Technical Efficiency and Allocative Efficiency of Beef Cattle Fattening in the Content of Digital Economy: An Empirical Study Based on Survey in China

Abstract

:1. Introduction

2. Literature Review

3. Materials and Methods

3.1. The Modeling Approaches

3.1.1. Efficiency Measurement Models

3.1.2. Evaluation Model of the Influencing Factors: Tobit Regression Model

3.2. Materials

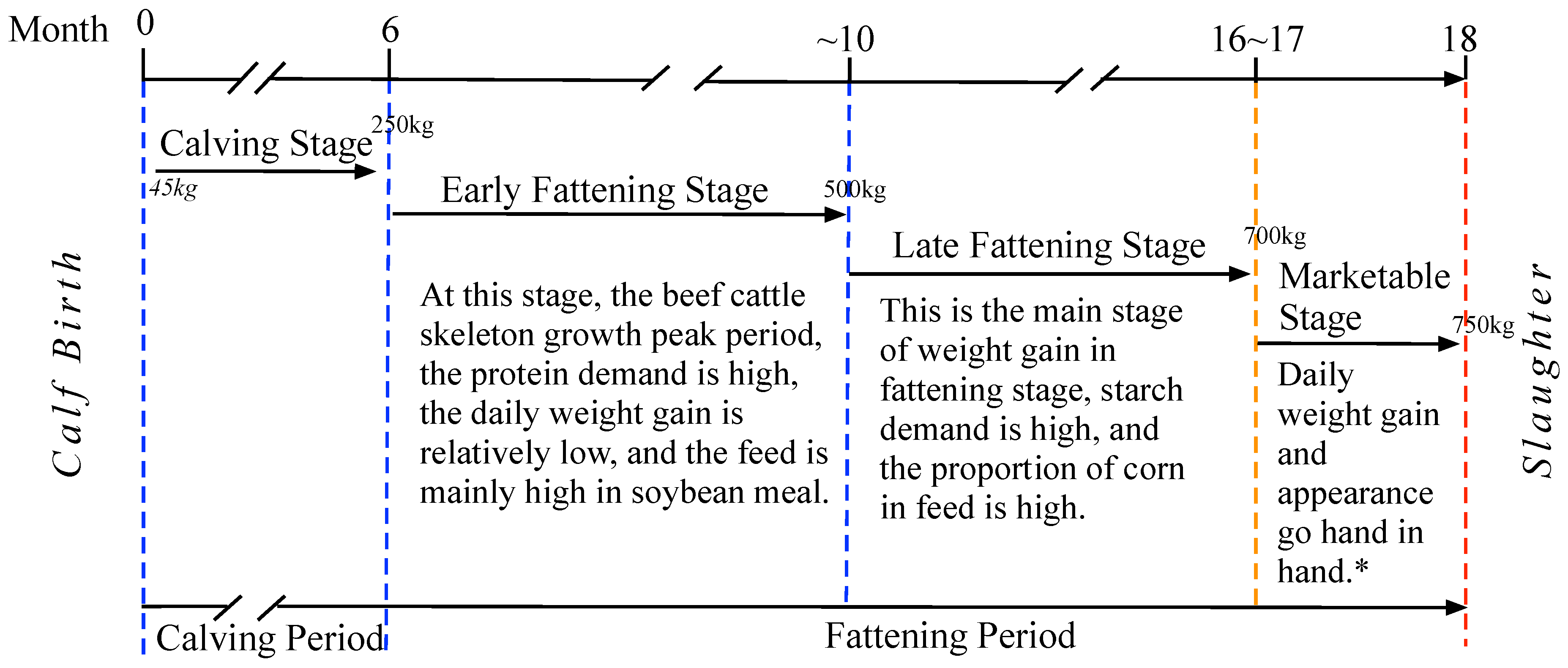

3.2.1. Beef Cattle Professional Fattening in China

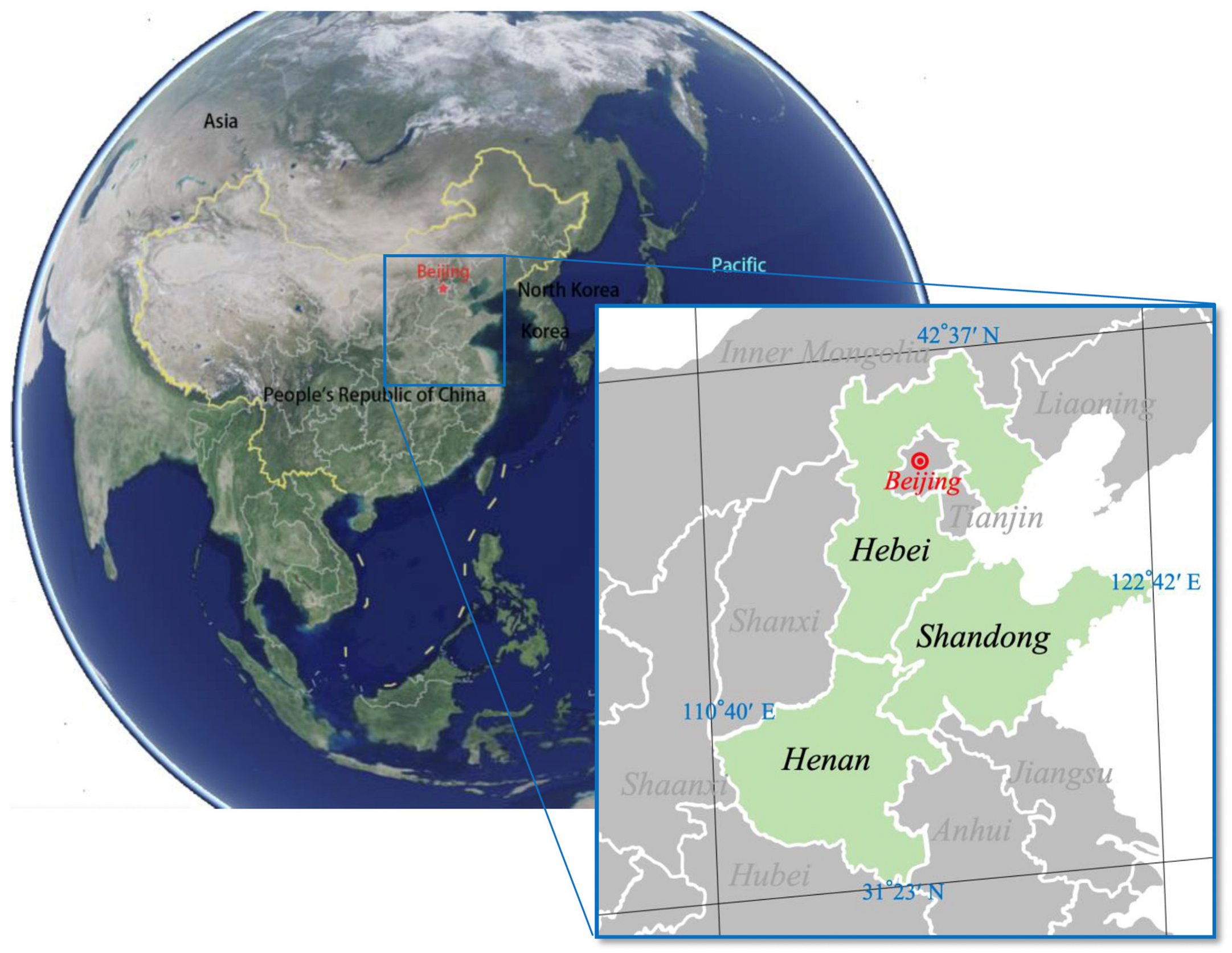

3.2.2. Areas of Survey

3.2.3. Variable Selection and Data Description

3.2.4. Data Description

4. Results

4.1. Technical Efficiency of Beef Cattle Fattening

4.2. Efficiency of Input Allocation in Beef Cattle Fattening

4.2.1. Cost Efficiency (CE) and Input Factor Allocation Efficiency (IAE)

4.2.2. Revenue Efficiency (RE) and Profit Efficiency (PE)

4.3. Estimation Results of Influencing Factors on the Efficiency of Beef Cattle Fattening

4.3.1. Estimation Results of Influencing Factors on the TE

4.3.2. Estimation Results of Influencing Factors on the Allocation Efficiency

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Farrell, M.J. The measurement of productive efficiency. J. R. Stat. Soc. Ser. A 1957, 120, 253–281. [Google Scholar] [CrossRef]

- Frenkel, J.A.; Razin, A. Variable Factor Supplies and the Production Possibility Frontier. S. Econ. J. 1975, 41, 410–419. [Google Scholar] [CrossRef]

- Cheng, G. Date Envelopment Analysis: Methods and Maxdea Softwave; Intellectual Property Publishing House: Beijing, China, 2014. [Google Scholar]

- Shi-quan, W.; Chang, Q.; Li, B.-l. Production Efficiency and Influencing Factors of Scale Farmers: Empirical Evidence from Mutton Sheep Aggregation Region. J. Agro-For. Econ. Manag. 2017, 16, 230–239. [Google Scholar]

- Leibenstein, H. Allocative efficiency vs. “X-efficiency”. Am. Econ. Rev. 1966, 56, 392–415. [Google Scholar]

- Coelli, T.J.; Rao, D.S.P.; O’Donnell, C.J.; Battese, G.E. An Introduction to Efficiency and Productivity Analysis; Springer Science & Bussiness Media: New York, NY, USA, 2005. [Google Scholar]

- Färe, R.; Grosskopf, S.; Lovell, C.K. The Measurement of Efficiency of Production; Springer Science & Business Media: New York, NY, USA, 2013; Volume 6. [Google Scholar]

- Cooper, W.W.; Seiford, L.M.; Tone, K. Data Envelopment Analysis: A Comprehensive Text with Models, Applications, References and DEA-Solver Software; Springer: New York, NY, USA, 2007. [Google Scholar]

- Färe, R.; Grosskopf, S.; Norris, M.; Zhang, Z. Productivity growth, technical progress, and efficiency change in industrialized countries. Am. Econ. Rev. 1994, 84, 66–83. [Google Scholar]

- Fare, R.; Grosskopf, S.; Lovell, C.K. Production Frontiers; Cambridge University Press: Cambridge, UK, 1994. [Google Scholar]

- Balk, B.M. Industrial Price, Quantity, and Productivity Indices: The Micro-Economic Theory and an Application; Springer Science & Business Media: New York, NY, USA, 2013. [Google Scholar]

- Xue, Y.; Yan, J.; Cui, Y.; Zhao, H.; Zhang, Y.n.; Ma, C.; Zheng, H. The Technical Efficiency of Beef Calf Production Systems: Evidence from a Survey in Hebei, China. Agriculture 2022, 12, 1604. [Google Scholar] [CrossRef]

- Ma, X.; Wang, M. Comparison of Economic Efficiency of Beef CattleProduction in Typical Countries and Its Enlightenment to China. J. Northwest AF Unvi. 2023, 23, 138–152. [Google Scholar] [CrossRef]

- Zhao, H.; Ma, C.; Gao, Y. Economic Study on Beef Cattle Industry in Hebei Province; China Agriculture Press: Beijing, China, 2021. [Google Scholar]

- Haixiu, G.; Mingli, W.; Zizhong, S. Analysis on eco-efficiency and influencing factors of beef cattle in China. Chin. J. Agric. Resour. Reg. Plan. 2021, 42, 153–159. [Google Scholar]

- Cao, B.; Zhang, Y.; Li, J.-y.; Wang, Z.; Guo, A.-z.; Liu, J.; Sun, B.-z. Beef Cattle and Yak Industry Technology Development Report of 2021. Chin. J. Anim. Sci. 2022, 58, 245–250. [Google Scholar]

- Xue, Y.J.; Yan, J.L. Breeding efficiency of beef cattle in Chinese suitable areas. J. Anim. Plant Sci. 2019, 29, 1413–1423. [Google Scholar]

- Yue, l.; Wang, X. Analysis of Agricultural technical efficiency and Total factor Productivity in China from the perspective of environmental regulation: Based on distance function method. Jilin Univ. J. Soc. Sci. Ed. 2013, 53, 85–92. [Google Scholar] [CrossRef]

- Martins, M.M.; Spolador, H.F.; Njuki, E. Production environment and managerial techniques in explaining productivity growth in Brazilian beef cattle production. Agribusiness 2022, 38, 371–385. [Google Scholar] [CrossRef]

- Li, L.; Liu, J. Analysis on Cost Efficiency and Influencing Factors of Free-Range Beef Cattle Breeding in China. Ph.D. Thesis, Beijing Technology and Business University, Beijing, China, 2019. Available online: https://link.cnki.net/doi/10.19463/j.cnki.sdjm.2019.22.022 (accessed on 20 July 2023).

- Oduniyi, O.S.; Rubhara, T.T.; Antwi, M.A. Sustainability of livestock farming in South Africa. Outlook on production constraints, climate-related events, and upshot on adaptive capacity. Sustainability 2020, 12, 2582. [Google Scholar] [CrossRef]

- Visser, C.; Van Marle-Köster, E.; Myburgh, H.C.; De Freitas, A. Phenomics for sustainable production in the South African dairy and beef cattle industry. Anim. Front. 2020, 10, 12–18. [Google Scholar] [CrossRef]

- Arelovich, H.M.; Bravo, R.D.; Martínez, M.F. Development, characteristics, and trends for beef cattle production in Argentina. Anim. Front. 2011, 1, 37–45. [Google Scholar] [CrossRef]

- Xue, Y.; Yan, J.; Zhao, H.; Zheng, H.; Ma, C. Can domestic animal husbandry develop independently? An empirical study of China’s beef cattle industry. Pak. J. Zool. 2022, 54, 1001–1500. [Google Scholar] [CrossRef]

- Krisztián, K.; Ratnesh, P. Hungarian dairy and beef production sector technical efficiency comparsion using DEA. Apstract Appl. Stud. Agribus. Commer. 2017, 11, 131–140. [Google Scholar]

- Zhang, C. A Study on The Competitiveness of Chinese Rice Sector and Its Determants. Ph.D. Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2018. [Google Scholar]

- Zhong, P.; Lu, W.; Xu, Z. Is rural labor migration bad for grain production? Analysis of farmers’ factor substitution and planting structure adjustment behavior and constraints. Chin. Rural Econ. 2016, 36–47. [Google Scholar]

- Mlote, N. Estimating technical efficiency of small scale beef cattle fattening in the lake zone in Tanzania. J. Dev. Agric. Econ. 2013, 5, 197–207. [Google Scholar] [CrossRef]

- Yu, L. The Impact of Environmental Regulation on Green Total Factor Productivity of Pig Breeding Industry. Ph.D. Thesis, Southwest University, El Paso, TX, USA, 2020. [Google Scholar]

- Khunchaikarn, S.; Mankeb, P.; Suwanmaneepong, S. Economic efficiency of beef cattle production in Thailand. J. Manag. Inf. Decis. Sci. 2020, 25, 1–9. [Google Scholar]

- Xue, Y.; Yan, J.; Zhao, H.; Zheng, H. Japan’s beef cattle industry and supporting policies under the COVID-19 epidemic. World Agric. 2021, 28–37+129. [Google Scholar]

- Porter, M.E. America’s green strategy. Sci. Merican 1991, 264, 168. [Google Scholar]

- Liu, W.; Tang, D. Environmental Regulation, Technological Efficiency and Total Factor Productivity Growth. Ind. Econ. Res. 2012, 27–35. [Google Scholar] [CrossRef]

- Xu, D.-l.; Dong, B. Empirical Analysis of the Impact of Environmental Regulations on Technical Efficiency and Productivity Loss. China Popul. Resour. Environ. 2009, 19, 91–96. [Google Scholar]

- Jiang, X.-l.; Chen, C.-b. The Efficiency Analysis on the New Direct Agricultural Subsidy Based on the Factor Allocation Model of Farmers. Econ. Surv. 2013, 22–26. [Google Scholar] [CrossRef]

- Wang, X. Research on Economic Efficiency of Mutton Sheep Production in China; China Agricultural University: Beijing, China, 2018. [Google Scholar]

- CARS-38; Research on Sustainable Development Strategy of Modern Agricultural Industry in China: Beef Cattle Yak Strategy Research Volume. China Agriculture Press: Beijing, China, 2016.

- Tone, K. Dealing with undesirable outputs in DEA: A slacks-based measure (SBM) approach. GRIPS Discuss. Pap. 2015, 1. [Google Scholar]

- Cooper, W.W.; Seiford, L.M.; Zhu, J. Handbook on Data Envelopment Analysis, 2nd ed.; Springer: New York, NY, USA, 2011. [Google Scholar] [CrossRef]

- Simar, L.; Wilson, P.W. Two-stage DEA: Caveat emptor. J. Product. Anal. 2011, 36, 205–218. [Google Scholar] [CrossRef]

- Johnson, A.L.; Kuosmanen, T. One-stage and two-stage DEA estimation of the effects of contextual variables. Eur. J. Oper. Res. 2012, 220, 559–570. [Google Scholar] [CrossRef]

- Badunenko, O.; Tauchmann, H. Simar and Wilson two-stage efficiency analysis for Stata. Stata J. 2019, 19, 950–988. [Google Scholar] [CrossRef]

- Terry, S.A.; Basarab, J.A.; Guan, L.L.; McAllister, T.A. Strategies to improve the efficiency of beef cattle production. Can. J. Anim. Sci. 2020, 101, 1–19. [Google Scholar] [CrossRef]

- Lv, W.; Zhang, X.; Wang, W. Agricultural machinery purchase subsidy, agricultural production efficiency and rural labor transfer. Chin. Rural Econ. 2015, 22–32. [Google Scholar]

- Liu, G.; Luo, Q.; Zhang, L. 40th anniversary of animal husbandry reform and opening up: Achievements, challenges and countermeasures. Chin. Rural Econ. 2018, 19–36. [Google Scholar]

- Cao, B.; Cao, J.; Lee, J.; Guo, A.; Wang, Z.; Sun, B.; Chen, Z. 2023 Beef yak Industry and Technology development Report. Chin. J. Anim. Sci. 2024, 60, 335–338. [Google Scholar] [CrossRef]

- Cao, B.; Lee, J.; Wang, Z.; Guo, A.; Chen, Z.; Sun, B.; Cao, J. Development trend and policy suggestions of beef yak industry in 2023. Chin. J. Anim. Sci. 2023, 59, 323–329. [Google Scholar] [CrossRef]

- Bascom, S.; Young, A. A summary of the reasons why farmers cull cows. J. Dairy Sci. 1998, 81, 2299–2305. [Google Scholar] [CrossRef]

- Yan, J.; Xue, Y.; Quan, C.; Wang, B.; Zhang, Y. Oligopoly in grain production and consumption: An empirical study on soybean international trade in China. Econ. Res.-Ekon. Istraživanja 2022, 36, 2142818. [Google Scholar] [CrossRef]

- Shi, S.; Li, C.; Li, M. Review of research from carbon emissions to carbon footprint in livestock husbandry. China Popul. Resour. Environ. 2017, 27, 36–41. [Google Scholar]

- Chen, X.; Kai, F. An Analysis on the Influencing Factors of Farmers Participating in Specialized Cooperative and Their Economic Benefits Empirical Analysis Based on 207 waterfowl farmers of Guangdong Province. Prices Mon. 2016, 80–86. [Google Scholar] [CrossRef]

- Porter, M.E. Competitive Strategy. Meas. Bus. Excell. 1997, 1, 12–17. [Google Scholar] [CrossRef]

- Huang, W.; Yang, C.; Min, R. Impact of new-type agricultural operating entities on green transformation of smallholders’ production. J. Arid Land Resour. Environ. 2024, 38, 69–78. [Google Scholar] [CrossRef]

- Gotoh, T.; Nishimura, T.; Kuchida, K.; Mannen, H. The Japanese Wagyu beef industry: Current situation and future prospects—A review. Asian Austral. J. Anim. 2018, 31, 933. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.-g.; Wang, M.-l.; Yang, C. Development Stage and Its Patio-Temporal Evolution of Beef Cattle Industry in China. Econ. Geogr. 2014, 34, 131–136+170. [Google Scholar] [CrossRef]

| 10,000 Tons | Nationwide | Hebei | Shandong | Henan | Total Proportion (%) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10,000 Heads | Slaughtered Fattened Cattle | Output of Beef | Slaughtered Fattened Cattle | Output of Beef | Slaughtered Fattened Cattle | Output of Beef | Slaughtered Fattened Cattle | Output of Beef | Slaughtered Fattened Cattle | Output of Beef |

| 2020 | 4565.45 | 672.4 | 335.2 | 55.57 | 275.71 | 59.7 | 241.25 | 36.71 | 18.67% | 22.60% |

| 2021 | 4707.43 | 697.51 | 339.9 | 55.85 | 280.03 | 61.3 | 235.94 | 35.53 | 18.18% | 21.89% |

| 2022 | 4839.91 | 718.26 | 353.2 | 58.08 | 275.6 | 60.4 | 243.78 | 36.71 | 18.03% | 21.61% |

| Type | Variables | Unit | Small-Scale Farm | Medium-Scale Farm | Large-Scale Farm | |||

|---|---|---|---|---|---|---|---|---|

| Mean | Variance | Mean | Variance | Mean | Variance | |||

| Input variables | Weight of Calf | Kg | 307.33 | 52.82 | 265.5 | 67.15 | 293.13 | 63.39 |

| Price of Calf | yuan/Kg | 45.94 | 3.66 | 46.32 | 3.86 | 47.74 | 5.11 | |

| Concentrated feed | Kg | 1995.86 | 259.47 | 1834.93 | 299.19 | 1676.97 | 264.49 | |

| Price of concentrated feed | yuan/Kg | 2.8 | 0.65 | 2.95 | 0.46 | 2.76 | 0.35 | |

| Roughage | Kg | 4777.15 | 665.55 | 5154.9 | 901.7 | 5021.25 | 891.22 | |

| Price of roughage | yuan/Kg | 0.43 | 0.04 | 0.54 | 0.07 | 0.53 | 0.08 | |

| Labor | hour | 38.66 | 20 | 31.18 | 18.43 | 35.16 | 16.01 | |

| Price of Labor | yuan/hour | 14.01 | 4.11 | 14.44 | 4.36 | 15 | 4.29 | |

| Others ① | yuan/head | 113.87 | 57.99 | 151.26 | 82.28 | 218.17 | 80.34 | |

| Output variables | Weight of beef cattle | Kg | 746.66 | 45.51 | 702.15 | 50.9 | 733.25 | 55.1 |

| Price of beef cattle | yuan/Kg | 33.33 | 3 | 34.17 | 2.66 | 34.21 | 2.15 | |

| Amount of pollution | kg/head | 103.11 | 13.32 | 90.05 | 12.52 | 89.22 | 13.76 | |

| Carbon emission | kg CO2e/head | 32.72 | 5.45 | 34.22 | 5.66 | 35.96 | 8.13 | |

| Individual characteristics of farms and Managers | Age of Farm Manager (AGE) | years old | 47.29 | 10.74 | 45.21 | 8.13 | 43.8 | 6.86 |

| Educational level of managers (EDU) | ② | 2.45 | 0.73 | 2.78 | 0.93 | 3.99 | 2.01 | |

| Years of professional fattening (YEA) | Year | 7.11 | 4.15 | 7.12 | 5.11 | 8 | 4.01 | |

| Social/Government part-time (CAD) | yes = 1, no = 0 | 0.07 | 0.31 | 0.4 | 0.36 | 0.17 | 0.25 | |

| Fattening scale (SCA) | head | 32.32 | 12.44 | 152.25 | 55.98 | 355.63 | 323.87 | |

| Management Level (MAG) ③ | Scores | 1.34 | 0.04 | 1.35 | 0.05 | 1.4 | 0.07 | |

| Social and Economic Characters | Main source of feed (FED) | Local = 1, others = 0 | 0.57 | 0.5 | 0.42 | 0.35 | 0.32 | 0.43 |

| Number of competitors (COM) ④ | Number | 1.58 | 0.48 | 1.92 | 0.61 | 1.7 | 0.81 | |

| Beef cattle are the Leading agricultural Industry Locally (DOC) | yes = 1, no = 0 | 0.67 | 0.47 | 0.41 | 0.51 | 0.23 | 0.55 | |

| Cooperative member (COO) | yes = 1, no = 0 | 0.47 | 0.5 | 0.68 | 0.49 | 0.72 | 0.5 | |

| Surroundings of Local Policy | Subsidized by policy (SUB) | yes = 1, no = 0 | 0.42 | 0.5 | 0.65 | 0.5 | 0.67 | 0.5 |

| Be impacted by Environmental regulatory policies (POL) | yes = 1, no = 0 | 0.41 | 0.48 | 0.37 | 0.49 | 0.53 | 0.55 | |

| Received Fattening training organized by the local government (TRA) | yes = 1, no = 0 | 0.49 | 0.5 | 0.6 | 0.5 | 0.83 | 0.38 | |

| Group | Population (N = 510) | Small-Scale Farm (N = 216) | Medium-Scale Farm (N = 139) | Large-Scale Farm (N = 155) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TE | PTE | SE | TE | PTE | SE | TE | PTE | SE | TE | PTE | SE | |

| [0.5, 0.6) | 3 | 0 | 0 | 0 | 0 | 0 | 3 | 0 | 0 | 0 | 0 | 0 |

| [0.6, 0.7) | 21 | 16 | 0 | 4 | 4 | 0 | 9 | 4 | 0 | 8 | 8 | 0 |

| [0.7, 0.8) | 114 | 100 | 0 | 57 | 46 | 0 | 29 | 42 | 0 | 28 | 12 | 0 |

| [0.8, 0.9) | 191 | 179 | 242 | 92 | 73 | 204 | 34 | 49 | 21 | 65 | 57 | 17 |

| [0.9, 1.0) | 124 | 132 | 239 | 45 | 69 | 12 | 49 | 25 | 106 | 30 | 38 | 121 |

| [1.0, 1.1) | 40 | 56 | 22 | 16 | 12 | 0 | 8 | 16 | 12 | 16 | 28 | 10 |

| [1.1, 1.2) | 10 | 20 | 4 | 2 | 9 | 0 | 5 | 3 | 0 | 3 | 8 | 4 |

| [1.2, 2.0) | 6 | 7 | 1 | 0 | 3 | 0 | 2 | 0 | 0 | 4 | 4 | 1 |

| [2.0, 3.0) | 1 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 2 |

| Mean | 0.8866 | 0.9157 | 0.9667 | 0.8496 | 0.8902 | 0.9551 | 0.9079 | 0.9505 | 0.9555 | 0.9198 | 0.9223 | 0.9916 |

| Std. err. | 0.1845 | 0.1209 | 0.1238 | 0.1007 | 0.1081 | 0.0299 | 0.1126 | 0.1035 | 0.0568 | 0.2842 | 0.1412 | 0.2098 |

| Maximum | 2.3750 | 1.4674 | 2.2334 | 1.1404 | 1.2449 | 0.9996 | 1.2886 | 1.1390 | 1.1681 | 2.3750 | 1.4674 | 2.2334 |

| Minimum | 0.6438 | 0.6598 | 0.8414 | 0.6555 | 0.6598 | 0.8559 | 0.7283 | 0.7955 | 0.8414 | 0.6438 | 0.6825 | 0.8426 |

| Group | Population (N = 510) | Small-Scale Farm (N = 216) | Medium-Scale Farm (N = 139) | Large-Scale Farm (N = 155) | ||||

|---|---|---|---|---|---|---|---|---|

| CE | IAE | CE | IAE | CE | IAE | CE | IAE | |

| [0.6, 0.7) | 48 (9.41) | 5 (0.98) | 25 (11.57) | 0 (0.00) | 0 (0.00) | 0 (0.00) | 0 (0.00) | 12 (9.26) |

| [0.7, 0.8) | 267 (52.35) | 39 (7.65) | 154 (71.3) | 25 (11.57) | 16 (7.41) | 74 (34.26) | 8 (6.02) | 27 (19.44) |

| [0.8, 0.9) | 122 (23.92) | 158 (30.98) | 25 (11.57) | 91 (42.13) | 99 (45.83) | 105 (48.61) | 38 (27.31) | 54 (38.89) |

| [0.9, 1.0) | 52 (10.20) | 232 (45.49) | 12 (5.56) | 83 (38.43) | 89 (41.2) | 25 (11.57) | 71 (50.93) | 23 (16.2) |

| [1.0, 1.1) | 21 (4.12) | 51 (10.00) | 0 (0.00) | 12 (5.56) | 9 (4.17) | 12 (8.63) | 22 (15.74) | 23 (16.2) |

| [1.1, 1.2) | 0 (0.00) | 25 (4.90) | 0 (0.00) | 5 (2.31) | 3 (1.39) | 0 (0.00) | 0 (0.00) | 0 (0.00) |

| Mean | 0.8071 | 0.9170 | 0.7791 | 0.8987 | 0.9029 | 0.8444 | 0.9047 | 0.8569 |

| Std. err. | 0.0895 | 0.0855 | 0.0634 | 0.0754 | 0.0818 | 0.0868 | 0.0934 | 0.1086 |

| Maximum | 1.0523 | 1.1638 | 0.9759 | 1.1021 | 1.1931 | 1.0939 | 1.0806 | 1.0686 |

| Minimum | 0.6774 | 0.7154 | 0.6866 | 0.7532 | 0.7606 | 0.7116 | 0.7259 | 0.6724 |

| Group | Population (N = 510) | Small-Scale Farm (N = 216) | Medium-Scale Farm (N = 139) | Large-Scale Farm (N = 155) | ||||

|---|---|---|---|---|---|---|---|---|

| RE | PE | RE | PE | RE | PE | RE | PE | |

| [0.6, 0.7) | 0 (0.00) | 19 (3.73) | 0 (0.00) | 0 (0.00) | 0 (0.00) | 12 (9.26) | 0 (0.00) | 4 (2.58) |

| [0.7, 0.8) | 24 (4.71) | 115 (22.55) | 16 (7.41) | 74 (34.26) | 8 (6.02) | 27 (19.44) | 0 (0.00) | 20 (12.9) |

| [0.8, 0.9) | 182 (35.69) | 211 (41.37) | 99 (45.83) | 105 (48.61) | 38 (27.31) | 54 (38.89) | 48 (30.97) | 57 (36.77) |

| [0.9, 1.0) | 239 (46.86) | 82 (16.08) | 89 (41.2) | 25 (11.57) | 71 (50.93) | 23 (16.2) | 78 (50.32) | 32 (20.65) |

| [1.0, 1.1) | 62 (12.16) | 77 (15.1) | 9 (4.17) | 12 (5.56) | 22 (15.74) | 23 (16.2) | 29 (18.71) | 37 (23.87) |

| [1.1, 1.2) | 3 (0.59) | 6 (1.18) | 3 (1.39) | 0 (0.00) | 0 (0.00) | 0 (0.00) | 0 (0.00) | 5 (3.23) |

| Mean | 0.9254 | 0.9161 | 0.9029 | 0.8444 | 0.9047 | 0.8569 | 0.9216 | 0.9068 |

| Std. err. | 0.0839 | 0.1074 | 0.0818 | 0.0868 | 0.0934 | 0.1086 | 0.0765 | 0.1058 |

| Maximum | 1.0838 | 1.1100 | 1.1931 | 1.0939 | 1.0806 | 1.0686 | 1.0838 | 1.1100 |

| Minimum | 0.7259 | 0.6835 | 0.7606 | 0.7116 | 0.7259 | 0.6724 | 0.7861 | 0.6938 |

| Type | Variable | Small-Scale Farm | Medium-Scale Farm | Large-Scale Farm | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TE | PTE | TE | PTE | TE | PTE | ||||||||

| Coeff. | t | Coeff. | t | Coeff. | t | Coeff. | t | Coeff. | t | Coeff. | t | ||

| C | cons | 0.6434 * | 2.21 | 0.5063 | 1.38 | 1.2276 *** | 3.84 | 1.1417 *** | 3.37 | 0.1581 | 1.01 | 0.1944 | 1.32 |

| Individual characteristics of farms and Managers | AGE | −0.0035 *** | −2.87 | −0.0026 * | −1.72 | −0.0152 *** | −4.42 | −0.0205 *** | −5.61 | 0.0042 * | 1.87 | 0.0039 * | 1.84 |

| EDU | 0.0343 * | 1.84 | 0.0300 | 1.28 | 0.0701 *** | −7.4 | 0.1697 *** | 6.97 | 0.1525 *** | 4.43 | 0.1600 *** | 5.36 | |

| YEA | 0.0013 | −0.74 | −0.0003 | −0.13 | 0.0263 *** | 4.82 | 0.0287 *** | 4.99 | 0.0088 *** | 4.41 | 0.0077 *** | 4.09 | |

| CAD | −0.0335 | −1.49 | −0.0192 | −0.68 | −0.1297 *** | −3.75 | −0.1257 *** | −3.43 | −0.0054 | −0.23 | −0.0120 | −0.55 | |

| SCA | −0.0002 | −0.38 | −0.0003 | −0.49 | 0.0008 | 1.31 | 0.0014 ** | 2.29 | 0.0000 | −0.35 | 0.0001 ** | 2.78 | |

| MAG | 0.2723 | 1.33 | 0.3322 | 1.29 | 0.2223 | 0.94 | 0.4589 * | 1.84 | 0.2278 ** | 2.35 | 0.1958 | 2.14 | |

| Social and Economic Characters | FED | 0.0148 | 1.14 | −0.0036 | −0.22 | 0.0718 ** | 2.38 | −0.0681 * | −2.12 | −0.0211 | −1.4 | −0.0315 ** | −2.21 |

| COM | 0.0370 ** | 2.73 | 0.074 *** | 4.32 | 0.1259 *** | 5.42 | 0.1223 *** | 4.97 | 0.0118 | 0.9 | 0.0135 | 1.09 | |

| DOC | 0.0205 *** | 1.21 | 0.0321 | 1.5 | 0.0613 ** | 2.45 | 0.0774 ** | 2.93 | 0.0389 * | 1.77 | 0.0192 | 0.93 | |

| COO | 0.0233 | 1.44 | 0.0334 | 1.63 | −0.0074 *** | −3.03 | −0.0938 ** | −3.59 | −0.0047 ** | −2.84 | −0.0025 * | −1.77 | |

| Surroundings of Local Policy | SUB | 0.0601 *** | 4.3 | 0.0433 ** | 2.45 | −0.0568 ** | −2.21 | −0.0621 ** | −2.28 | 0.0394 ** | 2.39 | 0.0004 * | 0.03 |

| POL | −0.0183 | −1.43 | −0.0112 | −0.7 | 0.0135 | 0.71 | 0.0182 | 0.91 | 0.1011 *** | 6.99 | 0.0843 *** | 6.18 | |

| TRA | 0.1534 *** | 2.98 | 0.1359 ** | 2.69 | 0.0991 *** | 3.01 | 0.1257 | 3.61 | 0.0545 ** | 2.76 | 0.0851 | 4.57 | |

| Type | Variable | CE | IAE | RE | PE | ||||

|---|---|---|---|---|---|---|---|---|---|

| Coef. | t | Coef. | t | Coef. | t | Coef. | t | ||

| C | cons | 0.8146 *** | 4.56 | 1.4244 *** | 5.88 | 0.5954 * | 1.89 | 1.0365 *** | 3.14 |

| Individual characteristics of farms and Managers | AGE | −0.0004 | −0.78 | 0.0021 *** | 3.02 | −0.0005 | −0.59 | −0.0011 | −1.18 |

| EDU | 0.0024 *** | 2.58 | 0.0510 *** | 0.76 | 0.0055 *** | 3.3 | 0.0005 | 0.29 | |

| YEA | −0.0004 | −0.36 | 0.0010 | 0.74 | −0.0011 | −0.6 | −0.0018 | −0.96 | |

| CAD | 0.0125 *** | 2.32 | 0.0248 *** | 3.41 | −0.0102 | −1.08 | 0.0128 | 1.29 | |

| SCA | 0.0001 | 0.31 | 0.0003 | 0.08 | −0.0002 | −0.37 | −0.0004 | −0.74 | |

| MAG | −0.1155 | −0.87 | 0.5116 *** | 2.84 | 0.1822 | 0.78 | −0.1866 | −0.76 | |

| Social and Economic Characters | FED | 0.0245 *** | 2.96 | 0.0266 ** | 2.37 | −0.0083 | −0.57 | 0.0155 | 1.01 |

| COM | 0.0431 *** | 5.16 | 0.0171 | 1.51 | 0.0291 * | 1.97 | 0.0171 | 1.1 | |

| DOC | 0.0198 * | 1.76 | −0.0015 | −0.1 | 0.0581 *** | 2.93 | 0.0732 *** | 3.51 | |

| COO | 0.0257 *** | 2.69 | −0.0017 | −0.13 | 0.0414 ** | 2.46 | 0.0649 *** | 3.68 | |

| Surroundings of Local Policy | SUB | 0.0319 *** | 3.55 | −0.0261 ** | −2.14 | 0.0078 | 0.49 | 0.024 * | 1.44 |

| POL | −0.0208 *** | −2.51 | 0.0042 | 0.38 | 0.0003 | 0.02 | 0.0035 | 0.23 | |

| TRA | 0.0163 * | 1.91 | 0.0657 *** | 5.66 | −0.01 | −0.66 | −0.0004 | −0.02 | |

| Type | Variable | CE | IAE | RE | PE | ||||

|---|---|---|---|---|---|---|---|---|---|

| Coef. | t | Coef. | t | Coef. | t | Coef. | t | ||

| C | cons | 0.7724 ** | 2.31 | 1.181 | 2.21 | 0.866 ** | 2.51 | 0.5279 | 1.47 |

| Individual characteristics of farms and Managers | AGE | −0.0001 | −0.03 | −0.0018 | −0.37 | −0.0054 | −1.7 | −0.0045 | −1.36 |

| EDU | 0.0045 * | 1.96 | 0.0017 *** | 0.53 | 0.001 | 0.48 | 0.0035 | 1.61 | |

| YEA | 0.0012 * | 0.22 | 0.0018 ** | −0.22 | 0.0096 ** | 1.76 | 0.0033 | 0.58 | |

| CAD | −0.0109 | −1.27 | 0.0138 ** | −1.01 | −0.0045 | −0.51 | 0.0011 | 0.12 | |

| SCA | −0.0001 | −0.18 | −0.0001 | −0.04 | 0.0002 | 0.28 | 0.0002 | 0.25 | |

| MAG | 0.5177 ** | 1.29 | 0.8214 *** | 3.38 | 0.0959 | 0.47 | 0.3182 *** | 1.49 | |

| Social and Economic Characters | FED | −0.0166 | −0.48 | 0.0299 | 0.54 | 0.0564 | 1.58 | −0.0885 ** | −2.37 |

| COM | 0.0078 | 0.3 | −0.0298 | −0.71 | 0.0072 | 0.27 | −0.036 | −1.27 | |

| DOC | 0.0552 * | 1.78 | −0.0435 | −0.88 | 0.0484 ** | 1.51 | 0.1399 *** | 4.18 | |

| COO | 0.0641 ** | 2.52 | 0.0447 | 1.1 | 0.0343 | 1.31 | 0.0413 | 1.51 | |

| Surroundings of Local Policy | SUB | 0.0483 * | 1.84 | 0.0311 ** | 0.74 | 0.0095 | 0.35 | 0.0463 | 1.63 |

| POL | 0.0054 * | 0.21 | −0.0654 | −1.58 | 0.0418 ** | 1.57 | 0.0458 * | 1.65 | |

| TRA | 0.0866 ** | 2.29 | 0.0979 | 1.62 | −0.0822 ** | −2.1 | 0.0925 ** | 2.27 | |

| Type | Variable | CE | IAE | RE | PE | ||||

|---|---|---|---|---|---|---|---|---|---|

| Coef. | t | Coef. | t | Coef. | t | Coef. | t | ||

| C | cons | −0.0611 | −0.27 | 1.2441 *** | 3 | 0.7592 *** | 4.14 | 0.3842 | 1.1 |

| Individual characteristics of farms and Managers | AGE | 0.0061 ** | 2.22 | −0.0113 ** | −2.24 | −0.0062 ** | −2.81 | −0.0032 ** | −2.75 |

| EDU | 0.0559 *** | 3.18 | −0.0003 | −1.05 | −0.013 | −0.92 | 0.0081 | 0.30 | |

| YEA | 0.001 | 0.35 | 0.0103 ** | 2.11 | 0.0005 | 0.22 | 0.0000 | 0.01 | |

| CAD | −0.0207 | −0.54 | 0.0169 | 0.24 | −0.0773 ** | −2.52 | −0.1214 ** | −2.08 | |

| SCA | 0.0001 | 1.48 | 0.0001 | 0.67 | 0.0001 | 2.28 | 0.0000 | 0.66 | |

| MAG | 0.2866 *** | 1.99 | 0.1569 * | 0.60 | 0.3447 *** | 2.98 | 0.432 * | 1.97 | |

| Social and Economic Characters | FED | 0.0213 | 0.98 | 0.064 | 1.62 | 0.0022 | 0.12 | 0.0081 * | 0.24 |

| COM | −0.0094 | −0.57 | −0.0443 | −1.48 | −0.0145 ** | −1.06 | −0.0009 ** | −0.04 | |

| DOC | 0.0732 *** | 2.77 | −0.1093 ** | −2.28 | −0.0004 | −0.02 | 0.062 | 1.54 | |

| COO | 0.0042 | 0.21 | 0.1036 ** | 2.88 | −0.0371 ** | −2.33 | −0.0402 | −1.33 | |

| Surroundings of Local Policy | SUB | −0.0015 | −0.06 | 0.0754 *** | 1.74 | 0.0492 ** | 2.57 | 0.0251 | 0.69 |

| POL | 0.0153 | 0.69 | −0.1364 *** | −3.36 | −0.0107 | −0.6 | −0.0002 ** | 0.01 | |

| TRA | 0.0379 * | 1.27 | 0.0196 | 0.36 | 0.0154 * | 0.64 | 0.0307 * | 0.67 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, Y.; Qi, Z.; Yan, J.; Li, D.; Zhao, H.; Zheng, H. Technical Efficiency and Allocative Efficiency of Beef Cattle Fattening in the Content of Digital Economy: An Empirical Study Based on Survey in China. Agriculture 2024, 14, 1007. https://doi.org/10.3390/agriculture14071007

Xue Y, Qi Z, Yan J, Li D, Zhao H, Zheng H. Technical Efficiency and Allocative Efficiency of Beef Cattle Fattening in the Content of Digital Economy: An Empirical Study Based on Survey in China. Agriculture. 2024; 14(7):1007. https://doi.org/10.3390/agriculture14071007

Chicago/Turabian StyleXue, Yongjie, Zhenhua Qi, Jinling Yan, Dahai Li, Huifeng Zhao, and Haijing Zheng. 2024. "Technical Efficiency and Allocative Efficiency of Beef Cattle Fattening in the Content of Digital Economy: An Empirical Study Based on Survey in China" Agriculture 14, no. 7: 1007. https://doi.org/10.3390/agriculture14071007

APA StyleXue, Y., Qi, Z., Yan, J., Li, D., Zhao, H., & Zheng, H. (2024). Technical Efficiency and Allocative Efficiency of Beef Cattle Fattening in the Content of Digital Economy: An Empirical Study Based on Survey in China. Agriculture, 14(7), 1007. https://doi.org/10.3390/agriculture14071007