Interaction Mechanisms between Blades and Maize Root–Soil Composites as Affected by Key Factors: An Experimental Analysis

Abstract

:1. Introduction

2. Materials and Methods

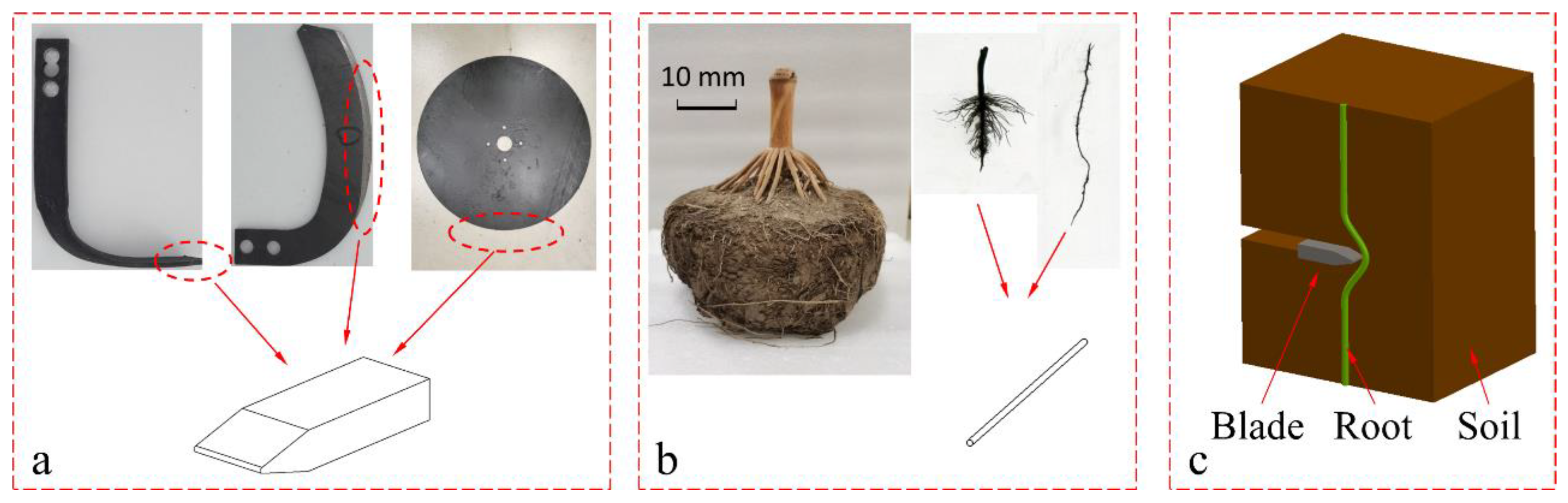

2.1. Simplified Method of the Experiment

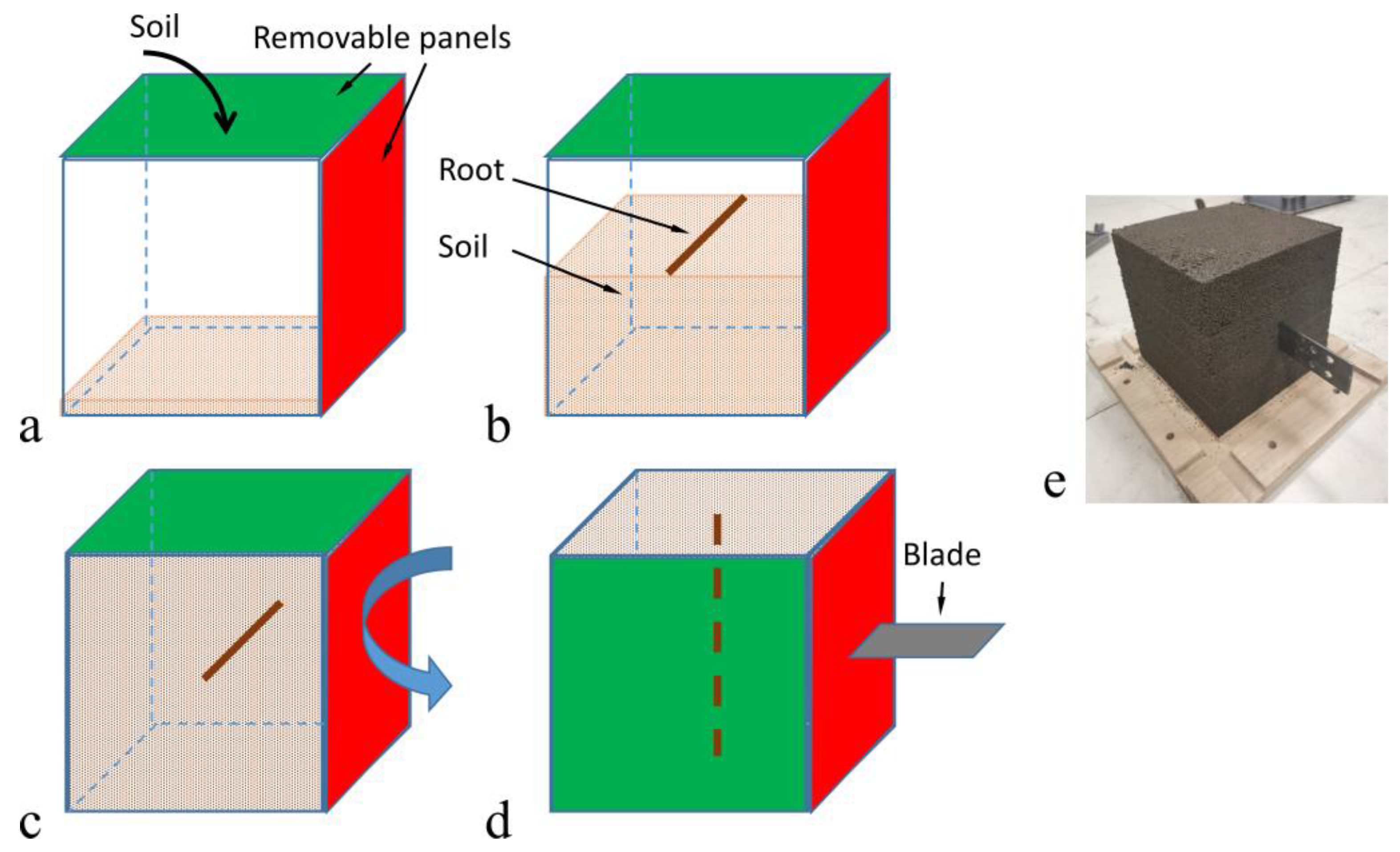

2.2. Sample Preparation

- Remove the green plate of the box, fill the box with the soil in four batches, and compact the soil to the specified compaction (Figure 2a);

- Place the root on the surface of the second layer of the compacted soil (Figure 2b);

- Remove the red plate, install the green plate, and rotate the box 90° (Figure 2c);

- Adjust the blade plane to be perpendicular to the root (Figure 2d).

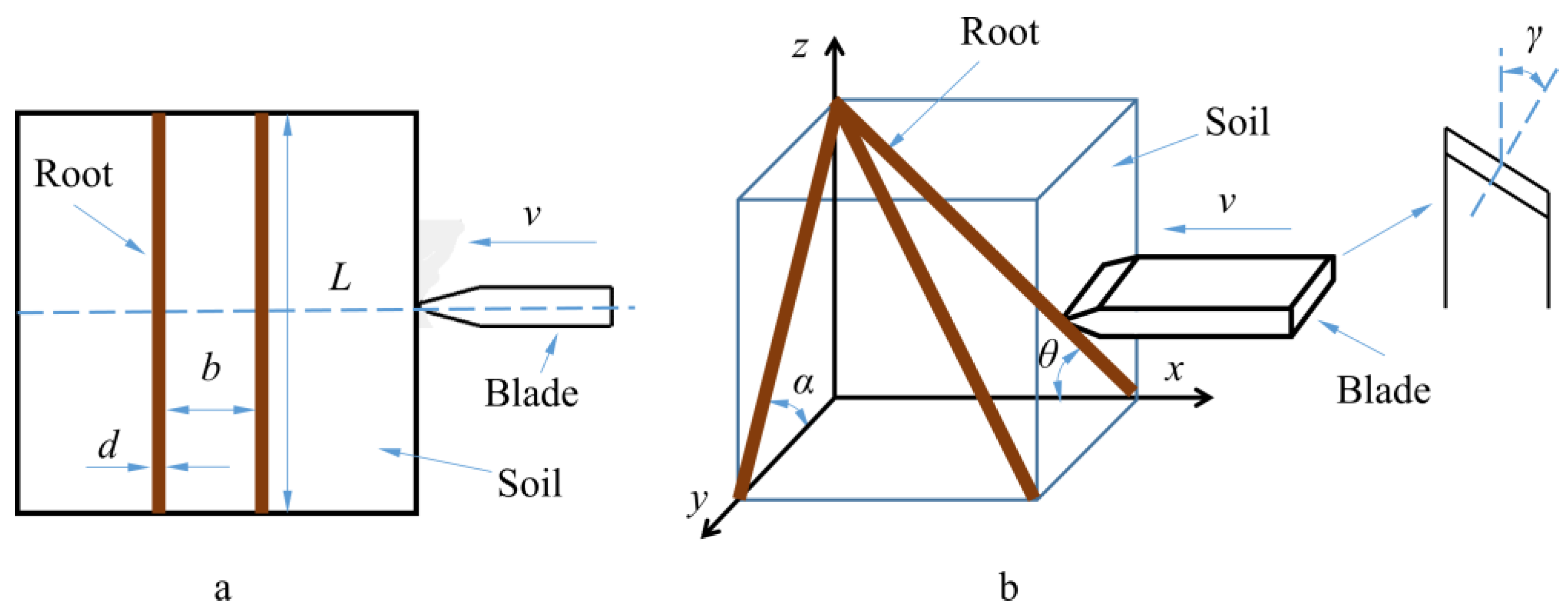

2.3. Experiment Method

3. Results

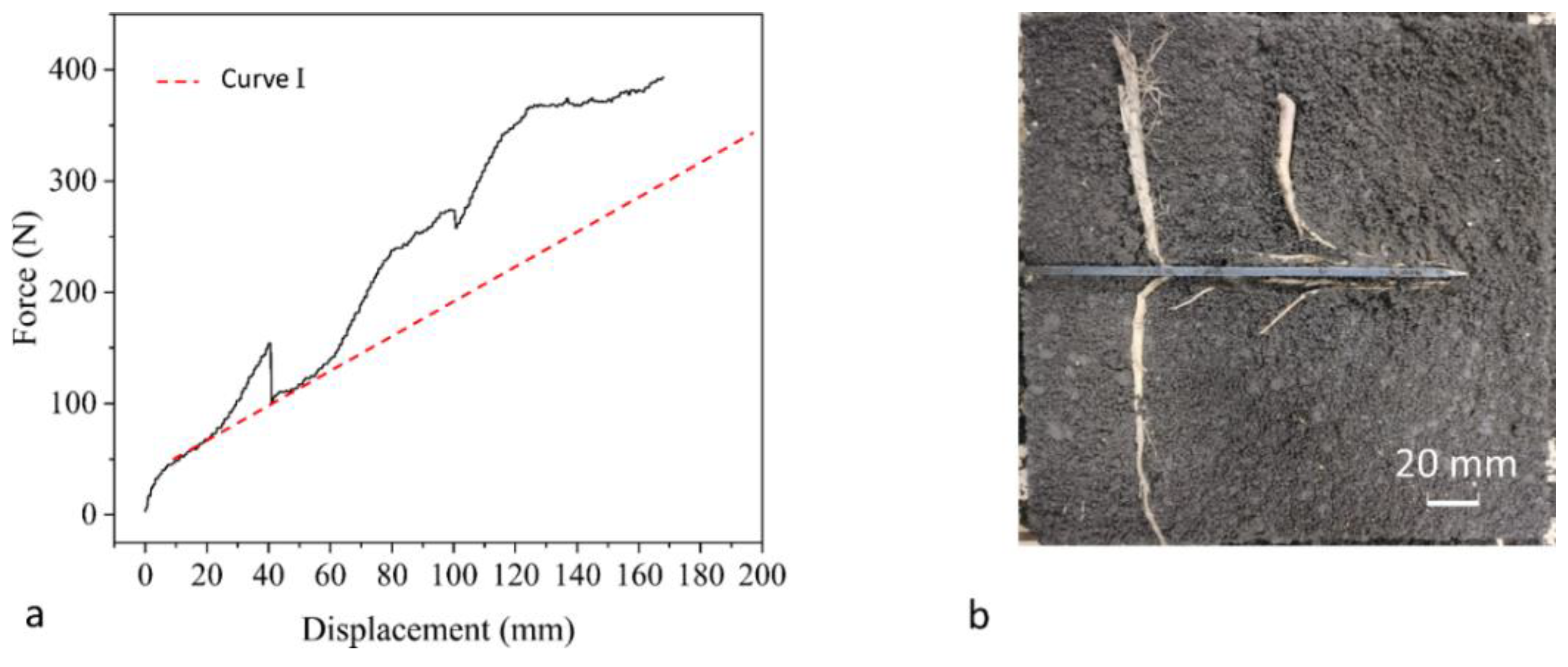

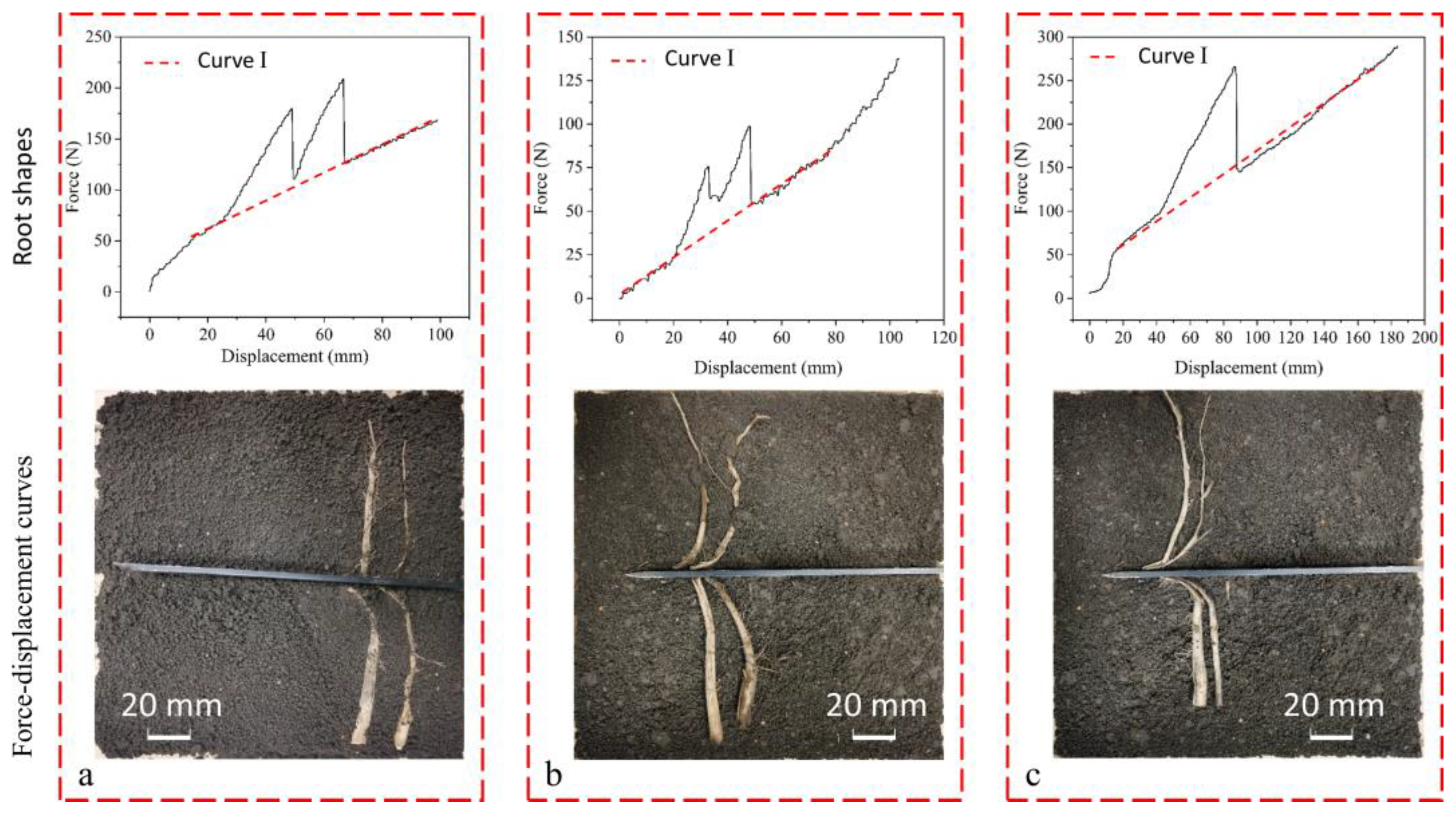

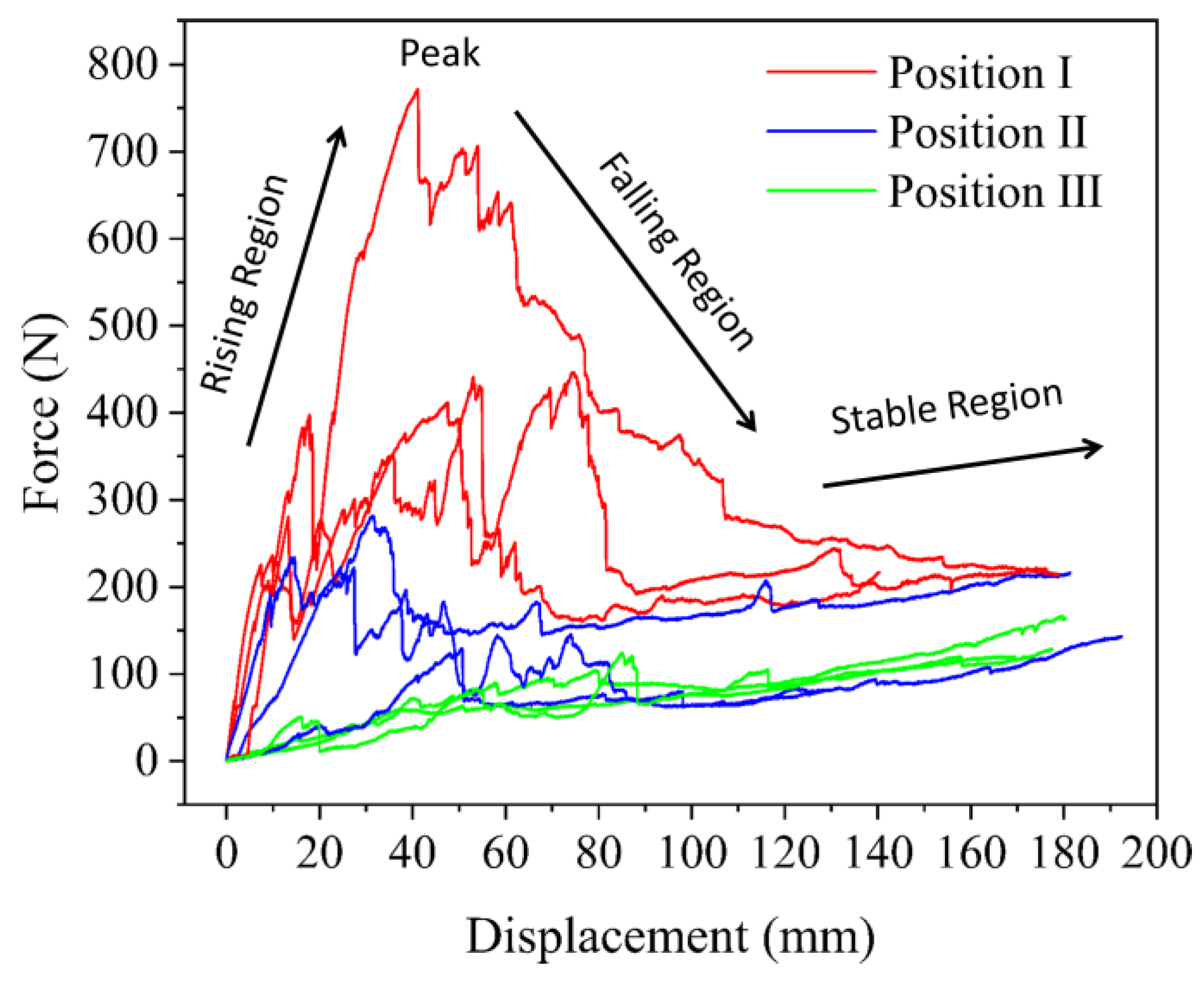

3.1. Process of Cutting Remolded Root–Soil Composites

3.1.1. Root-Cutting Force

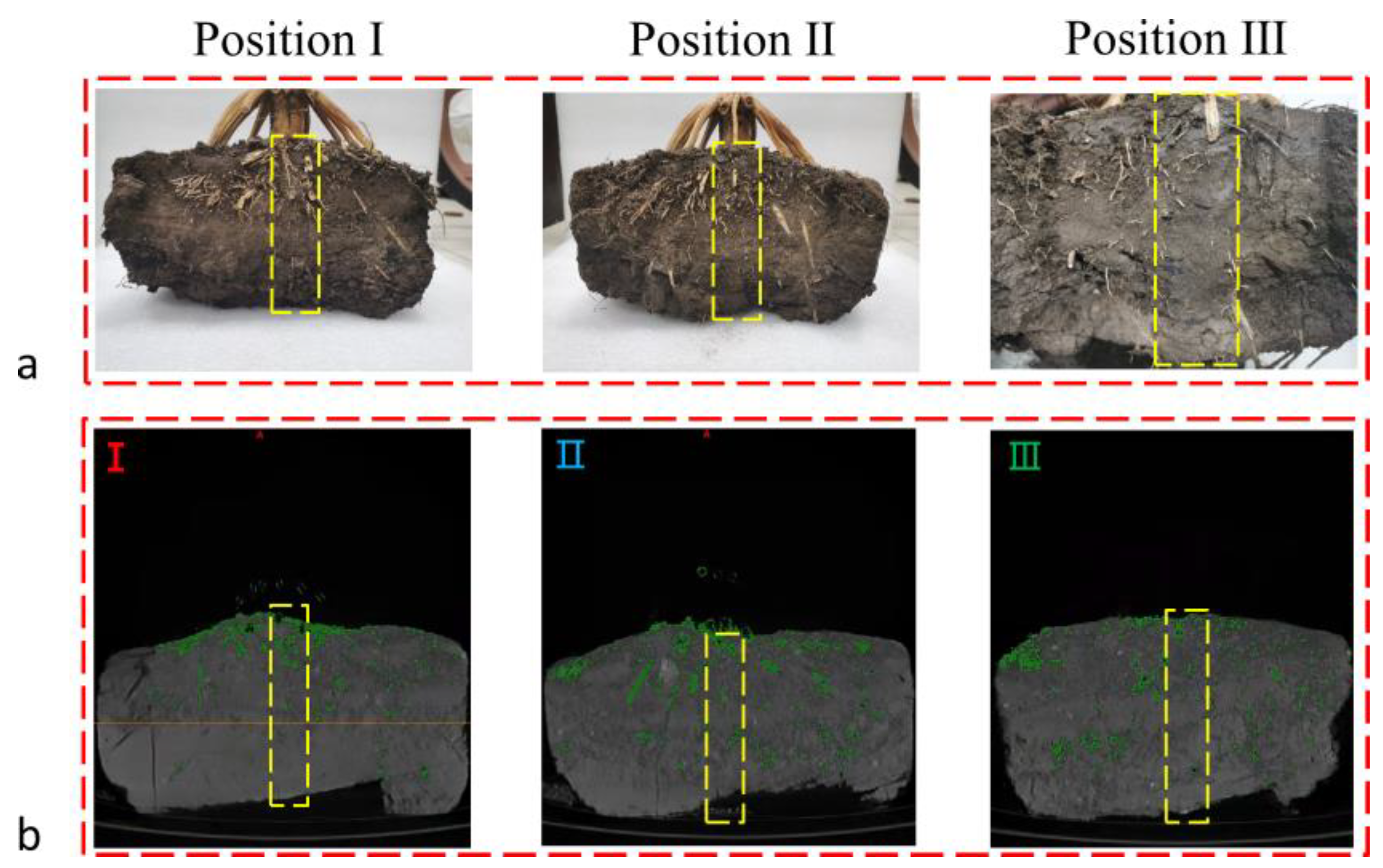

3.1.2. Root Deformation

3.1.3. Failure of the Root–Soil Interface

3.2. Effect of Key Parameters of Root–Soil Composites on Cutting

3.2.1. Effect of Soil Compaction on Cutting

3.2.2. Effect of the Root Diameter on Cutting

3.2.3. Effect of the Root–Soil Interface Force on Cutting

3.2.4. Effect of the Distance between Neighboring Roots on Cutting

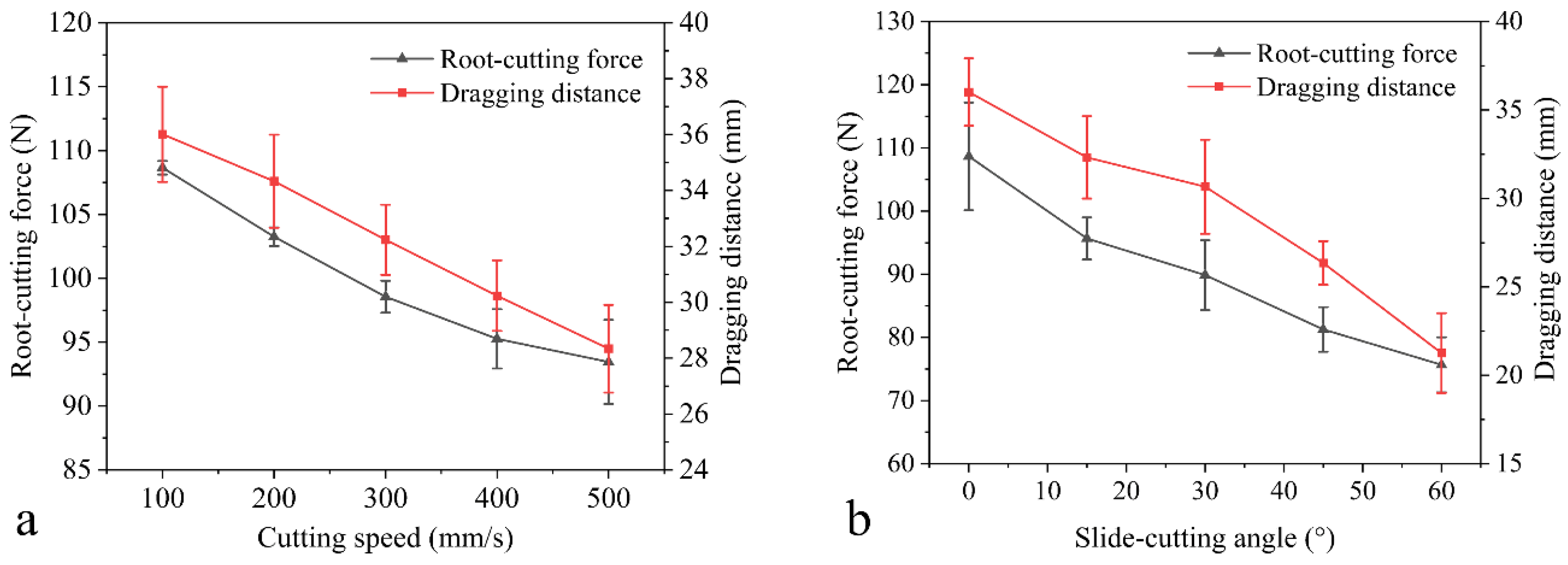

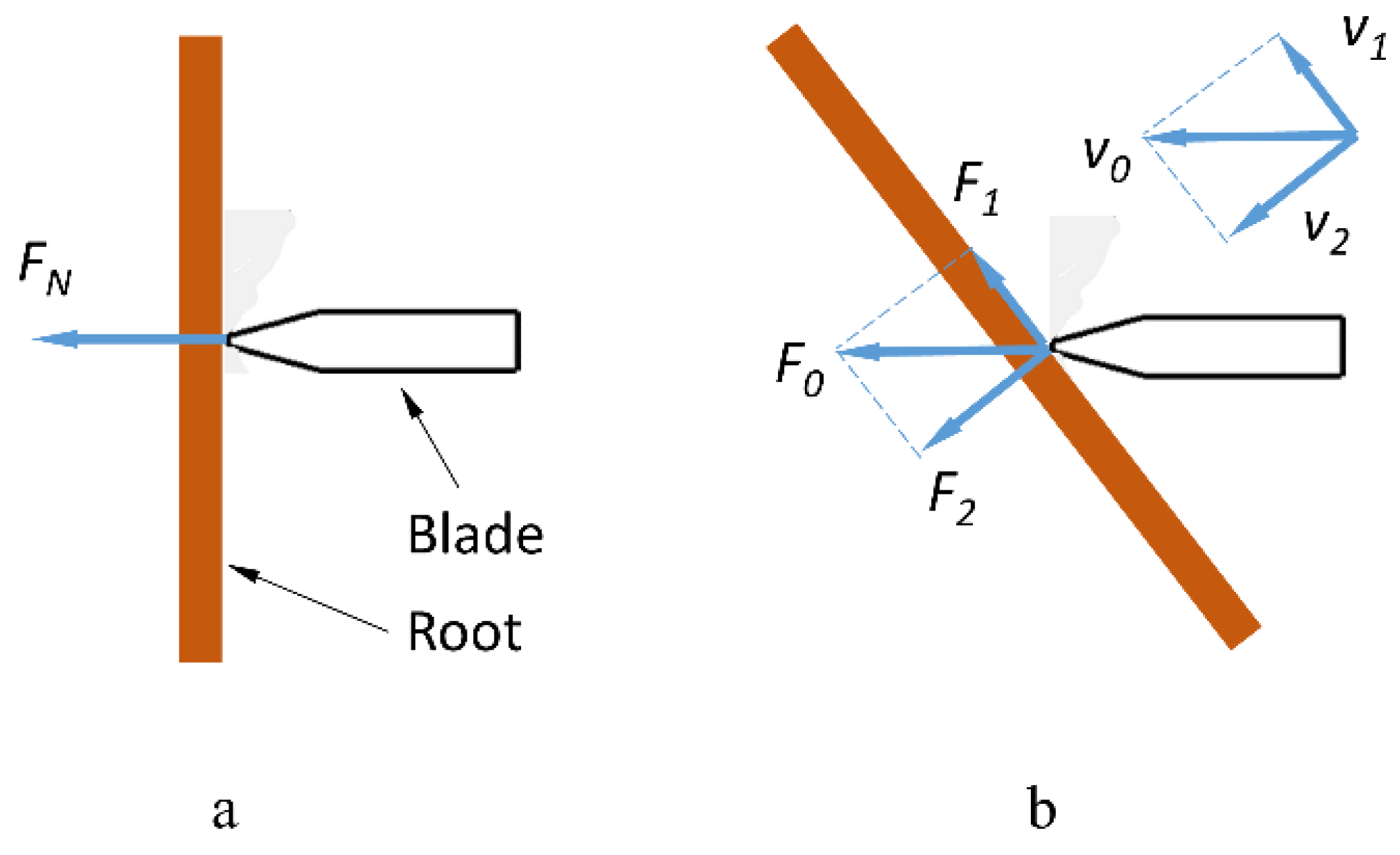

3.3. Effect of Blade Cutting Parameters on Cutting

3.3.1. Effect of the Slide-Cutting Angle on Cutting

3.3.2. Effect of the Cutting Speed on Cutting

3.3.3. Effect of the Bevel Angle on Cutting

3.3.4. Effect of the Oblique Angle on Cutting

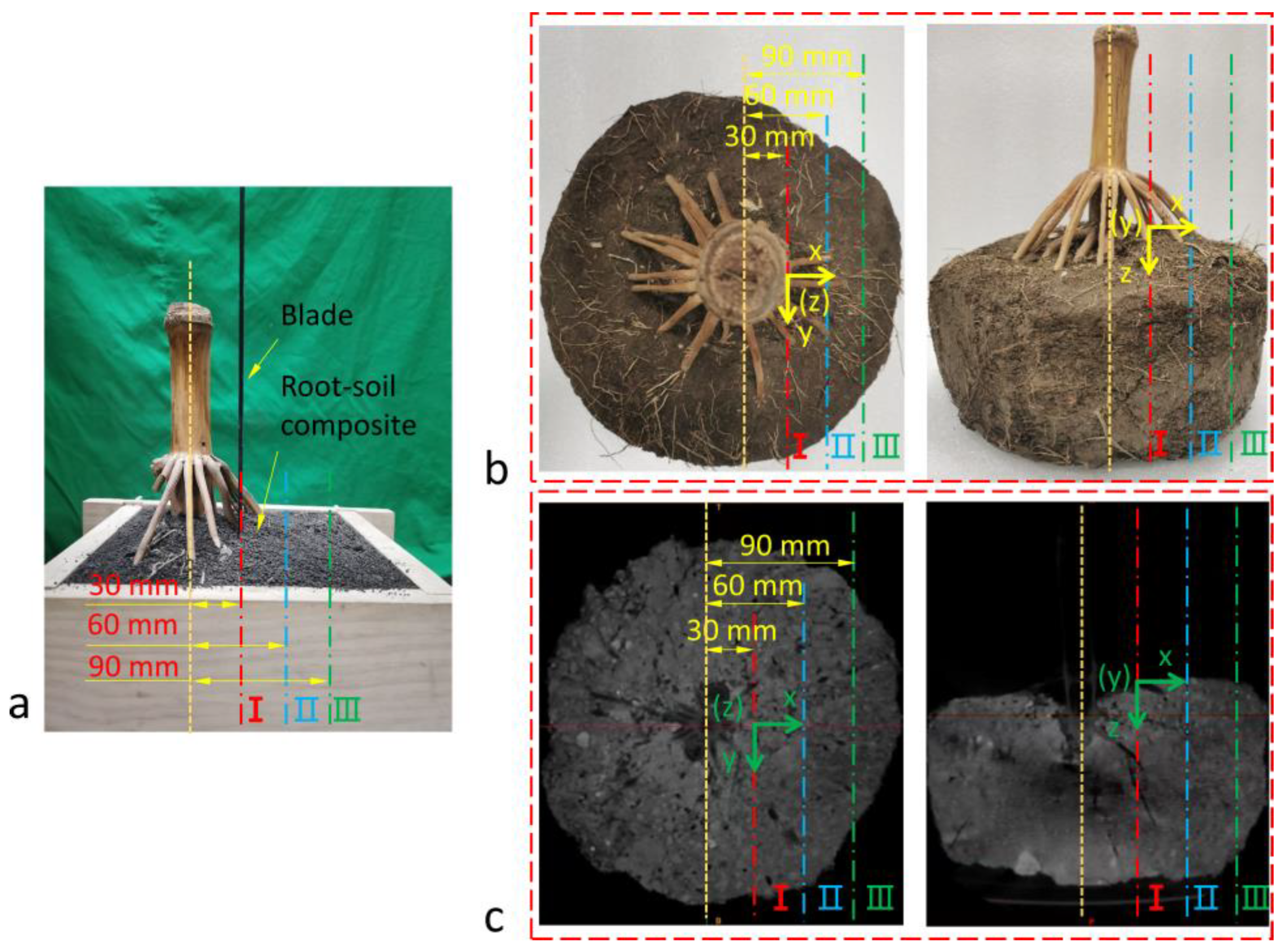

3.4. Process of Cutting Maize Root–Soil Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Keshavarz Afshar, R.; Cabot, P.; Ippolito, J.A.; Dekamin, M.; Reed, B.; Doyle, H.; Fry, J. Corn Productivity and Soil Characteristic Alterations Following Transition from Conventional to Conservation Tillage. Soil Tillage Res. 2022, 220, 105351. [Google Scholar] [CrossRef]

- Rocco, S.; Munkholm, L.J.; Jensen, J.L. Long-Term Soil Quality and C Stock Effects of Tillage and Cover Cropping in a Conservation Agriculture System. Soil Tillage Res. 2024, 241, 106129. [Google Scholar] [CrossRef]

- He, J.; Li, H.; Chen, H.; Lu, C.; Wang, Q. Research Progress of Conservation Tillage Technology and Machine. Trans. Chin. Soc. Agric. Mach. 2018, 49, 1–19. [Google Scholar] [CrossRef]

- Xie, M. A Study on the Soil Mechanical Role of Tree Roots in the Stability of Slopes. J. Soil Water Conserv. 1990, 4, 7–14. [Google Scholar]

- Zhang, S.; Zhao, H.; Wang, X.; Dong, J.; Zhao, P.; Yang, F.; Chen, X.; Liu, F.; Huang, Y. Discrete Element Modeling and Shear Properties of the Maize Stubble-Soil Complex. Comput. Electron. Agric. 2023, 204, 107519. [Google Scholar] [CrossRef]

- Zhao, J.; Lu, Y.; Guo, M.; Fu, J.; Wang, Y. Design and Experiment of Bionic Stubble Breaking-Deep Loosening Combined Tillage Machine. Int. J. Agric. Biol. Eng. 2021, 14, 123–134. [Google Scholar] [CrossRef]

- Zhu, H.; Wu, X.; Bai, L.; Qian, C.; Zhao, H.; Li, H. Development of the Biaxial Stubble Breaking No-Tillage Device for Rice Stubble Field Based on EDEM-ADAMS Simulation. Trans. Chin. Soc. Agric. Eng. 2022, 38, 10–22. [Google Scholar] [CrossRef]

- Lin, J.; Lv, Z.; Li, H.; Wang, X.; Wang, D. Design and Experiment of Passive Anti-Winding Stubble Breaking and Ridge Cleaning Device for No-Tillage Planter. Trans. Chin. Soc. Agric. Mach. 2023, 54, 19–27. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, S.; Gao, L.; Yuan, Y.; Yang, Y. Design and Experiment of Passive Disc Cutting Blade in Corn Ridges. Trans. Chin. Soc. Agric. Mach. 2021, 52, 59–67. [Google Scholar] [CrossRef]

- Zheng, L.; Luo, X.; Zeng, S.; Wang, Z.; Liu, C.; Qi, X. Shear Characteristics of Rice Root-Soil Composite. Trans. Chin. Soc. Agric. Mach. 2017, 48, 63–71. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Z.; Huang, Q.; Zhang, G. Cutting Performance of Corn Root-Soil Composite. Trans. Chin. Soc. Agric. Mach. 2013, 44, 126–132. [Google Scholar] [CrossRef]

- Li, M.; Xu, S.; Yang, Y.; Guo, L.; Tong, J. A 3D Simulation Model of Corn Stubble Cutting Using Finite Element Method. Soil Tillage Res. 2017, 166, 43–51. [Google Scholar] [CrossRef]

- Zou, L.; Yan, D.; Niu, Z.; Yuan, J.; Cheng, H.; Zheng, H. Parametric Analysis and Numerical Optimisation of Spinach Root Vibration Shovel Cutting Using Discrete Element Method. Comput. Electron. Agric. 2023, 212, 108138. [Google Scholar] [CrossRef]

- Zhang, S.; Jia, X.; Dong, J.; Wang, X.; Zhao, H.; Chen, X.; Zhang, Z.; Huang, Y.; Shi, J. Optimization of Operating Angles of Disc Coulters for Maize Residue Management Using Discrete Element Method. Comput. Electron. Agric. 2024, 218, 108691. [Google Scholar] [CrossRef]

- Yuan-jun, J.; Alam, M.; Li-Jun, S.; Umar, M.; Sadiq, S.; Jia, L.J.; Rahman, M. Effect of Root Orientation on the Strength Characteristics of Loess in Drained and Undrained Triaxial Tests. Eng. Geol. 2022, 296, 106459. [Google Scholar] [CrossRef]

- Zhang, C.B.; Chen, L.H.; Liu, Y.P.; Ji, X.D.; Liu, X.P. Triaxial Compression Test of Soil-Root Composites to Evaluate Influence of Roots on Soil Shear Strength. Ecol. Eng. 2010, 36, 19–26. [Google Scholar] [CrossRef]

- Ning, P.; Xia, X.; Jiang, Y. An Estimation Model of the Ultimate Shear Strength of Root-Permeated Soil, Fully Considering Interface Bonding. Forests 2023, 14, 819. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, L.C. On the Mechanics and Material Removal Mechanisms of Vibration-Assisted Cutting of Unidirectional Fibre-Reinforced Polymer Composites. Int. J. Mach. Tools Manuf. 2014, 80, 1–10. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, L. Mechanics of Fibre Deformation and Fracture in Vibration-Assisted Cutting of Unidirectional Fibre-Reinforced Polymer Composites. Int. J. Mach. Tools Manuf. 2016, 103, 40–52. [Google Scholar] [CrossRef]

- Voss, R.; Seeholzer, L.; Kuster, F.; Wegener, K. Analytical Force Model for Orthogonal Machining of Unidirectional Carbon Fibre Reinforced Polymers (CFRP) as a Function of the Fibre Orientation. J. Mater. Process. Technol. 2019, 263, 440–469. [Google Scholar] [CrossRef]

- Wu, T.H. Study of Soil-Root Interaction. J. Geotech. Eng. 1989, 114, 1351–1375. [Google Scholar] [CrossRef]

- Song, S.; Zhou, H.; Jia, Z.; Xu, L.; Zhang, C.; Shi, M.; Hu, G. Effects of Cutting Parameters on the Ultimate Shear Stress and Specific Cutting Energy of Sisal Leaves. Biosyst. Eng. 2022, 218, 189–199. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; Zhao, H.; Liu, B.; Ma, J.; He, Y.; Zhang, Y.; Xu, H. Effects of Cutting Parameters on Cutting of Citrus Fruit Stems. Biosyst. Eng. 2020, 193, 1–11. [Google Scholar] [CrossRef]

- Guo, H.; Goldsmith, J.; Delacruz, I.; Tao, M.; Luo, Y.; Koehler, S.A. Semi-Infinite Plates Dragged through Granular Beds. J. Stat. Mech. Theory Exp. 2012, 2012, P07013. [Google Scholar] [CrossRef]

- Schwarz, M.; Cohen, D.; Or, D. Root-Soil Mechanical Interactions during Pullout and Failure of Root Bundles. J. Geophys. Res. Earth Surf. 2010, 115, 1–19. [Google Scholar] [CrossRef]

- Dhaliwal, J.K.; Kumar, S. 3D-Visualization and Quantification of Soil Porous Structure Using X-ray Micro-Tomography Scanning under Native Pasture and Crop-Livestock Systems. Soil Tillage Res. 2022, 218, 105305. [Google Scholar] [CrossRef]

- Hou, L.H.; Gao, W.; van der Bom, F.; Weng, Z.H.; Doolette, C.L.; Maksimenko, A.; Hausermann, D.; Zheng, Y.; Tang, C.; Lombi, E.; et al. Use of X-Ray Tomography for Examining Root Architecture in Soils. Geoderma 2022, 405, 115405. [Google Scholar] [CrossRef]

- Bai, H.; Li, R.; Wang, W.; Xie, K.; Wang, X. Investigation on Parameter Calibration Method and Mechanical Properties of Root-Reinforced Soil by DEM. Math. Probl. Eng. 2021, 2021, 6623489. [Google Scholar] [CrossRef]

- Liang, T.; Knappett, J.A.; Duckett, N. Modelling the Seismic Performance of Rooted Slopes from Individual Root-Soil Interaction to Global Slope Behaviour. Geotechnique 2015, 65, 995–1009. [Google Scholar] [CrossRef]

- Song, S.; Zhou, H.; Xu, L.; Jia, Z.; Hu, G. Cutting Mechanical Properties of Sisal Leaves under Rotary Impact Cutting. Ind. Crops Prod. 2022, 182, 114856. [Google Scholar] [CrossRef]

- Igathinathane, C.; Womac, A.R.; Sokhansanj, S. Corn Stalk Orientation Effect on Mechanical Cutting. Biosyst. Eng. 2010, 107, 97–106. [Google Scholar] [CrossRef]

- Gill, W.R.; Vanden Berg, G.E. Soil Dynamics in Tillage and Traction, 1st ed.; U.S. Government Printing Office: Washington, DC, USA, 1967.

- Wu, T.H.; Watson, A. In Situ Shear Tests of Soil Blocks with Roots. Can. Geotech. J. 1998, 35, 579–590. [Google Scholar] [CrossRef]

- Hetenyi, M. Beams on Elastic Foundation Theory with Applications in the Fields of Civil and Mechanical Engineering; The University of Michigan Press: Ann Arborc, MI, USA, 1946. [Google Scholar]

- Tamás, K.; Bernon, L. Role of Particle Shape and Plant Roots in the Discrete Element Model of Soil–Sweep Interaction. Biosyst. Eng. 2021, 211, 77–96. [Google Scholar] [CrossRef]

- Bai, X.; Lin, J.; Lü, C.; Hu, Y. Analysis and Experiment on Working Performance of Disc Coulter for No-Tillage Seeder. Trans. Chin. Soc. Agric. Eng. 2014, 30, 1–9. [Google Scholar] [CrossRef]

- Jia, H.; Guo, M.; Guo, C.; Zheng, J.; Zhang, C.; Zhao, J. Design of Dynamic Bionic Stubble Cutting Device and Optimization Test of Parameters. Trans. Chin. Soc. Agric. Mach. 2018, 49, 103–114. [Google Scholar] [CrossRef]

- Saadati, N.; Mosaddeghi, M.R.; Sabzalian, M.R.; Jafari, M. Soil Mechanical Reinforcement by the Fibrous Roots of Selected Rangeland Plants Using a Large Soil-Root Shear Apparatus. Soil Tillage Res. 2023, 234, 105852. [Google Scholar] [CrossRef]

- Xiao, X.; Wu, L.; Li, X.; Zhang, H.; Zhou, J. Study on the Shear Strength of Root-Soil Composite and Root Reinforcement Mechanism. Forests 2022, 13, 898. [Google Scholar] [CrossRef]

- Sang, H.; He, C.; Bi, Y.; Liu, M.; Wang, X. Evaluation of the Performance of Very Narrow Tines with Different Geometrical Structures for Tilling Natural Grassland. Biosyst. Eng. 2022, 224, 34–48. [Google Scholar] [CrossRef]

- Moiceanu, G.; Voicu, P.; Paraschiv, G.; Voicu, G. Behaviour of Miscanthus at Cutting Shear with Straight Knives with Different Edge Angles. Environ. Eng. Manag. J. 2017, 16, 1203–1209. [Google Scholar] [CrossRef]

- Dowgiallo, A. Cutting Force of Fibrous Materials. J. Food Eng. 2005, 66, 57–61. [Google Scholar] [CrossRef]

- Karmakar, S.; Lal Kushwaha, R. CFD Simulation of Soil Forces on a Flat Tillage Tool. In Proceedings of the 2005 ASAE Annual International Meeting, Tampa, FL, USA, 17–20 July 2005; Volume 0300. [Google Scholar]

- Liu, Z.; Wang, T.; Liu, S.; Yan, X.; Zhao, H.; Wu, X.; Zhang, S. Design and Experimental Study of a Bionic Blade for Harvesting the Wild Chrysanthemum Stem. Agriculture 2023, 13, 190. [Google Scholar] [CrossRef]

- Aydın, İ.; Arslan, S. Mechanical Properties of Cotton Shoots for Topping. Ind. Crops Prod. 2018, 112, 396–401. [Google Scholar] [CrossRef]

- Zhang, C.L.; Chen, L.Q.; Xia, J.F.; Zhang, J.M. Effects of Blade Sliding Cutting Angle and Stem Level on Cutting Energy of Rice Stems. Int. J. Agric. Biol. Eng. 2019, 12, 75–81. [Google Scholar] [CrossRef]

- Ghahraei, O.; Ahmad, D.; Khalina, A.; Suryanto, H.; Othman, J. Cutting Tests of Kenaf Stems. Trans. ASABE 2011, 54, 51–56. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics, 1st ed.; Cambridge University Press: London, UK, 1985. [Google Scholar]

- Johnson, P.C.; Clementson, C.L.; Mathanker, S.K.; Grift, T.E.; Hansen, A.C. Cutting Energy Characteristics of Miscanthus x Giganteus Stems with Varying Oblique Angle and Cutting Speed. Biosyst. Eng. 2012, 112, 42–48. [Google Scholar] [CrossRef]

| Levels | Factors | |||

|---|---|---|---|---|

| Soil Compaction W/MPa | Root Length L/mm | Root Diameter d/mm | Distance between Roots b/mm | |

| 1 | 0.8 | 100 | 1.5 | 5 |

| 2 | 1 | 150 | 2.5 | 10 |

| 3 | 1.2 | 200 | 3.5 | 15 |

| Levels | Factors | |||

|---|---|---|---|---|

| Bevel Angle α/° | Oblique Angle θ/° | Slide-Cutting Angle γ/° | Cutting Speed v/(mm/s) | |

| 1 | 30 | 30 | 0 | 100 |

| 2 | 45 | 45 | 15 | 200 |

| 3 | 60 | 60 | 30 | 300 |

| 4 | 75 | 75 | 45 | 400 |

| 5 | 90 | 90 | 60 | 500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Gao, P.; Qi, H.; Zhang, Q.; Guo, M.; Ma, Y. Interaction Mechanisms between Blades and Maize Root–Soil Composites as Affected by Key Factors: An Experimental Analysis. Agriculture 2024, 14, 1179. https://doi.org/10.3390/agriculture14071179

Liu X, Gao P, Qi H, Zhang Q, Guo M, Ma Y. Interaction Mechanisms between Blades and Maize Root–Soil Composites as Affected by Key Factors: An Experimental Analysis. Agriculture. 2024; 14(7):1179. https://doi.org/10.3390/agriculture14071179

Chicago/Turabian StyleLiu, Xuanting, Peng Gao, Hongyan Qi, Qifeng Zhang, Mingzhuo Guo, and Yunhai Ma. 2024. "Interaction Mechanisms between Blades and Maize Root–Soil Composites as Affected by Key Factors: An Experimental Analysis" Agriculture 14, no. 7: 1179. https://doi.org/10.3390/agriculture14071179