Simulation Analysis and Parameter Optimization of Seed–Flesh Separation Process of Seed Melon Crushing and Seed Extraction Separator Based on DEM

Abstract

:1. Introduction

2. Materials and Methods

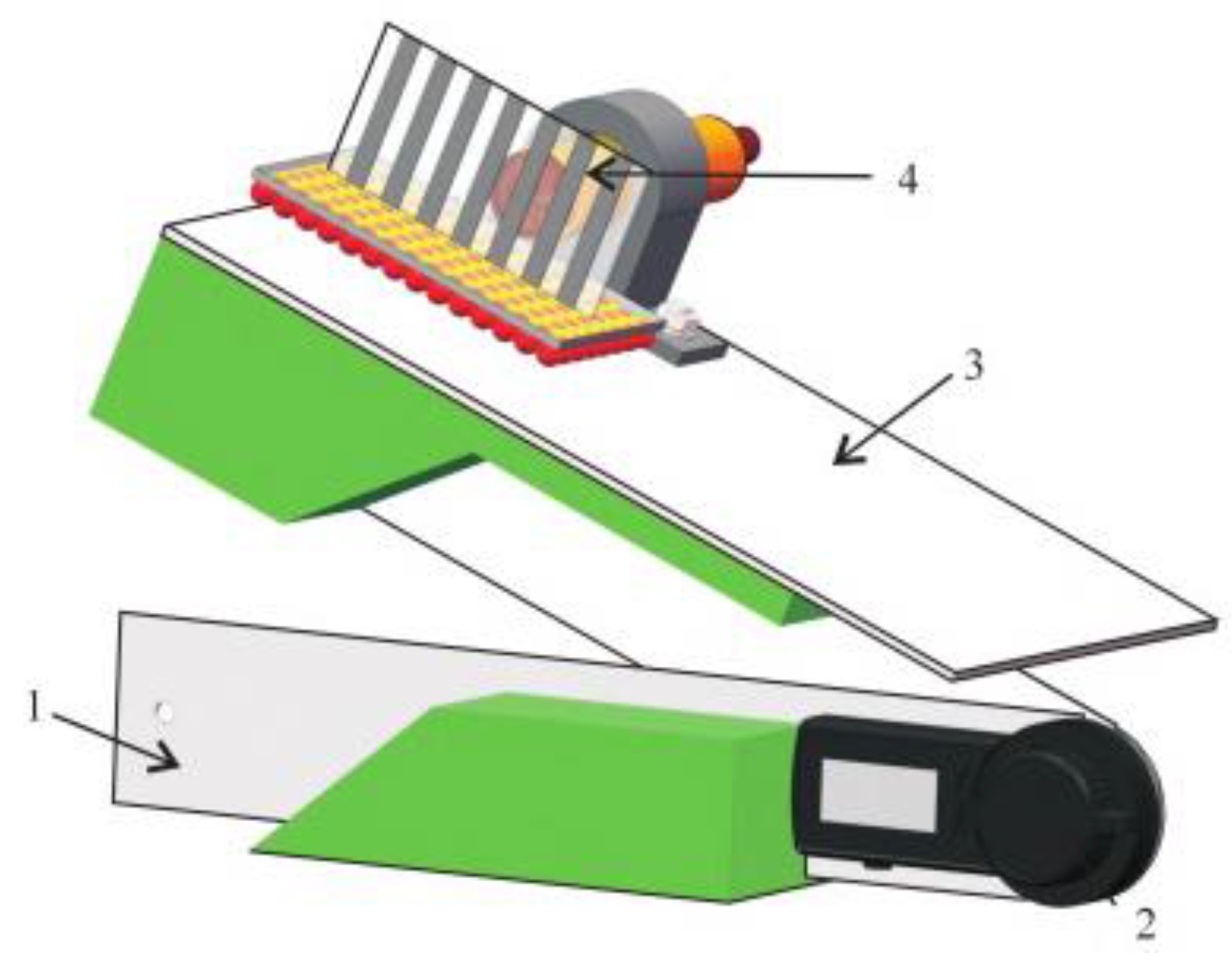

2.1. Structure of the Seed–Flesh Separation Device and Its Arrangement in the Whole Machine

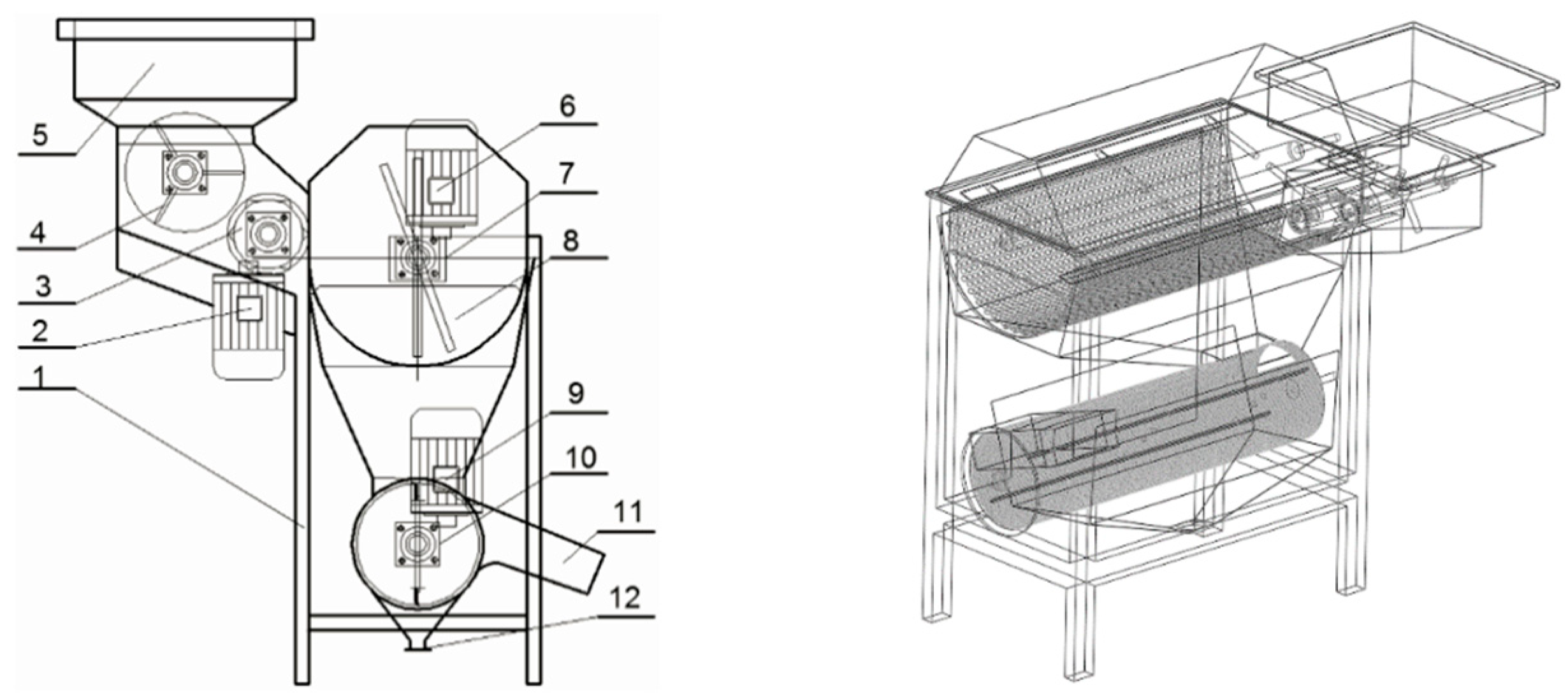

2.1.1. The Whole Machine Structure of Seed Melon Crushing and Seed-Extraction Separator

2.1.2. Structure of the Seed–Flesh Separation Device

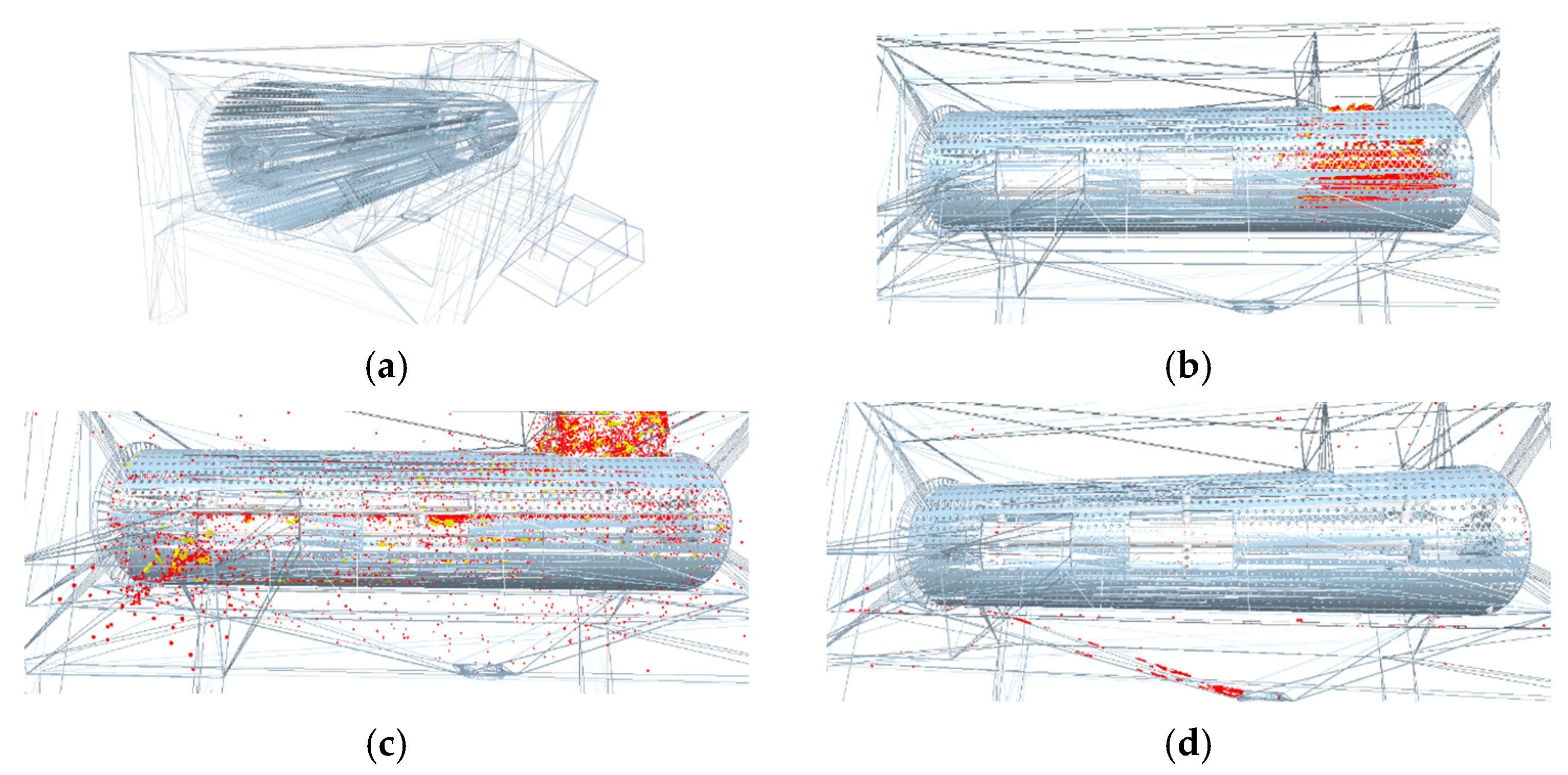

2.2. Simulation Modeling Based on DEM

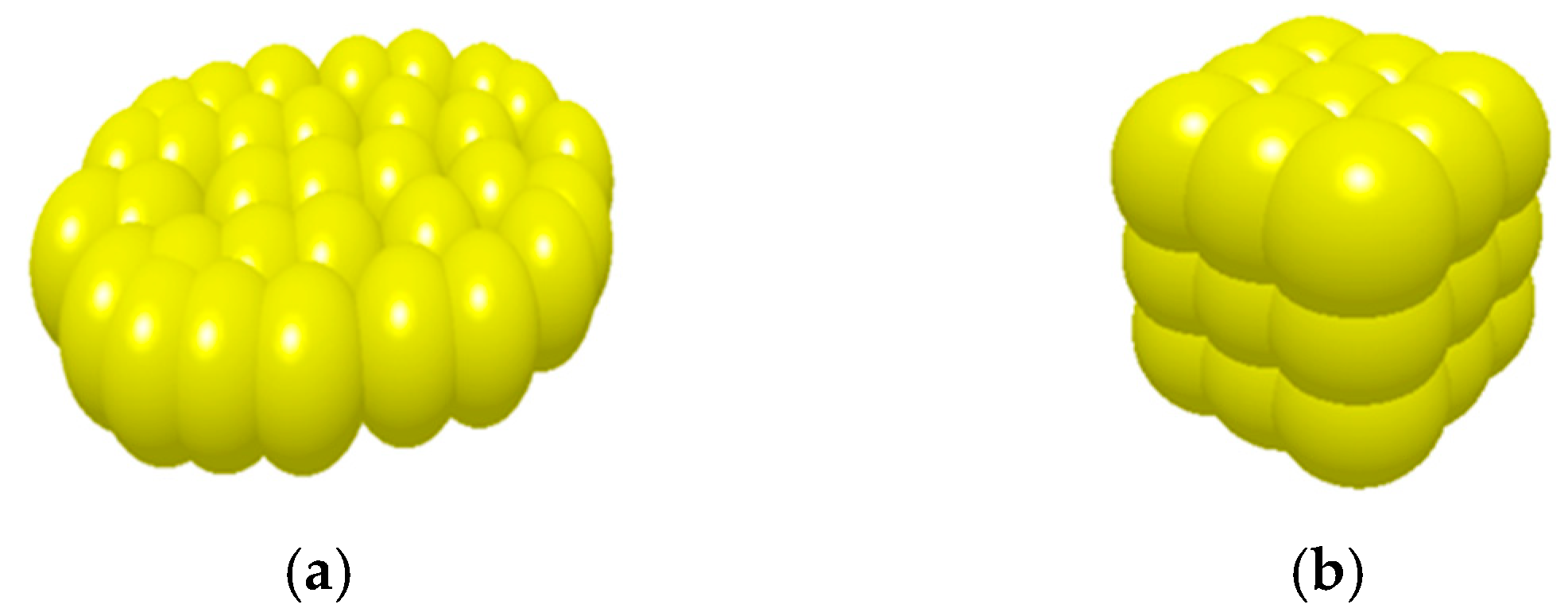

2.2.1. Simulation Model of Seed Melon Components

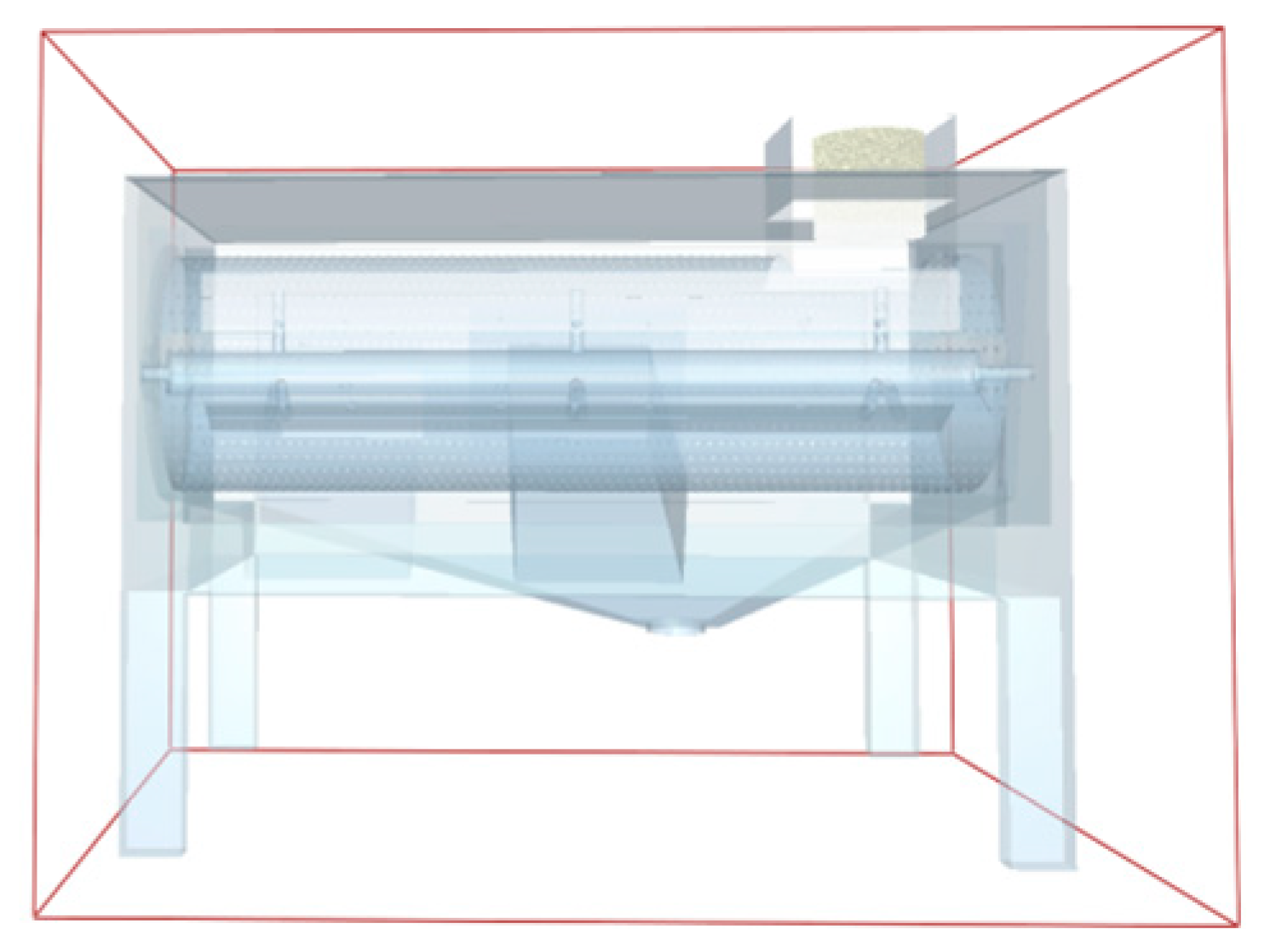

2.2.2. Simulation Model of the Seed–Flesh Separation Device

2.3. Calibration of Simulation Parameters

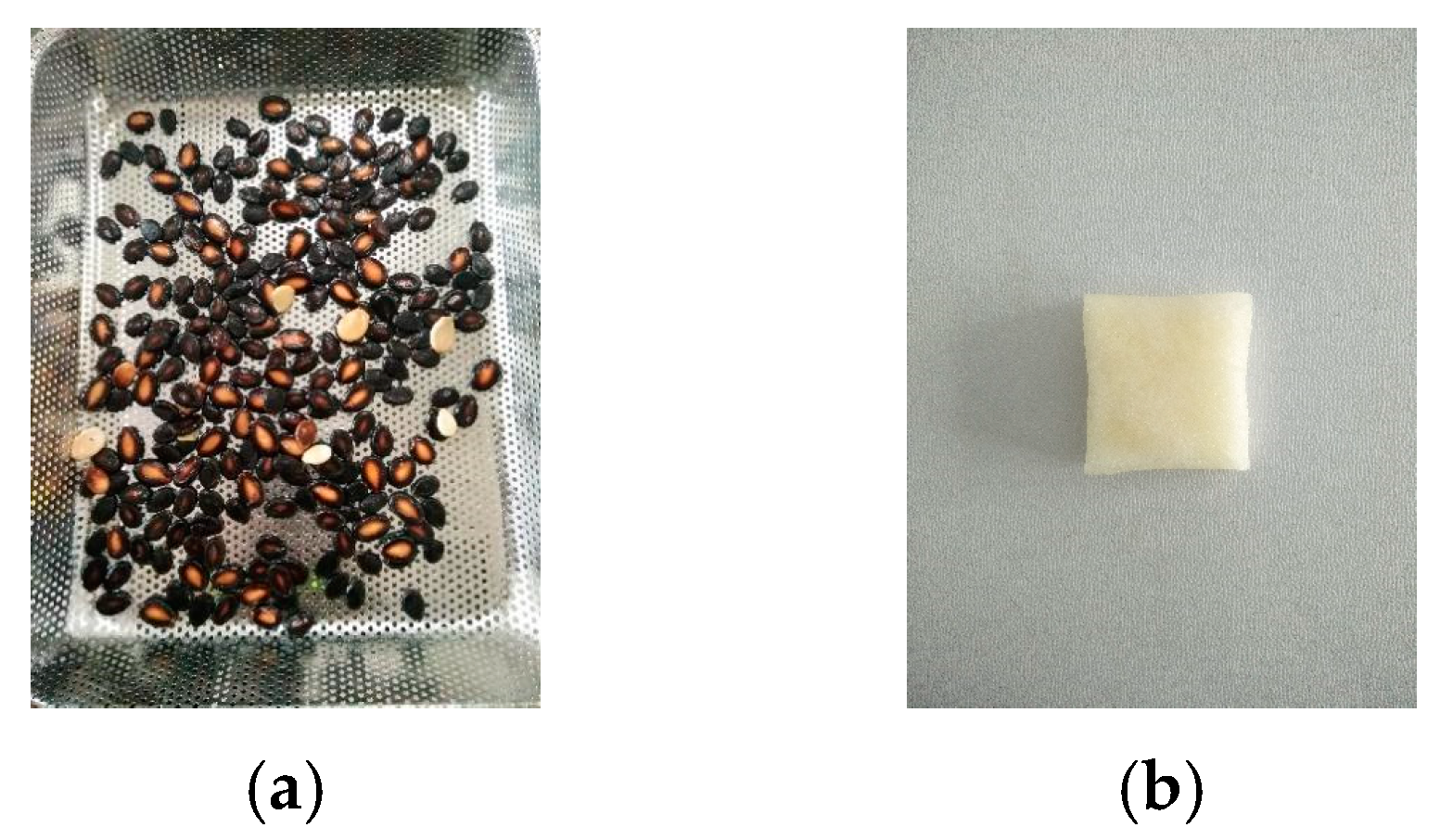

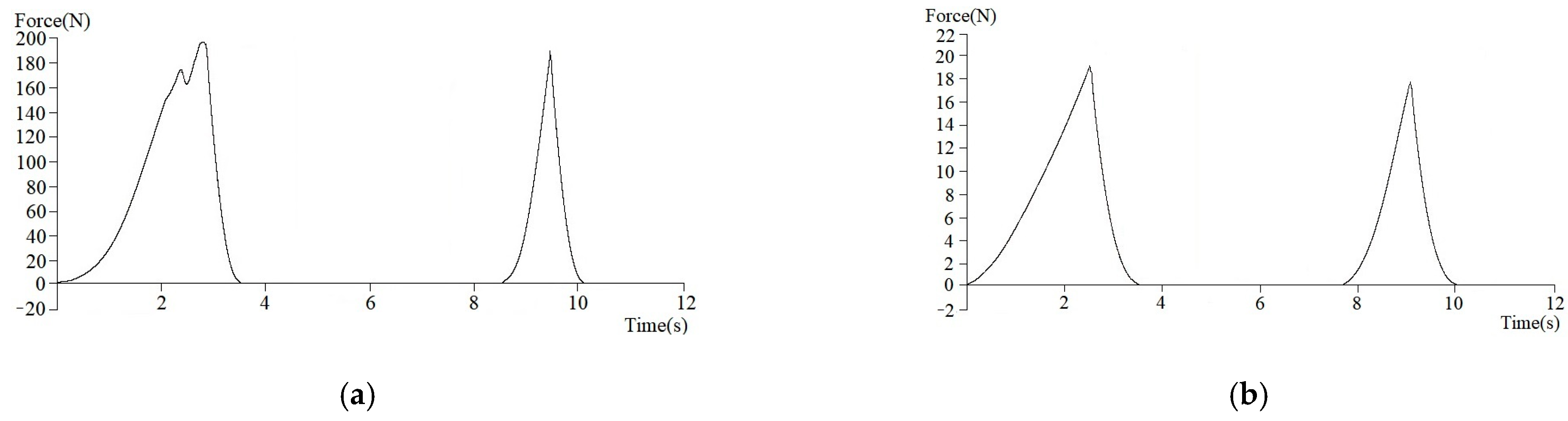

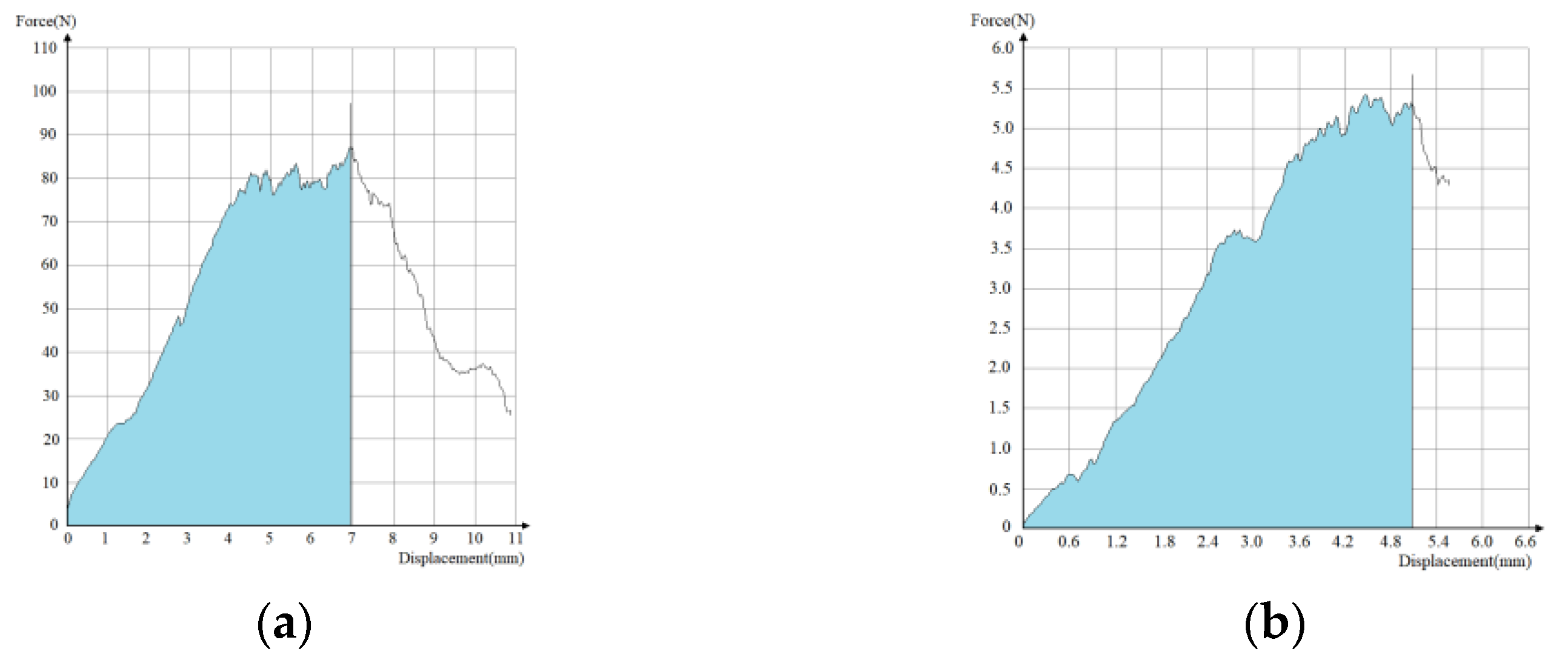

2.3.1. Calibration of Intrinsic Parameters

2.3.2. Calibration of Contact Parameters

- Between the materials of melon seeds and flesh

- 2.

- Between seed melon components and separation rollers

2.4. Simulation Design

2.4.1. Simulation Analysis and Effectiveness Validation in the Original Working State

2.4.2. Design of Simulation Experiment

2.5. Field Test Method

3. Simulation Results Analysis

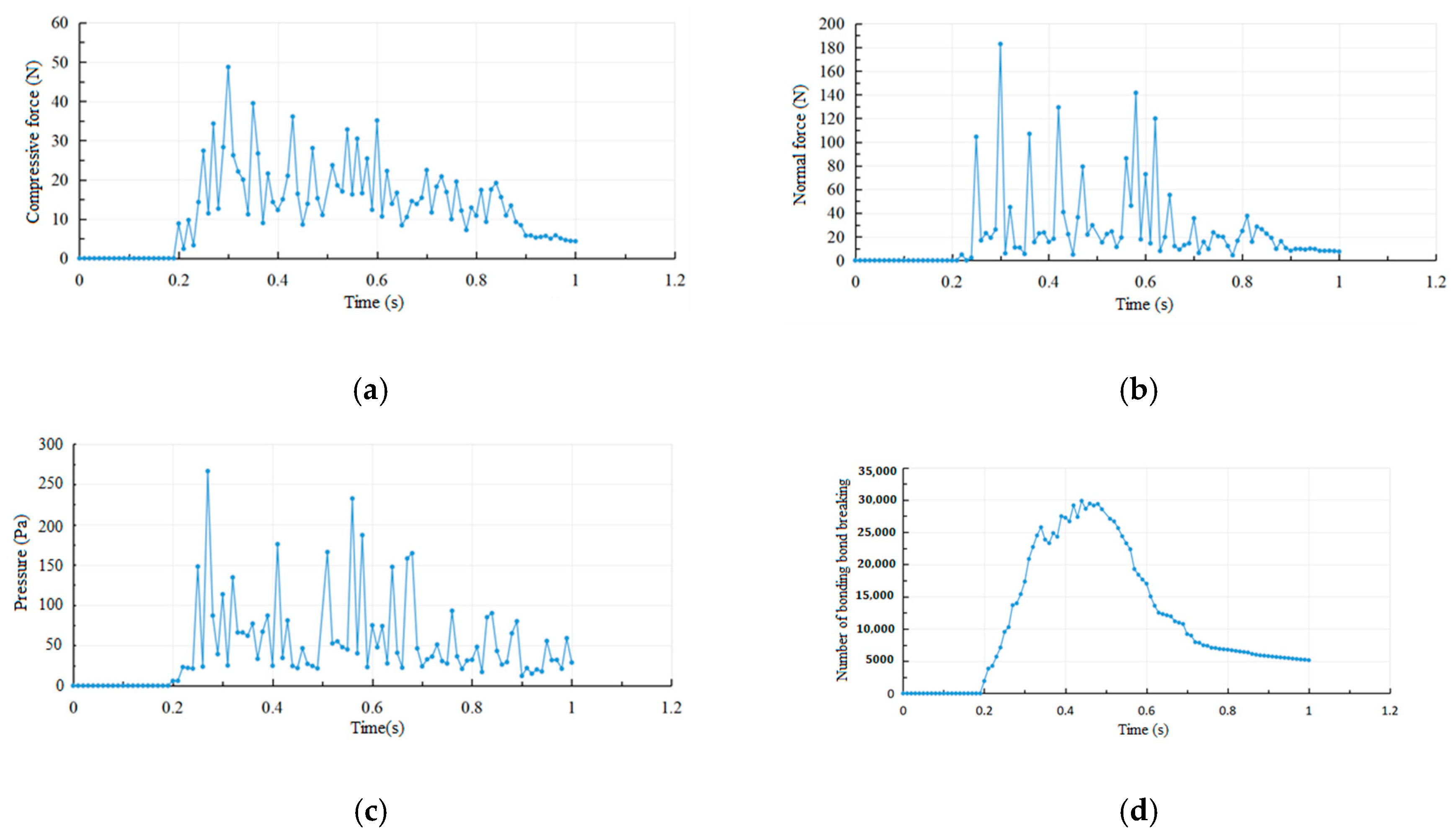

3.1. Discrete Element Simulation Analysis of Seed–Flesh Separation Process

3.2. Analysis of the Influence of Factors on the Effect of Seed–Flesh Separation

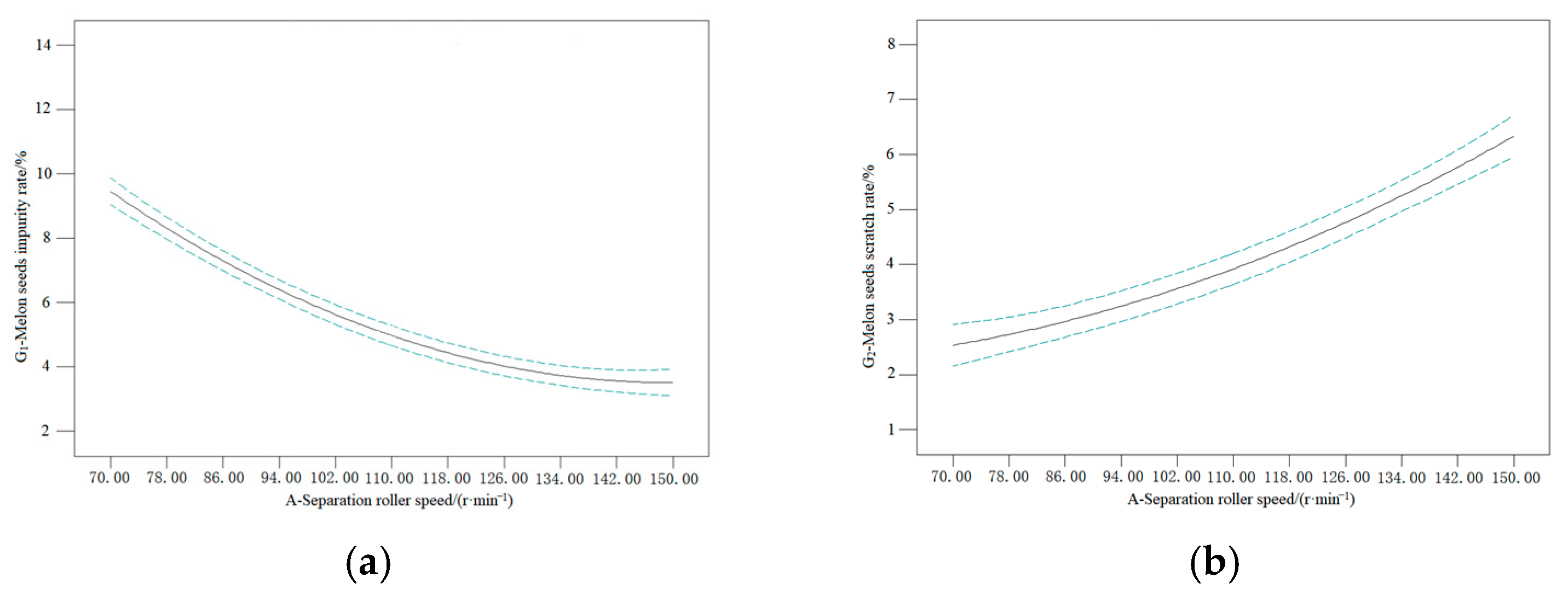

3.2.1. The Influence of Separation Roller Speed on the Efficiency of Seed–Flesh Separation

3.2.2. The Influence of the Spacing between Scraper and Screen on the Effectiveness of Seed–Flesh Separation

3.2.3. The Influence of Separation Roller Scraper Inclination Angle on the Effectiveness of Seed–Flesh Separation

3.3. Response Surface Test

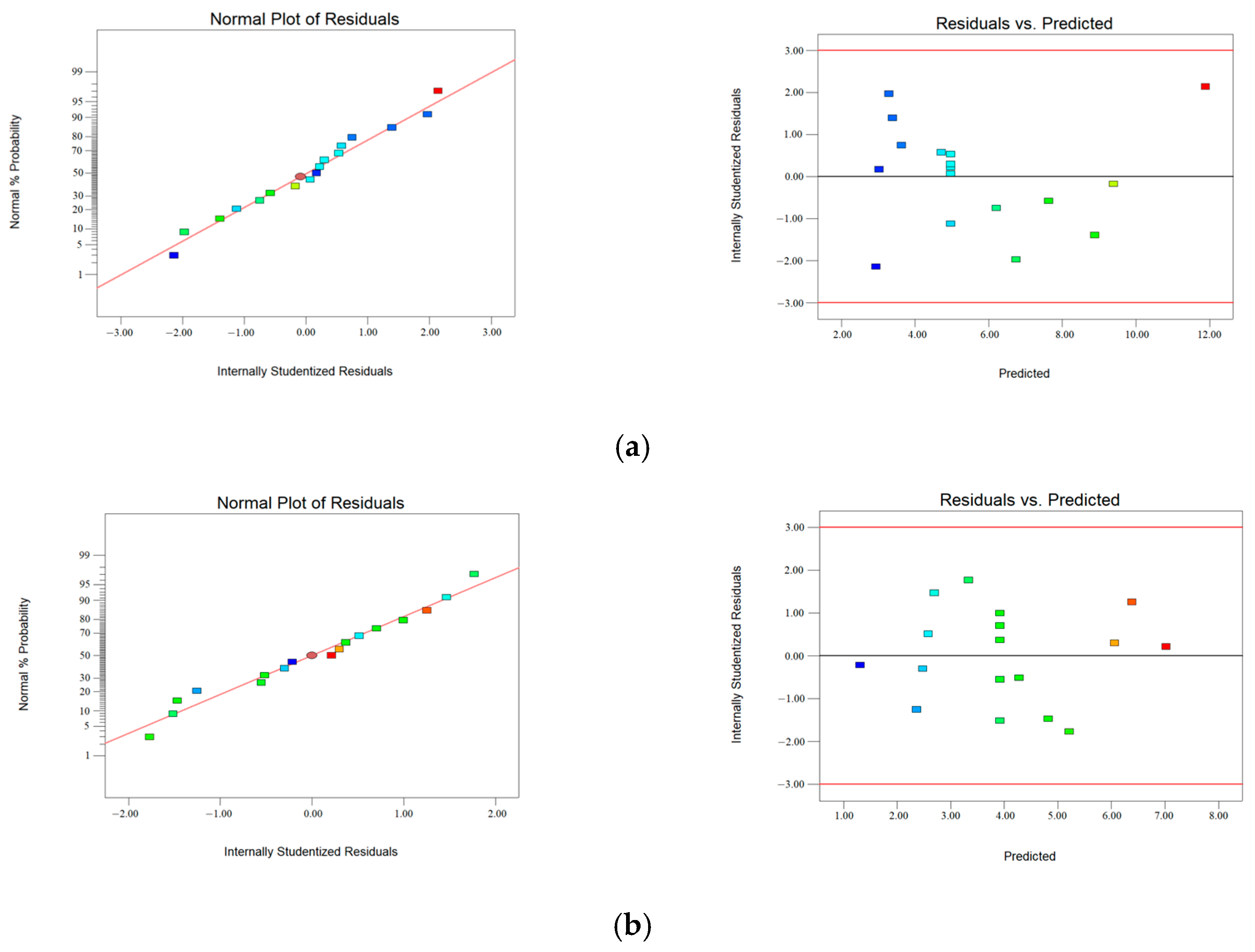

3.3.1. ANOVA of Influencing Factors

3.3.2. Separation Performance Analysis

3.4. Optimal Parameter Design

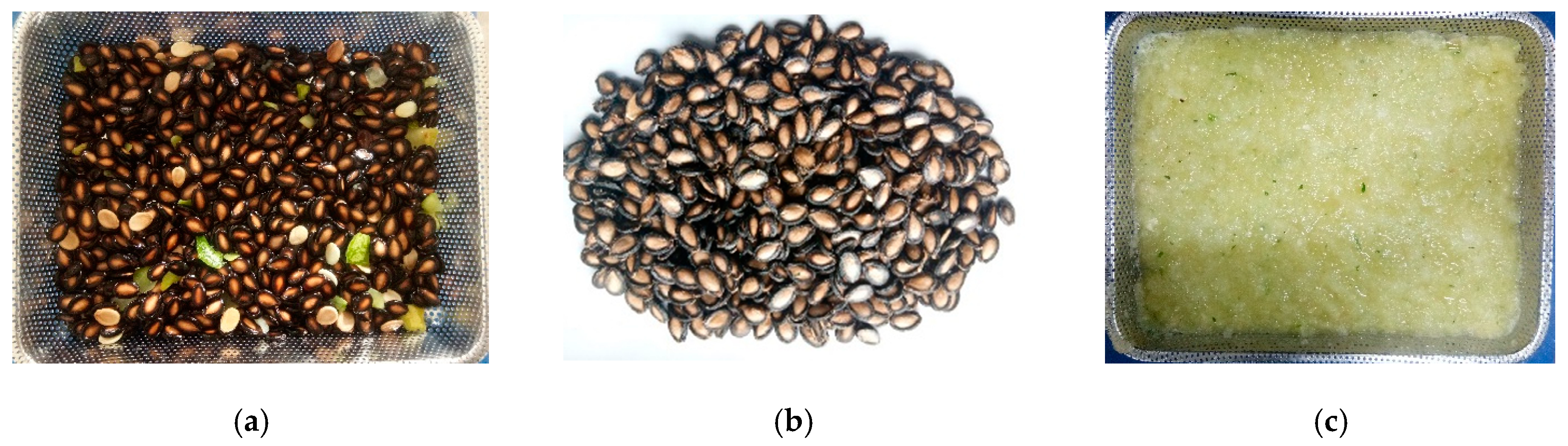

3.5. Prototype Separating Operation Test Verification

4. Conclusions

- (1)

- Aiming at the industrial bottleneck of poor seed–flesh separation and high rate of impurity and scratches in melon seeds in traditional seed melons, the group proposes a seed melon crushing and seed-extraction separator that realizes seed–flesh separation automatically and efficiently. Meanwhile, the discrete element model of melon seeds, melon flesh, and seed–flesh separating device was established by using DEM, and the contact parameters between melon seeds–melon seeds, melon flesh–melon flesh, and melon seeds–melon flesh materials were calibrated with the experimental angle repose as the optimization target value, as well as the contact parameters between melon seeds, melon flesh, and the material of separating rollers (304 stainless steel) were calibrated by using the homemade photoinductive friction coefficient determination platform.

- (2)

- The discrete element method (DEM) was used to analyze the one-factor simulation of separation roller speed (A), spacing between scraper and screen (B), and separation roller scraper inclination angle (C), and the investigated impact of the three factors on the efficiency of seed–flesh separation was explored by taking melon seed impurity rate (G1) and melon seed scratch rate (G2) as evaluation indexes.

- (3)

- The three-factor, three-level orthogonal test conducted on the seed–flesh separation process revealed that with separation roller speed (A) set at 117.53 r/min, spacing between scraper and screen (B) set at 5 mm, and separation roller scraper inclination angle (C) set at 10°, melon seed impurity rate (G1) was 5.59%, and melon seed scratch rate (G2) was 2.85%. Subsequent laboratory prototype testing indicated that under the optimized parameters, the average values for melon seed impurity rate (G1) and melon seed scratch rate (G2) were 5.71% and 2.91%, respectively. The relative errors compared to the simulated values were found to be 2.15% and 2.11%, respectively. These results indicate a comprehensive enhancement in the seed–flesh separation process, achieved through a balanced approach focusing on minimizing both melon seed impurity rate and melon seed scratch rate.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, H.W. The direction of research and production of seed melon in China through literature analysis. Gansu Agric. Sci. Technol. 2019, 6, 62–72. [Google Scholar]

- Huang, X.P.; Xiong, S.L.; Wang, Q.H.; Sun, C.G.; Wan, F.X. Analysis of electrical characteristics of seed melon pericarp in different parts. J. Anhui Agric. Univ. 2022, 49, 514–520. [Google Scholar]

- Ding, H.B.; Wu, L.; Zang, Z.P.; Xu, Y.R.; Huang, X.P.; Wu, J.F. Study on microwave vacuum drying characteristics and quality of seed melon solids. J. Chin. Agric. Mech. 2023, 44, 88–94. [Google Scholar]

- Zhou, Y.H.; Lu, W.D.; Ma, X.L.; Gao, J.L.; Fan, X.Q.; Guo, J.F.; Chen, Y.Q.; Lin, M.; Shi, S.B. Phenotypic characters identification and gengtic diversity analysis of seed melon germplasm resources. J. China Agric. Univ. 2023, 28, 119–132. [Google Scholar]

- Wu, J.; Tang, Q.; Mu, S.L.; Jiang, L.; Hu, Z.C. Test and optimization of oilseed rape (Brassica napus L.) threshing device based on DEM. Agriculture 2022, 12, 1580. [Google Scholar] [CrossRef]

- Zhang, D.M.; Yi, S.J.; Zhang, J.H.; Bao, Y.H. Establishment of millet threshing and separating model and optimization of harvester parameters. Alex. Eng. J. 2022, 61, 11251–11265. [Google Scholar] [CrossRef]

- Wang, Q.; Mao, H.; Li, Q. Modelling and simulation of the grain threshing process based on the discrete element method. Comput. Electron. Agric. 2020, 178, 105790. [Google Scholar] [CrossRef]

- Coetzee, C.J.; Lombard, S.G. The destemming of grapes: Experiments and discrete element modelling. Biosyst. Eng. 2013, 114, 232–248. [Google Scholar] [CrossRef]

- Li, X.P.; Zhang, W.T.; Wang, W.Z.; Huang, Y. Design and test of longitudinal axial flow staggered millet flexible threshing device. Agriculture 2022, 12, 1179. [Google Scholar] [CrossRef]

- Ma, Z.; Li, Y.; Xu, L. Discrete-element method simulation of agricultural particles’ motion in variable-amplitude screen box. Comput. Electron. Agric. 2015, 118, 92–99. [Google Scholar] [CrossRef]

- Yu, C.; Lin, D.D.; Xu, N.N.; Wang, X.W.; Pu, K.W.; Wang, Z.H.; Zhao, G.F.; Geng, R.H.; Gong, S.P. DEM simulation of particle flow and separation in a vibrating flip-flow screen. Particuology 2023, 73, 113–127. [Google Scholar] [CrossRef]

- You, Y.; Liu, M.L.; Ma, H.Q.; Xu, L.; Liu, B.; Shao, Y.L.; Tang, Y.P.; Zhao, Y.Z. Investigation of the vibration sorting of non-spherical particles based on DEM simulation. Powder Technol. 2018, 325, 316–332. [Google Scholar] [CrossRef]

- Ghodki, M.B.; Kumar, K.C.; Goswami, T.K. Modeling breakage and motion of black pepper seeds in cryogenic mill. Adv. Powder Technol. 2018, 19, 1055–1071. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.T.; Yang, Y.; Zhao, H.M.; Yang, C.H.; He, Y.; Wang, K.; Liu, D.; Xu, H.B. Discrete element modelling of citrus fruit stalks and its verification. Biosyst. Eng. 2020, 200, 400–414. [Google Scholar] [CrossRef]

- Su, Z.; Li, Y.M.; Dong, Y.H.; Tang, Z.; Liang, Z.W. Simulation of rice threshing performance with concentric and non-concentric threshing gaps. Biosyst. Eng. 2020, 197, 270–284. [Google Scholar] [CrossRef]

- Horabik, J.; Molenda, M. Parameters and contact models for DEM simulations of agricultural granular materials: A review. Biosyst. Eng. 2016, 147, 206–225. [Google Scholar] [CrossRef]

- Liu, F.Y.; Zhang, J.; Li, B.; Chen, J. Calibration of parameters of wheat required in discrete element method simulation based on repose angle of particle heap. Trans. Chin. Soc. Agric. Eng. 2016, 32, 247–253. [Google Scholar]

- Song, X.F.; Dai, F.; Zhang, F.W.; Wang, D.M.; Liu, Y.C. Calibration of DEM models for fertilizer particles based on numerical simulations and granular experiments. Comput. Electron. Agric. 2023, 204, 107507. [Google Scholar] [CrossRef]

- Rackl, M.; Hanley, K.J. A methodical calibration procedure for discrete element models. Powder Technol. 2017, 307, 73–83. [Google Scholar] [CrossRef]

- Chen, Z.P.L.; Wassgren, C.; Veikle, E.; Ambrose, K. Determination of material and interaction properties of maize and wheat grains for DEM simulation. Biosyst. Eng. 2020, 195, 208–226. [Google Scholar] [CrossRef]

- Ma, X.D.; Guo, B.J.; Li, L.L. Simulation and experiment study on segregation mechanism of rice from straws under horizontal vibration. Biosyst. Eng. 2019, 186, 1–13. [Google Scholar] [CrossRef]

- Guan, Z.H.; Mu, S.L.; Jiang, T.; Li, H.T.; Zhang, M.; Wu, C.Y.; Jin, M. Development of centrifugal disc spreader on tracked combine harvester for oilseed rape under sowing rice based on DEM. Agriculture 2022, 12, 562. [Google Scholar] [CrossRef]

- Makange, N.R.; Ji, C.; Torotwa, I. Prediction of cutting forces and soil behavior with discrete element simulation. Comput. Electron. Agric. 2020, 179, 105848. [Google Scholar] [CrossRef]

- Lei, X.; Hu, H.; Wu, W.; Liu, H.; Liu, L.; Yang, W.; Zhou, Z.; Ren, W. Seed Motion Characteristics and Seeding Performance of a Centralized Seed Metering System for Rapeseed Investigated by DEM Simulation and Bench Testing. Biosyst. Eng. 2021, 203, 22–33. [Google Scholar] [CrossRef]

- Sun, H.B.; Li, S.Y.; Huang, X.P.; Wu, J.F.; Wan, F.X. Discrete element model construction and seed-flesh separation process of seed gourd. J. Northwest Agric. For. Univ. (Nat. Sci. Ed.) 2022, 50, 144–154. [Google Scholar]

- Schramm, M.; Tekeste, M.Z. Wheat straw direct shear simulation using discrete element method of fibrous bonded model. Biosyst. Eng. 2022, 213, 1–12. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, Q.S.; Xia, Y.D.; Westover, T.; Eksioglu, S.; Roni, M. Discrete element modeling of switchgrass particles under compression and rotational shear. Biomass Bioenergy 2020, 141, 105649. [Google Scholar] [CrossRef]

- Li, P.; Ucgul, M.; Lee, S.H.; Saunders, C. A new approach for the automatic measurement of the angle of repose of granular materials with maximal least square using digital image processing. Comput. Electron. Agric. 2020, 172, 105356. [Google Scholar] [CrossRef]

- Zhang, N.; Fu, J.; Chen, Z.; Chen, X.G.; Ren, L.Q. Optimization of the process parameters of an air-screen cleaning system for frozen corn based on the response surface method. Agriculture 2021, 11, 794. [Google Scholar] [CrossRef]

- Li, X.Y.; Du, Y.F.; Guo, J.L.; Mao, E.R. Design, simulation, and test of a new threshing cylinder for high moisture content corn. Appl. Sci. 2020, 10, 4925. [Google Scholar] [CrossRef]

| Technical Parameters | Value |

|---|---|

| Weight of the whole machine (kg) | 500 |

| Matching power (KW) | 4.5 |

| Production capacity (t·h−1) | 1.5–2 |

| Appearance size (length·width·height) (mm) | 1460 × 1350 × 1735 |

| Material | SUS304 |

| Materials | Parameters | Numerical Value |

|---|---|---|

| Melon seeds | Density (kg·m−3) Poisson’s ratio Elastic modulus (MPa) Shear modulus (MPa) | 1028.4 0.35 4.66 1.72 |

| Melon flesh | Density (kg·m−3) Poisson’s ratio Elastic modulus (MPa) Shear modulus (MPa) | 995.8 0.47 4.57 1.55 |

| 304 stainless steel | Density (kg·m−3) Poisson’s ratio Elastic modulus (MPa) Shear modulus (MPa) | 2500 0.3 194 2.55 |

| Contact Material | Collision Recovery Coefficient | Static Friction Coefficient | Rolling Friction Coefficient | JKR Surface Energy (J·m2) |

|---|---|---|---|---|

| Melon seeds–melon seeds | 0.200 | 0.249 | 0.250 | 0.200 |

| Melon flesh–melon flesh | 0.100 | 0.332 | 0.114 | 1.271 |

| Melon seeds–melon flesh | 0.228 | 0.368 | 0.269 | 2.213 |

| Seed Melon Components–Separation Roller Material | Coefficient of Static Friction | Coefficient of Sliding Dynamic Friction | Coefficient of Collision Recovery |

|---|---|---|---|

| Melon seeds–304 stainless steel | 0.207 | 0.753 | 0.361 |

| Melon flesh–304 stainless steel | 0.345 | 0.150 | 0.100 |

| Factors | Separation Roller Speed (r·min−1) | Spacing between Scraper and Screen (mm) | Separation Roller Scraper Inclination Angle (°) | Melon Seed Impurity Rate (%) | ||

|---|---|---|---|---|---|---|

| Test Values | Simulation Values | Relative Errors | ||||

| Numerical value | 110 | 3 | 5 | 3.77 | 3.90 | 3.33 |

| Experimental Factors | Retrieve Value | ||

|---|---|---|---|

| Separation roller speed (r·min−1) | 70 | 110 | 150 |

| Spacing between scraper and screen (mm) | 1 | 3 | 5 |

| Separation roller scraper inclination angle (°) | 0 | 5 | 10 |

| Level | A-Separation Roller Speed (r·min−1) | B-Spacing Between Scraper and Screen (mm) | C-Separation Roller Scraper Inclination Angle (°) |

|---|---|---|---|

| 1 | 70 | 1 | 0 |

| 0 | 110 | 3 | 5 |

| −1 | 150 | 5 | 10 |

| Test Number | A-Separation Roller Speed | B-Spacing Between Scraper and Screen | C-Separation Roller Scraper Inclination Angle | G1-Melon Seed Impurity Rate/% | G2-Melon Seed Scratch Rate/% |

|---|---|---|---|---|---|

| 1 | −1 | −1 | 0 | 7.55 | 3.57 |

| 2 | 1 | −1 | 0 | 2.63 | 7.05 |

| 3 | −1 | 1 | 0 | 12.20 | 1.28 |

| 4 | 1 | 1 | 0 | 4.80 | 4.98 |

| 5 | −1 | 0 | −1 | 9.37 | 2.20 |

| 6 | 1 | 0 | −1 | 3.59 | 6.10 |

| 7 | −1 | 0 | 1 | 8.68 | 2.44 |

| 8 | 1 | 0 | 1 | 3.05 | 6.55 |

| 9 | 0 | −1 | −1 | 3.74 | 4.21 |

| 10 | 0 | 1 | −1 | 6.46 | 2.89 |

| 11 | 0 | −1 | 1 | 3.58 | 4.63 |

| 12 | 0 | 1 | 1 | 6.10 | 2.65 |

| 13 | 0 | 0 | 0 | 4.68 | 3.79 |

| 14 | 0 | 0 | 0 | 5.11 | 4.16 |

| 15 | 0 | 0 | 0 | 5.03 | 3.56 |

| 16 | 0 | 0 | 0 | 5.05 | 4.09 |

| 17 | 0 | 0 | 0 | 4.99 | 4.01 |

| Source | Sum of Squares | Degree of Freedom | F Value | p Value | Significant Degree |

|---|---|---|---|---|---|

| Regression model | 100.97 | 9 | 132.51 | <0.0001 | ** |

| A | 70.39 | 1 | 831.38 | <0.0001 | ** |

| B | 18.18 | 1 | 214.73 | <0.0001 | ** |

| C | 0.38 | 1 | 4.52 | 0.0710 | / |

| AB | 1.54 | 1 | 18.16 | 0.0037 | ** |

| AC | 5.625 × 10−3 | 1 | 0.066 | 0.8040 | / |

| BC | 0.01 | 1 | 0.12 | 0.7412 | / |

| A2 | 9.64 | 1 | 113.81 | <0.0001 | ** |

| B2 | 0.41 | 1 | 4.79 | 0.0649 | / |

| C2 | 0.41 | 1 | 4.85 | 0.0635 | / |

| Residual | 0.59 | 7 | |||

| Lack of fit terms | 0.48 | 3 | 5.59 | 0.0648 | / |

| Error | 0.11 | 4 | |||

| Total variation | 101.56 | 16 |

| Source | Sum of Squares | Degree of Freedom | F Value | p Value | Significant Degree |

|---|---|---|---|---|---|

| Regression model | 0.24 | 9 | 31.64 | <0.0001 | ** |

| A | 0.15 | 1 | 183.19 | <0.0001 | ** |

| B | 0.057 | 1 | 68.40 | <0.0001 | ** |

| C | 2.502 × 10−4 | 1 | 0.30 | 0.6014 | / |

| AB | 0.020 | 1 | 23.96 | 0.0018 | ** |

| AC | 9.860 × 10−5 | 1 | 0.12 | 0.7414 | / |

| BC | 5.927 × 10−4 | 1 | 0.71 | 0.4277 | / |

| A2 | 1.924 × 10−3 | 1 | 2.30 | 0.1732 | / |

| B2 | 4.457 × 10−3 | 1 | 5.33 | 0.0543 | * |

| C2 | 1.352 × 10−6 | 1 | 1.616 × 10−3 | 0.9691 | / |

| Residual | 5.855 × 10−3 | 7 | / | ||

| Lack of fit terms | 4.798 × 10−3 | 3 | 6.05 | 0.0573 | / |

| Error | 1.057 × 10−3 | 4 | / | ||

| Total variation | 0.24 | 16 | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Q.; Huang, X.; Wu, J.; Mou, X.; Xu, Y.; Li, S.; Ma, G.; Wan, F.; Peng, L. Simulation Analysis and Parameter Optimization of Seed–Flesh Separation Process of Seed Melon Crushing and Seed Extraction Separator Based on DEM. Agriculture 2024, 14, 1008. https://doi.org/10.3390/agriculture14071008

Luo Q, Huang X, Wu J, Mou X, Xu Y, Li S, Ma G, Wan F, Peng L. Simulation Analysis and Parameter Optimization of Seed–Flesh Separation Process of Seed Melon Crushing and Seed Extraction Separator Based on DEM. Agriculture. 2024; 14(7):1008. https://doi.org/10.3390/agriculture14071008

Chicago/Turabian StyleLuo, Qi, Xiaopeng Huang, Jinfeng Wu, Xiaobin Mou, Yanrui Xu, Shengyuan Li, Guojun Ma, Fangxin Wan, and Lizeng Peng. 2024. "Simulation Analysis and Parameter Optimization of Seed–Flesh Separation Process of Seed Melon Crushing and Seed Extraction Separator Based on DEM" Agriculture 14, no. 7: 1008. https://doi.org/10.3390/agriculture14071008

APA StyleLuo, Q., Huang, X., Wu, J., Mou, X., Xu, Y., Li, S., Ma, G., Wan, F., & Peng, L. (2024). Simulation Analysis and Parameter Optimization of Seed–Flesh Separation Process of Seed Melon Crushing and Seed Extraction Separator Based on DEM. Agriculture, 14(7), 1008. https://doi.org/10.3390/agriculture14071008