Comprehensive Review of the Quality and Processing Suitability of U.S. Hard Red Spring Wheat: Current Strategies, Challenges, and Future Potential Scope

Abstract

:1. Introduction

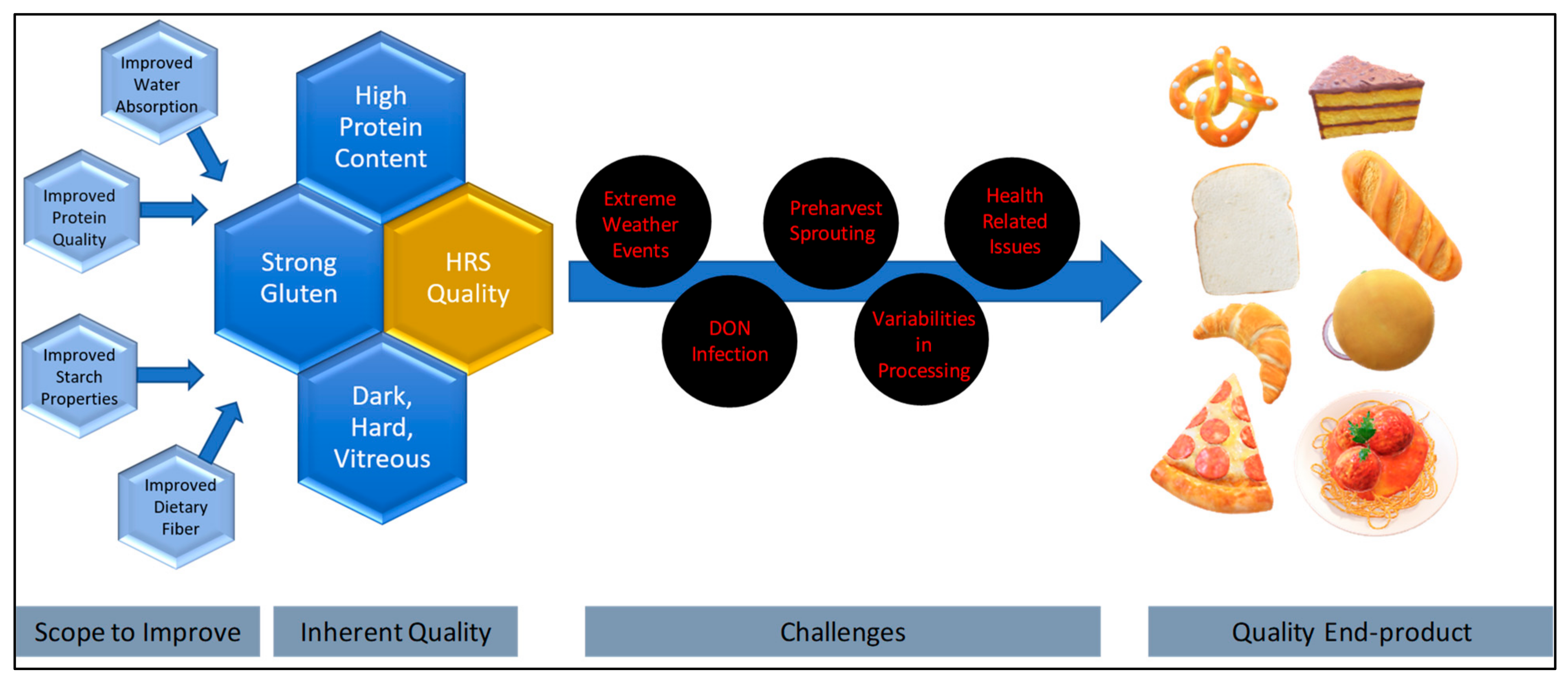

2. Unique Potential of Hard Red Spring Wheat to Improve Quality

2.1. Blending with Other Classes of Wheat to Improve Flour Protein Content and Quality

2.2. Strong Gluten for Sourdough Fermentation

2.3. HRS in Frozen or Refrigerated Dough and Pre-Baked Product Market

2.4. Clean-Label Food Production

2.5. HRS Wheat for Producing Specialized Products That Require Strong Dough

3. Major Challenges to HRS Quality

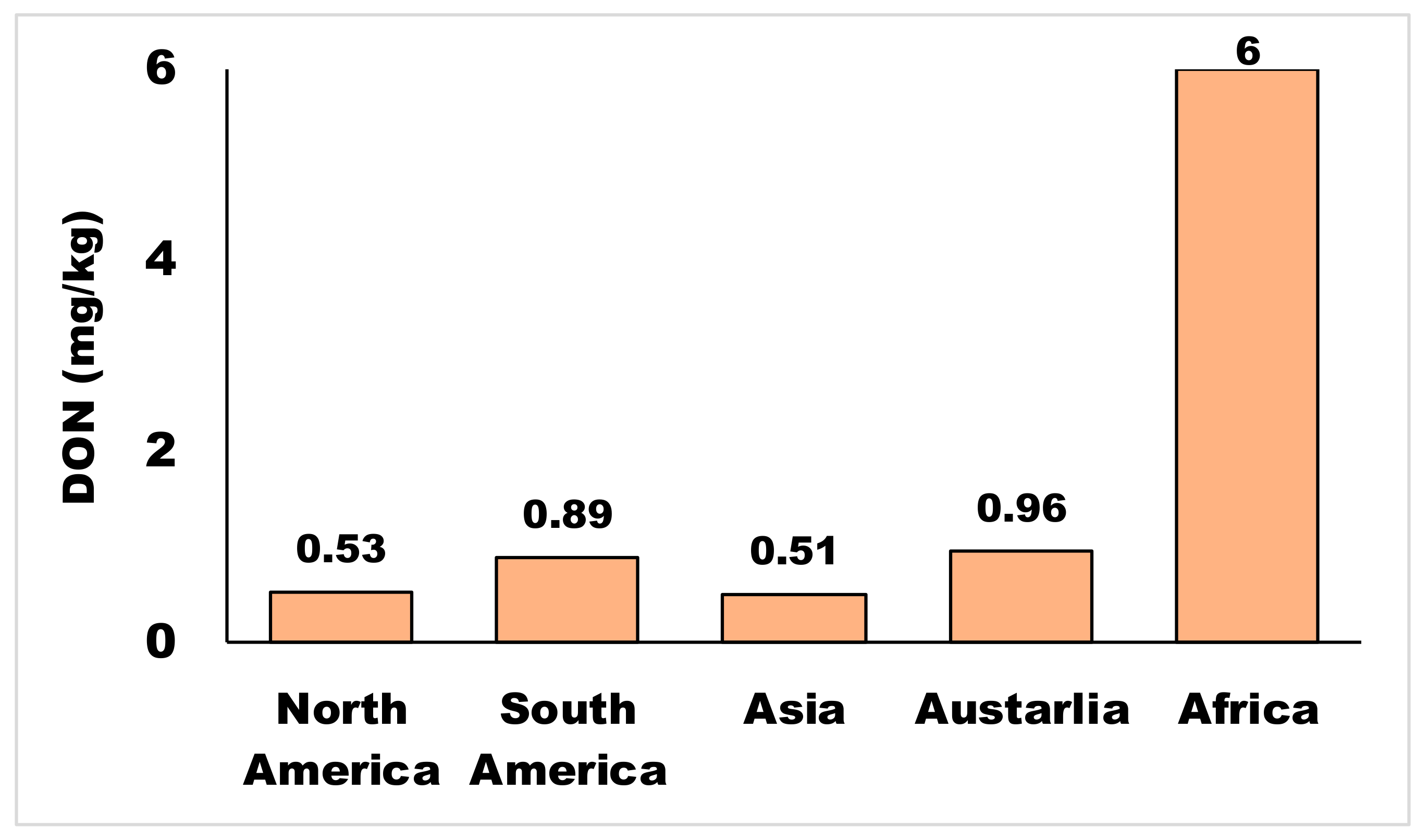

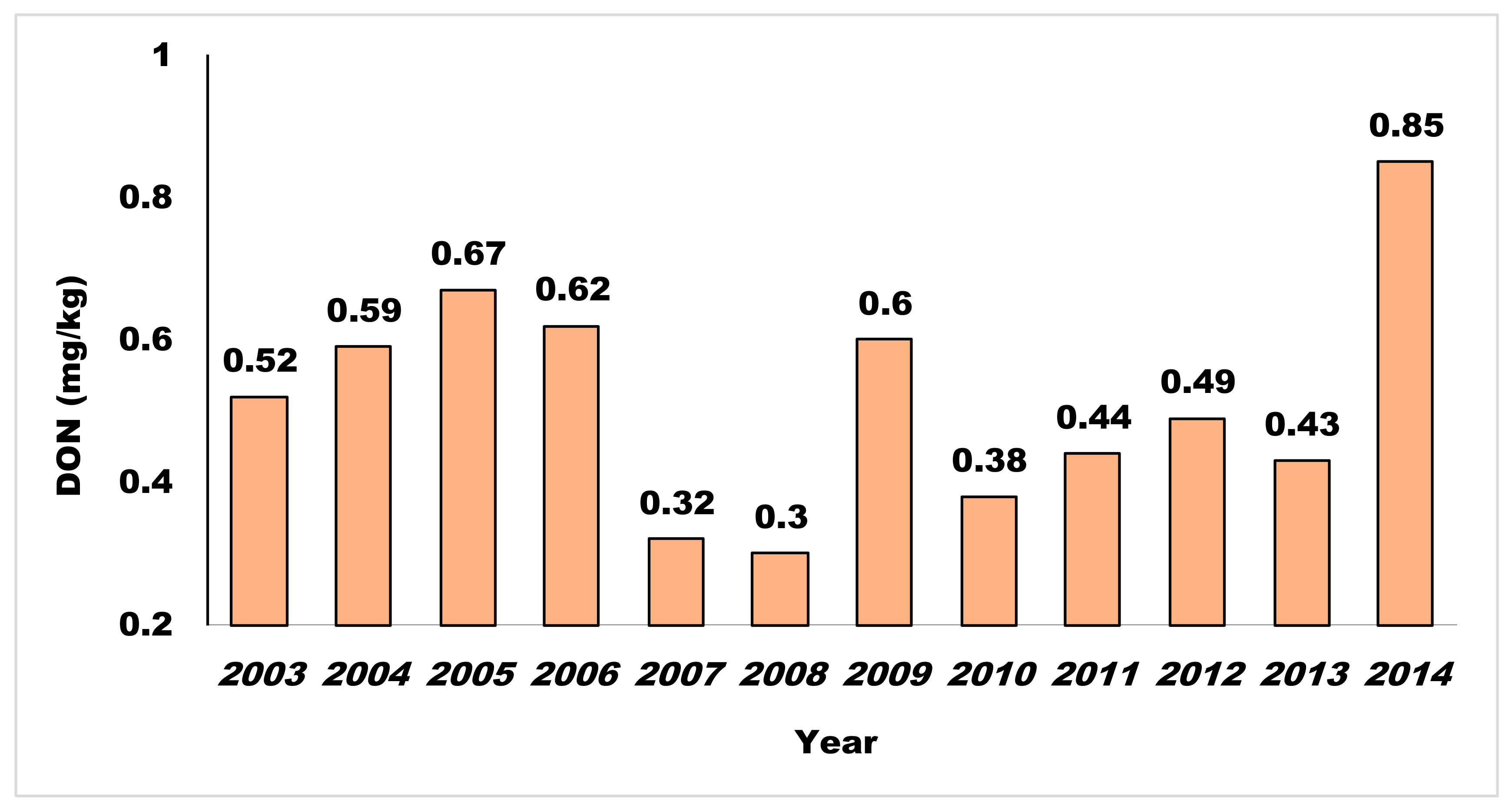

3.1. Deoxynivalenol Infection

3.2. Starch Damage

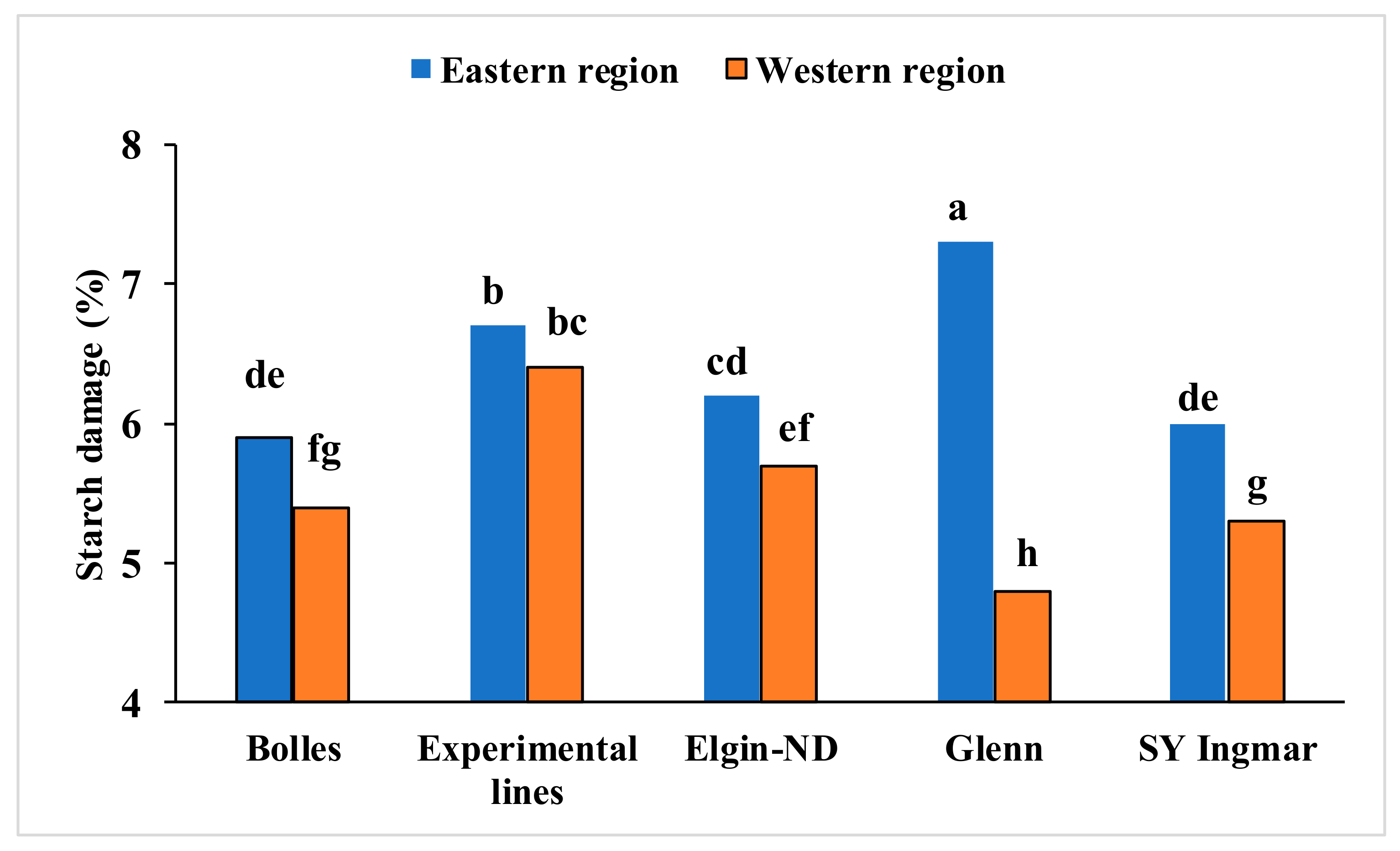

3.2.1. Starch Damage Due to Pre-Harvest Sprouting (PHS)

3.2.2. Starch Damage by Milling Process

3.3. Strong Environmental Influence and Complex Genetic Regulation

3.4. Influence of Processing on the End-Product Quality

3.5. Human-Health-Related Issues

4. Scope of Further Quality Improvement of HRS Wheat

4.1. Improving Water Absorption

4.2. Increasing Dietary Fiber Content

4.3. Increasing Bioactive Compounds

4.4. Improving Protein Quality

4.5. Improving Starch Properties

4.6. Optimizing End-Product Processing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Erenstein, O.; Jaleta, M.; Mottaleb, K.A.; Sonder, K.; Donovan, J.; Braun, H.-J. Global Trends in Wheat Production, Consumption and Trade. In Wheat Improvement: Food Security in a Changing Climate; Springer International Publishing: Cham, Switzerland, 2022; pp. 47–66. [Google Scholar] [CrossRef]

- Liu, Y.; Jochum, J.O.; Daniel, W.; Ars, U. Associations of Sulfur Content and Protein Molecular Weight Distribution with Bread-Making Quality for Patent and Mill Stream Flours in Hard Red Spring Wheat Grown under Sulfur Fertilization at Two Locations. J. Agric. Crop Res. 2021, 9, 60–71. [Google Scholar] [CrossRef]

- Kusunose, Y.; Rossi, J.J.; Van Sanford, D.A.; Alderman, P.D.; Anderson, J.A.; Chai, Y.; Gerullis, M.K.; Jagadish, S.V.K.; Paul, P.A.; Tack, J.B.; et al. Sustaining Productivity Gains in the Face of Climate Change: A Research Agenda for US Wheat. Glob. Chang. Biol. 2023, 29, 926–934. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Chen, M.; Hou, X.; Li, T.; Qian, H.; Zhang, H.; Li, Y.; Qi, X.; Wang, L. Effect of Phosphate Salts on the Gluten Network Structure and Quality of Wheat Noodles. Food Chem. 2021, 358, 129895. [Google Scholar] [CrossRef] [PubMed]

- USW Commercial Sales Report 2023. 2023. Available online: https://www.msci.com/www/quick-take/us-commercial-property-distress/04355163707 (accessed on 24 March 2023).

- Canadian Grain Commission Exports of Canadian Grain and Wheat Flour, 2014 to Date. 2023. Available online: https://www.grainscanada.gc.ca/en/grain-research/statistics/exports-grain-wheat-flour/index.html: (accessed on 25 March 2024).

- Fradgley, N.S.; Gardner, K.A.; Kerton, M.; Swarbreck, S.M.; Bentley, A.R. Balancing Quality with Quantity: A Case Study of UK Bread Wheat. Plants People Planet 2023, 5, 1–14. [Google Scholar] [CrossRef]

- USDA Russian Wheat: The New Reference for Cash Wheat Worldwide. From Net Importer to No. 1 Exporter. 2017. Available online: https://www.usda.gov/sites/default/files/documents/Swithun_Still.pdf: (accessed on 25 March 2024).

- Kingwell, R. Ukraine: An Emerging Challenge for Australian Wheat Exports. 2016. Available online: https://www.researchgate.net/publication/301558932_Ukraine_An_emerging_challenge_for_Australian_wheat_exports (accessed on 24 March 2024).

- Cseh, A.; Poczai, P.; Kiss, T.; Balla, K.; Berki, Z.; Horváth, Á.; Kuti, C.; Karsai, I. Exploring the Legacy of Central European Historical Winter Wheat Landraces. Sci. Rep. 2021, 11, 23915. [Google Scholar] [CrossRef]

- AEGIC Australian Wheat Australian Wheat for Premium Products. 2024. Available online: https://www.aegic.org.au/2024/ (accessed on 25 March 2024).

- Sun, X.; Marza, F.; Ma, H.; Carver, B.F.; Bai, G. Mapping Quantitative Trait Loci for Quality Factors in an Inter-Class Cross of US and Chinese Wheat. Theor. Appl. Genet. 2010, 120, 1041–1051. [Google Scholar] [CrossRef]

- Ronge, R.V.; Sardeshmukh, M.M. Comparative Analysis of Indian Wheat Seed Classification. In Proceedings of the 2014 International Conference on Advances in Computing, Communications and Informatics (ICACCI), Delhi, India, 24–27 September 2014; pp. 937–942. [Google Scholar] [CrossRef]

- Caplan, L.A.; Webb, A.J. Japan: Determinants of Wheat Import Demand; Staff Report no. AGES 9404; U.S. Department of Agriculture, Economic Research Service, Agriculture and Trade Analysis Division: Washington, DC, USA, 1994.

- Dorrian, K.; Mkhabela, M.; Sapirstein, H.; Bullock, P. Effects of Delayed Harvest on Wheat Quality, Gluten Strength, and Protein Composition of Hard Red Spring Wheat. Cereal Chem. 2023, 100, 196–212. [Google Scholar] [CrossRef]

- Baasandorj, T.; Ohm, J.B.; Simsek, S. Effects of Kernel Vitreousness and Protein Level on Protein Molecular Weight Distribution, Milling Quality, and Breadmaking Quality in Hard Red Spring Wheat. Cereal Chem. 2016, 93, 426–434. [Google Scholar] [CrossRef]

- Issarny, C.; Cao, W.; Falk, D.; Seetharaman, K.; Bock, J.E. Exploring Functionality of Hard and Soft Wheat Flour Blends for Improved End-Use Quality Prediction. Cereal Chem. 2017, 94, 723–732. [Google Scholar] [CrossRef]

- Mendis, M.; Leclerc, E.; Simsek, S. Arabinoxylans, Gut Microbiota and Immunity. Carbohydr. Polym. 2016, 139, 159–166. [Google Scholar] [CrossRef]

- Simsek, S. Clean-Label Bread: Using Hard Red Spring Wheat to Replace Dough Improvers in Whole Wheat Bread. J. Food Process. Preserv. 2020, 44, 1–9. [Google Scholar] [CrossRef]

- Mkhabela, M.; Bullock, P.; Sapirstein, H.; Courcelles, J.; Abbasi, S.; Koksel, F. Exploring the Influence of Weather on Gluten Strength of Hard Red Spring Wheat (Triticum aestivum L.) on the Canadian Prairies. J. Cereal Sci. 2022, 104, 103410. [Google Scholar] [CrossRef]

- Miguel-Rojas, C.; Cavinder, B.; Townsend, J.P.; Trail, F. Comparative Transcriptomics of Fusarium Graminearum and Magnaporthe Oryzae Spore Germination Leading up to Infection. MBio 2023, 14, e02442-22. [Google Scholar] [CrossRef]

- Rahman, M.M.; Simsek, S. Go Clean Label: Replacement of Commercial Dough Strengtheners with Hard Red Spring Wheat Flour in Bread Formulations. J. Food Sci. Technol. 2020, 57, 3581–3590. [Google Scholar] [CrossRef]

- Suprabha Raj, A.; Boyacioglu, M.H.; Dogan, H.; Siliveru, K. Investigating the Contribution of Blending on the Dough Rheology of Roller-Milled Hard Red Wheat. Foods 2023, 12, 2078. [Google Scholar] [CrossRef]

- Rahman, M.M.; Ohm, J.B.; Simsek, S. Clean-Label Breadmaking: Size Exclusion HPLC Analysis of Proteins in Dough Supplemented with Additives vs Hard Red Spring Wheat Flour. J. Cereal Sci. 2022, 104, 103426. [Google Scholar] [CrossRef]

- Seis Subaşı, A.; Ercan, R. The Effects of Wheat Variety, Sourdough Treatment and Sourdough Level on Nutritional Characteristics of Whole Wheat Bread. J. Cereal Sci. 2023, 110, 103637. [Google Scholar] [CrossRef]

- Mellen, P.B.; Walsh, T.F.; Herrington, D.M. Whole Grain Intake and Cardiovascular Disease: A Meta-Analysis. Nutr. Metab. Cardiovasc. Dis. 2008, 18, 283–290. [Google Scholar] [CrossRef]

- Future Market Insight Inc. Whole Wheat Flour Market Outlook (2022 to 2032). 2022. Available online: https://www.futuremarketinsights.com/reports/whole-wheat-flour-market (accessed on 24 March 2024).

- Bressiani, J.; Oro, T.; Santetti, G.S.; Almeida, J.L.; Bertolin, T.E.; Gómez, M.; Gutkoski, L.C. Properties of Whole Grain Wheat Flour and Performance in Bakery Products as a Function of Particle Size. J. Cereal Sci. 2017, 75, 269–277. [Google Scholar] [CrossRef]

- Xu, X.; Yang, Q.; Luo, Z.; Xiao, Z. Effects of Sourdough Fermentation and an Innovative Compound Improver on the Baking Performance, Nutritional Quality, and Antistaling Property of Whole Wheat Bread. ACS Food Sci. Technol. 2021, 2, 825–835. [Google Scholar] [CrossRef]

- Chochkov, R.; Savov, M.; Gotcheva, V.; Papageorgiou, M.; Rocha, J.M.; Baev, V.; Angelov, A. Effects of Sourdough on Rheological Properties of Dough, Quality Characteristics and Staling Time of Wholemeal Wheat Croissants. Ital. J. Food Sci. 2023, 35, 115–129. [Google Scholar] [CrossRef]

- Balestra, F.; Pinnavaia, G.G.; Romani, S. Evaluation of the Effects of Different Fermentation Methods on Dough Characteristics. J. Texture Stud. 2015, 46, 262–271. [Google Scholar] [CrossRef]

- Rinaldi, M.; Paciulli, M.; Caligiani, A.; Sgarbi, E.; Cirlini, M.; Dall’Asta, C.; Chiavaro, E. Durum and Soft Wheat Flours in Sourdough and Straight-Dough Bread-Making. J. Food Sci. Technol. 2015, 52, 6254–6265. [Google Scholar] [CrossRef] [PubMed]

- Omedi, J.O.; Huang, W.; Zhang, B.; Li, Z.; Zheng, J. Advances in Present-Day Frozen Dough Technology and Its Improver and Novel Biotech Ingredients Development Trends—A Review. Cereal Chem. 2019, 96, 34–56. [Google Scholar] [CrossRef]

- Simsek, S. Application of Xanthan Gum for Reducing Syruping in Refrigerated Doughs. Food Hydrocoll. 2009, 23, 2354–2358. [Google Scholar] [CrossRef]

- Simsek, S.; Whitney, K.L.; Ohm, J.B.; Anderson, J.; Mergoum, M. Refrigerated Dough Quality: Effect of Environment and Genotypes of Hard Red Spring Wheat. J. Food Sci. 2011, 76, S101–S107. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Li, Y.; Liu, Y.; Zhang, H. Effects of Multiple Freeze–Thaw Cycles on the Quality of Frozen Dough. Cereal Chem. 2018, 95, 499–507. [Google Scholar] [CrossRef]

- Malalgoda, M.; Ohm, J.B.; Meinhardt, S.; Simsek, S. Association between Gluten Protein Composition and Breadmaking Quality Characteristics in Historical and Modern Spring Wheat. Cereal Chem. 2018, 95, 226–238. [Google Scholar] [CrossRef]

- Zhang, Y.; Simsek, S. Physicochemical Changes of Starch in Refrigerated Dough during Storage. Carbohydr. Polym. 2009, 78, 268–274. [Google Scholar] [CrossRef]

- Aschemann-Witzel, J.; Varela, P.; Peschel, A.O. Consumers’ Categorization of Food Ingredients: Do Consumers Perceive Them as ‘Clean Label’ Producers Expect? An Exploration with Projective Mapping. Food Qual. Prefer. 2019, 71, 117–128. [Google Scholar] [CrossRef]

- Vargas, M.C.A.; Simsek, S. Clean Label in Bread. Foods 2021, 10, 2054. [Google Scholar] [CrossRef] [PubMed]

- Padalino, L.; Conte, A.; Del Nobile, M.A. Overview on the General Approaches to Improve Gluten-Free Pasta and Bread. Foods 2016, 5, 87. [Google Scholar] [CrossRef]

- Pareyt, B.; Delcour, J.A. The Role of Wheat Flour Constituents, Sugar, and Fat in Low Moisture Cereal Based Products: A Review on Sugar-Snap Cookies. Crit. Rev. Food Sci. Nutr. 2008, 48, 824–839. [Google Scholar] [CrossRef]

- Hu, X.; Cheng, L.; Hong, Y.; Li, Z.; Li, C.; Gu, Z. Impact of Celluloses and Pectins Restrictions on Gluten Development and Water Distribution in Potato-Wheat Flour Dough. Int. J. Biol. Macromol. 2022, 206, 534–542. [Google Scholar] [CrossRef] [PubMed]

- Baasandorj, T.; Ohm, J.B.; Dykes, L.; Simsek, S. Evaluation of the Quality Scoring System of Hard Red Spring Wheat Using Four Different Roller Mills. Int. J. Food Prop. 2018, 21, 1017–1030. [Google Scholar] [CrossRef]

- Færgestad, E.M.; Magnus, E.M.; Sahlström, S.; Næs, T. Influence of Flour Quality and Baking Process on Hearth Bread Characteristics Made Using Gentle Mixing. J. Cereal Sci. 1999, 30, 61–70. [Google Scholar] [CrossRef]

- Girard, A.L.; Awika, J.M. Effects of Edible Plant Polyphenols on Gluten Protein Functionality and Potential Applications of Polyphenol–Gluten Interactions. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2164–2199. [Google Scholar] [CrossRef] [PubMed]

- Xian, L.; Zhang, Y.; Hu, Y.; Zhu, S.; Wen, Z.; Hua, C.; Li, L.; Sun, Z.; Li, T. Mycotoxin DON Accumulation in Wheat Grains Caused by Fusarium Head Blight Are Significantly Subjected to Inoculation Methods. Toxins 2022, 14, 409. [Google Scholar] [CrossRef] [PubMed]

- McMullen, M.; Bergstrom, G.; De Wolf, E.; Dill-Macky, R.; Hershman, D.; Shaner, G.; Van Sanford, D. Fusarium Head Blight Disease Cycle, Symptoms, and Impact on Grain Yield and Quality Frequency and Magnitude of Epidemics Since 1997. Plant Dis. 2012, 96, 1712–1728. [Google Scholar] [CrossRef] [PubMed]

- Rasmussen, P.H.; Nielsen, K.F.; Ghorbani, F.; Spliid, N.H.; Nielsen, G.C.; Jørgensen, L.N. Occurrence of Different Trichothecenes and Deoxynivalenol-3-β-D-Glucoside in Naturally and Artificially Contaminated Danish Cereal Grains and Whole Maize Plants. Mycotoxin Res. 2012, 28, 181–190. [Google Scholar] [CrossRef]

- Ovando-Martínez, M.; Ozsisli, B.; Anderson, J.; Whitney, K.; Ohm, J.B.; Simsek, S. Analysis of Deoxynivalenol and Deoxynivalenol-3-Glucoside in Hard Red Spring Wheat Inoculated with Fusarium Graminearum. Toxins 2013, 5, 2522–2532. [Google Scholar] [CrossRef]

- Nganje, W.E.; Bangsund, D.A.; Larry Leistritz, F.; Wilson, W.W.; Tiapo, N.M. Regional Economic Impacts of Fusarium Head Blight in Wheat and Barley. Rev. Agric. Econ. 2004, 26, 332–347. [Google Scholar] [CrossRef]

- Mcmullen, M.; Jones, R.; Gallenberg, D.; America, S. Scab of Wheat and Barley: A Re-Emerging Disease of Devastating Impact. Plant Dis. 1997, 81, 1339–1472. [Google Scholar] [CrossRef] [PubMed]

- Bianchini, A.; Horsley, R.; Jack, M.M.; Kobielush, B.; Ryu, D.; Tittlemier, S.; Wilson, W.W.; Abbas, H.K.; Abel, S.; Harrison, G.; et al. DON Occurrence in Grains: A North American Perspective. Cereal Foods World 2015, 60, 32–56. [Google Scholar] [CrossRef]

- Simsek, S.; Ovando-Martínez, M.; Ozsisli, B.; Whitney, K.; Ohm, J.B. Occurrence of Deoxynivalenol and Deoxynivalenol-3-Glucoside in Hard Red Spring Wheat Grown in the USA. Toxins 2013, 5, 2656–2670. [Google Scholar] [CrossRef]

- Horvat, D.; Spanic, V.; Dvojkovic, K.; Simic, G.; Magdic, D.; Nevistic, A. The Influence of Fusarium Infection on Wheat (Triticum aestivum L.) Proteins Distribution and Baking Quality. Cereal Res. Commun. 2015, 43, 61–71. [Google Scholar] [CrossRef]

- Amit, S.K.; Uddin, M.M.; Rahman, R.; Islam, S.M.R.; Khan, M.S. A Review on Mechanisms and Commercial Aspects of Food Preservation and Processing. Agric. Food Secur. 2017, 6, 51. [Google Scholar] [CrossRef]

- Sánchez-Rubio, M.; Taboada-Rodríguez, A.; Cava-Roda, R.; López-Gómez, A.; Marín-Iniesta, F. Combined Use of Thermo-Ultrasound and Cinnamon Leaf Essential Oil to Inactivate Saccharomyces Cerevisiae in Natural Orange and Pomegranate Juices. LWT 2016, 73, 140–146. [Google Scholar] [CrossRef]

- Zhu, Z.; Hao, Y.; Mergoum, M.; Bai, G.; Humphreys, G.; Cloutier, S.; Xia, X.; He, Z. Breeding Wheat for Resistance to Fusarium Head Blight in the Global North: China, USA, and Canada. Crop J. 2019, 7, 730–738. [Google Scholar] [CrossRef]

- Wang, S.; Yu, J.; Xin, Q.; Wang, S.; Copeland, L. Effects of Starch Damage and Yeast Fermentation on Acrylamide Formation in Bread. Food Control 2017, 73, 230–236. [Google Scholar] [CrossRef]

- Liu, C.; Li, L.; Hong, J.; Zheng, X.; Bian, K.; Sun, Y.; Zhang, J. Effect of Mechanically Damaged Starch on Wheat Flour, Noodle and Steamed Bread Making Quality. Int. J. Food Sci. Technol. 2014, 49, 253–260. [Google Scholar] [CrossRef]

- Ortolan, F.; Brites, L.T.G.; Montenegro, F.M.; Schmiele, M.; Steel, C.J.; Clerici, M.T.P.S.; Almeida, E.L.; Chang, Y.K. Effect of Extruded Wheat Flour and Pre-Gelatinized Cassava Starch on Process and Quality Parameters of French-Type Bread Elaborated from Frozen Dough. Food Res. Int. 2015, 76, 402–409. [Google Scholar] [CrossRef] [PubMed]

- Baasandorj, T.; Ohm, J.B.; Simsek, S. Physicochemical and Bread-Making Characteristics of Millstreams Obtained from an Experimental Long-Flow Mill in Hard Red Spring Wheat. Cereal Chem. 2021, 98, 517–531. [Google Scholar] [CrossRef]

- Preston, K.R.; Kilborn, R.H.; Morgan, B.C.; Babb, J.C. Effects of Frost and Immaturity on the Quality of a Canadian Hard Red Spring Wheat. Cereal Chem. 1991, 68, 133–138. [Google Scholar]

- Khalid, K.H.; Manthey, F.; Simsek, S. Whole Grain Wheat Flour Production Using an Ultracentrifugal Mill. Cereal Chem. 2017, 94, 1001–1007. [Google Scholar] [CrossRef]

- Simsek, S.; Ohm, J.B.; Lu, H.; Rugg, M.; Berzonsky, W.; Alamri, M.S.; Mergoum, M. Effect of Pre-Harvest Sprouting on Physicochemical Changes of Proteins in Wheat. J. Sci. Food Agric. 2014, 94, 205–212. [Google Scholar] [CrossRef] [PubMed]

- Patwa, N.; Penning, B.W. Environmental Impact on Cereal Crop Grain Damage from Pre-harvest Sprouting and Late Maturity Alpha-Amylase. In Sustainable Agriculture in the Era of Climate Change; Roychowdhury, R., Choudhury, S., Hasanuzzaman, M., Srivastava, S., Eds.; Springer: Cham, Switzerland, 2020; Volume 4, pp. 23–41. [Google Scholar] [CrossRef]

- Nakamura, S. Grain Dormancy Genes Responsible for Preventing Pre-Harvest Sprouting in Barley and Wheat. Breed. Sci. 2018, 68, 295–304. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.; Cao, J.; Jiang, H.; Chang, C.; Zhang, H.P.; Sheikh, S.W.; Shah, L.; Ma, C. Unraveling Molecular and Genetic Studies of Wheat (Triticum aestivum L.) Resistance against Factors Causing Pre-Harvest Sprouting. Agronomy 2019, 9, 117. [Google Scholar] [CrossRef]

- Chen, Y.X.; Guo, X.N.; Xing, J.J.; Zhu, K.X. Effects of Tempering with Steam on the Water Distribution of Wheat Grains and Quality Properties of Wheat Flour. Food Chem. 2020, 323, 126842. [Google Scholar] [CrossRef]

- Khalid, K.H.; Manthey, F.; Simsek, S. Centrifugal Milling of Wheat Bran. Cereal Chem. 2018, 95, 330–341. [Google Scholar] [CrossRef]

- Mok, C.; Dick, J.W. Response of Starch of Different Wheat Classes to Ball Milling. Cereal Chem. 1991, 68, 409–412. [Google Scholar]

- Kumar, A.; Mantovani, E.E.; Seetan, R.; Soltani, A.; Echeverry-Solarte, M.; Jain, S.; Simsek, S.; Doehlert, D.; Alamri, M.S.; Elias, E.M.; et al. Dissection of Genetic Factors Underlying Wheat Kernel Shape and Size in an Elite × Nonadapted Cross Using a High Density SNP Linkage Map. Plant Genome 2016, 9, 1–22. [Google Scholar] [CrossRef] [PubMed]

- Xiao, D.; Bai, H.; Liu, D.L. Impact of Future Climate Change on Wheat Production: A Simulated Case for China’s Wheat System. Sustainability 2018, 10, 1277. [Google Scholar] [CrossRef]

- Richard, C.; Elwin, G.S.; Cynthia, G. Factors Influencing Wheat Yield and Variability: Evidence from Manitoba, Canada. J. Agric. Appl. Econ. 2015, 41, 625–639. [Google Scholar]

- Tsilo, T.J.; Hareland, G.A.; Simsek, S.; Chao, S.; Anderson, J.A. Genome Mapping of Kernel Characteristics in Hard Red Spring Wheat Breeding Lines. Theor. Appl. Genet. 2010, 121, 717–730. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Mantovani, E.E.; Simsek, S.; Jain, S.; Elias, E.M.; Mergoum, M. Genome Wide Genetic Dissection of Wheat Quality and Yield Related Traits and Their Relationship with Grain Shape and Size Traits in an Elite × Non-Adapted Bread Wheat Cross. PLoS ONE 2019, 14, e0221826. [Google Scholar] [CrossRef]

- Gao, X.; Tong, J.; Guo, L.; Yu, L.; Li, S.; Yang, B.; Wang, L.; Liu, Y.; Li, F.; Guo, J.; et al. Influence of Gluten and Starch Granules Interactions on Dough Mixing Properties in Wheat (Triticum aestivum L.). Food Hydrocoll. 2020, 106, 105885. [Google Scholar] [CrossRef]

- Deng, L. Whole-Wheat Flour Milling and the Effect of Durum Genotypes and Traits on Whole-Wheat Pasta Quality. Ph.D. Thesis, North Dakota State University, Fargo, ND, USA, 2017. Available online: https://ezproxy.lib.ndsu.nodak.edu/login?url=https://www.proquest.com/dissertations-theses/whole-wheat-flour-milling-effect-durum-genotypes/docview/2009010780/se-2 (accessed on 24 March 2024).

- Narpinder, S.; Jaspreet, S.; Lovedeep, K.; Navdeep, S.S.; Balmeet, S.G. Morphological, Thermal and Rheological Properties of Starches from Different Botanical Sources. Food Chem. 2003, 81, 219–231. [Google Scholar] [CrossRef]

- Zhang, P.; Hu, X.; Zhao, H.; Xia, X. Effects of High Hydrostatic Pressure and Thermal Processing on the Structure and Properties of Wheat Starch. Food Hydrocoll. 2019, 87, 72–82. [Google Scholar]

- Mehring, G.H.; Wiersma, J.J.; Stanley, J.D.; Ransom, J.K. Genetic and Environmental Predictors for Determining Optimal Seeding Rates of Diverse Wheat Cultivars. Agronomy 2020, 10, 332. [Google Scholar] [CrossRef]

- Malalgoda, M.; Meinhardt, S.W.; Simsek, S. Detection and Quantitation of Immunogenic Epitopes Related to Celiac Disease in Historical and Modern Hard Red Spring Wheat Cultivars. Food Chem. 2018, 264, 101–107. [Google Scholar] [CrossRef]

- Scherf, K.A.; Koehler, P.; Wieser, H. Gluten and Wheat Sensitivities—An Overview. J. Cereal Sci. 2016, 67, 2–11. [Google Scholar] [CrossRef]

- Schalk, K.; Lang, C.; Wieser, H.; Koehler, P.; Scherf, K.A. Quantitation of the Immunodominant 33-Mer Peptide from α-Gliadin in Wheat Flours by Liquid Chromatography Tandem Mass Spectrometry. Sci. Rep. 2017, 7, 45092. [Google Scholar] [CrossRef]

- Rahim, M.S.; Kumar, V.; Mishra, A.; Fandade, V.; Kumar, V.; Kiran Kondepudi, K.; Bishnoi, M.; Roy, J. High Resistant Starch Mutant Wheat ‘TAC 35’ Reduced Glycemia and Ameliorated High Fat Diet Induced Metabolic Dysregulation in Mice. J. Cereal Sci. 2022, 105, 103459. [Google Scholar] [CrossRef]

- Jouanin, A.; Gilissen, L.J.W.J.; Boyd, L.A.; Cockram, J.; Leigh, F.J.; Wallington, E.J.; van den Broeck, H.C.; van der Meer, I.M.; Schaart, J.G.; Visser, R.G.F.; et al. Food Processing and Breeding Strategies for Coeliac-Safe and Healthy Wheat Products. Food Res. Int. 2018, 110, 11–21. [Google Scholar] [CrossRef] [PubMed]

- Sharma, N.; Bhatia, S.; Chunduri, V.; Kaur, S.; Sharma, S.; Kapoor, P.; Kumari, A.; Garg, M. Pathogenesis of Celiac Disease and Other Gluten Related Disorders in Wheat and Strategies for Mitigating Them. Front. Nutr. 2020, 7, 1–26. [Google Scholar] [CrossRef]

- Mustafa, K.; Dizlek, H. The Effects of Two-Step Tempering Treatment on the Rheological Characteristics of Flour in Bread Wheat (Triticum aestivum L.). Kahramanmaraş Sütçü İmam Üniversitesi Tarım Doğa Derg. 2022, 25, 565–573. [Google Scholar]

- Duyvejonck, A.E.; Lagrain, B.; Pareyt, B.; Courtin, C.M.; Delcour, J.A. Relative Contribution of Wheat Flour Constituents to Solvent Retention Capacity Profiles of European Wheats. J. Cereal Sci. 2011, 53, 312–318. [Google Scholar] [CrossRef]

- Kulathunga, J.; Simsek, S. Dietary Fiber Variation in Ancient and Modern Wheat Species: Einkorn, Emmer, Spelt and Hard Red Spring Wheat. J. Cereal Sci. 2022, 104, 103420. [Google Scholar] [CrossRef]

- Sapirstein, H.; Wu, Y.; Koksel, F.; Graf, R. A Study of Factors Influencing the Water Absorption Capacity of Canadian Hard Red Winter Wheat Flour. J. Cereal Sci. 2018, 81, 52–59. [Google Scholar] [CrossRef]

- Maghirang, E.B.; Lookhart, G.L.; Bean, S.R.; Pierce, R.O.; Xie, F.; Caley, M.S.; Wilson, J.D.; Seabourn, B.W.; Ram, M.S.; Park, S.H.; et al. Comparison of Quality Characteristics and Breadmaking Functionality of Hard Red Winter and Hard Red Spring Wheat. Cereal Chem. 2006, 83, 520–528. [Google Scholar] [CrossRef]

- Waddell, I.S.; Orfila, C. Dietary Fiber in the Prevention of Obesity and Obesity-Related Chronic Diseases: From Epidemiological Evidence to Potential Molecular Mechanisms. Crit. Rev. Food Sci. Nutr. 2023, 63, 8752–8767. [Google Scholar] [CrossRef] [PubMed]

- Simsek, S.; Budak, B.; Schwebach, C.S.; Ovando-Martínez, M. Historical vs. Modern Hard Red Spring Wheat: Analysis of the Chemical Composition. Cereal Chem. 2019, 96, 937–949. [Google Scholar] [CrossRef]

- Kulathunga, J.; Reuhs, B.L.; Zwinger, S.; Simsek, S. Comparative Study on Kernel Quality and Chemical Composition of Ancient and Modern Wheat Species: Einkorn, Emmer, Spelt and Hard Red Spring Wheat. Foods 2021, 10, 761. [Google Scholar] [CrossRef] [PubMed]

- Ragaee, S.; Guzar, I.; Abdel-Aal, E.S.M.; Seetharaman, K. Bioactive Components and Antioxidant Capacity of Ontario Hard and Soft Wheat Varieties. Can. J. Plant Sci. 2012, 92, 19–30. [Google Scholar] [CrossRef]

- Žilić, S.; Basić, Z.; Hadži-Tašković Šukalović, V.; Maksimović, V.; Janković, M.; Filipović, M. Can the Sprouting Process Applied to Wheat Improve the Contents of Vitamins and Phenolic Compounds and Antioxidant Capacity of the Flour? Int. J. Food Sci. Technol. 2014, 49, 1040–1047. [Google Scholar] [CrossRef]

- Lin, L.; Yu, X.; Gao, Y.; Mei, L.; Zhu, Z.; Du, X. Physicochemical Properties and in Vitro Starch Digestibility of Wheat Starch/Rice Protein Hydrolysate Complexes. Food Hydrocoll. 2022, 125, 107348. [Google Scholar] [CrossRef]

- Hammed, A.M.; Ozsisli, B.; Ohm, J.B.; Simsek, S. Relationship between Solvent Retention Capacity and Protein Molecular Weight Distribution, Quality Characteristics, and Breadmaking Functionality of Hard Red Spring Wheat Flour. Cereal Chem. 2015, 92, 466–474. [Google Scholar] [CrossRef]

- Corassa, G.M.; Hansel, F.D.; Lollato, R.; Pires, J.L.F.; Schwalbert, R.; Amado, T.J.C.; Guarienti, E.M.; Gaviraghi, R.; Bisognin, M.B.; Reimche, G.B.; et al. Nitrogen Management Strategies to Improve Yield and Dough Properties in Hard Red Spring Wheat. Agron. J. 2018, 110, 2417–2429. [Google Scholar] [CrossRef]

- Hu, X.; Cheng, L.; Hong, Y.; Li, Z.; Li, C.; Gu, Z. Combined Effects of Wheat Gluten and Carboxymethylcellulose on Dough Rheological Behaviours and Gluten Network of Potato–Wheat Flour-Based Bread. Int. J. Food Sci. Technol. 2021, 56, 4149–4158. [Google Scholar] [CrossRef]

- Hu, X.; Cheng, L.; Hong, Y.; Li, Z.; Li, C.; Gu, Z. An Extensive Review: How Starch and Gluten Impact Dough Machinability and Resultant Bread Qualities. Crit. Rev. Food Sci. Nutr. 2023, 63, 1930–1941. [Google Scholar] [CrossRef] [PubMed]

- Simsek, S.; Budak, B.; Schwebach, C.S.; Ovando-Martínez, M. Starch Digestibility Properties of Bread from Hard Red Spring Wheat Cultivars Released in the Last 100 Years. Cereal Chem. 2020, 97, 138–148. [Google Scholar] [CrossRef]

- Park, S.H.; Wilson, J.D.; Seabourn, B.W. Starch Granule Size Distribution of Hard Red Winter and Hard Red Spring Wheat: Its Effects on Mixing and Breadmaking Quality. J. Cereal Sci. 2009, 49, 98–105. [Google Scholar] [CrossRef]

- Khalid, K.H.; Ohm, J.B.; Simsek, S. Influence of Bread-Making Method, Genotype, and Growing Location on Whole-Wheat Bread Quality in Hard Red Spring Wheat. Cereal Chem. 2022, 99, 467–481. [Google Scholar] [CrossRef]

- Lafiandra, D.; Sestili, F.; Sissons, M.; Kiszonas, A.; Morris, C.F. Increasing the Versatility of Durum Wheat through Modifications of Protein and Starch Composition and Grain Hardness. Foods 2022, 11, 1532. [Google Scholar] [CrossRef] [PubMed]

| Producing Country | Wheat Type | % Protein Content (12% mb) | Characteristics | Major Food Application | Reference(s) |

|---|---|---|---|---|---|

| USA | HWW | 10.0–14.0 | Medium to high protein | Asian noodles, pan or flat bread. | [5] |

| HRS | 12.0–15.80 | High protein, strong gluten, blendable, clean-label food | Bagels, artisan hearth baked breads, pizza crust, and other strong dough applications. | ||

| HRW | 10.0–13.0 | Medium to high protein, medium and mellow gluten, blendable | Pan breads, hard rolls, croissants, and flat bread. | ||

| SW | 8.50–10.50 | Low protein | Sponge cakes or Asian noodles. | ||

| SRW | 8.5–10.5 | High yield, low protein, weak gluten | Sponge cakes, cookies, crackers. | ||

| Durum | 12.0–15.0 | High protein and gluten | Pasta. | ||

| Canada | HRS | 13.5–14.0 | High protein, superior milling and baking quality | Pan bread, hearth baked bread, steamed bread, noodles, flat bread. | [6] |

| HRW | 11.0–13.0 | Medium to high protein, good milling quality | French breads, flat bread, steamed bread, noodles. | ||

| SRW | 8.50–12.0 | Low protein | Cakes, pastry, cereal, crackers, biscuits, and filling. | ||

| Durum | 13.5–14.0 | High yield | Pasta. | ||

| UK | HW | 10.0–15.0 | Medium to high protein | Bread, crakers. | [7] |

| SW | 11.0–11.50 | Low protein | Cakes, pastries. | ||

| Russia | HW | 12.5–16.0 | High protein | Bread and noodles. | [8] |

| SW | 12.5–13.5 | Low protein | Cakes, pastries. | ||

| Durum | 13.6 | Medium to high protein | Pasta. | ||

| Ukraine | HW | 13.51 | Medium to high protein | Bread and noodles. | [9] |

| SW | 10.79 | Low protein | Cakes and pastries. | ||

| EU | HW | 11.0–15.0 | Medium to high protein | Bread and noodles. | [10] |

| SW | 10.5–12.0 | Low protein | Cakes and pastries. | ||

| Australia | APH | >13.0 | High protein, strong dough with good WAC | Bread, noodles, and wonton skins. | |

| AH | >11.5 | Strong dough with good WAC | Pan bread, hearth baked bread, and noodles. | [11] | |

| APW | >10 | Low protein | Flat and pocket bread. | ||

| China | HW | 9.50–12.50 | Medium to high protein | Bread and noodles. | [12] |

| SW | 8.50–9.60 | Low protein | Cakes and pastries. | ||

| India | HW | 10.5–12.50 | Medium to high protein | Bread and noodles. | [13] |

| SW | 8.50–12.02 | Low protein | Cakes and pastries. | ||

| Japan | HW | 10.0–17.20 | High protein | Bread and noodles. | [14] |

| SW | 9.70–11.30 | Low protein | Cakes and pastries. |

| Sample | Protein (14%, MB) | Absorption (14%, MB) | Peak Time (Min) | Stability (Min) | Extensibility at 135 min (cm) | Resistance at 135 min (BU) | Area at 135 min (cm2) | |

|---|---|---|---|---|---|---|---|---|

| HRS | HRW | |||||||

| 0% | 100% | 12.7 | 53.7 | 1.5 | 10.6 | 686.7 | 96.3 | 8.1 |

| 10% | 90% | 12.4 | 55.9 | 1.6 | 11.4 | 639.3 | 98.7 | 10.6 |

| 20% | 80% | 12.8 | 56.4 | 6.8 | 11.5 | 694.7 | 107.3 | 13.5 |

| 30% | 70% | 12.1 | 58.3 | 6.4 | 12.1 | 723.0 | 116.0 | 13.7 |

| 40% | 60% | 12.9 | 58.2 | 7.8 | 12.0 | 779.7 | 131.7 | 13.9 |

| 100% | 0% | 13.8 | 61.7 | 13.0 | 12.7 | 1011.3 | 170.0 | 21.3 |

| Sample | Protein (14%, MB) | Absorption (14%, MB) | Pasting Temperature (°C) | Cooking Stability (Nm) | Protein Weakening Temperature (°C) | |

|---|---|---|---|---|---|---|

| HRS | HRW | |||||

| 0% | 100% | 9.4 | 62.9 | 19.59 | 0.1 | 686.7 |

| 25% | 75% | 10.8 | [24] 61.5 | 18.39 | 0.1 | 639.3 |

| 50% | 50% | 11.39 | 62.8 | 13.95 | 0.4 | 694.7 |

| 75% | 25% | 12.94 | 65.9 | 14.21 | 0.4 | 723.0 |

| 100% | 0% | 15.88 | 68.9 | 12.87 | 0.5 | 1011.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoque, M.N.; Islam, S. Comprehensive Review of the Quality and Processing Suitability of U.S. Hard Red Spring Wheat: Current Strategies, Challenges, and Future Potential Scope. Agriculture 2024, 14, 853. https://doi.org/10.3390/agriculture14060853

Hoque MN, Islam S. Comprehensive Review of the Quality and Processing Suitability of U.S. Hard Red Spring Wheat: Current Strategies, Challenges, and Future Potential Scope. Agriculture. 2024; 14(6):853. https://doi.org/10.3390/agriculture14060853

Chicago/Turabian StyleHoque, Md Najmol, and Shahidul Islam. 2024. "Comprehensive Review of the Quality and Processing Suitability of U.S. Hard Red Spring Wheat: Current Strategies, Challenges, and Future Potential Scope" Agriculture 14, no. 6: 853. https://doi.org/10.3390/agriculture14060853

APA StyleHoque, M. N., & Islam, S. (2024). Comprehensive Review of the Quality and Processing Suitability of U.S. Hard Red Spring Wheat: Current Strategies, Challenges, and Future Potential Scope. Agriculture, 14(6), 853. https://doi.org/10.3390/agriculture14060853