Design and Experiment of Double-Nest Eye-Type Hole-Wheel Dense-Planting Wheat Dibbler

Abstract

1. Research Highlights

- We designed the overall structure and key components of a double-hole-type hole-wheel close-planting wheat dibbler.

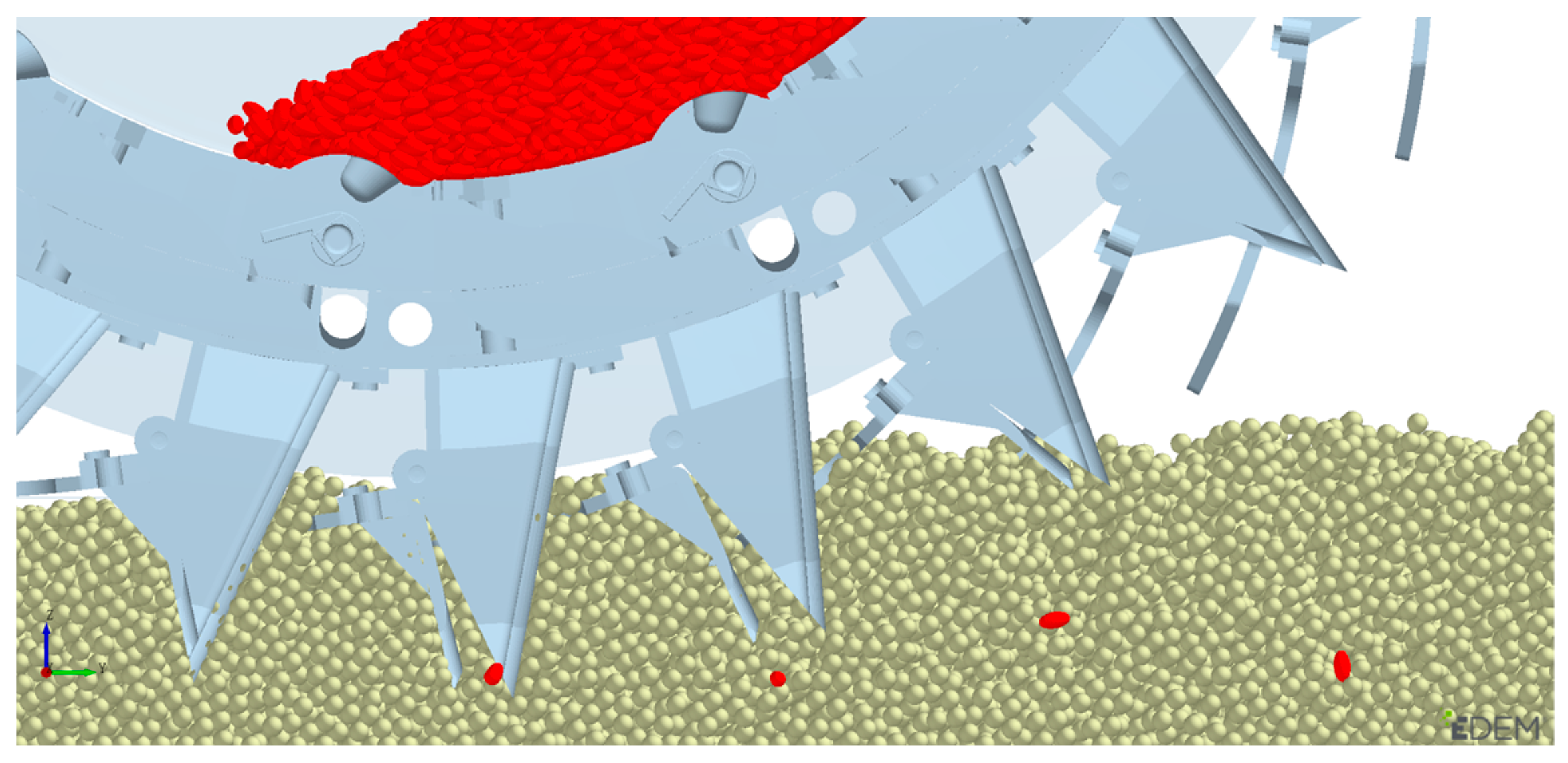

- The filling condition of the double-socket seeder was verified byEDEM 2020 discrete element simulation.

- Through EDEM 2020 and RecurDyn 2023 joint simulation, the working performance of the dibbler was verified.

- The results of the bench test showed that the designed dense-planting wheat dibbler meets the standard of a high yield and dense planting of “well”-type wheat.

2. Introduction

3. Overall Structure and Working Principle

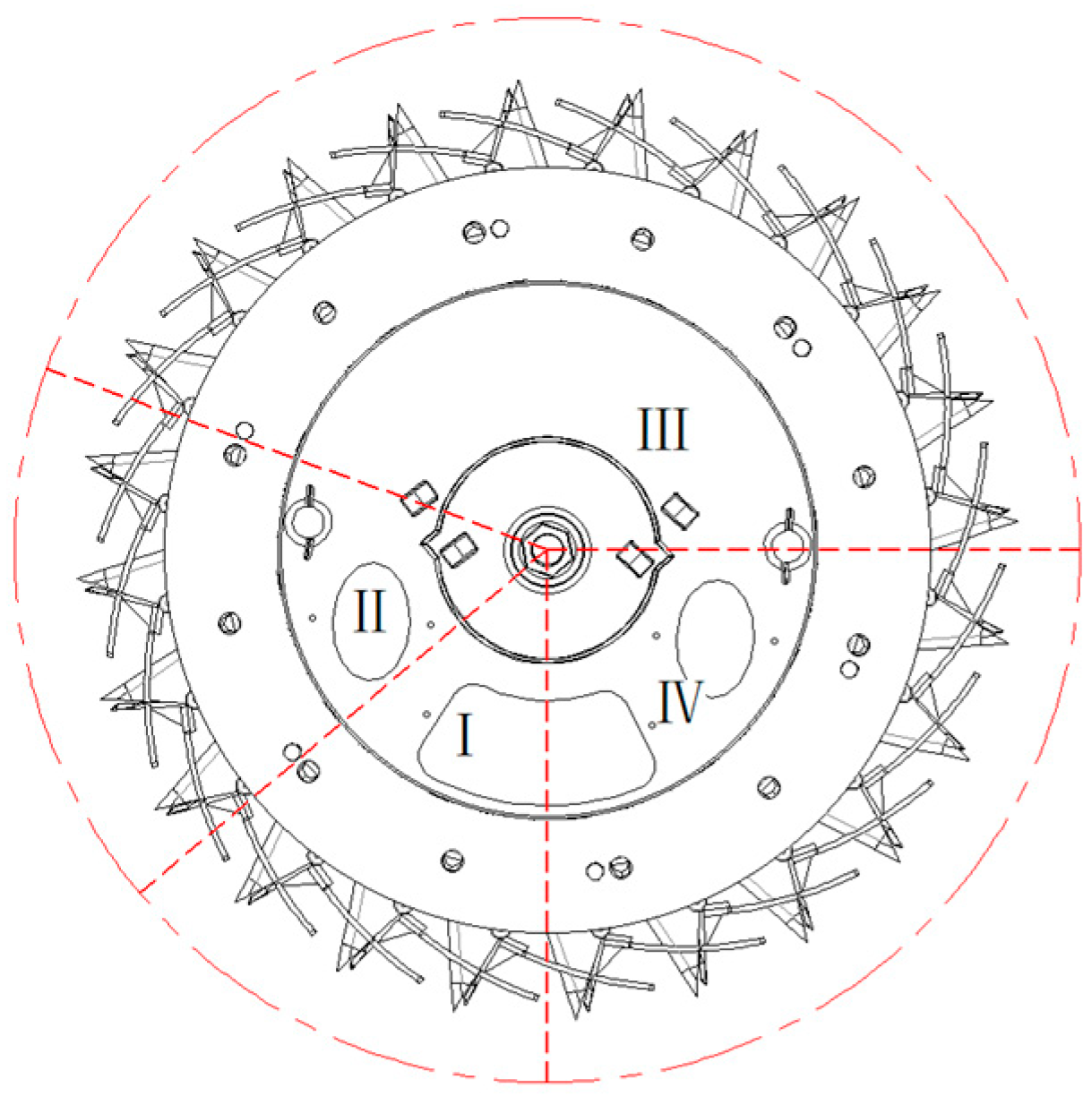

3.1. Overall Structure of Hole Seeder

3.2. Working Principle

4. Key Component Design

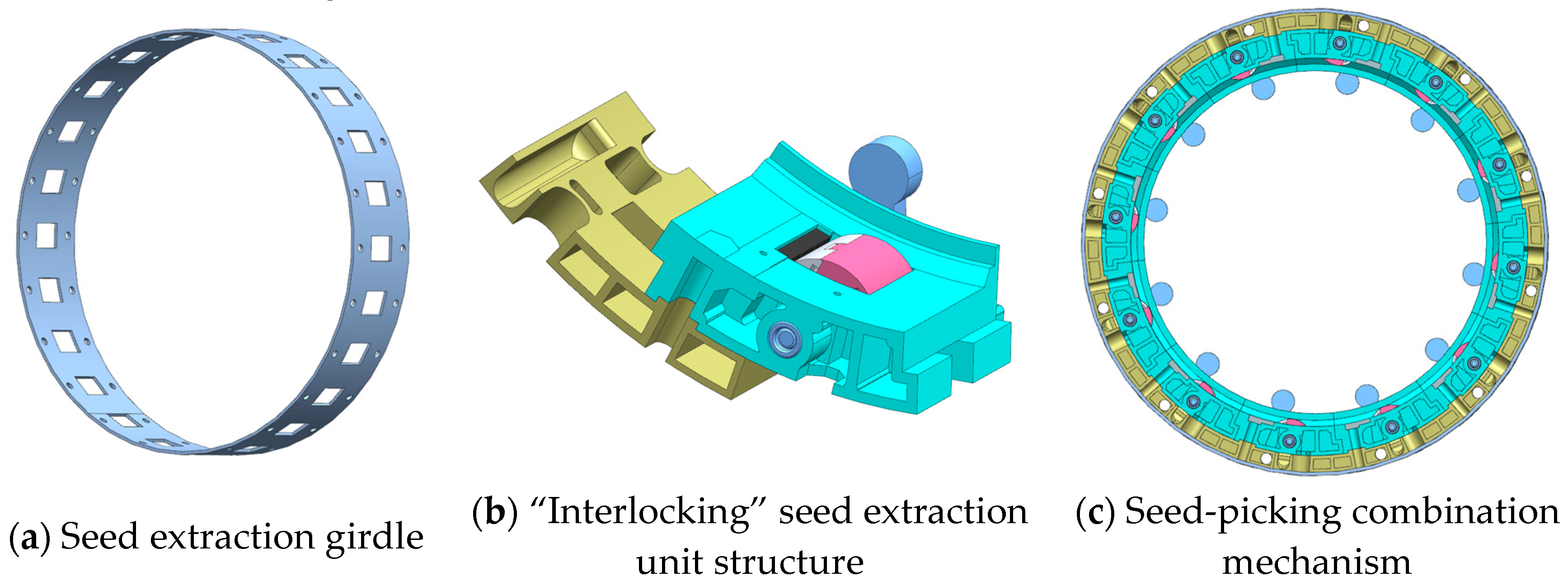

4.1. Structural Design of Seed Collection Mechanism

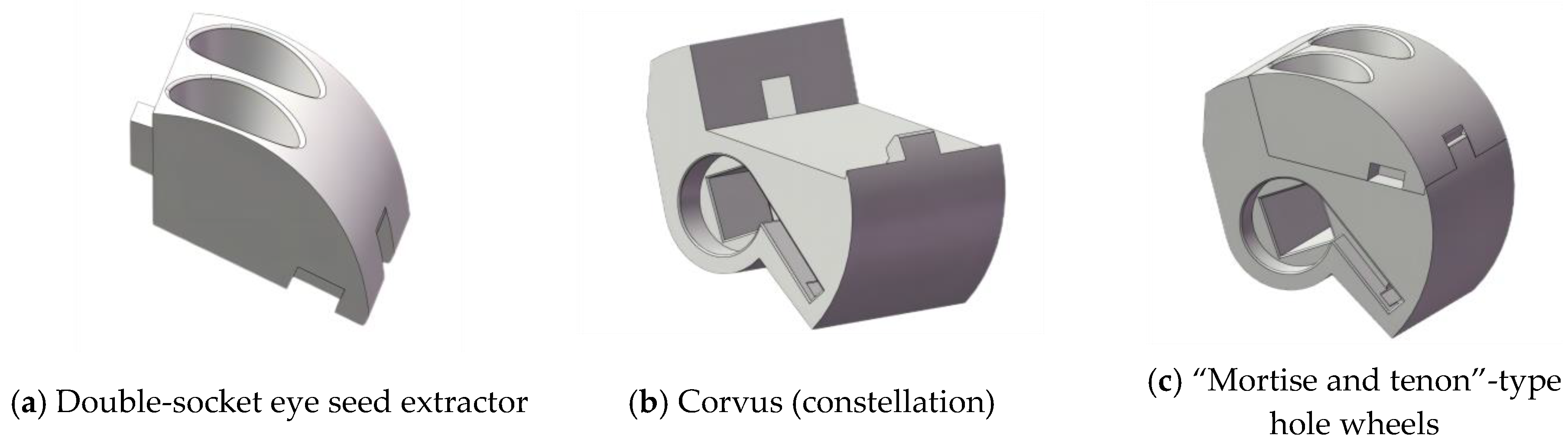

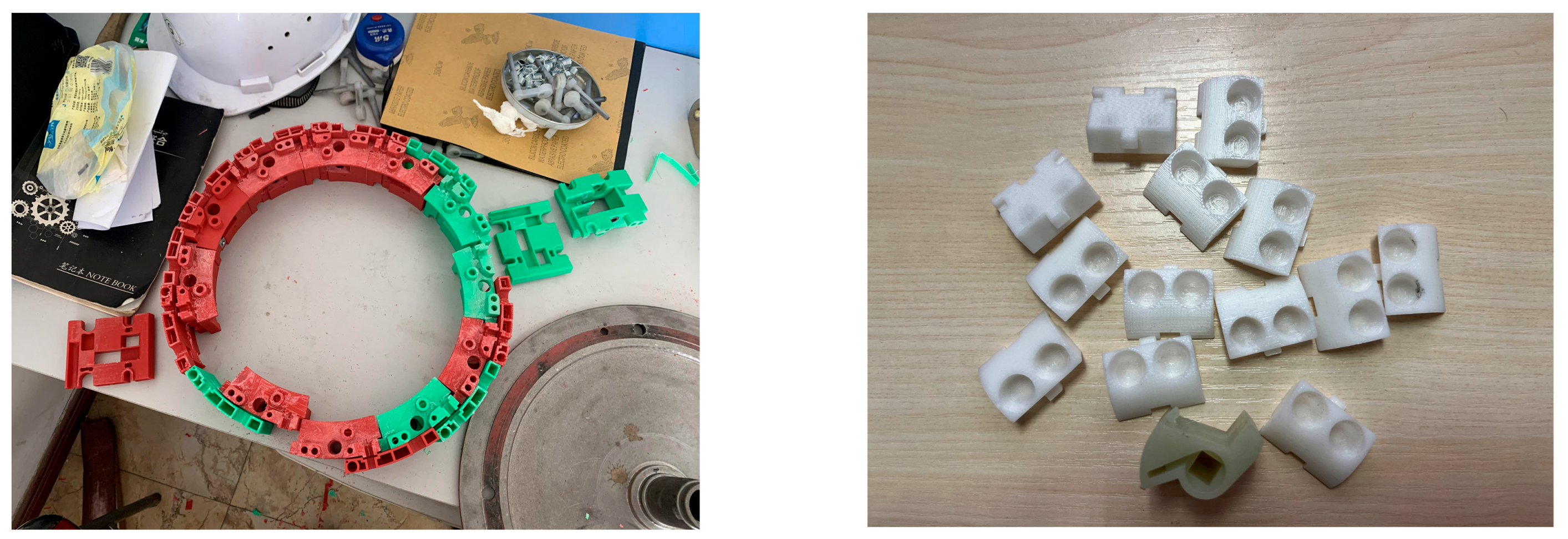

4.2. Structural Design of “Mosaic Structure” Seed Collection Unit

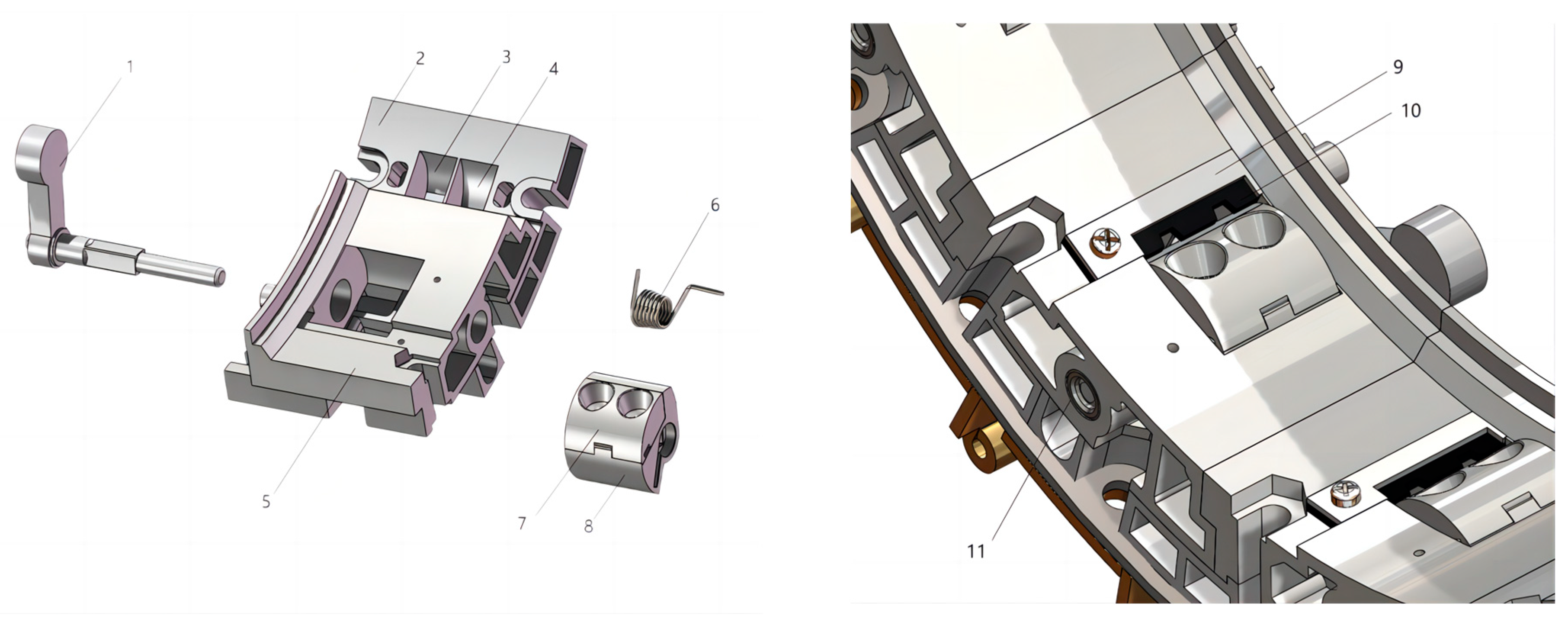

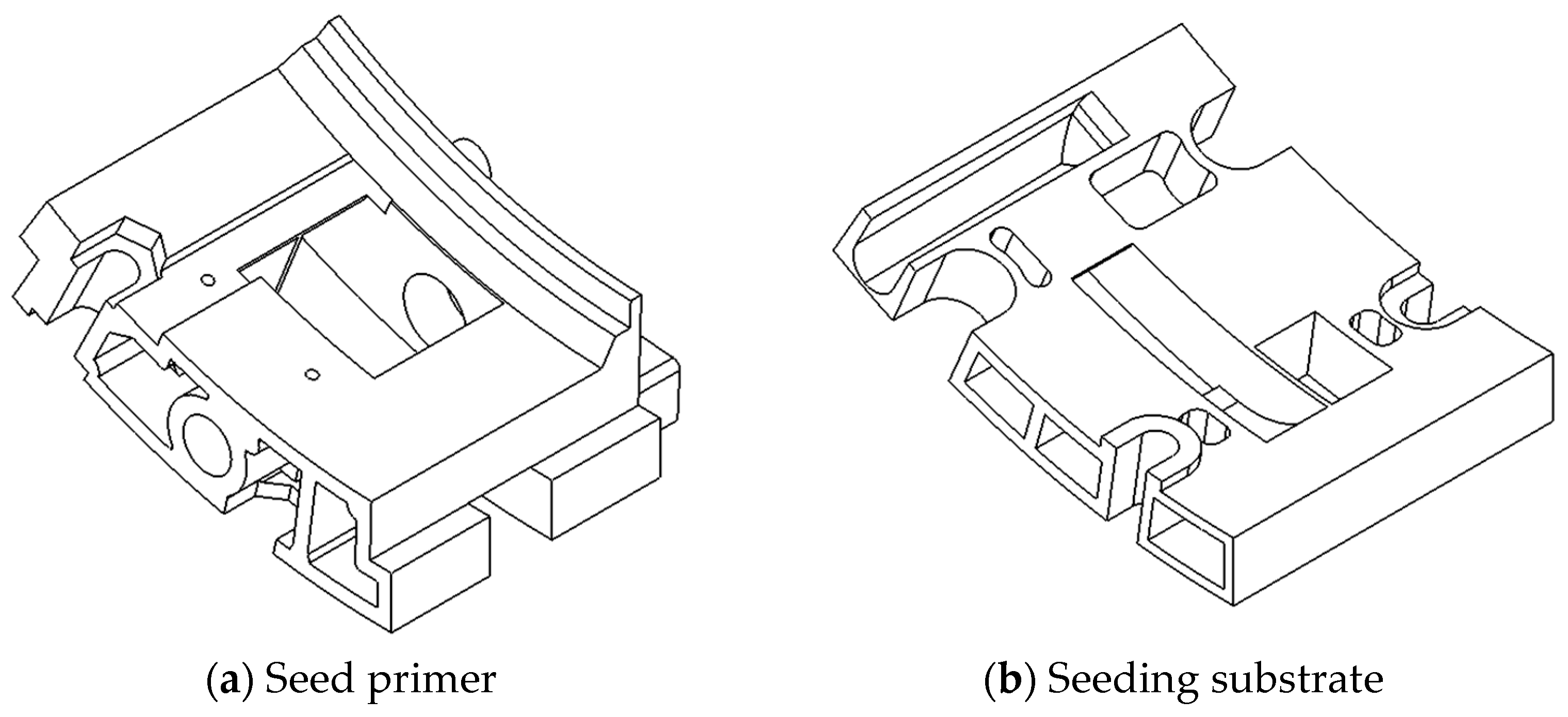

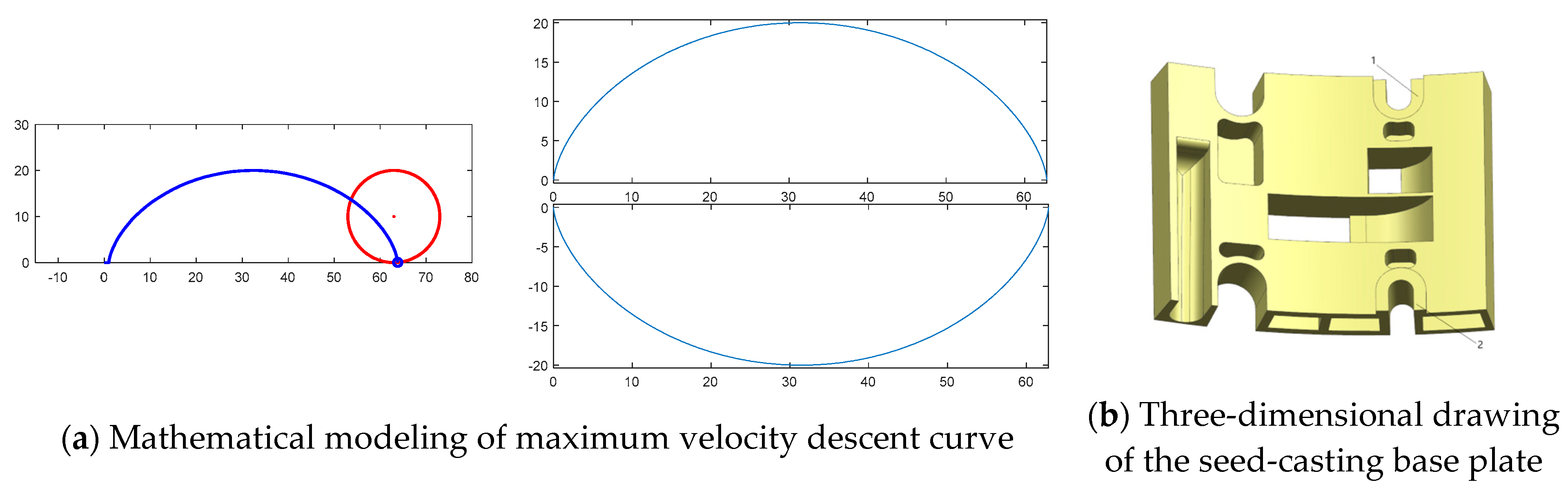

4.2.1. Seed Base Block Structure Design

4.2.2. Structural Design of Seeding Floor Track

4.3. Hole-Wheel-Type Structural Design

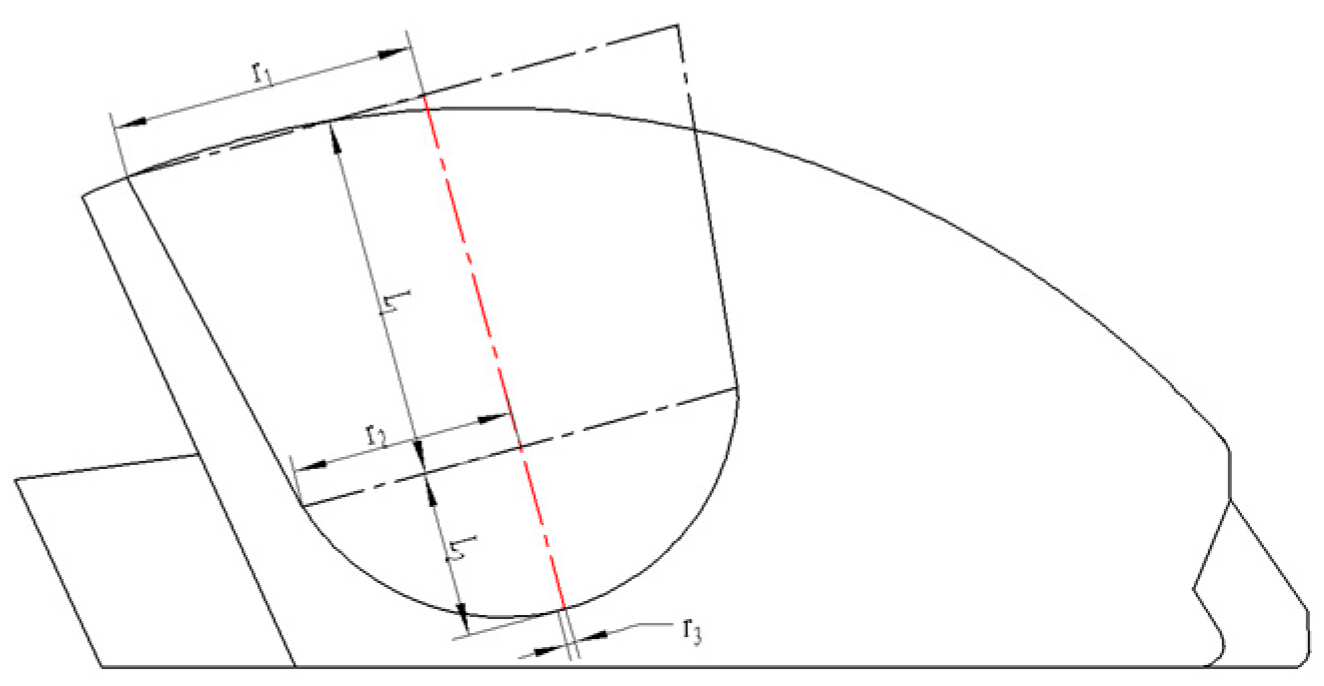

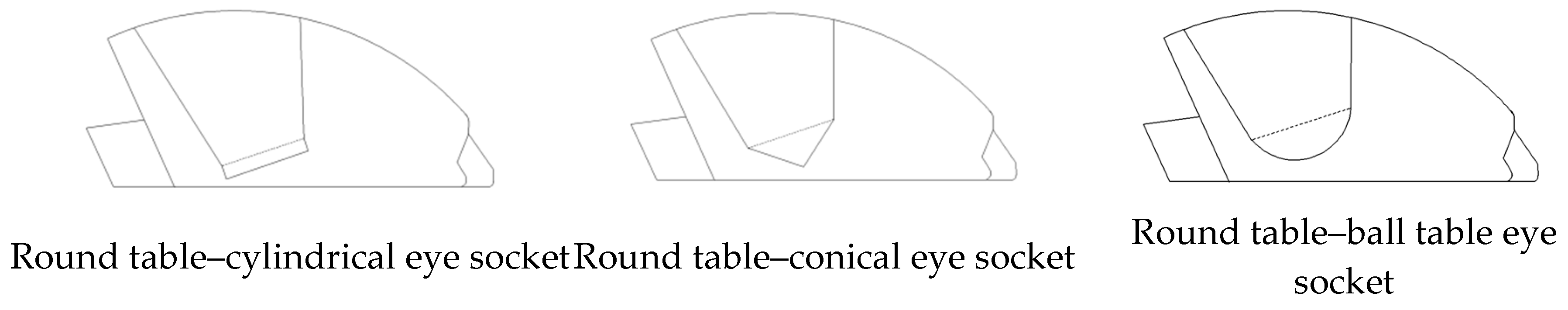

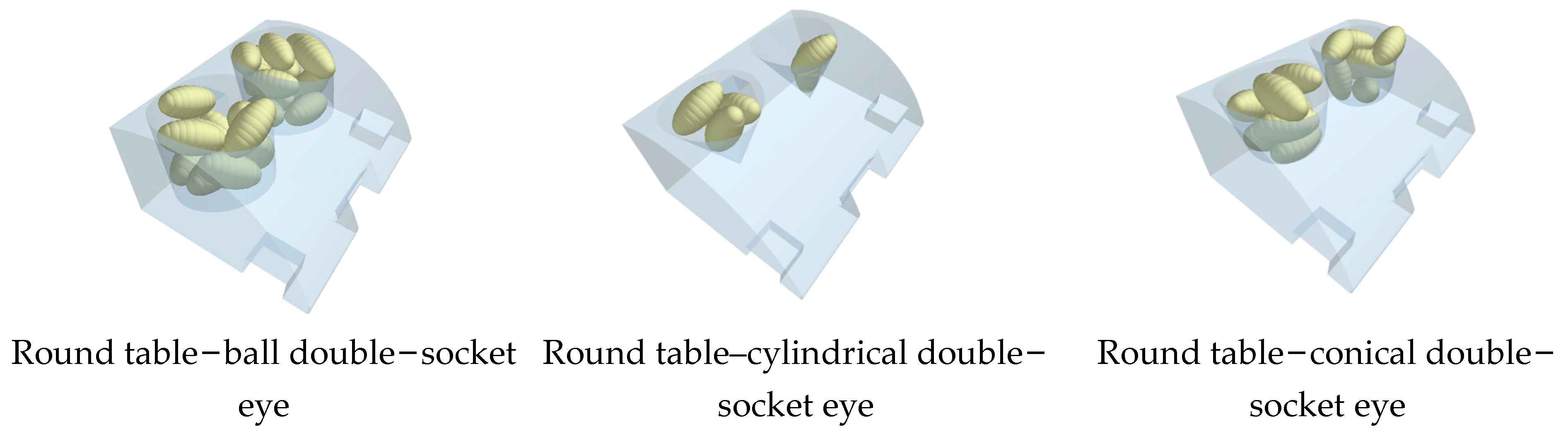

4.3.1. Dimensional Design of Double Socket Seed Taker

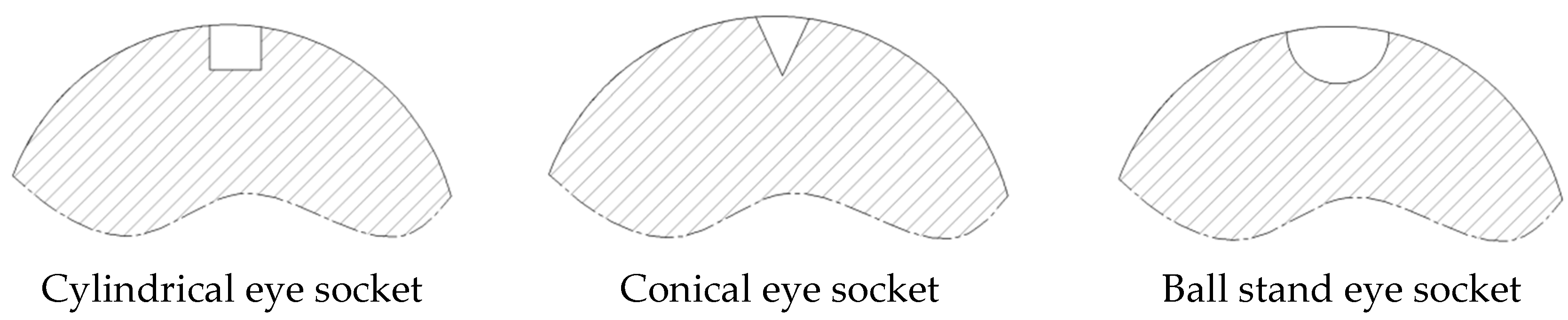

4.3.2. Selection of Double-Socket Shape

4.4. Structural Design of Cavitation Device

4.4.1. Quantity Design of Cavitation Devices

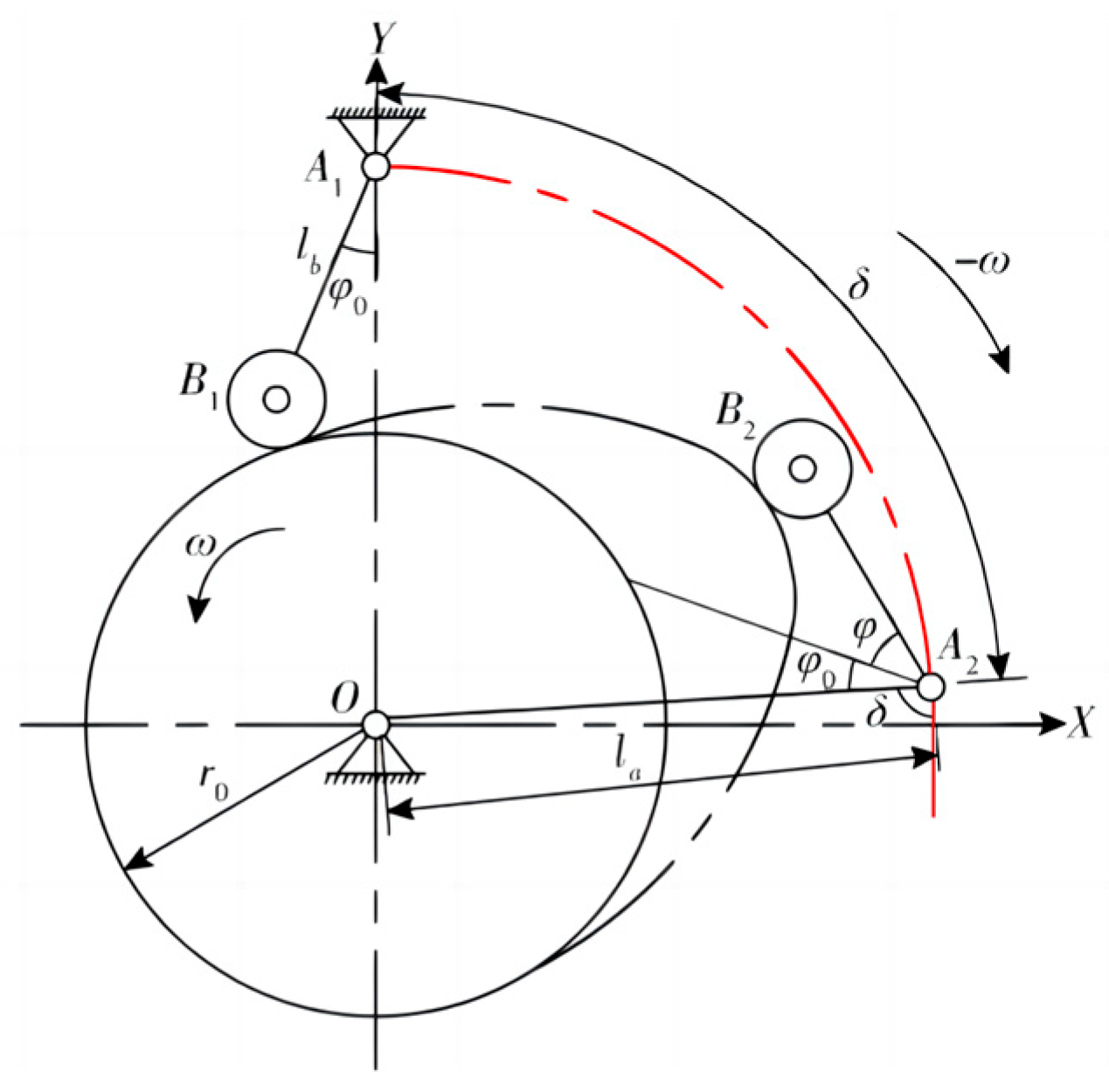

4.4.2. Calculation of Coincidence Degree of Cavitation Device

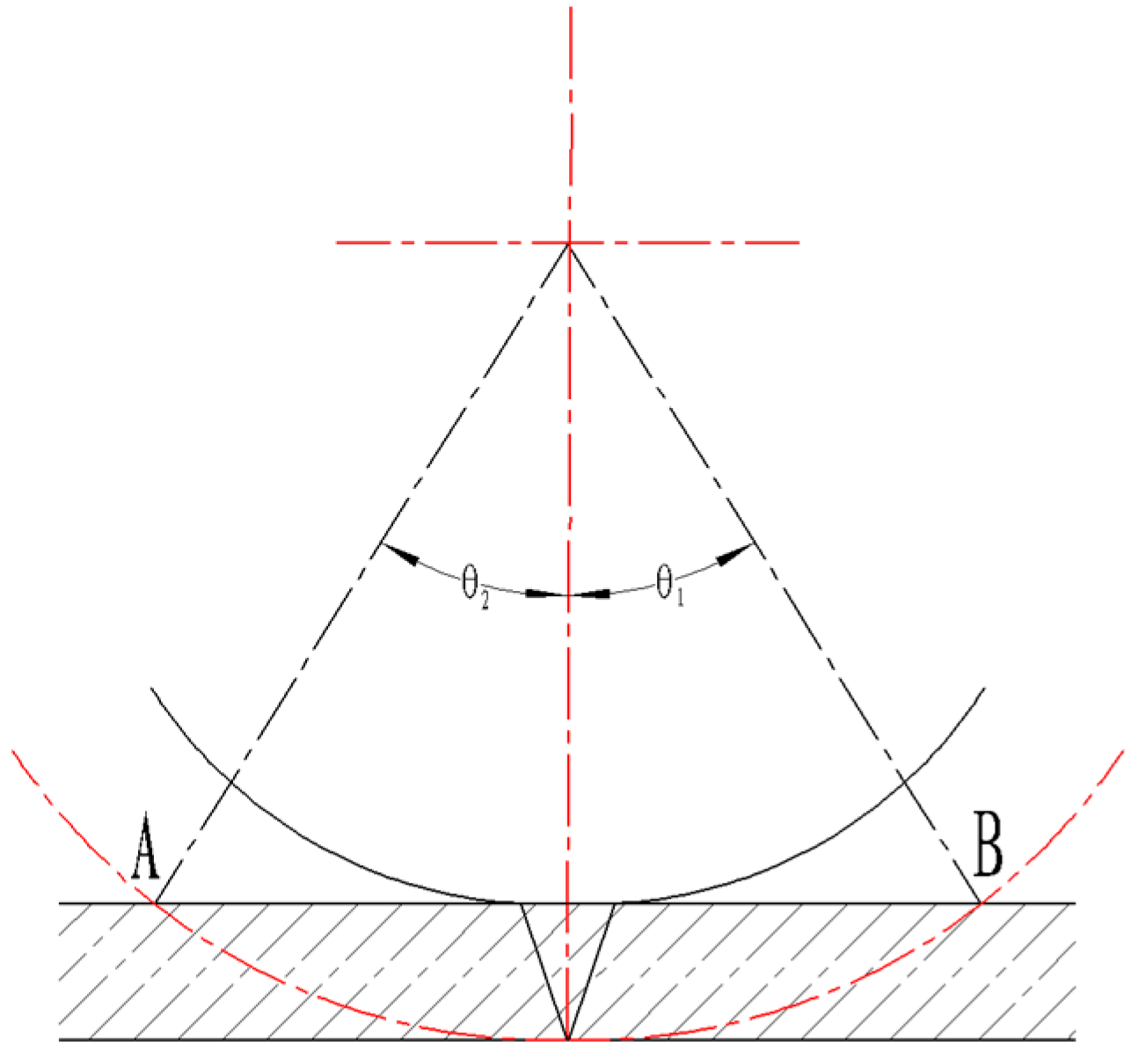

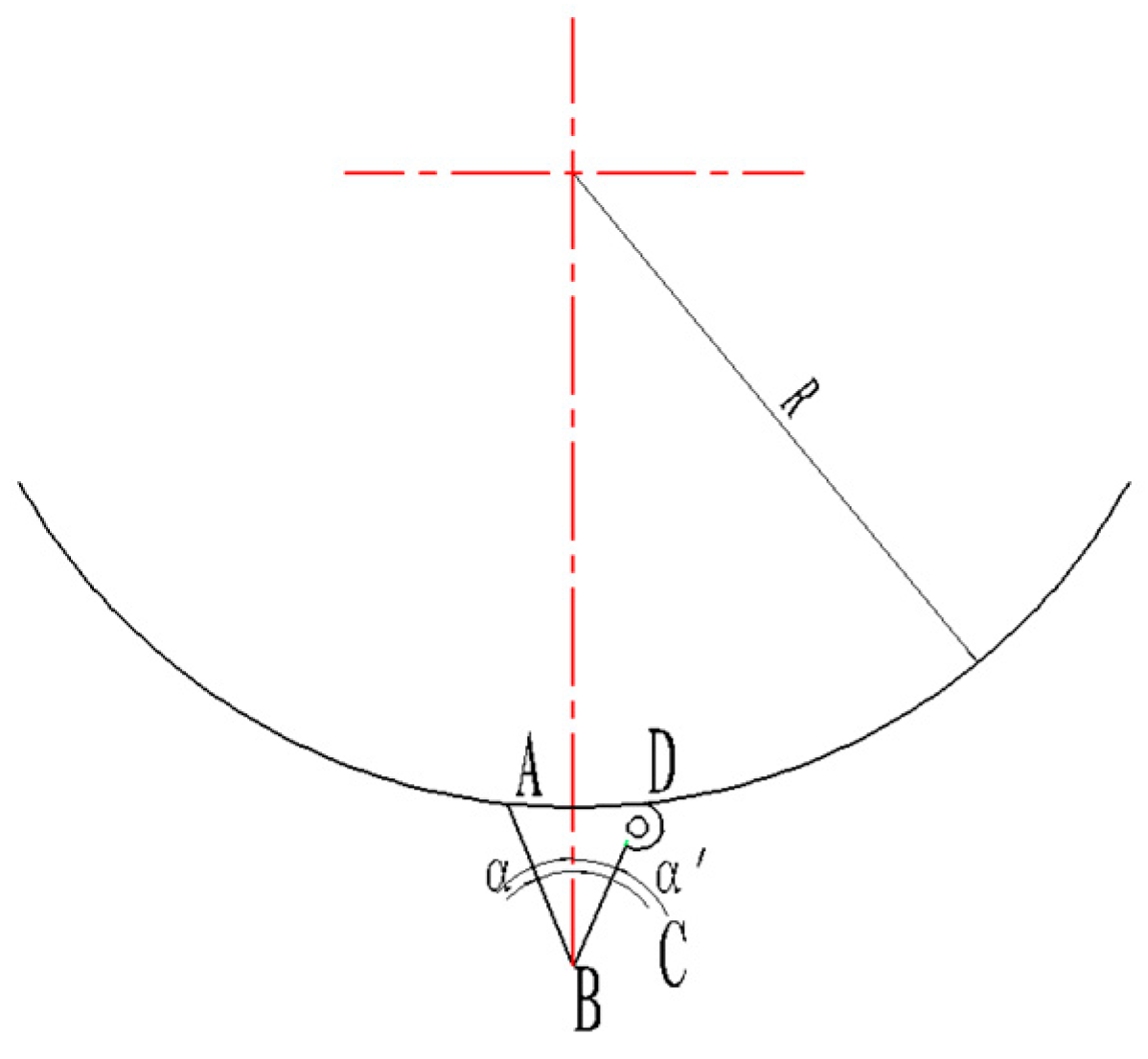

4.4.3. Pressure Angle of Cavitation Device

4.4.4. Simulation Analysis of Burrowing Performance of Burrowing Device in Soil

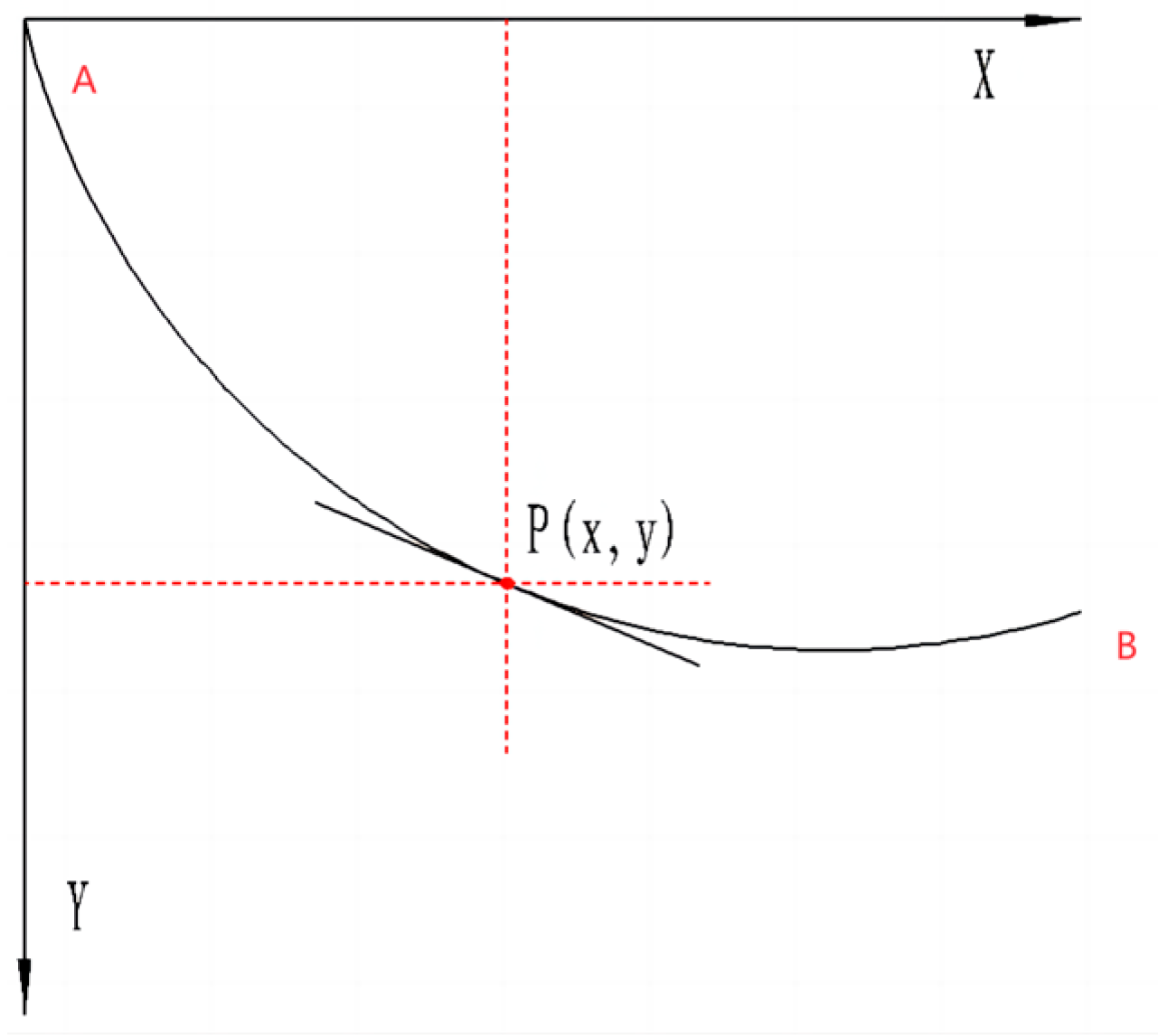

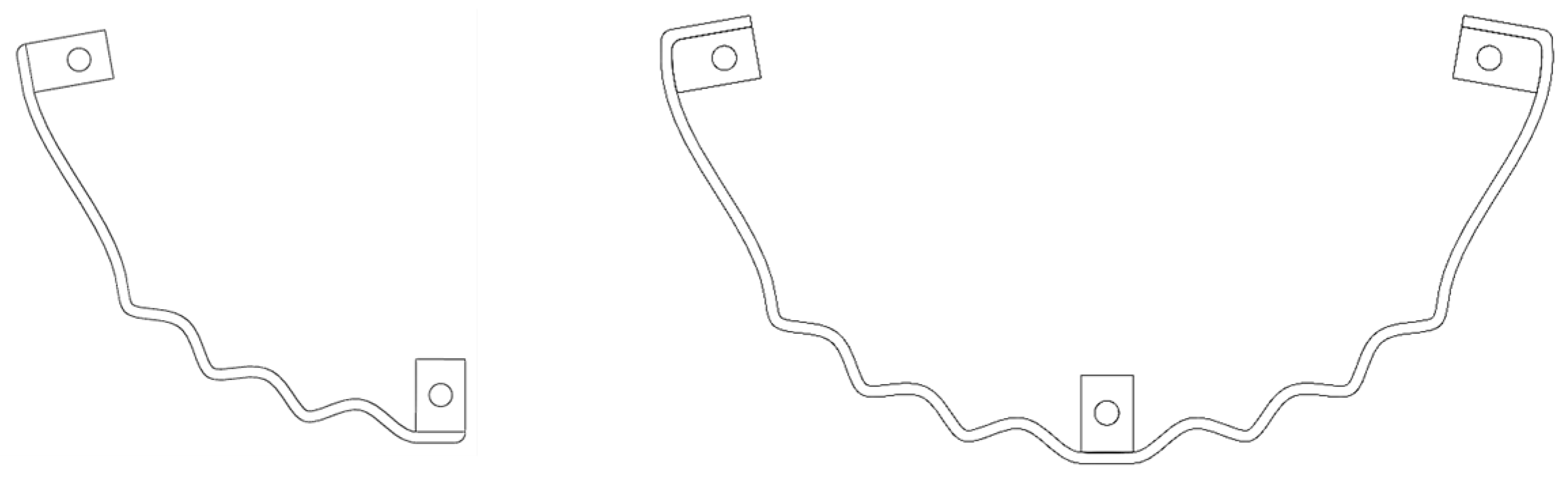

4.5. Design of Wave Guide Rail

5. Experimental Verification

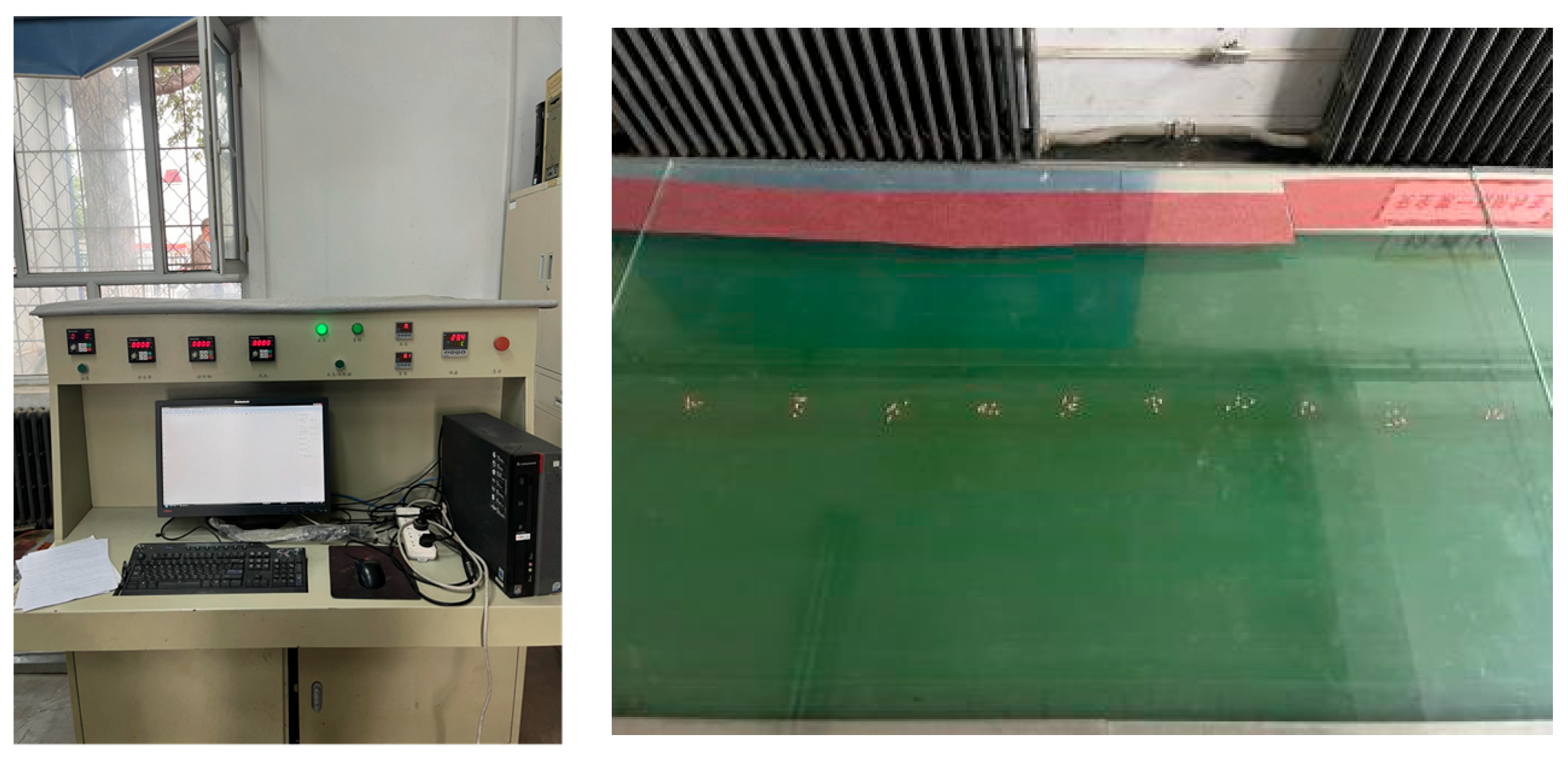

5.1. Test Equipment

5.2. Test Indicators

5.3. Central Composite Design

5.4. Test Results and Analysis

5.5. Parameter Optimization and Bench Verification Test

6. Conclusions

- (1)

- A double-socket hole-wheel-type densely planted wheat hole seeder was designed. Its working principle was analyzed, the overall structure and key components of the hole seeder were designed, and the mathematical relationship between the relative positions of the double-socket seed taker and the sockets was constructed. This model was used to determine the parameters and range that affect the seeding performance of densely planted wheat hole seeders. The central composite design was employed to establish a regression equation between the test indicators and test factors. In addition, the influence rules and interactive relationships of each test factor on test indicators were obtained.

- (2)

- Design-Expert 13 software was utilized to analyze the test results and perform multi-objective optimization on the regression equation. It can be concluded that the optimal parameter combination is that the rotation speed of the hole seeder was 40 r/min and the number of teeth of the wave guide was 4 teeth. At this juncture, the seeding pass rate was 87.76%, the replay rate was 4.15%, and the missed broadcast rate was 8.09%. The results of the bench verification test demonstrated that the seeding pass rate was 91.35%, the re-seeding rate was 3.74%, and the missed seeding rate was 4.91%. The number of seedlings per acre is expected to range from 400,000 to 500,000. These findings indicate that the seeding process meets the criteria for the high yield and dense planting of wheat in a “well” shape.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, M.; Peng, X.; Li, M.; Song, Y.; He, X.; Zhu, Y. Study on evaluation method of wheat grain uniformity. J. Nucl. Agric. 2023, 37, 290–301. [Google Scholar] [CrossRef]

- National Bureau of Statistics. The National Bureau of Statistics Issued an Announcement on Summer Grain Production Data for 2022; Food Processing (05); National Bureau of Statistics: Beijing, China, 2022; p. 95. [Google Scholar]

- National Bureau of Statistics. Announcement of the National Bureau of Statistics on summer grain production data for 2023. China Information, 18 July 2023. [CrossRef]

- Xinjiang has more than 23 million acres of spring-sown food crops. Fujian Rice Wheat Sci. Technol. 2023, 10. Available online: https://kns.cnki.net/kcms2/article/abstract?v=xpM8-w1VMS9MVA_-0uJkogMpDysEPmy2ZvuFlIdnS2AN6Ji_paNt-j-BEyvlFWbU9PjkSRpxWVK-wE5ClP0S4WltDG47TrZYEm-KAppHlFjFOCG4O4DLMKDM7Rz4e0ynqnqMWGuFQaMGBavFd0Psw3CJHZAga1XEy1fjMKGAJlhKKjzg1PQ3DtrJG6FCLLl7&uniplatform=NZKPT&language=CHS (accessed on 1 June 2018).

- Chang, X.; Wang, D.; Tao, Z.; Wang, Y.; Zhao, G.G. (Eds.) Three-dimensional uniform planting technology of wheat. In Abstracts of the 2017 Annual Academic Conference of the Chinese Crop Society; Institute of Crop Sciences, Chinese Academy of Agricultural Sciences/Key Laboratory of Crop Physiology and Ecology, Ministry of Agriculture: Beijing, China, 2017; p. 205. [Google Scholar]

- Li, H. Seeding technology and development exploration of wheat seeding machinery. Agric. Mach. Use Maint. 2019, 82. [Google Scholar] [CrossRef]

- Yang, L.; Shi, S.; Cui, T.; Zhang, D.; Gao, N. Pneumatic suction and mechanical assisted maize precision seed metering device. J. Agric. Mach. 2012, 43, 48–53. [Google Scholar] [CrossRef]

- Han, D. Simulation Optimization and Experimental Research of Internal Inflatable Blowing Corn Precision Seed Metering Device. Doctor Dissertation, China Agricultural University, Beijing, China, 2018. Available online: https://kns.cnki.net/kcms2/article/abstract?v=m22VhQxdXydQyM6s1P8mn4eQyEPHmW86aLGQ_uJICy5HTLQqdJv67Ki7gwokFVZxc3TCONS3hkU-y7BiI4otwPKGGKP78CJiI4Okto72di_SSJe4_tr9Zp2AgnLVh14aFiBWn2pMBC-aRv0vDYJSWP5t1R2DKgViPWd8CBKOctc=&uniplatform=NZKPT&language=CHS (accessed on 1 June 2018).

- Hu, M. Design and Simulation Analysis of Internal Inflatable Force Cotton Precision Seed Metering Device. Doctor Dissertation, Huazhong Agricultural University, Wuhan, China, 2022. Available online: https://link.cnki.net/doi/10.27158/d.cnki.ghznu.2022.001800 (accessed on 1 June 2018).

- Wu, W.; Chen, X.; Wang, S.; Yan, L.; Jiang, D.; Ji, C. Design and experiment of combined hole-wheel corn precision dibbler. J. Agric. Mach. 2022, 53, 60–70. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, X.; Shi, Z.; Fu, H.; Yu, Y. Design and experiment of swing rod clamping corn precision seed metering device. Agric. Res. Arid. Areas 2023, 41, 291–302. [Google Scholar]

- Jiang, B.; Shi, Z.; Chen, H.; Hu, X.; Mao, W.; Riziwanguli; Wang, J. Parameter optimization and test of precision hole seeding wheel on clamping corn film. Res. Agric. Mech. 2024, 46, 184–188. [Google Scholar] [CrossRef]

- Wang, J.; Tang, H.; Zhou, W.; Yang, W.; Wang, Q. Improved design and experiment of finger clip precision corn seed metering device. J. Agric. Mach. 2015, 46, 68–76. [Google Scholar] [CrossRef]

- Shi, L.; Sun, B.; Zhao, W.; Yang, X.; Xin, S.; Wang, J. Optimization and test of seeding performance parameters of elastic gas suction nozzle type corn roller seed metering device. J. Agric. Mach. 2019, 50, 88–95+207. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, Y.; Chen, J.; Zhou, H. The dynamic analysis of the suction process of the air-suction cylinder seed-metering device. J. Agric. Eng. 2011, 27, 112–116. [Google Scholar] [CrossRef]

- Li, J.; Zhang, H.; Bi, X.; Wang, J.; Hu, B.; Li, S. Simulation analysis and test of filling performance of rotary shaft type hole type precision seed metering device. ACTA Agric. Eng. Sci. 2020, 36, 38–49. [Google Scholar] [CrossRef]

- Dong, W.; Zhang, L.; Li, W.; Yu, S.; Wang, Y.; Bu, H. Application status and development trend of cotton planting machinery in Xinjiang. Xinjiang Agric. Mech. 2021, 11–15. [Google Scholar] [CrossRef]

- Lao, D. Basics of Variation, 2nd ed.; National Defense Industry Press: Beijing, China, 2007. [Google Scholar]

- Xu, L. The steepest descent curve experiment. Educ. Teach. Forum 2018, 190–191. Available online: https://kns.cnki.net/kcms2/article/abstract?v=xpM8-w1VMS8IOChUVcrSBtCxDUzoZ9G_7guYWwhY_xTJvdGMpmhHXXAX39tENAtLJdy8m8Iah4G7U_tn-WrxFbMwBeNNtI0Y3U2hvcfL7UsD9xBeIP7MQ-KqCR6rbfH6CnWiy6h3uVfEFqDjUCaCpdR2TxWtfHPLAlMs706acBWyCG-Iqu1O_qAUNNbjVkc9&uniplatform=NZKPT&language=CHS (accessed on 1 June 2018).

- You, M. Study on the solution of the steepest descent line and the influence of friction. J. Henan Polytech. Univ. Nat. Sci. Ed. 2005, 83–88. [Google Scholar] [CrossRef]

- Tang, X.; Weng, H. An application of variational method in optimal control problems. J. Jiangnan Univ. 2003, 521–525. Available online: https://kns.cnki.net/kcms2/article/abstract?v=xpM8-w1VMS9XrvZmOxYsVtjvUcFf6CQ3LQIcVWDT5mgQporr0crRs5a45Vm2nvns4teTfy1ZqF1_JU_BhUb8OtLHuAjIKUWdLCzHyPMu-Cpp73kTzhmVtNMgx7WOBkkD5He8u1mumftMst5y7n01IJLx5vjv6FXS5m8EeZ54uYd_e-10n56rxE6noyFx0jW6&uniplatform=NZKPT&language=CHS (accessed on 1 June 2018).

- Sun, T. Effects of Different Sowing Dates and Densities on Growth Characteristics and Yield Components of Drip Irrigation Winter Wheat in Southern Xinjiang. Master Dissertation, Tarim University, Xinjiang, China, 2020. Available online: https://link.cnki.net/doi/10.27708/d.cnki.gtlmd.2020.000136 (accessed on 1 June 2018).

- The 2023–2024 National Wheat Autumn and Winter Production Situation Experts Meeting Was Held in Beijing. China’s Agricultural Technology Extension. 2023, (09), 83. Available online: https://kns.cnki.net/kcms2/article/abstract?v=xpM8-w1VMS_y4y99pT7vWgysb-4vBzOZb1DP7sQWtFFpxdV_xGOzyhEt3_01OKfXNXepEUr4BSfV8S8hsJbkZY2AGH_BEsnw-aoHs9KKZeYshJ_9zxVkxbhov-L_Bm9WLXnwZ1EW7Qnobx5oLtcK4_FTsZ_nvhG0qfTKDIaZg7C0dOzEJCN7Cn8L02Oe-cmQ&uniplatform=NZKPT&language=CHS (accessed on 1 June 2018).

- Li, X.; Cui, Q.; Guo, Y.; Feng, J.; Sun, J.; Zhang, Y. Research on sub-pixel measurement method of three-axis dimension of buckwheat grain based on centroid method. Chin. J. Agric. Mach. Chem. 2017, 38, 50–56. [Google Scholar] [CrossRef]

- Li, B. Agricultural Mechanics; China Agricultural Press: Beijing, China, 2003. [Google Scholar]

- Liao, Q.; Gao, H. Experimental study on seeding performance of corn horizontal disc precision seed-metering device. J. Agric. Eng. 2003, 19, 99–103. [Google Scholar]

- Peng, Y.; Wen, H.; Pan, F.; Yang, H. Design and research of 24-hole cotton precision hill-drop planter. Xinjiang Agric. Mech. 2018, 14–15+18. [Google Scholar] [CrossRef]

- Feng, X.; Liu, J.; Yang, X.; Wu, X. The analysis on seeding uniformity of seedmeter. J. Hebei Agric. Univ. 2003, 93–96. Available online: https://kns.cnki.net/kcms2/article/abstract?v=xpM8-w1VMS9aQg4hIGmWL1H6mCpog3yAX6yUFtaNMijOyFXt49Rq5gfTB8tzDT05TJa3lzRbhBwBlWoVMOZ25F4R0Q7hBT3pkfAcbJ-iDOezOyxGKWjbkiHE0lny7oNPb5tyYvBkPqU9FyLGYmWPGf81qQ_9FEaaJiZ3UY3BIDifqc8_yVYVtVwF8UZZ0L9T&uniplatform=NZKPT&language=CHS (accessed on 1 June 2018).

- Xie, W.; Liu, Y. Experimental study on the performance of eyelet wheel rapeseed metering device. Contemp. Agric. Mach. 2018, 67–69. Available online: https://kns.cnki.net/kcms2/article/abstract?v=xpM8-w1VMS_X5gB_WUfx1GF_Df1PlvVwN2T254QjRRNknst_XyBgOypVrTeJ0eRpyByszz_m787OgDJzZF0d5mH88hjVmdp_72KvF2OWzJgfRMt_YiQbED1ksc8saNlqDAZJ5QLnw0dBq6xkx0tGKDe83hZN9-w2BxFnNUSYZTnYleP2zwkVOPNZ64TtVvXA&uniplatform=NZKPT&language=CHS (accessed on 1 June 2018).

- Zhang, B. Seeding Machine Design Principle; Mechanical Industry Press: Beijing, China, 1982. [Google Scholar]

- Ma, L.; Liu, J.; Wang, T.; Feng, X. Discussion on precision seeding of tillering crops with vertical disc seed metering device. J. Agric. Mach. 1998, 38–43. Available online: https://kns.cnki.net/kcms2/article/abstract?v=xpM8-w1VMS85ld__SuDi8ZwMD24TZjh2jtuFMy3K60NoD4x7Iw5XOPcwXsr2nSQimjFNyiN9hdYUQFwPwiRaPXDHnK_6UpPpsPqdCp76w-Bha7x1se3qYFC-06MVUkFS07e_m7U4mBHUOVeAXlid3oO69mCMTPZfByGOzFGODc_15IBVND8W5ysp1XOIaapX&uniplatform=NZKPT&language=CHS (accessed on 1 June 2018).

- Zhang, L.; Mao, X.; Ma, Y.; Sun, Z.; Zhang, L.; Wen, Z. Design and experimental study of a new type of socket wheel corn seeding device. Chin. J. Agric. Mach. Chem. 2017, 38, 20–25. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, Y. The design principle of roller dibbler. J. Tarim Agric. Univ. 1997, 30–33+44. Available online: https://kns.cnki.net/kcms2/article/abstract?v=xpM8-w1VMS8lqkNJADBJ43QaVwD-ZoePqxM-56maEluRt3dDJilgebE35RsjQmo0XzIvfEDWhgmlRvjK5iUD2GpBIMW_gGXjCBJtQKB1ck2bfpgLWkf82k-QwKjfLtPSm8Vpf1gho0GxMGsX_ZSpJMyTyZORIdKQXu92YvO-iVWKx7NjsNK-A1gnrLprf81U&uniplatform=NZKPT&language=CHS (accessed on 1 June 2018).

- Ma, X.; Li, C.; Li, Y.; Cheng, B.; Cheng, X.; Peng, H. Design and simulation analysis of welding flexible fixture for belt assembly of dibbler. J. Shihezi Univ. Nat. Sci. Ed. 2016, 36, 790–795. [Google Scholar] [CrossRef]

- Chang, X.; Wang, Y.; Tao, Z.; Wang, D.; Ma, S.; Yang, Y.; Zhao, G. Design and simulation analysis of welding flexible fixture for belt assembly of hole seeder. J. Crops 2019, 168–172. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, Y.; Huang, S. Punching principle of roller dibbler. J. Tarim Agric. Univ. 1995, 21–24. [Google Scholar]

- Sun, H.; Chen, Z.; Ge, W. Mechanical Principle, 7th ed.; Higher Education Press: Beijing, China, 2006. [Google Scholar]

- 20021054-T-604; Single-Grain (Precision) Seeder Test Method. National Agricultural Machinery Standardization Technical Committee: Beijing, China, 2005.

- Meng, H.; Li, X.; Qu, Z.; Li, H.; Yu, Y.; Liu, L. Design and experiment of self-perturbed internal seed-filling soybean precision seed-metering device. Jiangsu Agric. Sci. 2023, 51, 179–184. [Google Scholar] [CrossRef]

- Jiang, Y.; Hou, X.; Zhao, Y.; Hu, B.; Luo, X.; Chen, Y.; Zhang, H. Design and experiment of air-suction drum-type precision seed-metering device for air-blowing seeding. J. Gansu Agric. Univ. 2019, 54, 211–218. [Google Scholar] [CrossRef]

- Shi, S.; Zhou, J.; Liu, H.; Fang, H.; Jian, S.; Zhang, R. Design and experiment of air-suction precision seed metering device. Agric. Mach. J. 2019, 50, 61–70. [Google Scholar] [CrossRef]

| Length/mm | Width/mm | Thickness/mm |

|---|---|---|

| 6.97 | 3.82 | 3.27 |

| Coding | Factor | |

|---|---|---|

| Rotating Speed of Dibble (r/min) | Tooth Number of Wave Guide Rail (number) | |

| −1 | 30 | 3 |

| 0 | 40 | 5 |

| 1 | 50 | 7 |

| Std | Run | Experimental Factors | Evaluating Indicator | |||

|---|---|---|---|---|---|---|

| A | B | R1/% | R2/% | R3/% | ||

| 1 | 13 | −1 | −1 | 63.84 | 24.39 | 11.77 |

| 2 | 3 | 1 | −1 | 79.43 | 8.76 | 11.81 |

| 3 | 11 | −1 | 1 | 81.62 | 12.43 | 5.95 |

| 4 | 7 | 1 | 1 | 75.41 | 9.17 | 15.42 |

| 5 | 2 | −1.41421 | 0 | 76.82 | 14.87 | 8.31 |

| 6 | 12 | 1.41421 | 0 | 77.35 | 8.52 | 14.13 |

| 7 | 4 | 0 | −1.41421 | 73.86 | 16.94 | 9.2 |

| 8 | 8 | 0 | 1.41421 | 77.91 | 6.35 | 15.74 |

| 9 | 10 | 0 | 0 | 81.64 | 10.57 | 7.79 |

| 10 | 5 | 0 | 0 | 84.69 | 5.44 | 9.87 |

| 11 | 6 | 0 | 0 | 81.29 | 11.34 | 7.37 |

| 12 | 1 | 0 | 0 | 87.97 | 4.27 | 7.76 |

| 13 | 9 | 0 | 0 | 86.19 | 7.93 | 5.88 |

| Source | df | Percent of Pass R1 | Replay Rate R2 | Miss-Seeding Rate R3 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean Square | F-Value | p-Value | Mean Square | F-Value | p-Value | Mean Square | F-Value | p-Value | ||

| Model | 5 | 81.37 | 10.42 | 0.0038 | 58.66 | 6.83 | 0.0127 | 22.79 | 6.26 | 0.0161 |

| A | 1 | 12.83 | 1.64 | 0.2408 | 97.09 | 11.31 | 0.0120 | 39.34 | 10.80 | 0.0134 |

| B | 1 | 47.47 | 6.08 | 0.0431 | 87.96 | 10.25 | 0.0150 | 6.19 | 1.70 | 0.2334 |

| AB | 1 | 118.81 | 15.21 | 0.0059 | 38.25 | 4.46 | 0.0727 | 22.23 | 6.10 | 0.0428 |

| A2 | 1 | 110.64 | 14.17 | 0.0070 | 39.97 | 4.66 | 0.0678 | 17.61 | 4.84 | 0.0638 |

| B2 | 1 | 146.43 | 18.75 | 0.0034 | 39.14 | 4.56 | 0.0701 | 34.16 | 9.38 | 0.0182 |

| Residual | 7 | 7.81 | 8.58 | 3.64 | ||||||

| Lack of Fit | 3 | 7.12 | 0.8546 | 0.5327 | 7.29 | 0.7640 | 0.5705 | 5.79 | 2.84 | 0.1693 |

| Pure Error | 4 | 8.33 | 9.55 | 2.03 | ||||||

| Cor Total | 12 | |||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, X.; Yan, L.; Wang, L.; Jiang, D.; Tian, X.; Wu, T.; Zhang, J. Design and Experiment of Double-Nest Eye-Type Hole-Wheel Dense-Planting Wheat Dibbler. Agriculture 2024, 14, 1489. https://doi.org/10.3390/agriculture14091489

Fu X, Yan L, Wang L, Jiang D, Tian X, Wu T, Zhang J. Design and Experiment of Double-Nest Eye-Type Hole-Wheel Dense-Planting Wheat Dibbler. Agriculture. 2024; 14(9):1489. https://doi.org/10.3390/agriculture14091489

Chicago/Turabian StyleFu, Xuanhe, Limin Yan, Long Wang, Deli Jiang, Xinliang Tian, Tao Wu, and Jinhao Zhang. 2024. "Design and Experiment of Double-Nest Eye-Type Hole-Wheel Dense-Planting Wheat Dibbler" Agriculture 14, no. 9: 1489. https://doi.org/10.3390/agriculture14091489

APA StyleFu, X., Yan, L., Wang, L., Jiang, D., Tian, X., Wu, T., & Zhang, J. (2024). Design and Experiment of Double-Nest Eye-Type Hole-Wheel Dense-Planting Wheat Dibbler. Agriculture, 14(9), 1489. https://doi.org/10.3390/agriculture14091489