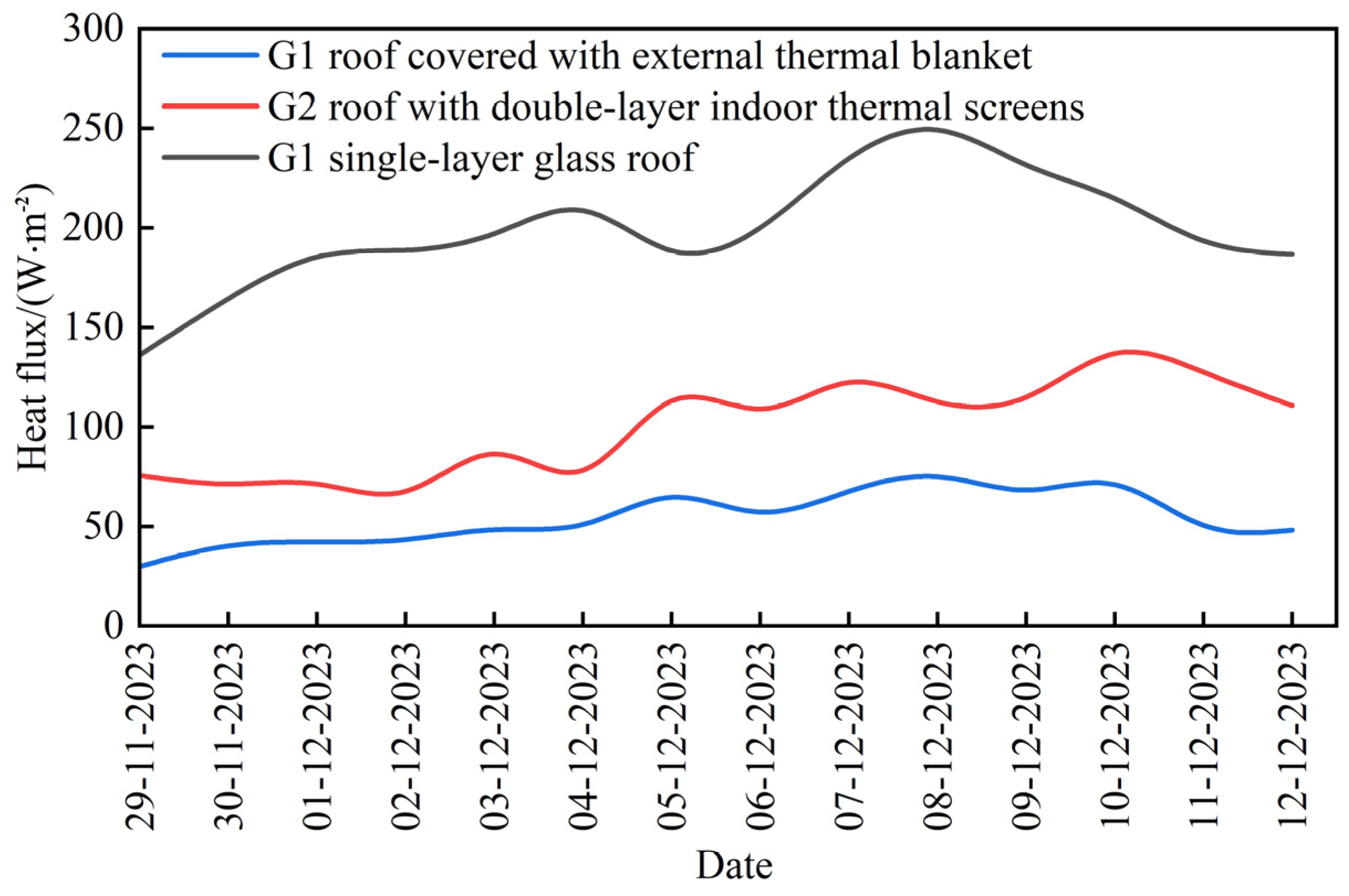

3.4. Heat Flux of the Greenhouse Roofs

4. Conclusions

- (1)

- This study proposes an approach for the external insulation of the roofs of multi-span glass greenhouses, The EIS was designed and built to practice this approach. The system achieved full coverage of the greenhouse roof through the mechanized unfurling and furling of external thermal blankets, thereby achieving energy-saving thermal insulation. The experimental analysis shows that the EIS runs stably, and the insulation effect is remarkable.

- (2)

- This paper provides detailed design and structural parameters for critical components such as the traction rope transmission mechanism and the rail-type sealing structure. Through a system verification experiment, the specifications of the traction rope were determined. The maximum tension of the traction rope was 719.1 N, which is less than the minimum breaking strength of 2296 N for the selected 2 mm steel wire rope. The average unfurling time for the thermal blanket was 4.303 min, and the average furling time was 3.682 min, meeting the current performance requirements for the time required to furl and unfurl thermal blankets in greenhouses.

- (3)

- The insulation effect of the EIS was analyzed via an insulation performance experiment. The results indicate that the average temperatures in the external insulation multi-span greenhouse and the Venlo-type multi-span greenhouse were 13.8 °C and 12.6 °C over a continuous 14-day period, respectively. The average thermal flux of the greenhouse roof with external insulation was 54.2 W/m2, compared to 198.6 W/m2 for the single-layer glass roof, indicating a 72.7% reduction in heat loss through the glass roof with external insulation. During the same period, the average thermal flux of the double-layer internally insulated Venlo-type multi-span greenhouse was 99.9 W/m2. In comparison, the heat loss from roofs with external insulation was only 50.3% of the heat loss from roofs with internal insulation. On the basis of maintaining the required temperature for normal greenhouse production, the external insulation multi-span greenhouse demonstrates superior energy-saving thermal insulation effect.

- (4)

- The above research provides a new solution for energy-saving insulation in multi-span greenhouses, and the external thermal blankets used in EIS show favorable thermal insulation performance. However, the material that these thermal blankets are made out of is relatively thick and heavy, which imposes certain requirements on the load-bearing capacity of the roofs of multi-span greenhouses, increasing greenhouse construction costs. Further research could explore the adoption of lighter, thinnerandbetter thermal insulation performance materials to alleviate the load pressure on the greenhouse’s structure.

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ahamed, M.S.; Guo, H.; Tanino, K. Energy saving techniques for reducing the heating cost of conventional greenhouses. Biosyst. Eng. 2019, 178, 9–33. [Google Scholar] [CrossRef]

- van Beveren, P.J.M.; Bontsema, J.; van Straten, G.; Van Henten, E.J. Minimal heating and cooling in a modern rose greenhouse. Appl. Energy 2015, 137, 97–109. [Google Scholar] [CrossRef]

- van Beveren, P.J.M.; Bontsema, J.; van Straten, G.; van Henten, E.J. Optimal control of greenhouse climate using minimal energy and grower defined bounds. Appl. Energy 2015, 159, 509–519. [Google Scholar] [CrossRef]

- Cuce, E.; Harjunowibowo, D.; Cuce, P.M. Renewable and sustainable energy saving strategies for greenhouse systems: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 64, 34–59. [Google Scholar] [CrossRef]

- Gupta, M.J.; Chandra, P. Effect of greenhouse design parameters on conservation of energy for greenhouse environmental control. Energy 2002, 27, 777–794. [Google Scholar] [CrossRef]

- Papadakis, G.; Briassoulis, D.; Scarascia Mugnozza, G.; Vox, G.; Feuilloley, P.; Stoffers, J.A. Review paper (SEdstructures and environment). J. Agric. Eng. Res. 2000, 77, 7e38. [Google Scholar] [CrossRef]

- Xue, F.; Zhang, Y.; Fu, Y.; Li, P.; Guo, S. Effect of Four Kinds of Thermal Insulation Quilts on the Thermal Insulaation of Ningxia Winter Solar Greenhouse. North. Hortic. 2019, 14, 66–72. [Google Scholar]

- Liu, H.; Lu, L.; Sun, D.; Liu, P.; Li, Y.; Li, T.; Liu, X. A Two-Factor Thermal Screen Control Strategy for Chinese Solar Greenhouses in High-Latitude Areas. Agronomy 2023, 13, 821. [Google Scholar] [CrossRef]

- Adesanya, M.A.; Na, W.; Rabiu, A.; Ogunlowo, Q.O.; Akpenpuun, T.D.; Rasheed, A.; Yoon, Y.; Lee, H. TRNSYS Simulation and Experimental Validation of Internal Temperature and Heating Demand in a Glass Greenhouse. Sustainability 2023, 14, 8283. [Google Scholar] [CrossRef]

- Cao, X.B.; Wang, S.X. Development and prospect of energy-saving technology of multi-span greenhouse in northern China. Modern Agric. Sci. Technol. 2014, 23, 212–213+218. [Google Scholar]

- Li, D.X.; Zhou, Z.C.; Yu, L.H.; Lan, L.B.; Li, X.G.; Li, L. Exploring the status quo and trend of smart greenhouse development. Vegetable 2019, 05, 12–17. [Google Scholar]

- Anifantis, A.S.; Colantoni, A.; Pascuzzi, S. Thermal energy assessment of a small scale photovoltaic, hydrogen and geothermal stand-alone system for greenhouse heating. Renew. Energy 2017, 103, 115–127. [Google Scholar] [CrossRef]

- Rorabaugh, P.; Jensen, M.; Giacomelli, G. Introduction to Controlled Environment Agriculture and Hydroponics; Controlled Environment Agriculture Center: Tucson, AZ, USA, 2002; pp. 1–130. [Google Scholar]

- Runkle, E.; Both, A. Greenhouse energy conservation strategies. Mich. State Univ. Ext. Bul. 2012, 1, 1–16. [Google Scholar]

- Kristinsson, J. The Energy-Producing Greenhouse. In Proceedings of the PLEA2006, the 23rd Conference on Passive and Low Energy Architecture, Geneva, Switzerland, 6–8 September 2006; pp. 6–8. [Google Scholar]

- Zhou, B.; Sun, W.; Guo, W.; Zhou, B.; Shi, L.; Li, G. Analysis and optimization of greenhouse gutter effect on radiation distribution inside multi-span greenhouses based on dynamic model. Trans. Chin. Soc. Agric. Mach. 2021, 52, 286–292. [Google Scholar]

- Hee, W.J.; Alghoul, M.A.; Bakhtyar, B.; Elayeb, O.; Shameri, M.A.; Alrubaih, M.S.; Sopian, K. The role of window glazing on daylighting and energy saving in buildings. Renew. Sustain. Energy Rev. 2015, 42, 323–343. [Google Scholar] [CrossRef]

- Frangi, P.; Piatti, R.; Amoroso, G. Evaluation of different screens for energy saving in the greenhouse. Acta Hortic. 2011, 893, 275–280. [Google Scholar] [CrossRef]

- Rasheed, A.; Lee, J.W.; Lee, H.W. Evaluation of Overall Heat Transfer Coefficient of Different Greenhouse Thermal Screens Using Building Energy Simulation. Prot. Hortic. Plant Fact. 2018, 27, 294–301. [Google Scholar] [CrossRef]

- Kim, H.K.; Kang, G.C.; Moon, J.P.; Lee, T.S.; Oh, S.S. Estimation of thermal performance and heat loss in plastic greenhouses with and without thermal curtains. Energies 2018, 11, 578. [Google Scholar] [CrossRef]

- Akpenpuun, T.D.; Na, W.H.; Ogunlowo, Q.O.; Rabiu, A.; Adesanya, M.A.; Addae, K.S.; Kim, H.T.; Lee, H.-W. Effect of glazing configuration as an energy-saving strategy in naturally ventilated greenhouses for strawberry (“Seolhyang” sp.) cultivation. J. Agric. Eng. 2021, 52, 1–8. [Google Scholar] [CrossRef]

- Rasheed, A.; Kwak, C.S.; Na, W.H.; Lee, J.W.; Kim, H.T.; Lee, H.W. Development of a Building Energy Simulation Model for Control of Multi-Span Greenhouse Microclimate. Agronomy 2020, 10, 1236. [Google Scholar] [CrossRef]

- Rasheed, A.; Kwak, C.S.; Kim, H.T.; Lee, H.W. Building Energy an Simulation Model for Analyzing Energy Saving Options of Multi-Span Greenhouses. Appl. Sci. 2019, 10, 6884. [Google Scholar] [CrossRef]

- Rabiu, A.; Adesanya, M.A.; Na, W.; Ogunlowo, Q.O.; Akpenpuun, T.D.; Kim, H.T.; Lee, H. Thermal performance and energy cost of Korean multispan greenhouse energy-saving screens. Energy 2023, 285, 129514. [Google Scholar] [CrossRef]

- Yao, X. Study on Thermal Insulation Performance and Energy-Saving Effect of Ultra-Low Energy Solar Greenhouse. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2011. [Google Scholar]

- Ge, Q. Research on the Properties of Agricultural Heal Preservation Quilt for Greenhouse. Master’s Thesis, Northwest A&F University, Xianyang, China, 2018. [Google Scholar]

- Li, J.Y.; Qin, H.; Ma, C.W. Requirements of greenhouse heat preservation quilt in gobi desert in Xinjiang. Xinjiang Agric. Sci. 2015, 52, 931–939. [Google Scholar]

- Chen, F.; Sun, W.T.; Yu, W.Y. Analyzing light and thermal environment and insulation performance of a multi-span greenhouse with external insulation. Trans. CSAE 2023, 39, 194–203. [Google Scholar]

- Zhan, Z.P.; Yang, Q.C.; Zhang, Y. Design and simulation test of an over-the-top rolling system for external insulation of arch-shaped greenhouse. J. China Agric. Univ. 2020, 25, 102–112. [Google Scholar]

- Yin, X.; Bowling, A.P. Dynamic performance limitations due to yielding in cable-driven robotic manipulators. J. Mech. Des. 2006, 128, 311–318. [Google Scholar] [CrossRef]

- Arikawa, K.; Hirose, S. Mechanical design of walking machines. Philos. Trans. Math. Phys. Eng. Sci. 2007, 365, 171–183. [Google Scholar] [CrossRef]

- Sun, W.; Wei, X.; Zhou, B.; Lu, C.; Guo, W. Greenhouse heating by energy transfer between greenhouses: System design and implementation. Appl. Energy 2022, 325, 119815. [Google Scholar] [CrossRef]

- Sun, H.; Teng, G.H.; Zhang, X.F. Design and test on real-time measurement system of mat foller workload for sunlight greenhouse. Trans. CSAE 2014, 30, 138–145. [Google Scholar]

- NY/T 2205-2012; Quality Evaluation Technical Specifications for Greenhouse Curtain Machines. National Agricultural Machinery Standardization Technical Committee: Beijing, China, 2012.

- Zhang, G.X.; Fu, Z.T.; Li, X.X. Design and experiment of rear fixed type rolling shutter device in solar greenhouse. Trans. Chin. Soc. Agric. Mach. 2016, 47, 299–308. [Google Scholar]

| Items | Parameters |

|---|---|

| Height of the guide rail, H (mm) | 40 |

| Opening size of the guide rail, h (mm) | 16 |

| Diameter of the nylon rope, D (mm) | 25 |

| Width of the cavity of the guide rail, S (mm) | 42 |

| Width of the guide rail, L (mm) | 150 |

| Width of the guide rail opening edge, C (mm) | 4 |

| Thickness of the thermal blanket at the guide rail, Δ (mm) | 15 |

| Items | Parameters |

|---|---|

| Diameter of the wire rope (mm) | 3 |

| Length of the wire rope (m) | 13.5 |

| Outside diameter of the drive rod (mm) | 20 |

| Wall thickness of the drive rod (mm) | 1.5 |

| Outside diameter of the coil rope shaft (mm) | 58 |

| Wall thickness of the coil rope shaft (mm) | 2 |

| Outside diameter of the coil blanket shaft (mm) | 58 |

| Wall thickness of the coil blanket shaft (mm) | 2 |

| Thinnest wall thickness (mm) | 4 |

| External diameter of the coil bobbin (mm) | 115 |

| Screw pitch of the coil bobbin (mm) | 6 |

| Thread turns of the coil bobbin | 27 |

| Thread groove width (mm) | 4 |

| Thread groove depth (mm) | 3 |

| Locating hole diameter of the coil bobbin (mm) | 5 |

| Test Number | Unfurling Time of Thermal Blankets/Min | Furling Time of Thermal Blankets/Min |

|---|---|---|

| 1 | 4.353 | 3.59 |

| 2 | 4.271 | 3.787 |

| 3 | 4.285 | 3.665 |

| Average value | 4.303 | 3.682 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, W.; Guo, W.; Chen, F.; Han, X.; Wang, H.; Sun, W.; Zhao, Q.; Jia, D.; Wei, X.; Zhu, Q. Multi-Span Greenhouse Energy Saving by External Insulation: System Design and Implementation. Agriculture 2024, 14, 281. https://doi.org/10.3390/agriculture14020281

Guan W, Guo W, Chen F, Han X, Wang H, Sun W, Zhao Q, Jia D, Wei X, Zhu Q. Multi-Span Greenhouse Energy Saving by External Insulation: System Design and Implementation. Agriculture. 2024; 14(2):281. https://doi.org/10.3390/agriculture14020281

Chicago/Turabian StyleGuan, Wenfei, Wenzhong Guo, Fan Chen, Xiaobei Han, Haiguang Wang, Weituo Sun, Qian Zhao, Dongdong Jia, Xiaoming Wei, and Qingzhen Zhu. 2024. "Multi-Span Greenhouse Energy Saving by External Insulation: System Design and Implementation" Agriculture 14, no. 2: 281. https://doi.org/10.3390/agriculture14020281

APA StyleGuan, W., Guo, W., Chen, F., Han, X., Wang, H., Sun, W., Zhao, Q., Jia, D., Wei, X., & Zhu, Q. (2024). Multi-Span Greenhouse Energy Saving by External Insulation: System Design and Implementation. Agriculture, 14(2), 281. https://doi.org/10.3390/agriculture14020281