Evaluation of Yield and Yield Components of Rice in Vertical Agro-Photovoltaic System in South Korea

Abstract

:1. Introduction

2. Materials and Methods

2.1. Solar Panel Installations

2.2. Field Experimental Design with Rice (O. sativa L.) between the APV System and the Control Conditions

2.3. The Open Filed Condition as Control

2.4. The Measurements of Yield and Yield Components of Rice

2.5. Statistical Analysis

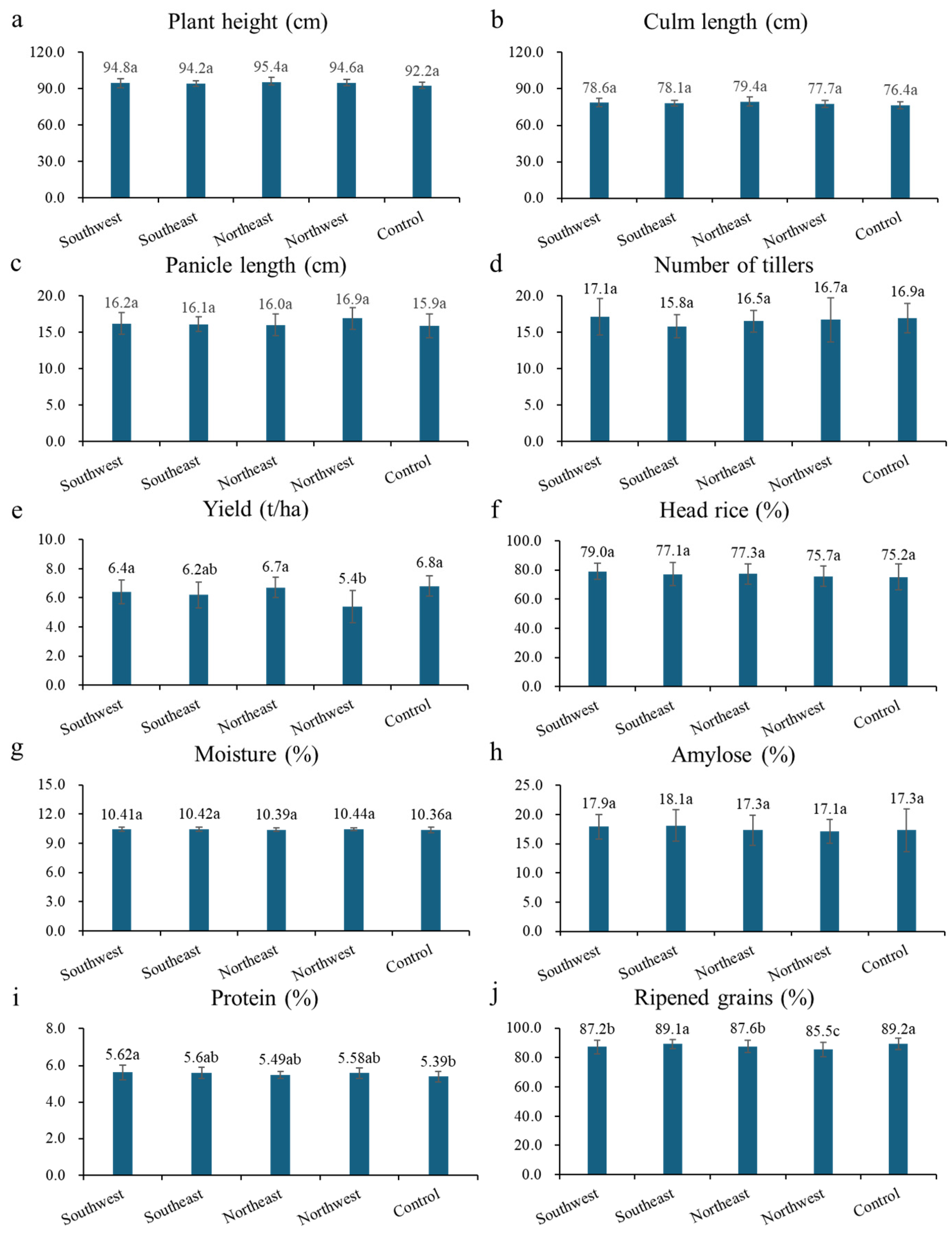

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pardey, P.G.; Beddow, J.M.; Hurley, T.M.; Beatty, T.K.; Eidman, V.R. A bounds analysis of world food futures: Global agriculture through to 2050. Aust. J. Agric. Resour. Econ. 2014, 58, 517–589. [Google Scholar] [CrossRef]

- Kim, J.Y.; Joo, G.J.; Do, Y. Through 100 years of Ecological Society of America publications: Development of ecological research topics and scientific collaborations. Ecosphere 2018, 9, e02109. [Google Scholar] [CrossRef]

- Lineman, M.; Do, Y.; Kim, J.Y.; Joo, G.J. Talking about climate change and global warming. PLoS ONE 2015, 10, e0138996. [Google Scholar] [CrossRef] [PubMed]

- Sampei, Y.; Aoyagi-Usui, M. Mass-media coverage, its influence on public awareness of climate-change issues, and implications for Japan’s national campaign to reduce greenhouse gas emissions. Glob. Environ. Chang. 2009, 19, 203–212. [Google Scholar] [CrossRef]

- Beck, M.; Bopp, G.; Goetzberger, A.; Obergfell, T.; Reise, C.; Schindele, S. Combining PV and food crops to Agrophotovoltaic–optimization of orientation and harvest. EU PVSEC Proc. 2012, 1, 4096–4100. [Google Scholar]

- Chopard, J.; Bisson, A.; Lopez, G.; Persello, S.; Richert, C.; Fumey, D. Development of a decision support system to evaluate crop performance under dynamic solar panels. AIP Publ. 2021, 2361, 050001. [Google Scholar]

- Dupraz, C.; Marrou, H.; Talbot, G.; Dufour, L.; Nogier, A.; Ferard, Y. Combining solar photovoltaic panels and food crops for optimising land use: Towards new agrivoltaic schemes. Renew. Energy 2011, 36, 2725–2732. [Google Scholar] [CrossRef]

- Marrou, H.; Guilioni, L.; Dufour, L.; Dupraz, C.; Wery, J. Microclimate under agrivoltaic systems: Is crop growth rate affected in the partial shade of solar panels? Agric. For. Meteorol. 2013, 177, 117–132. [Google Scholar] [CrossRef]

- Thompson, E.P.; Bombelli, E.L.; Shubham, S.; Watson, H.; Everard, A.; D’Ardes, V.; Schievano, A.; Bocchi, S.; Zand, N.; Howe, C.J.; et al. Tinted semi-transparent solar panels allow concurrent production of crops and electricity on the same cropland. Adv. Energy Mater. 2020, 10, 2001189. [Google Scholar] [CrossRef]

- Trommsdorff, M.; Kang, J.; Reise, C.; Schindele, S.; Bopp, G.; Ehmann, A.; Weselek, A.; Högy, P.; Obergfell, T. Combining food and energy production: Design of an agrivoltaic system applied in arable and vegetable farming in Germany. Renew. Sustain. Energy Rev. 2021, 140, 110694. [Google Scholar] [CrossRef]

- Malu, P.R.; Sharma, U.S.; Pearce, J.M. Agrivoltaic potential on grape farms in India. Sustain. Energy Technol. Assess. 2017, 23, 104–110. [Google Scholar] [CrossRef]

- Schindele, S.; Trommsdorff, M.; Schlaak, A.; Obergfell, T.; Bopp, G.; Reise, C.; Braun, C.; Weselek, A.; Bauerle, A.; Högy, P.; et al. Implementation of agrophotovoltaics: Techno-economic analysis of the price-performance ratio and its policy implications. Appl. Energy 2020, 265, 114737. [Google Scholar] [CrossRef]

- Barron-Gafford, G.A.; Pavao-Zuckerman, M.A.; Minor, R.L.; Sutter, L.F.; Barnett-Moreno, I.; Blackett, D.T.; Thompson, M.; Dimond, K.; Gerlak, A.K.; Nabhan, G.P.; et al. Agrivoltaics provide mutual benefits across the food–energy–water nexus in drylands. Nat. Sustain. 2019, 2, 848–855. [Google Scholar] [CrossRef]

- Dupraz, C.; Talbot, G.; Marrou, H.; Wery, J.; Roux, S.; Liagre, F.; Ferard, Y.; Nogier, A. To mix or not to mix: Evidences for the unexpected high productivity of new complex agrivoltaic and agroforestry systems. In Proceedings of the 5th World Congress of Conservation Agriculture: Resilient Food Systems for a Changing World, Brisbane, Australia, 26–29 September 2011. [Google Scholar]

- Fraunhofer, I.S.E. Harvesting the Sun for Power and Produce—Agrophotovoltaics Increases the Land Use Efficiency by over 60 Percent; Fraunhofer ISE: Freiburg, Germany, 2017. [Google Scholar]

- Gonocruz, R.A.; Nakamura, R.; Yoshino, K.; Homma, M.; Doi, T.; Yoshida, Y.; Tani, A. Analysis of the rice yield under an Agrivoltaic system: A case study in Japan. Environments 2021, 8, 65. [Google Scholar] [CrossRef]

- Jo, H.; Asekova, S.; Bayat, M.A.; Ali, L.; Song, J.T.; Ha, Y.S.; Hong, D.H.; Lee, J.D. Comparison of yield and yield components of several crops grown under agro-photovoltaic system in Korea. Agriculture 2022, 12, 619. [Google Scholar] [CrossRef]

- Goetzberger, A.; Zastrow, A. On the coexistence of solar-energy conversion and plant cultivation. Int. J. Sol. Energy 1982, 1, 55–69. [Google Scholar] [CrossRef]

- Amaducci, S.; Yin, X.; Colauzzi, M. Agrivoltaic systems to optimise land use for electric energy production. Appl. Energy 2018, 220, 545–561. [Google Scholar] [CrossRef]

- Katsikogiannis, O.A.; Ziar, H.; Isabella, O. Integration of bifacial photovoltaics in agrivoltaic systems: A synergistic design approach. Appl. Energy 2022, 309, 118475. [Google Scholar] [CrossRef]

- Khan, M.R.; Hanna, A.; Sun, X.; Alam, M.A. Vertical bifacial solar farms: Physics, design, and global optimization. Appl. Energy 2017, 206, 240–248. [Google Scholar] [CrossRef]

- Fischer, M.; Woodhouse, M.; Herritsch, S.; Trube, J. International Technology Roadmap for Photovoltaic (ITRPV), 12th ed.; VDMA: Frankfurt, Germany, 2021; Available online: https://itrpv.vdma.org/en/ (accessed on 1 May 2024).

- KOSIS 2023 Database Statistics. Available online: https://kosis.kr/index/index.do (accessed on 1 May 2024).

- Kern, F.; Rogge, K.S. The pace of governed energy transitions: Agency, international dynamics and the global Paris agreement accelerating decarbonisation processes? Energy Res. Soc. Sci. 2016, 22, 13–17. [Google Scholar] [CrossRef]

- UN Environment Programme. 2019. Available online: http://www.unenvironment.org/resources/emissions-gap-report-2019 (accessed on 1 May 2024).

- Homma, M.; Doi, T.; Yoshida, Y. A field experiment and the simulation on agrivoltaic-systems regarding to rice in a paddy field. J. Jpn. Soc. Energy Resour. 2016, 37, 23–31. [Google Scholar]

- Lott, J.E.; Ong, C.K.; Black, C.R. Understorey microclimate and crop performance in a Grevillea robusta-based agroforestry system in semi-arid Kenya. Agric. For. Meteorol. 2009, 149, 1140–1151. [Google Scholar] [CrossRef]

- Lee, H.J.; Park, H.H.; Kim, Y.O.; Kuk, Y.I. Crop cultivation underneath agro-photovoltaic systems and its effects on crop growth, yield, and photosynthetic efficiency. Agronomy 2022, 12, 1842. [Google Scholar] [CrossRef]

- Ahmed, M.S.; Khan, M.R.; Haque, A.; Khan, M.R. Agrivoltaics analysis in a techno-economic framework: Understanding why agrivoltaics on rice will always be profitable. Appl. Energy 2022, 323, 119560. [Google Scholar] [CrossRef]

- Martin, M.; Fitzgerald, M.A.Ã. Proteins in Rice Grains Influence Cooking Properties! J. Cereal Sci. 2002, 36, 285–294. [Google Scholar] [CrossRef]

- Shibata, Y. How Can “Solar PV + Battery System” Be Economically Competitive and Reliable Power Generation; The Institute of Energy Economics (IEEJ): Tokyo, Japan, 2017; pp. 1–23. [Google Scholar]

- Lamers, J.; Van Der Meer, T.; Testerink, C. How plants sense and respond to stressful environments. Plant Physiol. 2020, 182, 1624–1635. [Google Scholar] [CrossRef]

- Heidari, N.; Gwamuri, J.; Townsend, T.; Pearce, J.M. Impact of snow and ground interference on photovoltaic electric system performance. IEEE J. Photovolt. 2015, 5, 1680–1685. [Google Scholar] [CrossRef]

| Source of Variation | Degree of Freedom | Plant Height | Culm Length | Panicle Length | Number of Tillers | Yield | Head Rice | Moisture | Amylose | Protein | Ripened Grains |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Year | 1 | 507.0 *** | 1009.5 *** | 88.1 *** | 205.7 *** | 24.3 *** | 4180.8 *** | 0.25 * | 914.9 *** | 4.14 *** | 1455.3 *** |

| Rep(year) | 4 | 3.9 ns | 10.7 * | 9.1 *** | 9.6 ** | 2.3 *** | 20.9 ns | 0.27 *** | 3.2 * | 0.23 *** | 32.0 * |

| Direction (d) | 4 | 48.2 ns | 43.9 ns | 3.8 ns | 7.1 ns | 7.7 ns | 90.4 ns | 0.03 ns | 5.5 ** | 0.32 ns | 52.9 ** |

| Year × d | 4 | 31.8 *** | 33.3 *** | 7.7 *** | 4.6 ns | 1.3 ** | 131.8 *** | 0.18 ** | 8.0 *** | 0.09 ns | 2.3 ns |

| Sub-block (sb) | 9 | 8.5 * | 4.9 ns | 1.7 ns | 5.8 ns | 0.7 ns | 34.6 ns | 0.03 ns | 0.8 ns | 0.19 * | 5.4 ns |

| Year × sb | 9 | 2.4 ns | 2.5 ns | 0.9 ns | 3.7 ns | 0.8 * | 29.3 ns | 0.02 ns | 1.0 ns | 0.06 ns | 3.2 ns |

| d × sb | 18 | 10.1 ns | 6.5 ns | 1.1 ns | 5.6 ns | 0.7 ns | 17.9 ** | 0.06 ns | 1.0 ns | 0.12 ** | 7.9 ns |

| Year × d × sb | 18 | 7.6 * | 5.6 ns | 0.9 ns | 6.3 ** | 0.9 *** | 5.7 ns | 0.03 ns | 0.6 ns | 0.03 ns | 9.6 ns |

| Error | 104 | 4.3 | 3.6 | 1.4 | 2.4 | 0.3 | 24.1 | 0.04 | 1.3 | 0.04 | 9.5 |

| Environments | Plant Height (cm) | Culm Length (cm) | Panicle Length (cm) | Number of Tillers | Yield (t/ha) | Head Rice (%) | Moisture (%) | Amylose (%) | Protein (%) | Percentage of Ripened Grains per Hill (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| 2022 southwest | 95.4 ± 4.3a | 78.8 ± 4.0a | 16.5 ± 2.2a | 16.7 ± 2.4ab | 6.4 ± 0.8a | 78.5 ± 6.7a | 10.38 ± 0.24ab | 17.8 ± 2.5a | 5.7 ± 0.4a | 87.3 ± 4.9bc |

| 2022 southeast | 94.9 ± 3.4ab | 78.6 ± 3.9ab | 16.3 ± 1.3ab | 16.3 ± 2.6b | 6.4 ± 0.6a | 76.2 ± 7.4a | 10.46 ± 0.24a | 17.2 ± 3.6a | 5.6 ± 0.2ab | 88.0 ± 3.7ab |

| 2022 northeast | 94.7 ± 2.8ab | 78.5 ± 3.4ab | 16.2 ± 1.4ab | 16.0 ± 1.7b | 6.2 ± 1.0a | 77.5 ± 7.5a | 10.37 ± 0.20ab | 17.7 ± 2.5a | 5.6 ± 0.3ab | 87.6 ± 4.5abc |

| 2022 northwest | 94.2 ± 2.8abc | 78.3 ± 3.5ab | 15.8 ± 1.5ab | 16.7 ± 2.0ab | 6.3 ± 1.1a | 76.0 ± 8.0a | 10.44 ± 0.21ab | 17.6 ± 2.6a | 5.5 ± 0.2ab | 87.4 ± 3.8abc |

| 2022 control | 93.6 ± 3.1bc | 77.3 ± 3.6b | 16.3 ± 1.3a | 16.7 ± 1.9ab | 6.2 ± 1.1a | 76.6 ± 8.2a | 10.41 ± 0.23ab | 17.5 ± 2.5a | 5.5 ± 0.2ab | 88.1 ± 4.2ab |

| 2023 southwest | 94.2 ± 2.7abc | 78.1 ± 3.0ab | 16.2 ± 1.1ab | 17.4 ± 1.5ab | 6.8 ± 0.8a | 76.0 ± 4.8a | 10.36 ± 0.19ab | 17.4 ± 2.5a | 5.4 ± 0.2ab | 87.0 ± 5.2bc |

| 2023 southeast | 93.0 ± 2.1c | 77.6 ± 2.5ab | 15.4 ± 1.3b | 17.3 ± 2.4ab | 6.3 ± 10.7a | 80.4 ± 6.2a | 10.33 ± 0.18b | 17.7 ± 2.5a | 5.4 ± 0.2ab | 87.2 ± 4.7bc |

| 2023 northeast | 94.5 ± 3.3ab | 78.4 ± 3.0ab | 16.2 ± 1.5ab | 18.3 ± 3.1a | 6.6 ± 0.8a | 79.4 ± 3.6a | 10.38 ± 0.22ab | 17.4 ± 1.7a | 5.6 ± 0.2ab | 87.9 ± 4.8ab |

| 2023 northwest | 94.2 ± 2.5abc | 78.3 ± 2.9ab | 16.0 ± 0.9ab | 17.8 ± 2.3ab | 6.7 ± 0.7a | 78.9 ± 6.4a | 10.35 ± 0.23ab | 17.8 ± 2.4a | 5.2 ± 0.9c | 86.1 ± 6.4c |

| 2023 control | 93.8 ± 2.5bc | 77.7 ± 2.8ab | 16.1 ± 0.9ab | 17.5 ± 2.6ab | 6.8 ± 0.8a | 78.4 ± 6.7a | 10.42 ± 0.20ab | 18.0 ± 2.4a | 5.5 ± 0.2ab | 89.1 ± 3.5a |

| LSD | 1.5 | 1.5 | 0.9 | 1.8 | 0.8 | 5.1 | 0.13 | 0.9 | 0.2 | 1.7 |

| Direction | Sub-Block | 2022 | 2023 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Plant Height (cm) | Number of Tillers | Yield (t/ha) | Yield Index (%) | Plant Height (cm) | Number of Tillers | Yield (t/ha) | Yield Index (%) | ||

| Southwest | 1 | 103.2 ± 8.0 | 18.8 ± 0.4 | 6.4 ± 0.4 | 103.9 | 93.6 ± 1.9 | 15.4 ± 1.9 | 6.6 ± 0.9 | 97.4 |

| 2 | 99.4 ± 1.9 | 17.2 ± 2.5 | 6.2 ± 0.2 | 100.9 | 92.6 ± 2.3 | 14.7 ± 1.9 | 6.7 ± 0.7 | 97.7 | |

| 3 | 98.5 ± 0.8 | 16.7 ± 0.4 | 6.7 ± 0.9 | 108.9 | 93.5 ± 2.2 | 15.6 ± 1.2 | 6.6 ± 0.6 | 96.8 | |

| 4 | 97.0 ± 1.4 | 16.9 ± 1.1 | 5.1 ± 0.7 | 81.9 | 92.7 ± 1.6 | 15.7 ± 1.6 | 7.0 ± 0.7 | 102.1 | |

| 5 | 97.1 ± 0.6 | 19.3 ± 1.9 | 6.0 ± 0.7 | 96.9 | 91.5 ± 2.2 | 15.5 ± 1.2 | 6.5 ± 0.8 | 94.7 | |

| 6 | 95.7 ± 1.0 | 19.1 ± 1.3 | 5.7 ± 0.3 | 92.9 | 92.7 ± 2.9 | 16.2 ± 0.4 | 7.2 ± 0.5 | 105.0 | |

| 7 | 94.9 ± 0.1 | 20.5 ± 1.7 | 5.3 ± 0.4 | 85.9 | 91.7 ± 2.1 | 16.8 ± 1.2 | 7.2 ± 0.6 | 105.0 | |

| 8 | 96.3 ± 1.3 | 20.3 ± 2.7 | 6.0 ± 0.2 | 97.9 | 92.7 ± 4.1 | 16.2 ± 1.9 | 7.2 ± 0.8 | 105.0 | |

| 9 | 95.7 ± 0.8 | 19.6 ± 1.0 | 6.7 ± 0.9 | 108.9 | 92.8 ± 2.9 | 15.9 ± 1.4 | 6.7 ± 0.5 | 98.6 | |

| 10 | 95.2 ± 2.1 | 18.1 ± 3.5 | 6.3 ± 0.4 | 101.9 | 92.3 ± 2.2 | 16.9 ± 1.7 | 7.3 ± 0.7 | 107.7 | |

| LSD0.05 | 4.4 | 3.4 | 10.3 | 4.2 | 3.3 | 1.2 | |||

| Southeast | 1 | 94.3 ± 1.7 | 16.8 ± 1.2 | 6.8 ± 0.7 | 109.4 | 95.5 ± 3.6 | 14.7 ± 1.8 | 6.8 ± 0.2 | 99.1 |

| 2 | 97.2 ± 0.1 | 17.4 ± 1.1 | 6.0 ± 0.4 | 96.7 | 94.7 ± 3.9 | 13.3 ± 0.6 | 6.4 ± 1.7 | 93.4 | |

| 3 | 93.4 ± 0.5 | 15.3 ± 0.1 | 5.0 ± 0.9 | 81.5 | 96.0 ± 2.6 | 15.7 ± 0.8 | 6.8 ± 0.7 | 99.1 | |

| 4 | 92.2 ± 0.8 | 17.0 ± 1.7 | 5.8 ± 0.7 | 94.2 | 92.5 ± 0.4 | 14.7 ± 1.2 | 7.3 ± 0.3 | 107.2 | |

| 5 | 92.4 ± 3.7 | 17.2 ± 2.1 | 5.5 ± 0.2 | 89.1 | 93.8 ± 2.9 | 16.4 ± 1.1 | 5.3 ± 1.3 | 78.4 | |

| LSD0.05 | 4.8 | 3.7 | 1.6 | 7.6 | 3.1 | 2.6 | |||

| Northeast | 1 | 97.5 ± 1.7 | 17.1 ± 1.2 | 6.5 ± 0.2 | 105.9 | 95.1 ± 1.2 | 15.7 ± 1.2 | 7.1 ± 0.4 | 103.6 |

| 2 | 98.6 ± 0.6 | 17.5 ± 1.5 | 6.7 ± 0.3 | 107.9 | 92.6 ± 2.5 | 15.3 ± 2.3 | 6.8 ± 0.5 | 99.5 | |

| 3 | 98.9 ± 1.1 | 18.2 ± 2.6 | 6.7 ± 0.5 | 107.9 | 93.7 ± 0.9 | 14.7 ± 0.4 | 6.6 ± 0.7 | 96.4 | |

| 4 | 99.2 ± 1.4 | 17.8 ± 0.8 | 6.4 ± 1.1 | 102.9 | 94.3 ± 1.6 | 16.4 ± 0.8 | 7.0 ± 0.1 | 102.3 | |

| 5 | 97.1 ± 2.0 | 17.2 ± 0.5 | 6.3 ± 1.1 | 101.9 | 92.7 ± 1.5 | 15.5 ± 0.6 | 7.3 ± 0.3 | 107.2 | |

| 6 | 95.7 ± 2.1 | 18.2 ± 0.3 | 7.2 ± 0.8 | 116.9 | 93.9 ± 1.7 | 16.0 ± 0.3 | 7.5 ± 0.5 | 109.5 | |

| 7 | 93.8 ± 0.8 | 14.9 ± 1.0 | 5.7 ± 0.9 | 91.9 | 92.7 ± 1.2 | 16.6 ± 0.6 | 6.9 ± 0.2 | 100.5 | |

| LSD0.05 | 2.6 | 2.3 | 1.4 | 2.8 | 1.9 | 75.7 | |||

| Northwest | 1 | 97.1 ± 1.0 | 22.2 ± 0.3 | 5.5 ± 0.2 | 89.1 | 92.5 ± 0.9 | 15.7 ± 1.1 | 5.7 ± 0.4 | 83.0 |

| 2 | 98.6 ± 0.6 | 20.9 ± 5.6 | 5.5 ± 0.2 | 89.1 | 94.2 ± 1.7 | 16.4 ± 1.1 | 6.7 ± 0.6 | 98.0 | |

| 3 | 94.7 ± 1.8 | 13.9 ± 0.9 | 3.9 ± 0.2 | 63.6 | 94.0 ± 1.1 | 16.0 ± 1.3 | 6.3 ± 0.7 | 92.2 | |

| 4 | 95.2 ± 0.1 | 15.4 ± 1.0 | 4.2 ± 0.2 | 68.7 | 92.0 ± 0.3 | 15.1 ± 2.3 | 6.2 ± 10.0 | 91.1 | |

| 5 | 94.7 ± 0.3 | 15.5 ± 1.1 | 3.5 ± 0.4 | 56.0 | 92.8 ± 0.1 | 16.4 ± 0.1 | 6.3 ± 0.4 | 92.2 | |

| LSD0.05 | 2.5 | 6.7 | 0.7 | 2.6 | 3.5 | 1.7 | |||

| Control | 1 | 92.7 ± 0.9 | 15.9 ± 1.0 | 5.8 ± 0.3 | 100.0 | 92.0 ± 1.1 | 16.6 ± 1.9 | 7.4 ± 0.7 | 100.0 |

| 2 | 92.7 ± 0.8 | 16.9 ± 0.8 | 6.4 ± 0.5 | 90.8 ± 0.9 | 15.9 ± 1.4 | 6.5 ± 0.5 | |||

| 3 | 93.1 ± 1.7 | 17.0 ± 2.1 | 6.2 ± 0.7 | 90.5 ± 1.6 | 15.8 ± 0.9 | 7.0 ± 0.2 | |||

| 4 | 93.5 ± 2.7 | 20.4 ± 1.6 | 6.5 ± 0.1 | 91.0 ± 1.7 | 16.1 ± 1.3 | 7.7 ± 0.8 | |||

| 5 | 96.1 ± 2.2 | 19.2 ± 1.1 | 7.3 ± 0.3 | 90.1 ± 1.2 | 15.0 ± 0.5 | 6.6 ± 0.3 | |||

| LSD0.05 | 3.3 | 2.6 | 0.7 | 2.4 | 2.4 | 10.1 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jo, H.; Song, J.T.; Cho, H.; Lee, S.; Choi, S.; Jung, H.-J.; Lee, H.-N.; Lee, J.-D. Evaluation of Yield and Yield Components of Rice in Vertical Agro-Photovoltaic System in South Korea. Agriculture 2024, 14, 920. https://doi.org/10.3390/agriculture14060920

Jo H, Song JT, Cho H, Lee S, Choi S, Jung H-J, Lee H-N, Lee J-D. Evaluation of Yield and Yield Components of Rice in Vertical Agro-Photovoltaic System in South Korea. Agriculture. 2024; 14(6):920. https://doi.org/10.3390/agriculture14060920

Chicago/Turabian StyleJo, Hyun, Jong Tae Song, Hyeonjun Cho, Sangyeab Lee, Seungmin Choi, Ho-Jun Jung, Hyeong-No Lee, and Jeong-Dong Lee. 2024. "Evaluation of Yield and Yield Components of Rice in Vertical Agro-Photovoltaic System in South Korea" Agriculture 14, no. 6: 920. https://doi.org/10.3390/agriculture14060920