The Marginal Effect and LSTM Prediction Model under the Chinese Solar Greenhouse Film

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Greenhouse

2.2. Testing Methods and Materials

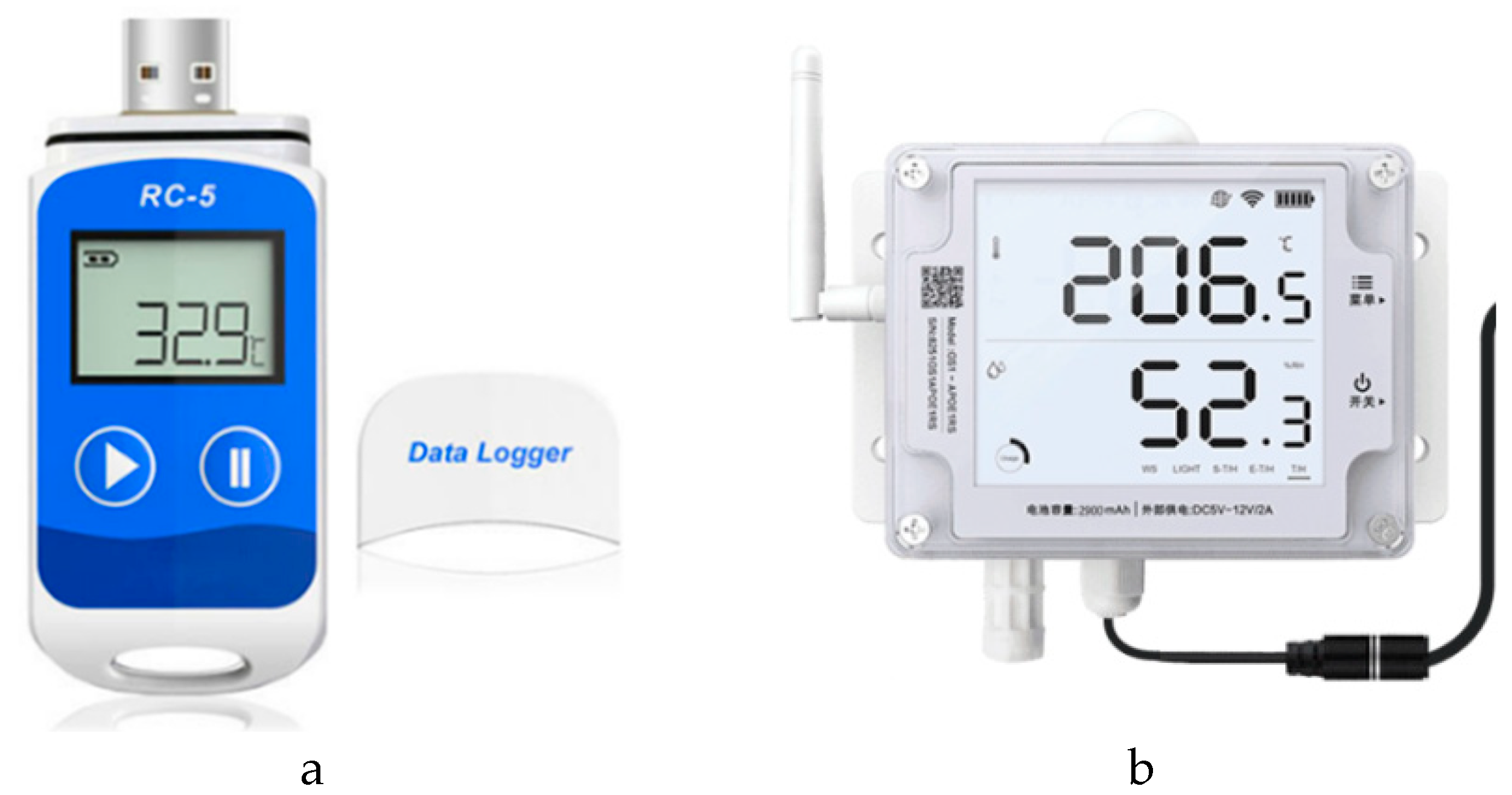

2.2.1. Test Materials

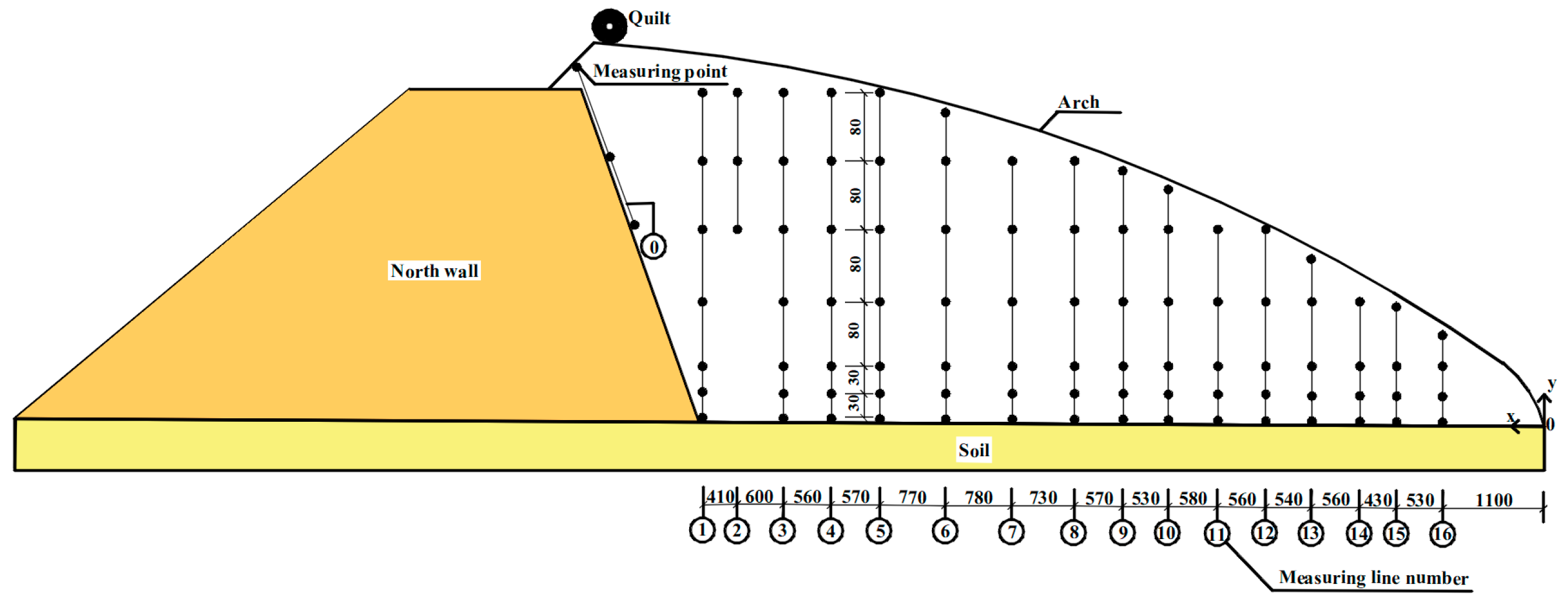

2.2.2. Test Method

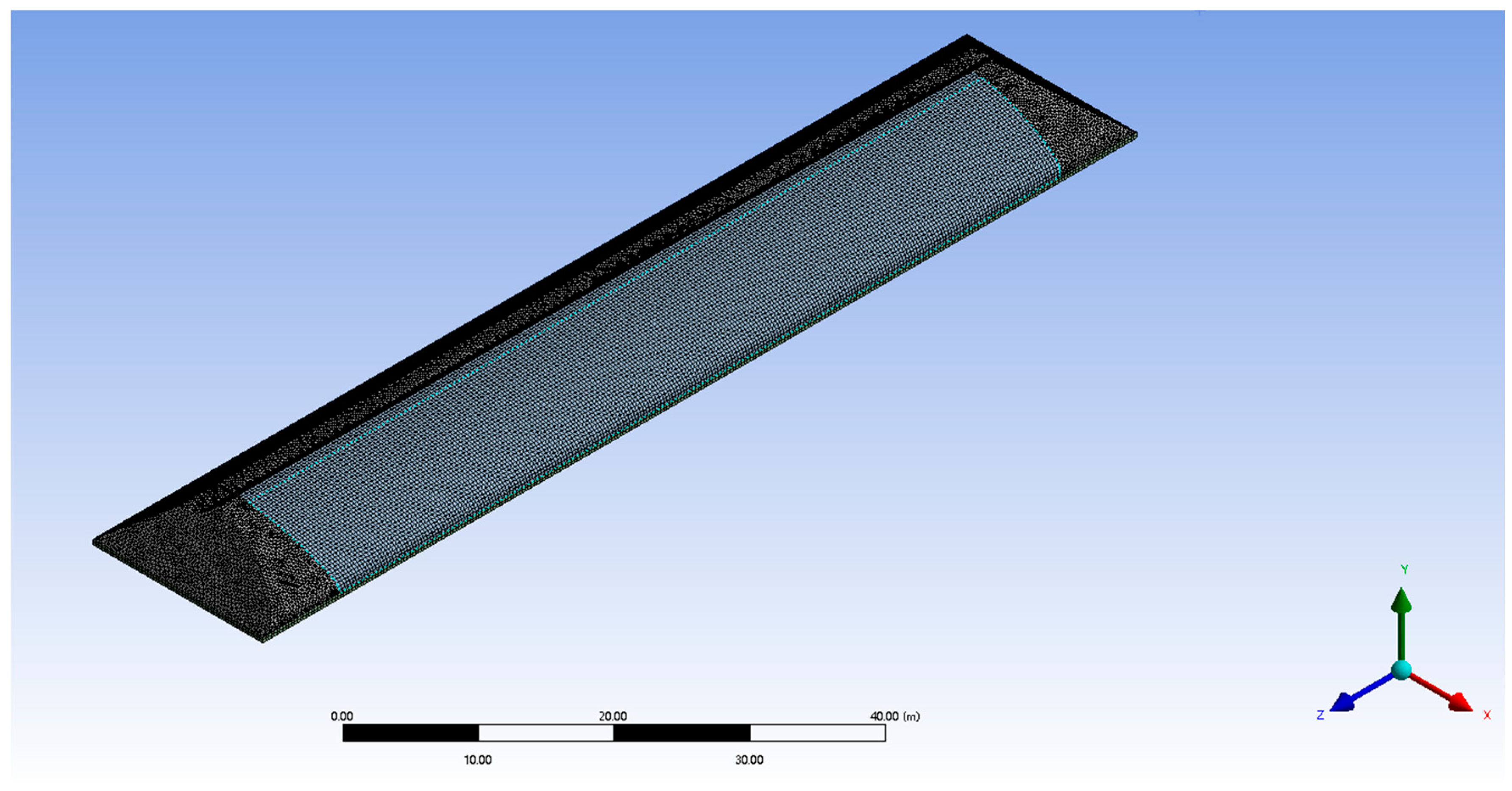

2.3. CFD Numerical Modelling

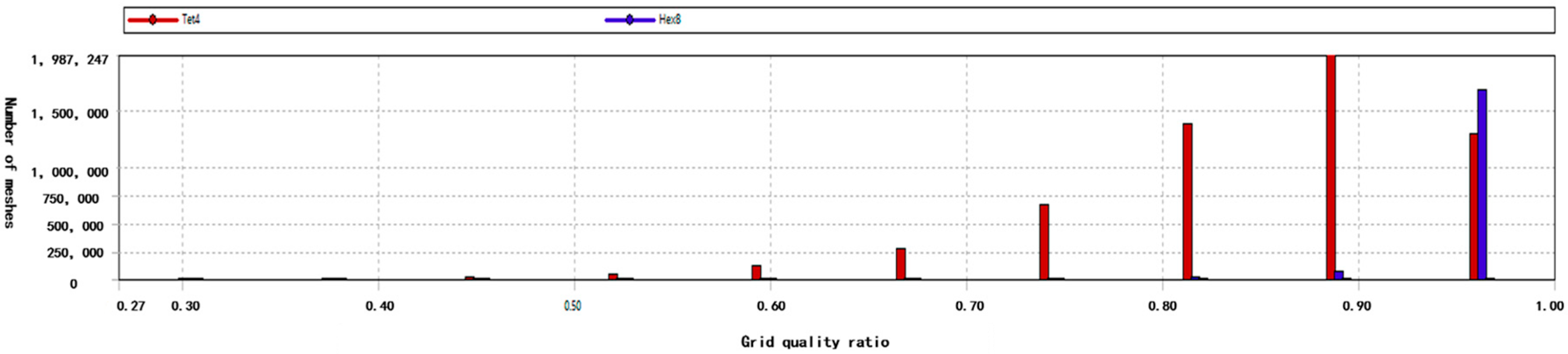

2.3.1. Meshing

2.3.2. Boundary Condition

2.4. Python-Based Classification and Prediction Model for Measuring Points

2.4.1. K-Means Classification

2.4.2. LSTM Prediction Model

3. Results

3.1. Indoor and Outdoor Light Temperature and Gas Change Rule

3.1.1. Indoor Light Temperature Change Rule

3.1.2. The Pattern of Change in the Concentration of Carbon Dioxide (CO2) Indoor

3.2. Law of Change of Indoor and Outdoor Temperature

3.2.1. Overall Rate of Change of Indoor Temperature

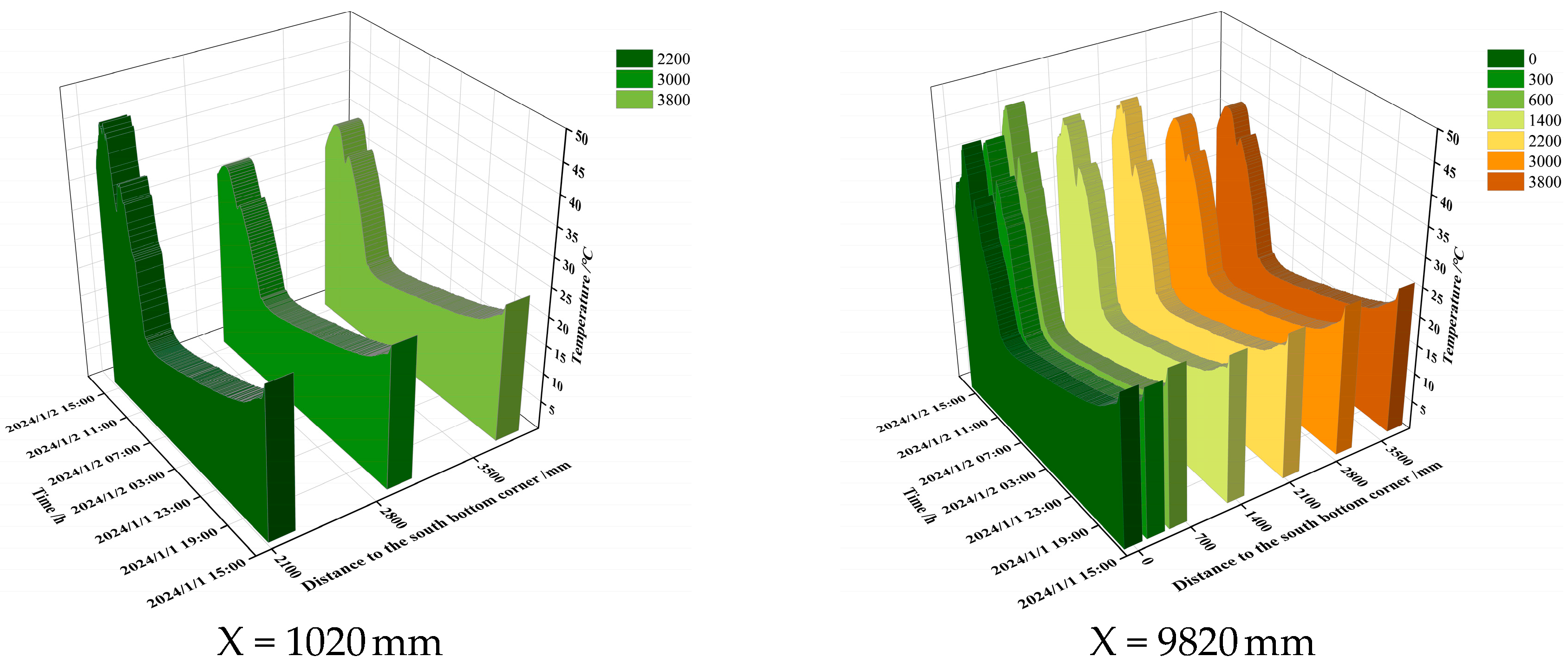

3.2.2. Temperature Change under the Film at Different Moments

3.3. Marginal Effects under the Film

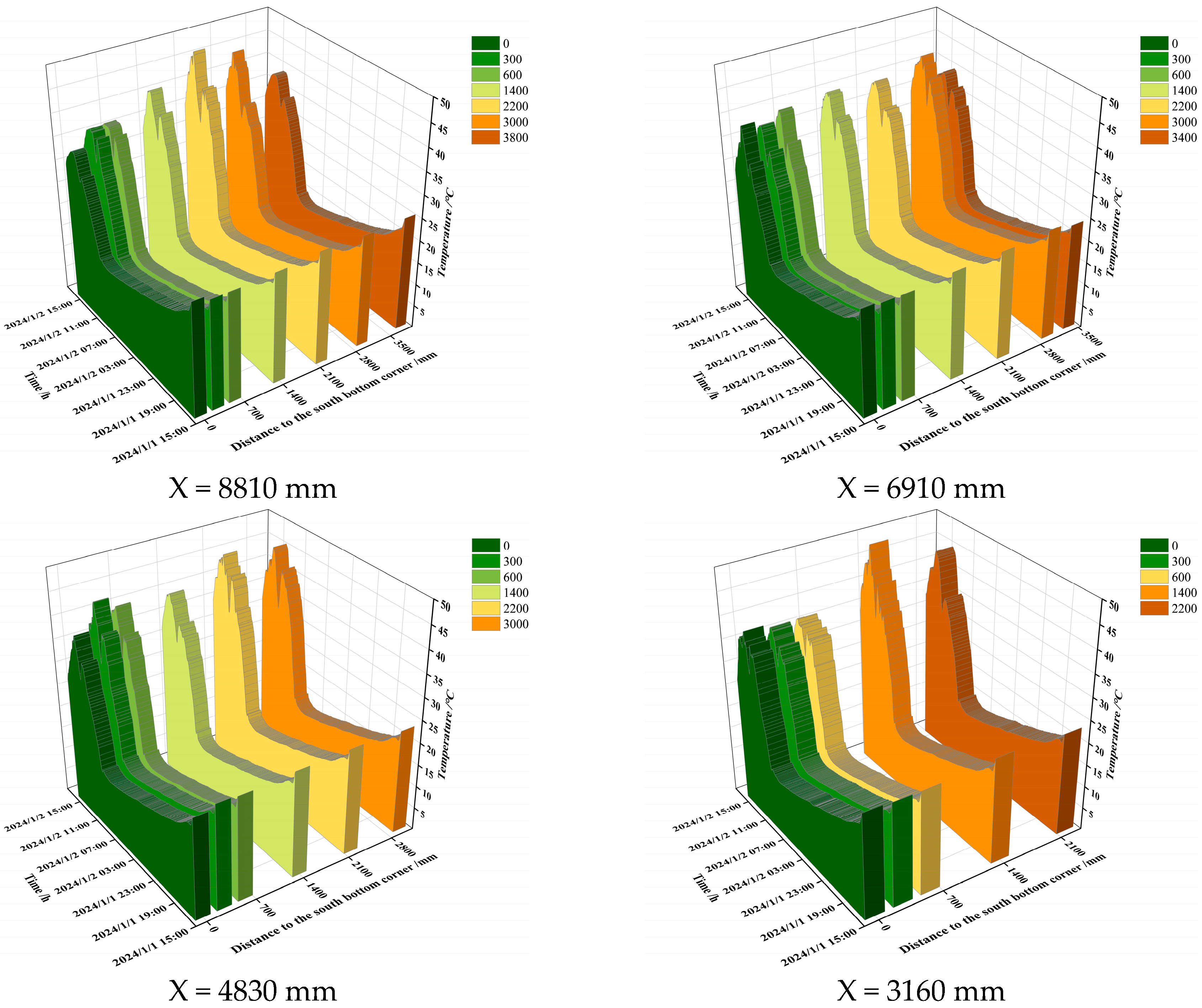

3.3.1. Marginal Effect Boundary Points under the Film

3.3.2. Marginal Regions of Low Temperature under the Shed Film for Temperature Minima in Different Months

3.3.3. Marginal Areas of High Temperatures under the Trellis Film for Temperature Maxima in Different Months

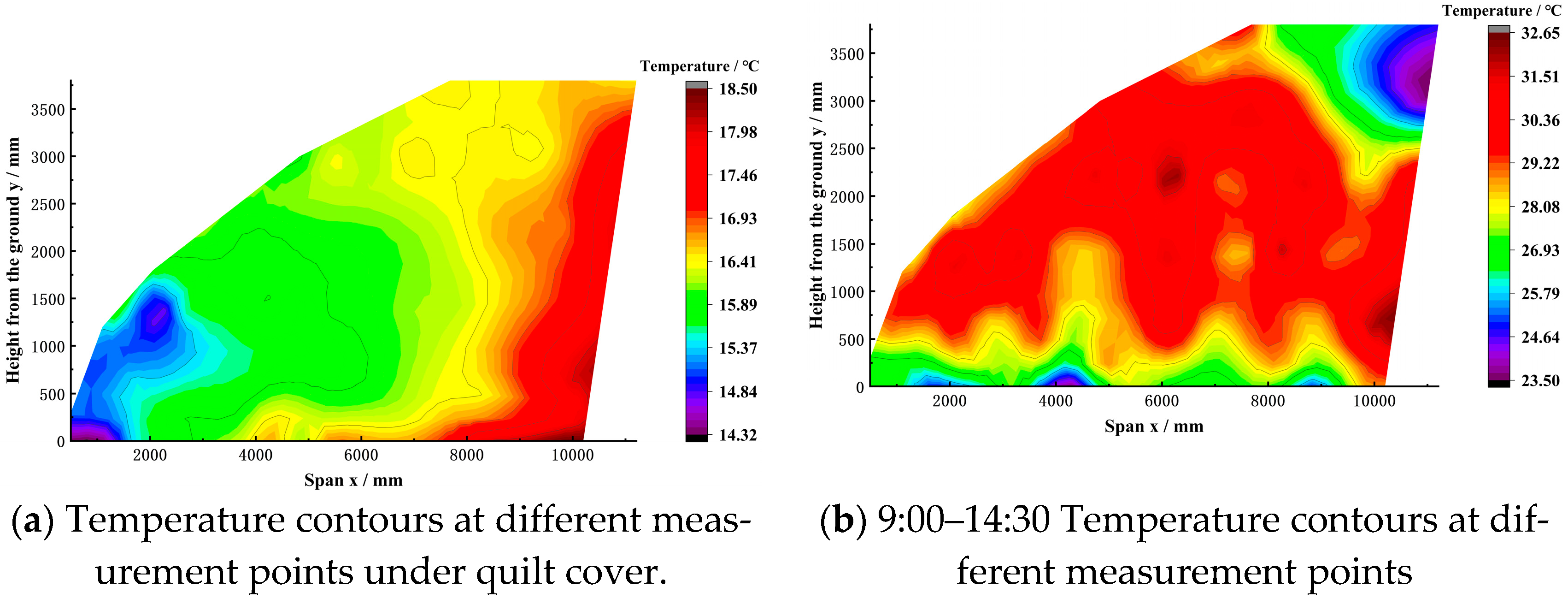

3.4. CFD Numerical Simulation

3.4.1. Verification of Model Accuracy

3.4.2. Cloud View of Spatial Temperature Distribution at Different Moments across the Mid-Section

3.4.3. Distribution of Temperature across Different Spans at 07:00 am

3.5. LSTM Prediction Model

4. Conclusions

- (1)

- The maximum horizontal point of the cut-off position of the low-temperature region of the marginal effect under the wintering shed film was 6130 mm, while the minimum was 4830 mm. In the low-temperature zone of the marginal effect under the film, the maximum height at the cut-off horizontal position was 3000 mm, while the minimum height was 600 mm. The temperature in the low-temperature region under the greenhouse film during the overwintering period exhibited a marginal effect. The highest temperature was 12.1 °C, while the lowest temperature was 4.0 °C. Furthermore, the maximum temperature difference in the low-temperature region was 1 °C in the same time period in different months.

- (2)

- The minimum horizontal distance between the start of the high-temperature area of the marginal effect under the film and the bottom foot of the south side was 1630 mm, while the maximum horizontal distance was 8810 mm. The maximum height at the cut-off of the high-temperature region of the marginal effect under the film was 1400 mm, while the minimum height was 300 mm. The starting maximum height at the starting position of the high-temperature region under the film was 1400 mm, while the minimum height was 300 mm. The maximum temperature recorded during the overwintering season in the high-temperature region of the marginal effect under the film was 51 °C, with the minimum temperature being 36.7 °C. Furthermore, there was a maximum temperature difference of 7 °C between the same time period in different months.

- (3)

- The numerical simulations based on the CFD method yielded accurate results. However, low temperatures were observed in the areas in close proximity to the shed film.

- (4)

- The LSTM prediction model presented in this paper demonstrated a high degree of accuracy in forecasting the temperature within an experimental greenhouse. The model exhibited an average absolute error of 0.2410 °C, an average squared error of 0.2853 °C, and a coefficient of determination (R2) of 0.9869. The proposed prediction model is capable of forecasting the temperature of a solar greenhouse with an identical type of earthen wall in Shanxi, China. Furthermore, it can provide a buffer period for the temperature control of the greenhouse, which is essential for the efficient production of greenhouse crops.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Lal, R. Home gardening and urban agriculture for advancing food and nutritional security in response to the COVID-19 pandemic. Food Secur. 2020, 12, 871–876. [Google Scholar] [CrossRef] [PubMed]

- Domenico, M.; Cristina, B.; Simone, P.; Congedo, P.M. Solar greenhouses: Climates, glass selection, and plant well-being. Sol. Energy 2021, 230, 222–241. [Google Scholar]

- Han, L. Reflections on the construction of facility agricultural engineering and agricultural modernisation. Agric. Technol. Equip. 2021, 10, 113–114. [Google Scholar]

- Dragićević, M.S. Determining the Optimum Orientation of a Greenhouse on the Basis of the Total Solar Radiation Availability. Therm. Sci. 2011, 15, 215–221. [Google Scholar] [CrossRef]

- Deng, L.; Huang, L.; Zhang, Y.; Li, A.; Gao, R.; Zhang, L.; Lei, W. Analytic model for calculation of soil temperature and heat balance of bare soil surface in solar greenhouse. Sol. Energy 2023, 249, 312–326. [Google Scholar] [CrossRef]

- Zhang, Y.; Henke, M.; Li, Y.; Xu, D.; Liu, A.; Liu, X.; Li, T. Towards the maximization of energy performance of an energy-saving Chinese solar greenhouse: A systematic analysis of common greenhouse shapes. Sol. Energy 2022, 236, 320–334. [Google Scholar] [CrossRef]

- Yan, D.; Hu, L.; Zhou, C. Structural performance analysis of elliptical tube single-tube arch daylight greenhouse. J. Agric. Eng. 2022, 38, 217–224. [Google Scholar]

- Lei, W.; Lu, H.; Qi, X.; Tai, C.; Fan, X.; Zhang, L. Field measurement of environmental parameters in solar greenhouses and analysis of the application of passive ventilation. Sol. Energy 2023, 263, 111851. [Google Scholar] [CrossRef]

- Wu, X.; Li, Y.; Jiang, L.; Wang, Y.; Liu, X.; Li, T. A systematic analysis of multiple structural parameters of Chinese solar greenhouse based on the thermal performance. Energy 2023, 273, 127193. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, L.; Zhu, X.; He, B.; Chen, Y. Thermal environment model construction of Chinese solar greenhouse based on temperature–wave interaction theory. Energy Build. 2023, 279, 112648. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Aljaghoub, H.; Alami, A.H.; Olabi, A.G. Selection criteria of cooling technologies for sustainable greenhouses: A comprehensive review. Therm. Sci. Eng. Prog. 2023, 38, 101666. [Google Scholar] [CrossRef]

- Jiao, W.; Liu, Q.; Gao, L.; Liu, K.; Shi, R.; Ta, N. Computational Fluid Dynamics-Based Simulation of Crop Canopy Temperature and Humidity in Double-Film Solar Greenhouse. J. Sens. 2020, 2020, 8874468. [Google Scholar] [CrossRef]

- Wang, C.; Yang, S.; Chen, Z.; Xie, Z.; Zhang, Z. Effects of increased CO2 application and LED supplemental light interaction on photosynthesis and quality of chilli peppers. Fujian Agric. J. 2022, 37, 67–73. [Google Scholar]

- Singh, M.C.; Singh, K.G.; Singh, J.P. Performance of soilless cucumbers under partially controlled greenhouse environment in relation to deficit fertigation. Indian J. Hortic. 2018, 75, 259. [Google Scholar] [CrossRef]

- Zhao, L.; Lu, L.; Liu, H.; Li, Y.; Sun, Z.; Liu, X.; Li, T. A one-dimensional transient temperature prediction model for Chinese assembled solar greenhouses. Comput. Electron. Agric. 2023, 215, 108450. [Google Scholar] [CrossRef]

- Lee, C.K.; Chung, M.; Shin, K.-Y.; Im, Y.-H.; Yoon, S.-W. A study of the effects of enhanced uniformity control of greenhouse environment variables on crop growth. Energies 2019, 12, 1749. [Google Scholar] [CrossRef]

- Hu, J.; Fan, G.; Gao, Y. Experimental study on the characteristics of air temperature change in daylight greenhouse during overwintering period. J. Taiyuan Univ. Technol. 2014, 45, 6. [Google Scholar]

- Moore, C.E.; MeachamHensold, K.; Lemonnier, P.; Slattery, R.A.; Benjamin, C.; Bernacchi, C.J.; Lawson, T.; Cavanagh, A.P. The effect of increasing temperature on crop photosynthesis: From enzymes to ecosystems. J. Exp. Bot. 2021, 72, 2822–2844. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.-S. Microclimate environment and its regulation in solar greenhouse. China Flower Hortic. 2005, 6, 47–52. [Google Scholar]

- Cheng, W.; Yu, W.; Wang, C.; Tao, W.; Junlin, H.E.; Liu, Z. Study study on the variation of thermal environment and photosynthesis characteristics of strawberry in a solar greenhouse. INMATEH—Agric. Eng. 2023, 70, 211–220. [Google Scholar] [CrossRef]

- Cheng, W.; Wang, C.; Wang, Y.; Cheng, M.; Qiao, P.; Liu, Z. Study of the Thermal Environment and Marginal Effects of a Sunken Solar Greenhouse. Eng. Agrícola Jaboticabal 2024, 44, e20230168. [Google Scholar] [CrossRef]

- Homa, E.; Ramin, R. Optimal design for solar greenhouses based on climate conditions. Renew. Energy 2020, 145, 1255–1265. [Google Scholar]

- Ahamed, M.S.; Guo, H.; Tanino, K. Sensitivity Analysis of CSGHEAT Model for Estimation of Heating Consumption in a Chinese-style Solar Greenhouse. Comput. Electron. Agric. 2018, 154, 99–111. [Google Scholar] [CrossRef]

- Hu, J.; Lei, W.; Lu, Y.; Wei, Z.; Liu, X.; Gao, M. Research on temperature prediction model of solar greenhouse based on 1D CNN-GRU. J. Agric. Mach. 2023, 54, 339–346. [Google Scholar]

- Zhang, C.; Wei, M.; Xu, P. Analysis of inverse temperature phenomenon in solar greenhouse based on soil heat storage. J. Shenyang Agric. Univ. 2019, 50, 114–119. [Google Scholar]

- Liu, Q.; Ta, N.; Jiao, W.; Kang, H.; Zhao, Z. Spatial and temporal distribution and prediction model of canopy temperature and humidity in solar greenhouse crops. North Hortic. 2019, 17, 56–65. [Google Scholar]

- Zhang, J.; Shen, K.; Chen, D.; Zhang, M.; Zhang, H.; Hu, J. Analysis of spatial and temporal variation rules of characteristic temperature of solar greenhouse canopy based on internet of things. J. Agric. Mach. 2021, 52, 335–342. [Google Scholar]

- Cheng, W.; Liu, Z. Study on the change rate of the indoor temperature of a sunken solar greenhouse. INMATEH-Agric. Eng. 2022, 68, 119–126. [Google Scholar] [CrossRef]

- Zhang, G.; Fu, Z.; Yang, M.; Liu, X.; Dong, Y.; Li, X. Nonlinear simulation for coupling modeling of air humidity and vent opening in Chinese solar greenhouse based on CFD. Comput. Electron. Agric. 2019, 162, 337–347. [Google Scholar] [CrossRef]

- Sun, S.; Dong, C.; Lai, Z.; Yang, H. Study on the internal temperature change of solar greenhouse under different ambient temperatures based on CFD. Tianjin Agric. Sci. 2020, 26, 5. [Google Scholar]

- Zhang, X.; Lv, J.; Xie, J.; Yu, J.; Zhang, J.; Tang, C.; Li, J.; He, Z.; Wang, C. Solar Radiation Allocation and Spatial Distribution in Chinese Solar Greenhouses: Model Development and Application. Energies 2020, 13, 1108. [Google Scholar] [CrossRef]

- Liu, Y.; Li, D.; Wan, S.; Wang, F.; Dou, W.; Xu, X.; Li, S.; Ma, R.; Qi, L. A long short-term memory-based model for greenhouse climate prediction. Int. J. Intell. Syst. 2021, 37, 135–151. [Google Scholar] [CrossRef]

- Dong, S.; Ahamed, M.S.; Ma, C.; Guo, H. A time-dependent model for predicting thermal environment of mono-slope solar greenhouses in cold regions. Energies 2021, 14, 5956. [Google Scholar] [CrossRef]

- Gong, J. Construction of Spatial Temperature Distribution Model in Solar Greenhouse. Ph.D. Thesis, Northwest Agriculture and Forestry University, Xianyang, China, 2023. [Google Scholar]

- Mahmood, F.; Govindan, R.; Bermak, A.; Yang, D.; Al-Ansari, T. Data driven robust model predictive control for greenhouse temperature control and energy utilisation assessment. Appl. Energy 2023, 343, 121190. [Google Scholar] [CrossRef]

- Jung, D.H.; Kim, H.S.; Jhin, C.; Kim, H.J.; Park, S.H. Time-serial analysis of deep neural network models for prediction of climatic conditions inside a greenhouse. Comput. Electron. Agric. 2020, 173, 105402. [Google Scholar] [CrossRef]

- Moon, T.; Lee, J.W.; Son, J.E. Accurate Imputation of Greenhouse Environment Data for Data Integrity Utilizing Two-Dimensional Convolutional Neural Networks. Sensors 2021, 21, 2187. [Google Scholar] [CrossRef] [PubMed]

- Laxmikant, D.; Jathar, K.N.; Awasarmol, U.V.; Gurav, R.; Patil, J.D.; Shahapurkar, K.; Soudagar, M.E.M.; Khan, T.M.Y.; Kalam, M.A.; Hnydiuk-Stefan, A.; et al. A comprehensive analysis of the emerging modern trends in research on photovoltaic systems and desalination in the era of artificial intelligence and machine learning. Heliyon 2024, 10, e25407. [Google Scholar]

- Yang, Y.; Gao, P.; Sun, Z.; Wang, H.; Lu, M.; Liu, Y.; Hu, J. Multistep ahead prediction of temperature and humidity in solar greenhouse based on FAM-LSTM model. Comput. Electron. Agric. 2023, 213, 108261. [Google Scholar] [CrossRef]

- Sun, W. Changing law of CO2 concentration and replenishment time of cucumber in sunlight greenhouse in Kazuo County. China Agric. Ext. 2020, 36, 67–68. [Google Scholar]

- Cheng, W.-W. Research on Three-Dimensional Thermal Environment and Marginal Effect of Sunken Solar Greenhouse. Ph.D. Thesis, Shanxi Agricultural University, Taiyuan, China, 2021. [Google Scholar]

- Yu, W.; Liu, W.; Bai, Y.; Ding, X. Simulating thermal environment in a two-span solar greenhouse using CFD. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2023, 39, 215–222. [Google Scholar]

| Measurement Point Number | ||||||||

|---|---|---|---|---|---|---|---|---|

| Line Number | x/mm | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 0 | 10,000 | 2200 | 3000 | 3800 | ||||

| 1 | 9820 | 0 | 300 | 600 | 1400 | 2200 | 3000 | 3800 |

| 2 | 9410 | 2200 | 3000 | 3800 | ||||

| 3 | 8810 | 0 | 300 | 600 | 1400 | 2200 | 3000 | 3800 |

| 4 | 8250 | 0 | 300 | 600 | 1400 | 2200 | 3000 | 3800 |

| 5 | 7680 | 0 | 300 | 600 | 1400 | 2200 | 3000 | 3800 |

| 6 | 6910 | 0 | 300 | 600 | 1400 | 2200 | 3000 | 3400 |

| 7 | 6130 | 0 | 300 | 600 | 1400 | 2200 | 3000 | |

| 8 | 5400 | 0 | 300 | 600 | 1400 | 2200 | 3000 | |

| 9 | 4830 | 0 | 300 | 600 | 1400 | 2200 | 3000 | |

| 10 | 4300 | 0 | 300 | 600 | 1400 | 2200 | 2700 | |

| 11 | 3720 | 0 | 300 | 600 | 1400 | 2200 | ||

| 12 | 3160 | 0 | 300 | 600 | 1400 | 2200 | ||

| 13 | 2620 | 0 | 300 | 600 | 1400 | 2000 | ||

| 14 | 2060 | 0 | 300 | 600 | 1400 | 1800 | ||

| 15 | 1630 | 0 | 300 | 600 | 1400 | |||

| 16 | 1100 | 0 | 300 | 600 | 1200 | |||

| Location | Initial Temperature/°C |

|---|---|

| Eastern wall interface | 21.4 |

| Western Wall Interface | 21.4 |

| Fluid | 21.61 |

| North wall | 21.7 |

| Soil | 21.8 |

| Outdoor air temperature | 3.3 |

| Parameters | Density kg/m3 | Specific Heat Capacity J/(kg·K) | Thermal Conductivity W/(m·K) | Absorption Coefficient | Scattering Coefficient | Refractive Index |

|---|---|---|---|---|---|---|

| PE film | 950 | 1600 | 0.34 | 0.15 | 0 | 1.72 |

| Soil Wall | 2000 | 1050 | 0.8 | 0.88 | 0.12 | 1.92 |

| Soil | 1600 | 1050 | 0.75 | 0.88 | 0.12 | 1.92 |

| Backslope | 600 | 2500 | 0.29 | 0.7 | 0 | 1.72 |

| Marginal Areas | 12 | 1 | 2 | 3 |

|---|---|---|---|---|

| Span position of survey line 16x1/mm | 1100 | 1100 | 1100 | 1100 |

| Horizontal cut-off position for low-temperature regions x2/mm | 6130 | 6130 | 4830 | 4830 |

| Medium-temperature region cut-off position x3/mm | 9820 | 9820 | 8810 | 6130 |

| Minimum temperatures at position x1 near the shed film | 5.8 °C | 11.7 °C | 9.6°C | 4.1 °C |

| Minimum temperatures at position x2 near the shed film | 6.6 °C | 12.0 °C | 9.8 °C | 4.2 °C |

| Minimum temperature in the medium zone | 7.6 °C | 12.1 °C | 9.98 °C | 7.8 |

| Height of the measuring point y1 at position x1 with similar temperature near the film/mm | 300 | 0 | 300 | 300 |

| Height of measuring point at x2 position close to the film./mm | 3000 | 3000 | 3000 | 3000 |

| Height of measurement point y2 at position x2 close to the temperature at the film film/mm | 600 | 600 | 600 | 900 |

| Mean value of temperature at (x1, y1) measurement point | 6.2 °C | 11.7 °C | 9.4 °C | 4.0 °C |

| Mean value of temperature at (x2, y2) measurement point | 7.2 °C | 12.1 °C | 10.1 °C | 4.3 °C |

| December | January | February | March | |

|---|---|---|---|---|

| High-Temperature Horizontal Position Start Point x1/mm | 3720 | 3720 | 2620 | 1630 |

| High-temperature horizontal position cut-off x2/mm | 8250 | 8250 | 6130 | 8810 |

| Highest temperatures in the x1–x2 region near the film/°C | 41.3 °C | 40.5 °C | 46.7 °C | 49.3 °C |

| Minimum temperature in the x1–x2 region near the film/°C | 37.6 °C | 38 °C | 42.7 °C | 45.8 °C |

| High-temperature start position height y1 /mm | 300 | 300 | 300 | 1400 |

| High-temperature cut-off position height y2/mm | 300 | 1400 | 1400 | 300 |

| Mean value of temperature (x1, y1)/°C | 38.2 °C | 36.7 °C | 40° C | 49 °C |

| Mean value of temperature (x2, y2)/°C | 40.3 °C | 41.4 °C | 47 °C | 51 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, W.; Wang, Y.; Wang, C.; Liu, Z. The Marginal Effect and LSTM Prediction Model under the Chinese Solar Greenhouse Film. Agriculture 2024, 14, 1195. https://doi.org/10.3390/agriculture14071195

Cheng W, Wang Y, Wang C, Liu Z. The Marginal Effect and LSTM Prediction Model under the Chinese Solar Greenhouse Film. Agriculture. 2024; 14(7):1195. https://doi.org/10.3390/agriculture14071195

Chicago/Turabian StyleCheng, Weiwei, Yu Wang, Changchao Wang, and Zhonghua Liu. 2024. "The Marginal Effect and LSTM Prediction Model under the Chinese Solar Greenhouse Film" Agriculture 14, no. 7: 1195. https://doi.org/10.3390/agriculture14071195

APA StyleCheng, W., Wang, Y., Wang, C., & Liu, Z. (2024). The Marginal Effect and LSTM Prediction Model under the Chinese Solar Greenhouse Film. Agriculture, 14(7), 1195. https://doi.org/10.3390/agriculture14071195