Variable-Rate Fertilization for Summer Maize Using Combined Proximal Sensing Technology and the Nitrogen Balance Principle

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Procedure

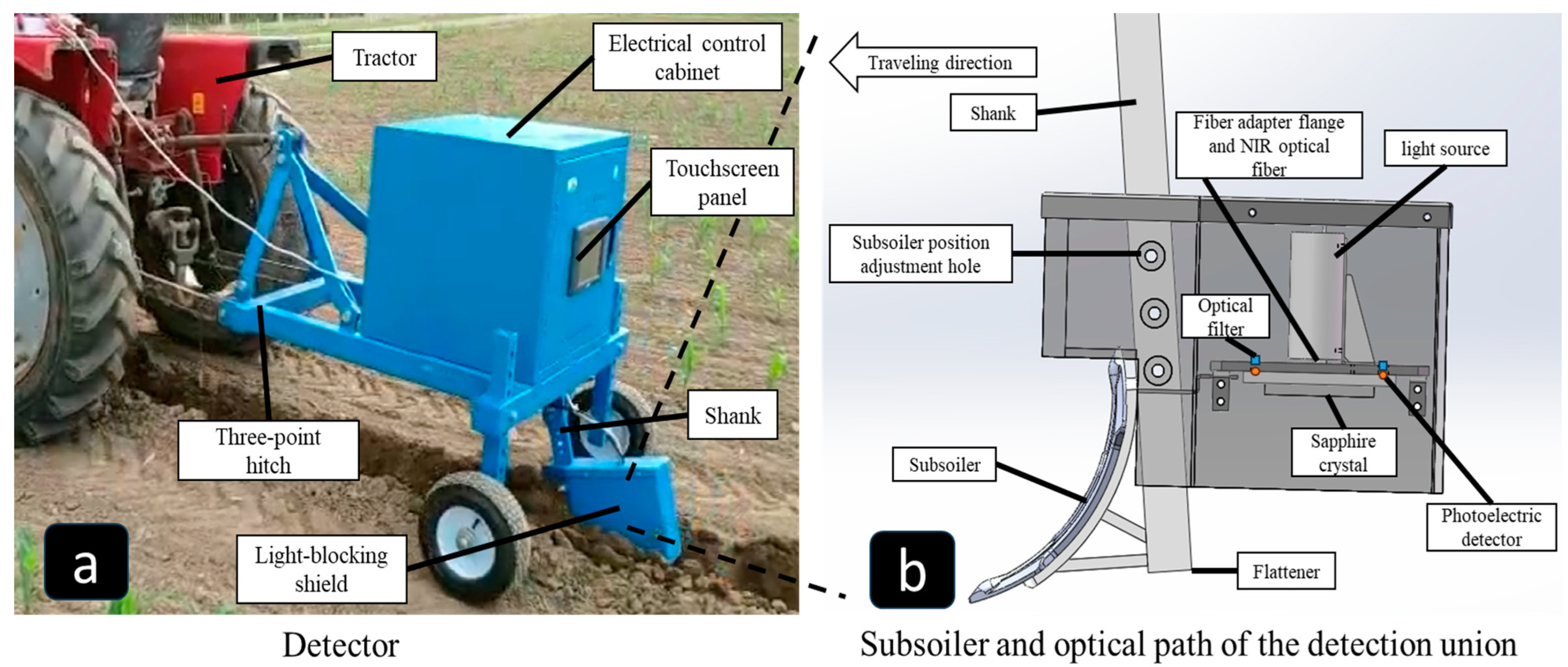

2.2. On-Line Soil Sensing

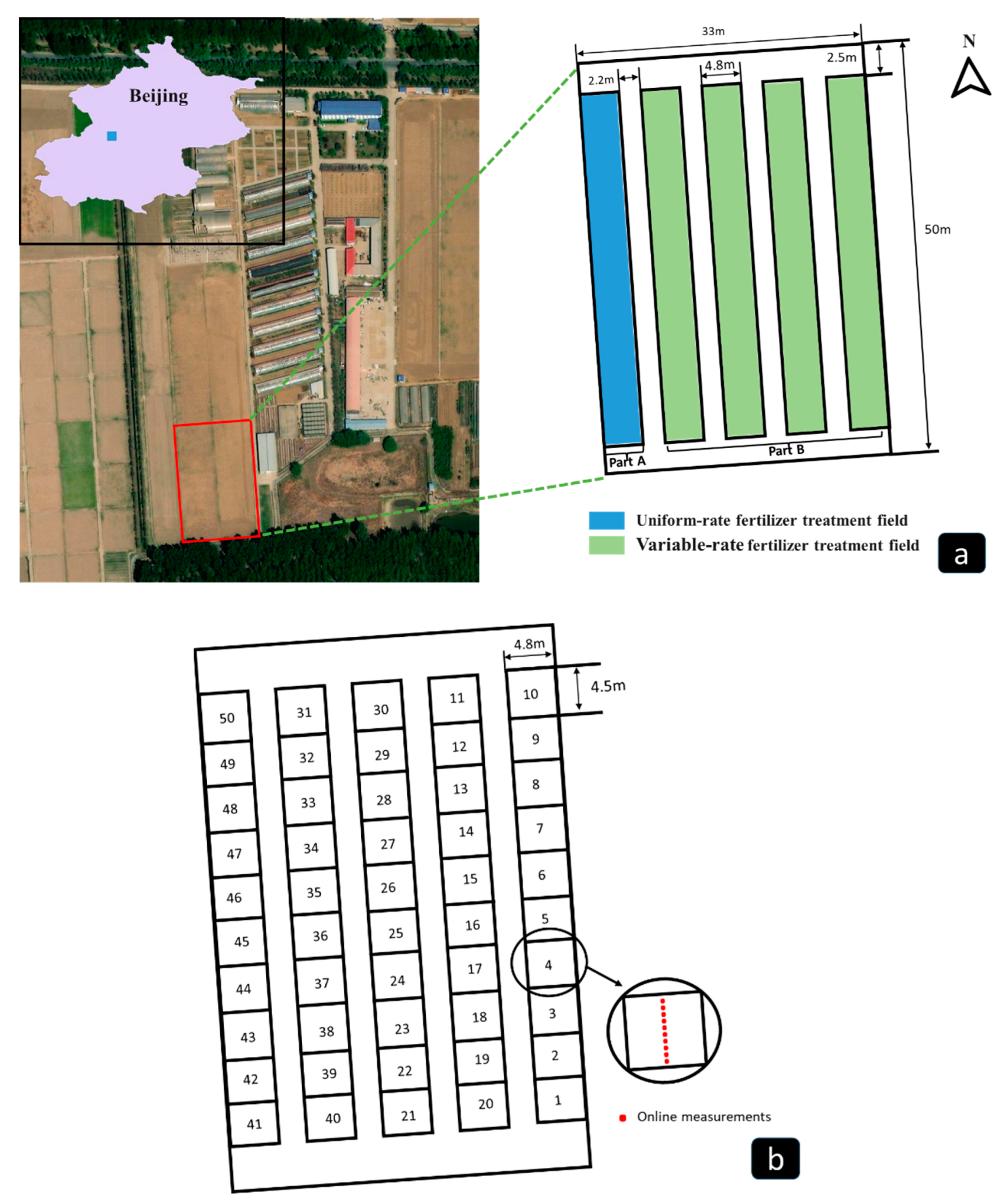

2.3. Experimental Field

2.4. Development of N Fertilizer Application Model

3. Results

3.1. Map Development for STN

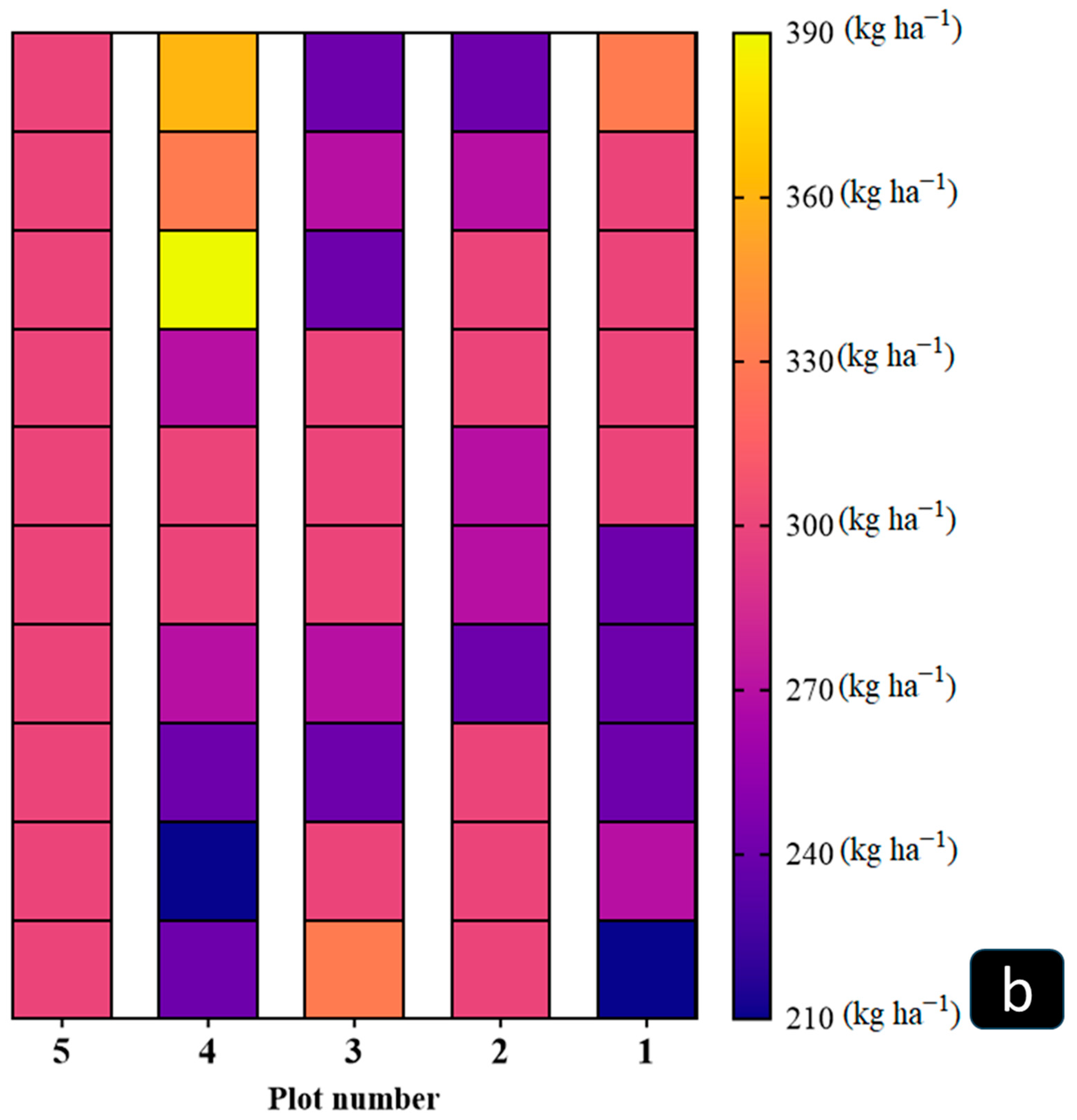

3.2. Fertilizer Consumption

3.3. Crop Yield and Economic Benefits

4. Discussion

4.1. Variation in Soil Total N

4.2. Economic Benefits and Environmental Protection by VRF

4.3. Feasibility Comparison of Experimental Results

4.4. Limitations of the Experiment and Future Research

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Koch, M.; Naumann, M.; Pawelzik, E.; Gransee, A.; Thiel, H. The Importance of Nutrient Management for Potato Production Part I: Plant Nutrition and Yield. Potato Res. 2020, 1, 97–119. [Google Scholar] [CrossRef]

- Martins, R.N.; Pinto, F.; Moura, A.D.; Siqueira, W.C.; Villar, F. Nitrogen Variable Rate Fertilization in Corn Crop Prescribed by Optical Sensor. J. Plant Nutr. 2020, 11, 1681–1688. [Google Scholar] [CrossRef]

- Silva, J.G.; Frana, M.G.C.; Gomide, F.T.F.; Magalhaes, J.R. Different Nitrogen Sources Affect Biomass Partitioning and Quality of Potato Production in a Hydroponic System. Am. J. Potato Res. 2013, 2, 179–185. [Google Scholar] [CrossRef]

- Azizan, F.A.; Roslan, N.; Ruslan, R.; Aznan, A.A.; Yusoff, A.Z.M. Soil NPK Variability Mapping for Harumanis Mango Grown in Greenhouse at Perlis, Malaysia. Int. J. Adv. Sci. Eng. Inf. Technol. 2019, 9, 495–501. [Google Scholar] [CrossRef]

- Jing, T.T.; Hu, H.T.; Qiu, C.X.; Li, C.J.; Zhou, J.P.; Zhang, Q.L.; Bai, C. Spatial Variability and Its Controlling Topographic Factors of Soil Moisture During Spring Plowing Season in Black Soil Hilly Region of Northeast China. Int. Soil Water Conserv. Res. 2022, 1, 58–65. [Google Scholar]

- Sanches, M.G.; Magalhães, G.S.P.; Franco, J.C.H. Site-specific Assessment of Spatial and Temporal Variability of Sugarcane Yield Related to Soil Attributes. Geoderma 2019, 334, 90–98. [Google Scholar] [CrossRef]

- Ichami, S.M.; Shepherd, K.D.; Hoffland, E.; Karuku, G.N.; Stoorvogel, J. Soil Spatial Variation to Guide the Development of Fertilizer Use Recommendations for Smallholder Farms in Western Kenya. Geoderma Reg. 2020, 22, e00300. [Google Scholar] [CrossRef]

- Siqueira, R.D.; Mandal, D.; Longchamps, L.; Khosla, R. Assessing Nitrogen Variability at Early Stages of Maize Using Mobile Fluorescence Sensing. Remote Sens. 2022, 12, 5077. [Google Scholar] [CrossRef]

- Raun, W.R.; Johnson, G.V.; Lees, H.L.; Sembiring, H.; Phillips, S.B. Microvariability in Soil Test, Plant Nutrient, and Yield Parameters in Bermudagrass. Soil Sci. Soc. Am J. 1998, 3, 683–690. [Google Scholar] [CrossRef]

- Ayoubi, S.; Zamani, S.M.; Khormali, F. Spatial Variability of Some Soil Properties for Site Specific Farming in Northern Iran. Int. J. Plant Prod. 2007, 1, 225–236. [Google Scholar]

- Atik, M.; Akdemir, B. Spatial Variability of NDVI and SPAD for Variable-and Fixed-Rate Fertilization in Olive Orchards. Erwerbs-Obstbau. 2022, 64, 647–655. [Google Scholar] [CrossRef]

- Burliai, A. Precision Agriculture as a Direction of Modernization of Agricultural Production. Modern Econ. 2021, 29, 29–34. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.Y.; Zhu, Y.; Wang, X.C.; Sun, X.; Ding, Y.F.; Cao, W.X.; Hu, Z.C. Progress and Development on Biological Information of Crop Phenotype Research Applied to Real-time Variable-rate Fertilization. Plant Methods 2020, 16, 11. [Google Scholar] [CrossRef] [PubMed]

- Martins, R.N.; Pinto, F.; Moura, A.D.; Siqueira, W.C.; Villar, F. Economic Feasibility of Optical Sensors for Variable Rate Nitrogen Fertilization in Corn. Idesia 2023, 4, 101–111. [Google Scholar]

- Wang, H.Y.; Xu, J.Z.; Chen, B.; Li, Y.W.; Li, S.; Hao, L.; Jiang, Q.J.; He, Y.; Xi, W.J. Performance of an Automatic Variable-Rate Fertilization System Subject to Different Initial Field Water Conditions and Fertilizer Doses in Paddy Fields. Agronomy 2023, 6, 1629. [Google Scholar] [CrossRef]

- Ali, M.M.; Al-Ani, A.; Eamus, D.; Tan, D.K.Y. Leaf Nitrogen Determination Using Non-Destructive Techniques—A Review. J. Plant Nutr. 2017, 40, 928–953. [Google Scholar] [CrossRef]

- Cilia, C.; Panigada, C.; Rossini, M.; Meroni, M.; Busetto, L.; Amaducci, S.; Boschetti, M.; Picchi, V.; Colombo, R. Nitrogen Status Assessment for Variable Rate Fertilization in Maize through Hyperspectral Imagery. Remote Sens. 2014, 6, 6549–6565. [Google Scholar] [CrossRef]

- Meena, R.M.; Jatav, H.S.; Dudwal, B.L.; Kumawat, P.; Meena, S.S.; Singh, V.K.; Khan, M.A.; Sathyanarayana, E.; Jatav, H.S. Fertilizer Recommendations by Using Different Geospatial Technologies in Precision Farming or Nanotechnology. Ecosyst Serv. 2022, 14, 241–257. [Google Scholar]

- Alameen, A.A.; AI-Gaadi, K.A.; Tola, E. Development and Performance Evaluation of a Control System for Variable Rate Granular Fertilizer Application. Comput. Electron. Agric. 2019, 160, 31–39. [Google Scholar] [CrossRef]

- Wang, W.H.; Cai, L.L.; Peng, P.Y.; Gong, Y.D.; Yang, X.Q. Soil Sampling Spacing Based on Precision Agriculture Variable Rate Fertilization of Pomegranate Orchard. Commun. Soil Sci. Plan. 2021, 20, 2445–2461. [Google Scholar] [CrossRef]

- Rogovska, N.; Laird, D.A.; Chiou, C.P.L.; Bond, L.J. Development of Field Mobile Soil Nitrate Sensor Technology to Facilitate Precision Fertilizer Management. Precis. Agric. 2019, 20, 40–55. [Google Scholar] [CrossRef]

- Xia, Y.; Zhang, M.; Tsang, D.; Geng, N.; Lu, D.B.; Zhu, L.F.; Igalavithana, A.D.; Dissanayake, P.D.; Rinklebe, J.; Xiao, Y.; et al. Recent Advances in Control Technologies for Non-point Source Pollution with Nitrogen and Phosphorous from Agricultural Runoff: Current Practices and Future Prospects. J. Appl. Biol. Chem. 2020, 1, 8. [Google Scholar] [CrossRef]

- Akdemir, B.; Saglam, C.; Bellitürk, K.; Makaraci, A.Z.; Urusan, A.Y.; Atar, E.S. Effect of Spatial Variability on Fertiliser Requirement of Olive Orchard Cultivated for Oil Production. J. Environ. Prot. Ecol. 2018, 19, 319–329. [Google Scholar]

- Behera, S.K.; Shukla, A.K.; Prakash, C.; Tripathi, A.; Kumar, A.; Trivedi, V. Establishing Management Zones of Soil Sulphur and Micronutrients for Sustainable Crop Production. Land Degrad Dev. 2020, 32, 3614–3625. [Google Scholar] [CrossRef]

- Rokhafrouz, M.; Latifi, H.; Abkar, A.; Wojciechwoski, T.; Czechlowski, M.; Naieni, A.S.; Maghsoudl, Y.; Niedba ła, G. Simplified and Hybrid Remote Sensing-Based Delineation of Management Zones for Nitrogen Variable Rate Application in Wheat. Agriculture 2021, 11, 1104. [Google Scholar] [CrossRef]

- Colaço, A.F.; Molin, J.P. Variable Rate Fertilization in Citrus: A Long Term Study. Precis. Agric. 2017, 18, 169–191. [Google Scholar] [CrossRef]

- Ortuani, B.; Mayer, A.; Bianchi, D.; Sona, G.; Crema, A.; Modina, D.; Bolognini, M.; Brancadoro, L.; Boschetti, M.; Facchi, A. Effectiveness of Management Zones Delineated from UAV and Sentinel-2 Data for Precision Viticulture Applications. Remote Sens. 2024, 16, 635. [Google Scholar] [CrossRef]

- Nawar, S.; Corstanje, R.; Halcro, G.; Mulla, D.J.; Mouazen, A.M. Delineation of Soil Management Zones for Variable-Rate Fertilization: A Review. Adv. Agron. 2017, 143, 175–245. [Google Scholar]

- Yang, C.; Everitt, J.H.; Bradford, J.M. Comparison of Uniform and Variable Rate Nitrogen and Phosphorus Fertilizer Application for Grain Sorghum. Trans. ASAE 2001, 2, 201–209. [Google Scholar]

- Stenberg, B.; Rossel, R.A.V.; Mouazen, A.M.; Wetterlind, J. Chapter Five-Visible and Near Infrared Spectroscopy in Soil Science. Adv. Agron. 2010, 107, 163–215. [Google Scholar]

- Sishodia, R.; Ray, R.L.; Singh, S.K. Applications of Remote Sensing in Precision Agriculture: A Review. Remote Sens. 2020, 12, 3136. [Google Scholar] [CrossRef]

- Aranguren, M.; Castellón, A.; Aizpurua, A. Wheat Yield Estimation with NDVI Values Using a Proximal Sensing Tool. Remote Sens. 2020, 12, 2749. [Google Scholar] [CrossRef]

- Knadel, M.; Thomsen, A.; Greve, M.H. Multisensor On-The-Go Mapping of Soil Organic Carbon Content. Soil Sci. Soc. Am. J. 2011, 5, 1799–1806. [Google Scholar] [CrossRef]

- Zhang, J.; Sleutel, S.; Mouazen, A.M. Phosphorus-based Variable Rate Manure Application in Wheat and Barley. Precis. Agric. 2024, 25, 1714–1730. [Google Scholar] [CrossRef]

- Maleki, M.R.; Mouazen, A.M.; Ketelaere, B.D.; Ramon, H.; Baerdemaeker, J.D. On-the-go Variable-Rate Phosphorus Fertilization Based on a Visible and Near-Infrared Soil Sensor. Biosyst. Eng. 2008, 1, 35–46. [Google Scholar] [CrossRef]

- Yang, W.; Wang, X.; Ma, W.; Li, M.Z. Variable-Rate Fertilizing for Winter Wheat Based on Canopy Spectral Reflectance. J. Jilin Univ. (Eng. Technol. Ed.) 2007, 6, 1455–1459. [Google Scholar]

- Skendžić, S.; Zovko, M.; Lesic, V.; Živković, I.P.; Lemic, D. Detection and Evaluation of Environmental Stress in Winter Wheat Using Remote and Proximal Sensing Methods and Vegetation Indices-A Review. Diversity 2023, 15, 481. [Google Scholar] [CrossRef]

- Li, T.; Xia, A.Q.; Mclaren, T.I.; Pandey, R.; Xu, Z.H.; Liu, H.D.; Manning, S.; Madgett, O.; Duncan, S.; Rasmussen, P.; et al. Preliminary Results in Innovative Solutions for Soil Carbon Estimation: Integrating Remote Sensing, Machine Learning, and Proximal Sensing Spectroscopy. Remote Sens. 2023, 15, 5571. [Google Scholar] [CrossRef]

- Marius, K.; Egidijus, Š.; Kristina, L.; Vilma, N.; Romaneckas, K.; Bruciene, I.; Buragienė, S.; Steponavičius, D. The Comparison Analysis of Uniform-and Variable-Rate Fertilizations on Winter Wheat Yield Parameters Using Site-Specific Seeding. Processes 2022, 12, 2717. [Google Scholar]

- Mirzakhaninafchi, H.; Singh, M.; Bector, V.; Gupta, O.P.; Singh, R. Design and Development of a Variable Rate Applicator for Real-Time Application of Fertilizer. Sustainability 2021, 16, 8694. [Google Scholar] [CrossRef]

- Moreno, H.; Andújar, D. Proximal Sensing for Geometric Characterization of Vines: A Review of the Latest Advances. Comput. Electron. Agric. 2023, 210, 107901. [Google Scholar] [CrossRef]

- Khakbazan, M.; Moulin, A.; Huang, J. Economic Evaluation of Variable Rate Nitrogen Management of Canola for Zones Based on Historical Yield Maps and Soil Test Recommendations. Sci. Rep. 2021, 1, 4439. [Google Scholar] [CrossRef]

- Zhou, P.; Li, M.; Yang, W.; Yao, X.Q.; Liu, Z.; Ji, R.H. Development and Performance Tests of an On-the-go Detector of Soil Total Nitrogen Concentration Based on Near-Infrared Spectroscopy. Precis. Agric. 2021, 5–6, 1479–1500. [Google Scholar] [CrossRef]

- Zhou, P.; Yang, W.; Li, M.Z.; Zheng, L.; Chen, Y. Soil Total Nitrogen Content Prediction Based on Gray Correlation-extreme Learning Machine. Trans. Chin. Soc. Agric. Mach. 2017, S1, 271–276. [Google Scholar]

- Guerrero, A.; Mouazen, A.M. Evaluation of Variable Rate Nitrogen Fertilization Scenarios in Cereal Crops From Economic, Environmental and Technical Perspective. Soil Till Res. 2021, 213, 105110. [Google Scholar] [CrossRef]

- Guerrero, A.; De Neve, S.; Mouazen, A.M. Current Sensor Technologies for In Situ and On-Line Measurement of Soil Nitrogen for Variable Rate Fertilization: A Review. Adv. Agron. 2021, 168, 1–38. [Google Scholar]

- Munnaf, M.A.; Haesaert, G.; Meirvenne, M.V.; Mouazen, A.M. Multi-Sensors Data Fusion Approach for Site-Specific Seeding of Consumption and Seed Potato Production. Precis. Agric. 2021, 1, 1890–1917. [Google Scholar] [CrossRef]

- Schillaci, C.; Tadiello, T.; Acutis, M.; Perego, A. Reducing Topdressing N Fertilization with Variable Rates Does Not Reduce Maize Yield. Sustainability 2021, 13, 8059. [Google Scholar] [CrossRef]

- Guerrero, A.; De Neve, S.; Mouazen, A.M. Data Fusion Approach for Map-Based Variable-Rate Nitrogen Fertilization in Barley and Wheat. Soil Till Res. 2020, 205, 104789. [Google Scholar] [CrossRef]

- Zhang, J.; Guerrero, A.; Mouazen, A.M. Map-Based Variable-Rate Manure Application in Wheat Using a Data Fusion Approach. Soil Till Res. 2021, 6, 104846. [Google Scholar] [CrossRef]

- Munnaf, M.A.; Guerrero, A.; Calera, M.; Mouazen, A.M. Precision Nitrogen Fertilization for Opium Poppy Using Combined Proximal and Remote Sensor Data Fusion. Remote Sens. 2023, 23, 5442. [Google Scholar] [CrossRef]

- Karapetsas, N.; Alexandridis, T.; Bilas, G.; Munnaf, M.A.; Guerrero, C.A.P.; Calera, M.; Osann, A.; Gobin, A.; Řezník, T.; Moshou, D.; et al. Mapping Soil Properties with Fixed Rank Kriging of Proximally Sensed Soil Data Fused with Sentinel-2 Biophysical Parameter. Remote Sens. 2022, 14, 1639. [Google Scholar] [CrossRef]

- Bhunia, G.S.; Shit, P.K.; Chattopadhyay, R. Assessment of Spatial Variability of Soil Properties Using Geostatistical Approach of Lateritic Soil (West Bengal, India). Ann. Agric. Sci. 2018, 16, 436–443. [Google Scholar] [CrossRef]

- Navidi, M.N.; Seyedmohammadi, J. Mapping and spatial analysis of soil chemical effective properties to manage precise nutrition and environment protection. Int. J. Environ. Anal. Chem. 2022, 8, 1948–1961. [Google Scholar] [CrossRef]

- Kempenaar, X.; Been, T.H.; Booij, J.A.; Evert, F.K.; Michielsen, J.M.G.P.; Kocks, C.G. Advances in Variable Rate Technology Application in Potato in The Netherlands. Eur. Potato J. 2018, 60, 295–305. [Google Scholar] [CrossRef]

- Kazlauskas, M.; Bruciene, I.; Algirdas, J. Comparative Analysis of Energy and GHG Emissions Using Fixed and Variable Fertilization Rates. Agronomy 2021, 1, 138. [Google Scholar] [CrossRef]

- Chen, Y.F.; Zhang, L.; Zhao, Y.H.; Zhang, L.J.; Zhang, J.W.; Liu, M.Y.; Zhou, M.; Luo, B. High-Resolution Ammonia Emissions from Nitrogen Fertilizer Application in China during 2005–2020. Atmosphere 2022, 13, 1297. [Google Scholar] [CrossRef]

- Park, J.R.; Jiang, Y.H.; Kim, E.G.; Lee, G.S.; Kim, K.-M. Nitrogen Fertilization Causes Changes in Agricultural Characteristics and Gas Emissions in Rice Field. Sustainability 2023, 4, 3336. [Google Scholar] [CrossRef]

- Shao, G.D.; Zhou, J.; Liu, B.C.; Alharbi, S.A.; Liu, E.K.; Kuzyakov, Y. Carbon footprint of maize-wheat cropping system after 40-year fertilization. Sci. Total Environ. 2024, 926, 172082. [Google Scholar] [CrossRef]

| Crop | Methodology (SNF-RHA or SNF-KA) | Result | Reference |

|---|---|---|---|

| Wheat, sugar, potatoes | SNF-RHA and SNF-KA | The RHA treatment reduced N fertilizer consumption by 16.4–118.1% compared to the KA treatment, and by 33.3–56.2% compared to the URF treatment. | [45] |

| Opium poppy | SNF-RHA and SNF-KA | The SNF-RHA treatment resulted in the highest yield at 27,400 kg ha−1, followed by the SNF-KA treatment at 27,200 kg ha−1, both of which were higher than the URF treatment yield of 26,400 kg ha−1. The N application rates were 493.5 kg ha−1 for SNF-KA, 577.9 kg ha−1 for SNF-RHA, and 560 kg ha−1 for URF. | [51] |

| Winter wheat andspring barley | SNF-RHA | For spring barley, VRF did not increase the yield, but N and phosphorus inputs were reduced by 10.7% and 17.4%, respectively. Similarly, for winter wheat, VRF did not result in a significant yield increase, but N and phosphorus inputs were reduced by 14.6% and 26.1%, respectively. | [34] |

| Maize | SNF-RHA | There was no difference in yield between VRF and URF, but VRF saved 15 kg ha−1 in N fertilizer input. | [48] |

| Winter wheat | SNF-RHA | Compared to URF, VRF increased the yield by 14.55% and saved 14 kg ha−1 in fertilizer input. | [39] |

| Maize | SNF-RHA | VRF reduced phosphorus fertilizer input by 1.25 kg ha−1 compared to URF, and significantly increased maize yield by 336 kg ha−1. | [35] |

| Potato | SNF-RHA | VRF saved an average of 25% on N fertilizer usage. | [55] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, P.; Ou, Y.; Yang, W.; Gu, Y.; Kong, Y.; Zhu, Y.; Jin, C.; Hao, S. Variable-Rate Fertilization for Summer Maize Using Combined Proximal Sensing Technology and the Nitrogen Balance Principle. Agriculture 2024, 14, 1180. https://doi.org/10.3390/agriculture14071180

Zhou P, Ou Y, Yang W, Gu Y, Kong Y, Zhu Y, Jin C, Hao S. Variable-Rate Fertilization for Summer Maize Using Combined Proximal Sensing Technology and the Nitrogen Balance Principle. Agriculture. 2024; 14(7):1180. https://doi.org/10.3390/agriculture14071180

Chicago/Turabian StyleZhou, Peng, Yazhou Ou, Wei Yang, Yixiang Gu, Yinuo Kong, Yangxin Zhu, Chengqian Jin, and Shanshan Hao. 2024. "Variable-Rate Fertilization for Summer Maize Using Combined Proximal Sensing Technology and the Nitrogen Balance Principle" Agriculture 14, no. 7: 1180. https://doi.org/10.3390/agriculture14071180

APA StyleZhou, P., Ou, Y., Yang, W., Gu, Y., Kong, Y., Zhu, Y., Jin, C., & Hao, S. (2024). Variable-Rate Fertilization for Summer Maize Using Combined Proximal Sensing Technology and the Nitrogen Balance Principle. Agriculture, 14(7), 1180. https://doi.org/10.3390/agriculture14071180