A Comprehensive Assessment of Rice Straw Returning in China Based on Life Cycle Assessment Method: Implications on Soil, Crops, and Environment

Abstract

1. Introduction

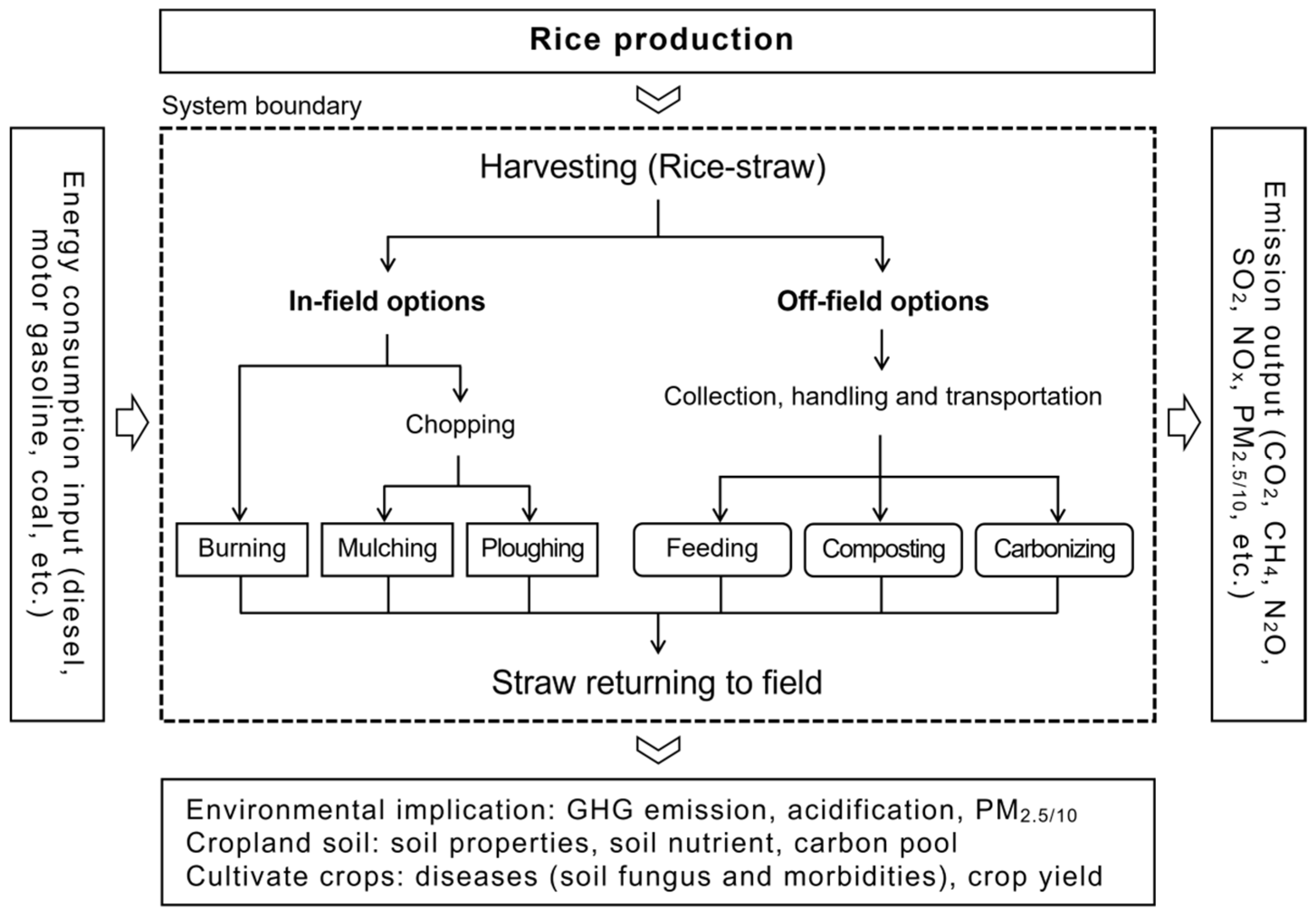

2. Material and Methods

2.1. Research Objective

2.2. Assessment Strategy

2.3. Evaluation Method

| Type | Global Warming | Environmental Acidification | ||||

|---|---|---|---|---|---|---|

| Influential substances | CO2 | CO | CH4 | N2O | SO2 | NOx |

| Equivalent coefficient | 1 | 2 | 21 | 310 | 1 | 0.7 |

| Type | Unit | Standard Value | Weight Coefficient |

|---|---|---|---|

| Energy depletion | MJ·per−1·a−1 | 2,590,457 | 0.15 |

| Global warming | kg·per−1·a−1 | 6869 | 0.12 |

| Environmental acidification | kg·per−1·a−1 | 52.26 | 0.14 |

2.4. Inventory Analysis

3. Results and Analysis

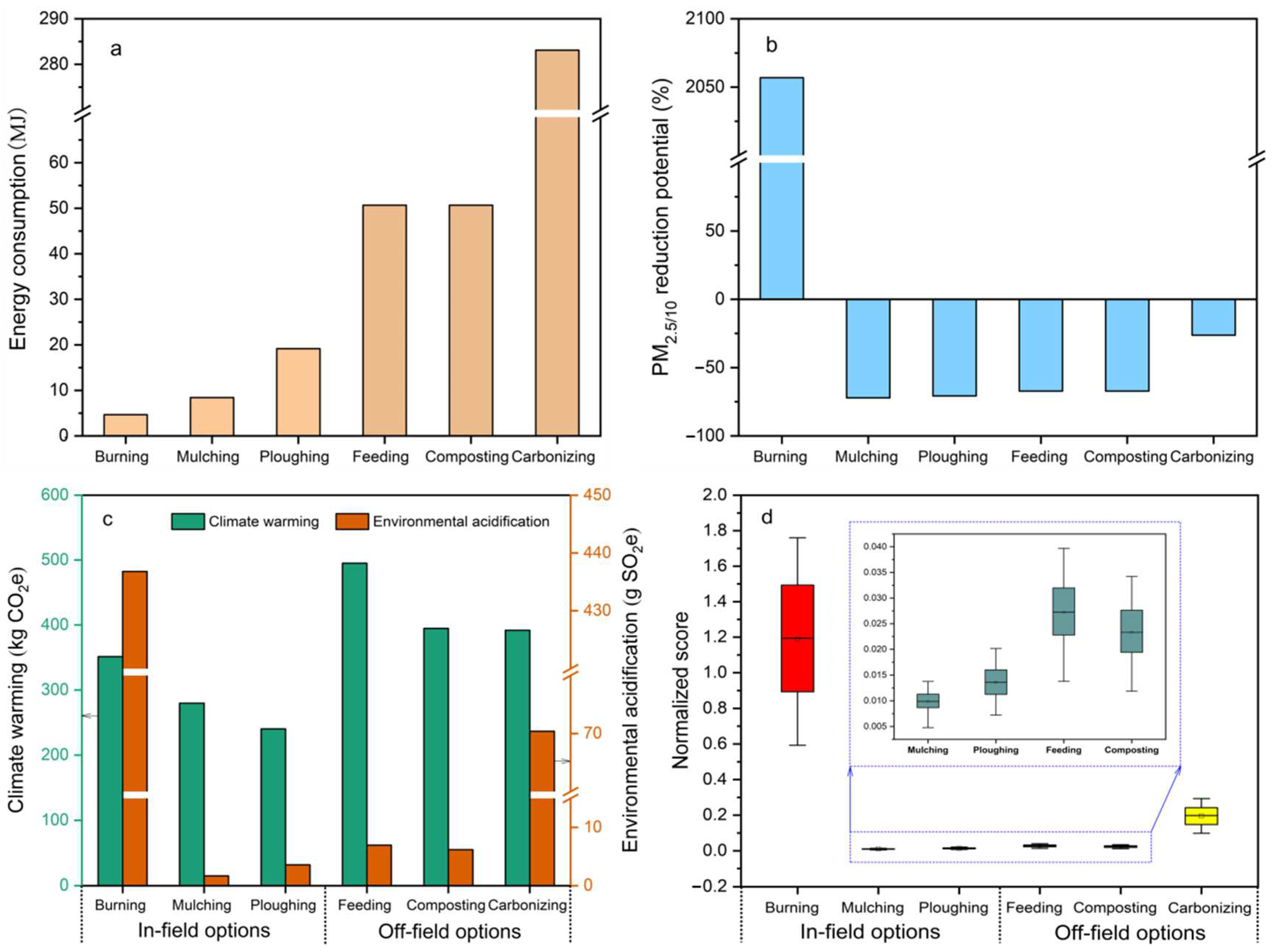

3.1. Environmental Impact

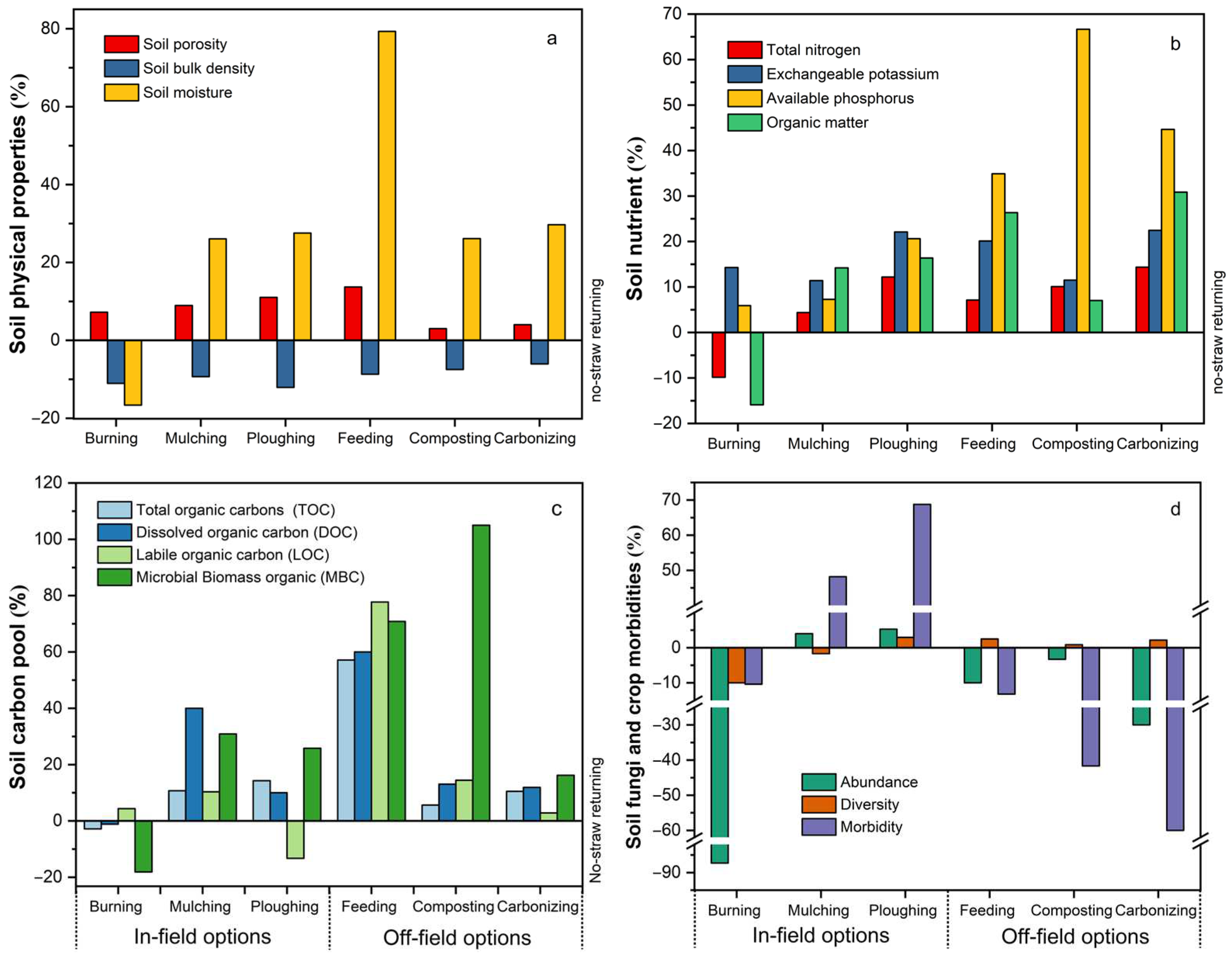

3.2. Evaluation of Soil Fertility

3.3. Evaluation of Soil Carbon Pool

3.4. Evaluation of Crop Diseases

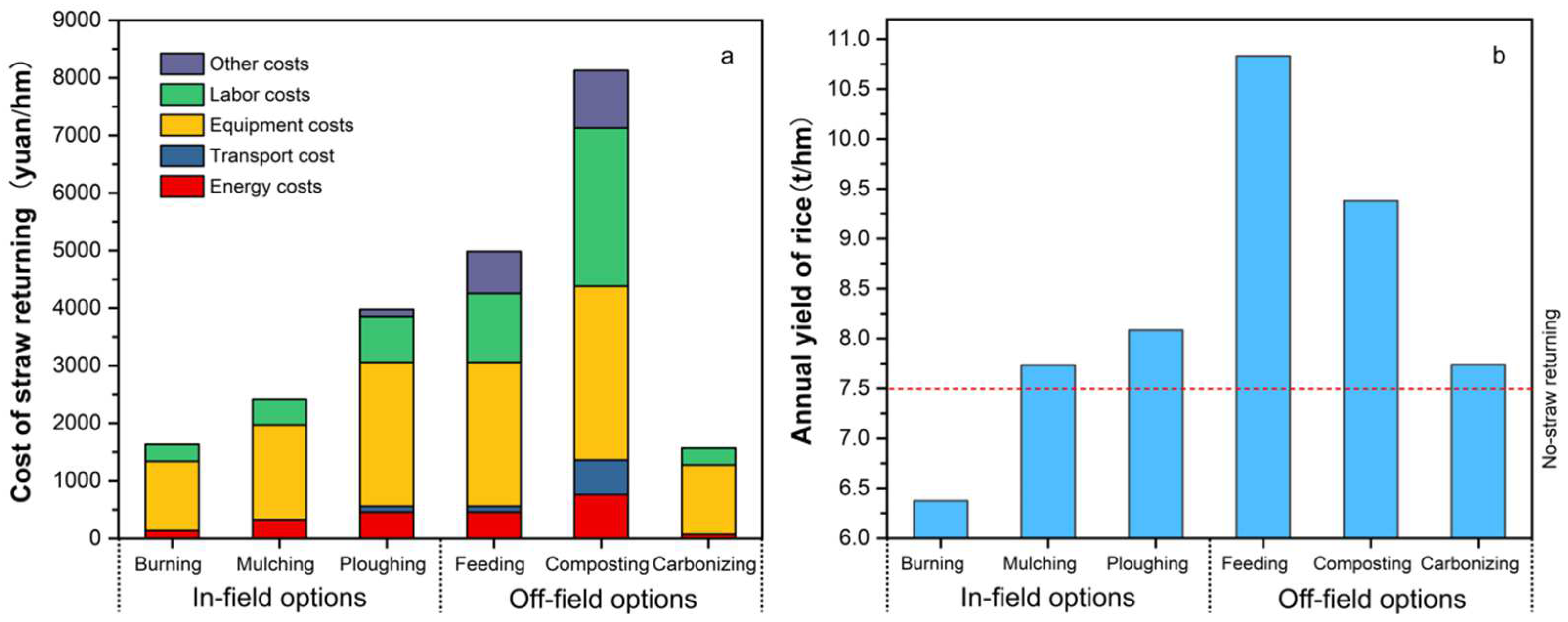

3.5. Benefit Evaluation of Straw-Returning Modes

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- National Bureau of Statistics. International Statistical Yearbook; China National Bureau of Statistics: Beijing, China, 2022. [Google Scholar]

- Yan, D. Report on the Comprehensive Utilization of Crop Straw in China. Available online: https://www.beipa.org.cn/newsinfo/4432098.html (accessed on 2 August 2023).

- Liang, F.; Li, B.; Vogt, R.D.; Mulder, J.; Song, H.; Chen, J.; Guo, J. Straw Return Exacerbates Soil Acidification in Major Chinese Croplands. Resour. Conserv. Recycl. 2023, 198, 107176. [Google Scholar] [CrossRef]

- Xie, W.; Zhu, A.; Ali, T.; Zhang, Z.; Chen, X.; Wu, F.; Huang, J.; Davis, K.F. Crop Switching Can Enhance Environmental Sustainability and Farmer Incomes in China. Nature 2023, 616, 300–305. [Google Scholar] [CrossRef] [PubMed]

- Huang, T.; Yang, N.; Lu, C.; Qin, X.; Siddique, K.H.M. Soil Organic Carbon, Total Nitrogen, Available Nutrients, and Yield under Different Straw Returning Methods. Soil Tillage Res. 2021, 214, 105171. [Google Scholar] [CrossRef]

- Liu, D.; Song, C.; Xin, Z.; Fang, C.; Liu, Z.; Xu, Y. Agricultural Management Strategies for Balancing Yield Increase, Carbon Sequestration, and Emission Reduction after Straw Return for Three Major Grain Crops in China: A Meta-Analysis. J. Environ. Manag. 2023, 340, 117965. [Google Scholar] [CrossRef] [PubMed]

- Sun, N.; Gao, C.; Ding, Y.; Bi, Y.; Seglah, P.A.; Wang, Y. Five-Dimensional Straw Utilization Model and Its Impact on Carbon Emission Reduction in China. Sustainability 2022, 14, 16722. [Google Scholar] [CrossRef]

- Ma, Y.; Shen, Y.; Liu, Y. State of the Art of Straw Treatment Technology: Challenges and Solutions Forward. Bioresour. Technol. 2020, 313, 123656. [Google Scholar] [CrossRef] [PubMed]

- Singh, G.; Gupta, M.K.; Chaurasiya, S.; Sharma, V.S.; Pimenov, D.Y. Rice Straw Burning: A Review on Its Global Prevalence and the Sustainable Alternatives for Its Effective Mitigation. Environ. Sci. Pollut. Res. 2021, 28, 32125–32155. [Google Scholar] [CrossRef] [PubMed]

- Dossou-Yovo, E.R.; Brüggemann, N.; Ampofo, E.; Igue, A.M.; Jesse, N.; Huat, J.; Agbossou, E.K. Combining No-Tillage, Rice Straw Mulch and Nitrogen Fertilizer Application to Increase the Soil Carbon Balance of Upland Rice Field in Northern Benin. Soil Tillage Res. 2016, 163, 152–159. [Google Scholar] [CrossRef]

- Han, R.; Chen, Z.; Yang, S. Effect of Straw-Returning on Nitrogen and Phosphorus and Water of Soil. Chin. Agric. Sci. Bull. 2016, 32, 148–154. [Google Scholar]

- Peng, W.; Chu, C.; Zhong, Y.; Lai, W.; Zhang, H.; Huang, L.; Shi, X.; Wei, J. Effect of Sweet Corn Straw Returning to the Field on Soil Fertility, Yield and Benefit. Meteorol. Environ. Res. 2016, 7, 59–63. [Google Scholar]

- The People’s Daily the Ecological Benefits of Straw Returning to the Field Gradually Emerged—The Comprehensive Utilization Rate of Straw in China Exceeded 88%. Available online: https://www.gov.cn/xinwen/2022-10/13/content_5718001.htm (accessed on 2 September 2023).

- Shao, J.; Gao, C.; Afi Seglah, P.; Xie, J.; Zhao, L.; Bi, Y.; Wang, Y. Analysis of the Available Straw Nutrient Resources and Substitution of Chemical Fertilizers with Straw Returned Directly to the Field in China. Agriculture 2023, 13, 1187. [Google Scholar] [CrossRef]

- Xu, J.; Han, H.; Ning, T.; Li, Z.; Lal, R. Field Crops Research Long-Term e Ff Ects of Tillage and Straw Management on Soil Organic Carbon, Crop Yield, and Yield Stability in a Wheat-Maize System. Field Crop. Res. 2019, 233, 33–40. [Google Scholar] [CrossRef]

- Hu, N.; Wang, B.; Gu, Z.; Tao, B.; Zhang, Z.; Hu, S.; Zhu, L.; Meng, Y. Agriculture, Ecosystems and Environment Effects of Different Straw Returning Modes on Greenhouse Gas Emissions and Crop Yields in a Rice—Wheat Rotation System. Agric. Ecosyst. Environ. 2016, 223, 115–122. [Google Scholar] [CrossRef]

- Yu, F.; Chen, Y.; Huang, X.; Shi, J.; Xu, J.; He, Y. Does Straw Returning Affect the Root Rot Disease of Crops in Soil? A Systematic Review and Meta-Analysis. J. Environ. Manag. 2023, 336, 117673. [Google Scholar] [CrossRef] [PubMed]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent Developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Yuan, S.; Chen, S.; Ci, H.; Dai, X.; Wang, X.; Li, C.; Wang, D.; Dong, B. Life-Cycle Assessment of Two Sewage Sludge-to-Energy Systems Based on Different Sewage Sludge Characteristics: Energy Balance and Greenhouse Gas-Emission Footprint Analysis. J. Environ. Sci. (China) 2022, 111, 380–391. [Google Scholar] [CrossRef] [PubMed]

- Li, S.H.; Guo, L.; Cao, C.; Li, C. Effects of Straw Returning Levels on Carbon Footprint and Net Ecosystem Economic Benefits from Rice-Wheat Rotation in Central China. Environ. Sci. Pollut. Res. 2021, 28, 5742–5754. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Wu, Q.; Wang, F.; Zhang, B. Is Straw Return-to-Field Always Beneficial? Evidence from an Integrated Cost-Benefit Analysis. Energy 2019, 171, 393–402. [Google Scholar] [CrossRef]

- Xu, X.; Ye, Y.; Li, J.; Xu, Z.; Sun, M.; Li, C.; Zhang, L.; Xue, Y. GHG Emissions of Straw Treatments in Rural China and Scenario Simulation Based on Life Cycle Perspective. J. Clean. Prod. 2022, 377, 134377. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Ministry of Agriculture and Rural Report on the Comprehensive Utilization of Crop Straw in China. Available online: https://www.gov.cn/xinwen/2022-10/10/content_5717116.htm (accessed on 27 August 2023).

- New Statistical Yearbooks of China Statistical Yearbook; China National Bureau of Statistics: Beijing, China, 2022.

- Liebig, M.A.; Bergh, E.L.; Archer, D.W. Variation in Methodology Obscures Clarity of Cropland Global Warming Potential Estimates. J. Environ. Qual. 2023, 52, 549–557. [Google Scholar] [CrossRef]

- Oladosu, Y.; Rafii, M.Y.; Abdullah, N.; Magaji, U.; Hussin, G.; Ramli, A.; Miah, G. Fermentation Quality and Additives: A Case of Rice Straw Silage. Biomed. Res. Int. 2016, 2016, 7985167. [Google Scholar] [CrossRef]

- Sleeswijk, A.W.; van Oers, L.F.C.M.; Guinée, J.B.; Struijs, J.; Huijbregts, M.A.J. Normalisation in Product Life Cycle Assessment: An LCA of the Global and European Economic Systems in the Year 2000. Sci. Total Environ. 2008, 390, 227–240. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Bao, Y.; Wu, W.; Liu, W. Life Cycle Environmental Impact Assessment of Winter Wheat in North China Plain. J. Agro-Environ. Sci. 2006, 25, 1127–1132. [Google Scholar] [CrossRef]

- Pennington, D.W.; Potting, J.; Finnveden, G.; Lindeijer, E.; Jolliet, O.; Rydberg, T.; Rebitzer, G. Life Cycle Assessment Part 2: Current Impact Assessment Practice. Environ. Int. 2004, 30, 721–739. [Google Scholar] [CrossRef] [PubMed]

- Ogino, A.; Orito, H.; Shimada, K.; Hirooka, H. Evaluating Environmental Impacts of the Japanese Beef Cow-Calf System by the Life Cycle Assessment Method. Anim. Sci. J. 2007, 78, 424–432. [Google Scholar] [CrossRef]

- Wang, S.; Gao, G.; Li, W.; Liu, S. Emission Inventory and Characteristics of PM10 from Agricultural Activities. Environ. Sci. Technol. 2022, 45, 185–194. [Google Scholar] [CrossRef]

- Tian, G.; Wang, Y.; Sun, L.; Shi, M.; Wu, F. Effects of Wheat Straw Burning on Content of Soil Organic Matter, nitrogen, phosphorus, and Potassium. ACTA Ecol. Sin. 2016, 36, 387–393. [Google Scholar] [CrossRef]

- Ministry of Agriculture and Rural Areas Guidance on Scientific Returning of Autumn Crop Straw in 2022. Available online: https://www.moa.gov.cn/gk/nszd_1/2022/202209/t20220916_6409394.htm (accessed on 23 August 2023).

- GB/T 24675.6-2021; Conservation Tillage Equipment—Part 6: Smashed Straw Machine. State Administration for Market Regulation, National Standardization Administration: Beijing, China, 2021.

- 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Global Environmental Strategies (IGES): Arlington, VA, USA, 2006.

- GB/T 42118-2022; Construction Specification for the System of Straw Collection, Storage and Transportation. State Administration for Market Regulation, National Standardization Administration: Beijing, China, 2022.

- Jia, S.P.; Mao, B.H.; Liu, S.; Sun, Q.P. Calculation and Analysis of Transportation Energy Consumption Level in China. Jiaotong Yunshu Xitong Gongcheng Yu Xinxi/J. Transp. Syst. Eng. Inf. Technol. 2010, 10, 22–27. [Google Scholar] [CrossRef]

- Jokiniemi, T.; Suokannas, A.; Ahokas, J. Energy Consumption in Agriculture Transportation Operations. Eng. Agric. Environ. Food 2016, 9, 171–178. [Google Scholar] [CrossRef]

- Manzone, M.; Airoldi, G.; Calvo, A. Transportation of Maize Silage to Biogas Plants. J. Agric. Eng. 2020, 51, 80–90. [Google Scholar] [CrossRef]

- Yu, X.; Wang, L.; Wang, F.; Xiao, J. Research on the Technical Model of Corn Straw Harvesting, Storage and Transportation in Northeast China. J. Agric. Mech. Res. 2013, 35, 24–28. [Google Scholar] [CrossRef]

- Zong, X. Straw Composting and Returning to the Field. Yunnan Agric. 2018, 355, 82–83. [Google Scholar]

- Zhang, W.; Li, Y.; Qin, X.; Li, J.; Wan, Y.; Wang, B.; Gao, Q.; Liu, S. Estimation on GHG Emission Reduction in Double Cropping Rice Paddy with Application of Biochar in Long-Term Period Using LCA Method. Trans. Chin. Soc. Agric. Eng. 2018, 34, 132–140. [Google Scholar]

- Zhang, H.; Ye, X.; Cheng, T.; Yang, X.; Chen, J.; Zhang, R.; Wang, L. Emission Simulation of Gaseous Pollutants and GIS Analysis from Agricultural Crop Residue Combustion in China. In Proceedings of the Te 26th CCS Congress, Division of Environmental Chemistry, Tianjin, China, 13–16 July 2008; Volume 43. [Google Scholar]

- Wang, S.; Zhang, C. Spatial and Temporal Distribution of Air Pollutant Emissions from Open Burning of Crop Residues in China. Sci. Online 2008, 3, 329–333. [Google Scholar]

- Wang, W.; Yi, X.; He, Y. Design of New Crawler Variable Rate Fertilizer Applicator Based on Beidou Navigation System. Xinjiang Agric. Mech. 2021, 05, 23–24. [Google Scholar] [CrossRef]

- Han, Y.; Cao, G.; Geng, Y.; Ye, Q.; Wang, Z.; Huang, Y. Effects of Agricultural Wastes on Greenhouse Gas Emission and Global Warming Potential in Black Soil. J. South China Agric. Univ. 2017, 38, 36–42. [Google Scholar]

- Hou, X.; Li, Y.; Wan, Y.; Shi, S.; Li, M. Greenhouse Gases Emission from Paddy Fields under Different Rice Straw Treatments. China Environ. Sci. 2012, 32, 803–809. [Google Scholar]

- Jie, W. Effects of Different Traw Return Modesand Traw Biochar Application Ongreenhouse Gas Emission and Soil Carbon Sequestration in Agriculture. Master’s Thesis, Nanjing Agricultural University, Nanjing, China, 2014. [Google Scholar]

- Wang, B. Effects of Different Rice Sraw Return Methods on Soil Nutrient, Organic Carbon Pool, Greenhouse Gas Emissions in Arice-Wheat Rotation System. Master’s Thesis, Nanjing Agricultural University, Nanjing, China, 2017. Available online: https://kns-cnki-net-s.webvpn.zafu.edu.cn (accessed on 20 August 2023).

- Wang, Z. Study of Greenhouse Gases Emission and Carbon Cycle from the Soil under the Condition of Several Agricultural Waste Returning to Field. Master’s Thesis, Jilin Agricultural University, Jilin, China, 2015. Available online: https://kns-cnki-net-s.webvpn.zafu.edu.cn (accessed on 19 August 2023).

- Yan, S. Effect of Straw Returning on Methane Emission and Methanogens in Rice Field in Cold Region. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2016. [Google Scholar]

- Zhao, D. Energy Consumption and Greenhouse Gas Emissions of Straw Disposal and Its Influence Factors—A Case Study of Jiangsu Province. Master’s Thesis, Nanjing University, Nanjing, China, 2018. [Google Scholar]

- Zhu, X. Soil Greenhouse Gas Emission and Influence Factors in Different Depths of Straw Returning. Master’s Thesis, Shenyang Agricultural University, Shenyang, China, 2020. [Google Scholar]

- Liu, E.; Guo, Z.; Shi, Y.; Qi, B.; Wang, Y.; Jiang, Y. Simulation of Cattle Stomach Processes Applied to the Fermentation of Mixed Manure and Straw. BioResources 2023, 18, 1096–1114. [Google Scholar] [CrossRef]

- Ge, J.; Huang, G.; Huang, J.; Zeng, J.; Han, L. Particle-Scale Modeling of Methane Emission during Pig Manure/Wheat Straw Aerobic Composting. Environ. Sci. Technol. 2016, 50, 4374–4383. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Chen, W.; Zhao, H.; Wu, X.; Zhang, M.; Tong, D.Q.; Xiu, A. Inventory of Atmospheric Pollutant Emissions from Burning of Crop Residues in China Based on Satellite-Retrieved Farmland Data. Chin. Geogr. Sci. 2020, 30, 266–278. [Google Scholar] [CrossRef]

- Bai, H. Study on the Impact of Agricultural Production on PM 2.5 Pollution-Based on the Panel Data Analysis of 298 Cities in China. Master’s Thesis, Northwest A&F University, Xianyang, China, 2021. [Google Scholar] [CrossRef]

- Maruf-Hossain, A.M.M.; Park, S.; Kim, J.S.; Park, K. Volatility and Mixing States of Ultrafine Particles from Biomass Burning. J. Hazard. Mater. 2012, 205–206, 189–197. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.L.T.; Hermansen, J.E.; Nielsen, R.G. Environmental Assessment of Gasification Technology for Biomass Conversion to Energy in Comparison with Other Alternatives: The Case of Wheat Straw. J. Clean. Prod. 2013, 53, 138–148. [Google Scholar] [CrossRef]

- Yin, H.; Zhao, W.; Li, T.; Cheng, X.; Liu, Q. Balancing Straw Returning and Chemical Fertilizers in China: Role of Straw Nutrient Resources. Renew. Sustain. Energy Rev. 2018, 81, 2695–2702. [Google Scholar] [CrossRef]

- Guo, C. Effects of Straw and Biochar Returned to the Field on Soil Acidity and Labile Organic Carbon. Master’s Thesis, Shenyang Agricultural Uinversity, Shenyang, China, 2019. [Google Scholar]

- Ju, L.; Xu, G.; Gao, F.; Bei, Q.; Yang, H.; Zhu, J. The Effect of Straw Composting and Returning to the Field on Soil Fertility and Crop Yield. Anhui Agric. Sci. Bull. 2012, 18, 82–83. [Google Scholar] [CrossRef]

- Liu, T.; Ji, X. Effects of Crop Straw Burning on Soil Organic Matter and Soil Microbes. Soils 2003, 35, 347–348. [Google Scholar] [CrossRef]

- Wang, Y. Study on the Improvement Effects of Wheat Straw and Biochar on the Tobacco Planting Cinnamon Soil in the Shandong Tobacco Region. Ph.D. Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2020. [Google Scholar] [CrossRef]

- Wang, Y.; Kuang, F.; Ma, S.; Wang, Y.; Li, L.; Tang, J.; Zhu, B. Effects of Shredded Straw and Burned Straw Returning to the Field on Soil Porosity and Organic Carbon in Cultivated Layer of Calcareous Purple Soil. J. Agro-Environ. Sci. 2022, 41, 526–536. [Google Scholar]

- Wei, R. Effects of No Tillage and Straw Returning on Rice Growth and Soil Properties. Master’s Thesis, Guang Xi University, Nanning, China, 2017. [Google Scholar]

- Yang, X. Analysis of the Effect of Returning Straw to the Field on the Improvement of Soil Nutrients and Crop Yield. Agric. Dev. Equip. 2021, 235, 141–142. Available online: https://kns-cnki-net-s.webvpn.zafu.edu.cn (accessed on 20 August 2023).

- Zhang, H.; Chang, J. The Effect of Straw Composting and Returning to the Field on Soil Fertility and Crop Yield. J. Anhui Agri. Sci. 2005, 33, 1399–1401. [Google Scholar]

- Zhen, A. The Effect of Straw Carbonization and Returning to the Field on Rice Soil Fertility and Rice Growth and Development. Chin. Agric. Dig. Eng. 2022, 34, 32–35. [Google Scholar] [CrossRef]

- Hao, M.; Hu, H.; Liu, Z.; Dong, Q.; Sun, K.; Feng, Y.; Li, G.; Ning, T. Shifts in Microbial Community and Carbon Sequestration in Farmland Soil under Long-Term Conservation Tillage and Straw Returning. Appl. Soil Ecol. 2019, 136, 43–54. [Google Scholar] [CrossRef]

- Xiu, L.; Zhang, W.; Sun, Y.; Wu, D.; Meng, J.; Chen, W. Effects of Biochar and Straw Returning on the Key Cultivation Limitations of Albic Soil and Soybean Growth over 2 Years. Catena 2019, 173, 481–493. [Google Scholar] [CrossRef]

- Ndzelu, B.S.; Dou, S.; Zhang, X. Corn Straw Return Can Increase Labile Soil Organic Carbon Fractions and Improve Water-Stable Aggregates in Haplic Cambisol. J. Arid Land 2020, 12, 1018–1030. [Google Scholar] [CrossRef]

- Wang, X.; Jia, Z.; Liang, L.; Zhao, Y.; Yang, B.; Ding, R.; Wang, J.; Nie, J. Straw Returning Mediates Soil Microbial Biomass Carbon and Phosphorus Turnover to Enhance Soil Phosphorus Availability in a Rice-Oilseed Rape Rotation with Different Soil Phosphorus Levels. Agric. Ecosyst. Environ. 2022, 335, 107991. [Google Scholar] [CrossRef]

- Wang, X.; Jia, Z.; Liang, L.; Zhao, Y.; Yang, B.; Ding, R.; Wang, J.; Nie, J. Changes in Soil Characteristics and Maize Yield under Straw Returning System in Dryland Farming. Field Crop. Res. 2018, 218, 11–17. [Google Scholar] [CrossRef]

- Huang, W.; Wu, J.F.; Pan, X.; Tan, X.; Zeng, Y.; Shi, Q.; Liu, T.; Zeng, Y. Effects of Long-Term Straw Return on Soil Organic Carbon Fractions and Enzyme Activities in a Double-Cropped Rice Paddy in South China. J. Integr. Agric. 2021, 20, 236–247. [Google Scholar] [CrossRef]

- Hu, X.; Xie, W.; Ma, X.; Zhou, H.; Yang, Z.; Liu, Z. Effects of Long-Term Straw Returning on Organic Carbon and Carbon Pool Management Index in Dryland Maize Soil. Chin. Agric. Sci. Bull. 2022, 38, 8–13. [Google Scholar]

- Yan, S. Effects of Rice Straw Return on Soil Organic Carbon Fractions, Phosphorus Fractions and Microbial Community in Cold Region. Ph.D. Thesis, Northeast Agricultural University, Harbin, China, 2021. [Google Scholar] [CrossRef]

- Solaiman, Z.M.; Yang, H.; Archdeacon, D.; Tippett, O.; Tibi, M.; Whiteley, A.S. Humus-Rich Compost Increases Lettuce Growth, Nutrient Uptake, Mycorrhizal Colonisation, and Soil Fertility. Pedosphere 2019, 29, 170–179. [Google Scholar] [CrossRef]

- Chen, S.; Wang, M.; Zhang, C.; Xin, X.; Zhu, X.; Guo, L.; Yan, R. Effects of Different Grazing Intensities on Soil Active Organic Carbon in Leymus Chinensis Meadow Steppe in Hulunbuir. Soil Fertil. Sci. China 2023, 8, 1–12. [Google Scholar]

- Cintas, N.A.; Webster, R.K. Effects of Rice Straw Management on Sclerotium Oryzae Inoculum, Stem Rot Severity, and Yield of Rice in California. Plant Dis. 2001, 85, 1140. [Google Scholar] [CrossRef]

- Cong, P.; Wang, J.; Li, Y.; Liu, N.; Dong, J.; Pang, H.; Zhang, L.; Gao, Z. Changes in Soil Organic Carbon and Microbial Community under Varying Straw Incorporation Strategies. Soil Tillage Res. 2020, 204, 104735. [Google Scholar] [CrossRef]

- Dong, H.; Dong, Z.; Liu, K.; Wang, L.; Liu, P.; Hou, Z. Effects of Different Straw Returning Patterns on the Occurrence and Damage of Main Maize Diseases. Crop Mag. 2020, 06, 104–108. [Google Scholar] [CrossRef]

- Ghorbani, R.; Koocheki, A.; Jahan, M.; Asadi, A. Impact of Organic Amendments and Compost Extracts on Tomato Production and Storability in Agroecological Systems. Agron. Sustain. Dev. 2008, 28, 307–311. [Google Scholar] [CrossRef]

- Gu, M.; Tang, G.; Ge, C.; Ma, H.; Zhang, Z.; Xu, W. Effects of Straw Incorporation Modes on Microbial Activity and Functional Diversity in Sandy Soil*. Chin. J. Eco-Agric. 2016, 24, 489–498. [Google Scholar] [CrossRef]

- QIan, S. Effects of Different Maize Straw Amendments on Soil Microbial Community Structure and Enzyme Activity in China. Master’s Thesis, Nanjing Agricultural University, Nanjing, China, 2021. [Google Scholar] [CrossRef]

- Qianwen, Z. Effect of Biochar on Growth and Clubroot of Brassica Campestris l.Ssp. Pekinesis(Lour) Olsson. Master’s Thesis, Shenyang Agricultural Uinversity, Shenyang, China, 2016. [Google Scholar]

- Yang, H.; Li, Y.; Zhai, S.; Fang, C.; Liu, J.; Zhang, Q. Long Term Ditch-Buried Straw Return Affects Soil Fungal Community Structure and Carbon-Degrading Enzymatic Activities in a Rice-Wheat Rotation System. Appl. Soil Ecol. 2020, 155, 103660. [Google Scholar] [CrossRef]

- Ji, C.; Sun, Y.; Meng, Y.; Liu, Y.; Xu, C.; Zhang, Y.; Gu, Y.; Wang, J. Effects of Long-Term Straw Incorporation on Soil Fungal Community Structure and Straw Decomposition Potential in a Rice–Wheat Rotation System. J. Agro-Environ. Sci. 2022, 41, 819–825. [Google Scholar] [CrossRef]

- Li, G. The Effect of Returning Straw to the Field on Rice Yield, Soil Nutrients, and Economic Benefits. Zhongguo Nongye Wenzhai 2023, 35, 63–67. [Google Scholar] [CrossRef]

- Liu, H.; Hu, Z. Effects of Compiling Straws Returning to Field on Soil Properties and Maize Yield in Windy Sandy Soil. Liaoning Agric. Sci. 2021, 3, 78–80. [Google Scholar]

- Yunlai, Z. Efforts of Different Draw Returning Methods on Soil Organic Carbon Sequencing and Crop Production. Master’s Thesis, Yangzhou University, Yangzhou, China, 2017. [Google Scholar]

- Yuan, G.; Huan, W.; Song, H.; Lu, D.; Chen, X.; Wang, H.; Zhou, J. Effects of Straw Incorporation and Potassium Fertilizer on Crop Yields, Soil Organic Carbon, and Active Carbon in the Rice–Wheat System. Soil Tillage Res. 2021, 209, 104958. [Google Scholar] [CrossRef]

| Modes | Burning | Mulching | Ploughing | Feeding | Composting | Carbonizing | |

|---|---|---|---|---|---|---|---|

| Input | Standard coal (kg) | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 6.51 |

| Gasoline (L) | 0.00 | 0.00 | 0.00 | 0.49 | 0.49 | 2.45 | |

| Diesel oil (L) | 0.14 | 0.26 | 0.58 | 0.84 | 0.84 | 1.19 | |

| Energy consumption (MJ) | 4.65 | 8.42 | 19.17 | 50.67 | 50.67 | 283.10 | |

| Output | CO2 (kg) | 240.80 | 150.17 | 130.08 | 183.20 | 179.46 | 128.26 |

| N2O (g) | 226.56 | 162.80 | 221.08 | 471.22 | 561.34 | 816.60 | |

| CH4 (g) | 1264.01 | 3766.03 | 1981.26 | 7896.10 | 1962.77 | 577.05 | |

| CO (g) | 6833.89 | 1.62 | 3.68 | 21.60 | 21.60 | 57.13 | |

| NOx (g) | 337.78 | 1.42 | 3.23 | 6.33 | 6.33 | 15.94 | |

| SO2 (g) | 200.36 | 0.65 | 1.28 | 2.49 | 1.72 | 59.23 | |

| PM2.5/10 (g) | 2053.34 | 26.52 | 27.86 | 31.24 | 31.24 | 48.07 | |

| Modes | Standardized Index | Weighted Index | ||||

|---|---|---|---|---|---|---|

| Energy Consumption(kg·per−1) | Global Warming(kg CO2e·a−1·per−1) | Environmental Acidification(kg SO2e·a−1·per−1) | Energy Consumption | Global Warming | Environmental Acidification | |

| Burning | 1.80 × 10−6 | 5.11 × 10−2 | 8.36 | 2.69 × 10−7 | 6.14 × 10−3 | 1.17 |

| Mulching | 3.25 × 10−6 | 4.07 × 10−2 | 3.15 × 10−2 | 4.87 × 10−7 | 4.89 × 10−3 | 4.40 × 10−3 |

| Ploughing | 7.40 × 10−6 | 3.50 × 10−2 | 6.78 × 10−2 | 1.11 × 10−6 | 4.20 × 10−3 | 9.49 × 10−3 |

| Feeding | 1.96 × 10−5 | 7.21 × 10−2 | 1.33 × 10−1 | 2.93 × 10−6 | 8.65 × 10−3 | 1.86 × 10−2 |

| Composting | 1.96 × 10−5 | 5.75 × 10−2 | 1.18 × 10−1 | 2.93 × 10−6 | 6.90 × 10−3 | 1.65 × 10−2 |

| Carbonizing | 1.09 × 10−4 | 5.70 × 10−2 | 1.37 | 1.64 × 10−5 | 6.84 × 10−3 | 1.89 × 10−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Z.; Zhang, X.; Chen, R.; Ge, C.; Tang, J.; Du, Y.; Jiang, P.; Fang, X.; Zheng, H.; Zhang, C. A Comprehensive Assessment of Rice Straw Returning in China Based on Life Cycle Assessment Method: Implications on Soil, Crops, and Environment. Agriculture 2024, 14, 972. https://doi.org/10.3390/agriculture14070972

Tang Z, Zhang X, Chen R, Ge C, Tang J, Du Y, Jiang P, Fang X, Zheng H, Zhang C. A Comprehensive Assessment of Rice Straw Returning in China Based on Life Cycle Assessment Method: Implications on Soil, Crops, and Environment. Agriculture. 2024; 14(7):972. https://doi.org/10.3390/agriculture14070972

Chicago/Turabian StyleTang, Zeyu, Xiaoyu Zhang, Ruxin Chen, Chaomin Ge, Jianjun Tang, Yanqiang Du, Peikun Jiang, Xiaobo Fang, Huabao Zheng, and Cheng Zhang. 2024. "A Comprehensive Assessment of Rice Straw Returning in China Based on Life Cycle Assessment Method: Implications on Soil, Crops, and Environment" Agriculture 14, no. 7: 972. https://doi.org/10.3390/agriculture14070972

APA StyleTang, Z., Zhang, X., Chen, R., Ge, C., Tang, J., Du, Y., Jiang, P., Fang, X., Zheng, H., & Zhang, C. (2024). A Comprehensive Assessment of Rice Straw Returning in China Based on Life Cycle Assessment Method: Implications on Soil, Crops, and Environment. Agriculture, 14(7), 972. https://doi.org/10.3390/agriculture14070972