Fatigue Analysis of PTO Gearboxes in Paddy Power Chassis Using Measured Loads

Abstract

1. Introduction

2. Simulation Analysis

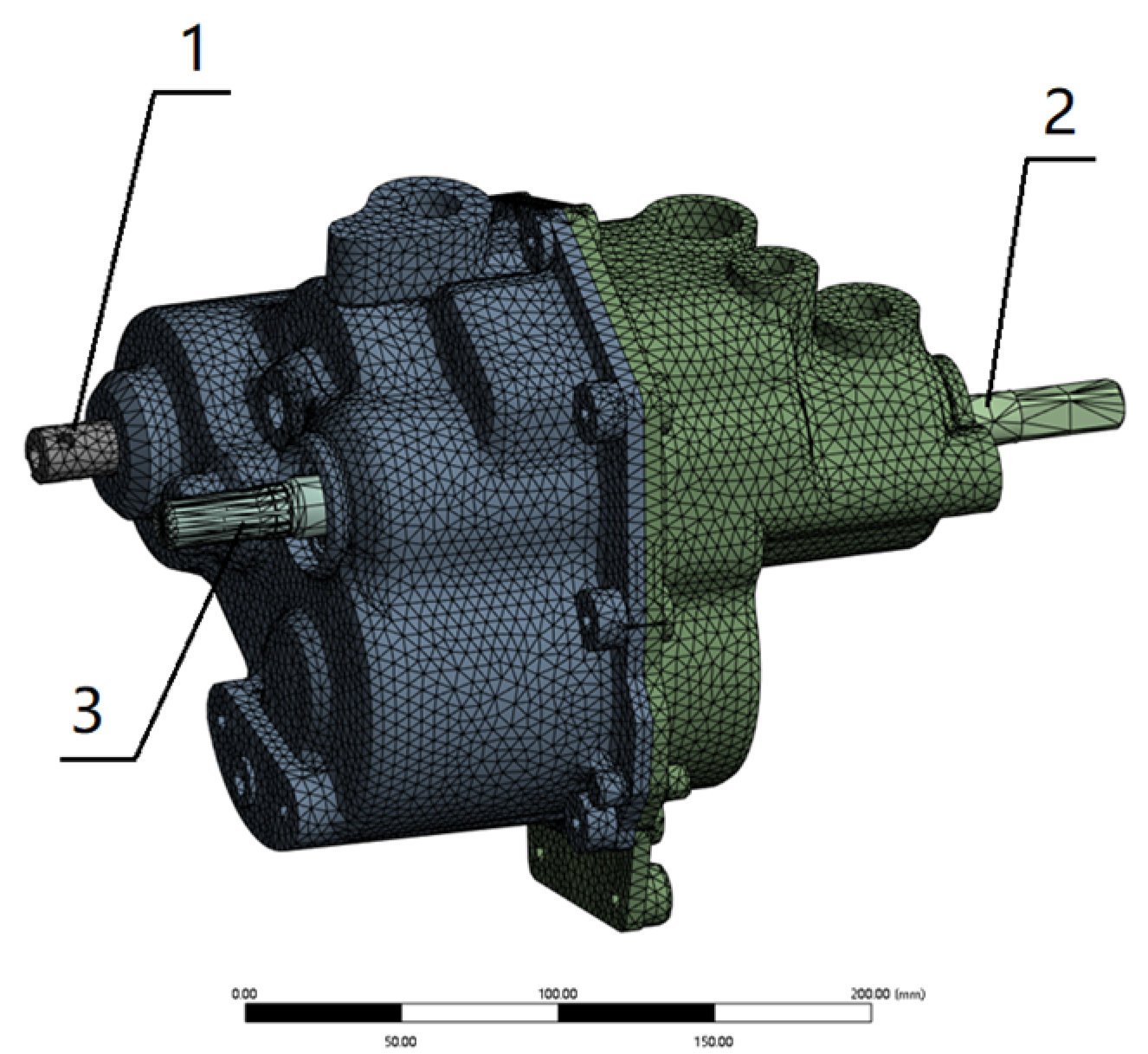

2.1. Finite Element Modelling

2.2. Parametric and Simulation Design of Experiments

2.3. Simulation Evaluation Indicators and Analysis of Results

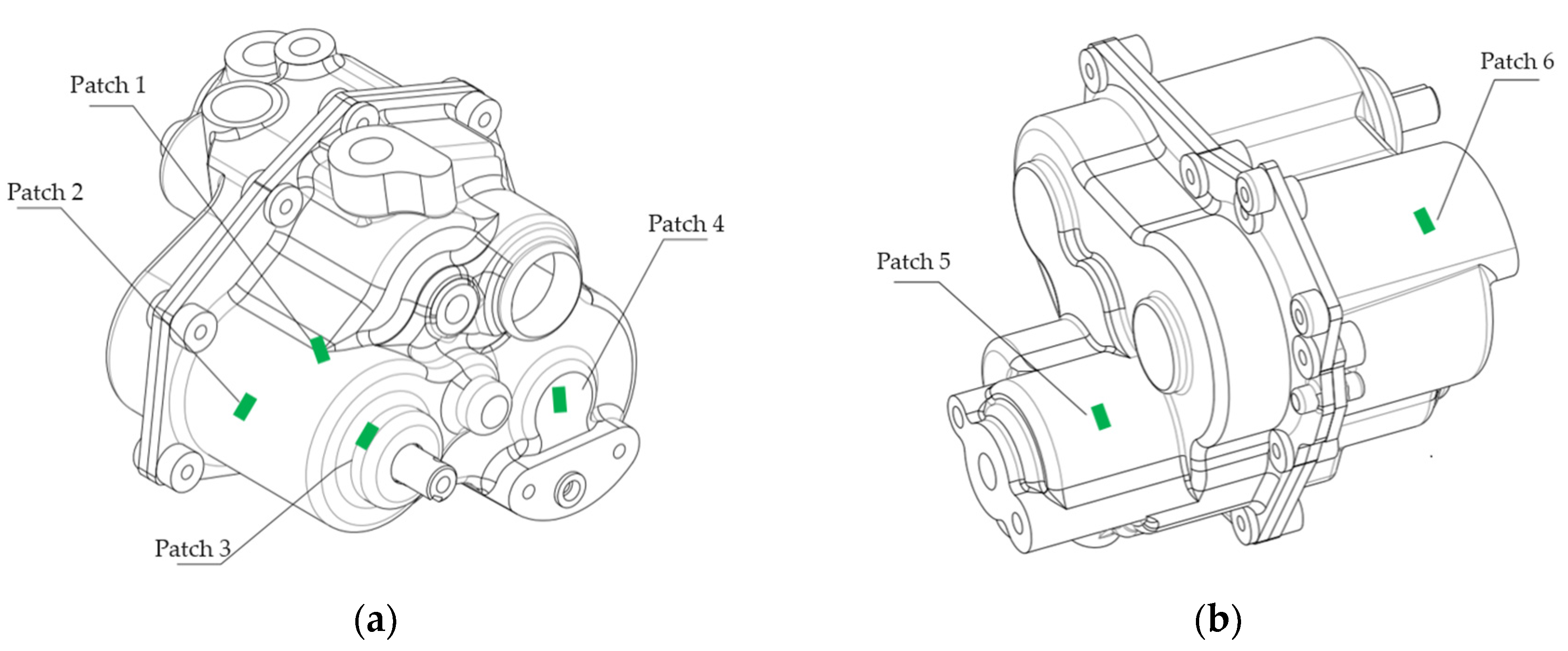

3. Experiment and Analysis

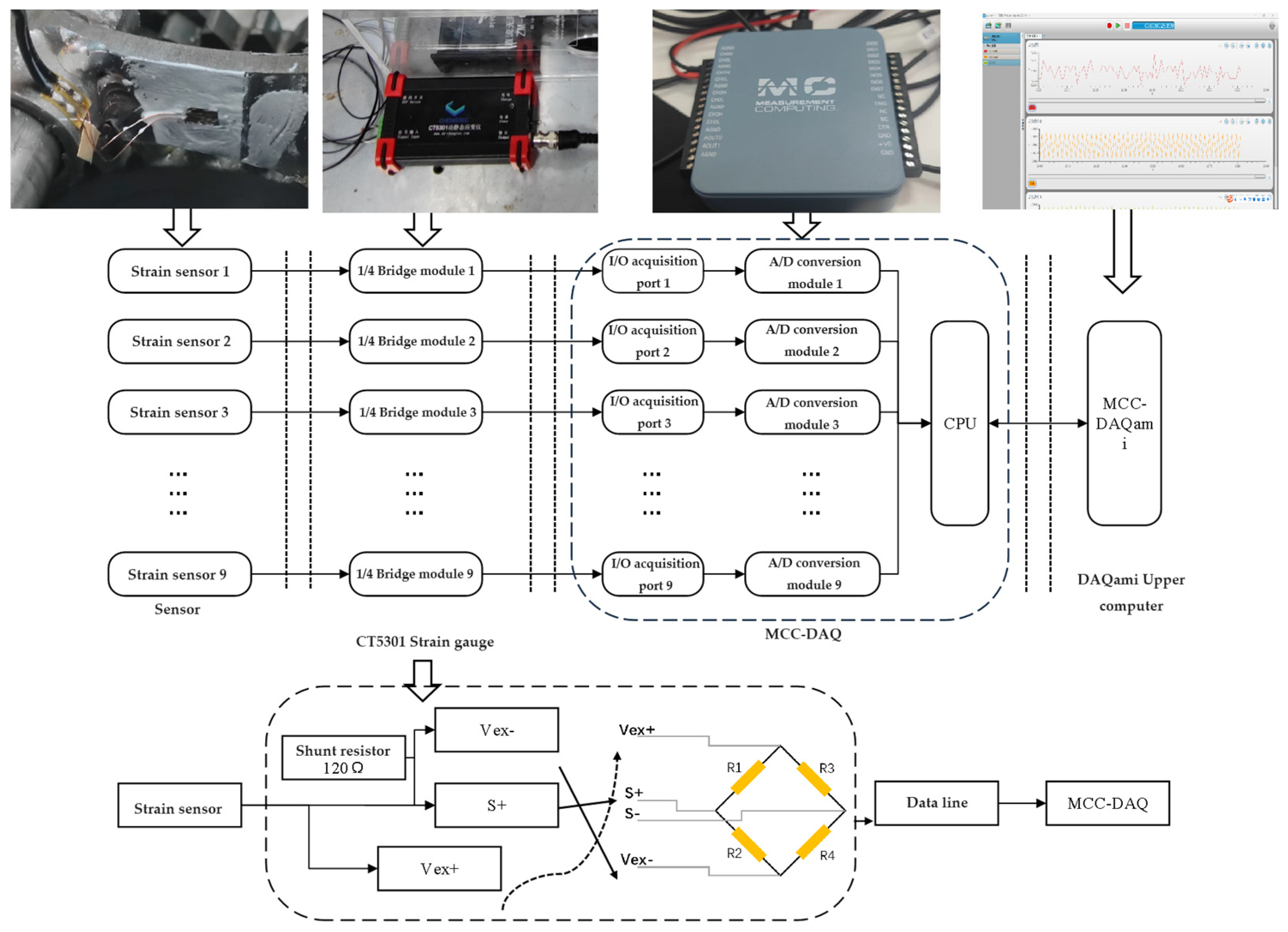

3.1. Test Instruments and Equipment

3.2. Measured Load Collection for Shift Operations

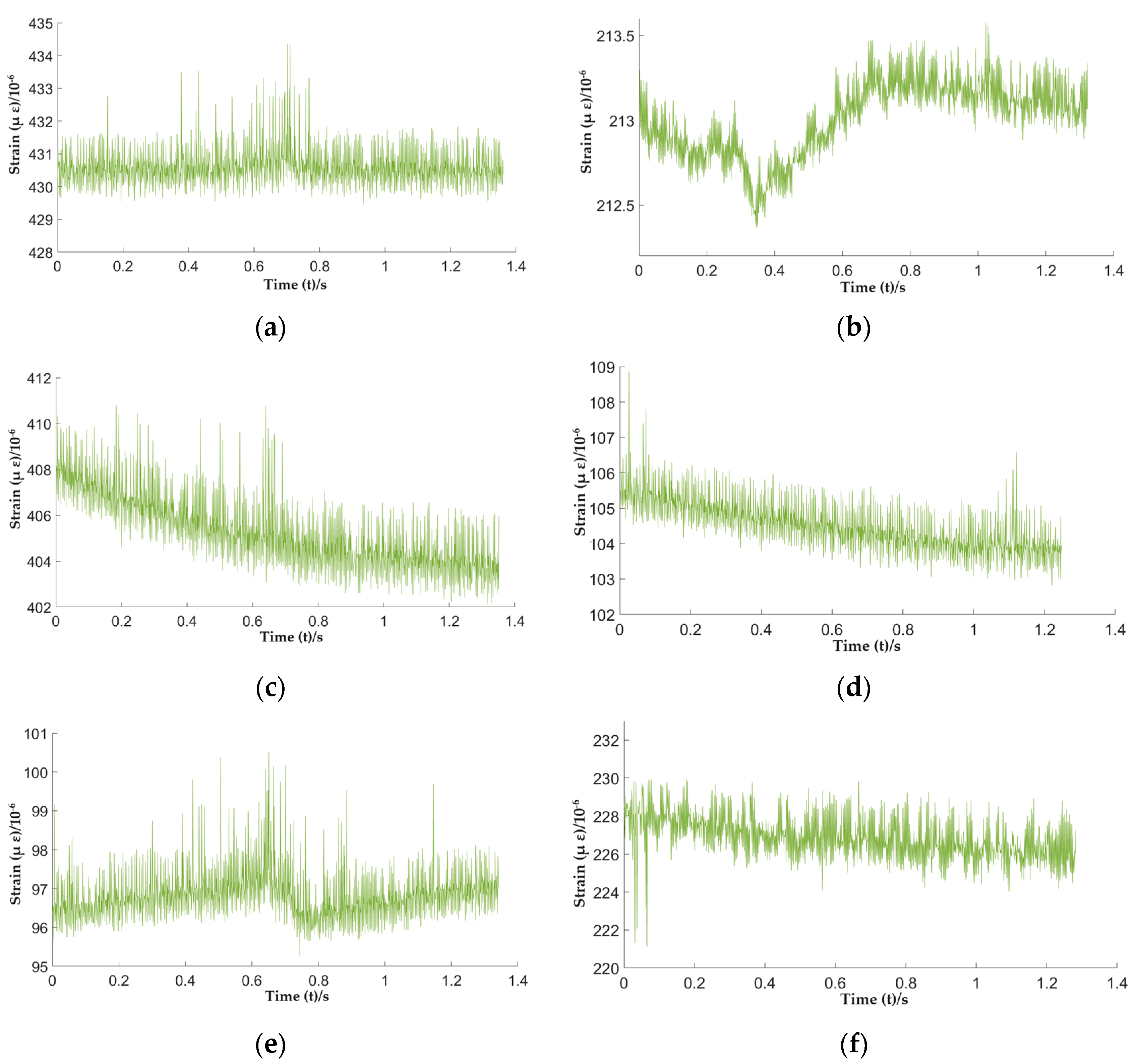

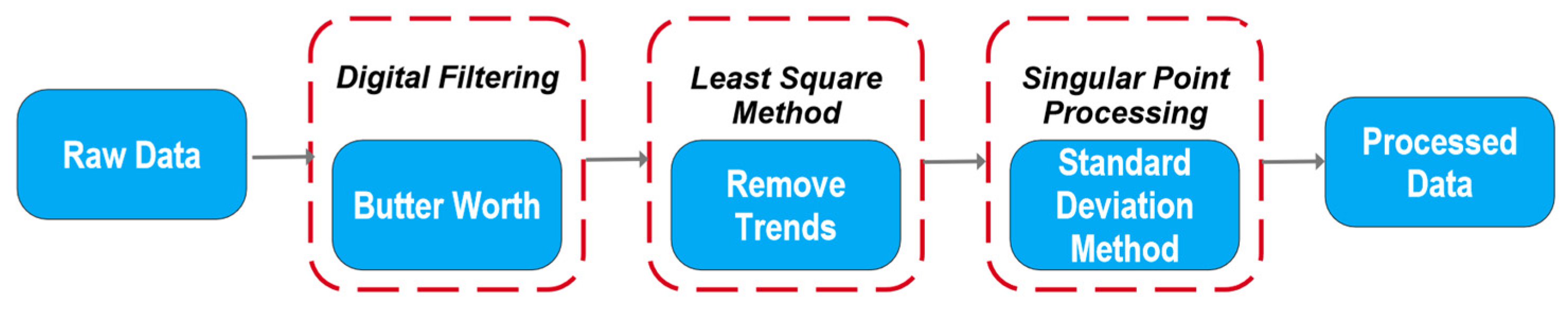

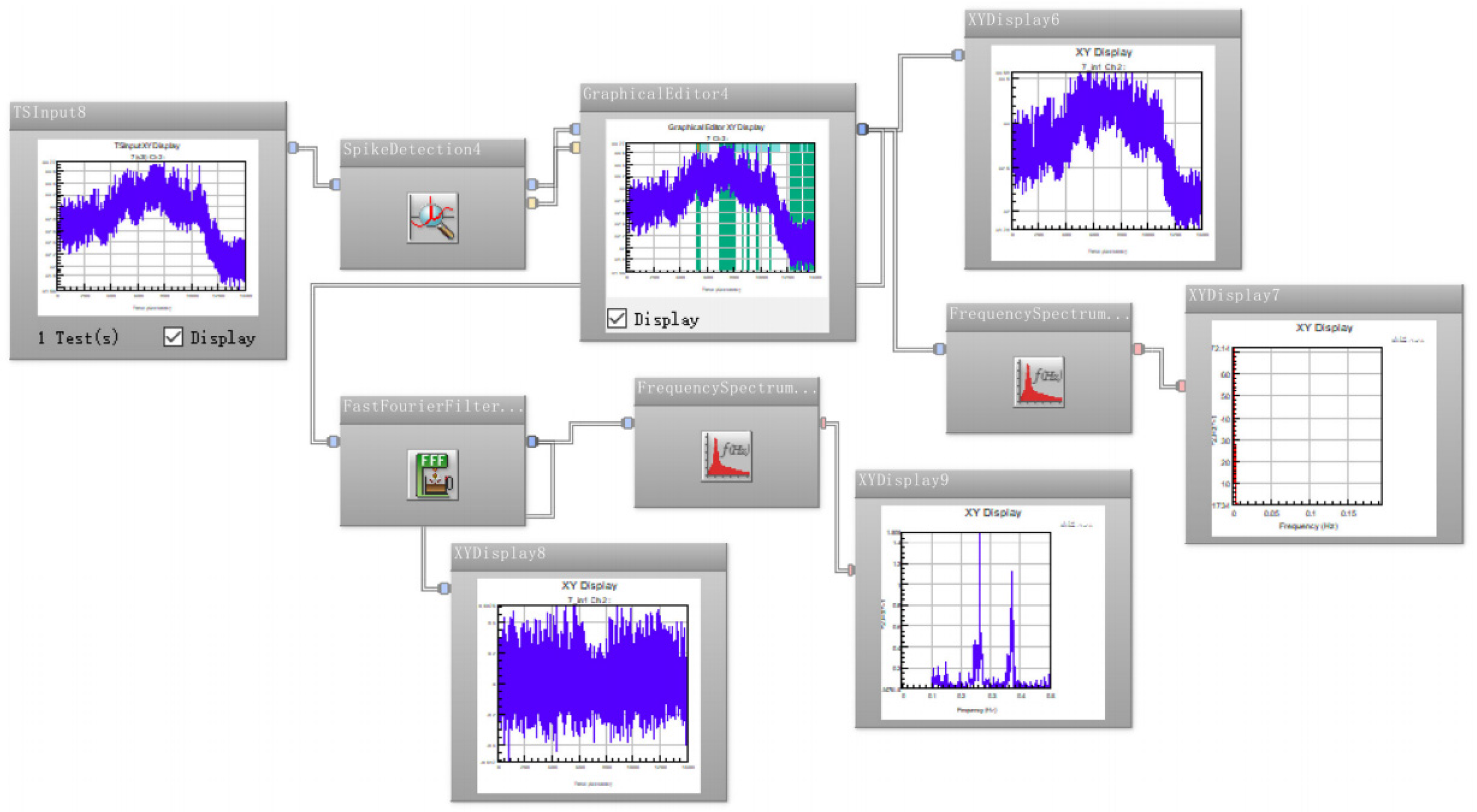

3.3. Analyzing and Calculating Measured Load Data

4. High Frequency PTO Gearbox Fatigue Analysis Method

4.1. Fatigue Analysis Theory

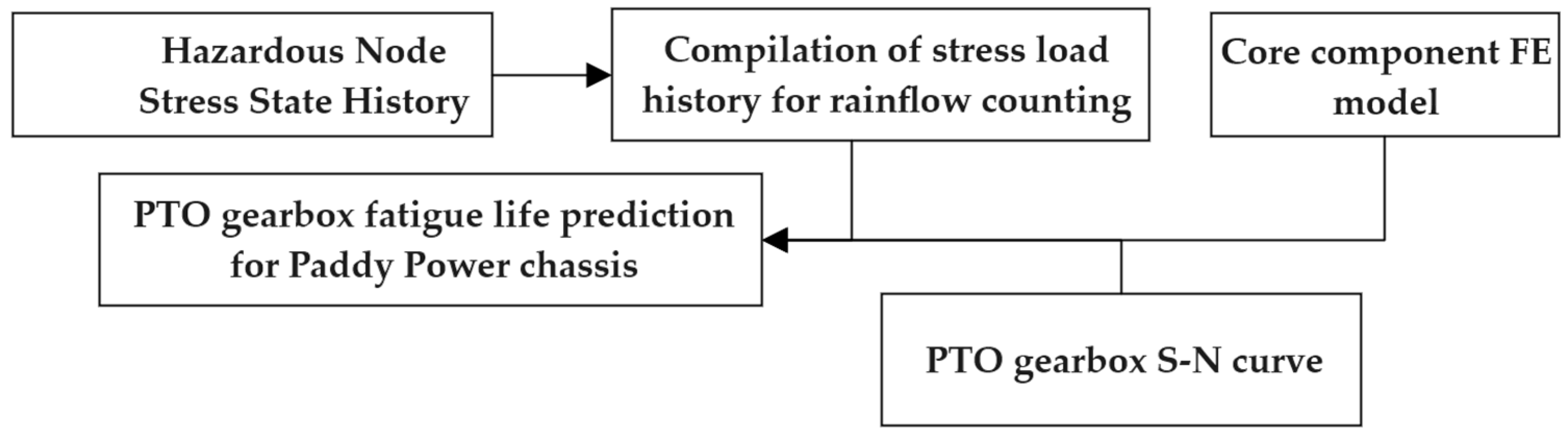

4.2. Methods for Predicting Fatigue Life

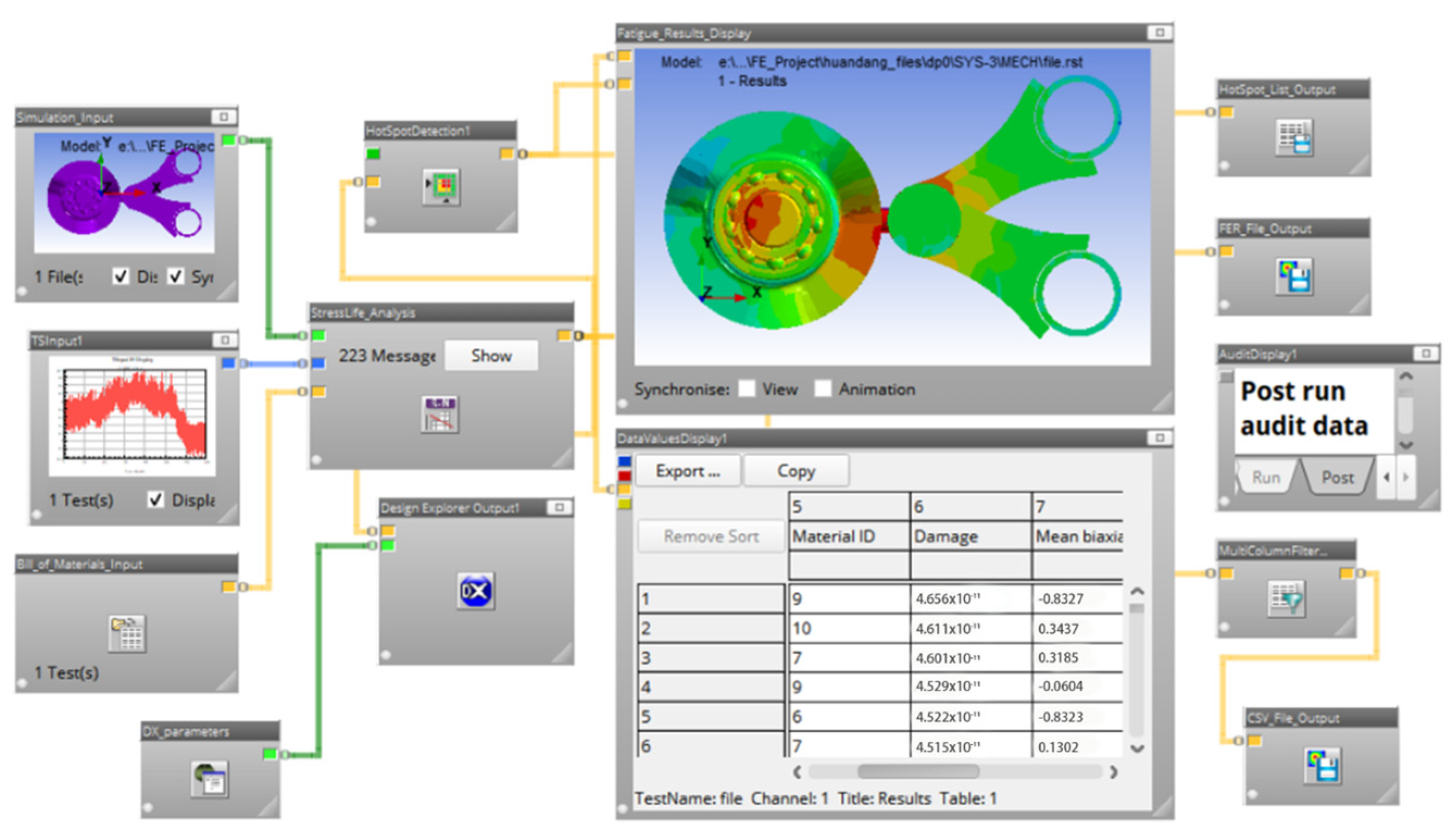

5. PTO Gearbox Fatigue Life Prediction

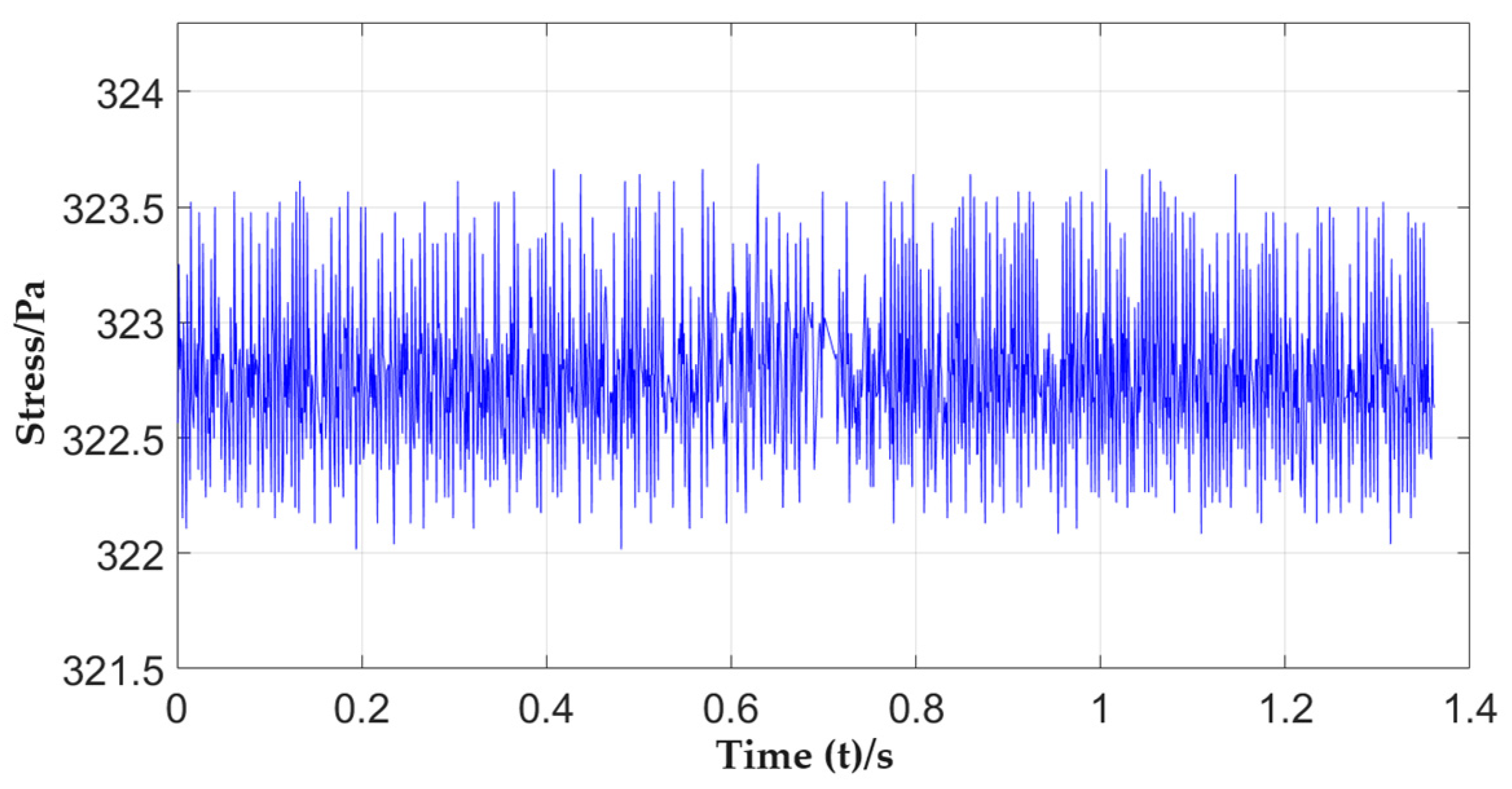

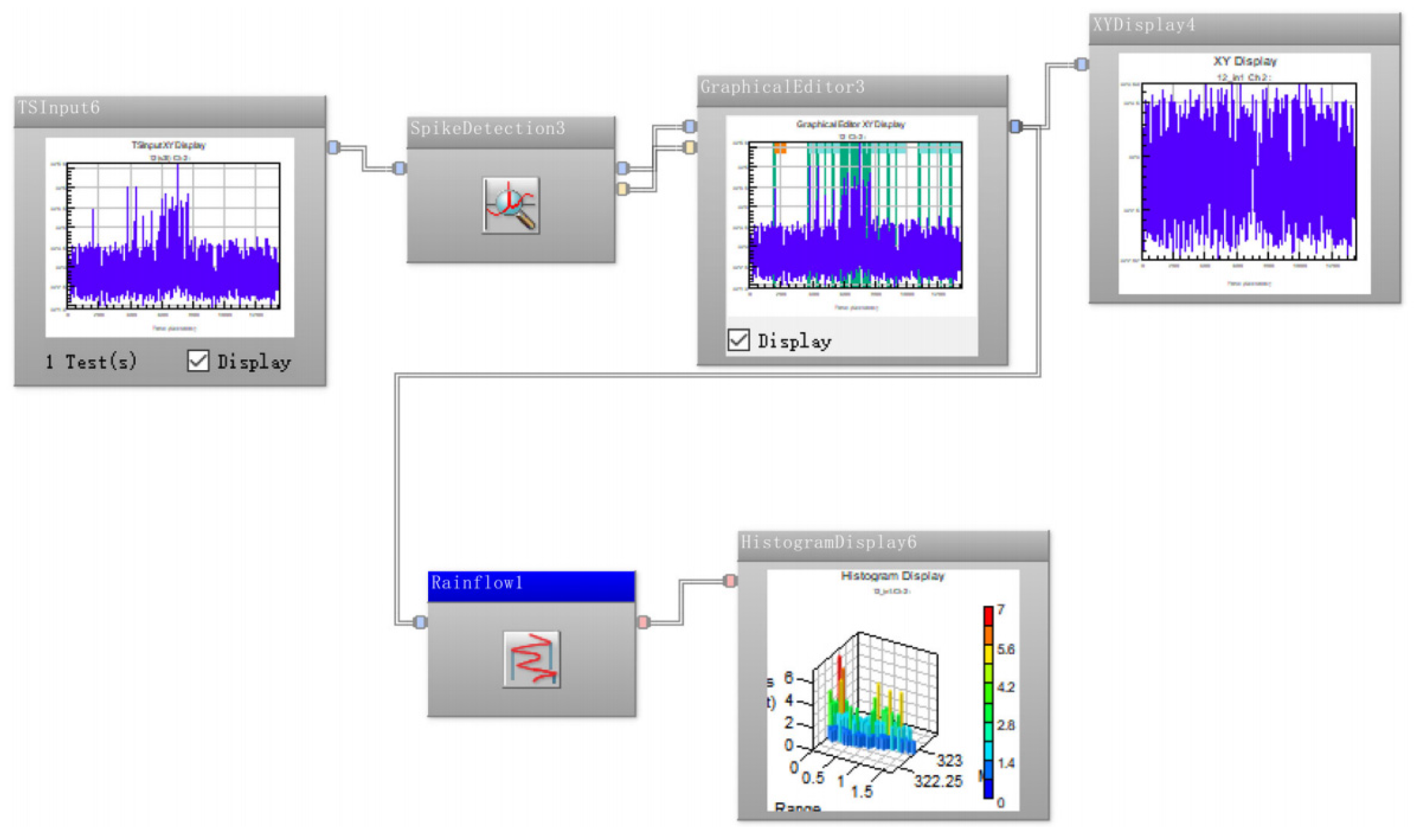

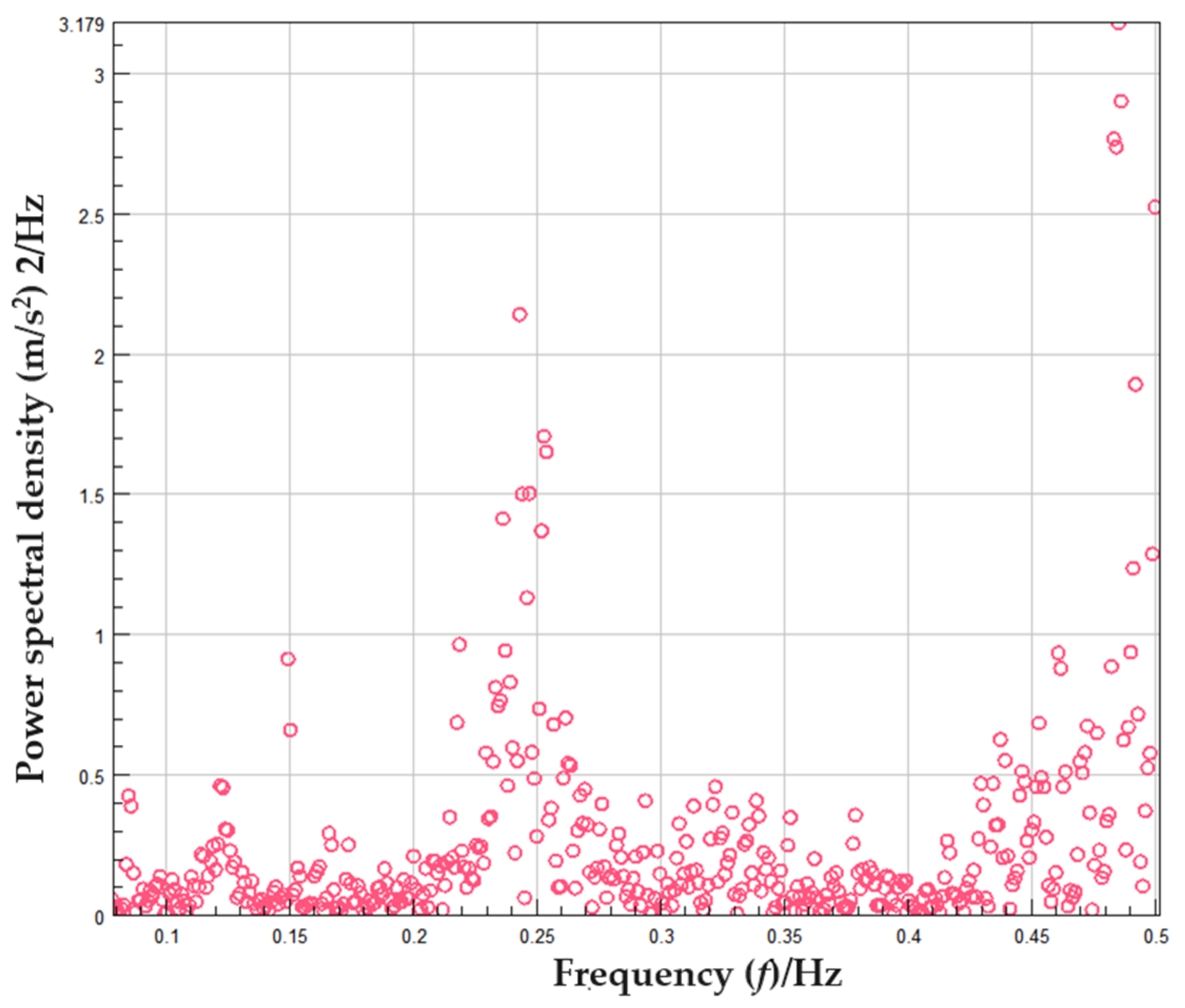

5.1. Spectroscopy of Fatigue Loading

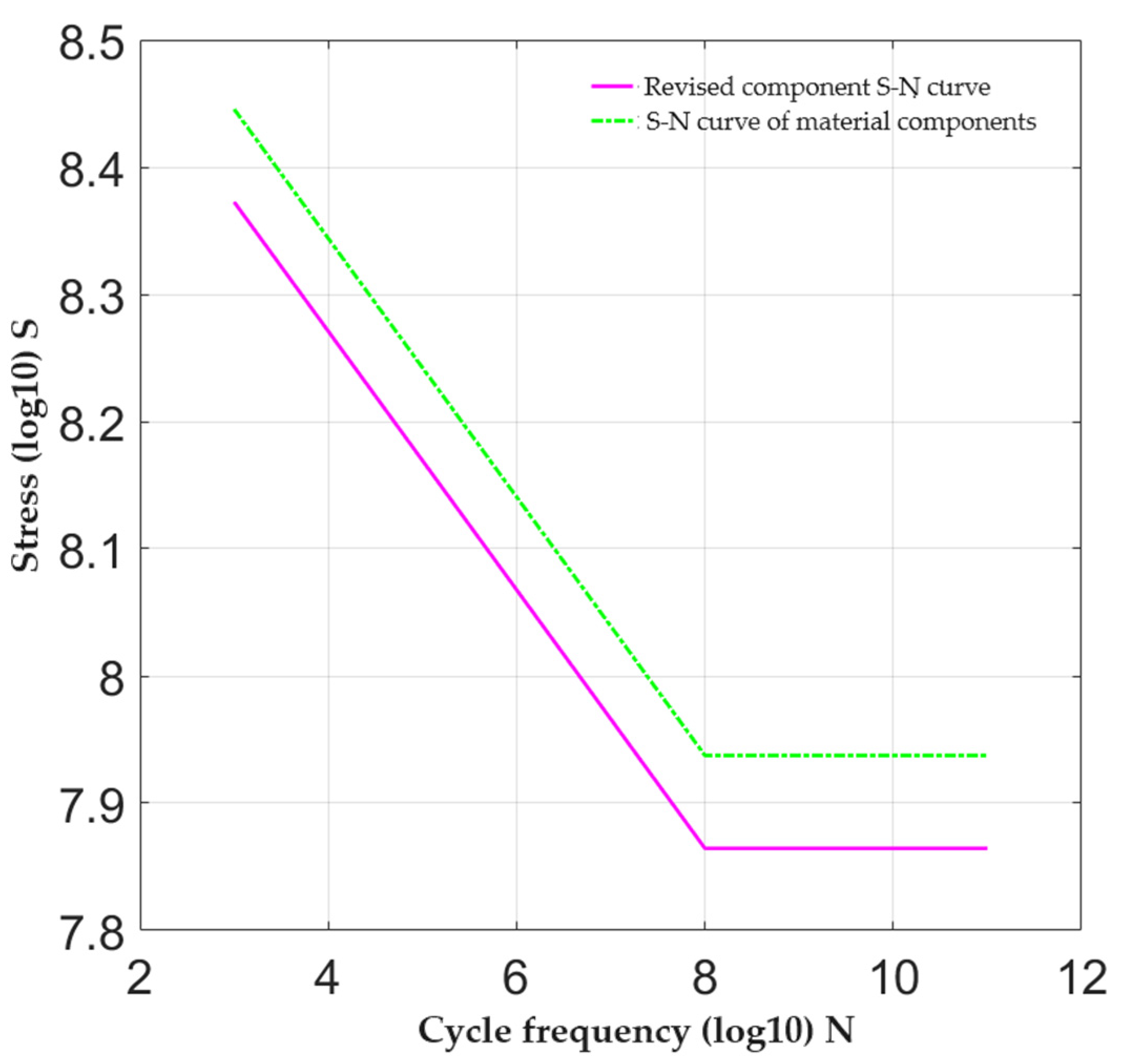

5.2. Component S-N Curve Correction

5.3. Fatigue Life Prediction

6. Results and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, B.; Wu, Z.B.; Mao, E.R. Development and prospect of key technologies on agricultural tractor. Trans. Chin. Soc. Agric. Mach. 2018, 49, 1–17. [Google Scholar]

- Liang, J.T.; Yang, G.T.; Zhu, C.X.; Yang, M.B. Present situation and development trend of PTO for agricultural tractor. Agric. Technol. Equip. 2021, 12, 55–58. [Google Scholar]

- Zhu, T.L. Research and Design of Tractor Power Take-Off Test Bench. Bachelor’s Thesis, Jilin University: Changchun, China, 2017. [Google Scholar]

- Pan, H.L.; Yang, Q.W.; Liu, J.H. On-line running-in filtration and dialysis mode of tractor transmission system. Agric. Eng. 2022, 12, 90–93. [Google Scholar]

- Wang, N.Y.; Yuan, W.; Chen, J.J.; Liu, K.; Pan, H.L. Development of FHC-200 power wagon for tractor. Tract. Farm Transp. 2017, 44, 52–54. [Google Scholar]

- Zheng, J.Q. Finite Element Analysis and Optimum Structural Design of Shell of a High-Power Tractor Transmission. Bachelor’s Thesis, Shandong University of Technology, Zibo, China, 2018. [Google Scholar]

- Pei, B. Finite Element Analysis and Lightweight Optimization Study on Rear Axle Housing of High-Powered Tractor. Bachelor’s Thesis, Shandong University of Technology, Zibo, China, 2018. [Google Scholar]

- Zhang, L.; Liu, S.; Mao, E.; Xie, B.; Li, F. Reliability analysis of agricultural machinery chassis drive axle housing based on ANSYS. Trans. CSAE 2013, 29, 37–44. [Google Scholar]

- Feng, F.Y.; Hou, J.J. Reliability Analysis on Power Take-off of Refrigerating Cooling Vehicle. Mech. Eng. Autom. 2018, 6, 135–136. [Google Scholar]

- Zhang, H.P.; Liu, L.R.; Li, B.; Deng, N.J. Design Method of Power Takeoff in Fire Truck. Spec. Purp. Veh. 2018, 10, 79–81. [Google Scholar]

- Zhang, X.M. Drive like a normal truck new sprinkler extractor developed successfully. Spec. Purp. Veh. 2018, 6, 66–68. [Google Scholar]

- Asonja, A.; Adamovic, Z.; Jevtic, N. Analysis of Reliability of Cardan Shafts Based on Condition Diagnostics of Bearing Assembly in Cardan Joints. Metal. Int. 2013, 18, 216–221. [Google Scholar]

- Wang, Y.W.; Luo, J.W.; Ye, J.; Chen, L.P. EFA based fatigue and its application. Mach. Des. Manuf. 2008, 1, 22–24. [Google Scholar]

- Zhang, L.X. Reliability Analysis and Evaluation Method Research on Combine Harvester Chassis. Ph.D. Thesis, China Agricultural University, Beijing, China, 2014. [Google Scholar]

- Wen, C.K.; Xie, B.; Yang, Z.H.; Dong, N.X.; Song, Z.H. Fatigue analysis of gearbox shell of high horsepower tractor based on power density. Trans. Chin. Soc. Agric. Mach. 2019, 50, 389–396. [Google Scholar]

- Song, Q.C. Study on Measured Load Spectrum for Steering Drive Axle of High-Horsepower Tractor. Ph.D. Thesis, China Agricultural University, Beijing, China, 2019. [Google Scholar]

- Dong, Z.; Wang, X.; Lou, W.; Huang, Y.; Zhong, M.; Fan, H.; Peng, L. Simulation of the Spindle Coupled Multi-Axial Loading Fatigue Test of a Minivan Rear Axle. Strength Mater. 2017, 49, 872–896. [Google Scholar] [CrossRef]

- Feng, W.; Pang, Y.; Li, P.; Cui, J.; Zhang, X.; Zhan, X. Lightweight design for rack of small harvester based on ISIGHT. Southwest China J. Agric. Sci. 2019, 32, 174–178. [Google Scholar]

- Li, X.; Zhang, D.; Wang, W.; Tao, C.; Tang, M. Performance parameter optimization and experiment of forced-vibration subsoiler. Trans. CSAE 2015, 31, 17–24. [Google Scholar]

- Zhang, Z.Y.; Xie, S.S.; Wang, K.; Zhang, Y.; Bing, T.; Sun, S. Fatigue Study of Tractor Frame Based on Complex Boundary. Automot. Eng. 2023, 25, 873–879. [Google Scholar]

- Xiang, C.L.; He, W.; Liu, H. Transient Dynamic Analysis of Tracked Vehicle Transmission during Gear Shift Process. Trans. Chin. Soc. Agric. Mach. 2016, 47, 288–293. [Google Scholar]

- Liu, H.Y.; Hu, Y.; Huang, X.H.; Yuan, T.P.; Wang, S.M.; Chen, M.Q.; Guo, G.X. Failure and fatigue analysis of floating structure of offshore cage. Trans. Chin. Soc. Agric. Eng. 2020, 36, 46–54. [Google Scholar]

- Zhang, J.; Adamu, A.; Su, X.C.; Guo, Z.H.; Gao, G.J. Effect of simplifying bogie regions on aerodynamic performance of high-speed train. J. Cent. South Univ. 2022, 29, 1717–1734. [Google Scholar] [CrossRef]

- Wang, M.Z. Research on Life Analysis Method for Structure Vibration Fatigue; Nanjing University of Aeronautics and Astronautics: Nanjing, China, 2009. [Google Scholar]

- Wang, L.; Zhang, X.; Leng, J.; Zhao, G.; Jiao, Z.; Qin, Y. Fatigue Life Analysis of Grain Combine Harvester Cleaning Device. Trans. Chin. Soc. Agric. Mach. 2018, 24, 282–287. [Google Scholar]

- Zheng, S. Failure Analysis and Fatigue Life Prediction on the off-Highway Wide-Body Mine Dump Truck Frame Structure. Ph.D. Thesis, Jilin University, Changchun, China, 2015. [Google Scholar]

- Song, Q.C.; Song, Z.H.; Du, Y.F. Load spectrum and fatigue life analysis of frame based on non-parametric rainflow extrapolation method. J. China Agric. Univ. 2019, 24, 154–160. [Google Scholar]

- Wang, Y.; Wang, L.; Wen, C.; Lv, D.; Wang, S. Extrapolation of tractor PTO torque load spectrum based on automated threshold selection with FDR. Trans. Chin. Soc. Agric. Mach. 2021, 52, 364–372. [Google Scholar]

- Wang, L.; Zong, J.H.; Wang, Y.; Fu, L.; Mao, X.; Wang, S. Compilation and bench test of traction force load spectrum of tractor three-point hitch based on optimal distribution fitting. Trans. Chin. Soc. Agric. Eng. 2022, 38, 41–49. [Google Scholar]

- Yang, Z.H.; Song, Z.H.; Yin, Y.Y.; Zhao, X.Y.; Liu, J.H.; Han, J.G. Time domain extrapolation method for load of drive shaft of high-power tractor based on POT mode. Trans. Chin. Soc. Agric. Eng. 2019, 35, 40–47. [Google Scholar]

- Feng, Z.H.; Ma, Q.; An, Z.; Ma, H.; Bai, X. New fatigue life prediction model for composite materials considering load interaction effects. Int. J. Appl. Mech. 2023, 15, 235007609. [Google Scholar] [CrossRef]

- Xi, S.J. Study on Virtual Fatigue Test Method of Electric Vehicle Reducer Based on Actual Load Spectrum. Bachelor’s Thesis, Chongqing University of Technology, Chongqing, China, 2021. [Google Scholar]

- Liu, H.N. Dynamic Performance Simulation and Fatigue Life Prediction of Eccentric Roll Crusher. Bachelor’s Thesis, Jilin University, Changchun, China, 2023. [Google Scholar]

| Experimental Materials | Experimental Parameters | Experimental Values |

|---|---|---|

| Aluminum alloy 6061 | Poisson’s ratio | 0.3 |

| Young’s modulus (Pa) | ||

| Density (kgm−3) | 7850 | |

| Ultimate tensile strength (Pa) |

| Working Condition | PTO Gearbox Shift Process | Condition Setting | |

|---|---|---|---|

| Restrictive Condition | Loading Conditions | ||

| Gearbox body | 1-2-3-4-5-6 | Box bolt hole mounting bracket ; Gearshift spindle ; Input shaft ; Output shaft . | Fork 1 counterforce 50 N, fork 2 counterforce 50 N; Shift rotary shaft torque 2.5, speed 20 r/min; Input shaft motor speed 700 r/min. |

| Test Point | Maximum Nominal Stress (Pa) | Minimum Nominal Stress (Pa) | Equivalent Mean Stress (Pa) | Standard Deviation (Pa) | Variance (Pa) |

|---|---|---|---|---|---|

| Patch 1 | 325.63 | 321.95 | 322.81 | 0.436 | 0.190 |

| Patch 2 | 160.15 | 159.24 | 159.72 | 0.166 | 0.028 |

| Patch 3 | 307.96 | 301.45 | 303.85 | 1.198 | 1.434 |

| Patch 4 | 81.64 | 77.11 | 78.37 | 0.531 | 0.282 |

| Patch 5 | 75.37 | 71.44 | 72.62 | 0.489 | 0.239 |

| Patch 6 | 172.43 | 165.82 | 170.12 | 0.865 | 0.748 |

| Object of Analysis | Experience and Knowledge Fatigue Life | Fatigue Life Prediction by Nominal Stress Method Modified by Stress Adjustment Factor | Nominal Stress Method | Fatigue Life Prediction Using Conventional Stress Field Strength Method |

|---|---|---|---|---|

| PTO housing | 20,000 h | 31,699 h | 41,053 h | 39,151 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, J.; Wang, Z.; Gao, B.; Yu, D.; Ma, Y.; Zhong, W.; Zeng, Z.; Guo, Z.; Wang, J. Fatigue Analysis of PTO Gearboxes in Paddy Power Chassis Using Measured Loads. Agriculture 2024, 14, 1436. https://doi.org/10.3390/agriculture14091436

He J, Wang Z, Gao B, Yu D, Ma Y, Zhong W, Zeng Z, Guo Z, Wang J. Fatigue Analysis of PTO Gearboxes in Paddy Power Chassis Using Measured Loads. Agriculture. 2024; 14(9):1436. https://doi.org/10.3390/agriculture14091436

Chicago/Turabian StyleHe, Jianfei, Zaiman Wang, Bo Gao, Dongyang Yu, Yifan Ma, Wenneng Zhong, Zhihao Zeng, Ziyou Guo, and Jun Wang. 2024. "Fatigue Analysis of PTO Gearboxes in Paddy Power Chassis Using Measured Loads" Agriculture 14, no. 9: 1436. https://doi.org/10.3390/agriculture14091436

APA StyleHe, J., Wang, Z., Gao, B., Yu, D., Ma, Y., Zhong, W., Zeng, Z., Guo, Z., & Wang, J. (2024). Fatigue Analysis of PTO Gearboxes in Paddy Power Chassis Using Measured Loads. Agriculture, 14(9), 1436. https://doi.org/10.3390/agriculture14091436