Design and Preliminary Experiment of Track Width Adjustment System for Sprayer Based on Integral Separated Fuzzy Proportional Integral Derivative Control Strategy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Overall Structure of the Track Width Adjustment System

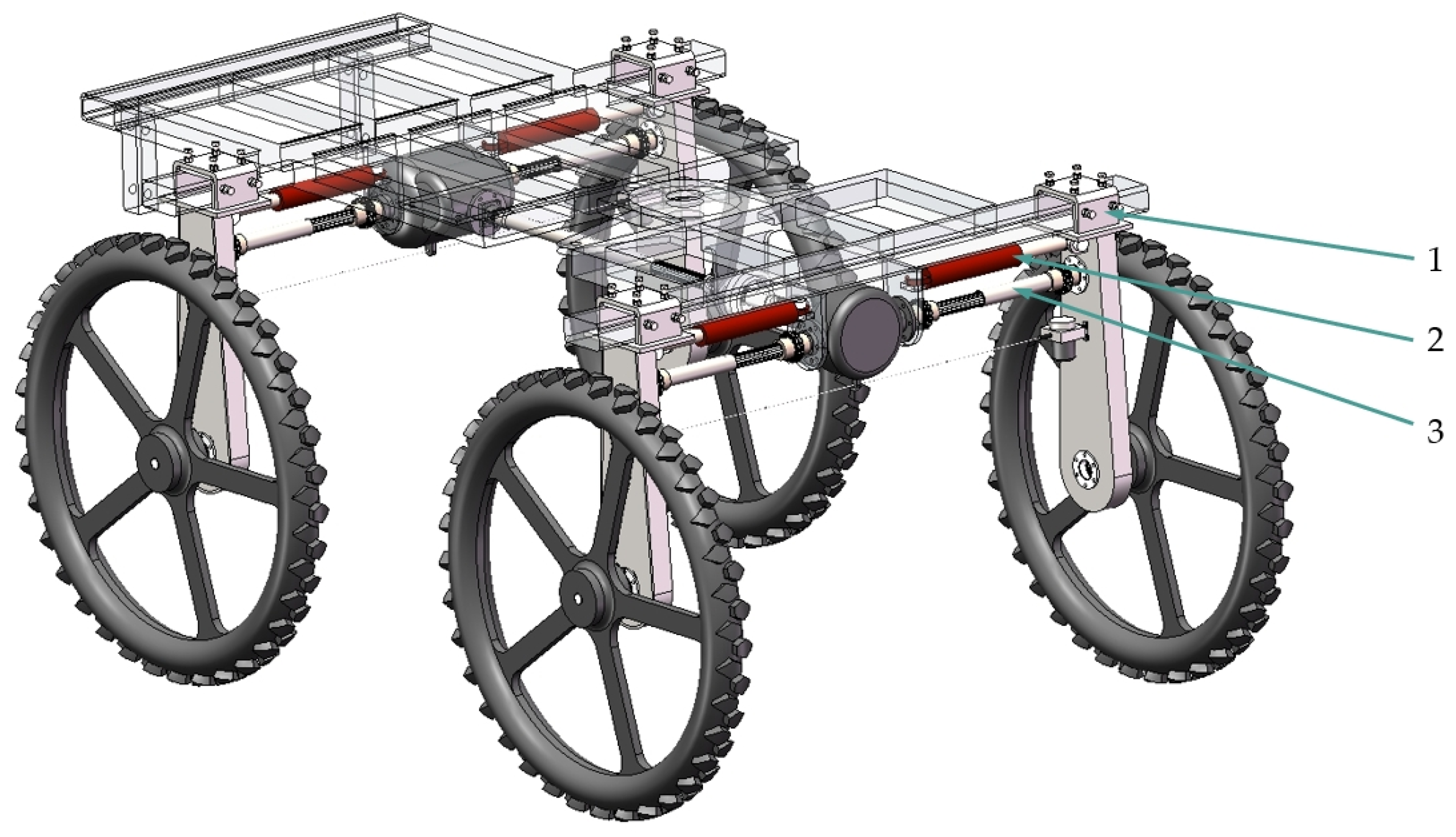

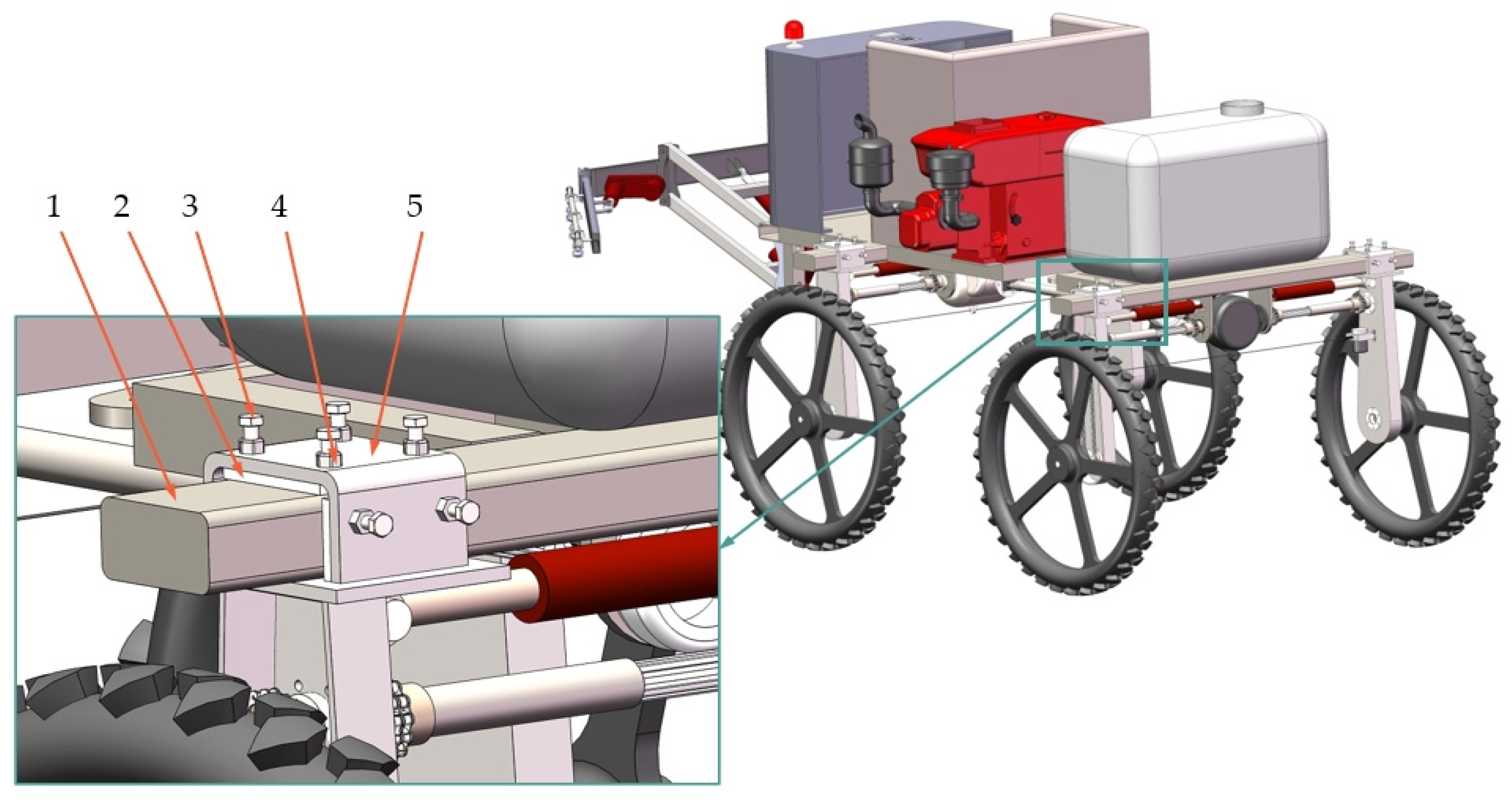

2.2. Design of Key Components of the Track Width Adjustment System

2.2.1. Transmission Mechanism

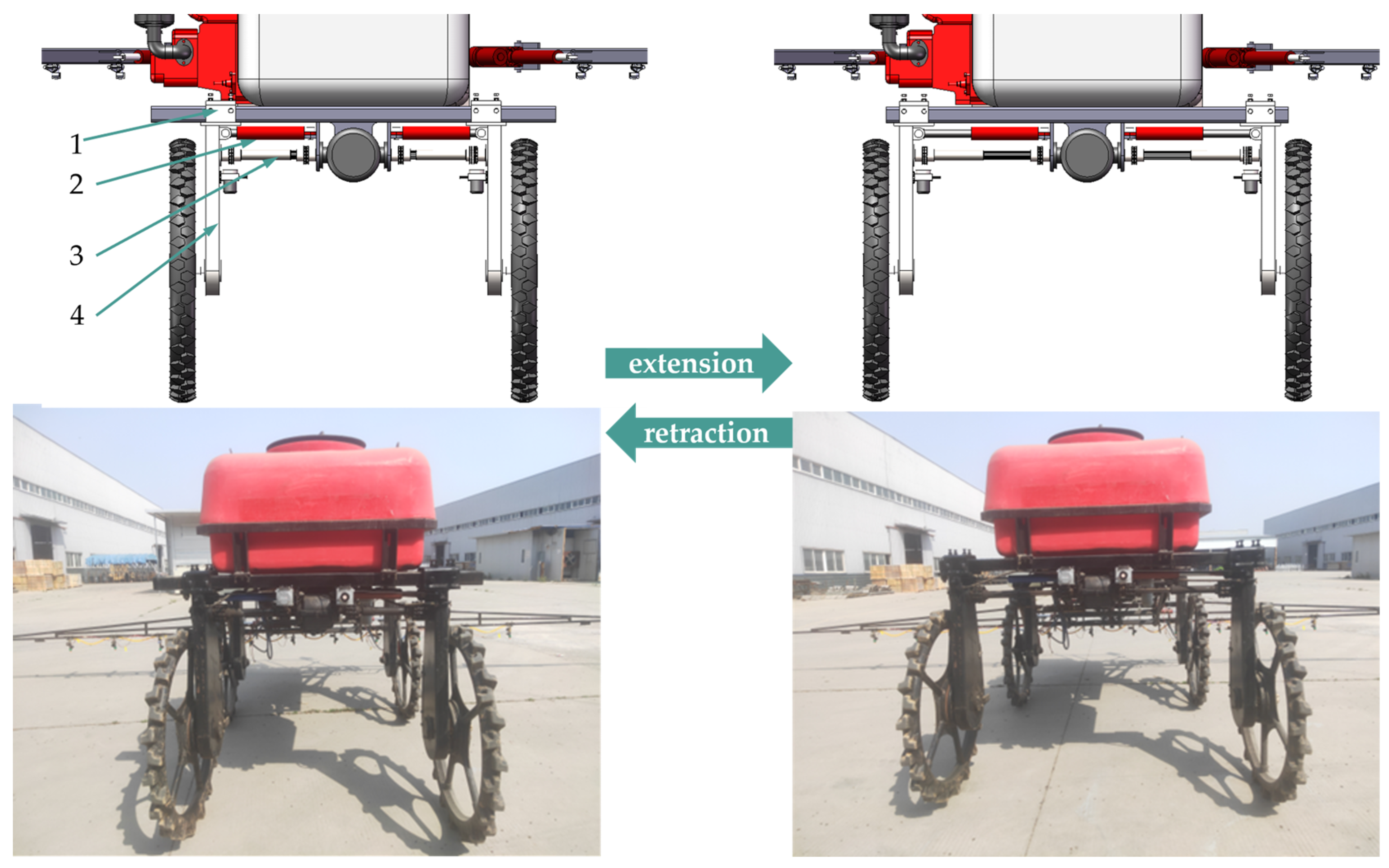

2.2.2. Telescopic Track Width Adjustment Mechanism

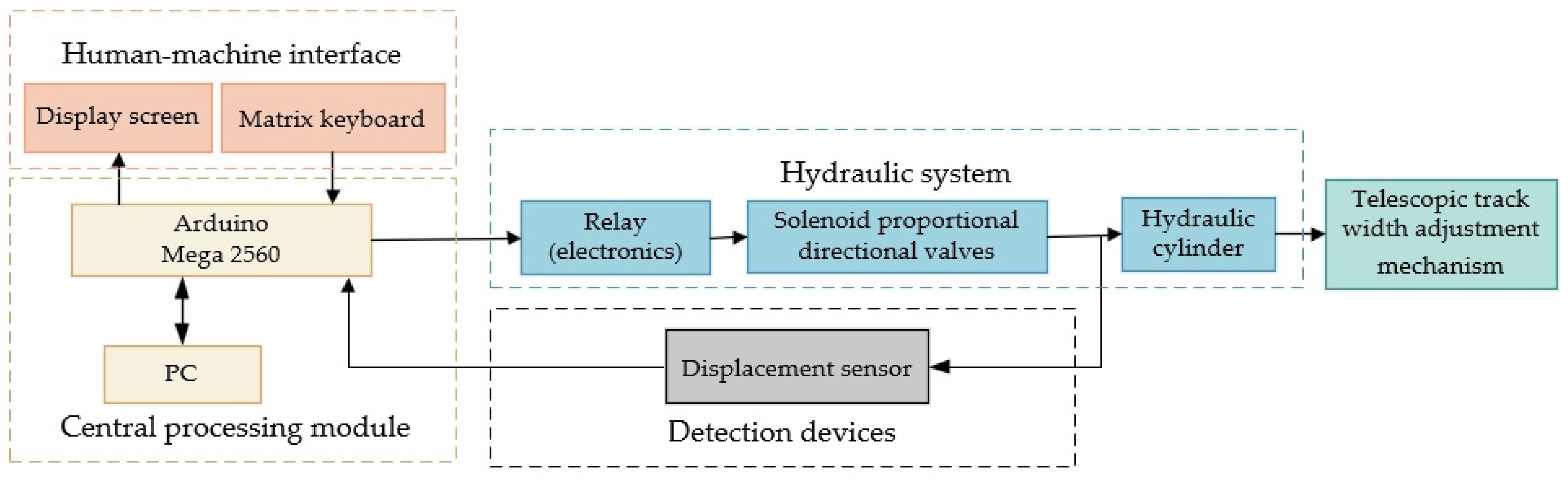

2.3. Electro-Hydraulic Control System

2.3.1. Overall Framework of the Electro-Hydraulic Control System

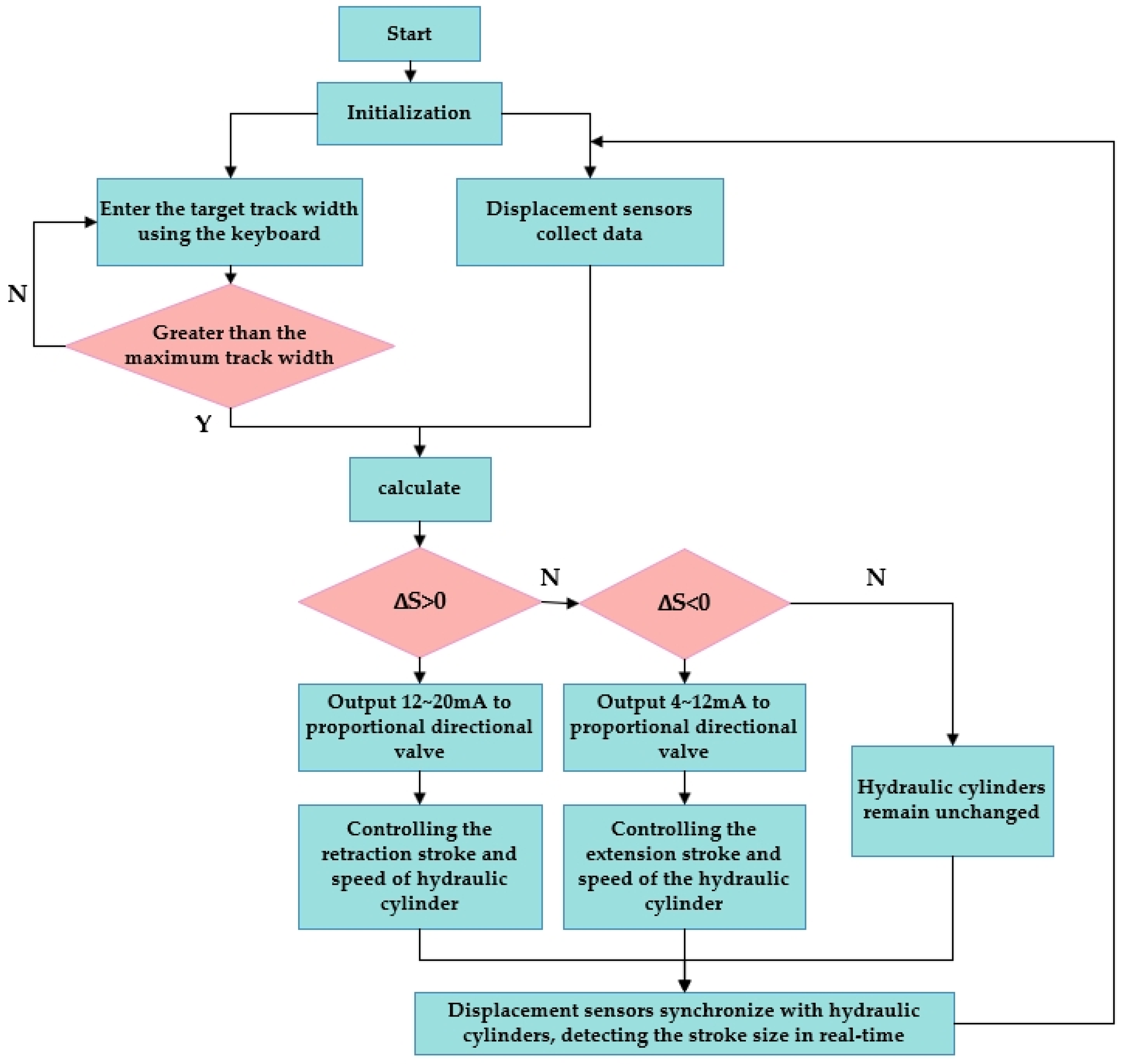

2.3.2. Control System Main Program

2.3.3. Hydraulic System

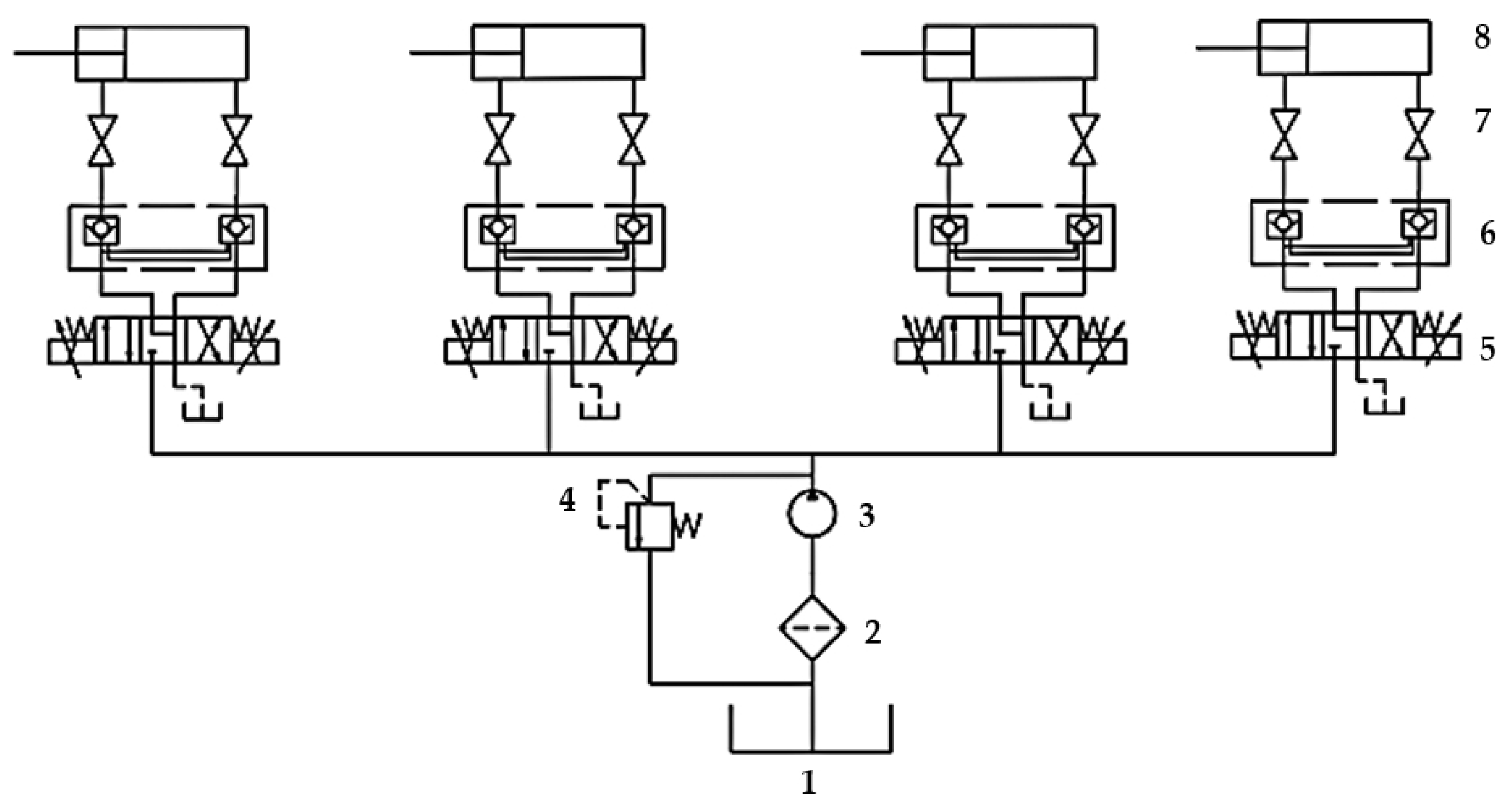

- Principle of the hydraulic system

- 2.

- Design of the hydraulic cylinder

2.4. Control Scheme Simulation Experiment

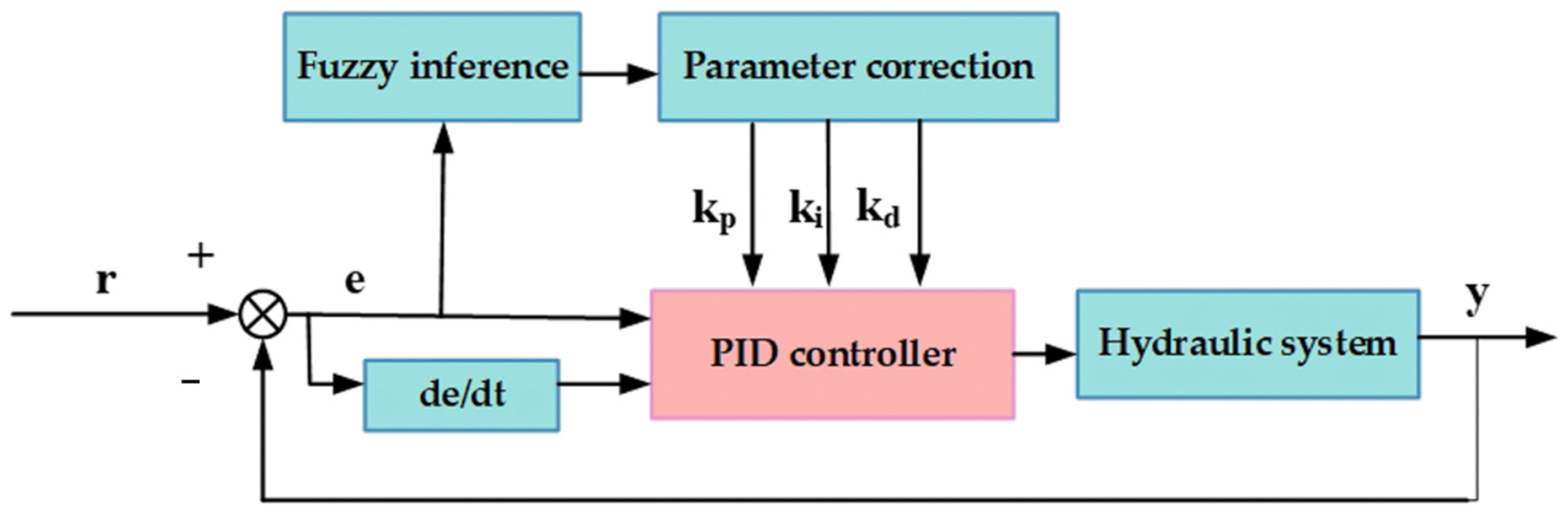

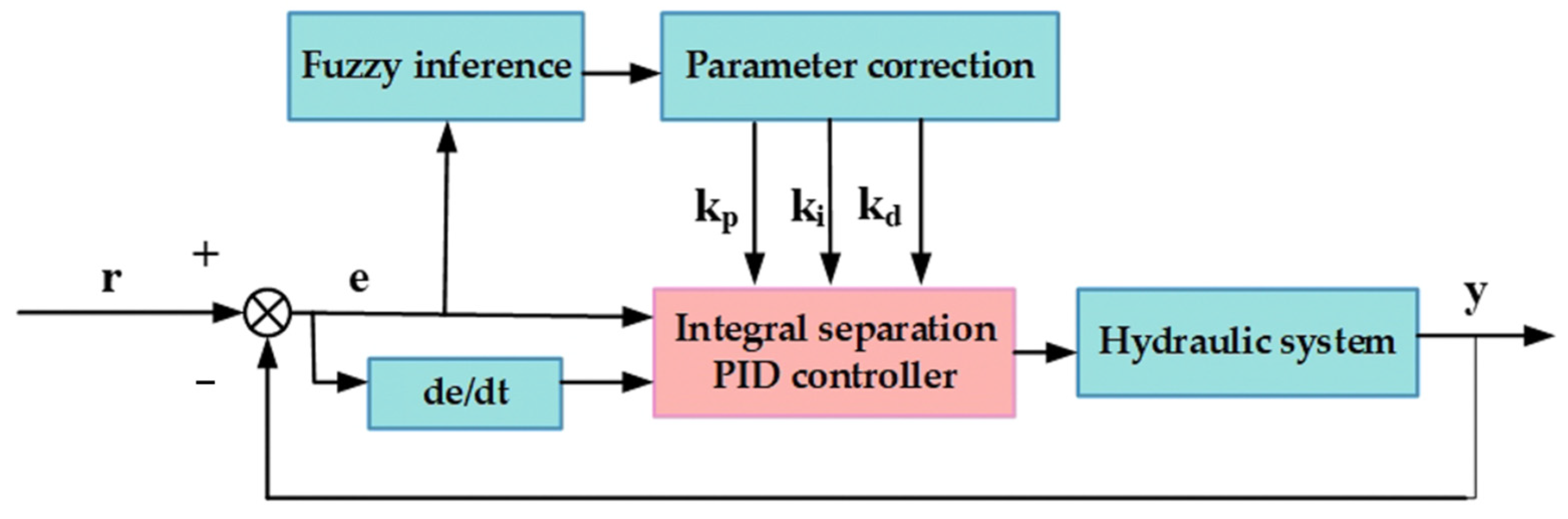

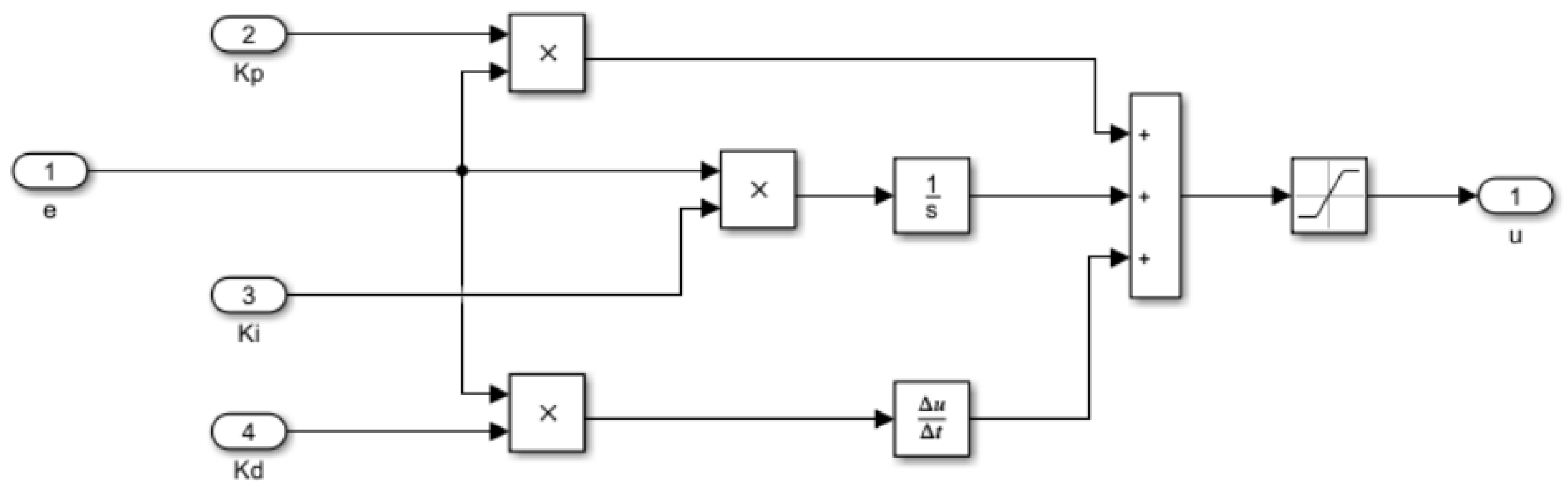

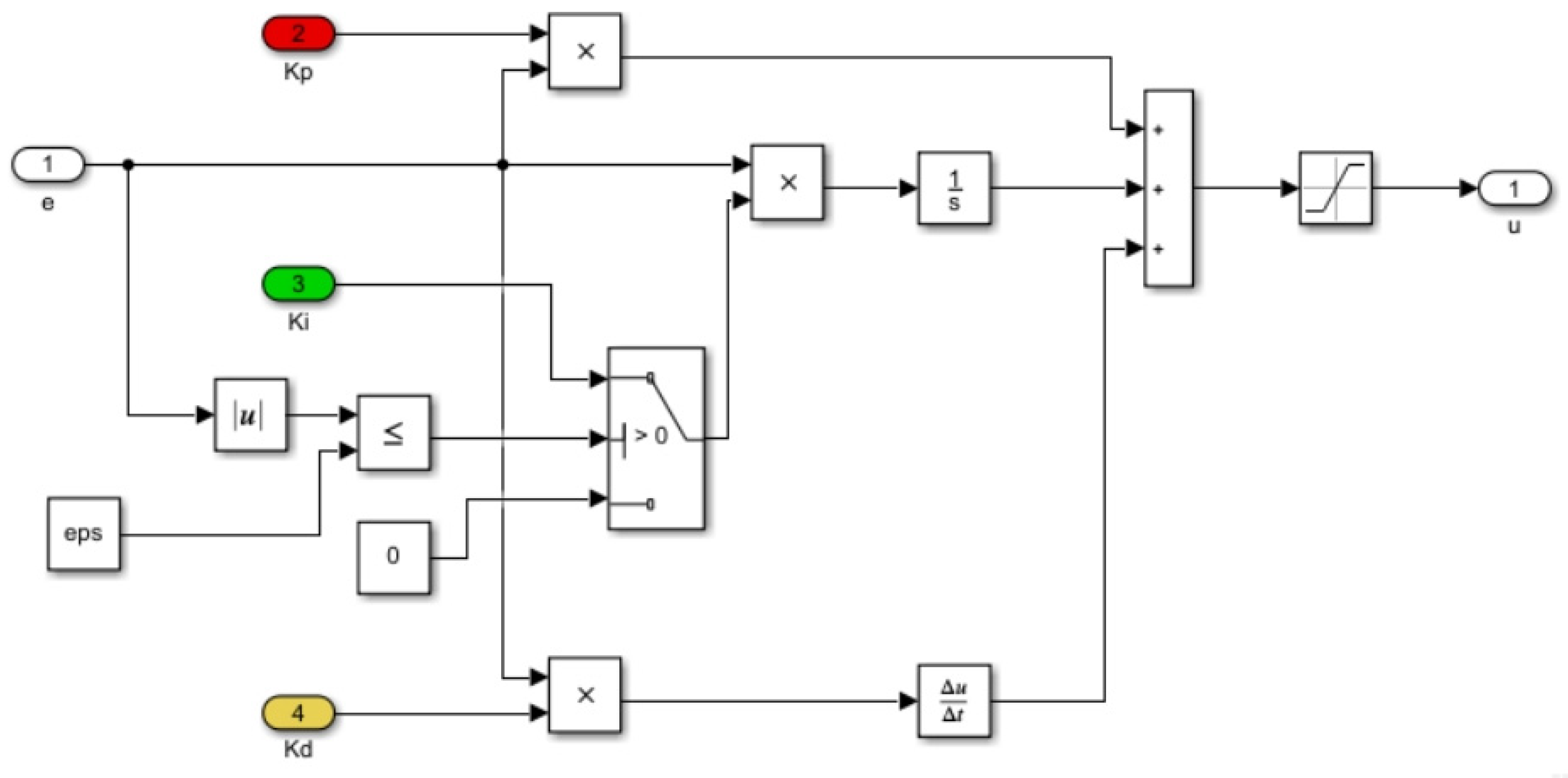

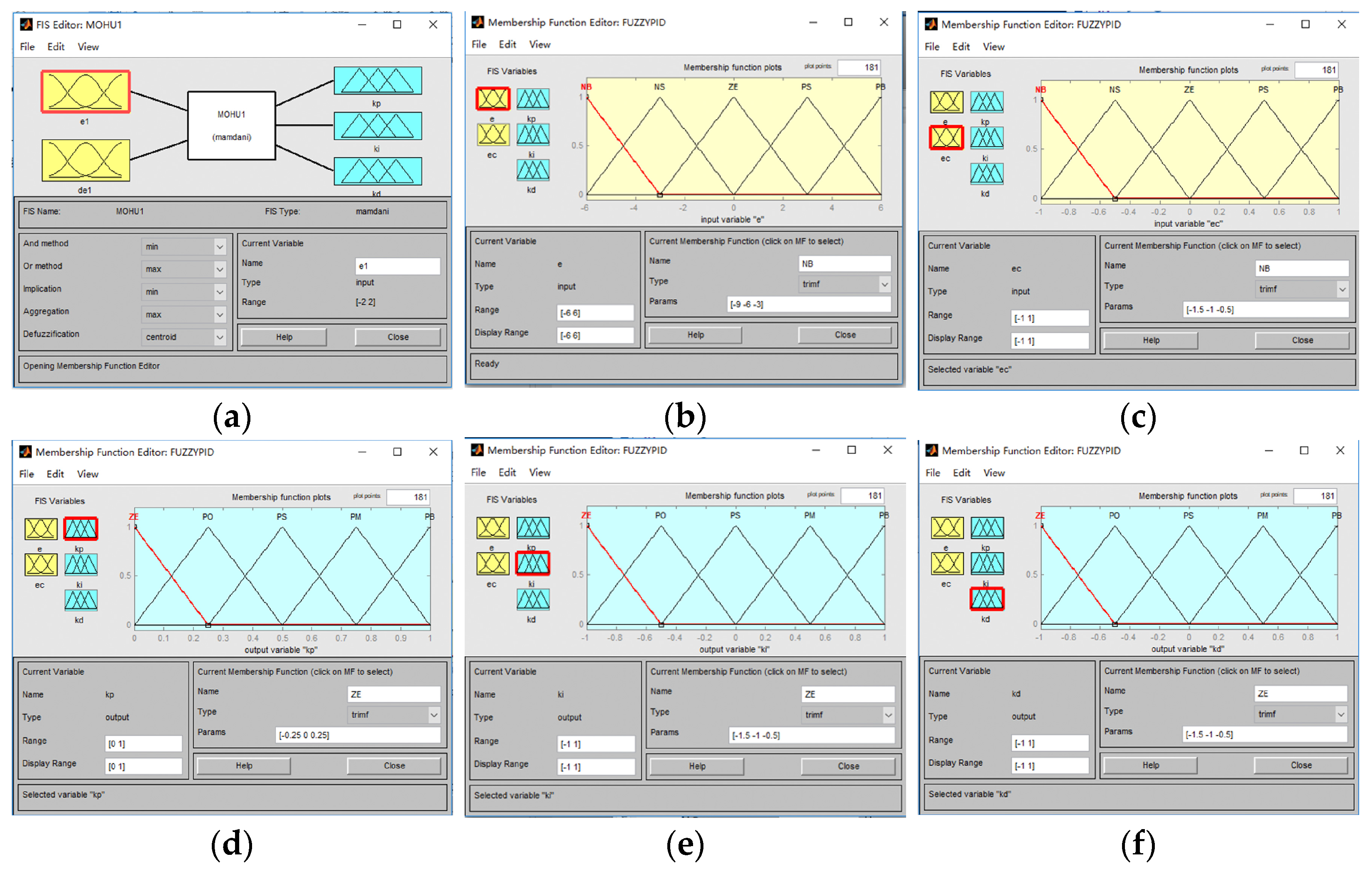

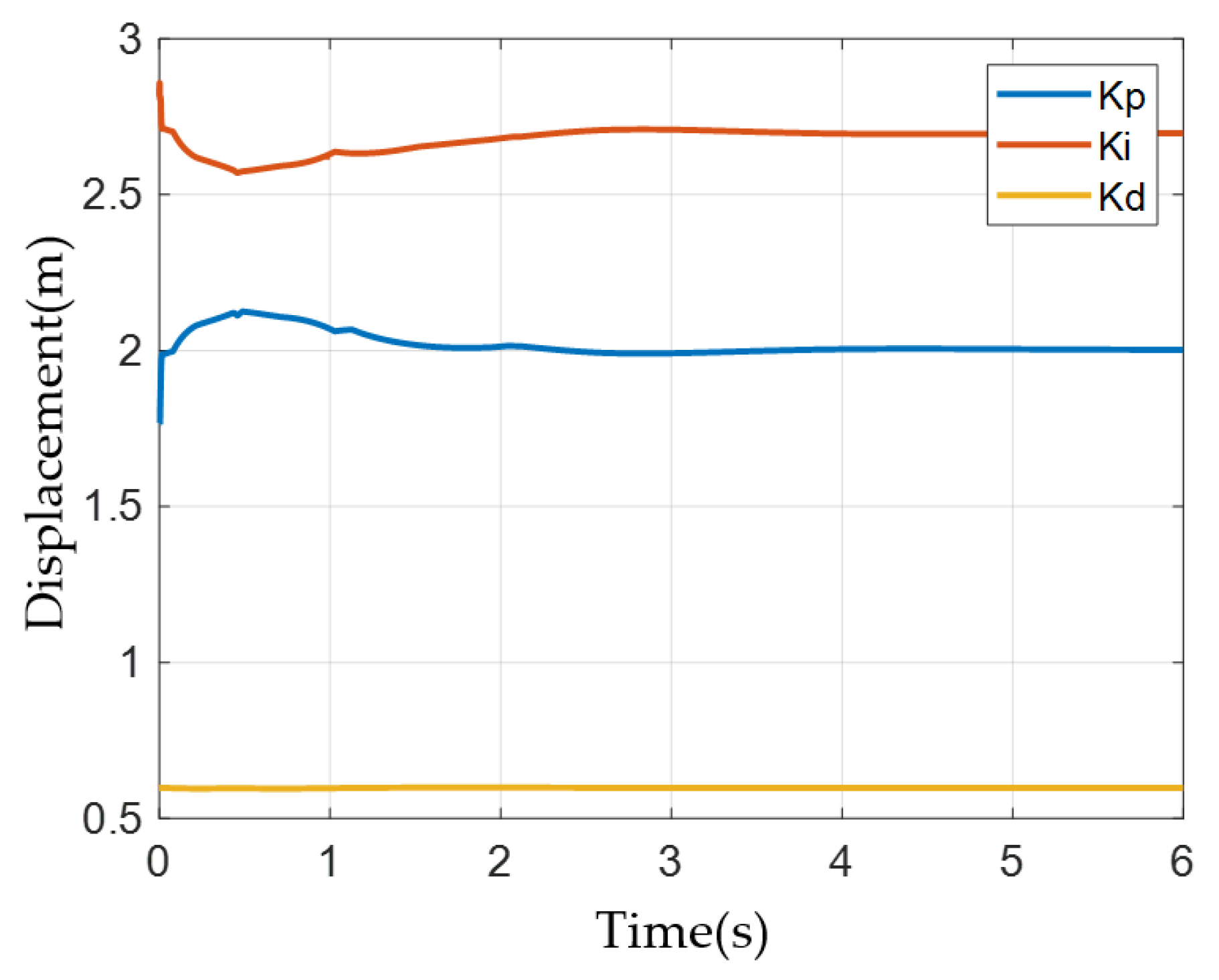

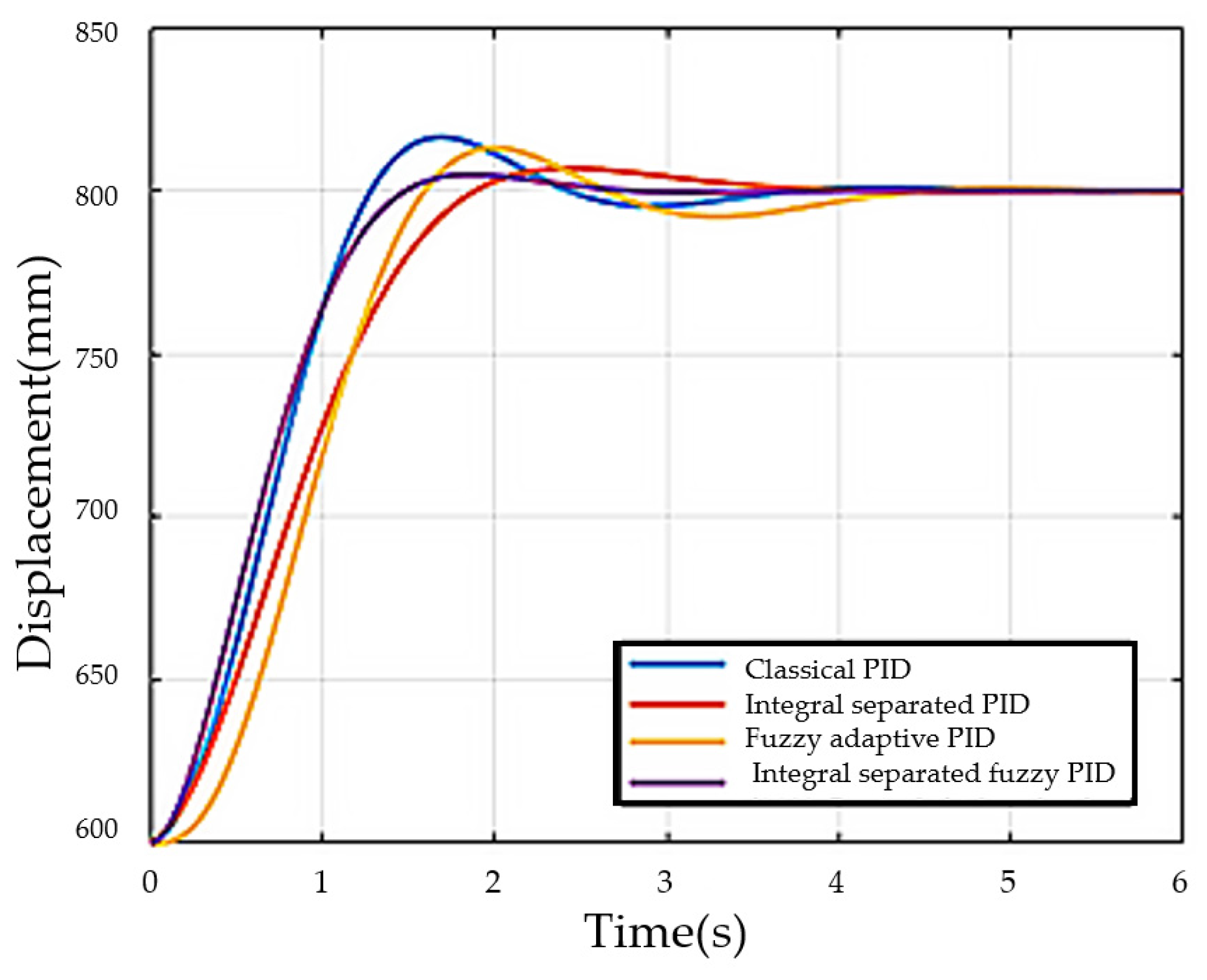

2.4.1. Design of Control Strategies

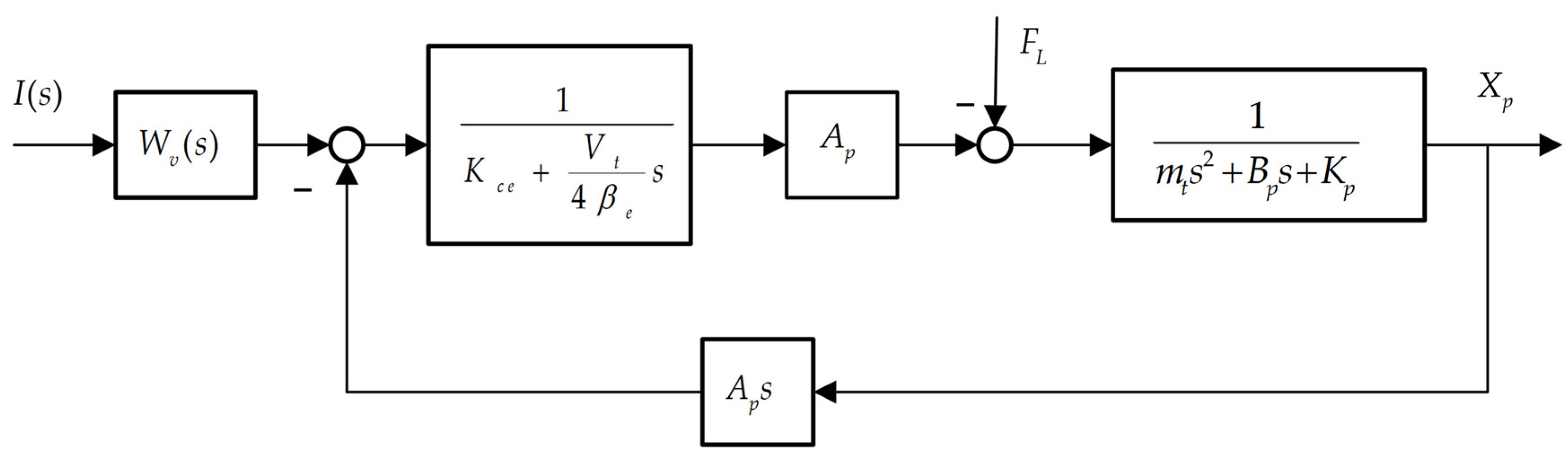

2.4.2. Mathematical Model of Hydraulic System

- Mathematical model of hydraulic cylinders

- The connecting pipelines between the valve and the hydraulic cylinder are symmetrical, short, and thick, allowing the pressure loss and dynamics within the pipelines to be neglected.

- The pressure within each working chamber of the hydraulic cylinder is equal.

- The initial volumes of the oil inlet and return chambers are equal.

- The oil temperature and bulk modulus are constant.

- Both internal and external leakage in the hydraulic cylinder are laminar flows.

- 2.

- Mathematical model of solenoid proportional directional valve

- 3.

- Mathematical model of solenoid proportional directional valve controlled hydraulic cylinder system

2.4.3. Construction of Simulation Models for Control Schemes

2.5. Field Performance Experiment

2.5.1. Description of the Field Experiment Area

2.5.2. Experimental Treatments

- Track Width Adjustment Stability Experiment Treatment

- 2.

- Track Width Adjustment Precision Experiment Treatment

3. Results and Discussion

3.1. Simulation Experiment Data Collection and Analysis

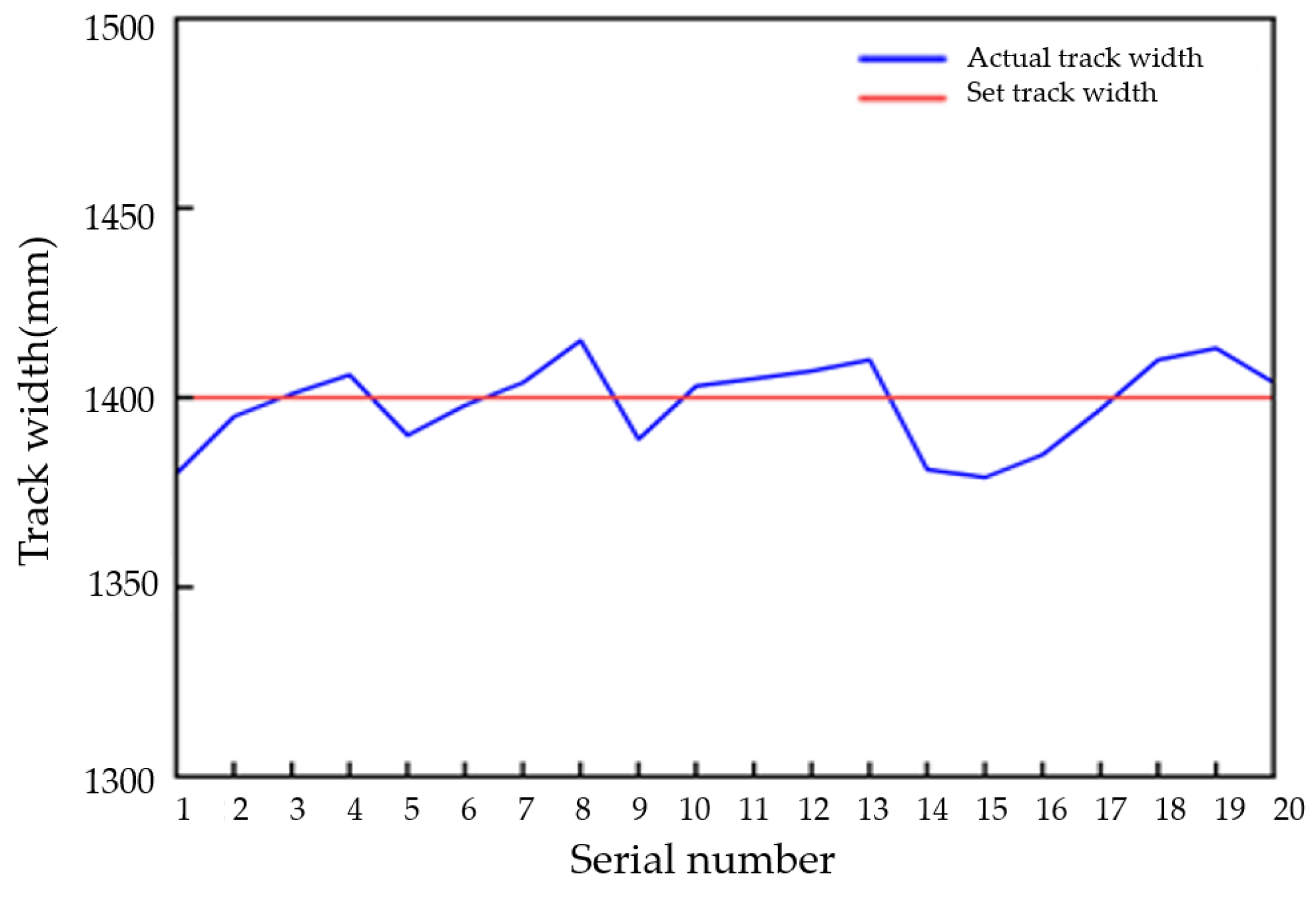

3.2. Track Width Adjustment Stability Experiment Data Collections and Analysis

3.3. Track Width Adjustment Precision Experiment Data Collections and Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- National Bureau of Statistics of China. China Statistical Yearbook-2023; China Statistics Press: Beijing, China, 2023. [Google Scholar]

- Shen, Z.; Han, T.F. Temporal and spatial variability of relative yield differences between wheat and maize and their response to nitrogen fertilizer. Chin. J. Agric. Sci. 2023, 56, 2724–2737. [Google Scholar]

- Zheng, R.J.; Luan, L. Application of boom sprayers in the control of diseases, pests, and weeds in Rice-Wheat rotation Areas. Mod. Agric. Sci. Technol. 2023, 15, 99–103. [Google Scholar]

- Sun, W.F.; Liu, H.Y. Design and experiment of PID control variable spraying system based on neural network tuning. Trans. Chin. Soc. Agric. Mach. 2020, 51, 55–64+94. [Google Scholar]

- Zhou, Z.Y.; Zhou, M.J. Research on automatic leveling control system of boom sprayer with rotor suspension. Trans. Chin. Soc. Agric. 2022, 53, 70–79. [Google Scholar]

- Xu, Y.D.; Liu, G.H. Four-wheel synchronous steering sprayer tracking control based on fuzzy MPC. Control Eng. 2024, 1–9. [Google Scholar] [CrossRef]

- Wan, T.; Wang, W.J. Development research and analysis of variable chassis technology for agricultural tractors. Tractor Farm Transp. 2020, 47, 4–6. [Google Scholar]

- Zuo, Z.J. Research and Design of Variable Ground Clearance and Track Width Tractor Chassis. Master’s Thesis, Shandong University, Jinan, China, 2016. [Google Scholar]

- Case New Holland. Case “Patriot” Patriot~(TM) 3230 sprayer, powerful. Agric. Mach. 2020, 4, 29. [Google Scholar]

- Zhang, Q. Stability Study of Variable Track Power Platform in Hilly and Mountainous Areas. Master’s Thesis, Xihua University, Chengdu, China, 2023. [Google Scholar]

- Liu, D.X.; Qi, J.H. Multifunctional Self-Propelled Adjustable Boom Spraying Detasseling Machine. Siping, China, 2015. Available online: http://search.cnipr.com/search!doDetailSearch.action (accessed on 25 July 2024).

- Wang, M.; Xie, F. Current development status of plant protection spraying devices in China. Agric. Eng. 2019, 9, 4–7. [Google Scholar]

- Li, J. Design of an Agricultural Variable Wheelbase Electric Mobile Platform. Master’s Thesis, Chongqing Three Gorges University, Chongqing, China, 2021. [Google Scholar]

- Xia, J.L.; Guan, C.S. A Device for Adjusting the Rear Wheel Spacing of a Wheeled Tractor. Yancheng, China, 2014. Available online: http://search.cnipr.com/search!doDetailSearch.action (accessed on 25 July 2024).

- Chipriana, A.A.; Puig Mauri, O.C. Equips para la mechanization del cultivate explanations frustules de Alta densipan. Investig. Agrar. Prod. Prot. 2000, 15, 125–142. [Google Scholar]

- Blanco, M.N.; Michael, R.A. Real-time monitoring of spray drift from three different orchard sprayers. Chemosphere 2019, 222, 46–55. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Xie, Y. Machine Vision-Based Obstacle Avoidance Hydraulic Chassis with Variable Wheel Track and Its Usage Method. 2018. Available online: http://search.cnipr.com/search!doDetailSearch.action (accessed on 25 July 2024).

- Wang, X.C.; Shang, Z.G. Current research status and development trends of plant protection machinery design and manufacturing technology. Mod. Agric. Sci. Technol. 2017, 2, 282–288. [Google Scholar]

- Huang, M.; Zheng, D.K. Synchronization study of sugarcane cultivator with rhombic self-propelled chassis based on AMESim. J. Agric. Mech. Res. 2017, 39, 7–12. [Google Scholar]

- Dou, L.J. Design and Research of Adjustable Track Steering System for High-Clearance Self-Propelled Sprayer. Master’s Thesis, Chinese Academy of Agricultural Mechanization Sciences, Beijing, China, 2012. [Google Scholar]

- Fan, G.Q.; Meng, X.G. Agricultural High-Clearance Operation Machine. 2015. Available online: http://search.cnipr.com/search!doDetailSearch.action (accessed on 25 July 2024).

- Cui, Y.J.; Zhang, Z.L. Kinematic simulation analysis of fruit picking manipulator based on ADAMS. J. Agric. Mech. Res. 2008, 4, 59–61. [Google Scholar]

- GB/T 2348-2018; Fluid Power Systems and Components—Cylinder Bores and Piston Rod Diameters. Standardization Administration of China: Beijing, China, 2018.

- Kwok, K.E.; Chong, P.M. A model based augmented PID algorithm. J. Process Control 2000, 10, 9–18. [Google Scholar] [CrossRef]

- Xue, D.Y. Control System Computer-Aided Design—MATLAB Language and Application; Tsinghua University Press: Beijing, China, 1996. [Google Scholar]

- Liu, J.K. Advanced PID Control and Simulation; Electronics Industry Press: Beijing, China, 2000; pp. 1–8. [Google Scholar]

- Qiu, L.; Zeng, G.E. Comparative study on several PID controller parameter tuning methods. Autom. Technol. Appl. 2005, 24, 28–31. [Google Scholar]

- Han, P.P. Research and Design of Fuzzy Self-Tuning PID Controller. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2010. [Google Scholar]

- Sun, C.Y. Principles and Design of Measurement and Control Systems; Beijing University of Aeronautics and Astronautics Press: Beijing, China, 2003; pp. 160–166, 174. [Google Scholar]

- Zhao, H.Q. Rapid empirical tuning method for PID control parameters. Chem. Ind. Autom. Instrum. 1997, 24, 43–45. [Google Scholar]

- Liu, J.Q.; Ding, P. Research on remote steering system of tractor based on fuzzy PID control. J. Agric. Mech. 2024, 1–8. [Google Scholar] [CrossRef]

| Experiment Number | Initial Track Width (mm) | Target Track Width (mm) | Final Track Width Adjustment Value (mm) | Error (mm) |

|---|---|---|---|---|

| 1 | 1400 | 1550 | 1563 | 13 |

| 2 | 1400 | 1550 | 1571 | 21 |

| 3 | 1400 | 1550 | 1562 | 12 |

| 3 | 1400 | 1550 | 1558 | 8 |

| 4 | 1400 | 1550 | 1564 | 14 |

| 5 | 1400 | 1550 | 1555 | 5 |

| 6 | 1550 | 1400 | 1380 | 20 |

| 7 | 1550 | 1400 | 1415 | 15 |

| 8 | 1550 | 1400 | 1410 | 10 |

| 9 | 1550 | 1400 | 1393 | 7 |

| 10 | 1550 | 1400 | 1421 | 21 |

| 11 | 1550 | 1400 | 1415 | 15 |

| 12 | 1400 | 1550 | 1563 | 13 |

| Average | / | / | / | 13.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, L.; Jia, M.; He, J.; Su, X.; Wang, Q.; Yang, H.; Li, H. Design and Preliminary Experiment of Track Width Adjustment System for Sprayer Based on Integral Separated Fuzzy Proportional Integral Derivative Control Strategy. Agriculture 2024, 14, 1247. https://doi.org/10.3390/agriculture14081247

Tan L, Jia M, He J, Su X, Wang Q, Yang H, Li H. Design and Preliminary Experiment of Track Width Adjustment System for Sprayer Based on Integral Separated Fuzzy Proportional Integral Derivative Control Strategy. Agriculture. 2024; 14(8):1247. https://doi.org/10.3390/agriculture14081247

Chicago/Turabian StyleTan, Lu, Mei Jia, Jin He, Xintong Su, Quanyu Wang, Hanyu Yang, and Hang Li. 2024. "Design and Preliminary Experiment of Track Width Adjustment System for Sprayer Based on Integral Separated Fuzzy Proportional Integral Derivative Control Strategy" Agriculture 14, no. 8: 1247. https://doi.org/10.3390/agriculture14081247