Analysis of Film Unloading Mechanism and Parameter Optimization of Air Suction-Type Cotton Plough Residual Film Recovery Machine Based on CFD—DEM Coupling

Abstract

:1. Introduction

2. Materials and Methods

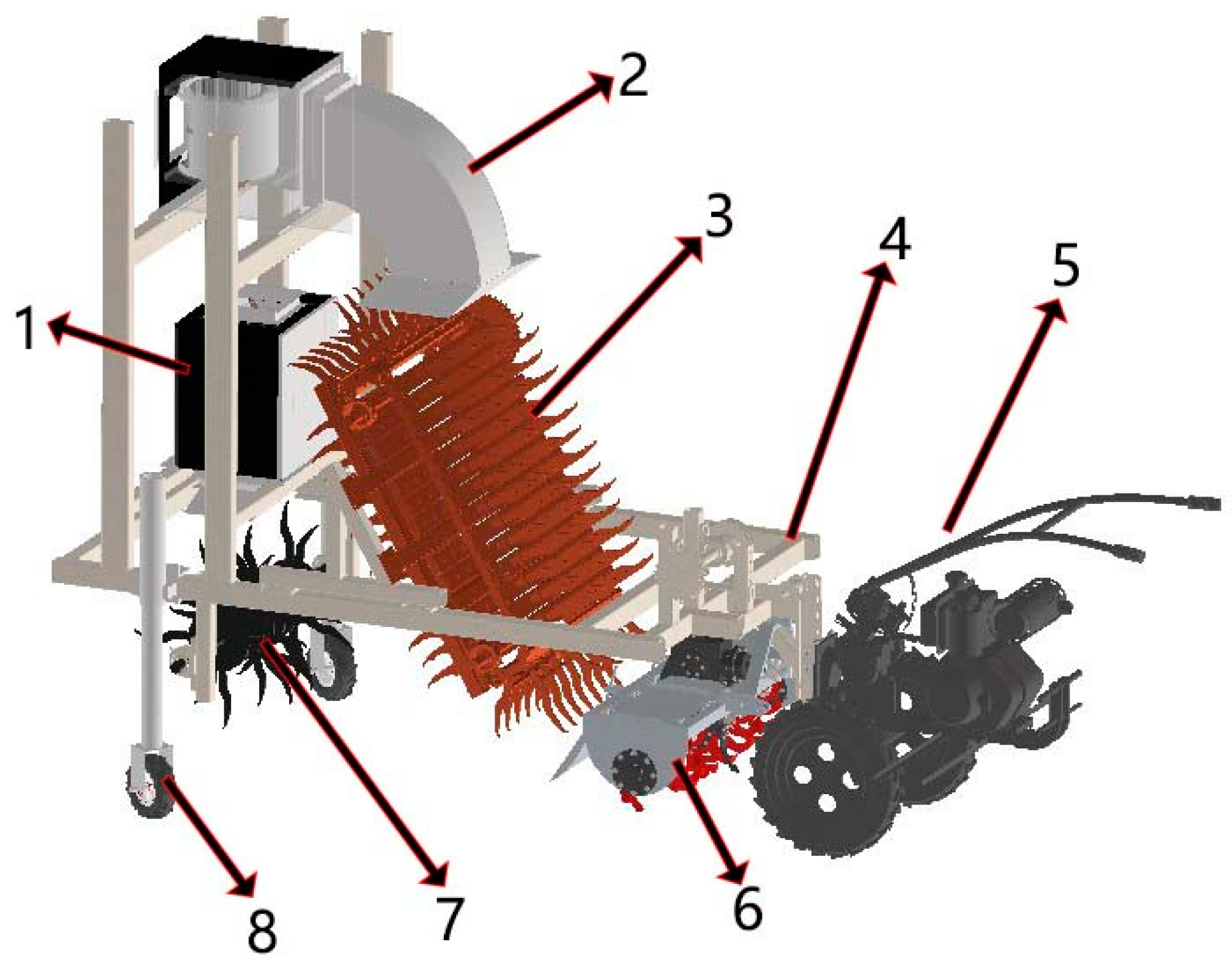

2.1. Design of Air Suction and Film-Lifting Devices

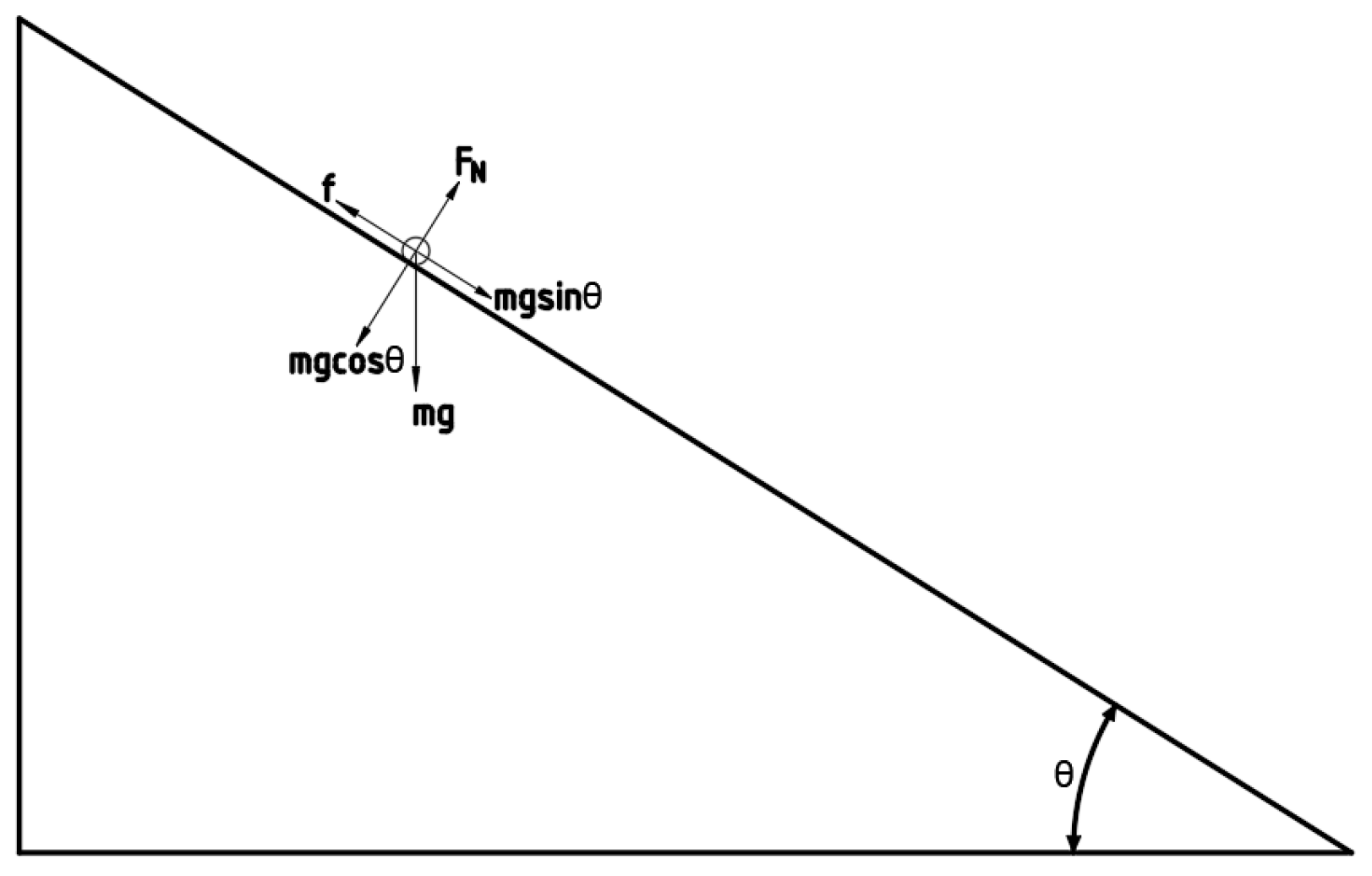

2.2. Calculation of Residual Film Suspended Velocity and Force Analysis of Residual Film at the Suction Port

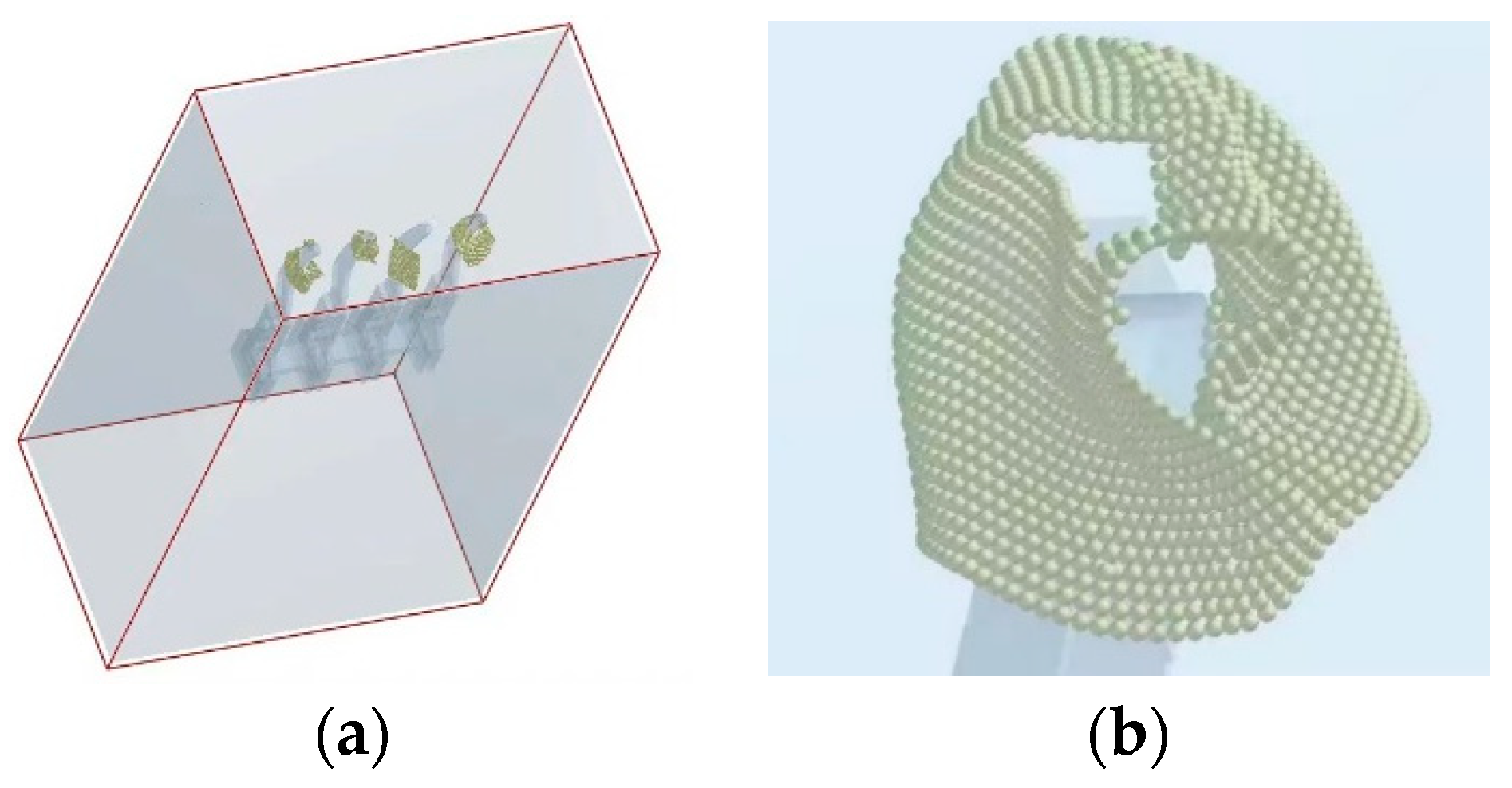

2.3. Determination of Basic Parameters for CFD—DEM Simulation

2.3.1. Measurement of Simulation Parameters Related to Residual Film and Soil

- (1)

- Particle density and granularity measurement

- (2)

- Inherent parameters of residual film and soil

2.3.2. Obtaining Soil Content and Statistics of Residual Film Area in the Cultivated Layer

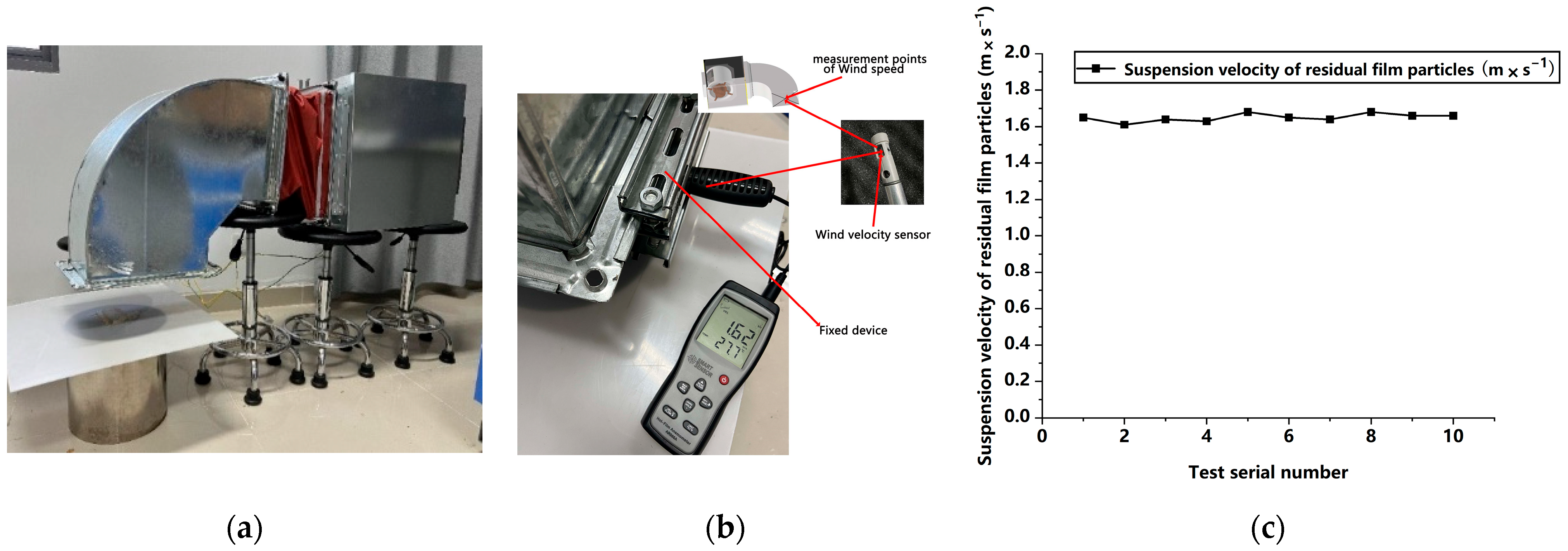

2.4. Test Method for Film–Soil Suspension Velocity and Film–Impurity Separation

2.4.1. Simulation and Experimental Methods for Material Properties

2.4.2. Measurement Scheme for Film–Impurity Separation

2.5. Simulation and Experimental Methods for Film Unloading

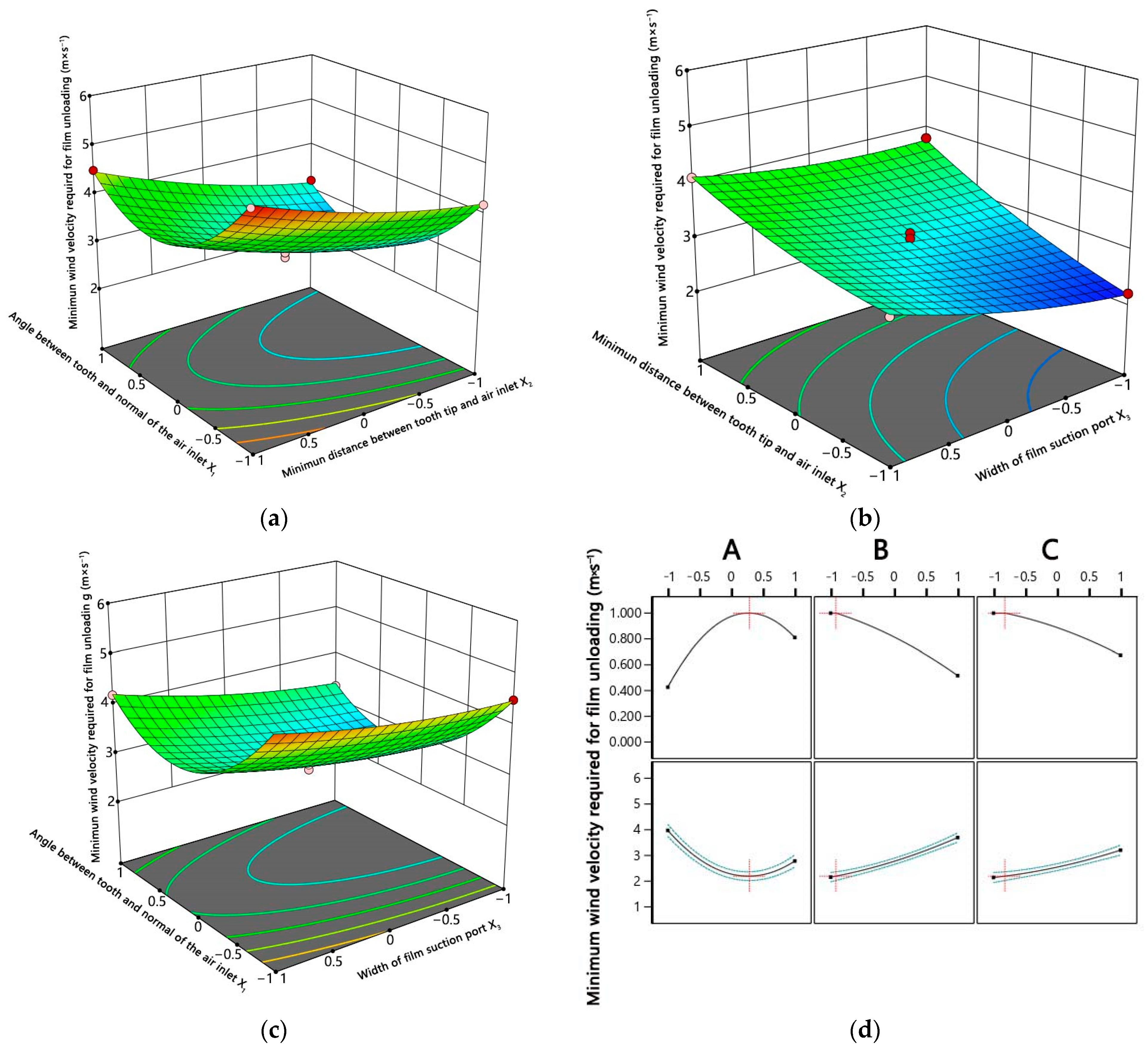

2.6. Optimization Scheme for Gas Suction Parameters Based on CFD—DEM Coupling Simulation

3. Results

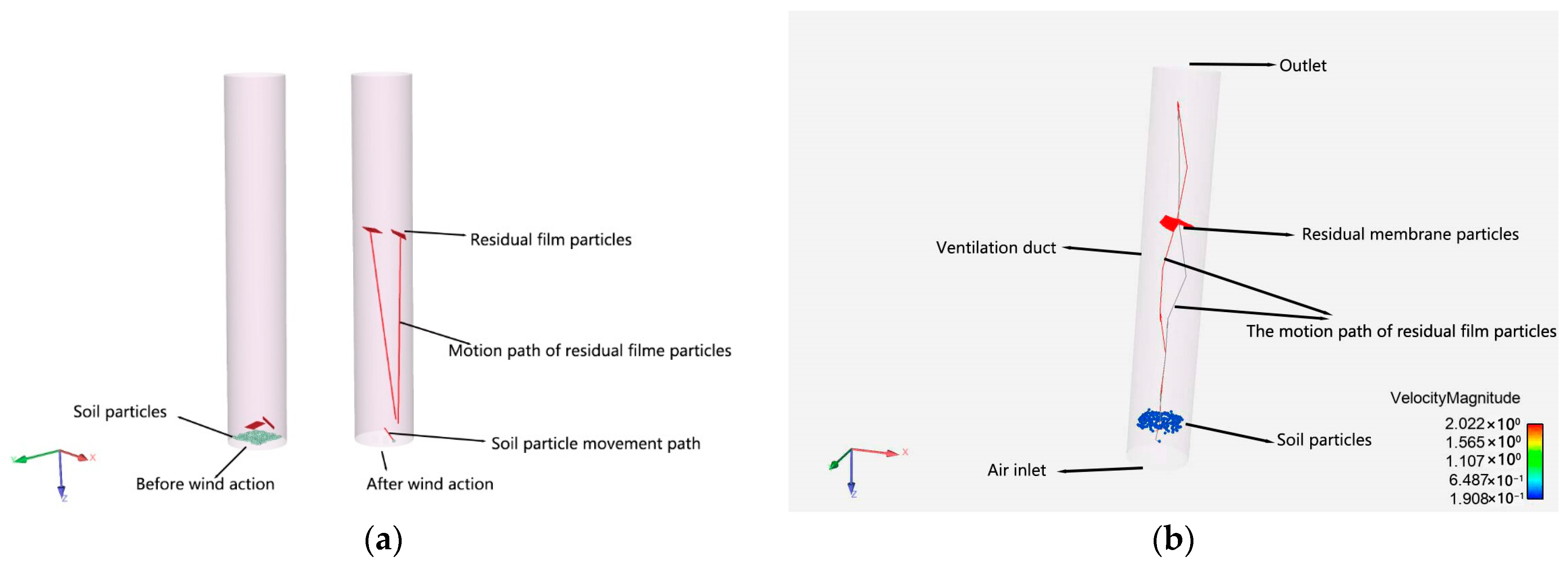

3.1. Simulation Analysis of Residual Film Suspension Velocity

3.2. Analysis of the Validation Results of Film–Soil Suspension Velocity and Film—Impurity Separation Experiments

3.2.1. Analysis of Measurement Results of Residual Film Suspension Characteristics

3.2.2. Analysis of Measurement Results of Soil Particle Suspension Characteristics

3.2.3. Analysis of Measurement Results of Film—Impurity Separation Rate

3.3. Simulation Analysis of Film Unloading Based on CFD—DEM Coupling

3.4. Analysis of Optimization Results of Gas Suction Parameters Based on CFD—DEM Coupling Simulation

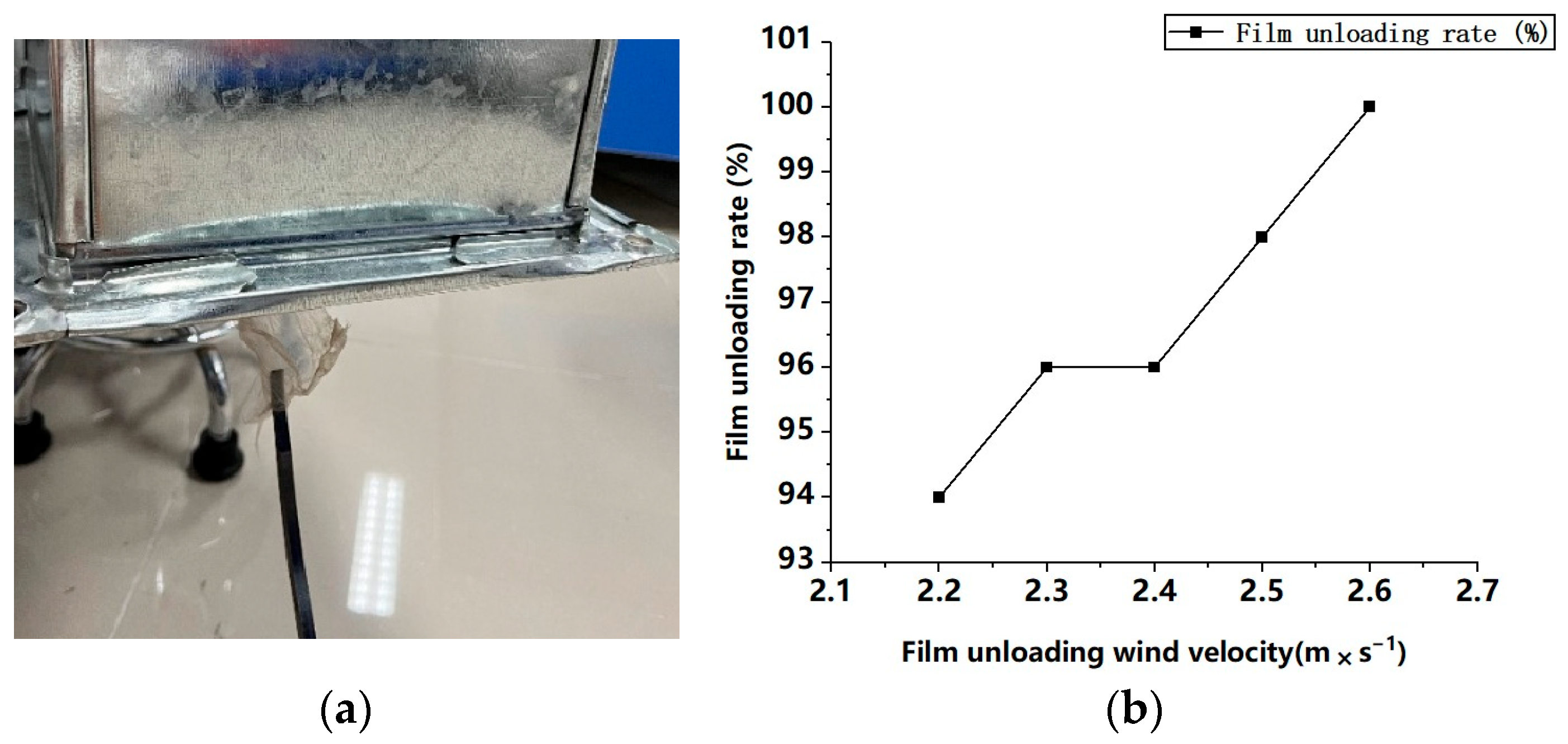

3.5. Analysis of Experimental Results on Film Unloading Wind Velocity and Film Unloading Rate after Parameter Optimization

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ren, J.; Wu, T.; Mo, W.; Li, K.; Hu, P.; Xu, F.; Liu, Q. Discrete Element Simulation Modeling Method and Parameters Calibration of Sugarcane Leaves. Agronomy 2022, 12, 1796. [Google Scholar] [CrossRef]

- Feng, X.; Gong, Z.; Wang, L.; Yu, Y.; Liu, T.; Song, L. Behavior of maize particle penetrating a sieve hole based on the particle centroid in an air-screen cleaning unit. Powder Technol. 2021, 385, 501–516. [Google Scholar] [CrossRef]

- Carvalho, R.M.; Oliveira, A.L.R.; Petit, H.A.; Tavares, L.M. Comparing modeling approaches in simulating a continuous pilot-scale wet vertical stirred mill using PBM-DEM-CFD. Adv. Powder Technol. 2023, 34, 104135. [Google Scholar] [CrossRef]

- Jiang, Z.; Rai, K.; Tsuji, T.; Washino, K.; Tanaka, T.; Oshitani, J. Upscaled DEM—CFD model for vibrated fluidized bed based on particle-scale similarities. Adv. Powder Technol. 2020, 31, 4598–4618. [Google Scholar] [CrossRef]

- Wang, L.; Li, Y.; Wang, H.; Wang, B.; Ma, Z. Behavior of maize particles on the bionic sieve designed based on the earthworm’s contour. Powder Technol. 2022, 403, 117399. [Google Scholar] [CrossRef]

- Peng, Z.; Alghamdi, Y.A.; Moghtaderi, B.; Doroodchi, E. CFD—DEM investigation of transition from segregation to mixing of binary solids in gas fluidised beds. Adv. Powder Technol. 2016, 27, 2342–2353. [Google Scholar] [CrossRef]

- Li, B.; Zhang, H.; Wei, J.; Zhang, O.; Guo, Y.; Zhang, J.; Si, L.; Xu, X. Coal particle transport behavior in a rotating drill pipe used for negative pressure pneumatic conveying. Powder Technol. 2022, 402, 117369. [Google Scholar] [CrossRef]

- Ji, Y.; Liu, S.; Li, J. Experimental study of supply pressure on spraying materials in horizontal pipe. Vacuum 2019, 159, 51–58. [Google Scholar] [CrossRef]

- Xi, X.; Wang, R.; Wang, X.; Shi, Y.; Zhao, Y.; Zhang, B.; Qu, J.; Gan, H.; Zhang, R. Parametric optimization and experimental verification of multi-fertilizer mixing by air blowing and blade stirring based on discrete element simulations. Comput. Electron. Agric. 2023, 210, 107895. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, J.; Li, H.; Yan, Y.; Xu, Z.; Cai, F. Research on the particle movement in a flexible air chamber jig. Adv. Powder Technol. 2023, 34, 103922. [Google Scholar]

- Ding, B.; Liang, Z.; Qi, Y.; Ye, Z.; Zhou, J. Improving Cleaning Performance of Rice Combine Harvesters by DEM—CFD Coupling Technology. Agriculture 2022, 12, 1457. [Google Scholar] [CrossRef]

- An, X.; Cheng, X.; Wang, X.; Han, Y.; Li, H.; Liu, L.; Liu, M.; Liu, M.; Zhang, X. Design and Experimental Testing of a Centrifugal Wheat Strip Seeding Device. Agriculture 2023, 13, 1883. [Google Scholar] [CrossRef]

- Xiao, Y.; Ma, Z.; Wu, M.; Luo, H. Numerical Study of Pneumatic Conveying of Rapeseed through a Pipe Bend by DEM—CFD. Agriculture 2022, 12, 1845. [Google Scholar] [CrossRef]

- Xu, J.; Liu, X.; Pang, M. Numerical and experimental studies on transport properties of powder ejector based on double venturi effect. Vacuum 2016, 134, 92–98. [Google Scholar] [CrossRef]

- Wang, Y.; Li, H.; Hu, H.; He, J.; Wang, Q.; Lu, C.; Liu, P.; Yang, Q.; He, D.; Jiang, S.; et al. A noncontact self-suction wheat shooting device for sustainable agriculture: A preliminary research. Comput. Electron. Agric. 2022, 197, 106927. [Google Scholar] [CrossRef]

- Dai, F.; Guo, W.; Song, X.; Shi, R.; Qu, J.; Zhao, W. Measurement and simulation of the suspension velocity of flax threshing material using CFD-DEM. Int. J. Agric. Biol. Eng. 2021, 14, 230–237. [Google Scholar] [CrossRef]

- Kushimoto, K.; Suzuki, K.; Ishihara, S.; Soda, R.; Ozaki, K.; Kano, J. Analysis of the particle collision behavior in spiral jet milling. Adv. Powder Technol. 2023, 34, 103993. [Google Scholar] [CrossRef]

- Dai, F.; Song, X.; Zhao, W.; Han, Z.; Zhang, F.; Zhang, S. Motion simulation and test on threshed grains in tapered threshing and transmission device for plot wheat breeding based on CFD—DEM. Int. J. Agric. Biol. Eng. 2019, 12, 66–73. [Google Scholar] [CrossRef]

- Fayzullayevich, J.V.; Tan, G.; Alex, F.J.; Wu, Y.; Agyeman, P.K. Numerical Study of Factors Affecting Particle Suction Efficiency of Pick-Up Head of a Regenerative Air Vacuum Sweeper. Processes 2022, 10, 1252. [Google Scholar] [CrossRef]

- Lei, X.; Liao, Y.; Liao, Q. Simulation of seed motion in seed feeding device with DEM—CFD coupling approach for rapeseed and wheat. Comput. Electron. Agric. 2016, 131, 29–39. [Google Scholar] [CrossRef]

- Ma, Q.; Lu, A.; Gao, L.; Wang, Z.; Tan, Z.; Li, X. Aerodynamic characteristics of lotus seed mixtures and test on pneumatic separating device for lotus seed kernel and contaminants. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2015, 31, 297–303. [Google Scholar]

- Tian, F.; Zhang, E.; Yang, C.; Shi, W.; Chen, Y. Research on the Characteristics of the Solid-Liquid Two-Phase Flow Field of a Submersible Mixer Based on CFD-DEM. Energies 2022, 15, 6096. [Google Scholar] [CrossRef]

- El-Emam, M.A.; Zhou, L.; Shi, W.D.; Han, C. True shape modeling of bio-particulate matter flow in an aero-cyclone separator using CFD-DEM simulation. Comput. Part. Mech. 2021, 8, 955–971. [Google Scholar] [CrossRef]

- Zhou, L.; Lv, W.; Bai, L.; Han, Y.; Wang, J.; Shi, W.; Huang, G. CFD—DEM study of gas-solid flow characteristics in a fluidized bed with different diameter of coarse particles. Energy Rep. 2022, 8, 2376–2388. [Google Scholar] [CrossRef]

- Zhao, R.; Zhou, Y.; Zhang, D.; Gao, X. Numerical investigation of the hydraulic transport of coarse particles in a vertical pipe based on a fully-coupled numerical model. Int. J. Multiph. Flow 2022, 155, 104094. [Google Scholar] [CrossRef]

- Fei, T.; Erfeng, Z.; Chen, Y.; Shi, W.; Zhang, C. Review of Numerical Simulation Research on Submersible Mixer for Sewage. Front. Energy Res. 2022, 9, 818211. [Google Scholar] [CrossRef]

- Han, D.; Zhang, D.; Jing, H.; Yang, L.; Cui, T.; Ding, Y.; Wang, Z.; Wang, Y.; Zhang, T. DEM—CFD coupling simulation and optimization of an inside-filling air-blowing maize precision seed-metering device. Comput. Electron. Agric. 2018, 150, 426–438. [Google Scholar] [CrossRef]

- Dong, H.; Zhang, B.; Jiang, T.; Zhang, Y.; Qu, J.; Chen, C.; Xiao, Y.; Ding, Y.; Xi, X. Design and Optimization of Rice Grain Screening System Based on DEM-CFD Coupled Rice Seed Testing Platform. Agronomy 2022, 12, 3069. [Google Scholar] [CrossRef]

- Zhang, F.; Yu, F.; Li, Z.; Zhang, H.; Lan, H.; Li, P.; Li, P.; Zhang, C. Design and field testing of the air-suction machine for picking up Chinese jujube fruits. J. Fruit Sci. 2020, 37, 278–285. [Google Scholar]

- Zhang, F.; Ran, J.; Li, Z.; Wang, D.; Li, P. Optimization of working parameters of air- suction machine for picking up ground jujube. J. Fruit Sci. 2021, 38, 1190–1200. [Google Scholar]

- Xu, H.; Hua, Y.; He, J.; Chen, Q. The Positive and Negative Synergistic Airflow-Type Jujube Fruit Harvester (P-N JH). Processes 2022, 10, 1486. [Google Scholar] [CrossRef]

- Markauskas, D.; Platzk, S.; Kruggel-Emden, H. Comparative numerical study of pneumatic conveying of flexible elongated particles through a pipe bend by DEM-CFD. Powder Technol. 2022, 399, 117170. [Google Scholar] [CrossRef]

- Guo, W.; Hu, C.; He, X.; Wang, L.; Hou, S.; Wang, X. Construction of virtual mulch film model based on discrete element method and simulation of its physical mechanical properties. Int. J. Agric. Biol. Eng. 2020, 13, 211–218. [Google Scholar] [CrossRef]

- Wang, J.; Guo, F.; Xu, Y.; Zhu, J.; Li, R.; Tang, H.; Zhou, W.; Wang, Q.; Sun, X. Analysis of the Interaction Mechanism between Preharvest Threshing Device and Rice at Harvesting Period Based on DEM Simulations and Bench Tests. Agriculture 2024, 14, 183. [Google Scholar] [CrossRef]

- Yan, K.; Yao, S.; Huang, Y.; Zhao, Z. Study on Pulling Dynamic Characteristics of White Radish and the Optimal Design of a Harvesting Device. Agriculture 2023, 13, 942. [Google Scholar] [CrossRef]

- Ren, Y.; Guo, W.; Wang, X.; Hu, C.; Wang, L.; He, X.; Xing, J. Separation and mechanical properties of residual film and soil. Int. J. Agric. Biol. Eng. 2023, 16, 184–192. [Google Scholar] [CrossRef]

- Gao, Y.; Song, L.; Wang, L.; Wang, H.; Li, Y. Behavior of maize grains on the three-dimensional translational vibrating sieve. Powder Technol. 2022, 412, 117999. [Google Scholar] [CrossRef]

- Shi, Q.; Sakai, M. Numerical study on the elucidation of powder mixing mechanism in a container blender. Adv. Powder Technol. 2023, 34, 104231. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, S.; Cui, T.; Gao, Y.; Wang, B. Kinetic characteristics of a bionic screen with continuous variable amplitude from front to rear and behavior of maize mixture on the screen. Powder Technol. 2023, 424, 118370. [Google Scholar] [CrossRef]

- Jin, W.; Zhang, X.; Ding, Y.; Bai, S.; Liu, W.; Zhou, X. Experiment on Suspension Separation of Residual Film and Impurity Based on EDEM-Fluent Coupling. Trans. Chin. Soc. Agric. Mach. 2022, 53, 89–98. [Google Scholar] [CrossRef]

- Guo, W.; He, X.; Wang, L.; Zhao, P.; Hu, C.; Hou, S.; Wang, X. Development of a comb tooth loosening and pneumatic stripping plough layer residual film recovery machine. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2020, 36, 1–10. [Google Scholar] [CrossRef]

- Ren, D.; Li, J.; Nie, Y.; Zhang, Y.; Cheng, H.; Zhang, L.; Gong, Y. Design and Experimental Study on Air-suction Hazelnut Picking and Cleaning Machine. J. Shenyang Agric. Univ. 2022, 53, 177–186. [Google Scholar]

- Fang, W.; Wang, X.; Han, D.; Chen, X. Review of Material Parameter Calibration Method. Agriculture 2022, 12, 706. [Google Scholar] [CrossRef]

- Liu, J.; Tang, Z.; Zheng, X.; Yang, H.; Zhang, L.; Xiang, J.; He, X. Design and test of deep fertilization shovel for opposite row ditching. J. Gansu Agric. Univ. 2021, 56, 169–176+186. [Google Scholar]

- Fang, W.; Wang, X.; Han, D.; Zang, N.; Xue, G.; Israel, E.O. Parameter Optimization and Disturbance Analysis of the Film Picking Device of the Chain-Type Plough Layer Residual Film Recovery Machine Based on DEM—MBD Coupling. Comput. Electron. Agric. 2024, 222, 109041. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, F.; Chen, X.; Han, Y.; Tang, W. Design and parameter optimization of arc tooth and rolling bundle type plastic film residue collector. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2019, 35, 26–37. [Google Scholar] [CrossRef]

- Xie, J.; Tang, W.; Zhang, X.; Zhang, F.; Yang, Y.; Duan, W. Design and parameter optimization of swing rod driven residual plastic film collector. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2019, 35, 56–63. [Google Scholar] [CrossRef]

- Jin, W.; Liu, J.; Xu, C.; Zhang, X.; Bai, S. Design, Simulation and Experimentation of a Polythene Film Debris Recovery Machine in Soil. Appl. Sci. 2022, 12, 1366. [Google Scholar] [CrossRef]

| Particle size (mm) | 0.075~0.25 | 0.25~0.5 | 0.5~1 | 1~2 | >2 |

| Proportion (%) | 3.70 | 63.21 | 10.68 | 6.22 | 15.49 |

| Parameter | Soil | 65 Mn Steel | Residual Plastic Film |

|---|---|---|---|

| Poisson’s ratio | 0.36 | 0.35 | 0.21 |

| Shear modulus/Pa | 1 × 106 | 7.27 × 1010 | 1.12 × 106 |

| Density/(kg·m−3) | 1.610 × 103 | 7.830 × 103 | 0.915 × 103 |

| Parameter | Soil—65 Mn Steel | Soil—Residual Film | Soil—Soil | Residual Film—Residual Film | Residual Film—65 Mn Steel |

|---|---|---|---|---|---|

| coefficient of static friction | 0.50 | 0.55 | 0.74 | 0.52 | 0.45 |

| coefficient of rolling friction | 0.31 | 0.46 | 0.22 | 0.4 | 0.4 |

| coefficient of collision recovery | 0.43 | 0.5 | 0.52 | 0.57 | 0.5 |

| Levels | A: Angle between the Tine and Normal of the Air Inlet (°) | B: Minimum Distance between Tine Tip and Air Inlet (mm) | C: Width of Film Suction Port (mm) |

|---|---|---|---|

| −1 | −30 | 40 | 40 |

| 0 | 0 | 80 | 80 |

| 1 | 30 | 120 | 120 |

| Serial Number | Factor 1 A: Angle between the Tine and Normal of the Air Inlet (°) | Factor 2 B: Minimum Distance between Tine Tip and Air Inlet (mm) | Factor 3 C: Width of Film Suction Port (mm) | Response 1 Minimum Wind Velocity Required for Film Unloading ) |

|---|---|---|---|---|

| 1 | −1 | −1 | 0 | 4.2 |

| 2 | −1 | 1 | 0 | 5.3 |

| 3 | −1 | 0 | −1 | 4.5 |

| 4 | −1 | 0 | 1 | 5.1 |

| 5 | 0 | −1 | −1 | 2.2 |

| 6 | 0 | 1 | −1 | 3.8 |

| 7 | 0 | −1 | 1 | 3.2 |

| 8 | 0 | 1 | 1 | 4.1 |

| 9 | 0 | 0 | 0 | 3 |

| 10 | 0 | 0 | 0 | 3 |

| 11 | 0 | 0 | 0 | 3.2 |

| 12 | 0 | 0 | 0 | 2.9 |

| 13 | 0 | 0 | 0 | 3.1 |

| 14 | 1 | −1 | 0 | 3.2 |

| 15 | 1 | 1 | 0 | 4.5 |

| 16 | 1 | 0 | −1 | 3.3 |

| 17 | 1 | 0 | 1 | 3.7 |

| Source | Minimum Wind Velocity Required for Film Unloading ) | |||

|---|---|---|---|---|

| Sum of Squares | Degree of Freedom | F | Significant Level (p-Value) | |

| Model | 11.54 | 9 | 129.14 | <0.0001 ** |

| A | 1.90 | 1 | 191.49 | <0.0001 ** |

| B | 3.00 | 1 | 302.28 | <0.0001 ** |

| C | 0.9800 | 1 | 98.71 | <0.0001 ** |

| AB | 0.0100 | 1 | 1.01 | 0.3490 |

| AC | 0.0225 | 1 | 2.27 | 0.1759 |

| BC | 0.1225 | 1 | 12.34 | 0.0098 |

| A2 | 5.14 | 1 | 517.81 | <0.0001 ** |

| B2 | 0.1012 | 1 | 10.19 | 0.0152 |

| C2 | 0.0712 | 1 | 7.17 | 0.0317 |

| Residual | 0.0695 | 7 | ||

| Lack of Fit | 0.0175 | 3 | 0.4487 | 0.7318 |

| Pure Error | 0.0520 | 4 | ||

| Cor Total | 11.61 | 16 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, W.; Wang, X.; Zhu, C.; Han, D.; Zang, N.; Chen, X. Analysis of Film Unloading Mechanism and Parameter Optimization of Air Suction-Type Cotton Plough Residual Film Recovery Machine Based on CFD—DEM Coupling. Agriculture 2024, 14, 1021. https://doi.org/10.3390/agriculture14071021

Fang W, Wang X, Zhu C, Han D, Zang N, Chen X. Analysis of Film Unloading Mechanism and Parameter Optimization of Air Suction-Type Cotton Plough Residual Film Recovery Machine Based on CFD—DEM Coupling. Agriculture. 2024; 14(7):1021. https://doi.org/10.3390/agriculture14071021

Chicago/Turabian StyleFang, Weiquan, Xinzhong Wang, Changshun Zhu, Dianlei Han, Nan Zang, and Xuegeng Chen. 2024. "Analysis of Film Unloading Mechanism and Parameter Optimization of Air Suction-Type Cotton Plough Residual Film Recovery Machine Based on CFD—DEM Coupling" Agriculture 14, no. 7: 1021. https://doi.org/10.3390/agriculture14071021

APA StyleFang, W., Wang, X., Zhu, C., Han, D., Zang, N., & Chen, X. (2024). Analysis of Film Unloading Mechanism and Parameter Optimization of Air Suction-Type Cotton Plough Residual Film Recovery Machine Based on CFD—DEM Coupling. Agriculture, 14(7), 1021. https://doi.org/10.3390/agriculture14071021